Residual Tensile Property of Plain Woven Jute Fiber/Poly(Lactic Acid) Green Composites during Thermal Cycling

Abstract

:1. Introduction

2. Materials and Molding Method

3. Testing Method

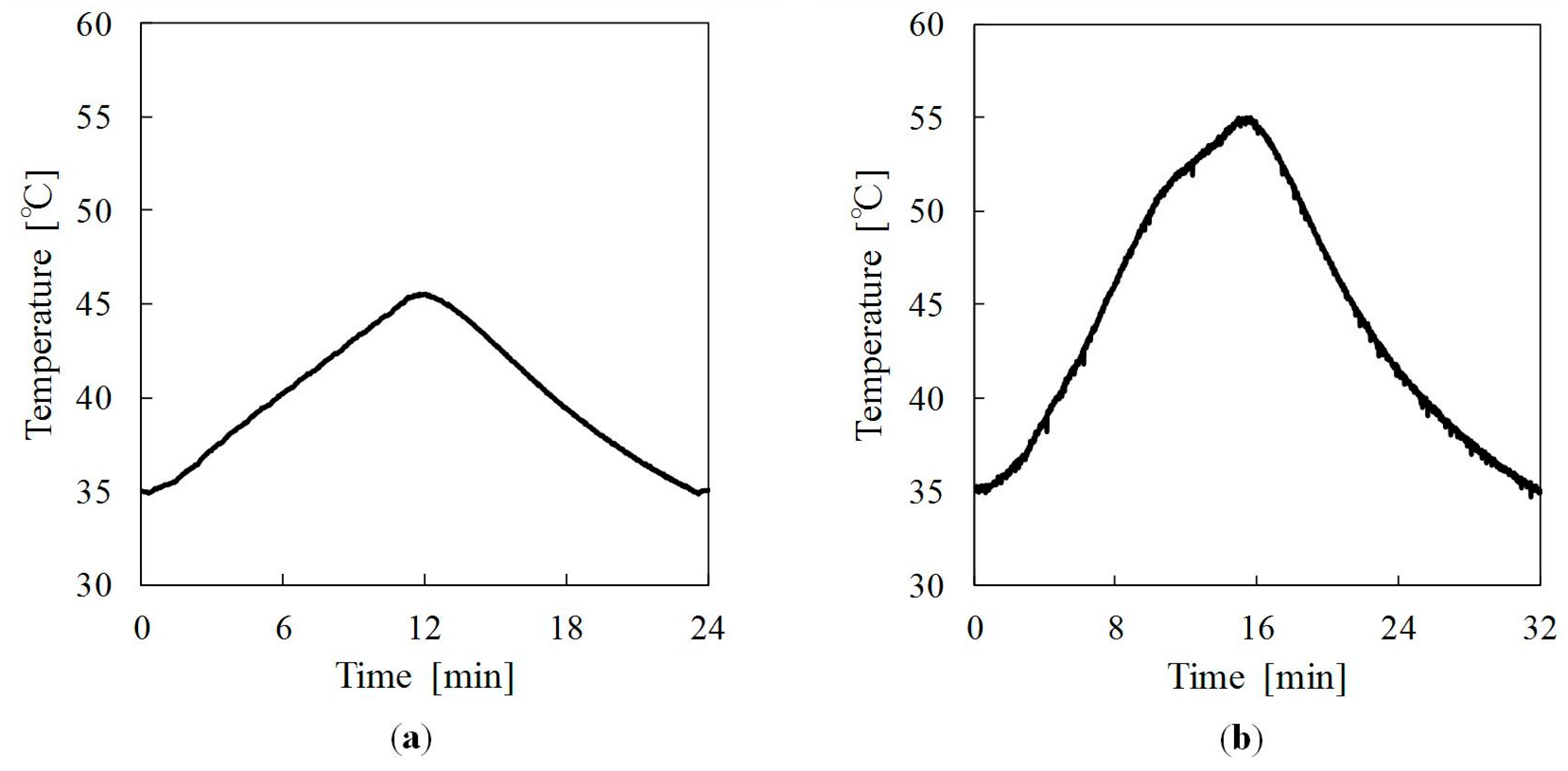

3.1. Thermal Cycling Test

3.2. Thermal Mechanical Anaysis

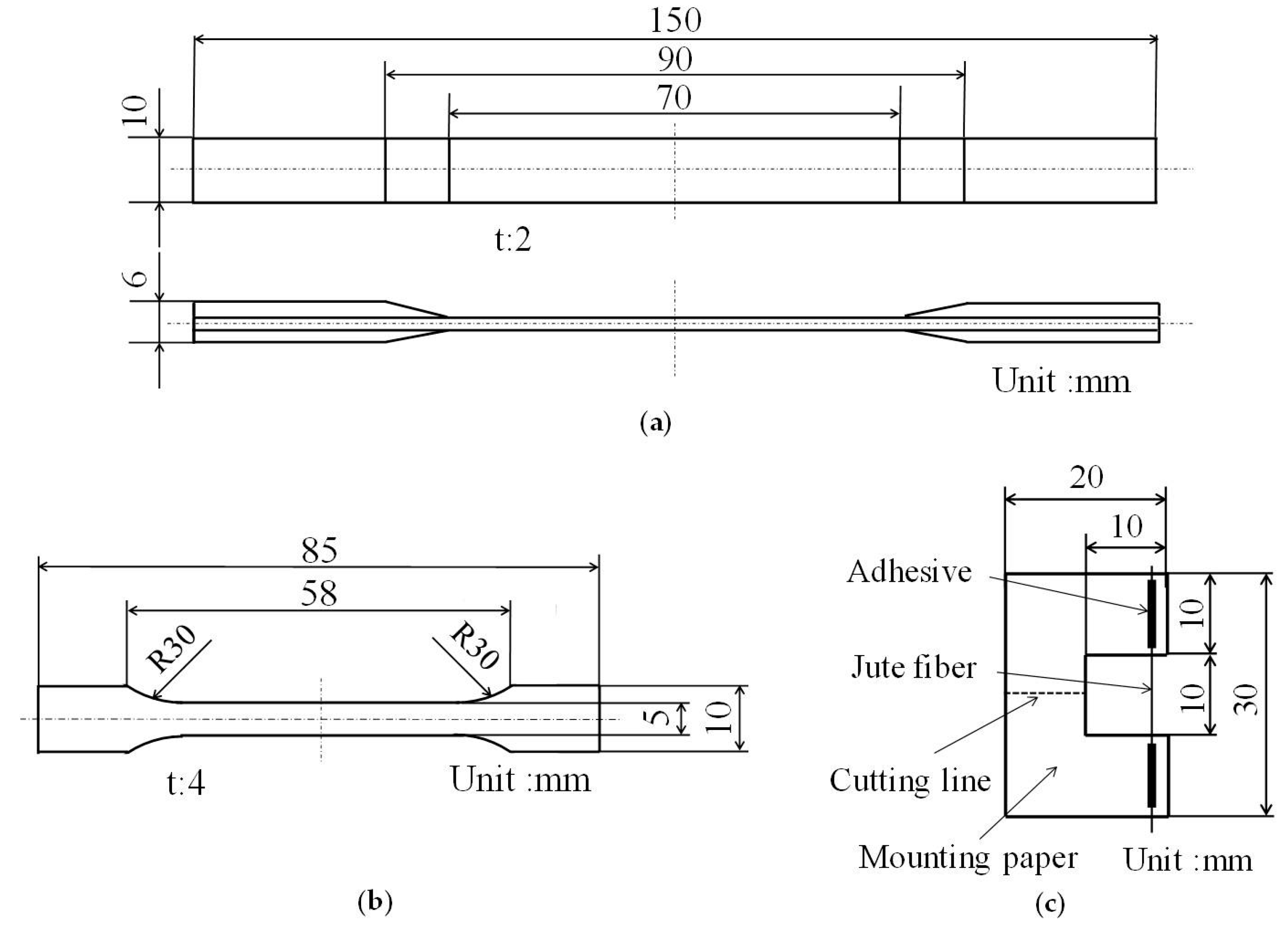

3.3. Quasi-Static Tensile Test after Thermal Cycling

