Sustainable Fashion Supply Chain: Lessons from H&M

Abstract

:1. Introduction

2. Literature Review in Sustainable Fashion Supply Chain

3. Sustainable Operation Practices at H&M

3.1. Eco-Material Preparation

3.2. Sustainable Manufacturing

3.3. Green Distribution

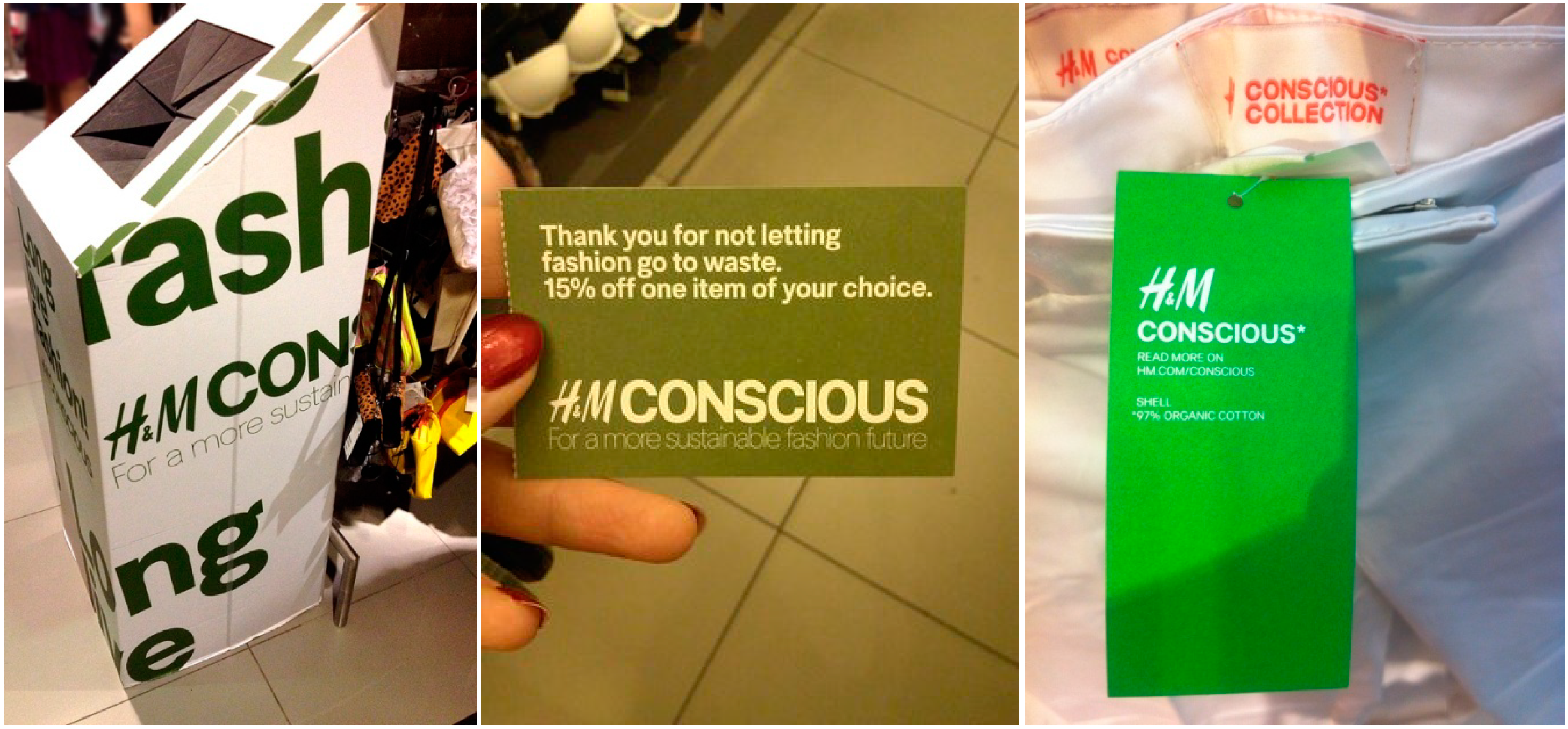

3.4. Green Retailing

4. Lessons of Sustainability at H&M from the Country Perspective

4.1. Lessons of Supplier Selection

| Country | No. of Suppliers | Human Wellbeing | Environmental Wellbeing | Economic Wellbeing |

