Dielectric Characteristics and Microwave Absorption of Graphene Composite Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Graphene Composite Material Fabrication

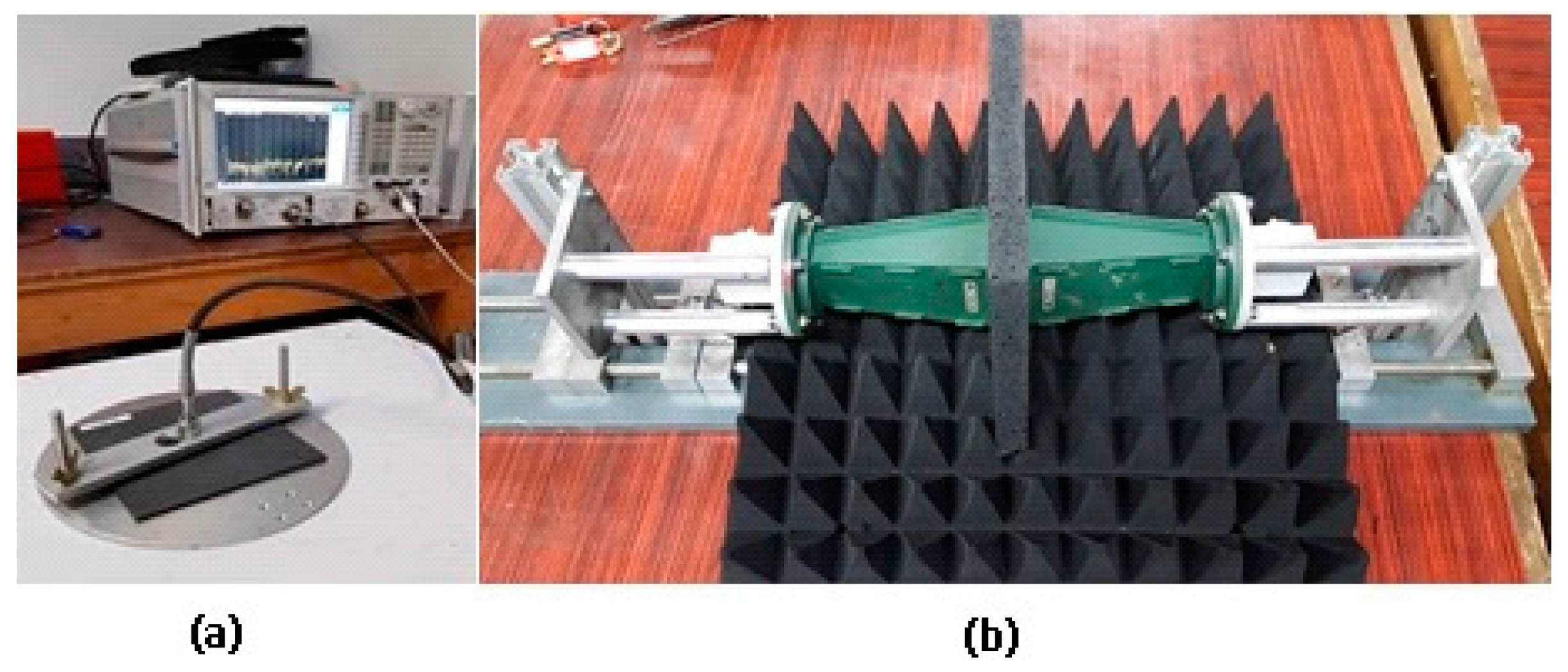

2.2. Measuring Process

3. Results and Discussion

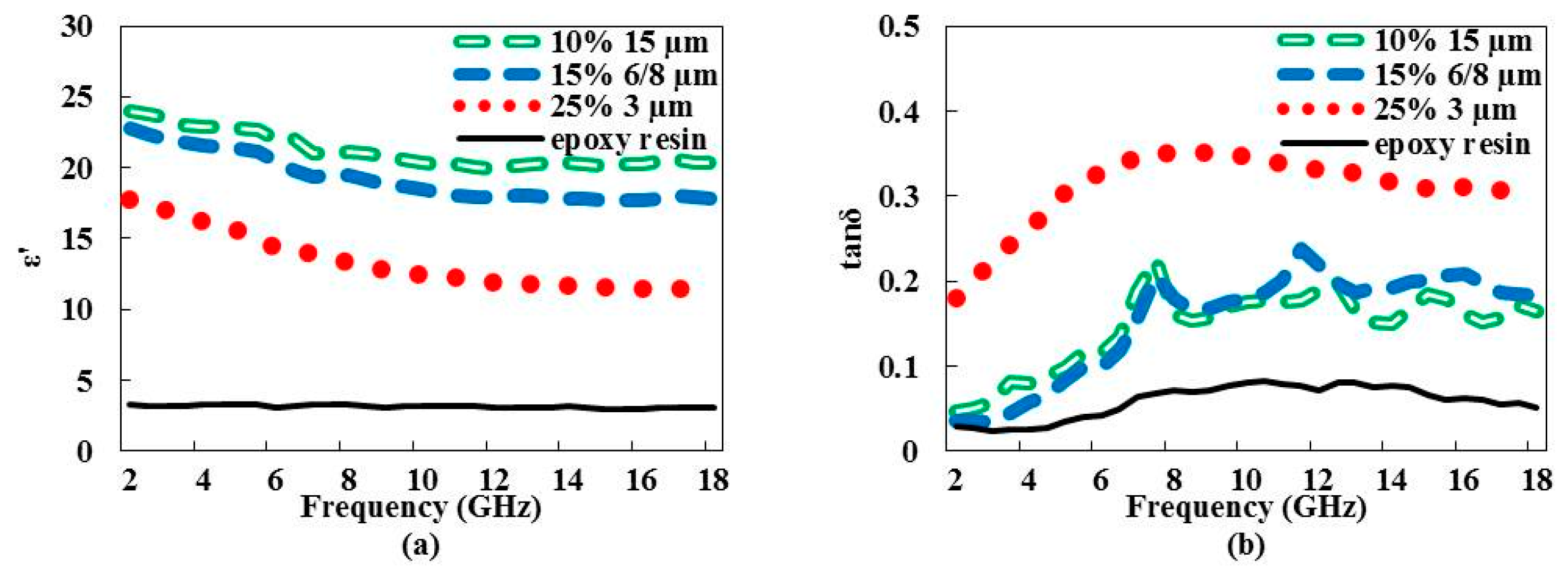

