1. Introduction

Business sustainability is the organizing principle for meeting human development goals while at the same time sustaining the ability of natural systems to provide the natural resources and ecosystem services upon which the economy and organization depend [

1]. In recent decades, the importance of building sustainable businesses is increasingly being recognised. For example, The World Summit on Sustainable Development (2002) proposed the phrase “people, planet, prosperity” to reflect the notion that sustainable development requires a balancing of economic, environmental, and social issues [

2]. Currently, many economic, environmental, and social analyses have been integrated with regards to various aspects of sustainability. The Waste Electrical and Electronic Equipment (WEEE) directive of the European Union has a strong impact in terms of “extended producer responsibility” by which all original equipment manufacturers (OEMs) are required to take responsibility for the collection and recycling of their products after they are disposed of by their owners.

Despite the fact that remanufacturing has been demonstrated to have economic, social, and environmental benefits, this process often creates an uneasy dilemma for OEMs. On the one hand, customers often perceive remanufactured products to be low-cost substitutes for new ones. As a result, they value remanufactured products much less than new ones, and the small cost savings for OEMs do not justify their adoption of remanufacturing [

3]. On the other hand, many customers will associate the lower quality of a remanufactured product to the OEM’s brand, which not only leads to a decrease in profits from new unit sales but also makes it difficult for OEMs to maintain a high-quality image [

4]. In addition, with global economic integration and the democratization of technology, many OEMs have chosen to outsource their manufacturing operations to offshore companies that, without this original manufacturing expertise, often find it difficult to set up low-cost remanufacturing operations by themselves [

5].

As a result, many OEMs do not engage in remanufacturing processes themselves, as they instead outsource it to the third-party service providers [

6]. For example, IBM creates certification programs for IBM equipment remanufactured by third-party firms, where IBM engineers inspect the remanufactured products and give them a seal of approval. Similarly, Caterpillar has established a remanufacturing division that markets both equipment and parts, including parts from other manufacturers [

7]. From this early success, Caterpillar and Land Rover signed an agreement where Caterpillar Remanufacturing Services acts as Land Rover’s lead global remanufacturing service provider. They provide integrated solutions for Land Rover on remanufacturing development and operations, core management, and distribution [

8]. Despite the demonstrated economic, social, and environmental benefits of remanufacturing, few OEMs have adopted the practice. For example, according to a survey from the United States, only 6% of more than 2000 remanufacturing firms were OEMs [

9].

In practice, the outsourcing of remanufacturing is not a purely make-or-buy decision, but involves a reverse channel, which determines the core return rate from customers and affects the performance of sustainability [

10]. On the one hand, although many OEMs decide to outsource their remanufacturing activities, they may still control the reverse channel by collecting the end-of-life products from users, which protects their sales of new products. An extreme case is that of Sun Microsystems (Sun), one of the world’s leading IT server firms. In 2004, Sun announced pricing and license availability for its used products. Marion [

11] notes that in such cases, the relicensing fee is deliberately set so high that “in the end, the potential buyer for the previously owned equipment may have no choice but to return to Sun for a new product”. As a result, “Sun is deliberately attempting to eliminate the secondary market for its machines worldwide”. In other words, Sun used pricing and license availability for its used products as a means of controlling the reverse channel, resulting in a lower availability of cores for collection by third-party remanufacturers (TPRs). However, on the other hand, many OEMs seem to be open to outsourcing collection activities to TPRs. For instance, BMW outsourced the processing of end-of-life vehicles to a select set of dismantlers in Germany and gave them the proprietary right to do so. Hence, controlling of the reverse channel was given to the third party [

12]. The availability of a robust reverse supply chain is critical in facilitating good core availability, which is the backbone of remanufacturing [

13].

From a research perspective, the discussion above raises the fundamental question addressed in this paper. When outsourcing remanufacturing, should OEMs also outsource their reverse channels to third-party remanufacturers? Which is more beneficial for the economic, social, and environmental outcomes? To answer these two questions, we need to understand the factors that influence the choice between owning take-back operations (e.g., Sun) or outsourcing them to a third-party service provider (e.g., BMW).