|---|---|---|---|---|

| Bulgaria | 27 | 33 | 104 | 39 |

| Egypt | 4 | 48 | 117 | 65 |

| Greece | 3 | 27 | 120 | 105 |

| Italy | 65 | 25 | 83 | 25 |

| Latvia | 1 | 42 | 50 | 14 |

| Netherlands | 2 | 8 | 124 | 18 |

| Poland | 1 | 26 | 105 | 17 |

| Portugal | 18 | 23 | 82 | 72 |

| Romania | 24 | 50 | 81 | 23 |

| Sweden | 3 | 3 | 73 | 2 |

| Tunisia | 5 | 49 | 114 | 43 |

| Turkey | 194 | 69 | 113 | 27 |

| Ukraine | 4 | 62 | 121 | 53 |

| Cambodia | 34 | 110 | 5 | 75 |

| China | 262 | 98 | 80 | 50 |

| Indonesia | 56 | 85 | 53 | 64 |

| Korea | 37 | 24 | 127 | 20 |

| Thailand | 1 | 71 | 55 | 42 |

| Vietnam | 11 | 83 | 60 | 70 |

| Bangladesh | 163 | 107 | 62 | 81 |

| India | 104 | 116 | 65 | 103 |

| Pakistan | 8 | 115 | 61 | 93 |

| Sri Lanka | 31 | 61 | 29 | 57 |

| R Square | Adjusted R Square | F-Value | Standardized Coefficients Beta | T-Value | Significance | |

|---|---|---|---|---|---|---|

| Human wellbeing | 0.220 | 0.183 | 5.916 | 0.469 | 2.432 | 0.024 * |

| Environmental Wellbeing | 0.003 | −0.044 | 0.066 | −0.056 | −0.257 | 0.800 |

| Economic Wellbeing | 0.011 | −0.036 | 0.233 | 0.105 | 0.483 | 0.634 |

4.2. Lessons of Sales per Store with Human Wellbeing

| Country | Sales 2013 | No. of Stores 30 November 2013 | Sales per Store | First Store |

|---|---|---|---|---|

| China | 6655 | 205 | 29.0 | 2007 |

| Japan | 2945 | 39 | 71.8 | 2008 |

| Malaysia | 379 | 7 | 54.1 | 2012 |

| South Korea | 810 | 16 | 46 | 2010 |

| Austria | 4821 | 72 | 55.8 | 1994 |

| Belgium | 3445 | 73 | 39 | 1992 |

| Bulgaria | 264 | 11 | 20 | 2012 |

| Croatia | 704 | 13 | 43.3 | 2011 |

| Czech Republic | 834 | 38 | 18.1 | 2003 |

| Denmark | 4612 | 97 | 38.0 | 1967 |

| Finland | 2529 | 58 | 35.4 | 1997 |

| France | 10,636 | 204 | 43.5 | 1998 |

| Germany | 31,140 | 418 | 62.6 | 1980 |

| Greece | 981 | 27 | 29.5 | 2007 |

| Hungary | 792 | 33 | 18.9 | 2005 |

| Ireland | 616 | 19 | 27.5 | 2005 |

| Italy | 5490 | 116 | 39.0 | 2003 |

| Luxembourg | 386 | 10 | 34.6 | 1996 |

| Netherlands | 6750 | 130 | 42.93 | 1989 |

| Norway | 5535 | 114 | 38.87 | 1964 |

| Poland | 3193 | 122 | 21.29 | 2003 |

| Portugal | 918 | 27 | 27.6 | 2003 |

| Romania | 893 | 28 | 25.7 | 2011 |

| Russia | 2566 | 51 | 43.2 | 2009 |

| Slovenia | 373 | 13 | 23.9 | 2004 |

| Spain | 6011 | 156 | 32.0 | 2000 |

| Sweden | 8257 | 177 | 37.5 | 1947 |

| Switzerland | 5516 | 87 | 58.7 | 1978 |

| Turkey | 721 | 20 | 33.0 | 2010 |

| Canada | 3024 | 66 | 41.1 | 2004 |

| USA | 13,675 | 305 | 42.6 | 2000 |

| UK | 10,256 | 245 | 36.0 | 1976 |

4.3. Lessons of Launching Online Stores

| Country | Human Wellbeing | Environmental Wellbeing | Economic Wellbeing |

|---|---|---|---|

| Austria | 5 | 70 | 11 |

| Denmark | 17 | 126 | 34 |

| Finland | 4 | 103 | 8 |

| France | 11 | 99 | 37 |

| Germany | 10 | 107 | 22 |

| Netherlands | 8 | 124 | 18 |

| Norway | 2 | 94 | 3 |

| Sweden | 3 | 73 | 2 |

| USA | 32 | 125 | 102 |

| UK | 15 | 89 | 36 |

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Chen, H.; Burns, D.L. Environmental analysis of textile products. Cloth. Text. Res. J. 2006, 24, 248–261. [Google Scholar]

