The Effect of Ultrasonic Peening Treatment on Fatigue Performance of Welded Joints

Abstract

:1. Introduction

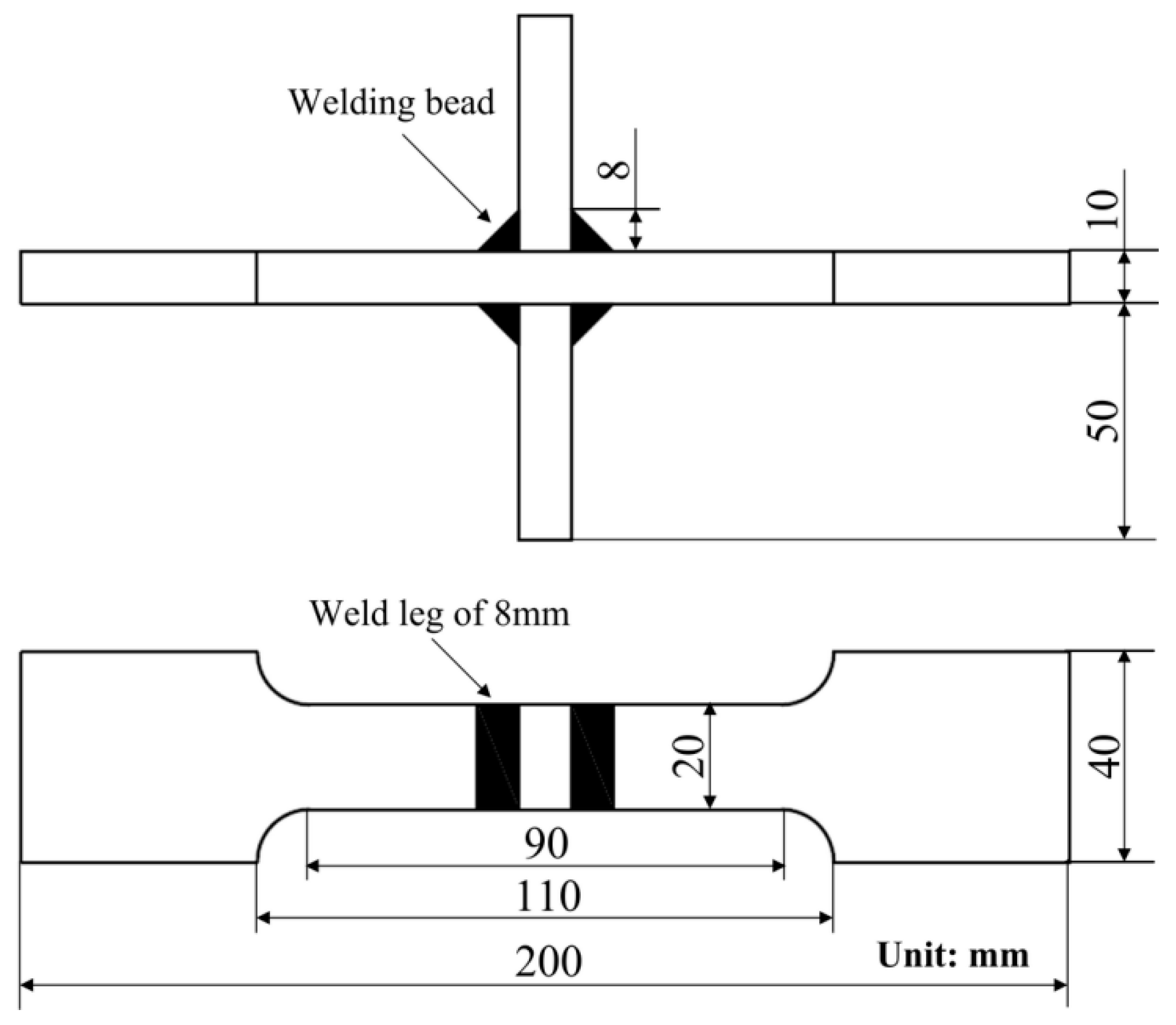

2. Material and Experimental Procedures

2.1. Joint Type and Experimental Material

2.2. Surface Strengthening Treatment

2.3. Fatigue Testing Scheme

- (1)

- Fatigue tests of two kinds of welded joints (as-welded joint and UPT-welded joint) were carried out. The effect of UPT can be observed through the S-N curves.

