1. Introduction

As the concept of extended producer responsibility has emerged around the world, there are plenty of practical cases showing that third-party power intervention (TPPI) by governments and non-profit organizations has significantly influenced supply chain performance as supply chains evolve toward collaborative green supply chains. This argument holds particularly for the global manufacturing industries of fashionable consumer electronics products (FCEPs). In this work, an FCEP refers to the consumer electronics product (e.g., personal computers, mobile phones, computer notebooks, and game consoles) with the features of a well-known brand associated, a short product lifecycle, timely and fashionable design fit for market trends, and quick responsiveness to the variations of market demands. From a supply chain perspective, FCEPs requires agile and sustainable supply chains with the operational features of shortened lead times, faster inventory turnovers, high order fulfillment rates and quick responses to customer demands, integrated with well-established reverse logistics services (e.g., repairing, maintenance, customer returns, and recycling) and networks for sustainable competitive advantage [

1,

2,

3,

4]. For example, the Waste Electrical and Electronic Equipment (WEEE) directive and Restriction on Hazardous Substances (RoHS) have increased regulatory-compliance costs by 3%–10% for branders of consumer electronics products [

5]. In the US, 22 states have passed e-waste bills which have caused producers to bear additional responsibility for e-waste collection and recycling, leading producers to seek new partners for solutions in reverse channels [

6,

7,

8]. Another TPPI example is the guide to green electronics products issued by Greenpeace International which ranks the top 18 global FCEP branders quarterly, based on the manufacturers’ policies for toxic chemicals, recycling, and climate change. Accordingly, TPPI-induced expenses and responsibilities have increased not only the producers’ burdens, but also their awareness of the need for close collaboration with reverse channel members. Notably, TPPI is likely to engender the awareness of reverse channel members of their importance in green supply chains. Thus, channel power structure and the interdependence of producers and reverse channel members are likely altered in green supply chains.

Nevertheless, several examples from well-known brands (e.g., IBM, Apple, and Hewlett-Packard) have transformed regulatory compliance into a requirement of sustainable competitive advantage. For example, by transforming recycling and compliance into a sustainable business model, IBM now collects and recycles about 20,000 end-of-lease machines weekly, adding several millions of dollars in revenue and less than 2% of end-of-lease products to landfills [

9]. Another case is Apple, which collaborates with its worldwide retail stores to implement elaborately integrated green marketing and recycling programs, where end-customers are strongly encouraged to return Apple products for recycling by providing them with such economic incentives as Apple gift cards. Under close producer-retailer collaboration, the goals of green regulatory compliance and sustainable competitive advantage can be achieved efficiently [

10].

Due to the necessity of managing forward and reverse logistics flows of FCEP green supply chains in the TPPI contexts, the role of a retailer, which acts as a producer’s partner in a bi-directional FCEP green supply chain composed of a forward distribution channel and reverse channel is drawing increasing attention. According to the concept of product stewardship [

11], retailers should act as an interface between producers and consumers when managing the lifecycles of FCEPs. This holds true, particularly in the case of individual producer-operated e-waste management systems that are based on the concept of individual producer responsibility. In Japan, for example, FCEP-branders prefer collecting and recycling their own products via contracted retailers so they can control cost, control quality in green manufacturing, and optimize product recyclability by green design [

12]. Several European states such as Belgium, France, and Germany rely heavily on retailers for e-waste collection [

13].

In the case that a retailer has to jointly bear the additional responsibility of managing reverse logistics flows for repair and recycling in an FCEP green supply chain, issues of producer-retailer interdependence and power imbalance may become increasingly complex. In practice, producer-retailer collaboration in bidirectional distribution operations to collect used FCEPs, e.g., mobile phones and single-use cameras, from end-customers for repair and recycling, have been increasingly adopted by the dyadic members. These collaborative operations are easily found in the producer-retailer distribution channels for FCEPs. A producer and retailer, thus, may no longer be limited to a producer-retailer transaction relationship typically revealed in a one-directional forward supply chain. Rather, so-called reciprocal task interdependence may exist between dyadic channel members [

14,

15]. Furthermore, the political and social power driven by TPPI may push FCEP-producers and retailers to be inextricably linked as the dyadic members conjecture the increase in the interdependence on mutual resources to carry out extended producer responsibility. Numerous practical cases have also indicated that producers that were powerful supply chain members require support from reverse channel partners, including contracted retailers, to comply with take-back directives; otherwise, producers risk violating WEEE directives [

16]. Therefore, both FCEP-producers and retailers must resolve issues related to interdependence and power imbalance when moving toward green supply chain collaboration with improved chain performance.

The aforementioned FCEP producer-retailer bidirectional channel collaboration, in reality, stems from the concept of green supply chain management, which claims that functions of forward and reverse supply chains should be integrated efficiently, and chain members should be coordinated to solve joint problems, and achieve joint goals via joint strategic planning and actions [

17,

18]. Despite remarkable advances made by pioneering green supply chain management research [

17,

19,

20,

21,

22,

23,

24], issues related to the interplays and relational governance as green supply chain members move toward a long-term collaborative green supply chain under TPPI remain challenging [

18,

25,

26]. As argued in Sarkis

et al. [

18], the interdependency of green supply chain members and their effectiveness determine the success of green supply chain management from a resource dependence perspective; however, they have not yet been satisfactorily addressed in literature. According to Dill [

27] and Duncan [

28], governments and green organizations can be regarded as a part of “task environments” in green supply chains. By Bourgeois [

29], we speculate that the TPPI-oriented political and social power is one of exogenous sources causing environmental heterogeneity and complexity in business operations, contributing to the increased uncertainties of task environments for green supply chain members. From a resource dependence perspective, for those firms (e.g., producers) lacking the resources needed to carry out extended producer responsibility, developing long-term collaborative relationships with other chain members that possess the necessary resources is indispensible to ensure their on-going viability and success under TPPI [

30,

31]. Nevertheless, the aforementioned power-interaction phenomena between dyadic green supply chain members under TPPI, and its effects on green supply chain collaboration and performance are rarely investigated in green supply chain management literature. Founded on resource dependence theory [

30], this study investigates direct effects of TPPI-oriented political and social power on channel power restructuring, and its indirect effects on collaborative relationships in, and channel performance of, producer-retailer channel dyads in green supply chains.

