Structural Integrity of an Electron Beam Melted Titanium Alloy

Abstract

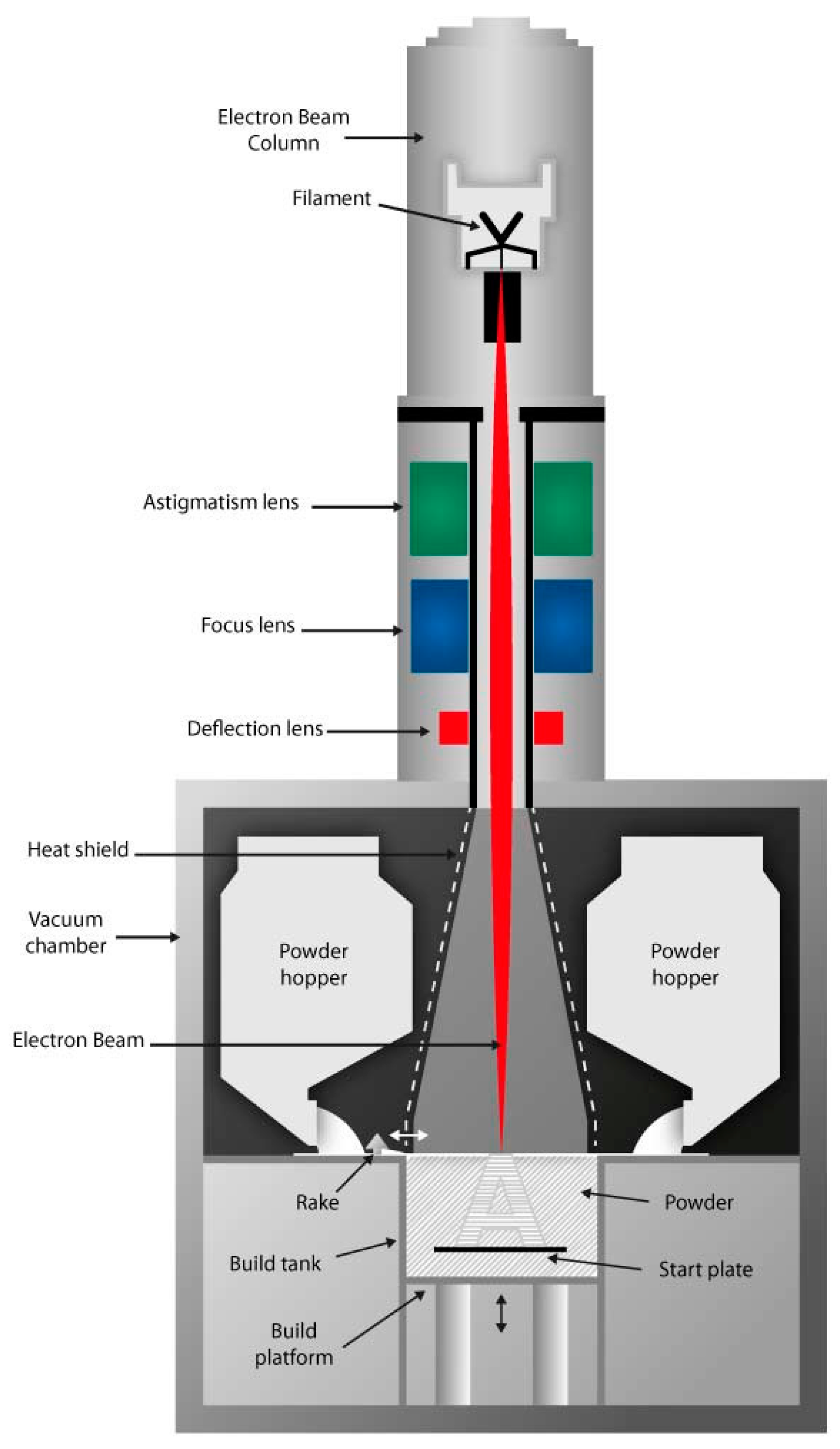

:1. Introduction

- Powder raking

- Preheating/sintering

- Contour

- Hatch profiling

2. Experimental Procedures

