Pickering Emulsion-Based Marbles for Cellular Capsules

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Pickering Emulsion

2.3. Preparation of Pickering Emulsion-Based Marbles and Cellular Capsules

2.4. In Vitro Drug Release

2.5. Characterization

2.6. Estimation of H30 Particles Content Using for Stabilizing Emulsion Marbles

3. Result and Discussion

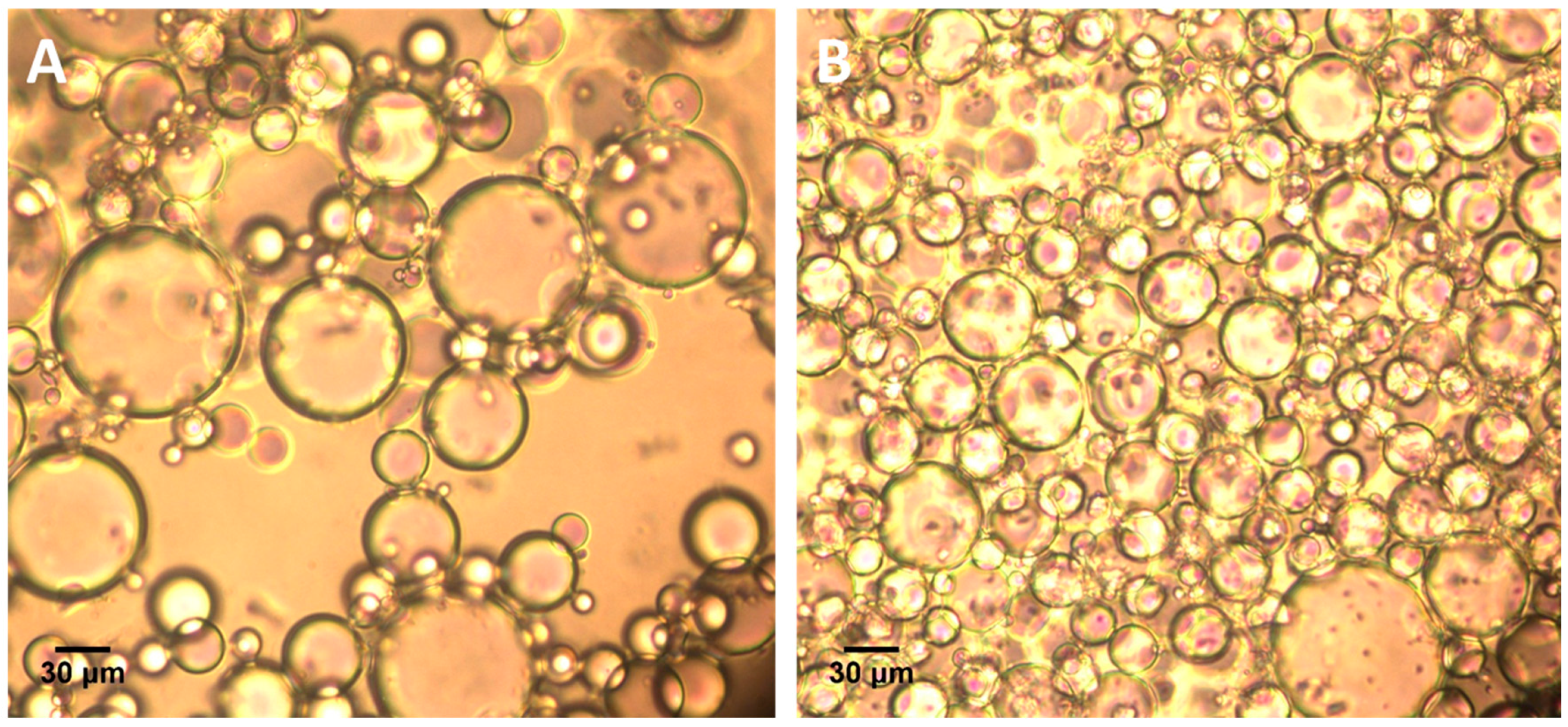

3.1. Preparation of Pickering Emulsion

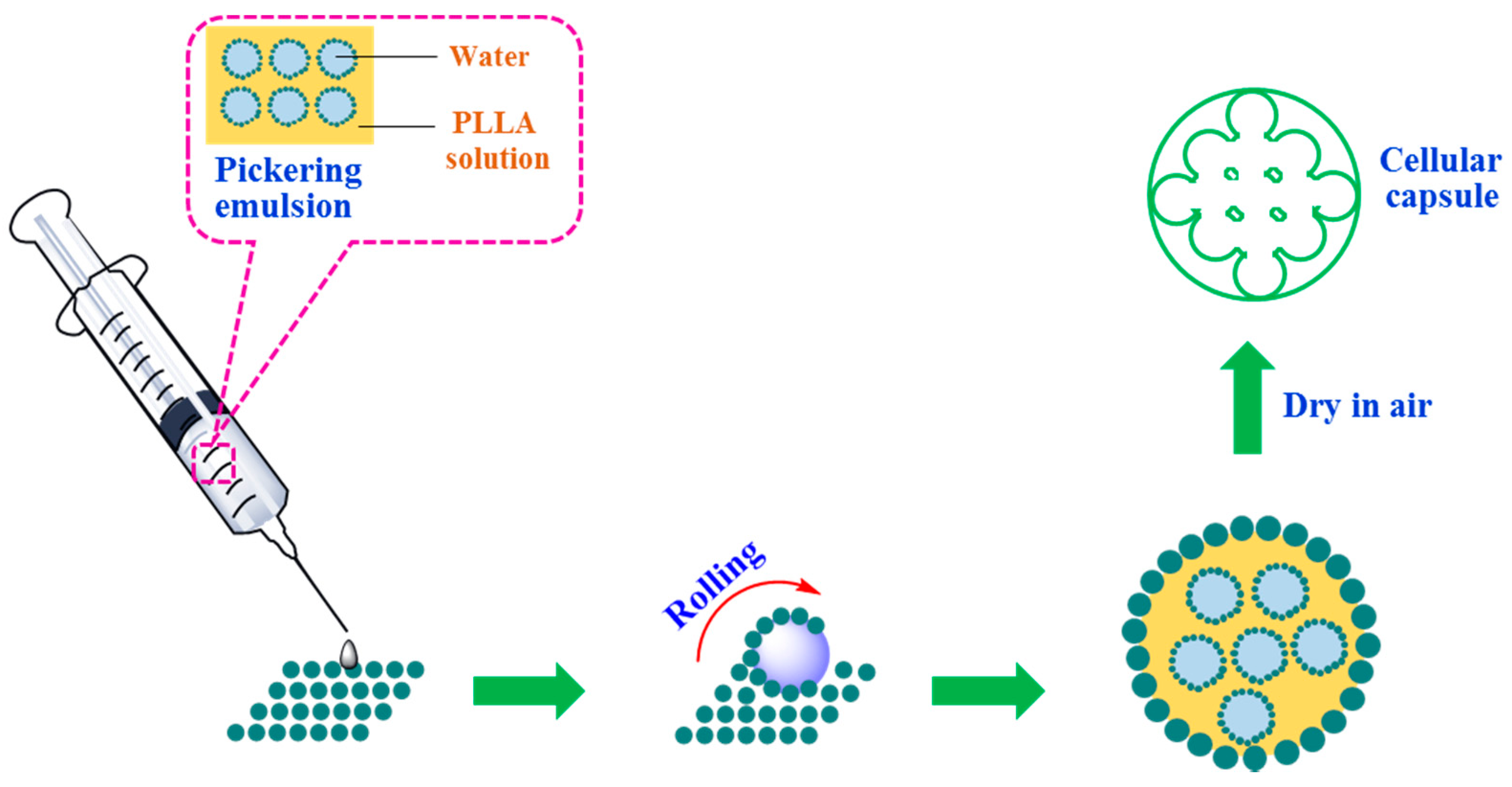

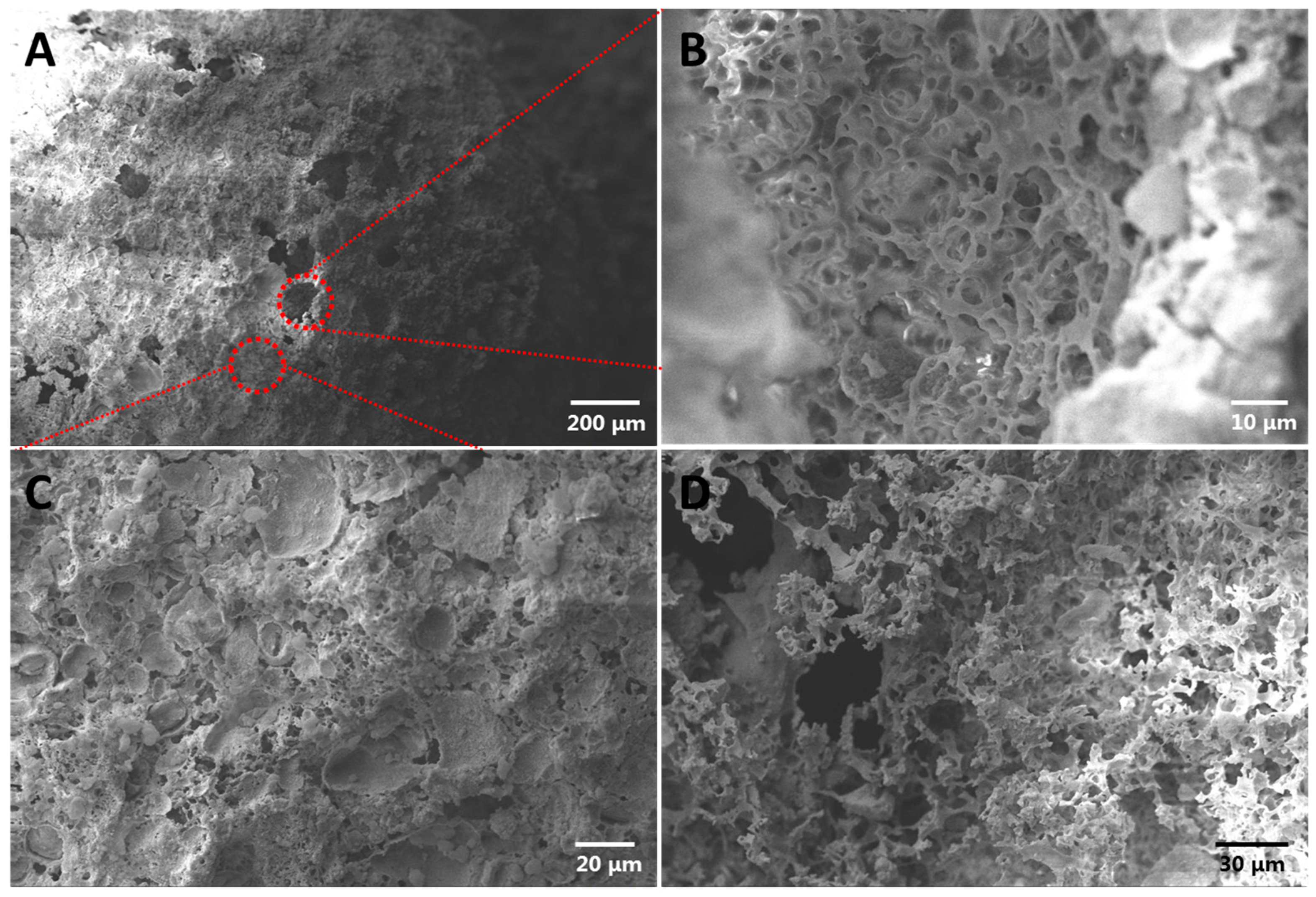

3.2. Preparation of Pickering Emulsion Marbles and Cellular Capsule