Resource dependence theory has been broadly applied to explain how organizations reduce environmental uncertainty by seeking and controlling the resources required to move toward the goal of maximizing organizational power for survival and success [

30,

31,

32]. Although resource dependence theory assumes that organizations struggle to acquire control over resources that either minimize their dependence on other organizations or maximize the dependence of other organizations on themselves, the corresponding measures are unnecessarily coercive [

33,

34]. Instead, a growing number of researchers advocate that channel dependence should be built upon harmonic, symbiotic, and collaborative relationships [

35,

36,

37,

38,

39]. Based on resource dependence theory literature [

15,

30], we argue that resource dependence theory provides a foundation to rationalize channel power restructuring phenomena, characterized particularly by resource interdependence and power asymmetry, to achieve the collective goals of a green distribution channel under TPPI. For instance, Crook and Combs [

15] applied resource dependence theory to describe the relationship between bargaining power and supply chain members’ benefits gained via collaboration. Hillman

et al. [

40] pointed out that uncertainty and dependence on law and social sanctions were noted by Pfeffer and Salancik [

30]; however, their effect on organizational performance is often overlooked in resource dependence theory literature. Similar arguments can also be found in the study by Aharoni

et al. [

41], who claim that governments are one of the most difficult environmental uncertainties to control due to the heterogeneous interests of different agencies and political decision makers. Motivated by the studies by Hillman

et al. [

40] and Aharoni

et al. [

41], this work addresses the issue of intervention by governments and green organizations in FCEP green supply chain collaboration. Moreover, we argue that FCEP green supply chain members, such as producers and contracted retailers, should work together to collectively reduce the environmental uncertainties of the larger socio-political system. This is in contrast to the use of either power control over dyadic members or political means to alter the conditions of external environments under TPPI.

Accordingly, from the collaborative perspective of resource dependence theory, this work contributes to green supply chain management by offering managerial insights into the relationships between resource interdependence, power interactions, green supply chain collaboration and performance under TPPI-induced environmental uncertainty. This work investigates an FCEP "bidirectional green supply chain" that contains the forward and reverse distribution channels associated with an FCEP producer-retailer channel dyad. We argue that under TPPI, managing such a bidirectional green supply chain relationship becomes more complicated and challenging due to the resulting bidirectional power restructuring in a channel dyad. Furthermore, this work accounts for the constructs of resource interdependence and power asymmetry that characterize the potential responses of FCEP dyadic members to TPPI. Therefore, this work seeks the optimal form for a sustainable and collaborative green supply chain relationship, not merely for a reverse channel relationship. Then, this work investigates the resulting effect on the collaborative relationship and performance of an FCEP producer-retailer bidirectional green supply chain. Specifically, this work enhances green supply chain management from the collaborative perspective of resource dependence theory and addresses issues ranging from the spontaneous resource interdependence of chain members to TPPI-induced resource interdependence. To our best knowledge, this work is one of the first empirical studies linking TPPI with channel power restructuring and collaborative relationships in green supply chain management.

The remainder of this paper is organized as follows.

Section 2 provides an overview of the main constructs investigated in this work.

Section 3 presents the proposed conceptual model that characterizes the causal relationships among the proposed constructs by hypotheses postulated in this work.

Section 4 describes the analytical process, including instrument development and methods used for data collection and testing the validity of the proposed model. Analytical results and important findings are discussed in

Section 5, followed by concluding remarks and managerial implications in

Section 6. Finally, research limitations and suggestions for future research are presented in

Section 7.

3. Model and Hypotheses

Building upon advances in the green supply chain management and resource dependence theory literature, this work investigates the issue of FCEP producer-retailer green supply chain collaboration under TPPI from a resource dependence perspective. As mentioned, TPPI differs worldwide, and the resulting effects of political and social power on channel power restructuring, collaborative relationship management and green supply chain performance must be identified. From a producer’s point of view, extending the existing producer-retailer distribution channels into bi-directional green supply chains to serve end-customers can be more efficient and effective than outsourcing to logistics companies for implementing extended producer responsibility. Particularly, in considering accessibility to end-customers, we assert that an FCEP producer may rely markedly on the resources of a contracted retailer (e.g., favorable store locations and human resources) to fulfill not only forward logistics/marketing but reverse logistics activities as used-product repairing and recycling under TPPI. Nevertheless, some literature [

105] has noted that third-party (e.g., governments) intervention via regulatory and financial instruments may increase the reverse logistics partners’ bargaining power when negotiating with producers before achieving cooperative contracts. We conjecture that such a power-shift phenomenon may stem from the changes in inter-organizational resource dependence situations revealed in FCEP green supply chains under the influence of political and social power. This argument may hold particularly when a producer relies heavily on a contracted retailer’s resources to facilitate green product marketing as well as reverse logistics service such as used-produced repairing and end-of-life product collection to carry extended producer responsibility.