4. Results and Discussion

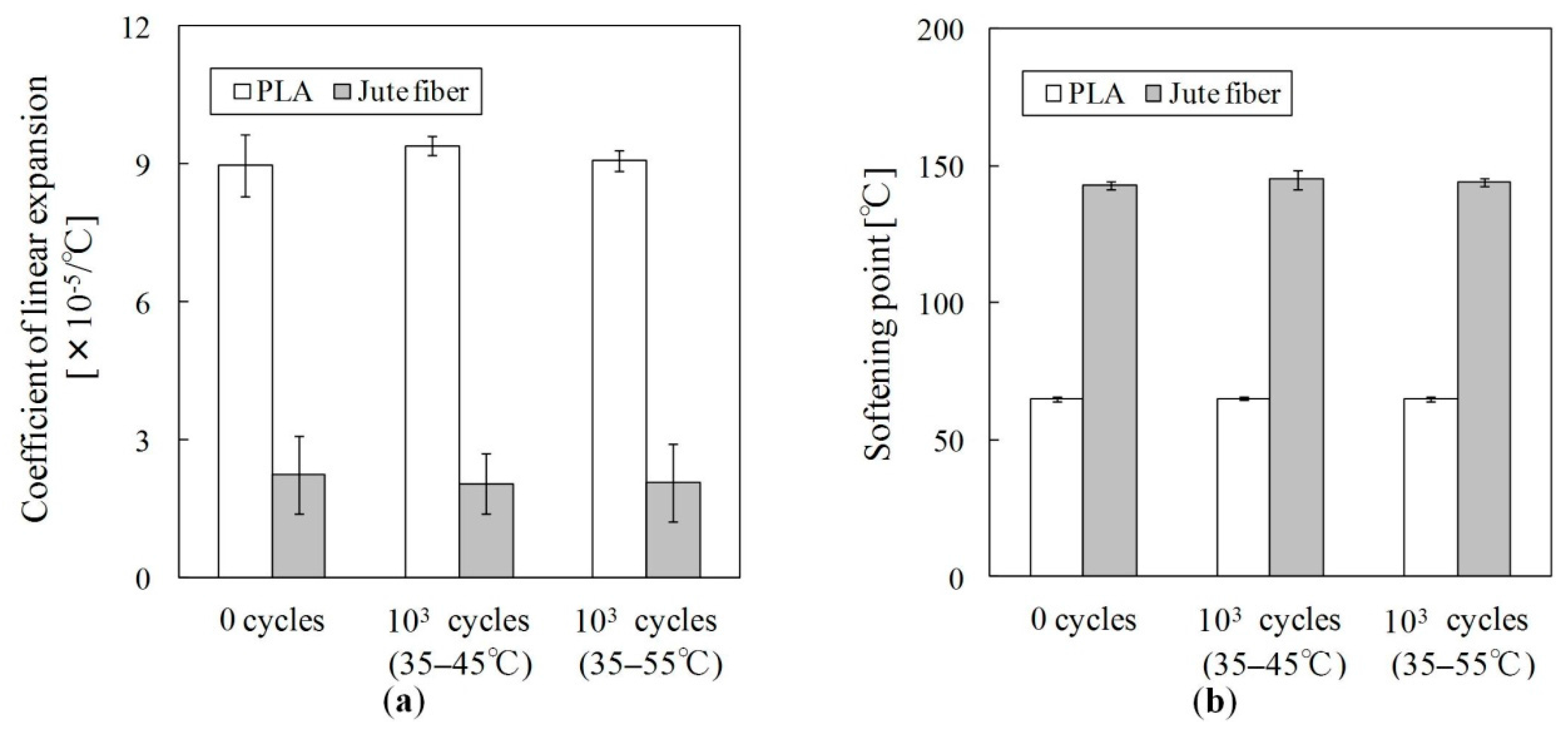

4.1. Thermal Mechanical Analyses of Jute Fiber amd PLA after Thermal Cycling

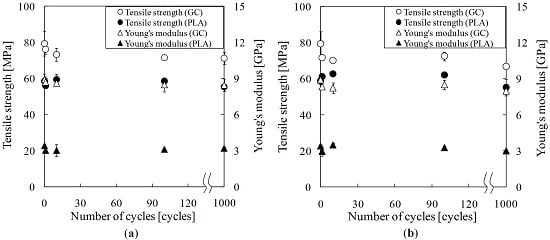