- (2)

- UPT-welded joints were given an extra supplement of ultrasonic peening during the process of fatigue tests every 50,000, 100,000, and 150,000 cycles, respectively. The effect of residual compression stress release on fatigue life can be studied by this way.

3. Results and Discussion

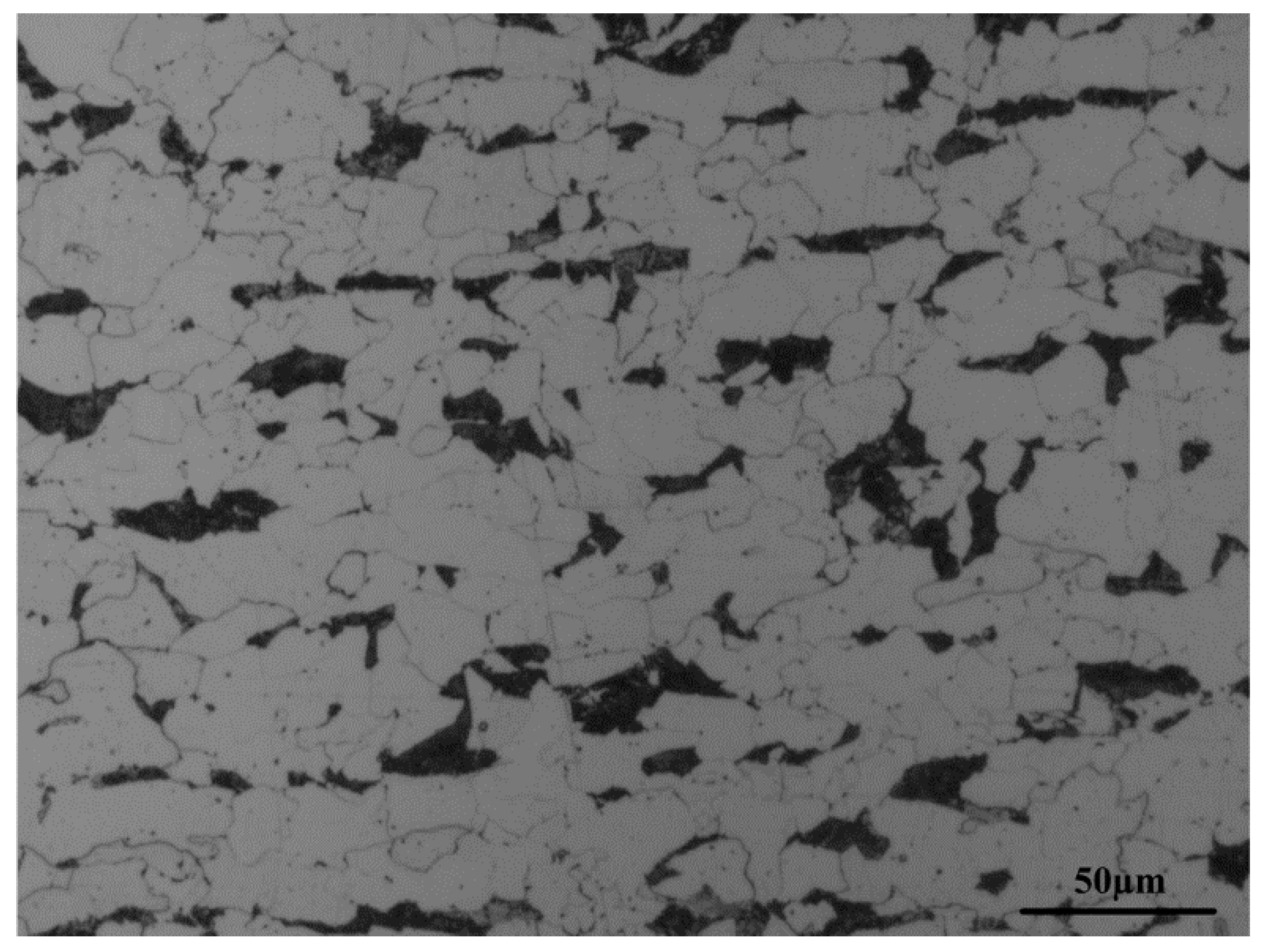

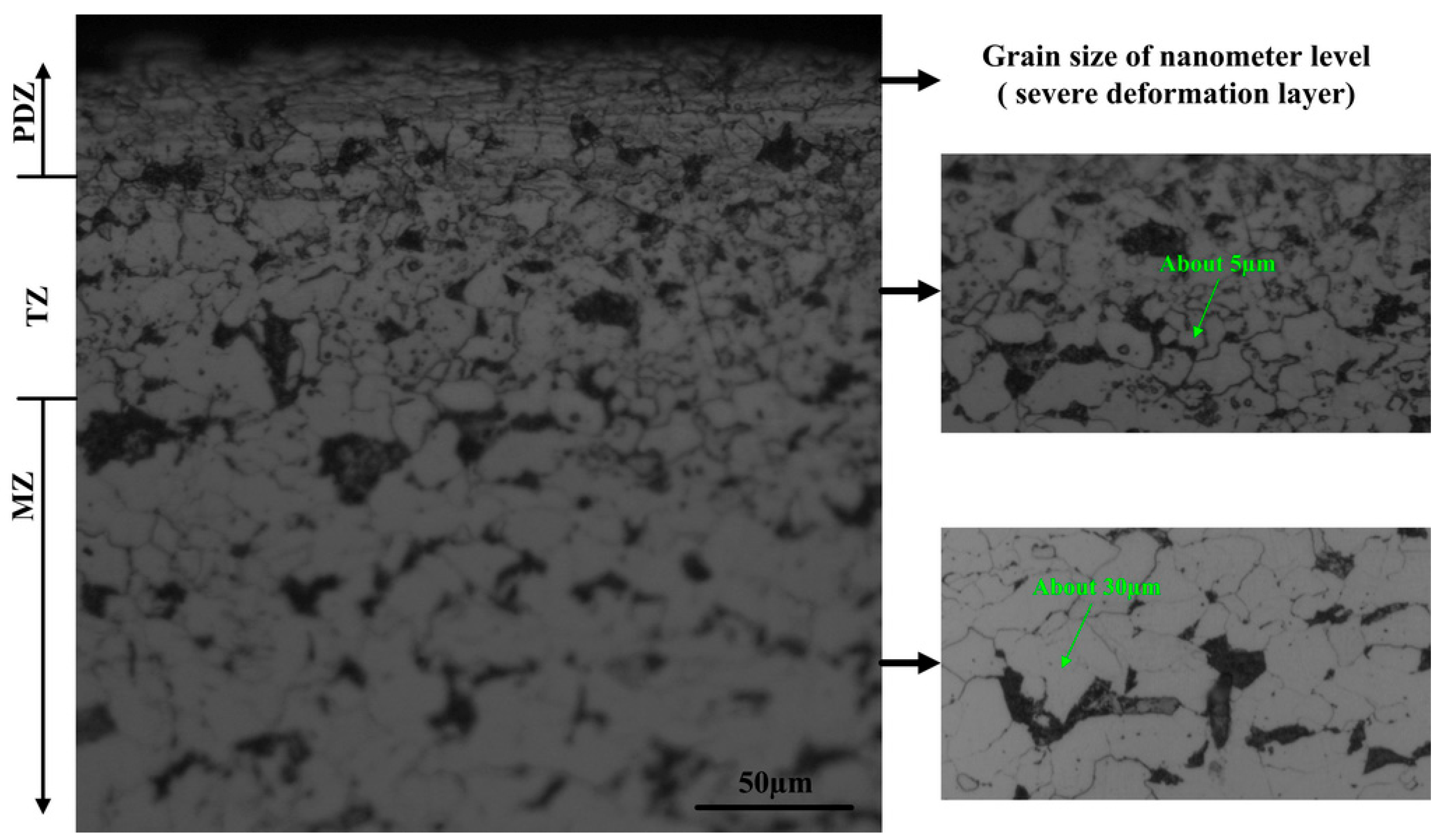

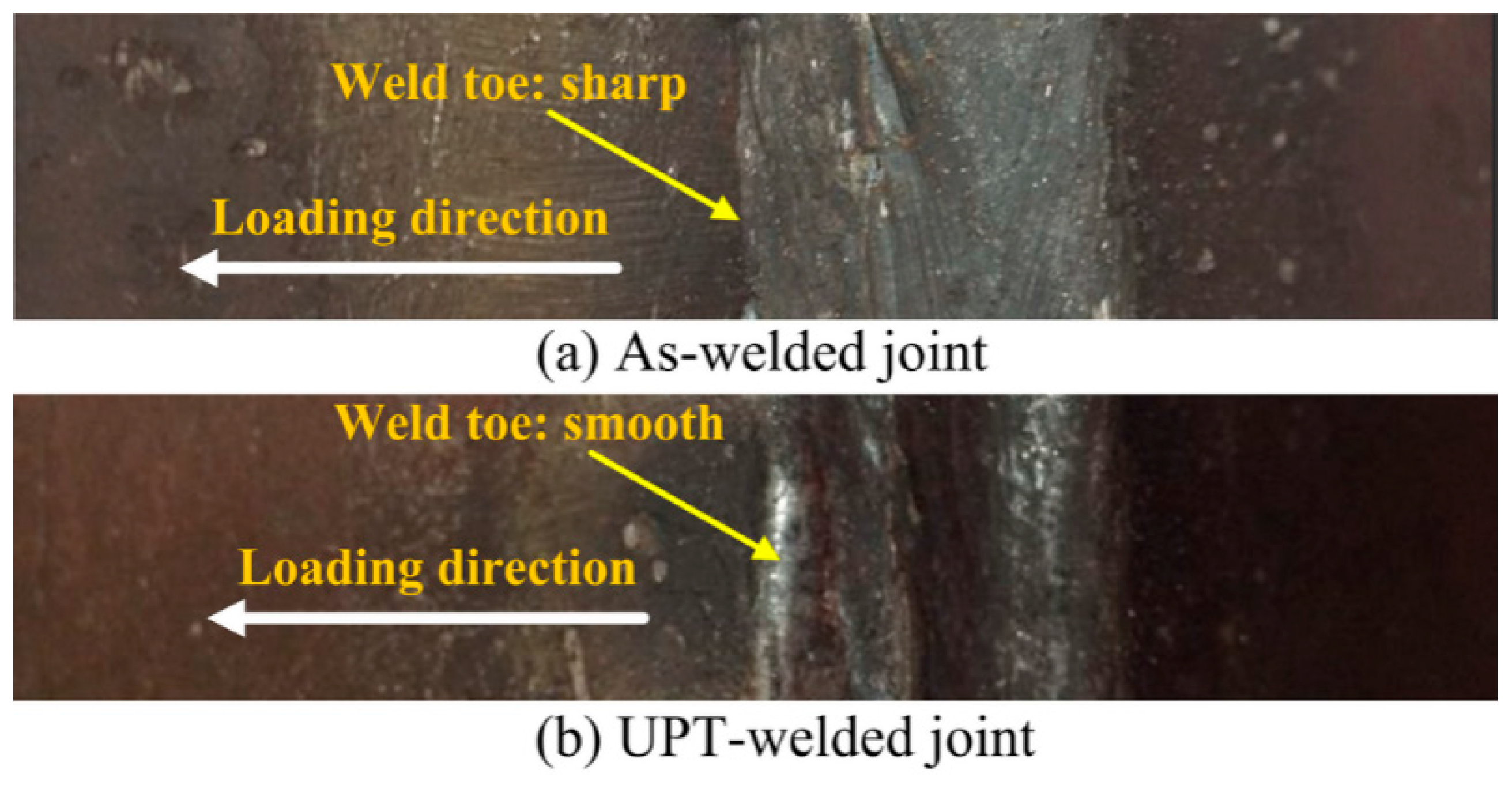

3.1. Surface Strengthening Mechanism of UPT

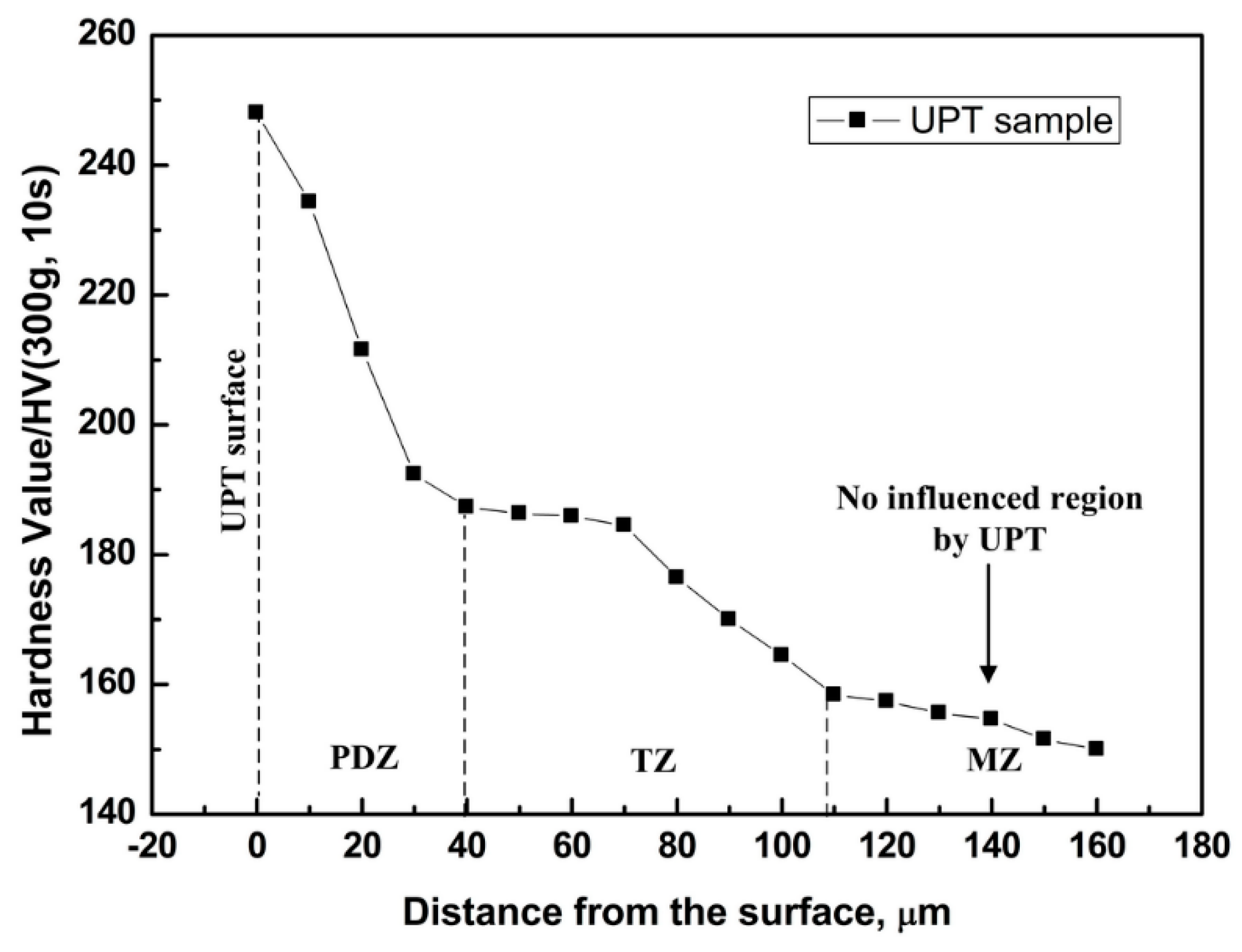

3.2. Hardness Analysis

3.3. Fatigue Life Analysis

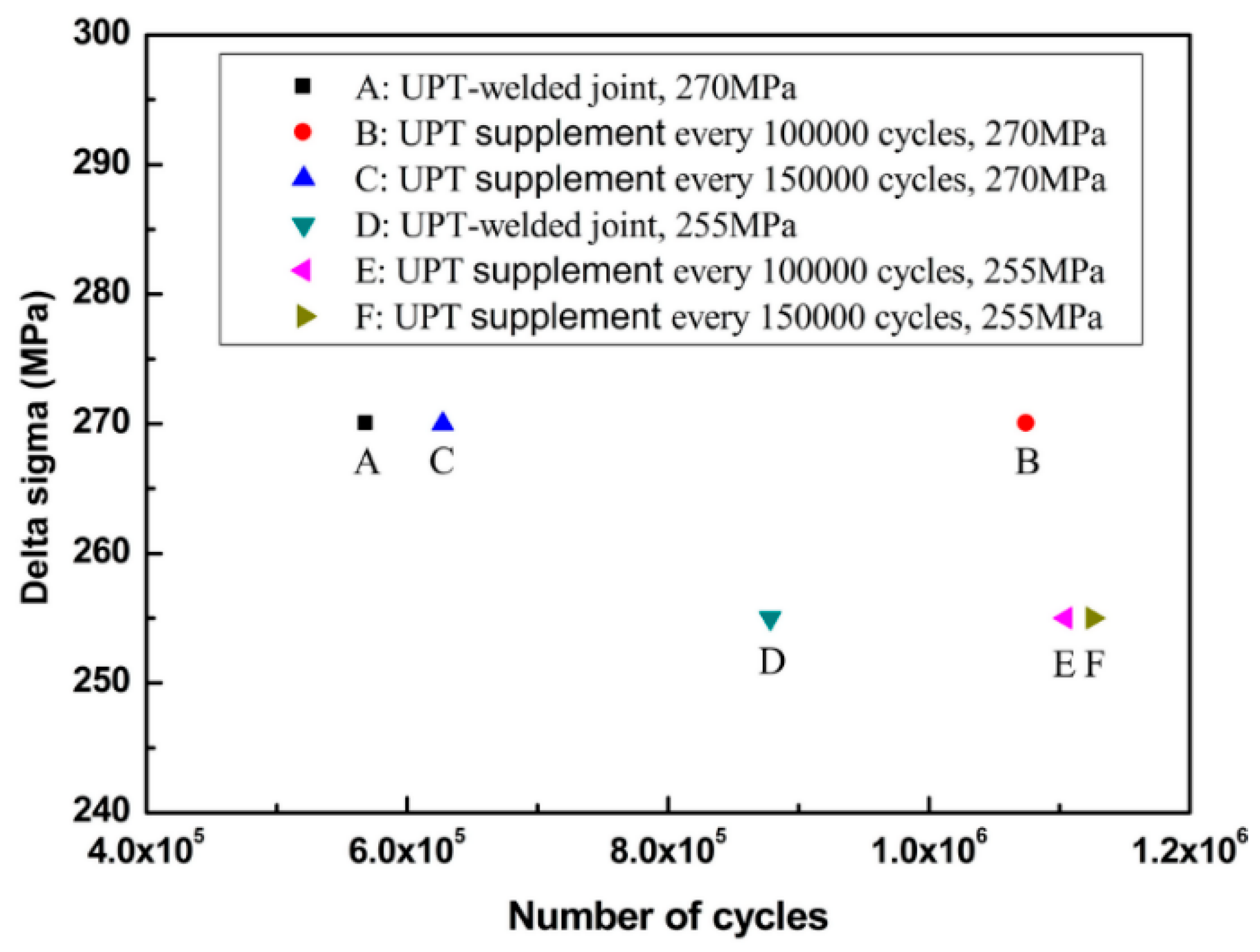

3.4. The Effect of Stress Release on Fatigue Life

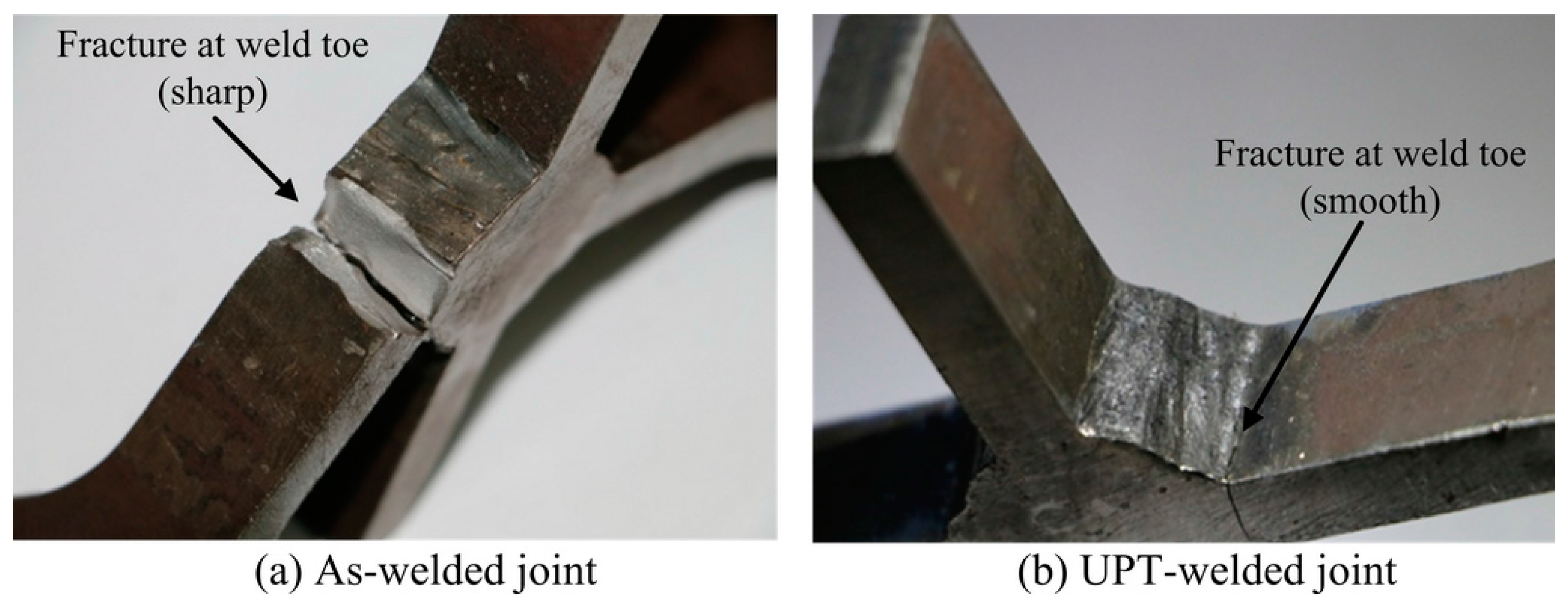