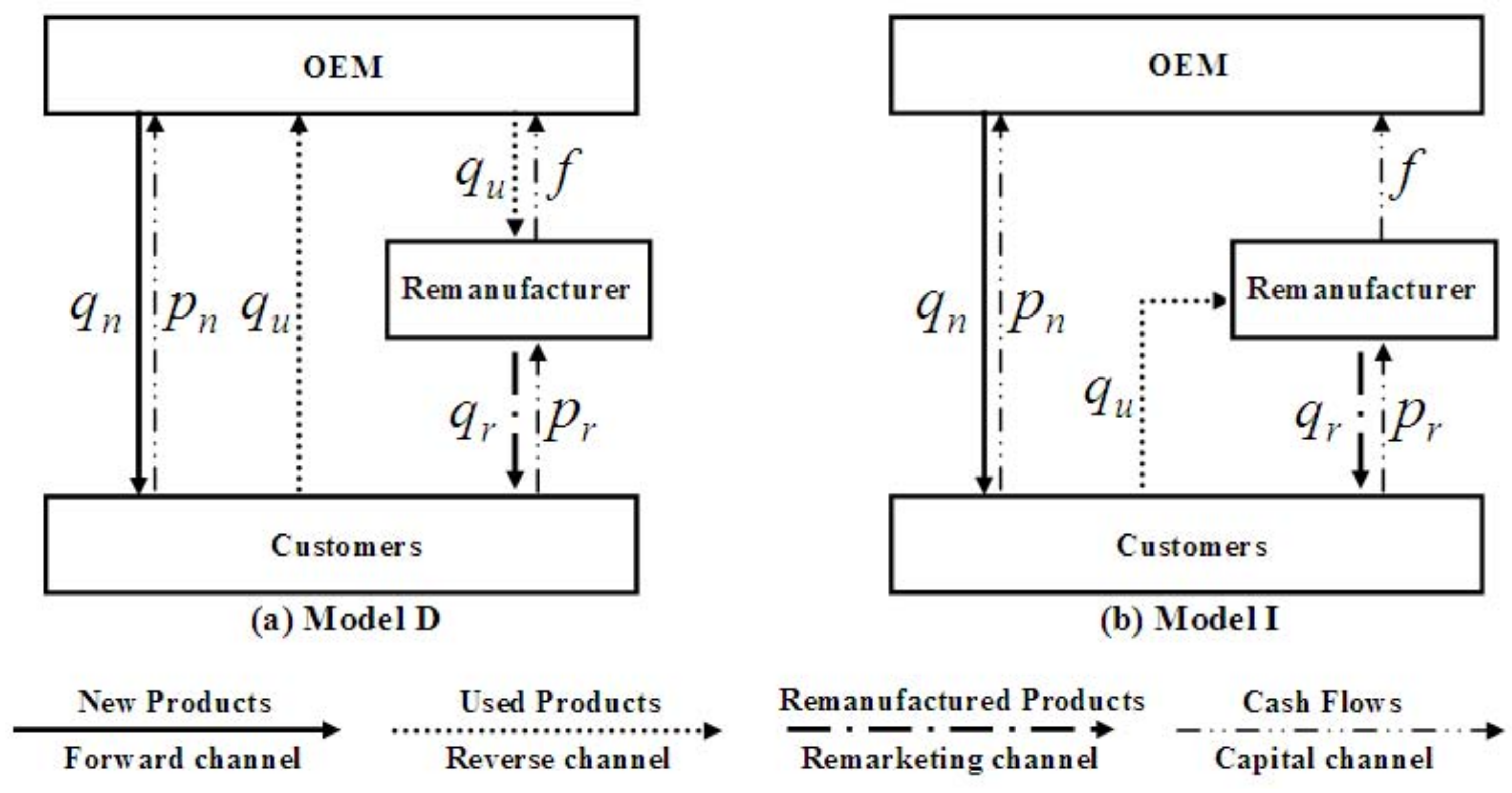

In this paper, we developed two models for outsourcing remanufacturing operations to a TPR with two options for take-back operations: (1) collecting cores itself (“direct collecting”, Model D) or (2) outsourcing collection efforts to the TPR (“indirect collecting”, Model I). Subsequently, we examine the implications of these strategies for issues relating to economic, environmental, and social sustainability.

Although there is a considerable body of research on strategies for outsourcing remanufacturing (e.g., Zou et al. [

14] and references therein), the issue of owning or outsourcing collection operations has received little attention in the literature. While recycling reverse supply chains have been thoroughly studied in terms of logistics network design, operational planning and the organization of channel operations (e.g., Karakayali et al. [

12] and references therein), little is known about how owning or outsourcing the reverse channel affects sustainability issues related to remanufacturing. Therefore, from a managerial perspective, this paper shows how the strategies of owning or outsourcing take-back operations have strategic consequences in terms of economic, environmental, and social issues.

We first studied the differences in economic sustainability estimated by two models. Our key finding was that when an OEM undertakes take-back operations, it is always beneficial for the OEM and the industry. Furthermore, we found that there is a threshold cost below which a TPR can also benefit from a reverse channel owned by an OEM. In essence, we found that under certain conditions, all parties prefer Model D to Model I.

Following this, We examined the differences in the environmental sustainability estimated by each model. This involves investigating whether manufacturers should own or outsource their take-back operations and which approach is better for the environment. Our analysis reveals that Model D always has a smaller environmental impact compared to Model I. In essence, outsourcing the reverse channel to a TPR is always more detrimental to the environment.