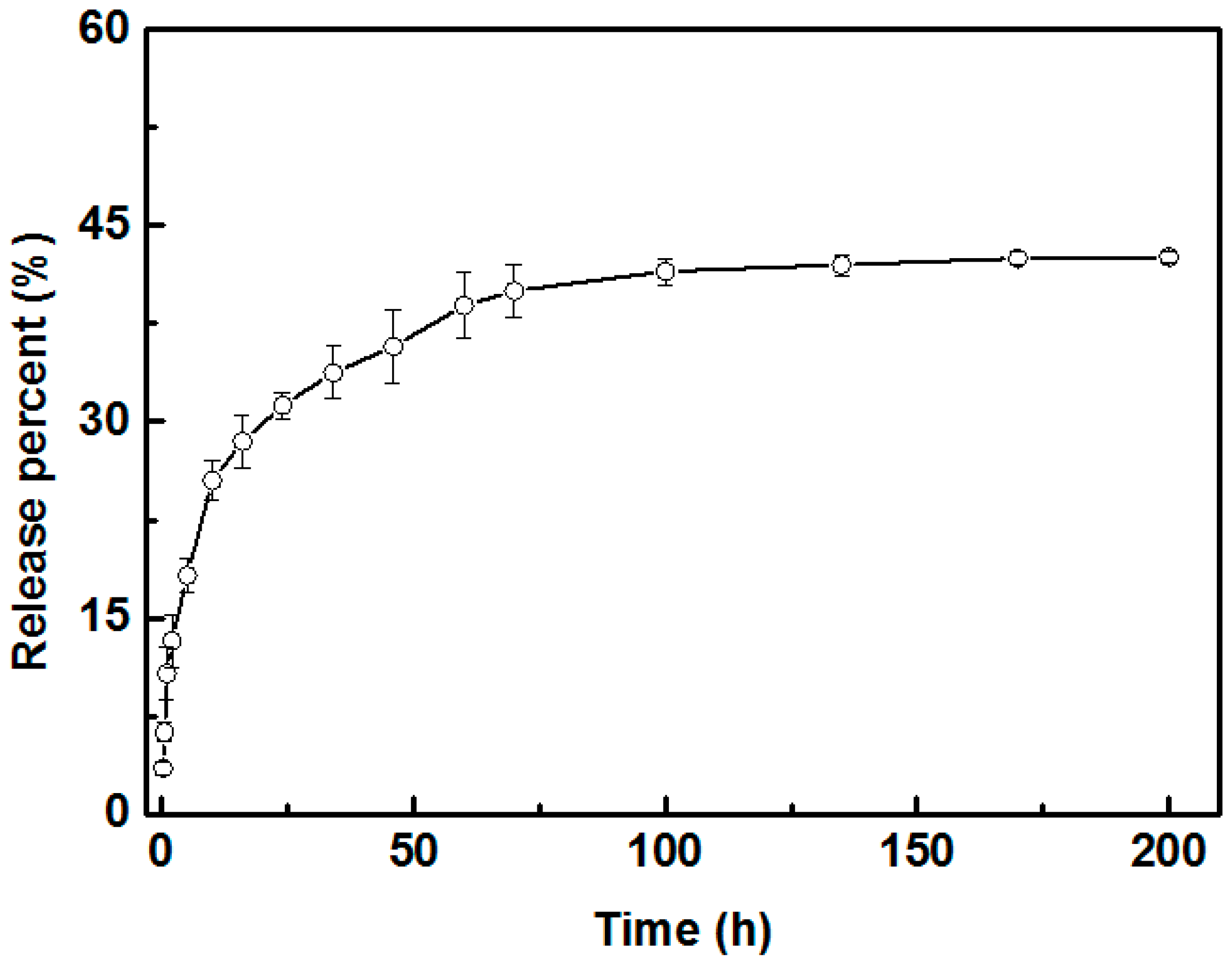

3.3. In Vitro Drug Release

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shuttle, D.; Schmitz, F.T.; Brunner, H. Predominantly Aqueous Compositions in a Fluffy Powdery form Approximating Powdered Solids Behavior and Process for Forming Same. U.S. Patent 3393155A, 16 July 1968. [Google Scholar]

- Aussillous, P.; Quéré, D. Properties of liquid marbles. Proc. R. Soc. A 2006, 462, 973–999. [Google Scholar] [CrossRef]

- Aussillous, P.; Quéré, D. Liquid marbles. Nature 2001, 411, 924–927. [Google Scholar] [CrossRef] [PubMed]