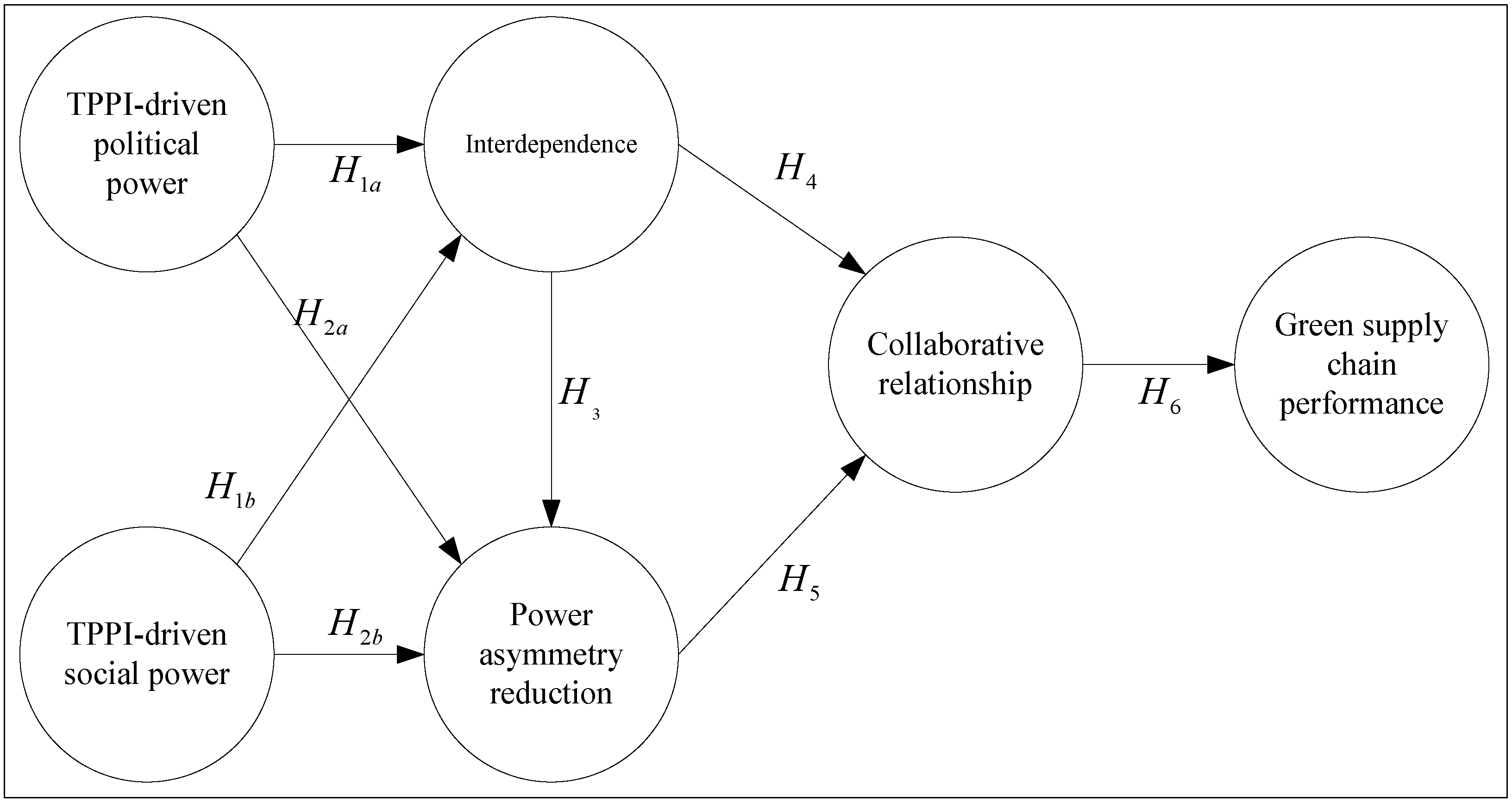

To characterize the power interplay and collaborative relationship between an FCEP producer and its contracted retailer as they move toward a collaborative green supply chain under the influence of political and social powers in the TPPI context, this work proposes a conceptual framework (

Figure 1). Specifically, we investigate whether TPPI-driven political and social power has significant effects on the interdependence and power structure of FCEP producer-retailer channel dyads, and subsequently influences their collaborative relationship and channel performance. Therein, we argue that an FCEP green supply chain’s sustainable competitive advantage relies on a sustainable collaborative relationship and superior green supply chain performance, including consumer green value adding. Therefore, the correlations among four primary domains, (1) TPPI-driven political and social power; (2) channel power restructuring; (3) collaborative relationship; and (4) green supply chain performance, are codified in the proposed conceptual framework.

Six hypotheses and their theoretical underpinnings are proposed below. For clarity, the producer and contracted retailer are referred to as the source member and target member, respectively.

Figure 1.

Proposed conceptual framework.

Figure 1.

Proposed conceptual framework.

3.1. TPPI-Driven Political and Social Powers vs. Interdependence

Observed from green supply chain practices under TPPI, an FCEP producer and its contracted retailer likely work together closely and collectively to gain long-term joint competitive advantage and for extended producer responsibility from a resource dependence perspective. In reality, serious e-waste problems worldwide and the resulting take-back laws that make producers bear most responsibility for collecting and recycling e-wastes have become a global issue in efficient e-waste management [

13]. According to resource dependence theory [

30], political and social powers oriented from a larger socio-political system have increased the uncertainties of task environments of the producer-retailer channel dyad in an FCEP green supply chain [

40,

41]. Despite the fact that WEEE directives identify producers as the entity that must bear most extended producer responsibility, numerous EU states have involved retailers in take-back systems to bear jointly the responsibility of e-waste collection with producers. Collection at retail outlets is the primary measure facilitating end-of-life product returns from end-customers [

106]. Similar phenomena exist in Asia (e.g., Japan, South Korea, and Taiwan), where retailers play the key role of e-waste collectors, even though producers bear the major responsibility of e-waste collection and recycling [

107]. In Japan, FCEP branders favor establishing their own reverse channels with contracted retailers to facilitate end-of-life product returns from end-customers, controlling recycled-material input quality for green manufacturing, and optimizing recyclability by greener designs [

12]. As a supply chain partner of an FCEP producer, the contracted retailer is likely to bear extended producer responsibility with the producer coercively and non-coercively under the influence of governments and green organizations, respectively [

11,

108]. When the FCEP producer fails to comply with green regulations (e.g., take-back laws and RoHS), the contracted retailer’s economic performance (e.g., sales and profits) will be influenced, particularly when the producer is the retailer’s key supplier [

9,

16].