Finally, we intended to answer whether manufacturers should own or outsource take-back operations from a social welfare perspective and which approach has better outcomes. More specifically, apart from regular profitability, we compared the social benefits of both models in terms of adding consumer surplus to profits. We found that when the cost of remanufacturing is not too pronounced, OEM-owned take-back operations have significant social benefits.

The rest of the paper is organized as follows.

Section 2 reviews the related literature and explains our contributions in more detail.

Section 3 describes both models and analyzes their optimal decisions.

Section 4 examines both models from a sustainability perspective and presents the main results.

Section 5 concludes our work and provides future research directions.

2. Literature Review

To the best of our knowledge, Majumder and Groenevelt [

15] were the first that tried to analyze the interaction between an OEM and a TPR using a game theoretical model. They found that the profit of OEMs increases the TPR’s remanufacturing cost, which implies that the entry of TPR is detrimental to the OEM. Recently, Zou et al. [

14] compared these two modes by modeling the game between the OEM and the TPR. This suggested that when consumers perceive that the remanufactured products have low value, the TPR prefers the authorization approach. Otherwise, the TPR prefers the outsourcing approach. More recently, Jin et al. [

16] developed a game theoretical model to revisit the impact of third-party remanufacturing on a forward supply chain, and showed that regardless of the OEM’s remanufacturing capability, third-party remanufacturing could be beneficial to the OEM due to the supplier lowering the wholesale price as a response to the entry of the TPR. Huang et al. [

17] and Govindan et al. [

18] provide complete literature reviews that examined the outsourcing issues related to remanufacturing. As mentioned earlier, rather than focusing on the outsourcing remanufacturing operations between OEM and the TPRs, we provide an alternative and complementary approach to consider: when outsourcing remanufacturing, should OEMs also outsource their reverse channels to TPRs?

Our work is also related to the literature on reverse logistics, which involves a process that accepts previously-shipped products or parts from the point of consumption for possible reuse, remanufacturing, recycling, or disposal. For example, Savaskan et al. [

19] compared three options of collecting products, and found that when considering the decentralized channel, the retailer is the most effective undertaker of product collection operations. Ordoobadi [

20] presented a multi-phased decision model for strategic analysis of outsourcing remanufacturing operations, which is a comprehensive tool for effective decision making that considers both economic and strategic factors. Supposing an OEM that can choose between three reverse hybrid collection channel structures, Hong et al. [

21] showed that with all things being equal, the OEM and the retailer hybrid collection channel is the most effective reverse channel structure for the OEM. Several other papers have studied problems that arise in the reverse logistics network design [

21,

22,

23], operations planning [

24,

25,

26], and the organization of channel operations [

27,

28,

29].

In particular, our work is closely related to Karakayali et al. [

12] but differs from this study in two important aspects. First, they assumed that the demand for remanufactured parts is independent of the price of new parts, and thus they have ignored the cannibalization problems between new and remanufactured products. In contrast, we assume that the primary consumers will discount the value of the remanufactured product to be proportional to the willingness of consumers to pay for a new product. Consequently, there is a cannibalization problem between new and remanufactured products. Second, they mainly focused on how the differentiated power structure of leadership power in the collector-driven channel and remanufacturer-driven channel impacts the profitability of both parties. In contrast, we assume that the OEM is always the Stackelberg leader and focus on how owning or outsourcing the reverse channel affects sustainability issues relating to economic, environmental, and social outcomes in remanufacturing.

4. Model Analysis

Our analysis in this section aims to understand the differences between the two models. To do so, we need to address the questions posed at the beginning of this paper. We started by analyzing the differences in the optimal decisions provided by the models. Subsequently, we enriched our analysis by investigating the differences in the economic, social, and environmental sustainability outcomes of both models.

4.1. Comparison of Optimal Outcomes

Regarding the differences in the patent license fees charged by the OEM under Model D and Model I, we offer the following proposition based on the outcomes presented in

Table 2.

Proposition 1. The OEM is more likely to charge a higher patent license fee in Model D than in Model I (i.e., ).

Not surprisingly, the outsourcing of take-back operations increases the patent license fee charged by the OEM. We mentioned earlier that in Model D, the OEM participates in take-back operations by collecting end-of-life products from consumers and bearing the cost of collection. However, in Model I, such collection costs are paid by the TPR. Hence, as Proposition 1 shows, the OEM usually sets a lower patent license fee to compensate the TPR for their collection costs in Model I .

Comparing the optimal quantities under Model D and Model I establishes the following proposition.

Proposition 2. (i) Compared to Model I, the OEM provides lesser quantities of new products in Model D, with essentially .

(ii) Compared to Model I, the remanufacturer remanufactures more units in Model D, with essentially .