3.5. Fatigue Fracture of Welded Joint before and after UPT

4. Conclusions

- (1)

- Ultrasonic peening treatment can achieve nanocrystallization on the surface of the peening sample, reduce stress concentration, and form residual compressive stresses at the weld toe.

- (2)

- Stress concentration and residual tensile stress are the main reasons to reduce fatigue strength of cruciform welded joints.

- (3)

- Residual compressive stress caused by ultrasonic peening treatment will be released with the increase of fatigue life. A very significant fatigue strength improvement occurs when the ultrasonic peening treatment is reapplied repeatedly after a certain number of cycles.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, Z.Y.; Wang, Q.Y.; Liu, Y.J. Evaluation of fatigue strength improvement by CFRP laminates and shot peening onto the tension flanges joining corrugated steel webs. Materials 2015, 8, 5348–5362. [Google Scholar] [CrossRef]

- Han, Q.H.; Guo, Q.; Yin, Y.; Xing, Y. Fatigue behaviour of G20Mn5QT cast steel and butt welds with Q345B steel. Int. J. Steel Struct. 2016, 16, 139–149. [Google Scholar] [CrossRef]

- Jiang, C.; Liu, Z.C.; Wang, X.G.; Zhang, Z.; Long, X.Y. A structural stress-based critical plane method for multiaxial fatigue life estimation in welded joints. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 372–383. [Google Scholar] [CrossRef]