- Battaglia, M.; Testa, F.; Bianchi, L.; Iraldo, F.; Frey, M. Corporate social responsibility and competitiveness within SMEs of the fashion industry: Evidence from Italy and France. Sustainability 2014, 6, 872–893. [Google Scholar] [CrossRef]

- Nagurney, A.; Yu, M. Sustainable fashion supply chain management under oligopolistic competition and brand differentiation. Int. J. Prod. Econ. 2012, 135, 532–540. [Google Scholar] [CrossRef]

- Seuring, S.; Muller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Shen, B.; Wang, Y.; Lo, C.; Shum, M. The impact of ethical fashion on consumer purchase behavior. J. Fash. Mark. Manag. 2012, 16, 234–245. [Google Scholar]

- Lo, C.K.Y.; Yeung, A.C.L.; Cheng, T.C.E. The impact of environmental management systems on financial performance in fashion and textiles industries. Int. J. Prod. Econ. 2012, 135, 561–567. [Google Scholar] [CrossRef]

- Chan, T.Y.; Wong, C.W.Y. The consumption side of sustainable fashion supply chain: Understanding fashion consumer eco-fashion consumption decision. J. Fash. Mark. Manag. 2012, 16, 193–215. [Google Scholar]

- De Brito, M.P.; Carbone, V.; Blanquart, C.M. Towards a sustainable fashion retail supply chain in Europe: Organization and performance. Int. J. Prod. Econ. 2008, 114, 534–553. [Google Scholar]

- Ellis, J.L.; McCracken, V.A.; Skuza, N. Insights into willingness to pay for organic cotton apparel. J. Fash. Mark. Manag. 2012, 16, 290–305. [Google Scholar]

- Shen, B.; Zheng, J.; Chow, P.; Chow, K. Perception of fashion sustainability in online community. J. Text. Inst. 2014, 105, 971–979. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, X.; Shi, D.; Li, X. Governance of sustainable supply chains in the fast fashion industry. Eur. Manag. J. 2014, 32, 823–836. [Google Scholar] [CrossRef]

- Conscious Action Sustainability Report 2010. Available online: http://about.hm.com/content/dam/hm/about/documents/en/CSR/reports/Conscious%20Actions%20Sustainability%20Report%202010_en.pdf (accessed on 15 June 2014).

- Conscious Action Sustainability Report 2011. Available online: http://about.hm.com/content/dam/hm/about/documents/en/CSR/reports/Conscious%20Actions%20Sustainability%20Report%202011_en.pdf (accessed on 15 June 2014).

- Conscious Action Sustainability Report 2012. Available online: http://about.hm.com/content/dam/hm/about/documents/en/CSR/reports/Conscious%20Actions%20Sustainability%20Report%202012_en.pdf (accessed on 15 June 2014).

- Conscious Action Sustainability Report 2013. Available online: http://sustainability.hm.com/content/dam/hm/about/documents/en/CSR/reports/Conscious%20Actions%20Sustainability%20Report%202013_en.pdf (accessed on 15 June 2014).

- World Commission on Environment and Development. Our Common Future; Oxford University Press: New York, NY, USA, 1987. [Google Scholar]

- Elkington, J. Enter the triple bottom line. In The Triple Bottom Line: Does It All Add up? Henriques, A., Richardson, J., Eds.; Earthscan: London, UK, 2004; pp. 1–16. [Google Scholar]

- Sustainable Society Index. Available online: http://www.ssfindex.com (accessed on 15 June 2014).