Proposition 1 shows that, compared to Model D, the OEM is more likely to charge a lower patent license fee in Model I. However, Proposition 2 further reveals that although bearing a lower patent license fee in Model I, the TPR prefers to provide fewer units of remanufactured products. It is important to note that the quantities of remanufactured products vary with changes in two of the model components: this quantity increases when the patent license fee is lowered, but decreases when the OEM increases the number of units sold in the new product market. Thus, Proposition 2 can be interpreted as follows. When the OEM outsources operations to the remanufacturer, the latter component above is always dominant. As a result, although bearing a lower patent license fee in Model I, the TPR prefers to provide fewer units of remanufactured products, as shown in Proposition 2.

4.2. Comparison of Economic Sustainability

Taticchi et al. [

36] stated that maximizing supply chain performance and meeting the economic needs of all parties are the two key components of economic sustainability in supply chains. Azevedo et al. [

37] and Hariga et al. [

38] also focused on economic sustainability with the argument that if a strategy is economically sustainable, it should not only maximize profitability but also be well-supported by all parties. As a result, following this line of research, we highlight economic sustainability from two main perspectives in this subsection. Which strategy is more beneficial to the OEM, the retailer and, in particular, the industry? Is this strategy well supported by all parties? We first looked at the difference in the OEM profitability predicted by the two models.

Proposition 3. It is more profitable for the OEM to undertake take-back operations directly, with essentially .

Proposition 3 shows that the OEM would benefit more by undertaking take-back operations itself. In order to understand the rationale behind this proposition, it should be noted that in Model D, when the OEM controls the reverse channel, it relies less on adjusting the patent fees charged to the TPR, and sets them more aggressively for profit extraction (see Proposition 1). Therefore, compared to Model I, although the numbers of new products decrease, the numbers of remanufactured products increase (see Proposition 2). As a result, Proposition 3 further reveals that the benefits obtained from remanufactured products under Model D are sufficiently large to compensate for the losses in new product sales.

This observation differs from those of Yu et al. [

3], which we believe stems from our model’s focus on whether or not the OEM outsources its take-back operations, rather than whether it centralizes or decentralizes its manufacturing and remanufacturing divisions. This proposition is also inconsistent with the results of Arya et al. [

39], who focused on new product marketing in a dual-channel supply chain and argued that an OEM can benefit from decentralized control and the use of transfer prices that are above marginal cost.

After this, we turned our attention to addressing the differences in TPR profitability predicted by the models. We summarize our finding as follows.

Proposition 4. There exists a threshold such that if , the TPR’s profits in Model D are higher than those in Model I (i.e., ). Otherwise, these profits are lower (i.e., ).

It is important to note that the remanufacturing operations are always undertaken by the TPR in our two models. As a result, the cost of remanufacturing (i.e., ) has no strategic impact on the difference in TPR profitability. However, Proposition 4 shows that, unlike the cost of remanufacturing (i.e., ), the scaling parameter of collection cost plays an important role in determining in both models. In particular, when , the TPR’s profits in Model D are higher than in Model I. It is important to note that the OEM cares greatly about the TPR’s revenue in Model D, because it can derive more profit in Model D than in Model I (see Proposition 3). In particular, when , it means that the collection cost is relatively low and remanufacturing becomes more profitable than producing new products. In order to earn greater profits from remanufacturing, the OEM would produce fewer new products (see Proposition 2). Thus, when , the TPR’s substantial profits stem from the OEM’s desire to obtain greater profitability for the remanufacturer by limiting the output of new products.

We were then able to highlight the differences in industry profit predicted by the models. Based on the outcomes in

Table 2, we provided the following proposition.

Proposition 5. The outsourcing of take-back operations is always detrimental to the industry; that is, .

Propositions 3 and 4 show that the outsourcing of the reverse channel is always beneficial for the OEM but may be detrimental to the TPR (i.e., when

, in Proposition 4). Proposition 5 further indicates that the benefits for OEM profitability (see Proposition 3) can “compensate” for TPR’s loss of profit (see Proposition 4). This observation is partially similar to that of Savaskan et al. [

19], who concluded that “the total profits in the closed-loop supply channel with OEM collection always dominate the total profits in that with the third-party collection” (p. 246). However, we noted that they did not pay any attention to outsourcing strategies.

Regarding the differences in the economic sustainability of the two models (i.e., the effects of reverse-channel outsourcing on all parties’ profitability) based on Propositions 3–5, we offer the following remark (without proof).

Remark 1. Compared to outsourcing take-back operations, if , all cores collected by the OEM can create benefits for the OEM, the TPR, and the industry.

The implication of Remark 1 and this subsection is that the ranking of different reverse channel structures (in terms of benefits to the OEM, the TPR, and the industry) indicates which strategy is well supported by all parties. Remark 1 shows that when , OEM-led take-back operations should be supported by all parties.