2.1. Materials

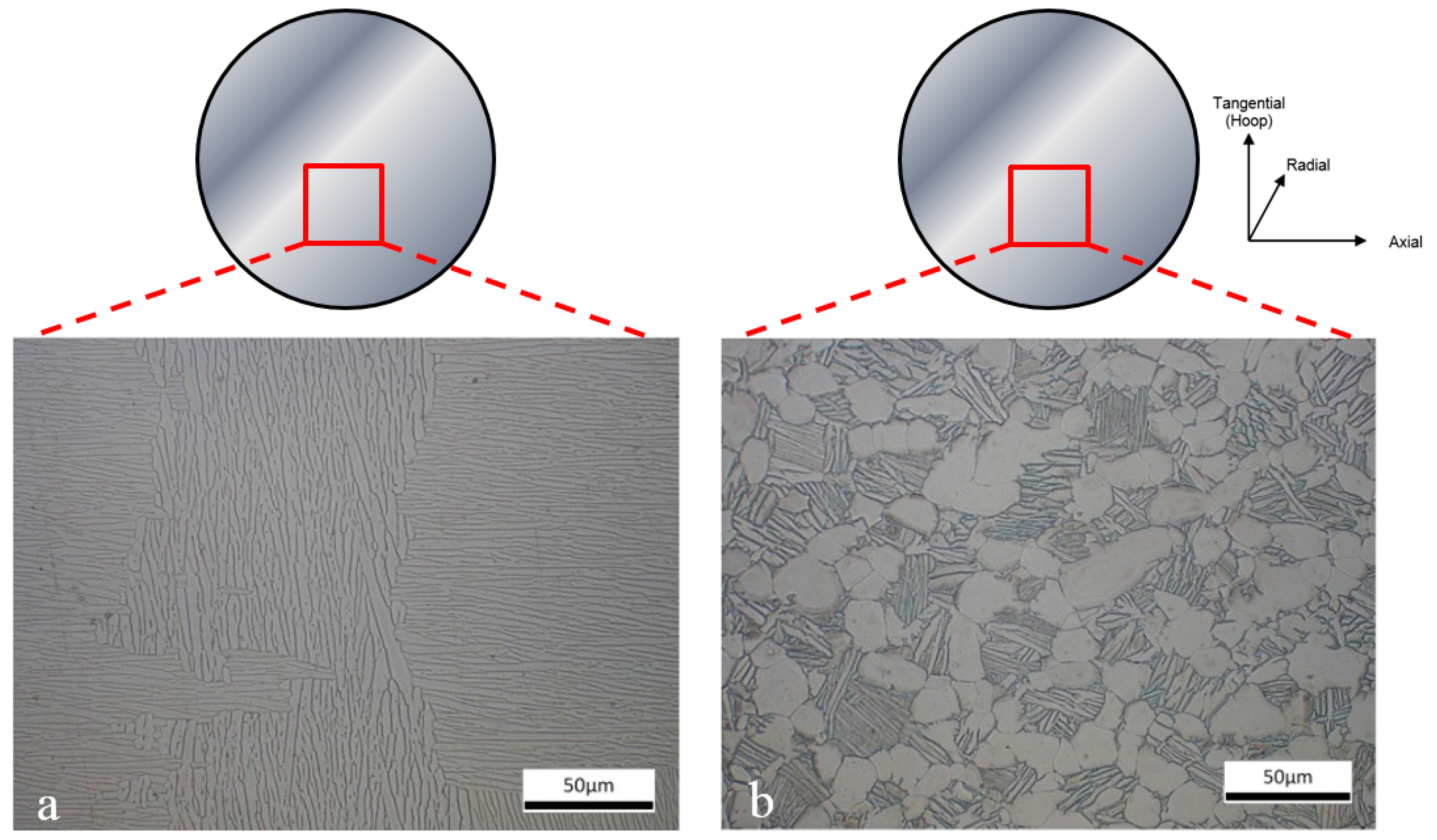

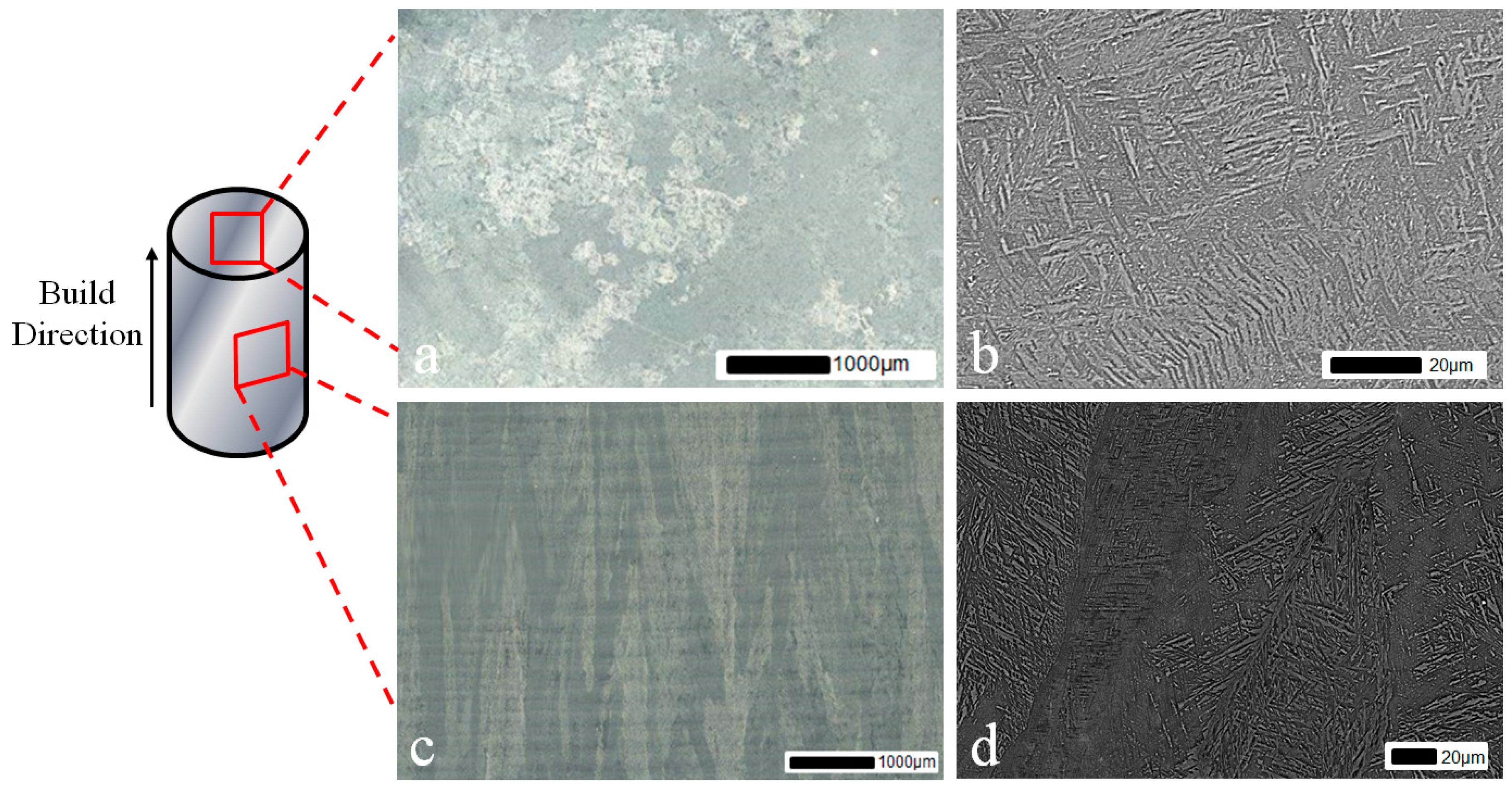

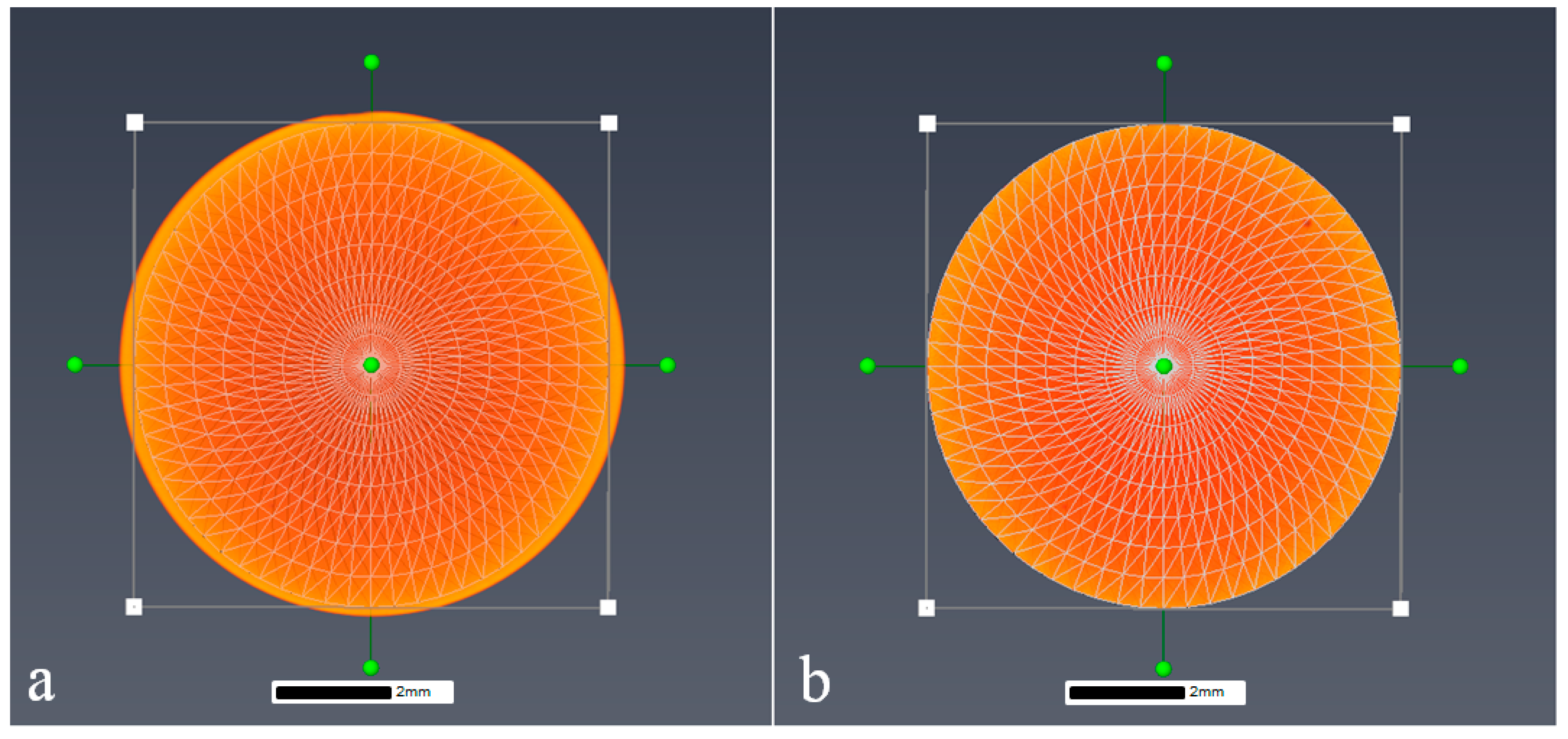

2.1.1. Microstructure

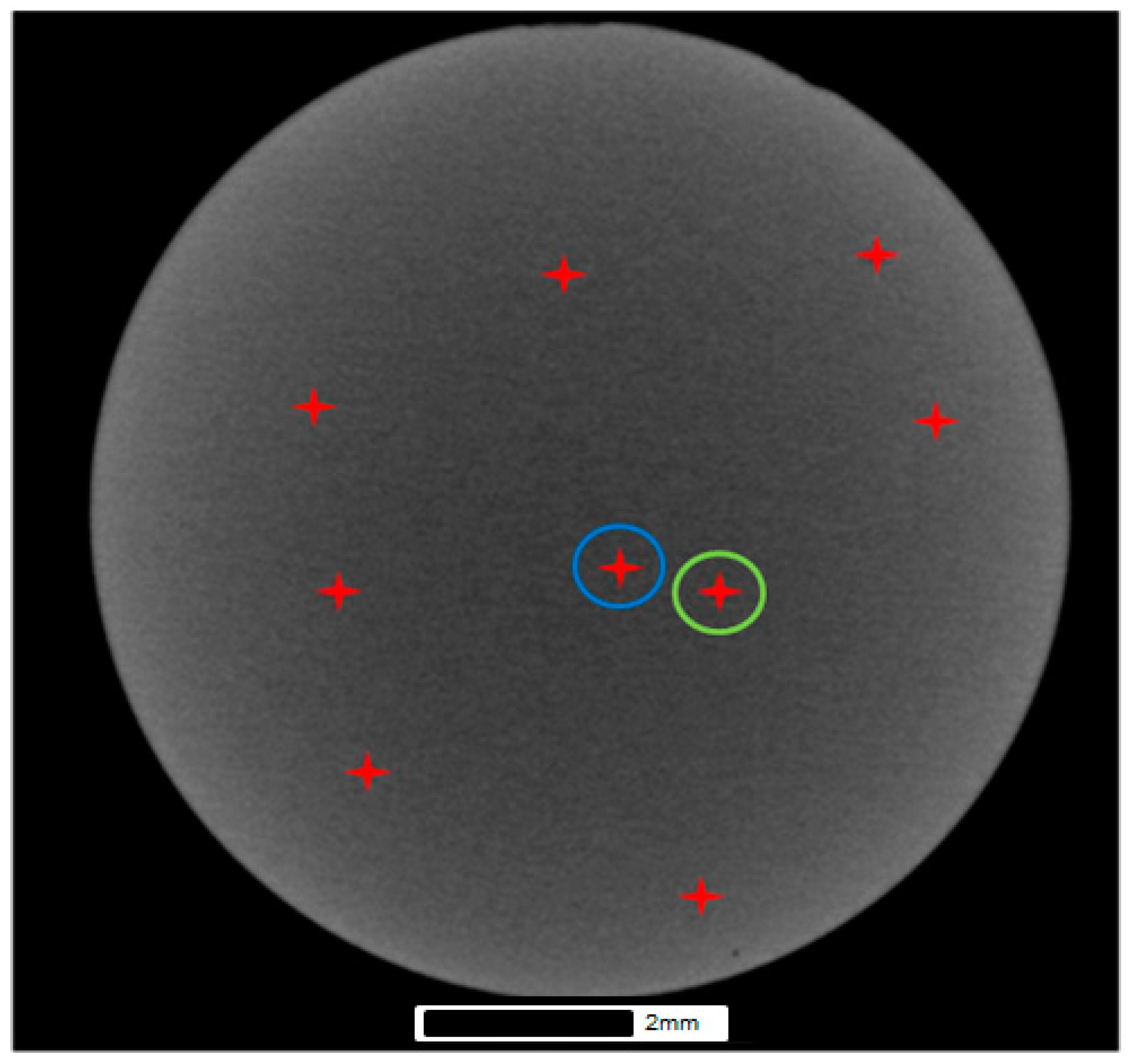