Furthermore, we argue that TPPI-driven political and social power likely increases the mutual dependence of the FCEP producer and contracted retailer in the forward channel. For instance, to comply with RoHS or green criteria issued by Greenpeace, an FCEP producer is likely to invest, coercively or non-coercively, in green production technology and eco-friendly materials/components to achieve green production [

59,

109]. Such green investment increases the FCEP producer’s channel power as expert power [

48], thus increasing the contracted retailer’s dependence on the producer’s research and development (R&D) resources to improve economic performance (e.g., sales and profits). Nevertheless, the success of green marketing seems to rely on the contracted retailer’s resources (e.g., sales points and salesmen’s capabilities) and cooperative efforts [

110]. In reality, evidence from numerous practical cases have indicated that producers rely heavily on the resources and cooperation of contracted retailers to introduce and promote the green features of products (e.g., hybrid vehicles and power-efficient home appliances) in forward distribution channels [

111,

112]. Such an inference holds particularly true when the producer adopts the green differentiation strategy as a competitive strategy that highlights the green features and eco-benefits of green products to gain competitive advantage in green markets.

Accordingly, we assert that under TPPI-driven political and social power, an FCEP producer and its contracted retailer increasingly rely on each other in a bi-directional green supply chain to reduce the uncertainty of task environments. Thus, we postulate the following hypotheses.

Hypothesis 1a. TPPI-driven political power has a positive effect on the interdependence between a producer and its contracted retailer in an FCEP bi-directional green supply chain.

Hypothesis 1b. TPPI-driven social power has a positive effect on the interdependence between a producer and its contracted retailer in an FCEP bi-directional green supply chain.

3.2. TPPI-Driven Political and Social Power vs. Power Asymmetry Reduction

Despite the ubiquity of power asymmetry in inter-organizational power interplays, including that in green supply chains, this work is concerned with how the FCEP producer-retailer members’ power is restructured under TPPI. Drawn from resource dependence theory, we argue that political and social power in the larger socio-political system push an FCEP producer and its contracted retailer to seek balanced power under TPPI. In this work, a power balance is defined as a symmetric mutual dependence condition in which no players, neither FCEP producers nor contracted retailers, have the power advantage needed to control unique resources under TPPI. According to resource dependence theory, TPPI via direct (e.g., regulatory instruments) or indirect (e.g., green organizations claims) measures increases the uncertainty of external environments of FCEP green supply chains [

18,

30]. Therein, neither producers nor retailers can be isolated from the lifespan of an FCEP [

11]. Instead, FCEP producers and retailers are more likely to work together in the form of reciprocal resource interdependence to reduce TPPI-induced environmental uncertainties jointly encountered by dyadic members. Consequently, dyadic members may have two sources of organizational and environmental uncertainties under TPPI: one is the diversity and volatility of green laws and policies (e.g., take-back directives and RoHS) imposed by governments; and the other is social norms and challenges typically raised by green organizations [

29,

113,

114]. These environmental uncertainties under TPPI contribute to operational and relational risks commonly faced by all producers and retailers in FCEP green supply chains [

115,

116]. Particularly, relational risks generally arise from the possible defection of the reverse channel partner, and not fulfilling a commitment or tasks to comply with green laws and directives [

117,

118]. To alleviate these uncertainties under TPPI, both the producer and contracted retailer will likely seek closer cooperation rather than leveraging power advantage to gain short-term benefits exploited from the partner under reciprocal task interdependence [

15,

62]. Accordingly, we argue that TPPI may stimulate the willingness of dyadic members to seek a power-balanced cooperative relationship in an FCEP producer-retailer bi-directional green supply chain; thus, the following hypotheses are postulated.

Hypothesis 2a. TPPI-driven political power has a positive effect on alleviating the power asymmetry between a producer and its contracted retailer in an FCEP bi-directional green supply chain.

Hypothesis 2b. TPPI-driven social power has a positive effect on alleviating power asymmetry between a producer and its contracted retailer in an FCEP bi-directional green supply chain.

3.3. Interdependence vs. Power Asymmetry Reduction

As noted by Preffer and Salanick [

30], inter-organizational interdependence is characterized as either outcome or behavioral interdependence, implying that dyadic members must rely on the resources and actions of each other to achieve mutually dependent business goals. Therein, neither dyadic member can fully control all the resources required for completing an action or gaining the desired outcome from an action. Such an argument particularly holds true in the study case—the FCEP producer-retailer bi-directional green supply chains under TPPI—as the FCEP producer and contracted retailer might be best off working together in the form of reciprocal interdependence to reduce the uncertainty of external environments under TPPI [

14,

15]. As resource dependence theory views resources as a set of power, the channel power of dyadic members (either a producer or retailer) under TPPI is rather minor compared to the political and social power of the larger socio-political system. Thus, we argue that no dyadic member can reduce TPPI-based environmental uncertainty without the help of dyadic partners, even when they possess dominant channel power such as the expert and referent power of an FCEP producer and the informational power of a contracted retailer [

48,

119]. Through reciprocal interdependence, the dyadic producer-retailer members are, thus, unlikely to leverage their power advantage, including bargaining power, to covet short-term benefits squeezed from their partners under TPPI [

15]. Instead, they tend to seek power-balanced equilibrium in response to the increased uncertainty of task environments under TPPI. Accordingly, we propose the following hypothesis.

Hypothesis 3. TPPI-induced interdependence reduces power asymmetry between a producer and its contracted retailer in an FCEP bi-directional green supply chain.

3.4. Interdependence vs. Collaborative Relationship

Motivated by Thompson [

14], and Crook and Combs [

15], this work posits that the interdependence between a producer and its contracted retailer in an FCEP green supply chain likely exists as reciprocal task interdependence under TPPI. As noted in Crook and Combs [

15], supply chain members’ tasks under reciprocal interdependence are highly dependent on how their partners perform, and, thus, coordination must be achieved by active mutual adjustment via such measures as sharing information, knowledge, and discussion to jointly resolve problems and conflicts [

120]. Thus, we argue that, under the increased uncertainty of task environments under TPPI, cooperation and coordination of dyadic members (

i.e., a producer and contracted retailer) likely extends from a typical distribution channel to an FCEP bi-directional green supply chain for joint extended producer responsibility. As the concept of product stewardship emerges, increasing consensus exists in that the FCEP supply chain partners of producers, including retailers, must be involved and regulated by green laws and social norms [

108,

121].