- Morana, R.; Seuring, S. A three level framework for closed-loop supply chain management—Linking society, chain and actor level. Sustainability 2011, 3, 678–691. [Google Scholar] [CrossRef]

- Faisal, M.N. Sustainable supply chains: A study of interaction among the enablers. Bus. Process Manag. J. 2010, 16, 508–529. [Google Scholar] [CrossRef]

- Yang, C.L.; Lin, S.P.; Chan, Y.H.; Sheu, C. Mediated effect of environmental management on manufacturing competitiveness: An empirical study. Int. J. Prod. Econ. 2010, 123, 210–220. [Google Scholar] [CrossRef]

- Paulins, V.A.; Hillery, J.L. Ethics in the Fashion Industry; Fairchild Books: New York, NY, USA, 2009. [Google Scholar]

- Lee, H. Don’t tweak your supply chain: Re-think it end-to-end. Harv. Bus. Rev. 2010, 88, 62–69. [Google Scholar] [PubMed]

- Lakhal, S.Y.; Sidibe, H.; H’Mida, S. Comparing conventional and certified organic cotton supply chains: The case of Mali. Int. J. Agric. Resour. Gov. Ecol. 2008, 7, 243–255. [Google Scholar]

- Anson, R. Editorial: Can the shift of textile and clothing production to Asia be reversed? Text. Outlook Int. 2012, 19, 4–9. [Google Scholar]

- Fletcher, K. Sustainable Fashion and Textiles: Design Journeys; Earthscan: London, UK, 2008. [Google Scholar]

- Blanchard, T. Marks & Spencer launch the world’s most sustainable suit. Telegraph. 19 June 2012. Available online: http://fashion.telegraph.co.uk/columns/tamsin-blanchard/TMG9340870/Marks-and-Spencer-launch-the-worlds-most-sustainable-suit.html (accessed on 15 June 2014).

- Hustvedt, G.; Bernard, J.C. Consumer willingness to pay for sustainable apparel: The influence of labeling for fibre origin and production methods. Int. J. Consum. Stud. 2008, 32, 491–498. [Google Scholar] [CrossRef]

- Dickson, M. US consumers’ knowledge of and concern with apparel sweatshops. J. Fash. Mark. Manag. 1999, 3, 44–55. [Google Scholar]

- Bajaj, V. Factory Fire Kills More Than 100 People in Bangladesh. The New York Times. 25 November 2012. Available online: http://www.nytimes.com/2012/11/26/world/asia/bangladesh-fire-kills-more-than-100-and-injures-many.html (accessed on 15 June 2014).

- Claudio, L. Waste couture: Environmental impact of the clothing industry. Environ. Health Perspect. 2007, 115, 449–454. [Google Scholar] [CrossRef]

- Ho, P.Y.; Choi, T.M. A five-R analysis for sustainable fashion supply chain management in Hong Kong: A case analysis. J. Fash. Mark. Manag. 2012, 16, 161–175. [Google Scholar]

- Choi, T.M. Multi-Period Risk Minimization Purchasing Models for Fashion Products with Interest Rate, Budget, and Profit Target Considerations. Ann. Oper. Res. 2013. [Google Scholar] [CrossRef]

- Lai, K.H.; Cheng, T.C.E.; Tang, K.Y. Green retailing: Factors for success. Calif. Manag. Rev. 2010, 52, 6–31. [Google Scholar] [CrossRef]

- Subic, A.; Shabani, B.; Hedayati, M.; Crossin, E. Capability framework for sustainable manufacturing of sports apparel and footwear. Sustainability 2012, 4, 2127–2145. [Google Scholar] [CrossRef]

- Delmas, M.; Toffel, M.W. Stakeholders and environmental management practices: An institutional framework. Bus. Strategy Environ. 2004, 13, 209–222. [Google Scholar] [CrossRef]

- Choi, T.M. Local sourcing and fashion quick response system: The impacts of carbon footprint tax. Transp. Res. Part E 2013, 55, 43–54. [Google Scholar] [CrossRef]

- Niinimäki, K.; Hassi, L. Emerging design strategies in sustainable production and consumption of textiles and clothing. J. Clean. Prod. 2011, 13, 1876–1883. [Google Scholar]

- Etsy, D.; Winston, A. Green to Gold; Yale University Press: New Haven, CT, USA, 2009. [Google Scholar]

- Muntean, A.; Stremtan, F. Green marketing: A new challenge for Romanian organizations. J. Environ. Prot. Ecol. 2010, 11, 1472–1474. [Google Scholar]

- Sharma, A.; Lyer, G.R.; Mehrotra, A.; Krishnan, R. Sustainability and business-to-business marketing: A framework and implications. Ind. Mark. Manag. 2010, 39, 330–341. [Google Scholar] [CrossRef]