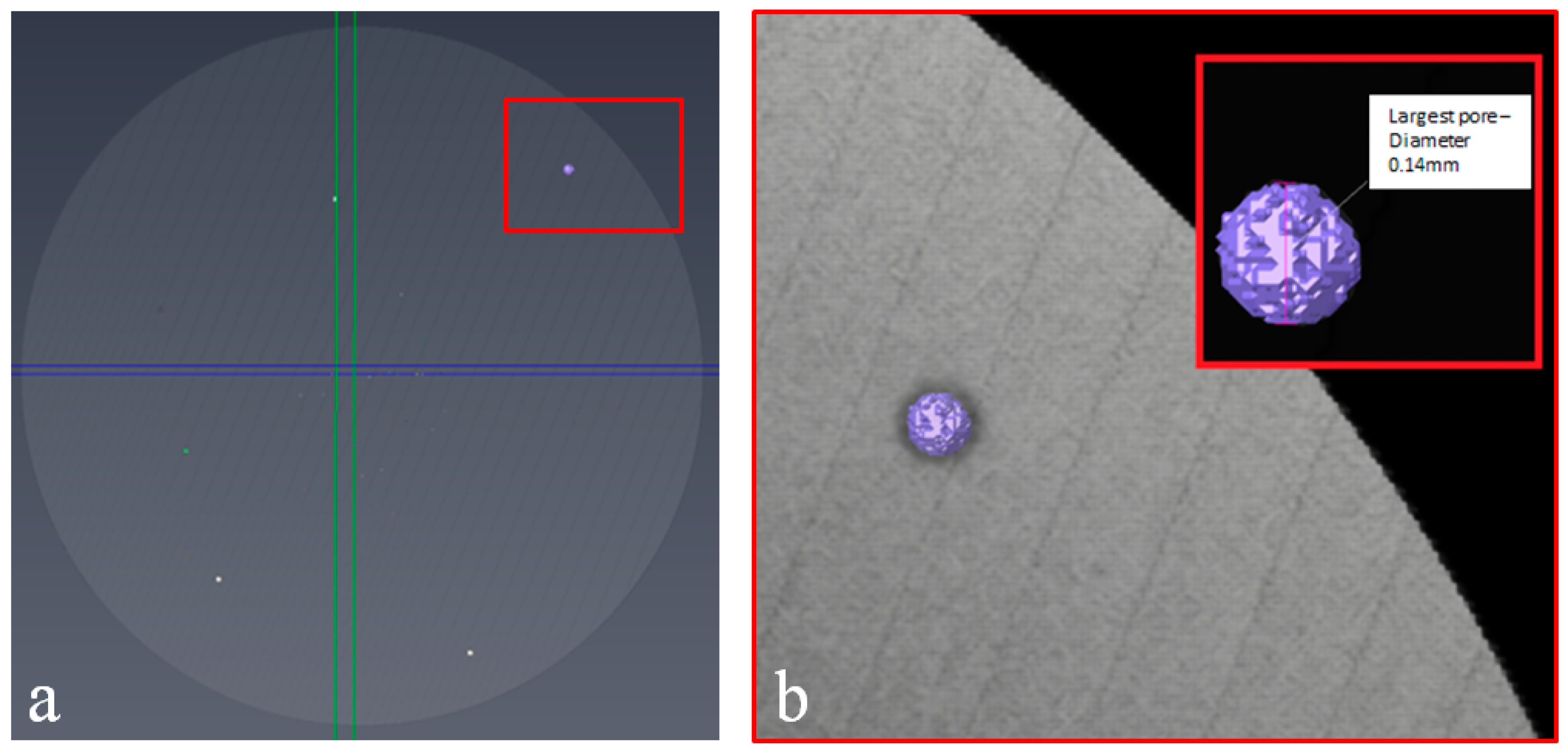

2.1.2. X-ray Computed Tomography

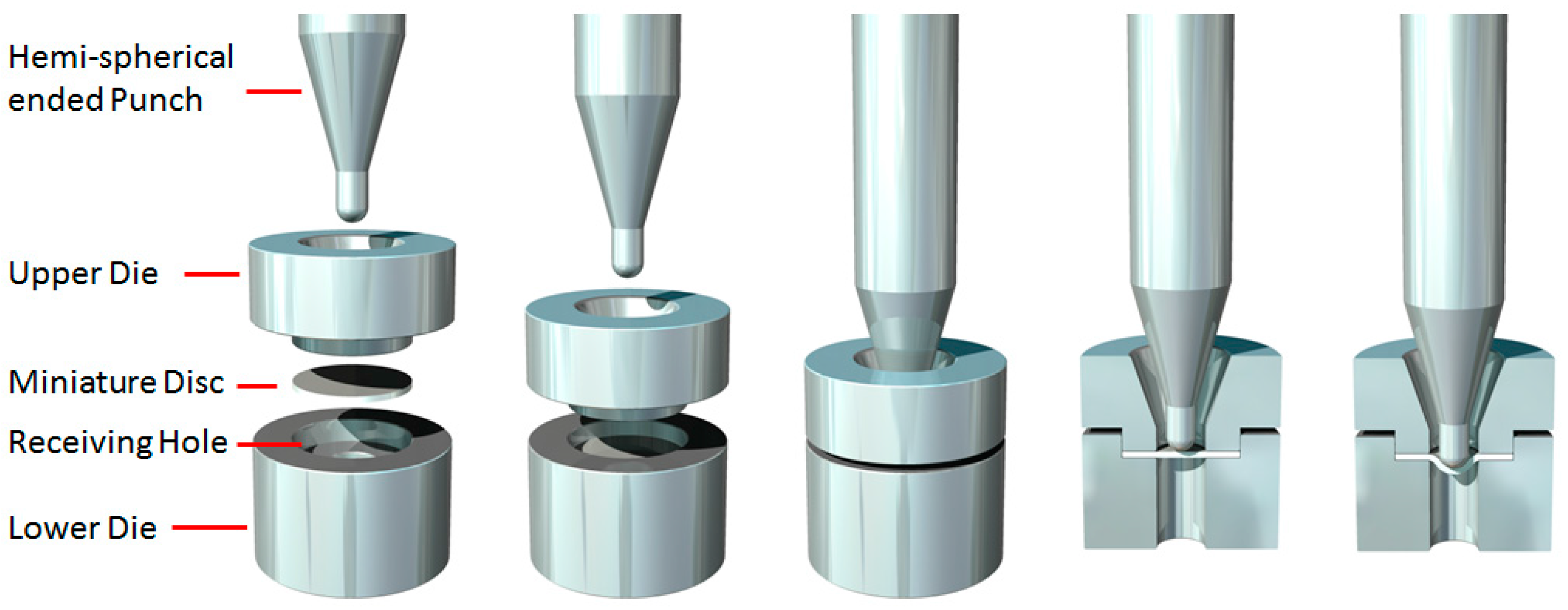

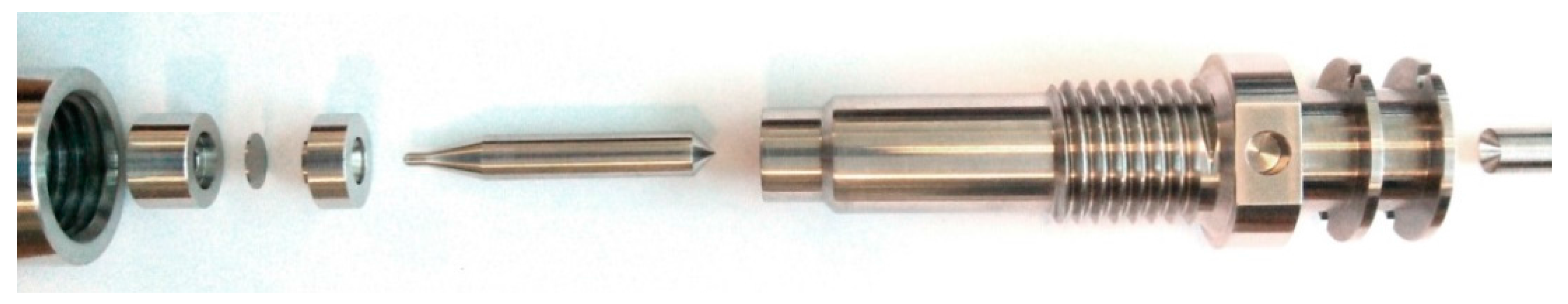

2.2. Small Punch Testing

3. Results and Discussion

