Fatigue and Fracture Behavior of a Cold-Drawn Commercially Pure Aluminum Wire

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

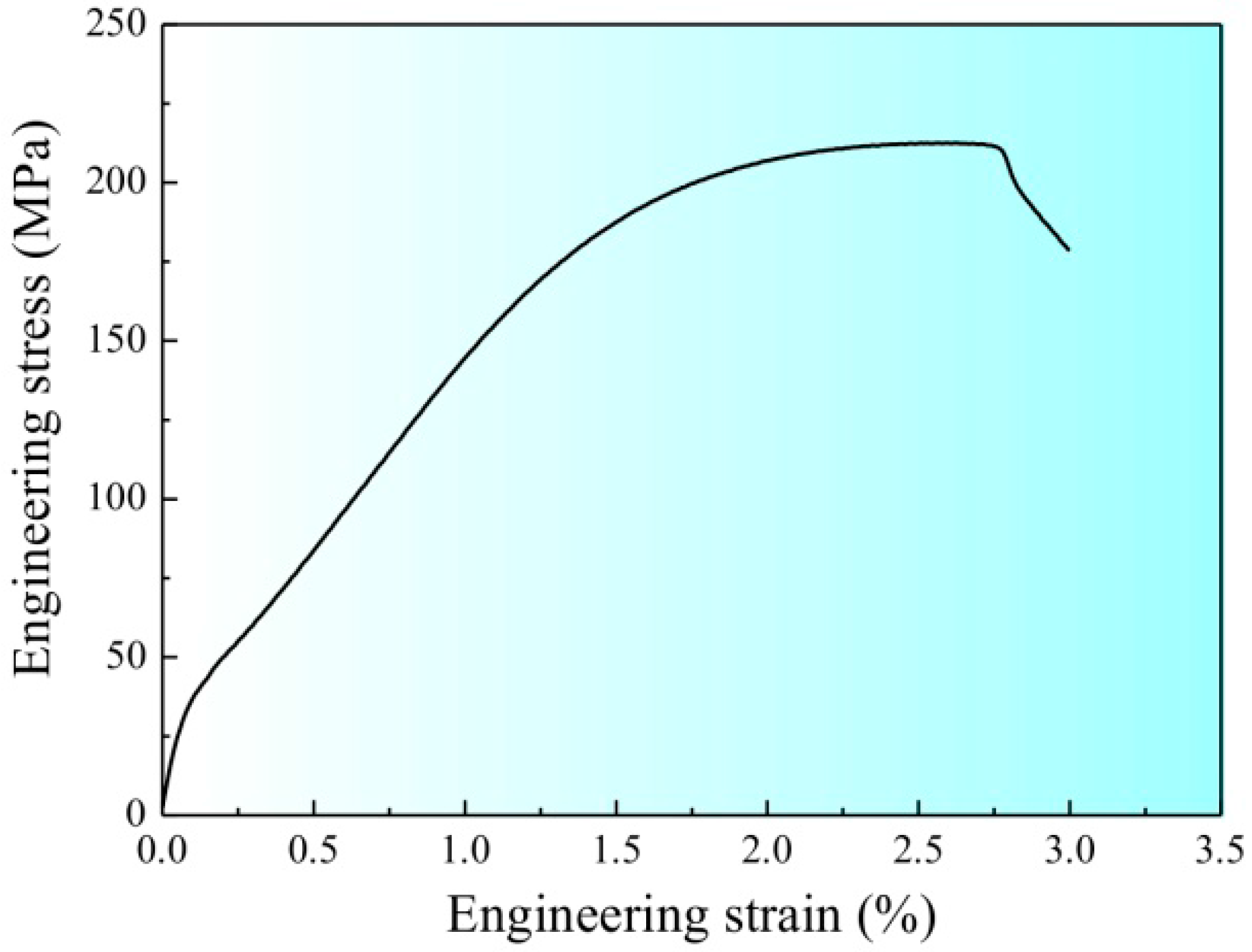

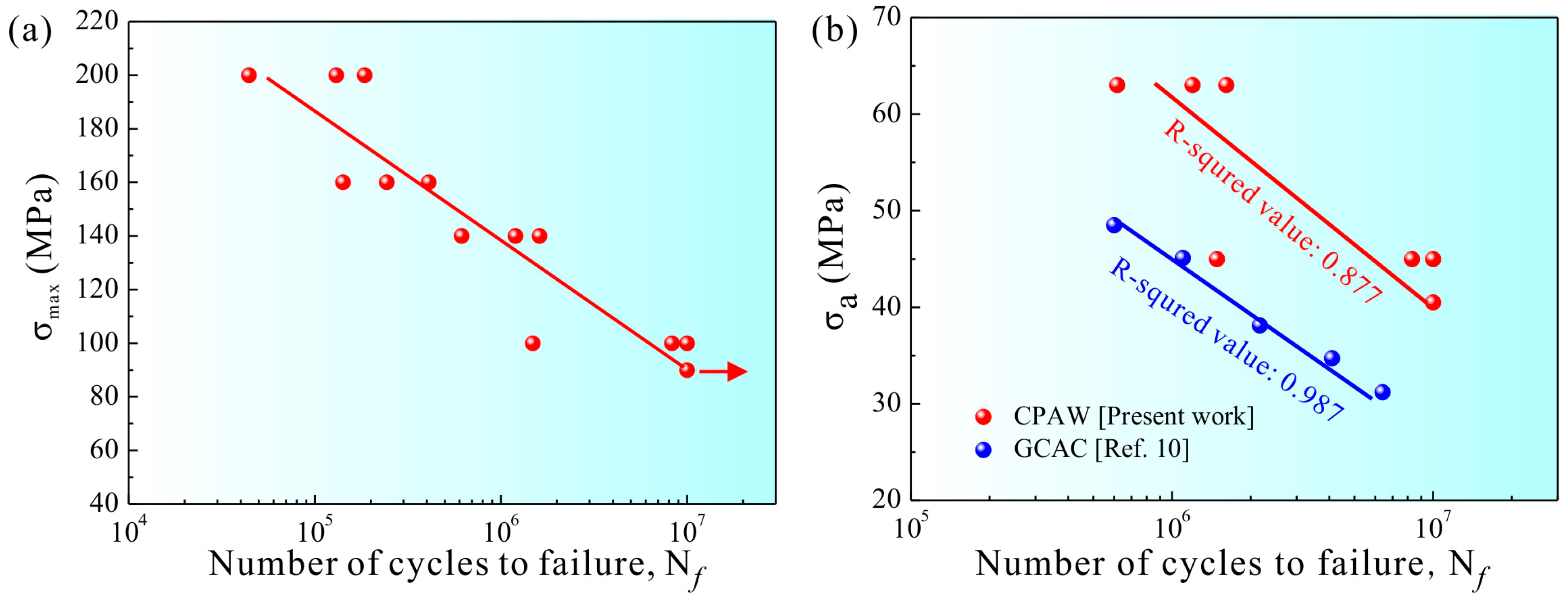

3.1. S-N Curve

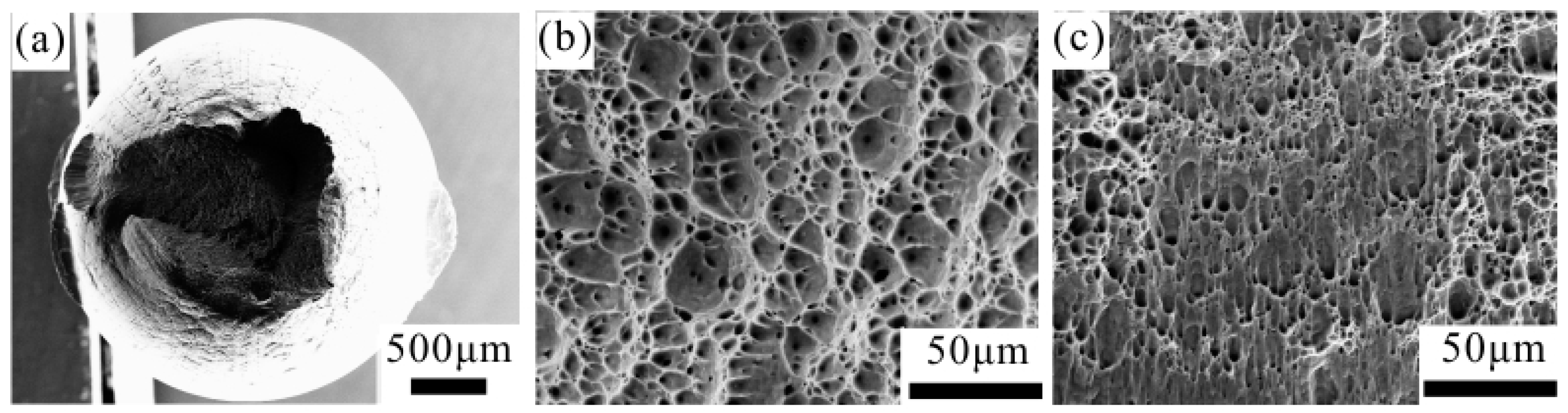