3.1. Complex Permittivity Results

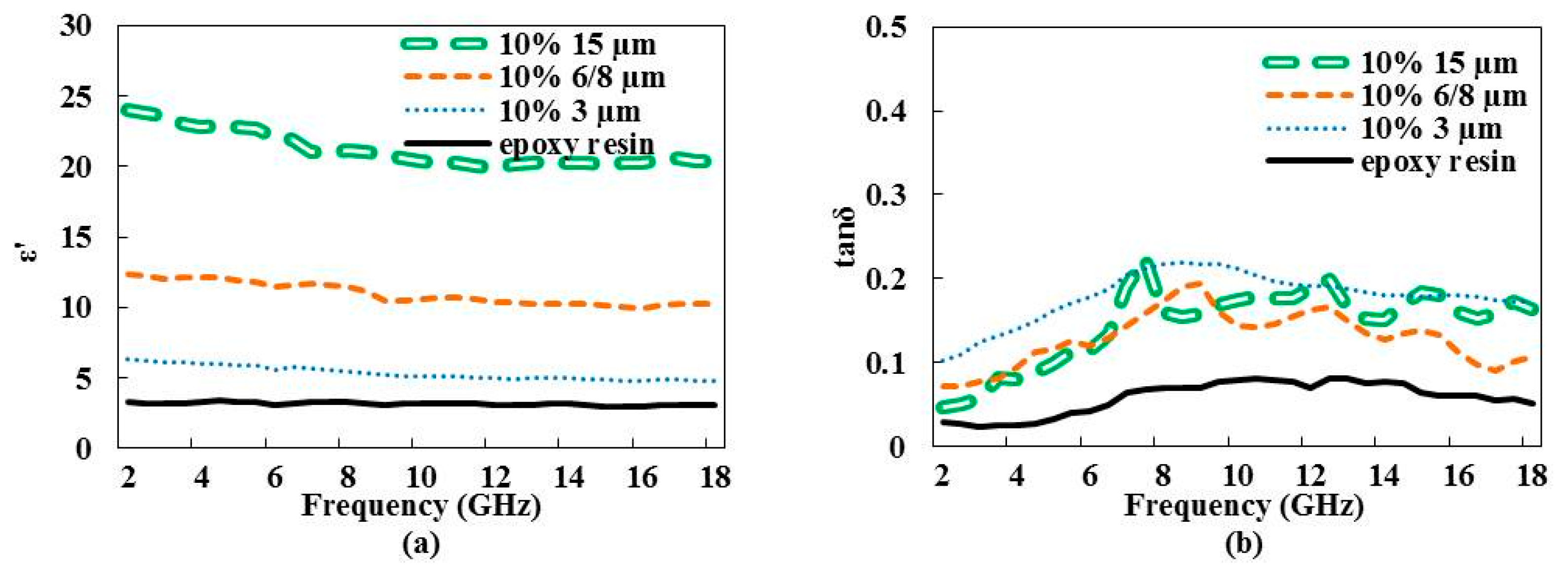

3.1.1. Influence of the Particle Size

3.1.2. Influence of the Weight Ratio