- Nykanen, T.; Bjork, T. A new proposal for assessment of the fatigue strength of steel butt-welded joints improved by peening (HFMI) under constant amplitude tensile loading. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 566–582. [Google Scholar] [CrossRef]

- Morisada, Y.; Fujii, H.; Inagaki, F.; Kamai, M. Development of high frequency tungsten inert gas welding method. Mater. Des. 2012, 44, 12–16. [Google Scholar] [CrossRef]

- Roy, S.; Fisher, J.W.; Yen, B.T. Fatigue resistance of welded details enhanced by ultrasonic impact treatment (UIT). Int. J. Fatigue 2003, 25, 1239–1247. [Google Scholar] [CrossRef]

- Vidal, C.; Infante, V.; Vilaça, P. Assessment of improvement techniques effect on fatigue behaviour of friction stir welded aerospace aluminium alloys. Procedia Eng. 2010, 2, 1605–1616. [Google Scholar] [CrossRef]

- Branco, C.M.; Infante, V.; Baptista, R. Fatigue Behaviour of Welded Joints, Repaired by Hammer Peening. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 785–798. [Google Scholar] [CrossRef]

- Huo, L.X.; Wang, D.P.; Zhang, Y.F. Investigation of the fatigue behaviour of the welded joints treated by TIG dressing and ultrasonic peening under variable-amplitude load. Int. J. Fatigue 2005, 27, 95–101. [Google Scholar] [CrossRef]

- Cheng, X.H.; Fisher, J.W.; Prask, H.J. Residual stress modification by post-weld treatment and its beneficial effect on fatigue strength of welded structures. Int. J. Fatigue 2003, 25, 1259–1269. [Google Scholar] [CrossRef]

- Maddox, S.J. Fatigue of steel fillet welds hammer peened under load. Weld World 1998, 41, 343–349. [Google Scholar]

- Zhao, X.H.; Wang, D.P.; Deng, C.Y. Fatigue behavior of welded joint spray fused by nickel-base alloy powder. J. Mater. Process. Technol. 2011, 211, 2039–2044. [Google Scholar] [CrossRef]

- Vidal, C.; Infante, V. Fatigue behaviour of friction stir-welded joints repaired by grinding. J. Mater. Eng. Perform. 2014, 23, 1340–1349. [Google Scholar] [CrossRef]