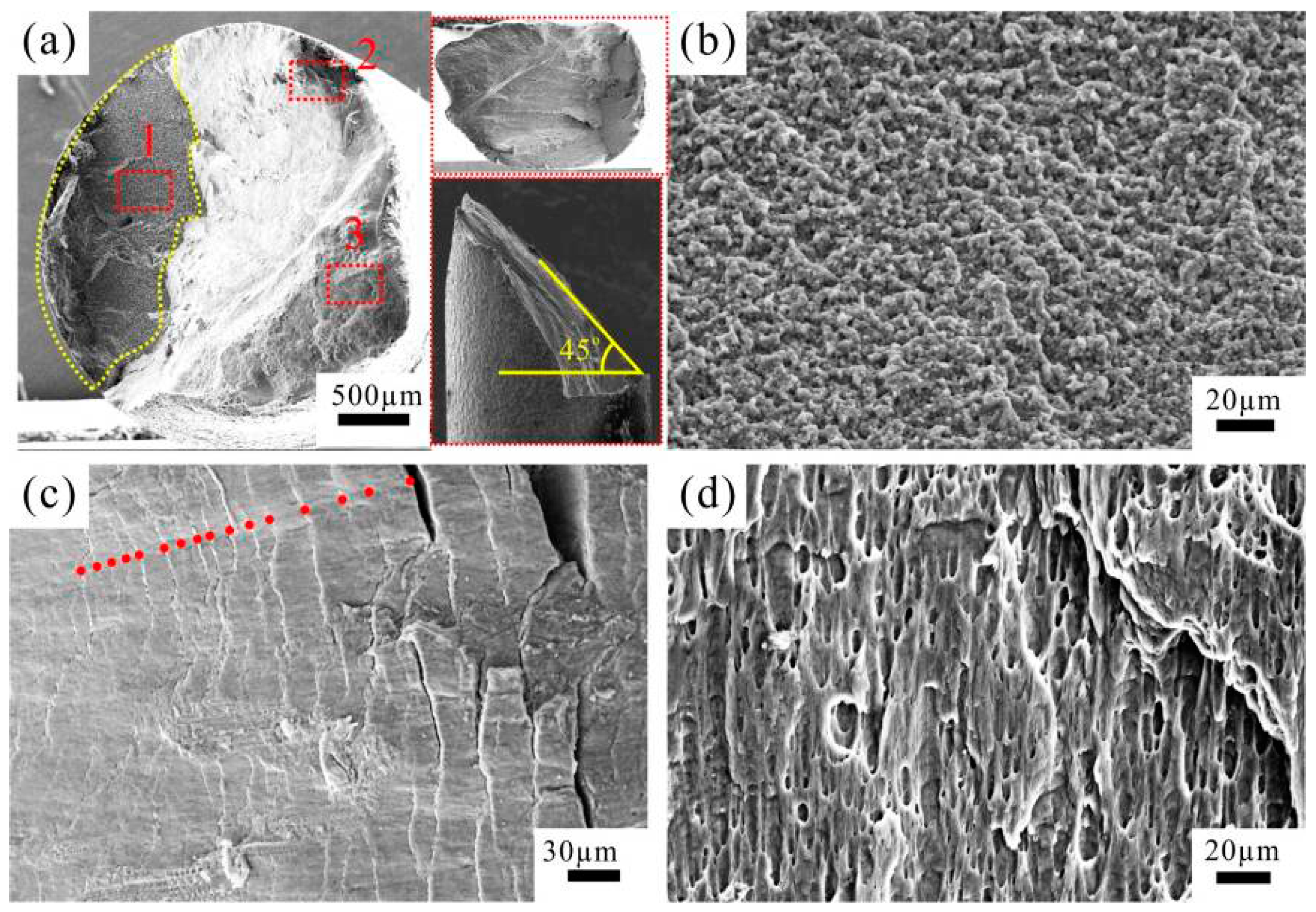

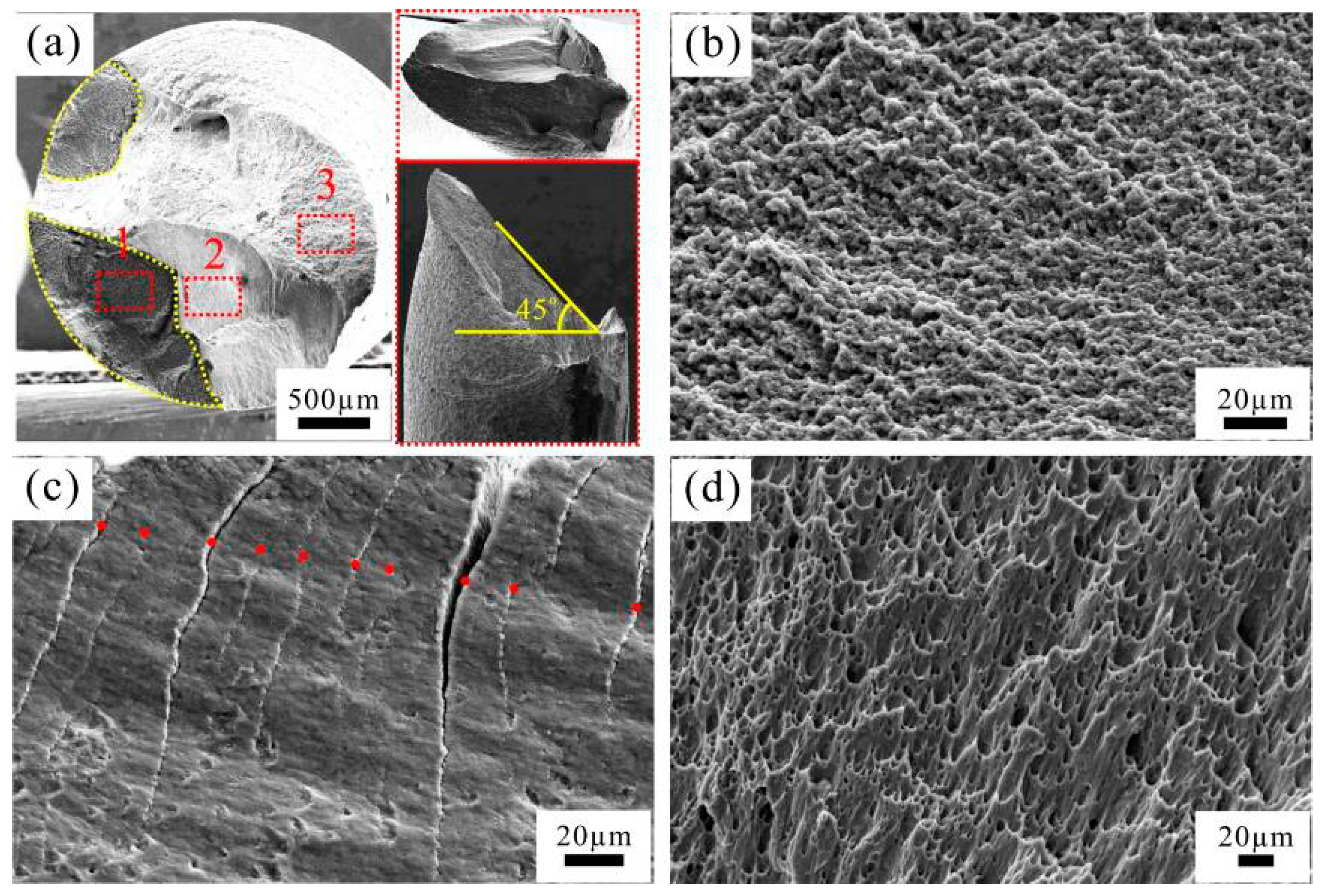

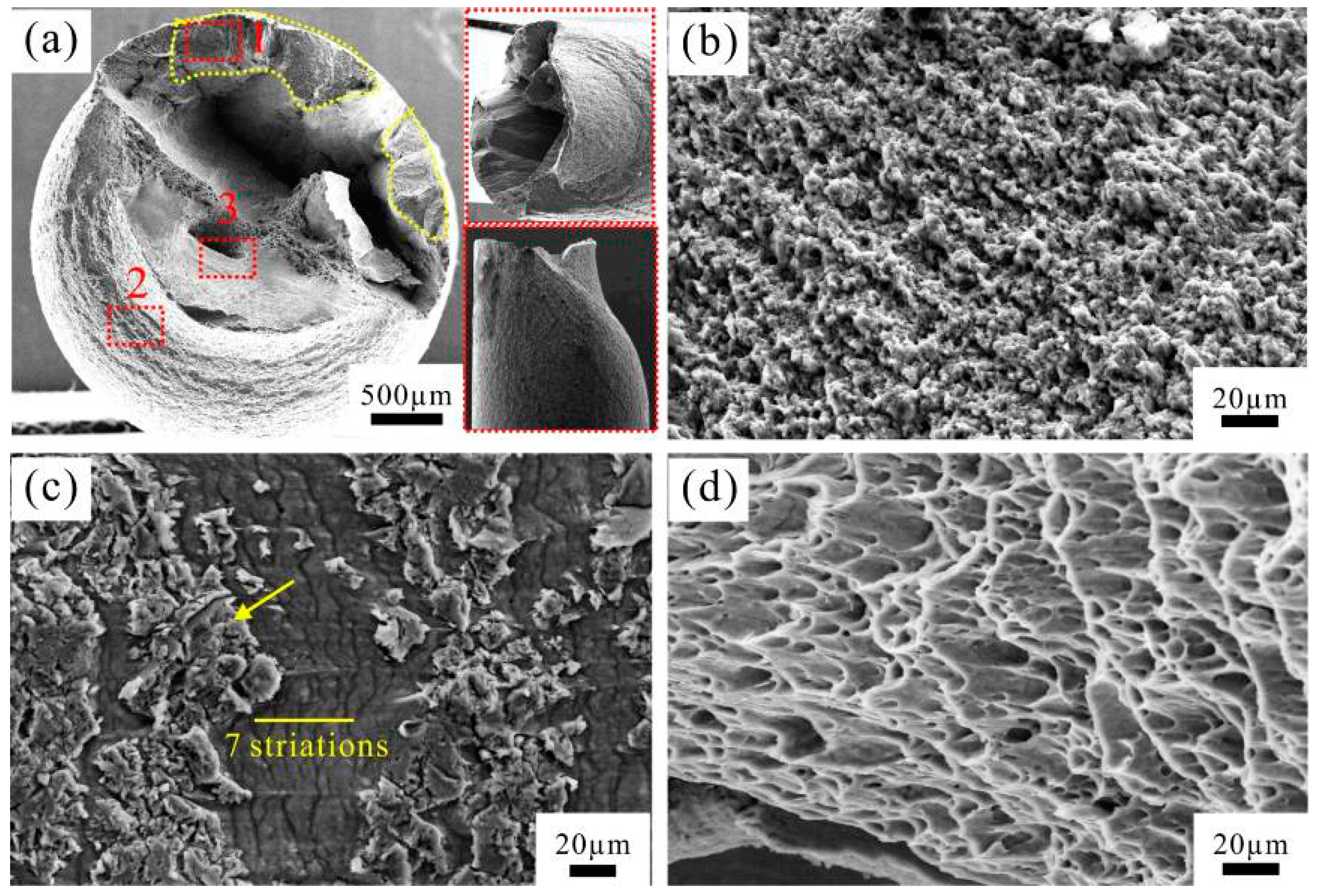