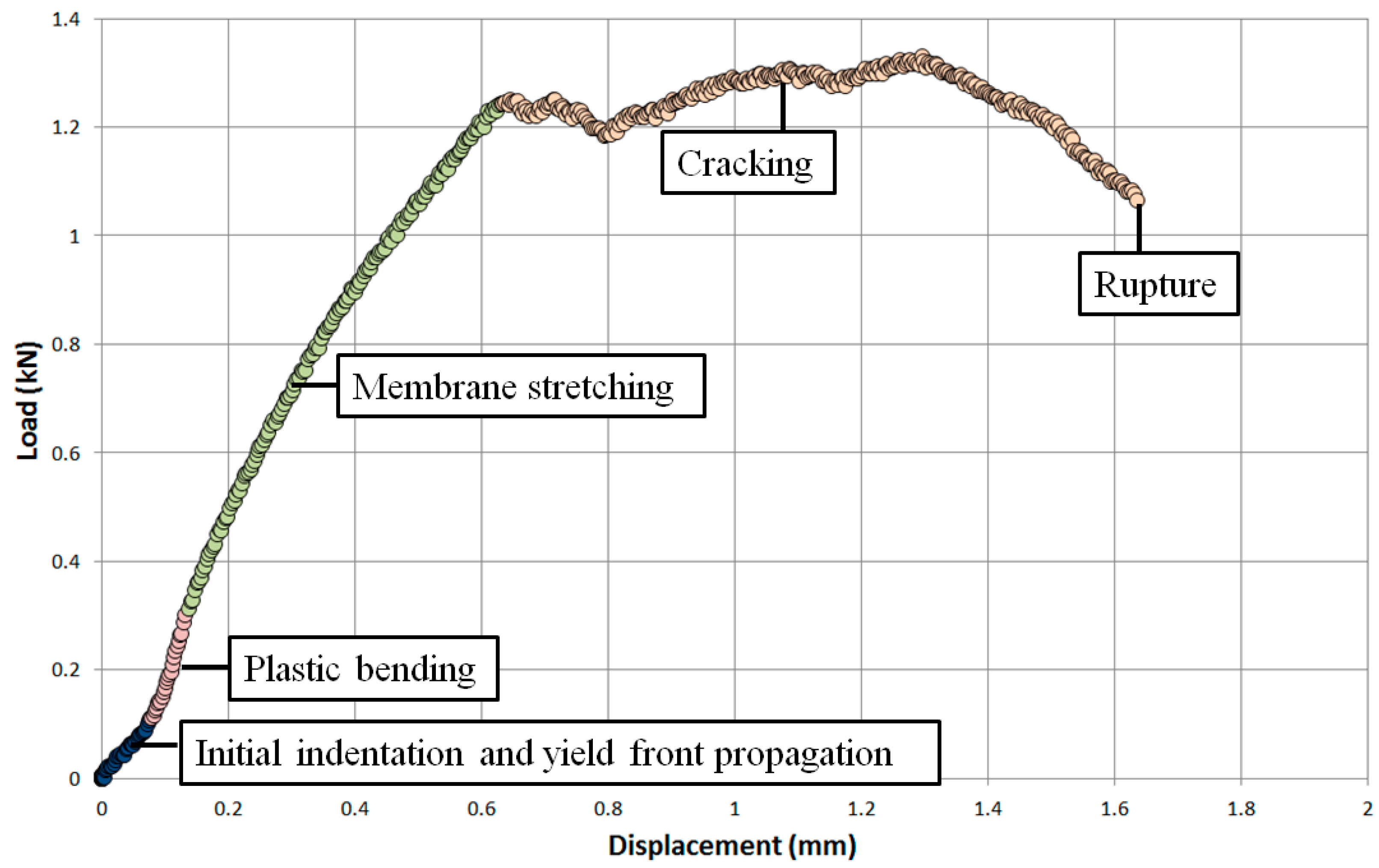

3.1. Small Punch Test Results

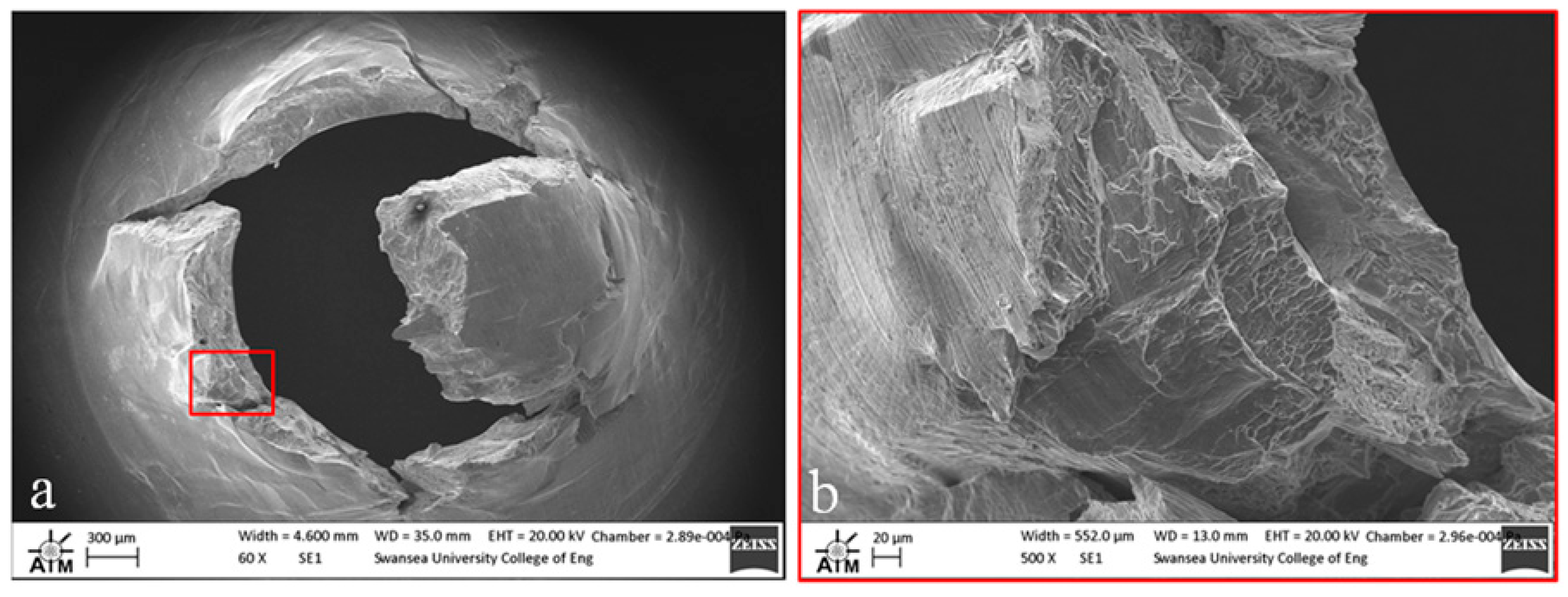

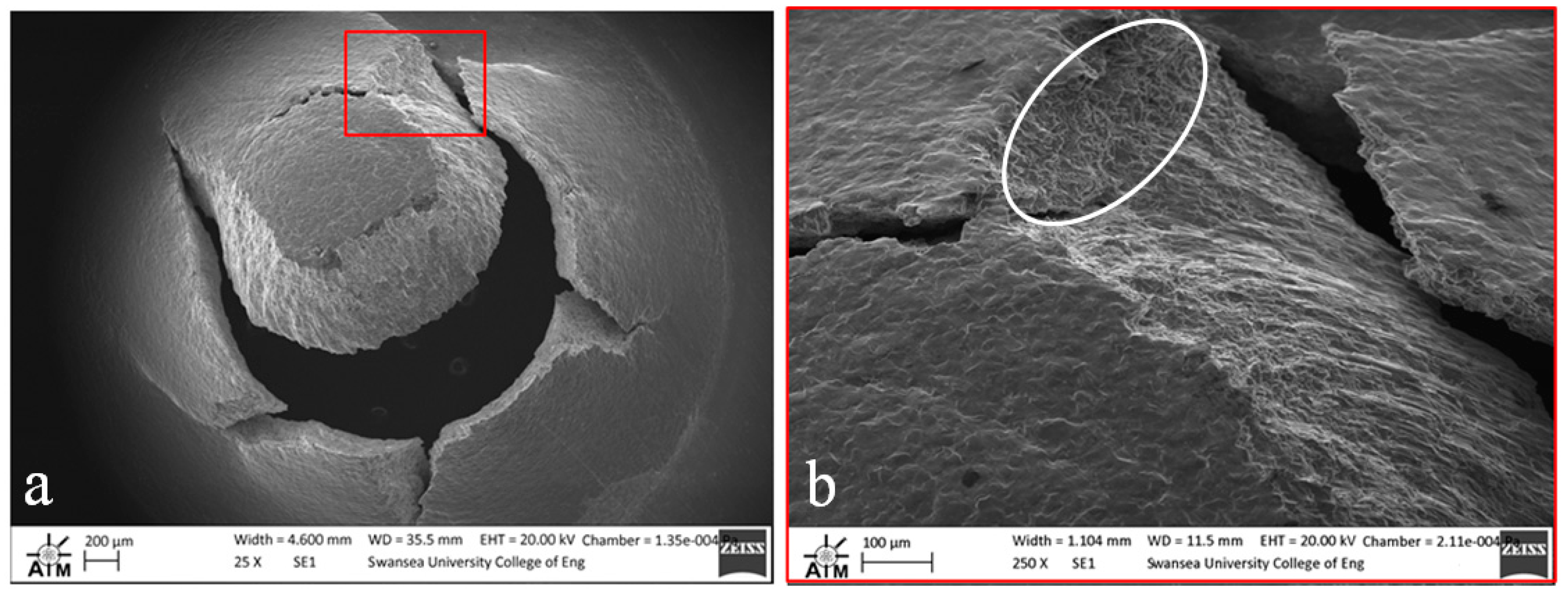

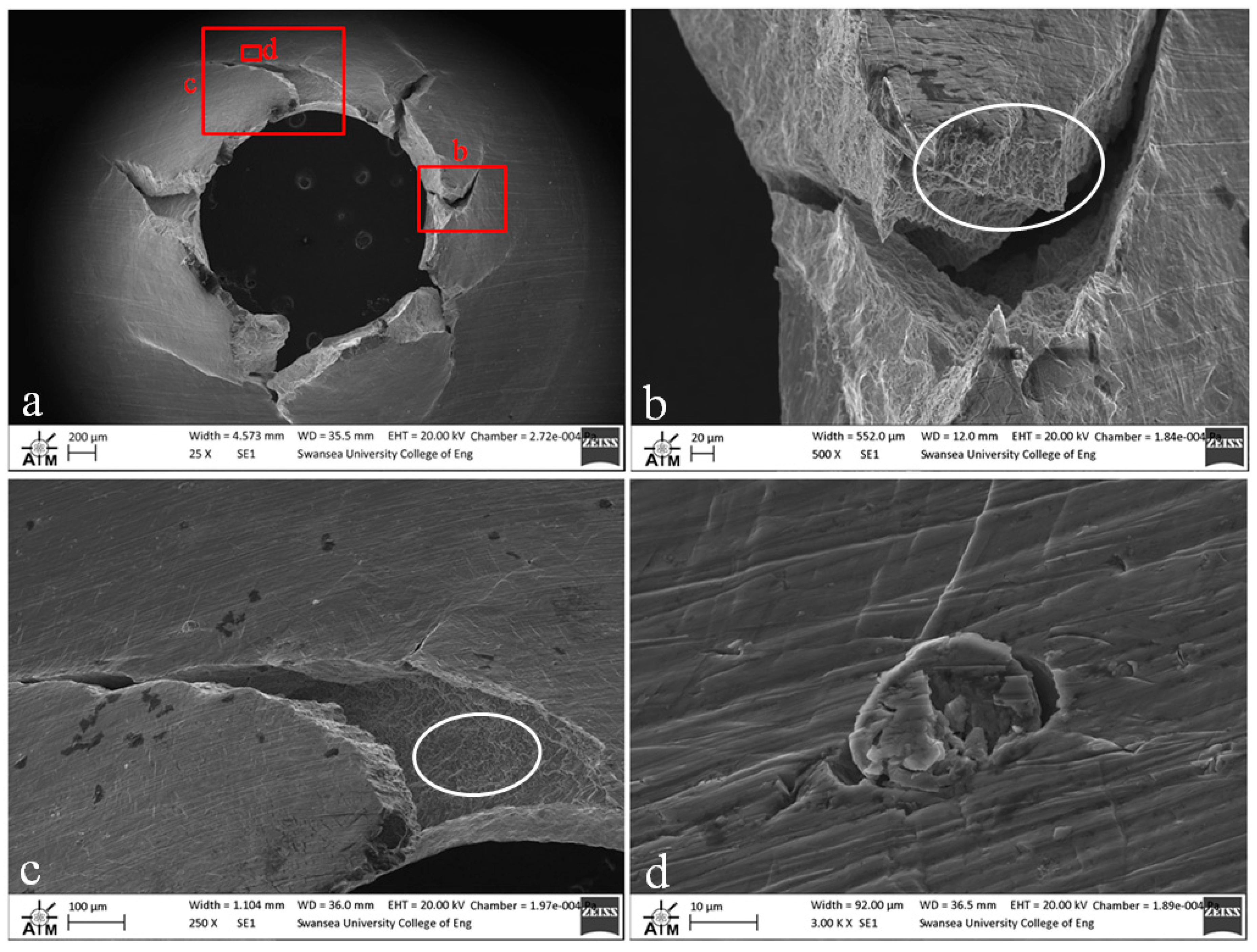

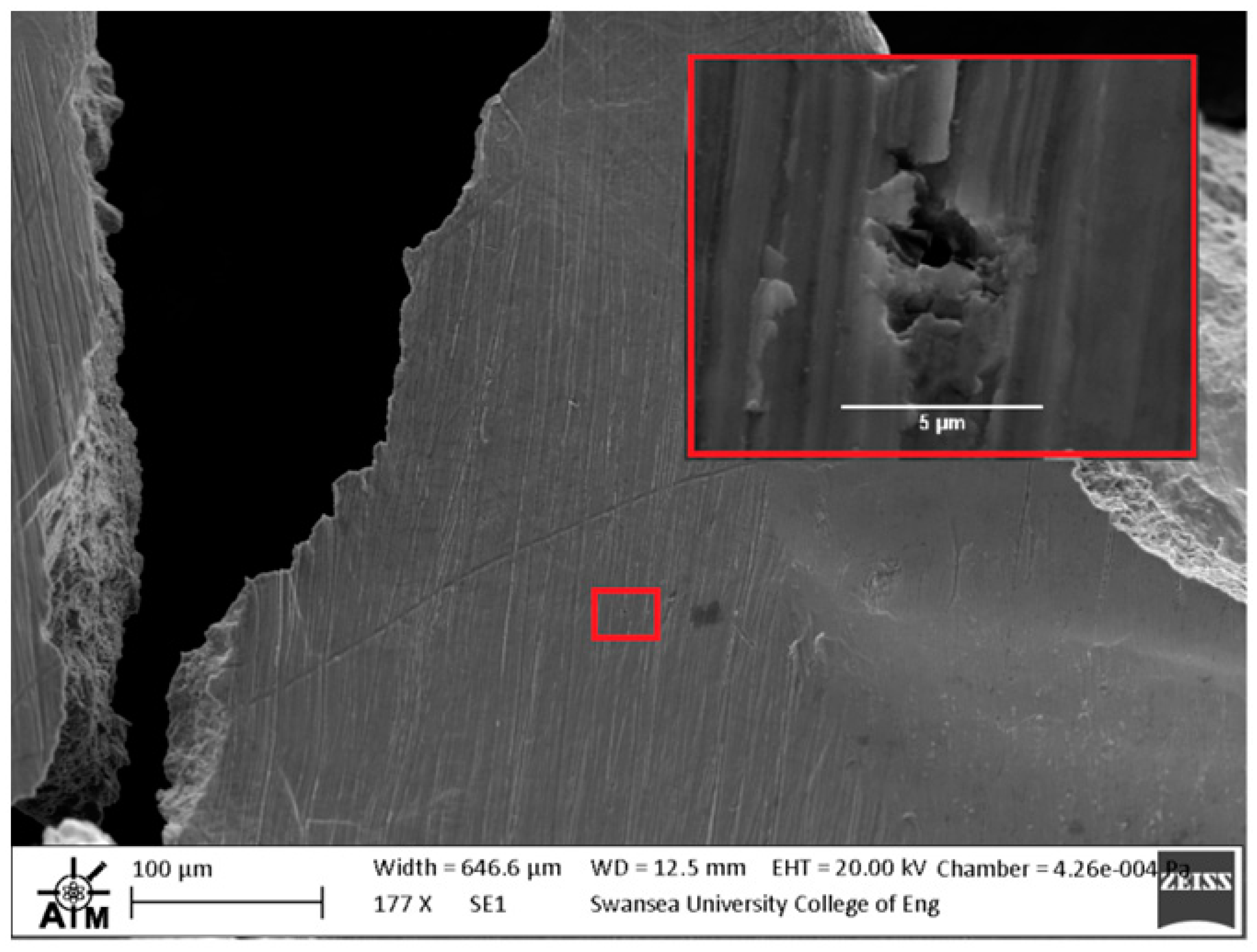