Consequently, such TPPI-induced reciprocal task interdependence may facilitate the dyadic collaborative behavior of members in either the process or relational domains; that is, increased interdependence promotes the structural and attitudinal convergence of dyadic members in strategic goals and cooperative activities [

122,

123]. Therein, joint actions taken for joint planning and joint problem solving characterize the collaborative behavior of dyadic members from the process perspective [

71,

91,

92]. For instance, an FCEP producer and its contracted retailer may collectively plan green marketing and promotion programs to jointly create consumer values and profits in a forward distribution channel [

110,

124,

125], and moreover, jointly identify problems and work out solutions for compliance with take-back laws [

125,

126]. Conversely, mutual trust and relationship commitment characterize the dyadic members’ collaboration from the relational perspective [

93,

94,

127]. Therein, we argue that reciprocal interdependence likely fosters the collaboration between dyadic members that is characterized in the relational domain because reciprocal interdependence reflects the willingness of dyadic members to bear a short-term sacrifice to maintain a stable and cooperative relationship [

128], and pursue common interests, mutual understanding, and reciprocity [

129]. The increase in reciprocal interdependence increases friendliness and reduces the number of disagreements, conflicts, and the degree of opportunistic behavior in a channel dyad [

130]. Therefore, we propose the following hypothesis.

Hypothesis 4. TPPI-induced interdependence strengthens the collaborative relationship between a producer and its contracted retailer in an FCEP bi-directional green supply chain.

3.5. Reduction in Power Asymmetry vs. Collaborative Relationship

As noted, the TPPI-driven political and social power likely coercively and non-coercively pushes an FCEP producer and its contracted retailer to move toward a power-balanced equilibrium for joint extended producer responsibility. From a resource dependence perspective, no dyadic member has the power advantage to control alone the critical resources required in a green supply chain, and ability to address solely the issue of TPPI-induced environmental uncertainty [

30,

40]. Moreover, no dyadic member can be isolated from the lifespan of an FCEP without sharing the responsibility of managing the lifecycle of the product [

11]. Such a TPPI-induced process that seeks balanced power in an FCEP producer-retailer green supply chain is rooted in reciprocal resource interdependence [

14]. This interdependence pushes dyadic members to collaborate synergistically to respond collectively to the larger political and social power. Therein, we argue that a source member (e.g., an FCEP producer) is likely to refrain from the use of coercive power, including bargaining power, to resolve channel conflicts in a process of seeking balanced power [

44,

131]. Furthermore, the mutual trust and commitment of dyadic members can be improved under power symmetry [

67]. Accordingly, a reduction in power asymmetry by TPPI likely causes dyadic members to collaborate closely to respond jointly to the increased uncertainty of task environments under TPPI [

15,

84].

Furthermore, a source member (e.g., an FCEP producer) will likely adopt relational governance mechanisms to enhance the cooperative relationship of dyadic members, including mutual trust and commitment, as channel power is restructured toward a power-balanced equilibrium under TPPI [

71,

91,

92]. From a source member perspective, relational risks always exist in a channel dyad. This is true particularly when dyadic members perceive that power asymmetry is reduced, where the source member’s dependence on the target member’s resources increases and task uncertainty increases [

132]. The development of mutual trust via relational governance mechanisms is thus an alternative to resolve relational risks that may exist between dyadic members under task uncertainty. According to Zaheer and Venkatraman [

91], a source member’s effort in relational governance reflects its willingness to move toward a close relationship involving dyadic members fulfilling focal activities cooperatively. For instance, a producer may reciprocally provide technical support and training for the retailer’s personnel to enhance the retailer’s competence for sales of new/green products, and jointly solve problems encountered in an FCEP green supply chain [

94]. Such an idiosyncratic relational governance measure, thus, may further enhance the contracted retailer’s trust and commitment to a long-term collaborative relationship with the producer [

81]. Therefore, a source member (e.g., an FCEP producer) is likely to adopt relational governance measures to mitigate relational risks when dyadic power asymmetry is reduced under the increased uncertainty of TPPI-induced task environments [

71,

92].

Accordingly, we propose the following hypothesis to characterize the relationship between power asymmetry reduction and a collaborative relationship in the green supply chain.

Hypothesis 5. Power asymmetry reduction enhances the collaborative relationship between a producer and its contracted retailer in an FCEP bi-directional green supply chain under TPPI.

3.6. Collaborative Relationship vs. Green Supply Chain Performance

The inter-organizational collaborative relationship and its effects on supply chain performance have been investigated by numerous studies [

84,

115], and proved to be positively correlated [

25,

77,

92,

133,

134,

135,

136,

137]. As claimed in Kalwani and Narayandas [

77], maintaining a long-term partnership with consumer firms facilitates s supplier to increase not only short-term benefits (e.g., sales and profits) but also long-term benefits (e.g., market share and competitive advantage). Empirical results from Nyaga

et al. [

92] demonstrated that trust and commitment do have positive effects positive on performance in a supply chain collaborative context. Moreover, some supply chain management scholars have provided evidence showing that collaborative relationships help improve operational performance (e.g., reduced inventory, fill rate, stockout frequency, and lead time) [

138,

139,

140] and financial performance [

34,

84,

141,

142,

143]. Based on survey data collected from U.S. producers, Cao and Zhang [

84] showed that, via the mediating effect of collaborative advantage, supply chain collaboration does deliver benefits, including superior financial performance, to all partners in a collaborative supply chain. Stemming from the collaborative perspective of resource dependence theory, Hofer

et al. [

34], for example, analytically demonstrated that, via a collaborative relationship, an organization can benefit from the channel partner’s dominant market power and obtain improved financial performance.