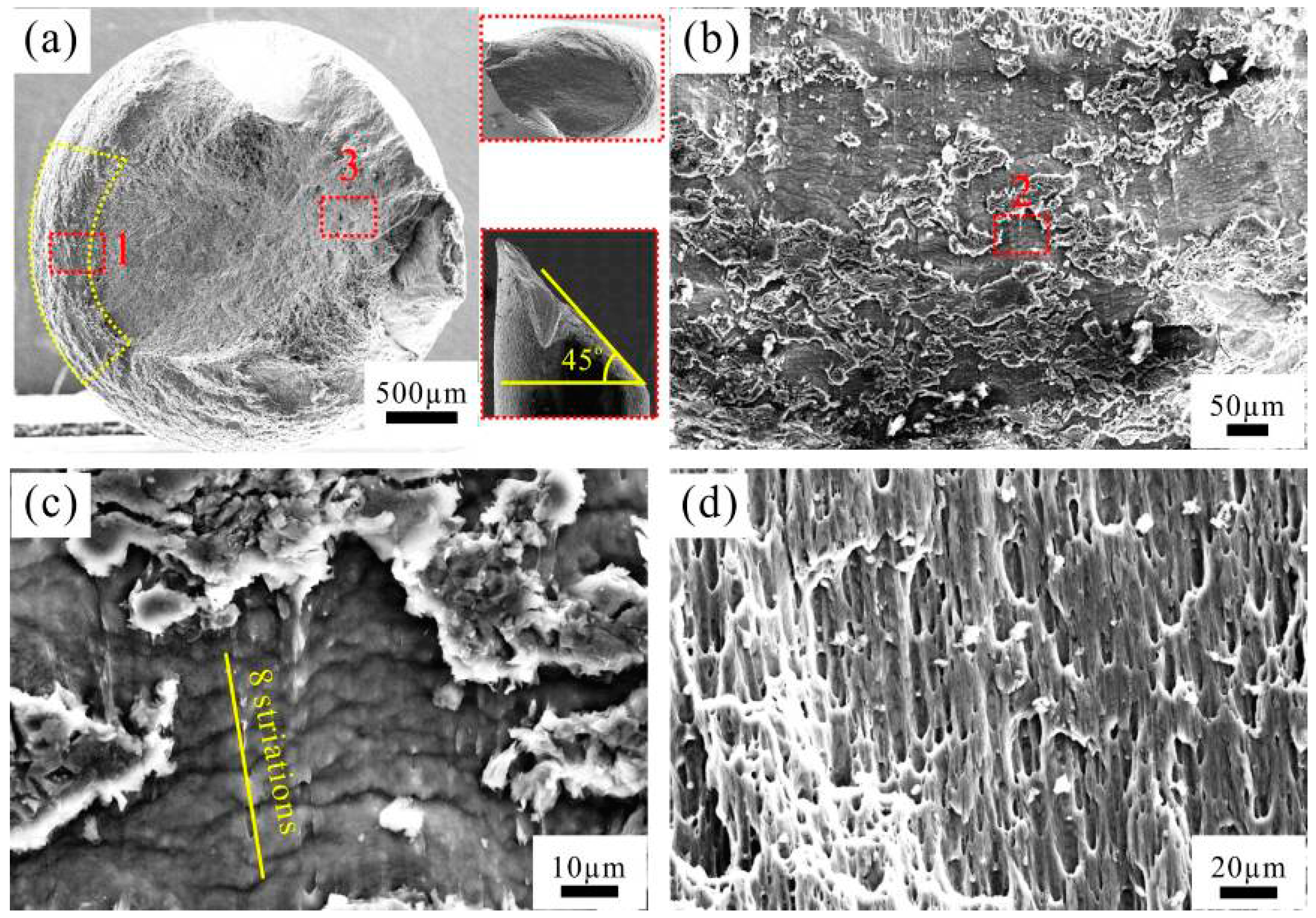

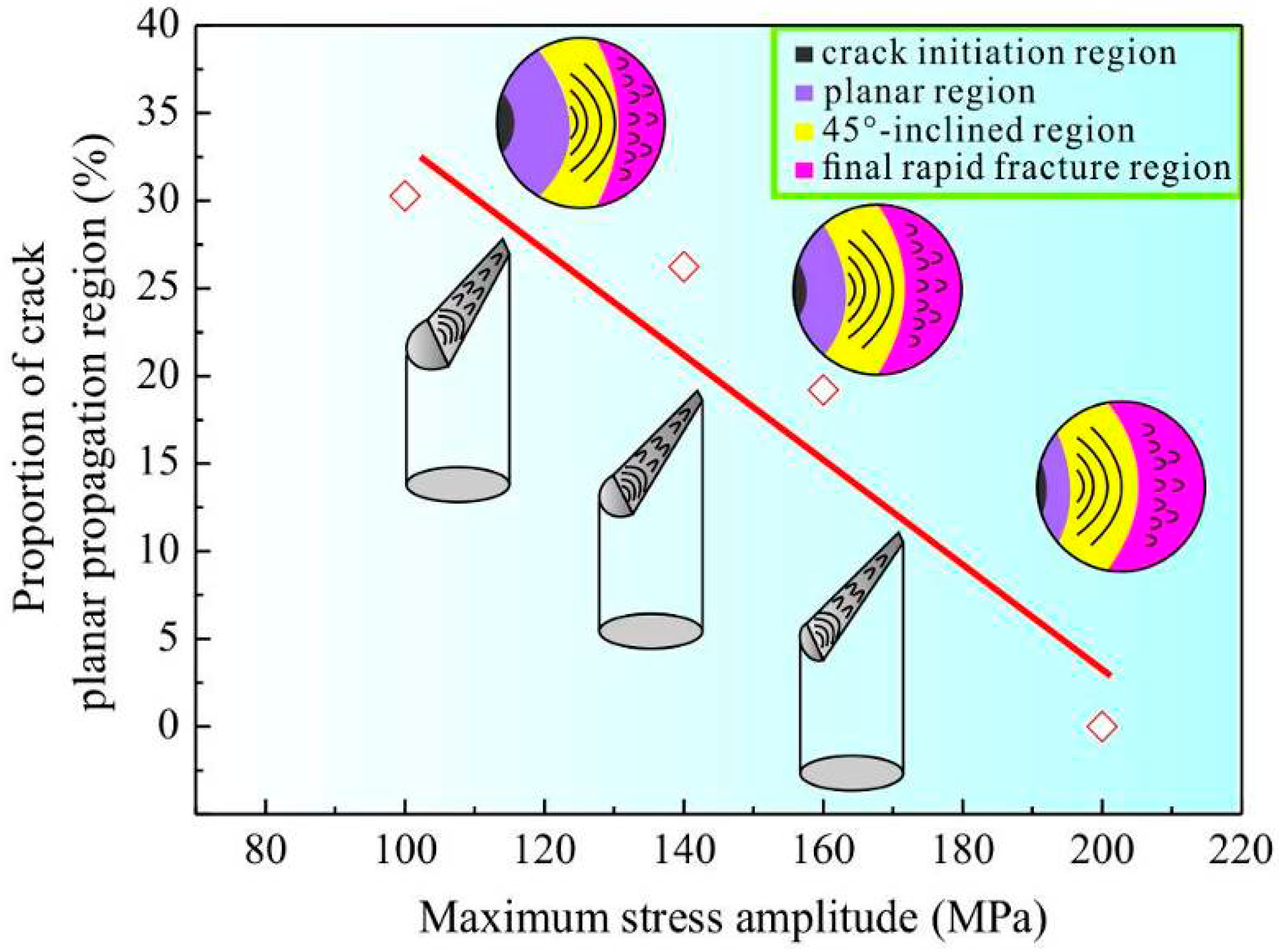

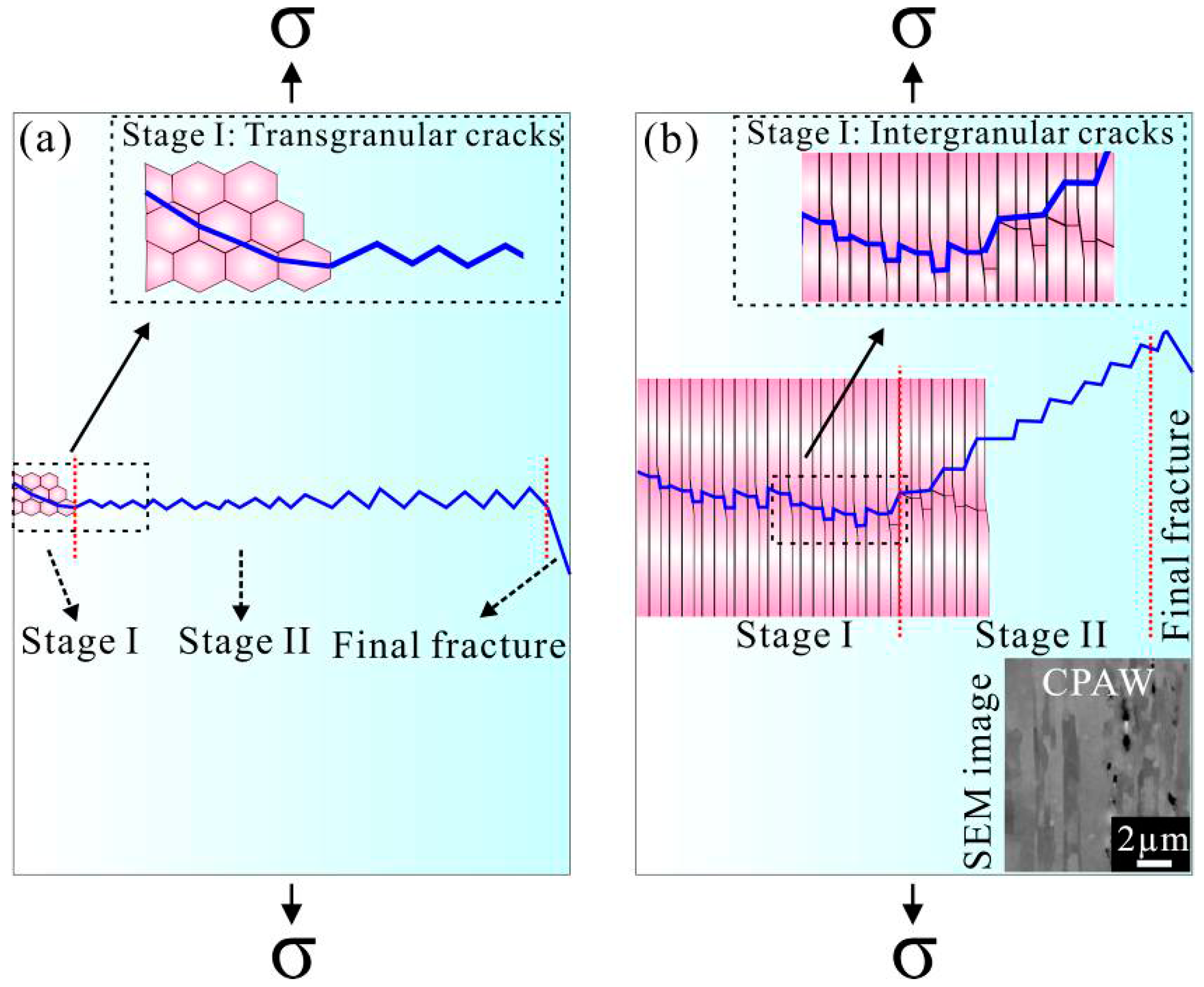