4.3. Comparison of Environmental Sustainability

In this subsection, we focus on issues of environmental sustainability. Specifically, we intend to answer the question posed at the beginning of this paper: from an environmental sustainability perspective, should manufacturers own or outsource take-back operations, and which is better for the environment? The environmental impact

consists of two components, which are namely the impact of new products and the impact of remanufactured products, and can be calculated as follows:

Proposition 6 states that the outsourcing of the reverse channel to a TPR is always detrimental to the environment.

Proposition 6. Model D is always greener than Model I, with essentially .

Comparing the equilibrium quantities when the OEM performs the take-back operations with those when the TPR fulfils this role, we found that compared to the TPR collection, the OEM (TPR) will provide fewer (more) new (remanufactured) products in Model D according to Proposition 2, with essentially (). As shown by Proposition 6, the total environmental impact predicted by Model D is smaller than that of Model I, due to greater quantities of remanufactured products and fewer new products (i.e., ).

4.4. Comparison of Social Welfare

In this subsection, we studied the differences in social welfare outcomes (

) between the models. We focused on the social welfare implications of OEMs outsourcing their take-back operations to a TPR. To evaluate the social impact of outsourcing a reverse channel, we compared the optimal welfare values obtained by the two models, where our welfare function includes the consumer willingness-to-pay for remanufactured and new products as well industry profits. Based on the findings of Orsdemir et al. [

40] and Yenipazarli [

41], our social welfare function consists of three components:

Consumer surplus,

, which consists of two components: consumer willingness-to-pay for remanufactured and new products. It is calculated as follows:

Industry profits, which follows our definition in Proposition 5.

Environmental damage, which follows our definition of the disposal impact in Proposition 6.

Comparing the consumer surplus and social welfare outcomes () of the two models, we obtained the following proposition.

Proposition 7. (i) When , the consumer surplus in Model D is larger than that in Model I (i.e., ). Otherwise, the opposite is true.

(ii) When , the social welfare in Model D is larger than that in Model I (i.e., ). Otherwise, the opposite is true.

Proposition 7 presents an interesting result: if the remanufacturing cost is not pronounced (), there is a larger consumer surplus in Model D than in Model I. In turn, this induces the social welfare of Model D to be higher than that in Model I. It is important to note that the OEM cares greatly about the TPR’s revenue in Model D, because it can derive greater profit in Model D than in Model I (see Proposition 3). In particular, when , the OEM would let the third party remanufacture more cores in order to earn more profits from remanufactured products (, in Proposition 2). On the other hand, in order to provide more cores for remanufacturing, the level of availability of new products in Model D is larger than that in Model I, with essentially . Said differently, when cr < c1, the competition between new products and remanufactured ones in Model D becomes stronger than that in Model I, which benefits consumers (CSD* > CSI*). When remanufacturing costs are pronounced (i.e., cr > c1, the opposite is true. Proposition 7 further shows that when remanufacturing costs are pronounced (i.e., ), the benefits to industry profitability predicted by Model D (see Proposition 5) are insufficient in fully compensating for the loss in consumer surplus compared to Model I, though the environmental damage of Model D is lower than that of Model I (see Proposition 6). Hence, when , the social welfare predicted by Model D is smaller than that in Model I.

In the analysis thus far, we have considered cases where the OEM undertakes take-back operations directly or indirectly, with several interesting results found from economic, social, and environmental perspectives. In order to have a more comprehensive understanding of when to outsource remanufacturing, whether manufacturers should own or outsource their take-back operations, we present the following remark (without proof), which is based on Remark 1 and Propositions 6 and 7.

Remark 2. Compared to outsourcing take-back operations, if and , then manufacturers undertaking take-back operations can create an overall beneficial outcome that meets the economic, environmental, and social sustainability.

Remark 2 reveals that, under certain conditions, manufacturers undertaking take-back operations can achieve inherent economic, social, and environmental benefits. Put differently, when remanufacturing operations are undertaken by a TPR, the take-back operations undertaken by the OEM do not necessarily harm the third party. On the contrary, controlling the reverse channel can achieve gains in terms of economic, social, and environmental sustainability.

4.5. Numerical Example

From a managerial perspective, our analysis highlights how the strategies of owning or outsourcing take-back operations have strategic consequences in terms of economic, environmental, and social issues. To better emerge in how the parameters—in particular, the remanufacturing cost—affect the performance of sustainability under two different models, in this section we reanalyze the economic, environmental, and social outcomes using numerical examples.

In our numerical examples, in order to examine the impacts of the remanufacturing cost () on the economic, environmental, and social outcomes, the parameters about the production cost and the scaling parameter of collection cost are characterized by and , respectively. We set the consumer value discount for the remanufactured product () to 0.9 (i.e., ). The per-unit disposal impact of the new/remanufactured product is and , respectively. Ensuring that all parameters and variables in this paper must satisfy non-negativity constraints, we let ; that is, in our numerical examples, . All figures are obtained from numerical simulation in Matlab 2014.