Extended from the above literature in supply chain performance, we further argue that a closely collaborative channel relationship is favorable for green supply chain performance, particularly in terms of environmental performance (e.g., e-waste management and resources usage) and customer green value creation. From a resource dependence perspective [

30], inter-organizational collaboration facilitates the establishment of a negotiated task environment that enhances inter-organizational links in goal setting, problem solving, and resource sharing. Through close collaboration, dyadic members (

i.e., a producer and its contracted retailer) can easily identify the unique resources required, critical problems to solve, and common norms to follow to manage environmental uncertainty efficiently in the socio-political system, including actors of governments and consumers under TPPI [

14,

144]. Particularly, a closely collaborative relationship underlying a cooperative producer-retailer green supply chain likely facilitates fulfilling not only joint (green) marketing strategies but also reverse logistics services provided for end-customers through joint planning and actions, thus enhancing green brand image, green value adding, and customer satisfaction in green.

As the above theoretical and practical evidence indicates that as the collaborative relationship increases in closeness, the superiority of channel performance increases for the dyadic producer-retailer green supply chain under TPPI, we postulate the following hypothesis.

Hypothesis 6. The closeness of the collaborative relationship improves joint performance between a producer and its contracted retailer in an FCEP bi-directional green supply chain under TPPI.

6. Concluding Remarks and Implications

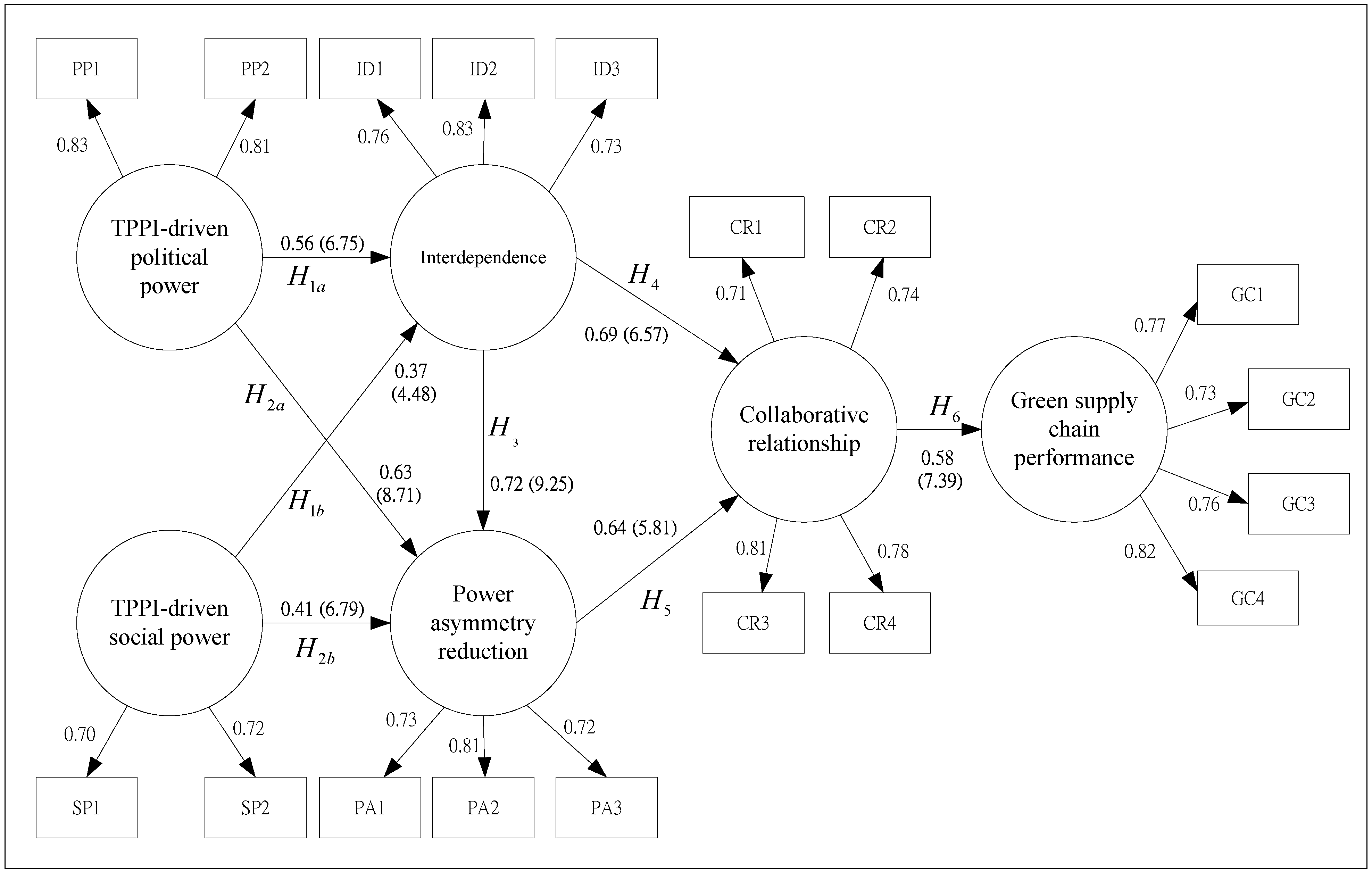

This work uses an resource dependence theory-based comprehensive conceptual framework to investigate the interrelationships among channel power restructuring, collaborative relationship, and FCEP green supply chain performance under TPPI. Six hypotheses are given and tested using SEM. A hypothetical model is established to analyze correlations among related constructs in the proposed conceptual framework.