- Mchale, G.; Newton, M.I. Liquid marbles: Topical context within soft matter and recent progress. Soft Matter 2015, 11, 2530–2546. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Y.F.; Sun, G.Q.; Wu, J.; Ma, G.H.; Ngai, T. Silica-Based Liquid Marbles as Microreactors for the Silver Mirror Reaction. Angew. Chem. Int. Ed. 2015, 54, 7012–7017. [Google Scholar] [CrossRef] [PubMed]

- Yildirim, A.; Budunoglu, H.; Daglar, B.; Deniz, H.; Bayindir, M. One-Pot Preparation of Fluorinated Mesoporous Silica Nanoparticles for Liquid Marble Formation and Superhydrophobic Surfaces. ACS Appl. Mater. Interfaces 2011, 3, 1804–1808. [Google Scholar] [CrossRef] [PubMed]

- Mchale, G.; Newton, M.I. Liquid marbles: Principles and applications. Soft Matter 2011, 7, 5473–5481. [Google Scholar] [CrossRef]

- Sivan, V.; Tang, S.Y.; O’Mullane, A.P.; Petersen, P.; Eshtiaghi, N.; Kalantar-zadeh, K.; Mitchell, A. Liquid Metal Marbles. Adv. Funct. Mater. 2013, 23, 144–152. [Google Scholar] [CrossRef]

- Xue, Y.H.; Wang, H.X.; Zhao, Y.; Dai, L.M.; Feng, L.F.; Wang, X.G.; Lin, T. Magnetic Liquid Marbles: A “Precise” Miniature Reactor. Adv. Mater. 2010, 22, 4814–4818. [Google Scholar] [CrossRef] [PubMed]

- Fujii, S.; Kameyama, S.; Armes, S.P.; Dupin, D.; Suzaki, M.; Nakamura, Y. pH-responsive liquid marbles stabilized with poly(2-vinylpyridine) particles. Soft Matter 2010, 6, 635–640. [Google Scholar] [CrossRef]

- Han, X.M.; Lee, H.K.; Lee, Y.H.; Hao, W.; Liu, Y.J.; Phang, I.Y.; Li, S.Z.; Ling, X.Y. Identifying Enclosed Chemical Reaction and Dynamics at the Molecular Level Using Shell-Isolated Miniaturized Plasmonic Liquid Marble. J. Phys. Chem. Lett. 2016, 7, 1501–1506. [Google Scholar] [CrossRef] [PubMed]

- Samiei, E.; Tabrizian, M.; Hoorfar, M. A review of digital microfluidics as portable platforms for lab-on a-chip applications. Lab Chip 2016, 16, 2376–2396. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.Y.; Zhang, Y.; Shi, J.F.; Huang, W.P. Superhydrophobic particles derived from nature-inspired polyphenol chemistry for liquid marble formation and oil spills treatment. ACS Sustain. Chem. Eng. 2016, 4, 676–681. [Google Scholar] [CrossRef]

- Arbatan, T.; Li, L.Z.; Tian, J.F.; Shen, W. Liquid Marbles as Micro-bioreactors for Rapid Blood Typing. Adv. Healthc. Mater. 2012, 1, 80–83. [Google Scholar] [CrossRef] [PubMed]

- Paven, M.; Mayama, H.; Sekido, T.; Butt, H.J.; Nakamura, Y.; Fujii, S. Light-Driven Delivery and Release of Materials Using Liquid Marbles. Adv. Funct. Mater. 2016, 26, 3199–3206. [Google Scholar] [CrossRef]

- Chu, Y.; Wang, Z.K.; Pan, Q.M. Constructing Robust Liquid Marbles for Miniaturized Synthesis of Graphene/Ag Nanocomposite. ACS Appl. Mater. Interfaces 2014, 6, 8378–8386. [Google Scholar] [CrossRef] [PubMed]

- Destribats, M.; Rouvet, M.; Gehin-Delval, C.; Schmitt, C.; Binks, B.P. Emulsions stabilised by whey protein microgel particles: Towards food-grade Pickering emulsions. Soft Matter 2014, 10, 6941–6954. [Google Scholar] [CrossRef] [PubMed]