3.2. Fracture Characteristics

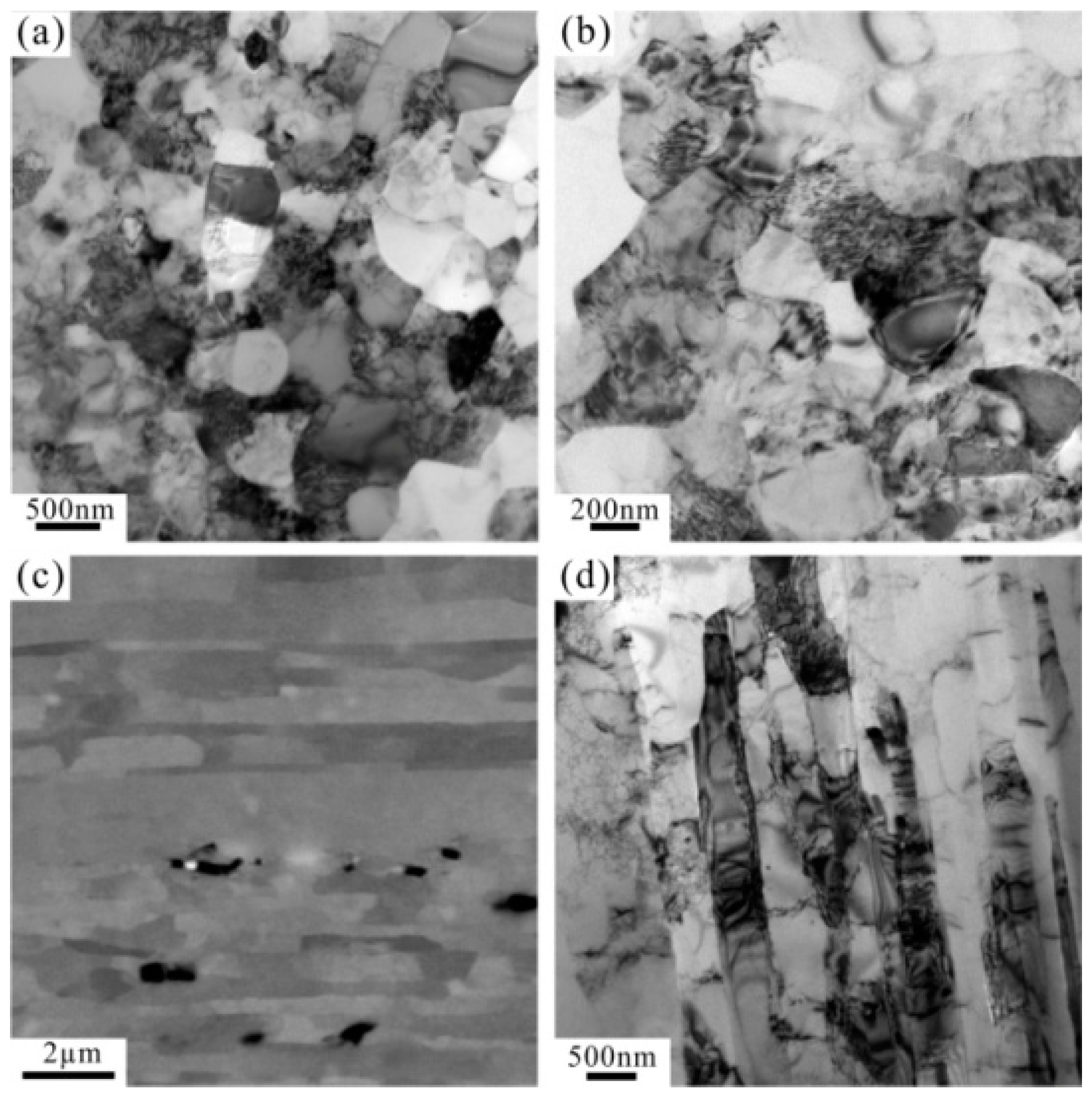

3.3. Deformation Microstructures

4. Conclusions

- The fatigue strength defined at 107 cycles for the CPAW is determined to be ~90 MPa under tension–tension fatigue tests with a stress ratio R = 0.1.