- Baptista, R.; Infante, V.; Branco, C.M. Study of the Fatigue Behaviour in Welded Joints of Stainless Steels Treated by Weld Toe Grinding and Subjected to Salt Water Corrosion. Int. J. Fatigue 2008, 30, 453–462. [Google Scholar] [CrossRef]

- Bagheri, S.; Guagliano, M. Review of shot peening processes to obtain nanocrystalline surfaces in metal alloys. Surf. Eng. 2009, 25, 3–14. [Google Scholar] [CrossRef]

- Padilla, H.A.; Boyce, B.L. A Review of Fatigue Behavior in Nanocrystalline Metals. Exp. Mech. 2010, 50, 5–23. [Google Scholar] [CrossRef]

- Wen, A.L.; Ren, R.M.; Wang, S.; Yang, J.Y. Effect of surface nanocrystallization method on fatigue strength of TA2. Mater. Sci. Forum. 2009, 620, 545–549. [Google Scholar] [CrossRef]

- Bagherifard, S.; Fernandez-Pariente, I.; Ghelichi, R.; Guagliano, M. Fatigue behavior of notched steel specimens with nanocrystallized surface obtained by severe shot peening. Mater. Des. 2013, 45, 497–503. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, S.M.; Moridi, A.; Guagliano, M.; Ghidini, A. Nitriding duration reduction without sacrificing mechanical characteristics and fatigue behavior: The beneficial effect of surface nano-crystallization by prior severe shot peening. Mater. Des. 2014, 55, 492–498. [Google Scholar] [CrossRef]

- Carvalho, A.L.M.; Voorwald, H.J.C. Influence of shot peening and hard chromium electroplating on the fatigue strength of 7050-T7451 aluminum alloy. Int. J. Fatigue 2007, 29, 1282–1291. [Google Scholar] [CrossRef]

- Zhao, X.H.; Wang, D.P.; Huo, L.X. Analysis of the S–N curves of welded joints enhanced by ultrasonic peening treatment. Mater. Des. 2011, 32, 88–96. [Google Scholar] [CrossRef]

- Malaki, M.; Ding, H.T. A review of ultrasonic peening treatment. Mater. Des. 2015, 87, 1072–1086. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, D.P.; Deng, C.Y.; Xia, L.Q.; Huo, L.X.; Wang, L.J.; Gong, B.M. Influence of re-ultrasonic impact treatment on fatigue behaviors of S690QL welded joints. Int. J. Fatigue 2014, 66, 155–160. [Google Scholar] [CrossRef]

- Yang, X.J.; Ling, X.; Zhou, J.X. Optimization of the fatigue resistance of AISI304 stainless steel by ultrasonic impact treatment. Int. J. Fatigue 2014, 61, 28–38. [Google Scholar] [CrossRef]

| Material | Yield Strength/MPa | Ultimate Tensile Strength/MPa | Elongation Rate/% | HV |

|---|---|---|---|---|

| Q345 steel | ≥345 | 490–675 | ≥22 | 150 |

| Current/A | Frequency/KHz | Amplitude/µm | Time/min | Impact Needle Shape | Impact Position |

|---|---|---|---|---|---|

| 3.5–4.0 | 19 ± 1 | 48 | 5 | Circular | Weld toe |

| Samples | Nominal Stress Range/MPa | Fatigue Life/Cycles | Peening Interval/Cycles |

|---|---|---|---|

| A | 270 | 568,516 | No supplement |

| B | 270 | 1,074,959 | 100,000 |

| C | 270 | 627,278 | 150,000 |

| D | 255 | 878,512 | No supplement |

| E | 255 | 1,104,878 | 100,000 |

| F | 255 | 1,125,487 | 150,000 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Wang, M.; Zhang, Z.; Liu, Y. The Effect of Ultrasonic Peening Treatment on Fatigue Performance of Welded Joints. Materials 2016, 9, 471. https://doi.org/10.3390/ma9060471

Zhao X, Wang M, Zhang Z, Liu Y. The Effect of Ultrasonic Peening Treatment on Fatigue Performance of Welded Joints. Materials. 2016; 9(6):471. https://doi.org/10.3390/ma9060471

Chicago/Turabian StyleZhao, Xiaohui, Mingyi Wang, Zhiqiang Zhang, and Yu Liu. 2016. "The Effect of Ultrasonic Peening Treatment on Fatigue Performance of Welded Joints" Materials 9, no. 6: 471. https://doi.org/10.3390/ma9060471