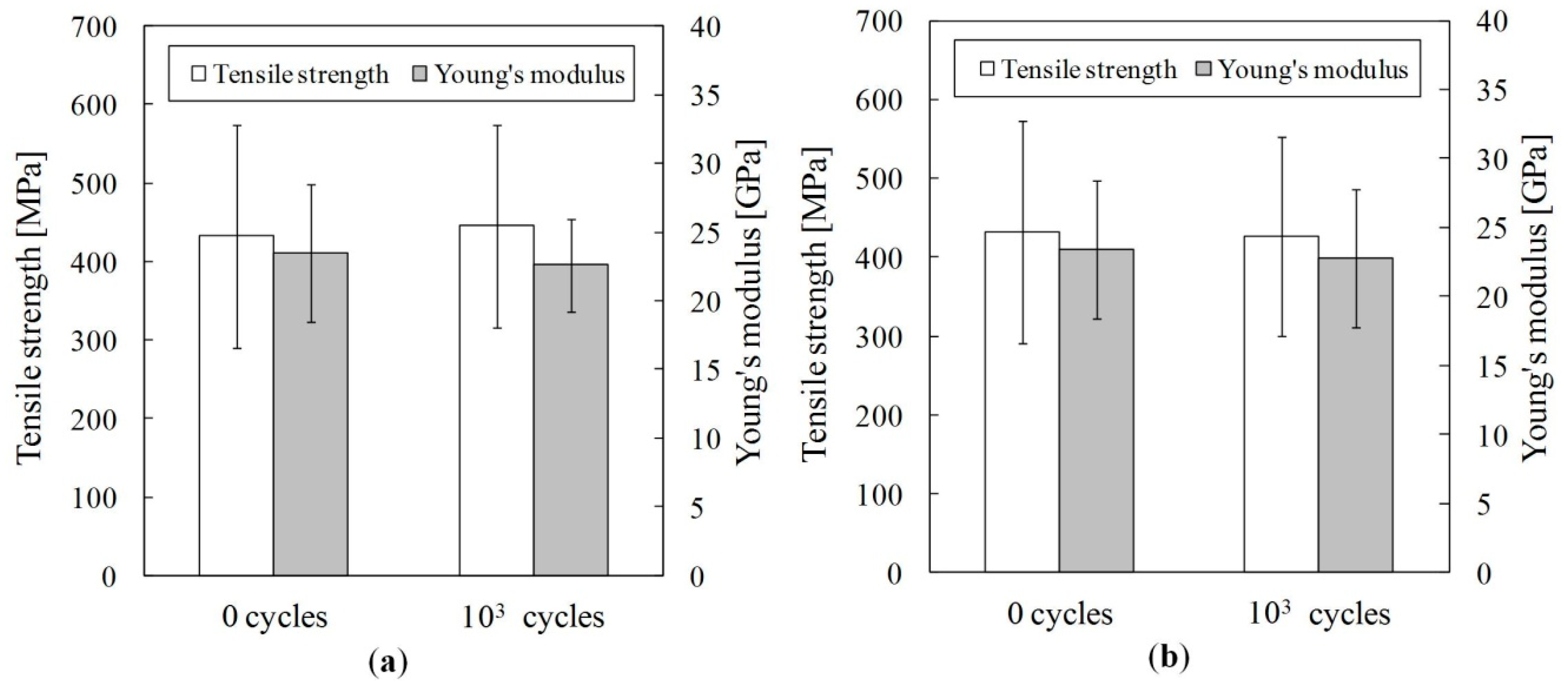

4.2. Tensile Properties of Jute Fiber, PLA, and Green Composite during Thermal Cycling

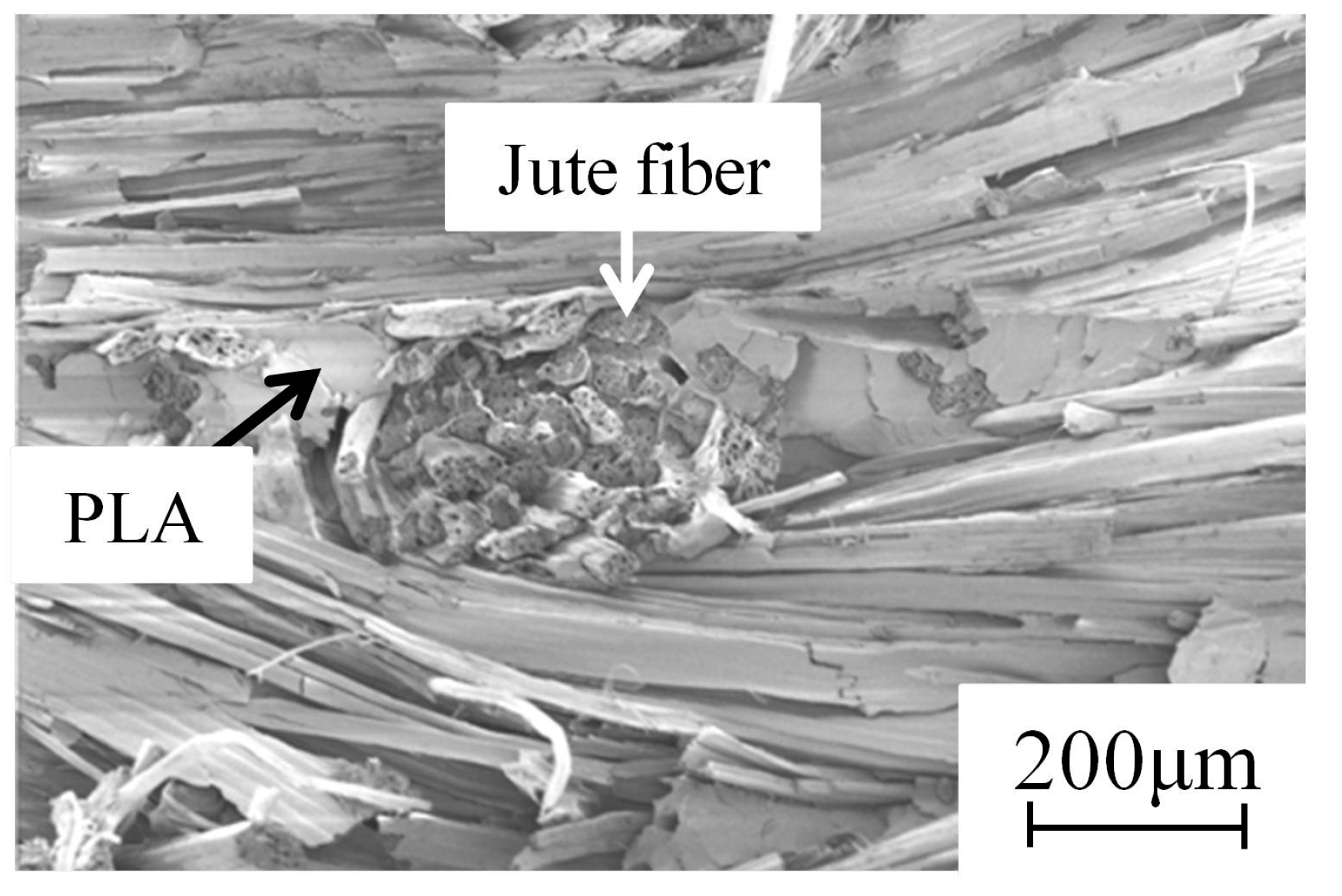

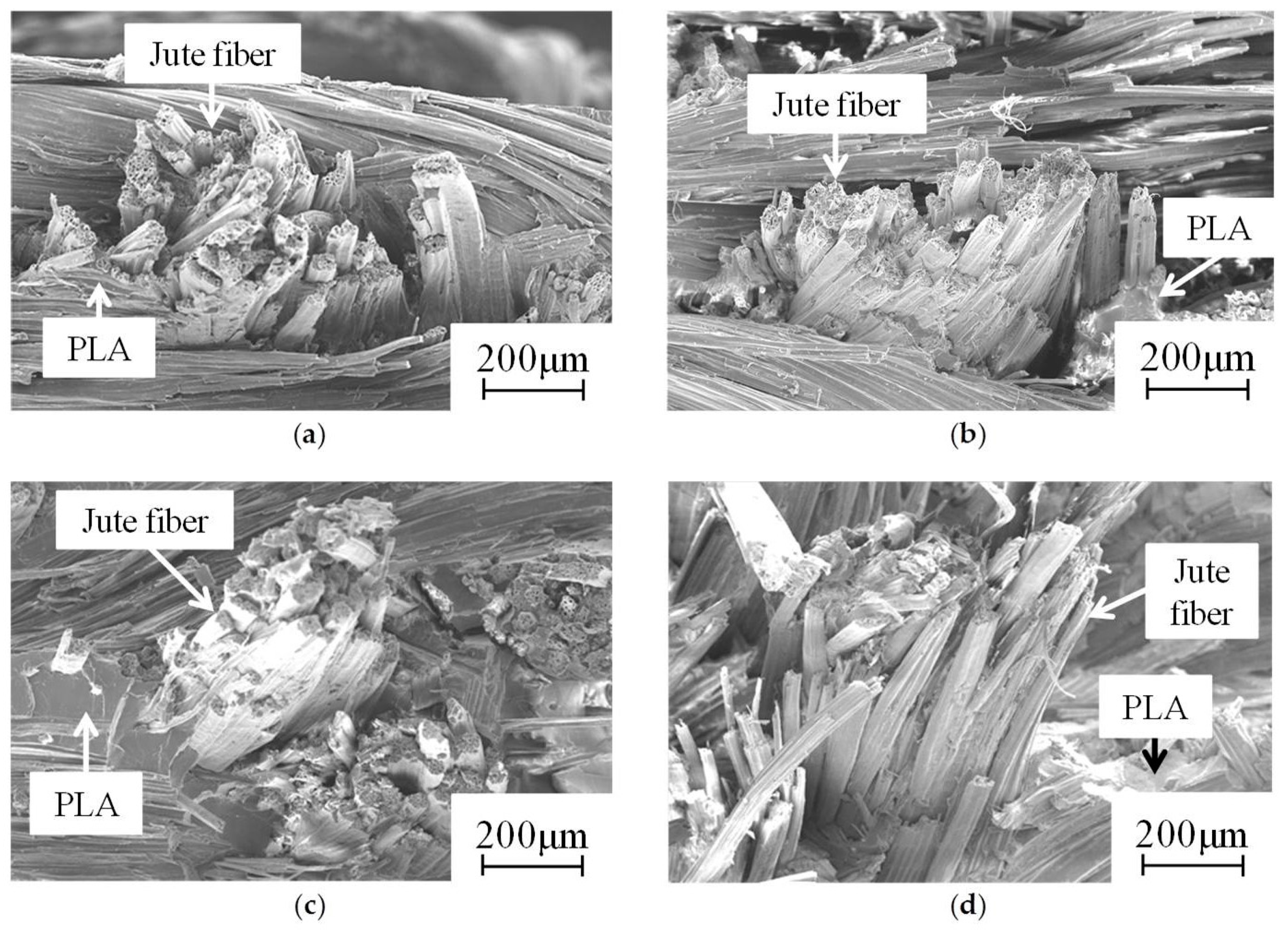