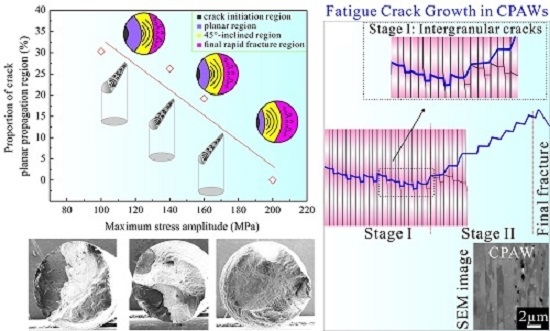

- Fracture surfaces of the CPAWs fatigued at different stress amplitudes exhibit a four-stage characteristic, i.e., crack initiation region, planar crack propagation region, 45°-inclined crack propagation region and final rapid fracture region. The proportion of the planar crack propagation region decreases with increasing fatigue load. The crack growth mechanism for the CPAW is quite different from that for the coarse-grained materials. The cracks in the CPAWs firstly grow along the grain boundaries, and then propagate along the plane of maximum shear stress during the last stage of cycling, showing the distinctive crack growth mechanisms and fracture surfaces, i.e., the granular surface in the planar crack propagation region (Stage I) and the coarse fatigue striations in the 45°-inclined crack propagation region (Stage II).

- The GB migration was observed in the fatigued CPAWs. With increasing fatigue load, the dislocation recovery becomes more evident, and the GB migration rate increases, promoting the occurrence of softening and damage localization and resulting in the final failure.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rhee, H.; Whittington, W.R.; Oppedal, A.L.; Sherif, A.R.; King, R.L.; Kim, H.J.; Lee, C. Mechanical properties of novel aluminum metal matrix metallic composites: Application to overhead conductors. Mater. Des. 2015, 88, 16–21. [Google Scholar] [CrossRef]

- Sauvage, X.; Bobruk, E.V.; Murashkin, M.Y.; Nasedkina, Y.; Enikeev, N.A.; Valiev, R.Z. Optimization of electrical conductivity and strength combination by structure design at the nanoscale in Al-Mg-Si alloys. Acta Mater. 2015, 98, 355–366. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Murashkin, M.Y.; Sabirov, I. A nanostructural design to produce high-strength Al alloys with enhanced electrical conductivity. Scr. Mater. 2014, 76, 13–16. [Google Scholar] [CrossRef]

- Karabay, S. Modification of AA-6201 alloy for manufacturing of high conductivity and extra high conductivity wires with property of high tensile stress after artificial aging heat treatment for all-aluminium alloy conductors. Mater. Des. 2006, 27, 821–832. [Google Scholar] [CrossRef]

- Karabay, S. Influence of AlB2 compound on elimination of incoherent precipitation in artificial aging of wires drawn from redraw rod extruded from billets cast of alloy AA-6101 by vertical direct chill casting. Mater. Des. 2008, 29, 1364–1375. [Google Scholar] [CrossRef]

- Hou, J.P.; Wang, Q.; Yang, H.J.; Wu, X.M.; Li, C.H.; Li, X.W.; Zhang, Z.F. Microstructure evolution and strengthening mechanisms of cold-drawn commercially pure aluminum wire. Mater. Sci. Eng. A 2015, 639, 103–106. [Google Scholar] [CrossRef]

- Ma, K.K.; Wen, H.M.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Chakkingal, U.; Suriadi, A.B.; Thomson, P.F. The development of microstructure and the influence of processing route during equal channel angular drawing of pure aluminum. Mater. Sci. Eng. A 1999, 266, 241–249. [Google Scholar] [CrossRef]

- Lee, S.H.; Saito, Y.; Sakai, T.; Utsunomiya, H. Microstructures and mechanical properties of 6061 aluminum alloy processed by accumulative roll-bonding. Mater. Sci. Eng. A 2002, 325, 228–235. [Google Scholar] [CrossRef]

- Azevedo, C.R.F.; Henriques, A.M.D.; Pulino Filho, A.R.; Ferreira, J.L.A.; Araújo, J.A. Fretting fatigue in overhead conductors: Rig design and failure analysis of a Grosbeak aluminium cable steel reinforced conductor. Eng. Fail. Anal. 2009, 16, 136–151. [Google Scholar] [CrossRef]

- DeVries, P.H.; Ruth, K.T.; Dennies, D.P. Counting on fatigue: Striations and their measure. J. Fail. Anal. Prev. 2010, 10, 120–137. [Google Scholar] [CrossRef]

- Provan, J.W.; Zhai, Z.H. Fatigue crack initiation and stage-I propagation in polycrystalline materials. I: Micromechanisms. Int. J. Fatigue 1991, 13, 99–109. [Google Scholar] [CrossRef]

- Yi, J.Z.; Gao, Y.X.; Lee, P.D.; Lindley, T.C. Effect of Fe-content on fatigue crack initiation and propagation in a cast aluminum–silicon alloy (A356-T6). Mater. Sci. Eng. A 2004, 386, 396–407. [Google Scholar] [CrossRef]

- Fan, J.L.; Guo, X.L.; Wu, C.W.; Zhao, Y.G. Research on fatigue behavior evaluation and fatigue fracture mechanisms of cruciform welded joints. Mater. Sci. Eng. A 2011, 528, 8417–8427. [Google Scholar] [CrossRef]

- Bai, S.; Liu, Z.Y.; Li, Y.T.; Hou, Y.H.; Chen, X. Microstructures and fatigue fracture behavior of an Al-Cu-Mg-Ag alloy with addition of rare earth Er. Mater. Sci. Eng. A 2010, 527, 1806–1814. [Google Scholar] [CrossRef]

- Jana, S.; Mishra, R.S.; Baumann, J.B.; Grant, G. Effect of friction stir processing on fatigue behavior of an investment cast Al-7Si-0.6Mg alloy. Acta Mater. 2010, 58, 989–1003. [Google Scholar] [CrossRef]