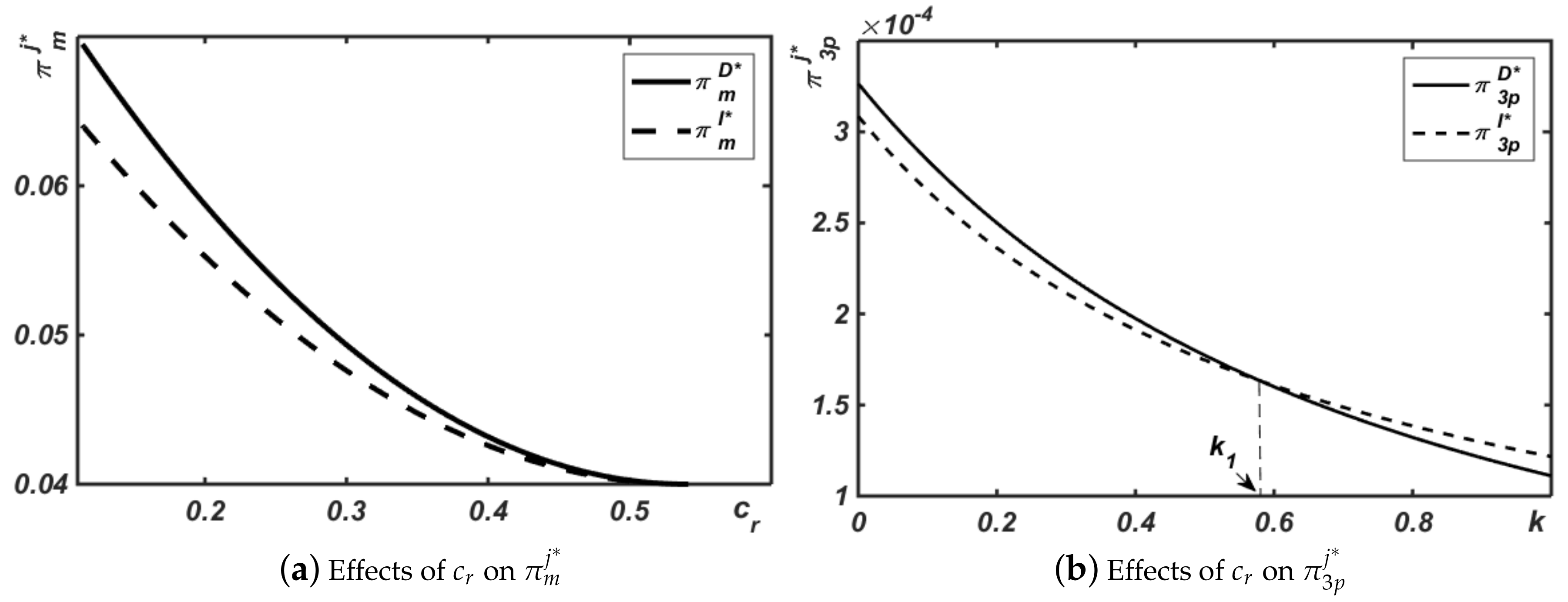

We first present three figures of results for economic outcomes.

Figure 2 reports the profits of the OEM, TPR, and industry on both models. As illustrated in

Figure 2a, we can obtain that the manufacturer’s profit in Model D is always larger than that in Model I (i.e.,

). In addition, the difference in the manufacturer’s profitability between both models decreases with

. Similarly, as

Figure 2c shows, the industry profits in Model D are always higher than that in Model I, and furthermore, as the remanufacturing cost,

, increases, the difference between both profits decreases. The variations in the TPR’s profits in both models are as shown in

Figure 2b. Based on

Figure 2b, we find that there exists a threshold

; when

, the third-party remanufacturer’s profits in Model D are higher than those in Model I (i.e.,

); but are lower (i.e.,

) otherwise. In sum, based on

Figure 2, we can conclude our results in Remark 1.