3.2. Small Punch Fractography

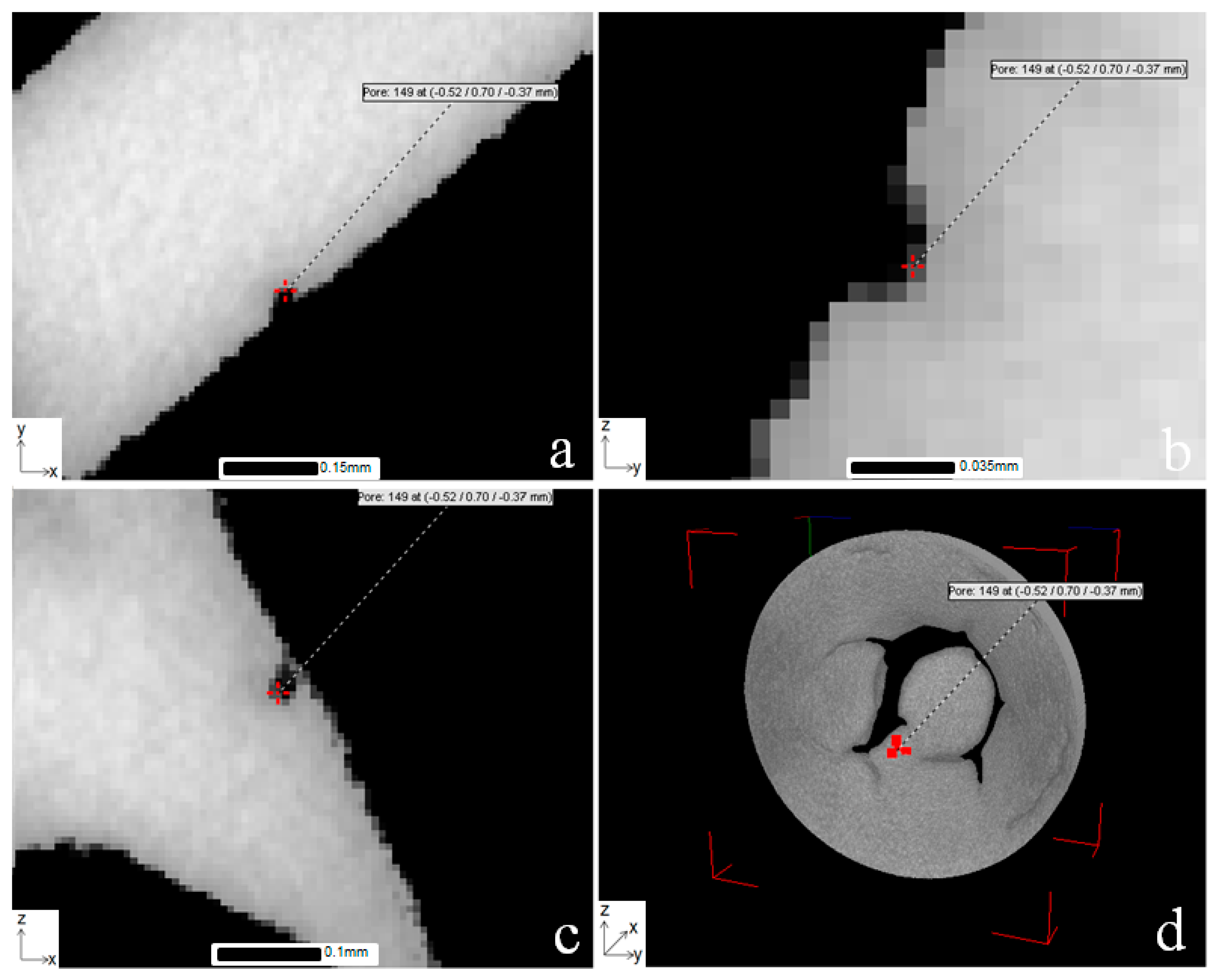

3.3. Post Test X-ray CT

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pham, D.; Gault, R. A comparison of rapid prototyping technologies. Int. J. Mach. Tools Manuf. 1998, 38, 1257–1287. [Google Scholar] [CrossRef]

- Baufeld, B.; van der Biest, O.; Gault, R. Additive manufacturing of Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, 106–111. [Google Scholar] [CrossRef]

- Ackelid, U.; Svensson, M. Additive manufacturing of dense metal parts by electron beam melting. In Proceedings of the Materials Science & Technology Conference, Pittsburgh, PA, USA, 2009; pp. 2711–2719.