This work adds two unique features to literature on supply chain relationship management. Drawing from resource dependence theory, this work reveals that TPPI generates a high degree of interdependence between an FCEP producer and its contracted retailer in a cooperative extended producer responsibility system when the contracted retailer is allocated additional responsibility in a reverse channel. In this work, TPPI is treated as an influence in the form of social and political power exerted by the socio-political system, which is one major cause of uncertainties of external task environments for green supply chains. Thus, the dyadic producer-retailer members of an FCEP green supply chain must rely not only on a typical vendor-buyer exchange relationship, but also on the reciprocal interdependence underlying a collaborative relationship to reduce external environmental uncertainties under TPPI. Therein, efforts to enhance green supply chain management with resource interdependence and address the issue of extended producer responsibility extended from an organizational perspective to TPPI-driven channel collaboration are implicit in this work. Moreover, this work is one of the first empirical studies linking TPPI with channel power restructuring and collaborative relationship in FCEP green supply chains. To fill this research gap, analytical results indicate that correlations exist among TPPI, inter-organizational interdependence, power asymmetry reduction, collaborative relationship, and green supply chain performance under the influences of political and social power.

Drawing from analytical results, several managerial implications in relation to seeking a channel power-balanced condition and collaborative relationships for superior green supply chain performance under TPPI are summarized as follows.

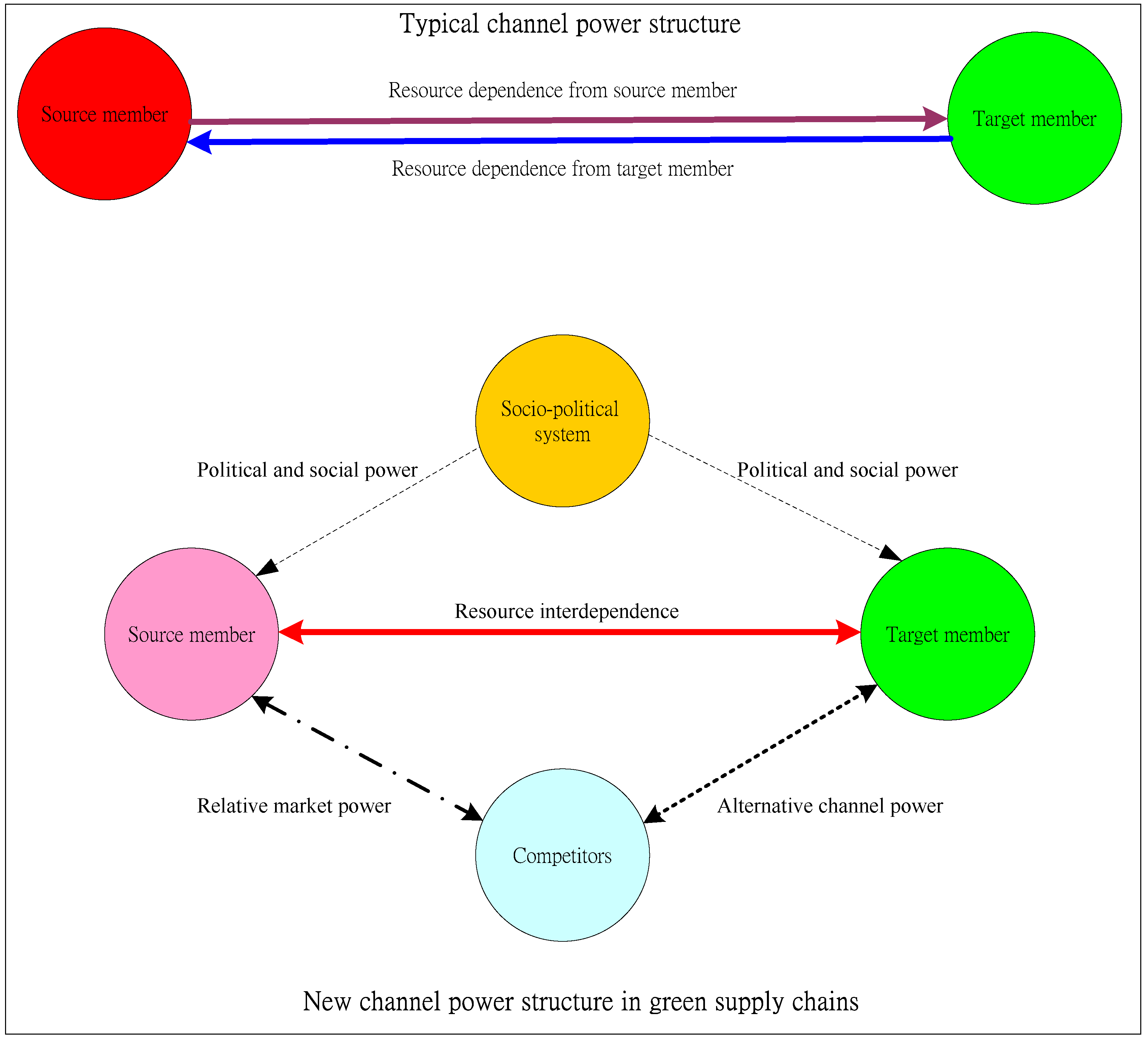

Based on analytical results, we argue that the characterization of channel power in FCEP green supply chains should not be limited to typical seller-buyer organizational power interplay. Instead, a comprehensive conceptual framework of channel power should account for the influences of political and social power, as the socio-political system has vested interests in FCEP green supply chains. Consequently, we argue that a new channel power structure in green supply chain contexts should contain interdependent power influences from three actors: (1) the source member; (2) the target member; and (3) the socio-political system, including governments, green organizations, and consumers. Additionally, a fourth actor, the market influence of competitors/outside options in a competing green supply chain, should also be considered.