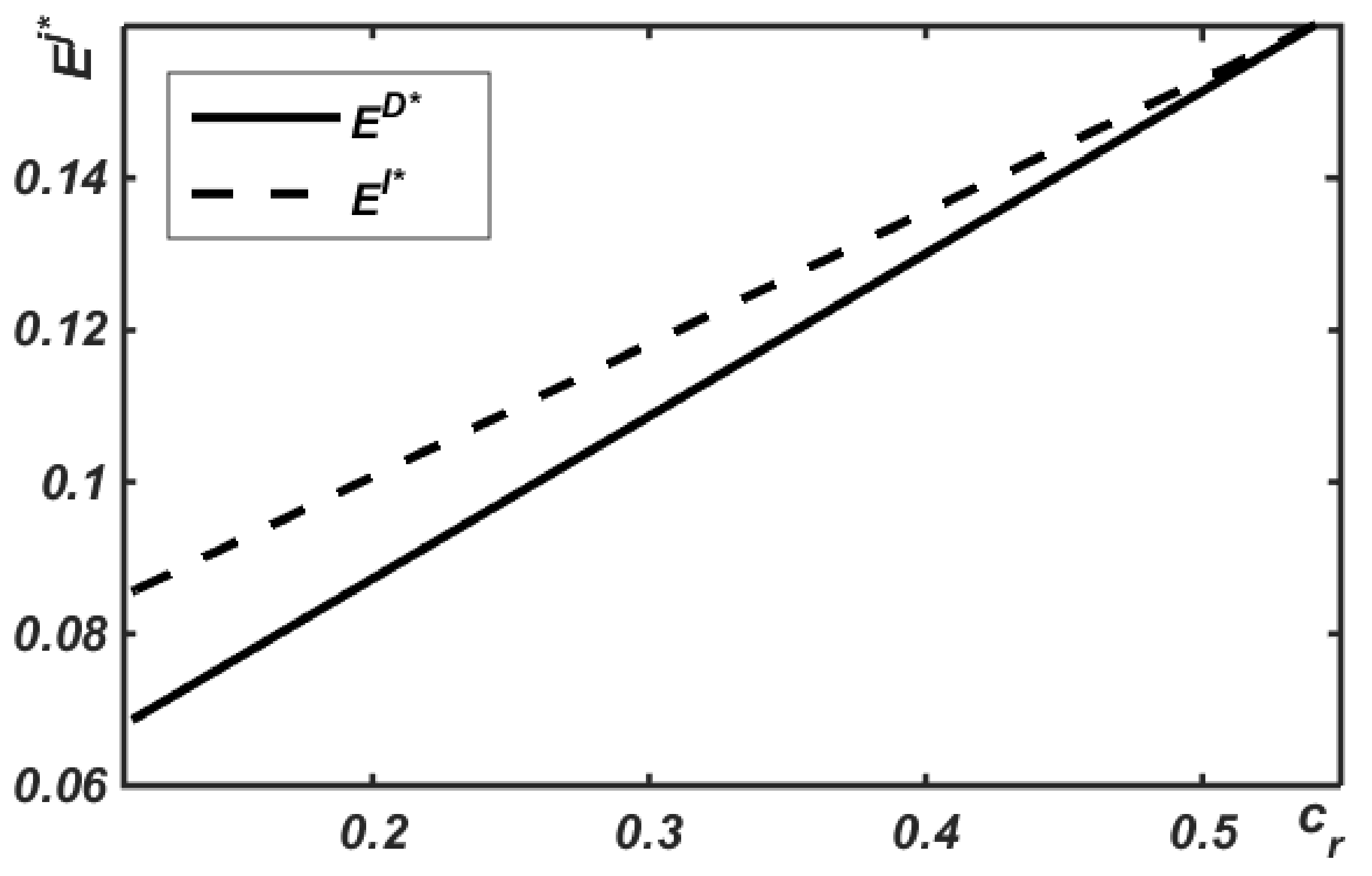

We are now in a position to address the effects of the remanufacturing cost

on the environmental outcomes,

(see

Figure 3).

Figure 3 illustrates two important phenomena: First, the environmental impact in Model D is always smaller than that in Model I. Second, as

increases, the difference in environmental impacts between the two models decreases.