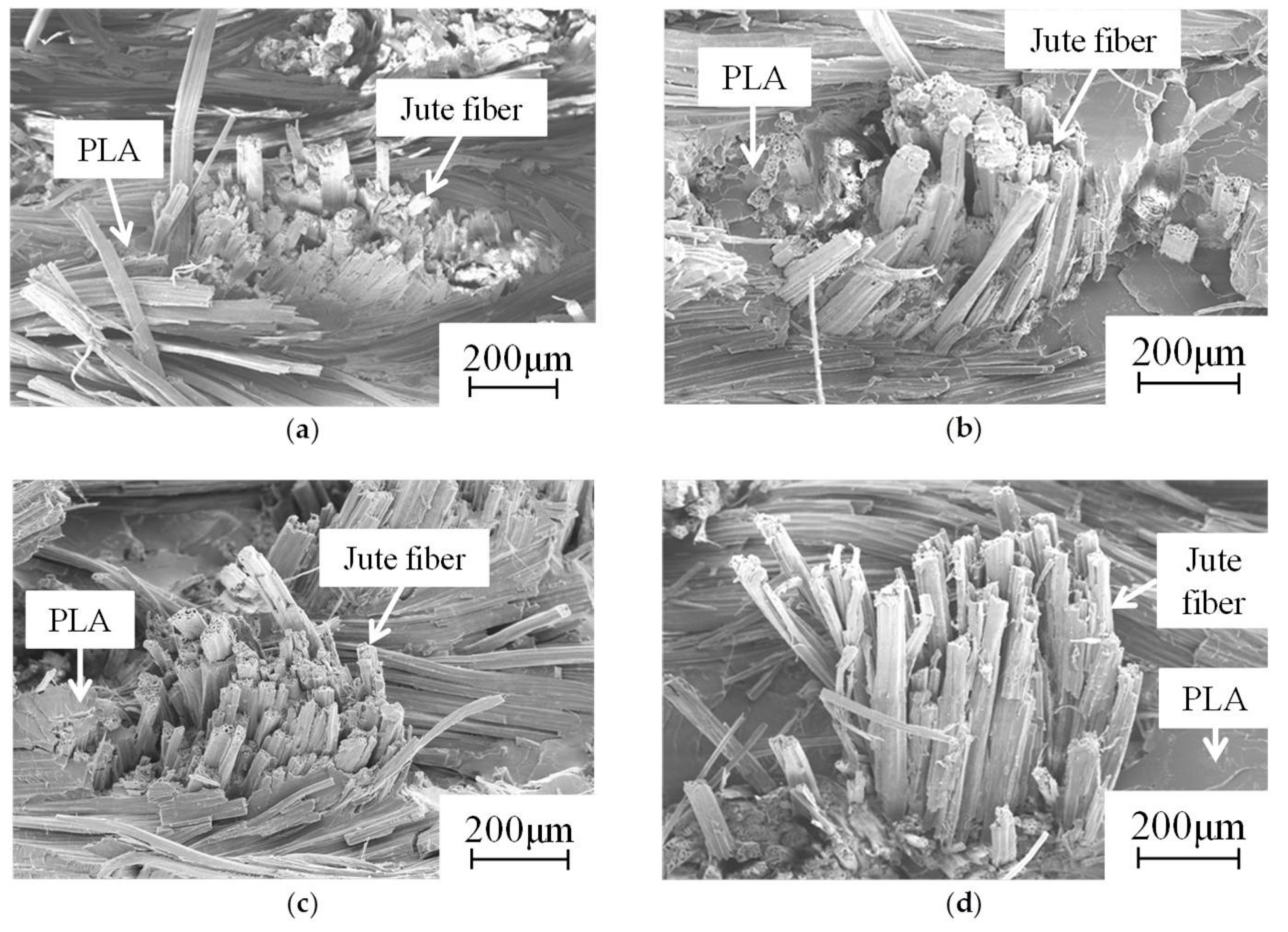

4.3. Fracture Surface of Green Comsposite after Thermal Cycling

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composite in automotive application. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Japan Automobile Recycling Promotion Center. Available online: http://www.jarc.or.jp/en/recycling/ (accessed on 21 June 2016).