- Mohammadhosseini, A.; Masodd, S.H.; Fraser, D.; Jahedi, M. Dynamic compressive behavior of Ti-6Al-4V alloy processed by electron beam melting under high strain rate loading. Adv. Manuf. 2015, 3, 232–243. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Edwards, P.; O’Conner, A.; Ramulu, M. Electron Beam Additive Manufacturing of Titanium Components: Properties and Performance. J. Manuf. Sci. Eng. 2013, 135. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Murr, L.E.; Esquivel, E.V.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Martinez, E.Y.; Martinez, J.L.; Stafford, S.W.; Brown, D.K.; Hopee, T.; et al. Microstructures and mechanical properties of electron beam-rapid manufactured Ti-6Al-4V biomedical prototypes compared to wrought Ti-6Al-4V. Mater. Charact. 2009, 60, 96–105. [Google Scholar] [CrossRef]

- Chan, K.S.; Koike, M.; Mason, R.L.; Okabe, T. Fatigue life of titanium alloys fabricated by additive layer manufacturing techniques for dental implants. Metall. Mater. Trans. A 2012, 44, 1010–1022. [Google Scholar] [CrossRef]

- Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of titanium alloys fabricated using rapid prototyping technologies-electron beam melting and laser beam melting. Materials 2011, 4, 1776–1792. [Google Scholar] [CrossRef]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti-6Al-4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Mater. Sci. Eng. A 2013, 573, 271–277. [Google Scholar] [CrossRef]

- Manahan, M.P.; Argon, A.S.; Harling, O.K. The development of a miniaturized disk bend test for the determination of postirradiation mechanical properties. J. Nucl. Mater. 1981, 104, 1545–1550. [Google Scholar] [CrossRef]

- Kameda, J.; Mao, X. Small-punch and TEM-disc testing techniques and their application to characterization of radiation damage. J. Mater. Sci. 1992, 27, 983–989. [Google Scholar] [CrossRef]

- Dobeš, F.; Milička, K. Application of creep small punch testing in assessment of creep lifetime. Mater. Sci. Eng. A 2009, 510–511, 440–443. [Google Scholar] [CrossRef]

- Izaki, T.; Kobayashi, T.; Kusumoto, J.; Kanaya, A. A creep life assessment method for boiler pipes using small punch creep test. Int. J. Press. Vessel. Pip. 2009, 86, 637–642. [Google Scholar] [CrossRef]

- Ule, B.; Šuštar, T.; Dobeš, F.; Milička, K. Small punch test method assessment for the determination of the residual creep life of service exposed components: Outcomes from an interlaboratory exercise. Nucl. Eng. Des. 1999, 192, 1–11. [Google Scholar] [CrossRef]

- Norris, S.D.; Parker, J.D. Deformation processes during disc bend loading. Mater. Sci. Technol. 1996, 12, 163–170. [Google Scholar] [CrossRef]

- Small Punch Test Method for Metallic Materials; CWA 15627; CEN Workshop Agreement: Brussels, Belgium, 2007.

- Di Persio, F.; Stratford, G.C.; Hurst, R.C. Validation of the small punch test as a method for assessing ageing of a V modified low alloy steel. In Proceedings of the Baltica VI International Conference on Life Management and Maintenance for Power Plants, Helsinki, Finland, 8–10 June 2004; Volume 2.

- Bicego, V.; di Persio, F.; Hurst, R.C.; Stratford, G.C. Comparibility of Results Via the Miniaturised Small Punch Test Method and Traditional Uniaxial Creep Testing. In Proceddings of the 11th International Conference on Fracture, Turin, Italy, 20–25 March 2005; pp. 4808–4814.

- Moreno-Valle, E.C.; Pachla, W.; Kulczyk, M.; Savoini, B.; Monge, M.A.; Ballesteros, C.; Sabirov, I. Anisotropy of uni-axial and bi-axial deformation behavior of pure Titanium after hydrostatic extrusion. Mater. Sci. Eng. A 2013, 588, 7–13. [Google Scholar] [CrossRef]

- Hurst, R.C.; Lancaster, R.J.; Norton, G.; Banik, R.; Bache, M.R. A Renaissance in Small Punch Testing at Swansea University. In Proceedings of the Baltica IX International Conference on Fast Tools for Condition and Life Assessment of Power Plants, Helsinki, Finland, 11–13 June 2013.

- Jeffs, S.P.; Lancaster, R.J. Elevated temperature creep deformation of a single crystal superalloy through the small punch creep method. Mater. Sci. Eng. A 2015, 626, 330–337. [Google Scholar] [CrossRef]

- Lancaster, R.J.; Harrison, W.J.; Norton, G. An analysis of small punch creep behaviour in the γ titanium aluminide Ti–45Al–2Mn–2Nb. Mater. Sci. Eng. A 2015, 626, 263–274. [Google Scholar] [CrossRef]

- Lancaster, R.J.; Banik, R.; Hurst, R.C.; Bache, M.R.; Baxter, G. Application of Small Punch Test Methods to Advanced Manufactured Structures. In Proceedings of the 3rd International Small Sampling Test Techniques Conference, Schloss Seggau, Austria, 23–25 September 2014; pp. 170–178.

- Tammas-Williams, S.; Zhao, H.; Léonard, F.; Derguti, F.; Todd, I.; Prangnell, P.B. XCT Analysis of the Influence of Melt Strategies on Defect Population in Ti-6Al-4V Components Manufactured by Selective Electron Beam Melting. Mater. Charact. 2015, 102, 47–61. [Google Scholar] [CrossRef]

- Anthonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti–6Al–4V by selective electron beam melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- Lin, Y.H.; Wu, S.M.; Kao, F.H.; Wang, S.H.; Yang, J.R.; Yang, C.C.; Chiou, C.S. Microtwin formation in the α phase of duplex titanium alloys affected by strain rate. Mater. Sci. Eng. A 2011, 528, 2271–2276. [Google Scholar] [CrossRef]

- Lutjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin, Germany; New York, NY, USA, 2003. [Google Scholar]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

| Measurement | Cast | Forged | EBM |

|---|---|---|---|

| Mean Linear Intercept (1/µm) | 0.0050 | 0.0778 | 0.0041 |

| Prior-β grain width (µm) | 201 | 13 | 246 |

| Transformed alpha width (µm) | 2.4410 | 1.6868 | 0.7867 |

| Sample | Accelerating Voltage (kV) | Current (μA) | Filter | Filter Thickness (mm) | Number of Projections | Frames per Projection | Exposure (ms) | Target Metal |

|---|---|---|---|---|---|---|---|---|

| Pre Test | 90 | 459 | Ti | 2.1 | 3016 | 2 | 1000 | W |

| Post Test | 105 | 490 | Ti | 2.1 | 3016 | 1 | 1000 | W |

| Measurement | Cast | Forged | EBM |

|---|---|---|---|

| Maximum Pore Diameter (μm) | n/a | n/a | 136.7 |

| Minimum Pore Diameter (μm) | n/a | n/a | 16.8 |

| Average Pore Diameter (μm) | n/a | n/a | 19.6 |

| Number of features | 0 | 0 | 897 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lancaster, R.; Davies, G.; Illsley, H.; Jeffs, S.; Baxter, G. Structural Integrity of an Electron Beam Melted Titanium Alloy. Materials 2016, 9, 470. https://doi.org/10.3390/ma9060470

Lancaster R, Davies G, Illsley H, Jeffs S, Baxter G. Structural Integrity of an Electron Beam Melted Titanium Alloy. Materials. 2016; 9(6):470. https://doi.org/10.3390/ma9060470

Chicago/Turabian StyleLancaster, Robert, Gareth Davies, Henry Illsley, Spencer Jeffs, and Gavin Baxter. 2016. "Structural Integrity of an Electron Beam Melted Titanium Alloy" Materials 9, no. 6: 470. https://doi.org/10.3390/ma9060470

APA StyleLancaster, R., Davies, G., Illsley, H., Jeffs, S., & Baxter, G. (2016). Structural Integrity of an Electron Beam Melted Titanium Alloy. Materials, 9(6), 470. https://doi.org/10.3390/ma9060470