- Li, P.; Lee, P.D.; Maijer, D.M.; Lindley, T.C. Quantification of the interaction within defect populations on fatigue behavior in an aluminum alloy. Acta Mater. 2009, 57, 3539–3548. [Google Scholar] [CrossRef]

- Shen, F.H.; Yi, D.Q.; Jiang, Y.; Wang, B.; Liu, H.Q.; Tang, C.; Shou, W.B. Semi-quantitative evaluation of texture components and fatigue properties in 2524 T3 aluminum alloy sheets. Mater. Sci. Eng. A 2016, 657, 15–25. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Wu, S.D.; Li, Y.J.; Liu, S.M.; Wang, Z.G. Cyclic deformation and fatigue properties of Al-0.7 wt.% Cu alloy produced by equal channel angular pressing. Mater. Sci. Eng. A 2005, 412, 279–286. [Google Scholar] [CrossRef]

- Fang, D.R.; Zhang, P.; Duan, Q.Q.; Wu, S.D.; Zhang, Z.F.; Li, J.J.; Zhao, N.Q. Fatigue behavior of Al-Cu alloy subjected to different numbers of ECAP passes. Adv. Eng. Mater. 2007, 9, 860–866. [Google Scholar] [CrossRef]

- Xue, Y.; El Kadiri, H.; Horstemeyer, M.F.; Jordon, J.B.; Weiland, H. Micromechanisms of multistage fatigue crack growth in a high-strength aluminum alloy. Acta Mater. 2007, 55, 1975–1984. [Google Scholar] [CrossRef]

- Forsyth, P.J.E. A two-stage process of fatigue crack growth. In Proceedings of Crack Propagation Symposium, The College of Aeronautics, Cranfield, UK, September 1961; pp. 76–94.

- McDowell, D.L.; Gall, K.; Horstemeyer, M.F.; Fan, J. Microstructure-based fatigue modeling of cast A356-T6 alloy. Eng. Fract. Mech. 2003, 70, 49–80. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Goto, M.; Han, S.Z.; Euh, K.; Kang, J.H.; Kim, S.S.; Kawagoishi, N. Formation of a high-cycle fatigue fracture surface and a crack growth mechanism of ultrafine-grained copper with different stages of microstructural evolution. Acta Mater. 2010, 58, 6294–6305. [Google Scholar] [CrossRef]

- Laird, C.; Smith, G.C. Initial stages of damage in high stress fatigue in some pure metals. Philos. Mag. 1963, 8, 1945–1963. [Google Scholar] [CrossRef]

- Zhang, X.D.; Godfrey, A.; Huang, X.X.; Hansen, N.; Liu, Q. Microstructure and strengthening mechanisms in cold-drawn pearlitic steel wire. Acta Mater. 2011, 59, 3422–3430. [Google Scholar] [CrossRef]

- Pirgazi, H.; Akbarzadeh, A.; Petrov, R.; Kestens, L. Microstructure evolution and mechanical properties of AA1100 aluminum sheet processed by accumulative roll bonding. Mater. Sci. Eng. A 2008, 497, 132–138. [Google Scholar] [CrossRef]

- Hu, T.; Ma, K.K.; Topping, T.D.; Saller, B.; Yousefiani, A.; Schoenung, J.M.; Lavernia, E.J. Improving the tensile ductility and uniform elongation of high-strength ultrafine-grained Al alloys by lowering the grain boundary misorientation angle. Scr. Mater. 2014, 78–79, 25–28. [Google Scholar] [CrossRef]

- Winning, M.; Gottstein, G.; Shvindlerman, L.S. Migration of grain boundaries under the influence of an external shear stress. Mater. Sci. Eng. A 2001, 317, 17–20. [Google Scholar] [CrossRef]

- Winning, M.; Gottstein, G.; Shvindlerman, L.S. Stress induced grain boundary motion. Acta Mater. 2001, 49, 211–219. [Google Scholar] [CrossRef]

- Winning, M. Motion of <100>-tilt grain boundaries. Acta Mater. 2003, 51, 6465–6475. [Google Scholar] [CrossRef]

- Badirujjaman, S.; Li, X.W.; Winning, M. Motion of [100]-tilt grain boundaries under cyclic stresses. Mater. Sci. Eng. A 2007, 448, 242–248. [Google Scholar] [CrossRef]

- Badirujjaman, S.; Winning, M. Cyclic motion of [100] twist grain boundaries in aluminium bicrystals. Scr. Mater. 2006, 55, 907–910. [Google Scholar] [CrossRef]

- Martorano, M.A.; Sandim, H.R.Z.; Fortes, M.A.; Padilha, A.F. Observations of grain boundary protrusions in static recrystallization of high-purity bcc metals. Scr. Mater. 2007, 56, 903–906. [Google Scholar] [CrossRef]

| Maximum Stress Amplitude (MPa) | 0 | 90 | 140 | 200 |

| Average Grain Size (μm) | 0.39 | 0.39 | 0.41 | 0.45 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, J.-P.; Wang, Q.; Yang, H.-J.; Wu, X.-M.; Li, C.-H.; Zhang, Z.-F.; Li, X.-W. Fatigue and Fracture Behavior of a Cold-Drawn Commercially Pure Aluminum Wire. Materials 2016, 9, 764. https://doi.org/10.3390/ma9090764

Hou J-P, Wang Q, Yang H-J, Wu X-M, Li C-H, Zhang Z-F, Li X-W. Fatigue and Fracture Behavior of a Cold-Drawn Commercially Pure Aluminum Wire. Materials. 2016; 9(9):764. https://doi.org/10.3390/ma9090764

Chicago/Turabian StyleHou, Jia-Peng, Qiang Wang, Hua-Jie Yang, Xi-Mao Wu, Chun-He Li, Zhe-Feng Zhang, and Xiao-Wu Li. 2016. "Fatigue and Fracture Behavior of a Cold-Drawn Commercially Pure Aluminum Wire" Materials 9, no. 9: 764. https://doi.org/10.3390/ma9090764