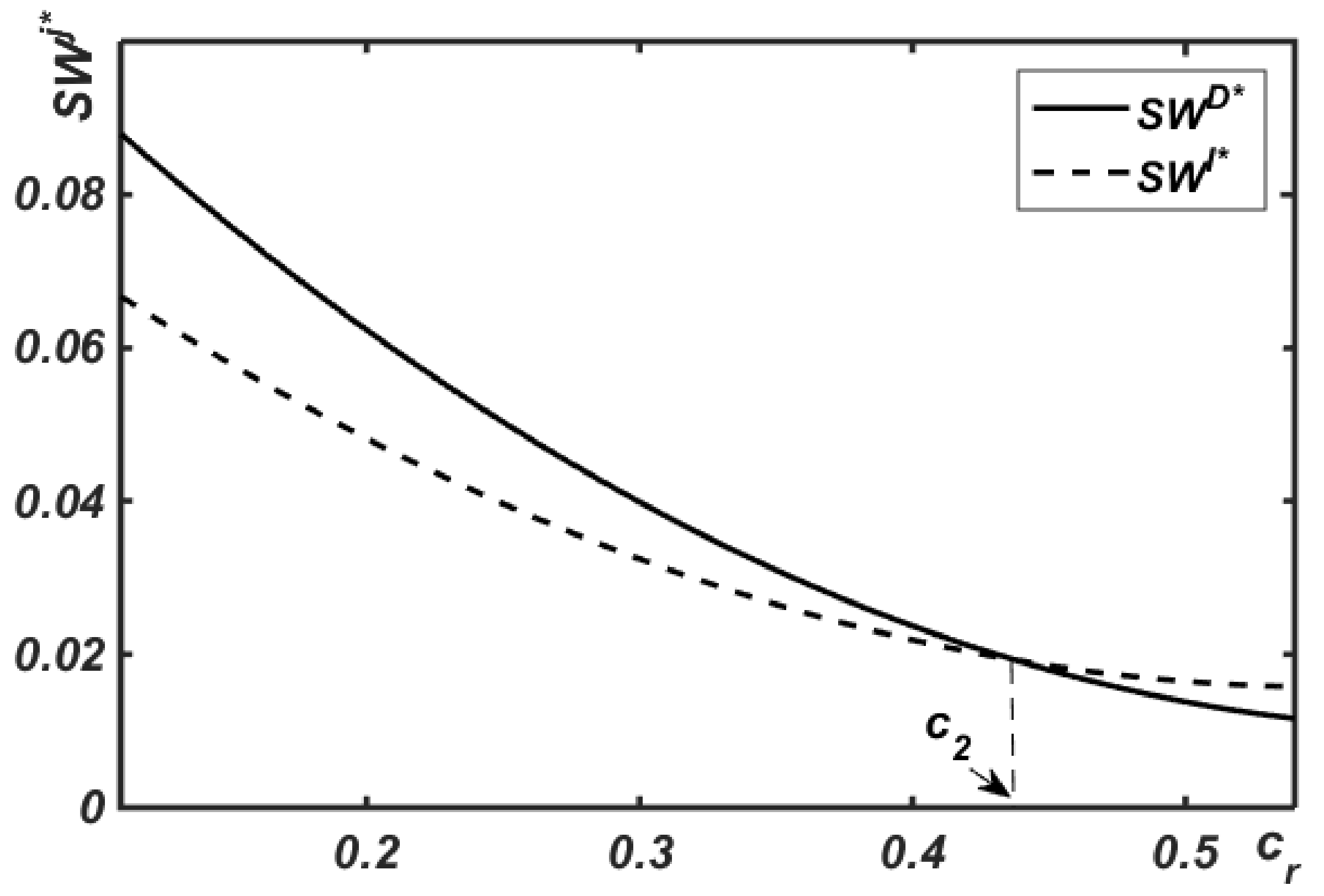

Finally, we analyze the difference in social welfare between the two models. Based on

Figure 4, we find that both

and

decrease with the remanufacturing cost of

. Furthermore, there exists a threshold

; when

, the social welfare in Model D is larger than that in Model I (i.e.,

); otherwise, the opposite is true.

5. Conclusions

Despite the fact that remanufacturing has been demonstrated to have economic, social, and environmental benefits, few OEMs engage in remanufacturing themselves as they instead outsource it to a TPR. It is important to note that the outsourcing of remanufacturing is not a purely make-or-buy decision, but involves a reverse channel that determines the rate of core return from customers and affects the performance of forward channel decisions. In practice, there are two different options or modes that OEMs can use when considering take-back operations. Many OEMs that outsource their remanufacturing activities still control the reverse channel by collecting end-of-life products from consumers, which protects the sales of new products. Meanwhile, other OEMs outsource collection activities to TPRs. This raises the question of whether OEMs should also outsource their reverse channels to TPR, especially considering the issues that the outsourcing of remanufacturing raises between the OEMs and the TPR. To answer this strategic question, we need to understand the optimal strategy for each party.

We developed two models to better understand the effects of outsourcing the reverse channel to a TPR or keeping it in-house. We examined the implications of each strategy for economic, environmental, and social sustainability. Therefore, our paper makes the following contributions to the remanufacturing literature. First, rather than focusing on outsourcing issues between OEMs and TPRs, we provide an alternative and partially complementary approach that considers the outsourcing of take-back operations. Second, although reverse supply chains for recycling have been thoroughly studied in terms of logistics network design, operational planning, and channel operation organization, little is known about how owning or outsourcing take-back operations affects sustainability issues. In particular, our finding of the economic, social, and environmental benefits of take-back operations managed by OEMs has implications for both academics and managers.

We do acknowledge a few limitations of our models. First, we assumed a monopoly OEM, complete information, and no consumer preference—all of which could be relaxed in future research. Second, to keep our focus on our research questions, we assumed that all decisions were considered in a single-period setting. While this assumption is common in the remanufacturing literature [

19,

30,

40], it does not reflect the relationship between a product’s lifecycle and remanufacturing decisions. Third, we viewed OEMs as producers of new products and did not allow them to engage in remanufacturing. However, there are also situations where remanufacturing is unappealing to third parties yet attractive to OEMs. The competitive relationship between an OEM and their TPRs could be an interesting research question for future work. Finally, in both of our models, the quantities of remanufactured products were limited by the availability of new products. Without this limitation, the results obtained may be different.