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohantym, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Goda, K.; Cao, Y. Research and development of fully green composites reinforced with natural fiber. J. Solid Mech. Mater. Eng. 2007, 1, 1073–1084. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Ashori, A. Wood-plastic composite as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Hill, C.A.H.; Xiao, Z.; Militz, H.; Mai, C. Silane Coupling agents used for natural fiber/polymer composites: A review. Compos. Part A 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Mantia, F.P.L.; Morreale, M. Green composites: A brief review. Compos. Part A 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatment on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B 2012, 43, 2883–2889. [Google Scholar] [CrossRef]

- Vink, E.T.H.; Rabago, K.R.; Glassner, D.A.; Gruber, P.R. Applications of life cycle assessment to natureworks™ polylactide (PLA) production. Polym. Degrad. Stab. 2003, 80, 403–419. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Tummala, P.; Liu, W.; Misra, M.; Mulukutla, P.V.; Drzal, L.T. Injection molded biocomposites form soy protein based bioplastic and short industrial hemp fiber. J. Polym. Environ. 2005, 13, 279–285. [Google Scholar] [CrossRef]

- Huang, X.; Netravali, A. Characterization of flax fiber reinforced soy protein resin based green composites modified with nano-clay particles. Compos. Sci. Tech. 2007, 67, 2005–2014. [Google Scholar] [CrossRef]

- Ogihara, S.; Okada, A.; Kobayashi, S. Mechanical properties in a bamboo fiber/PBS biodegradable composite. J. Solid Mech. Mater. Eng. 2008, 2, 291–299. [Google Scholar] [CrossRef]

- Ren, B.; Mizue, T.; Goda, K.; Noda, J. Effects of fluctuation of fibre orientation on tensile properties of flax sliver-reinforced green composites. Compos. Struct. 2012, 94, 3457–3464. [Google Scholar] [CrossRef]

- Katogi, H.; Shimamura, Y.; Tohgo, K.; Fujii, T.; Takemura, K. Fatigue behavior of unidirectional jute spun yarn reinforced PLA. Adv. Compos. Mater. 2012, 21, 1–10. [Google Scholar]

- Ben, G.; Hirabayashi, A.; Kawazoe, Y. Evaluation of quasi-isotropic plate and cylindrical shell fabricated with green composite sheets. Adv. Compos. Mater. 2013, 22, 377–387. [Google Scholar] [CrossRef]

- Kobayashi, S. Damage behavior of hemp fiber reinforced poly(l-lactic acid) composites under fatigue loading. J. Solid Mech. Mater. Eng. 2013, 7, 317–323. [Google Scholar] [CrossRef]

- Kim, Y.; Kwon, O.H.; Park, W.H.; Cho, D. Thermomechanical and flexural properties of chopped silk fiber-reinforced poly(butylenes succinate) green composites: Effect of electron beam treatment of worm silk. Adv. Compos. Mater. 2013, 22, 437–449. [Google Scholar] [CrossRef]

- Katogi, H.; Takemura, K. The effect of soil on the biodegradable behavior of green composites under various environmental (ambient) temperature. WIT Trans. Eng. Sci. 2015, 90, 47–55. [Google Scholar]

- Katayama, T.; Tanaka, K.; Murakami, T.; Uno, K. Compression moulding of jute fabric reinforced thermoplastics composites based on PLA non-woven fabric. WIT Trans. Built Environ. 2006, 85, 159–167. [Google Scholar]

- Khondker, O.K.; Ishiaku, U.S.; Nakai, A.; Hamada, H. A novel processing technique for thermoplastic manufacturing of unidirectional composites reinforced with jute fiber. Compos. Part A 2006, 37, 2274–2284. [Google Scholar] [CrossRef]

- Takagi, H.; Asano, A. Effects of processing conditions on flexural properties of cellulose nanofiber reinforced “green” composites. Compos. Part A 2007, 39, 685–689. [Google Scholar] [CrossRef]

- Takemura, K.; Minekage, M. Effect of molding condition on tensile properties of hemp fiber reinforced composite. Adv. Compos. Mater. 2007, 16, 385–394. [Google Scholar] [CrossRef]

- Arao, Y.; Fujiura, T.; Itani, S.; Tanaka, T. Strength improvement in injection-molded jute-fiber-reinforced polylactide green composites. Compos. Part B 2015, 68, 2000–2006. [Google Scholar] [CrossRef]

- Toyota Boshoku Co., Ltd. Available online: http://www.toyota-boshoku.com/jp/about/development/flash/index.html (accessed on 3 March 2016).

- Ministry of Land, Infrastructure, Transport and Tourism. Available online: http://www.mlit.go.jp/jidosha/kensatoroku/question/ (accessed on 21 June 2016).

- Ben, G.; Kihara, Y.; Nakamori, K.; Aoki, Y. Examination of heat resistant tensile properties and molding conditions of green composite composed of kenaf fibers and PLA resin. Adv. Compos. Mater. 2007, 16, 361–376. [Google Scholar] [CrossRef]

- Nassiopoulos, E.; Njuguna, J. Thermo-mechanical performance of poly(lactic acid)/flax fibre-reinforced biocomposites. Mater. Des. 2015, 66, 473–485. [Google Scholar] [CrossRef]

- Katogi, H.; Takemura, K.; Miyamoto, S. Effect of surface treatment on flexural creep behavior of plain woven jute fiber reinforced PLA. In Proceedings of the 9th International Conference on Fracture and Strength of Solids, Jeju, Korea, 9–13 June 2013. OS31-010.