- Tan, H.; Sun, G.Q.; Lin, W.; Mu, C.D.; Ngai, T. Gelatin Particle-Stabilized High Internal Phase Emulsions as Nutraceutical Containers. ACS Appl. Mater. Interfaces 2014, 6, 13977–13984. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, A.; Murray, B.; Holmes, M.; Ettelaie, R.; Abdalla, A.; Yang, X.Y. In vitro digestion of Pickering emulsions stabilized by soft whey protein microgel particles: Influence of thermal treatment. Soft Matter 2016, 12, 3558–3569. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.H.; Fu, L.M.; Zhang, F.W.; Zhou, T.; Yang, H.Q. Pickering-Emulsion Inversion Strategy for Separating and Recycling Nanoparticle Catalysts. Chem. Phys. Chem. 2014, 15, 841–848. [Google Scholar] [CrossRef] [PubMed]

- Zou, S.W.; Hu, Y.; Wang, C.Y. One-Pot Fabrication of Rattle-Like Capsules with Multicores by Pickering Based Polymerization with Nanoparticle Nucleation. Macromol. Rapid Commun. 2014, 35, 1414–1418. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Ma, S.S.; Yang, Z.H.; Zhou, W.Y.; Du, Z.S.; Huang, J.; Yi, H.; Wang, C.Y. Facile fabrication of poly(l-lactic acid) microsphere-incorporated calcium alginate/hydroxyapatite porous scaffolds based on Pickering emulsion templates. Coll. Surf. B Biointerfaces 2016, 140, 382–391. [Google Scholar] [CrossRef] [PubMed]

- Appel, A.E.; Tibbitt, M.W.; Webber, M.J.; Mattix, B.A.; Veiseh, O.; Langer, R. Self-assembled hydrogels utilizing polymer–nanoparticle interactions. Nat. Commun. 2015, 6, 6295–6313. [Google Scholar] [CrossRef] [PubMed]

- Dou, Y.; Guo, J.W.; Chen, X.; Han, S.L.; Xu, X.Q.; Shi, Q.; Jia, Y.; Liu, Y.; Deng, Y.C.; Zhang, J.X.; et al. Sustained delivery by a cyclodextrin material-based nanocarrier potentiates antiatherosclerotic activity of rapamycin via selectively inhibiting mTORC1 in mice. J. Control. Release 2016, 235, 48–62. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Gu, X.Y.; Yang, Y.; Huang, J.; Hu, M.; Chen, W.K.; Tong, Z.; Wang, C.Y. Facile Fabrication of Poly(l-lactic Acid)-Grafted Hydroxyapatite/Poly(lactic-co-glycolic Acid) Scaffolds by Pickering High Internal. ACS Appl. Mater. Interfaces 2014, 6, 17166–17175. [Google Scholar] [CrossRef] [PubMed]

| Serial | H30 (w/v %) a | PLLA (w/v %) a | CH2Cl2 (mL) | Water (mL) |

|---|---|---|---|---|

| P0-0.1 | 0 | 5 | 2 | 0 |

| P0.01-0.1-2 | 0.5 | 5 | 2 | 2 |

| P0.02-0.1-2 | 1.0 | 5 | 2 | 2 |

| P0.04-0.1-2 | 2.0 | 5 | 2 | 2 |

| P0.04-0.12-2 | 2.0 | 6 | 2 | 2 |

| P0.04-0.1-3 | 2.0 | 5 | 2 | 3 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Wang, C. Pickering Emulsion-Based Marbles for Cellular Capsules. Materials 2016, 9, 572. https://doi.org/10.3390/ma9070572

Zhang G, Wang C. Pickering Emulsion-Based Marbles for Cellular Capsules. Materials. 2016; 9(7):572. https://doi.org/10.3390/ma9070572

Chicago/Turabian StyleZhang, Guangzhao, and Chaoyang Wang. 2016. "Pickering Emulsion-Based Marbles for Cellular Capsules" Materials 9, no. 7: 572. https://doi.org/10.3390/ma9070572