From a source member (e.g., a producer) perspective, political and social power as intervention by the socio-political system undoubtedly exists, and increases task uncertainty in global and green supply chain contexts. Furthermore, such political and social power codified in TPPI is likely to contribute to “push force” to restructure dyadic members’ channel power as they move toward power-balanced equilibrium in an FCEP green supply chain. Particularly, governments’ regulatory approaches influence task environments in which those actors operate, including business processes (e.g., green production, reverse logistics operations, and contracting) and performance (e.g., financial reporting, audits, and security compliance). Therefore, the source member must rely on additional resources from the target member (e.g., contracted retailer) for extended producer responsibility and green marketing programs (e.g., the collaboration between Apple and its global contracted retailers to provide gift cards to end-customers for green marketing and recycling programs). Meanwhile, other competitors (e.g., competing producers) characterized by relative market power also exist and compete with the source member for complementary resources from the target member, resulting in “pull force” that may dilute the interdependence of the incumbent channel dyad (

i.e., source and target members) under TPPI. The influence attributed to competitors’ relative market power also suggests that a large number of negotiation opportunities exist for the target member (e.g., a contracted retailer). For instance, an FCEP producer must consider a contracted retailer’s response in negotiation under the bidding effect of its competitors (

i.e., competing producers), which may provide alternatives [

174] to the contracted retailer, on the negotiated decision of the contracted retailer.

Conversely, like the target member, a contracted retailer is also likely to perceive the increase in the interdependence and collaborative relationship in an FCEP green supply chain, moving dyadic members toward a power-balanced equilibrium under TPPI (

i.e., political and social power). From a sustainable resource dependence perspective, the target member can leverage the power restructuring effect to gain additional benefits from the collaborative advantage jointly created with the source member while moving toward power-balanced equilibrium. Therein, the manager of a contracted retailer can leverage such TPPI (e.g., green regulations and intervention by green organizations) to shift channel power characterized as legitimate and informational power [

48] into its firm’s favorable resources. For instance, the contracted retailer can request specific investment from the source member, joint brand strategies, joint promotion and advertising programs, and priority in new-product franchises in an FCEP bi-directional green supply chain.

Accordingly, the source member must adopt ambidextrous relational governance mechanisms to alleviate the reverse effects induced by the “push” and “pull” forces for viability and transform them into positive effects for sustainable development under TPPI. We argue that typical resource dependence theory [

30] can be further extended to deal with resource dependence and power interplay issues from a “micro-inter-organizational” level to a “macro-inter-organizational” level. Therein, key members (e.g., governments, green organizations, and consumers) of the socio-political system may no longer be treated only as sources of uncertainties in task environments. Instead, treating them as partners, and getting them involved in a larger collaborative green supply chain system to identify joint goals, taking collaborative actions (e.g., sharing information and knowledge), and sharing collaborative advantage are “triple-win” measures noteworthy. In reality, optimal green policy instruments, e.g., take-back and recycling programs, should also get feedbacks from green supply chain members. Additionally, a lot of anecdotal evidence has suggested that governments can also join in collaborative green supply chains in different forms, e.g., buyers of recycled products for public procurements.

Figure 3 shows this new power structure relative to the typical channel power structure. The influence of political and social power as TPPI and that of relative market power are involved when characterizing comprehensively the resource interdependence and power interplay between the source and target members under the uncertainty of external environments.

Figure 3.

New channel power structure in green supply chain contexts.

Figure 3.

New channel power structure in green supply chain contexts.

7. Limitations and Future Research

Despite the contribution of this work to literature, it has limitations that warrant further investigation. The study scope is limited to two-tier bi-directional distribution channels formed typically by dyadic members (e.g., FCEP producers and contracted retailers). Model extension and tests for various types of power structures, including direct and indirect power interplays with third parties (e.g., governments, green organizations, competitors, and end-customers) may enrich generalizations and managerial insights into resource dependence theory-based supply chain collaboration. The relational governance mechanisms, including the combined use of transactional and relational mechanisms applying for different types of power structures, are also noteworthy. Moreover, other forms of channel relationships, such as producer–reverse logistics supplier and producer-green component supplier channels under the influence of TPPI also warrant additional research. For instance, the cross-country transfer of hazardous waste, particularly in terms of illegal e-waste export, remains as a critical issue in global reverse supply chain management, where the transnational supply collaboration with additional chain partners (e.g., carriers and logistics companies) should be investigated further. Such an issue, however, seems to go beyond the scope of this work, in which a contracted retailer is allocated the responsibility of local collection and repairing in a reverse channel, thereby acting as the interface between end-customers and the producer in this work. In the case of cross-country transfer of e-waste, a producer remains the source member, which also acts as a shipper/exporter, whereas the target member can be an international carrier/logistics company. Therefore, a new partnership with a new target member should be defined to address the aforementioned issue. As this work investigates bi-directional channel relationships between FCEP producers and contracted retailers, a survey respondent should ideally be familiar with activities in both forward and reverse distribution channels, and involved in the corresponding decision processes in a sampled firm. Nevertheless, practices of forward and reverse channel activities are typically handled by two different departments, namely, the marketing and logistics departments in a firm. As explicated in

Section 4, in addition to survey respondents as key informants, their colleagues working in these two departments were invited to assist them in answering survey questions. However, elaborate sampling and survey methods can be adopted to enhance the validity of data samples.

Future research should collect additional data from various industries or across different countries for comparative analyses to test the validity of the proposed conceptual framework and hypotheses. Further extension of the conceptual model linked with issues of resource dependence theory-based sustainable competitive advantage of a green supply chain for competing and strategic marketing planning may also warrant further investigation. Moreover, the influence of competitor power via the mediating effects of threats and bidding on source and target members is ignored in this work, but is worthy of future research. Power reorientation and relationship quality management for the case of a source member dealing with the strategic alliance of target members in a green supply chain is another interesting issue to address in future research. In addition to trust and commitment, we suggest that other constructs characterizing the dyadic members’ attitudes about collaborative advantage sharing and risk sharing as they moves toward sustainable supply chain collaboration are also noteworthy.

In summary, this work systematically characterizes the interrelationships among TPPI, channel power restructuring, collaborative relationship, and FCEP green supply chain performance in a resource dependence theory-based conceptual framework, and demonstrates the applicability of resource dependence theory and channel power theory to practical cases for green supply chain relationship management. More importantly, we claim that creating a chain-based collective regulatory compliance strategy via collaboration across FCEP green supply chain members is urgently needed, and will be the next global issue in global TPPI contexts.