- Japan Automobile Federation. Available online: http://www.jaf.or.jp/eco-safety/safety/usertest/temperature/detail2.htm (accessed on 3 March 2016).

- Sakiyama, M.; Katogi, H.; Takemura, K. Thermal fatigue and water absorption on mechanical properties of natural fiber reinforced plastics. Reinf. Plast. 2012, 58, 13–16. (In Japanese) [Google Scholar]

- Ray, D.; Sarkar, B.K. Characterization of alkali-treated jute fibers for physical and mechanical properties. J. Appl. Polym. Sci. 1997, 80, 1013–1020. [Google Scholar] [CrossRef]

- Japanese Industrial Standard. Testing Method for Linear Thermal Expansion Coefficient of Plastic by Thermomechanical Analysis; JIS K 7197; Japanese Standards Association: Tokyo, Japan, 2013. [Google Scholar]

- Japanese Industrial Standard. Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics; JIS K 7162; Japanese Standards Association: Tokyo, Japan, 2013. [Google Scholar]

- Japanese Industrial Standard. Testing Method for Tensile Properties of Glass Fiber Reinforced Plastics; JIS K 7054; Japanese Standards Association: Tokyo, Japan, 2003. [Google Scholar]

- Nishino, T.; Matsuda, I.; Hirao, K. All-cellulose composite. Macromolecules 2004, 37, 7683–7687. [Google Scholar] [CrossRef]

- Goring, D.A.I. Thermal softening of lignin, hemicelluloses and cellulose. Pulp Pap. Mag. Can. 1964, 64, 517–527. [Google Scholar]

| Material | Temperature Range | Cycle | Young’s Modulus (GPa) | Tensile Strength (MPa) | Failure Strain (%) | |||

|---|---|---|---|---|---|---|---|---|

| AVG | SD | AVG | SD | AVG | SD | |||

| Green composite | – | 0 | 8.9 | 0.4 | 79 | 6.8 | 1.5 | 0.1 |

| 35–45 °C | 1 | 8.7 | 0.4 | 76 | 2.7 | 1.3 | 0.1 | |

| 10 | 8.6 | 0.2 | 73 | 3.6 | 1.3 | 0.1 | ||

| 100 | 8.5 | 0.6 | 72 | 0.5 | 1.2 | 0.1 | ||

| 1000 | 8.5 | 0.5 | 71 | 3.4 | 1.3 | 0.1 | ||

| 35–55 °C | 1 | 8.3 | 0.2 | 72 | 1.3 | 1.4 | 0.1 | |

| 10 | 8.2 | 0.4 | 70 | 1.3 | 1.4 | 0.1 | ||

| 100 | 8.5 | 0.4 | 72 | 2.5 | 1.4 | 0.1 | ||

| 1000 | 8.0 | 0.4 | 67 | 1.3 | 1.3 | 0.2 | ||

| PLA | – | 0 | 3.4 | 0.1 | 59 | 0.3 | 12 | 3.5 |

| 35–45 °C | 1 | 3.0 | 0.2 | 56 | 0.7 | 9.0 | 1.2 | |

| 10 | 3.0 | 0.5 | 60 | 2.9 | 12 | 4.2 | ||

| 100 | 3.1 | 0.1 | 58 | 1.7 | 9.0 | 3.0 | ||

| 1000 | 3.2 | 0.1 | 55 | 1.3 | 8.7 | 2.3 | ||

| 35–55 °C | 1 | 3.0 | 0.4 | 61 | 0.1 | 16 | 1.4 | |

| 10 | 3.5 | 0.1 | 63 | 0.6 | 12 | 3.2 | ||

| 100 | 3.3 | 0.2 | 62 | 1.0 | 13 | 2.1 | ||

| 1000 | 3.0 | 0.1 | 55 | 4.7 | 8.4 | 2.0 | ||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katogi, H.; Takemura, K.; Akiyama, M. Residual Tensile Property of Plain Woven Jute Fiber/Poly(Lactic Acid) Green Composites during Thermal Cycling. Materials 2016, 9, 573. https://doi.org/10.3390/ma9070573

Katogi H, Takemura K, Akiyama M. Residual Tensile Property of Plain Woven Jute Fiber/Poly(Lactic Acid) Green Composites during Thermal Cycling. Materials. 2016; 9(7):573. https://doi.org/10.3390/ma9070573

Chicago/Turabian StyleKatogi, Hideaki, Kenichi Takemura, and Motoki Akiyama. 2016. "Residual Tensile Property of Plain Woven Jute Fiber/Poly(Lactic Acid) Green Composites during Thermal Cycling" Materials 9, no. 7: 573. https://doi.org/10.3390/ma9070573