- Joergens, C. Ethical fashion: Myth or future trend? J. Fash. Mark. Manag. 2006, 10, 360–371. [Google Scholar]

- Beard, N. The branding of ethical fashion and the consumer: A luxury niche or mass market reality? Fash. Theory 2008, 12, 447–468. [Google Scholar]

- Fraj, E.; Martinez, E. Environmental values and lifestyles as determining factors of ecological consumer behaviour: An empirical analysis. J. Consum. Mark. 2006, 23, 133–144. [Google Scholar] [CrossRef]

- Oke, A.; Gopalakrishnana, M. Managing disruptions in supply chains: A case study of a retail supply chain. Int. J. Prod. Econ. 2009, 118, 168–174. [Google Scholar] [CrossRef]

- Oliva, R.; Watson, N. Cross-functional alignment in supply chain planning: A case study of sales and operations planning. J. Oper. Manag. 2011, 29, 434–448. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; Sage Publications: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Daily Mail. Nothing Shameless about Her! Emmy Rossum Oozes Old Hollywood Glamour at H&M Conscious Collection Dinner. Available online: http://www.dailymail.co.uk/tvshowbiz/article-2584990/Emmy-Rossum-oozes-old-Hollywood-glamour-H-M-Conscious-Collection dinner.html (accessed on 15 June 2014).

- Taplin, I.M. Who is to blame? A re-examination of Fast Fashion after the 2013 factory disaster in Bangladesh. Crit. Perspect. Int. Bus. 2014, 10, 72–83. [Google Scholar] [CrossRef]

- Sustainable society index. Available online: http://www.ssfindex.com/results-2012/ (accessed on 15 June 2014).

- Anson, R. Will textile and clothing suppliers in Bangladesh, Cambodia and Vietnam gain market share from China. Text. Outlook Int. 2014, 169, 1–35. [Google Scholar]

- H&M website. Available online: http://www.about.hm.com (accessed on 15 June 2014).

- Choi, T.M. Optimal Apparel Supplier Selection with Forecast Updates under Carbon Emission Taxation Scheme. Comp. Oper. Res. 2013, 40, 2646–2655. [Google Scholar] [CrossRef]

- Dong, C.W.; Shen, B.; Chow, P.S.; Yang, L.; Ng, C.T. Sustainability investment under cap-and-trade regulation. Ann. Oper Res. 2014. [Google Scholar] [CrossRef]

- Choi, T.M.; Chiu, C.H. Mean-Downside-Risk and Mean-Variance Newsvendor Models: Implications for Sustainable Fashion Retailers. Int. J. Prod. Econ. 2012, 135, 552–560. [Google Scholar] [CrossRef]

- Zheng, J.; Shen, B.; Chow, P.S.; Chiu, C.H. The impact of the strategic advertising on luxury fashion brands with social influences. Available online: http://dx.doi.org/10.1155/2013/534605 (accessed on 15 June 2014).

- Shen, B.; Chow, P.S.; Choi, T.M. Supply chain contracts in fashion department stores: Coordination and risk analysis. Available online: http://dx.doi.org/10.1155/2014/954235 (accessed on 15 June 2014).

- Choi, T.M.; Chow, P.S.; Liu, S.C.; Kwok, B.; Shen, B. Service quality of online shopping platforms: A case based empirical and analytical study. Math. Prob. Eng. 2013. [Google Scholar] [CrossRef]

- Shen, B.; Choi, T.M.; Wang, Y.L.; Lo, K.Y. The coordination of fashion supply chains with a risk-averse supplier under markdown money policy. IEEE Trans. Sys. Man. Cyber Sys. 2013, 43, 266–276. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Shen, B. Sustainable Fashion Supply Chain: Lessons from H&M. Sustainability 2014, 6, 6236-6249. https://doi.org/10.3390/su6096236

Shen B. Sustainable Fashion Supply Chain: Lessons from H&M. Sustainability. 2014; 6(9):6236-6249. https://doi.org/10.3390/su6096236

Chicago/Turabian StyleShen, Bin. 2014. "Sustainable Fashion Supply Chain: Lessons from H&M" Sustainability 6, no. 9: 6236-6249. https://doi.org/10.3390/su6096236

APA StyleShen, B. (2014). Sustainable Fashion Supply Chain: Lessons from H&M. Sustainability, 6(9), 6236-6249. https://doi.org/10.3390/su6096236