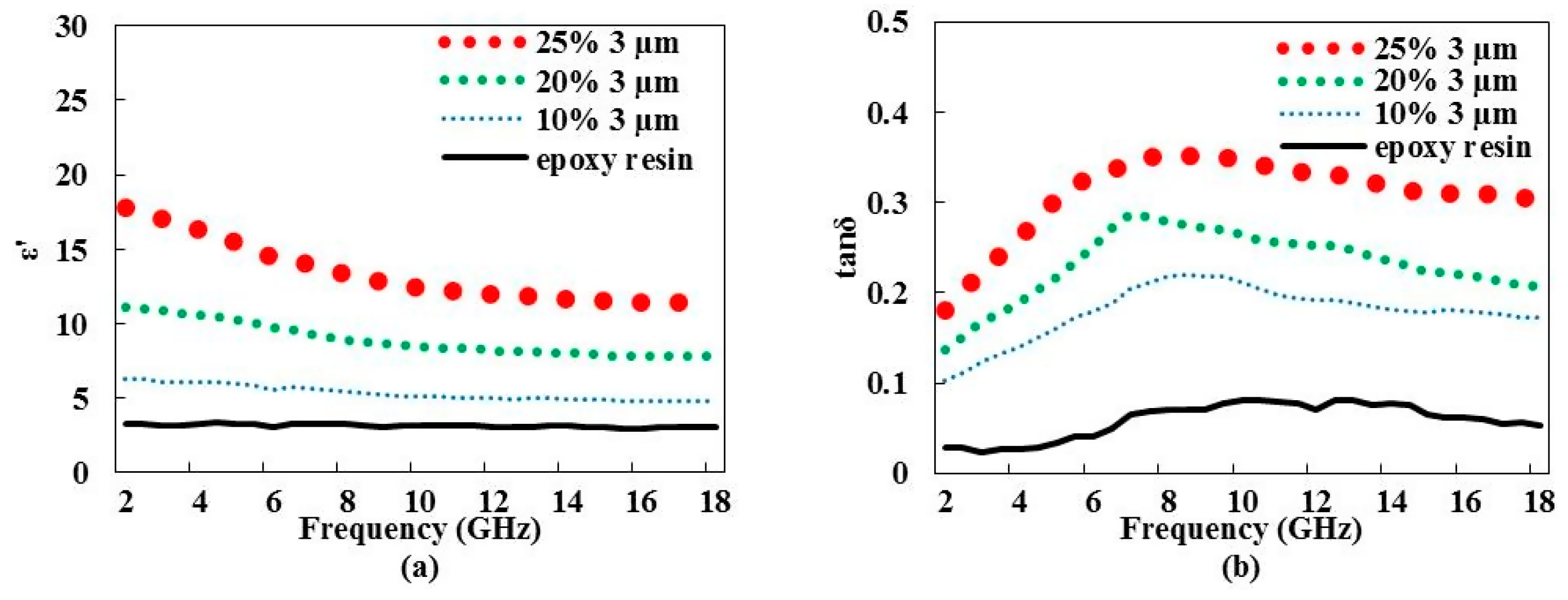

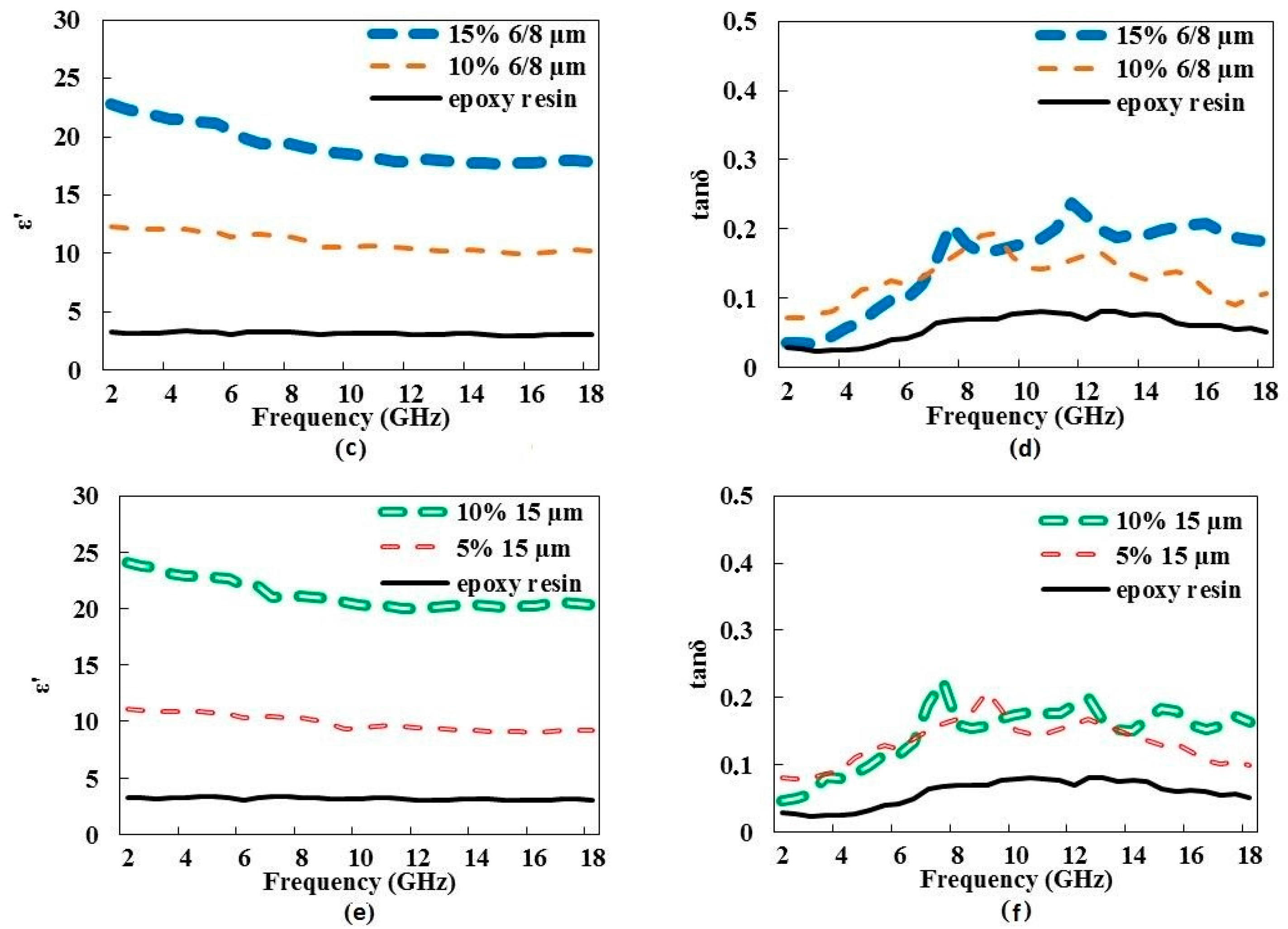

3.1.3. Particle Size and Weight Ratio Twofold Influence

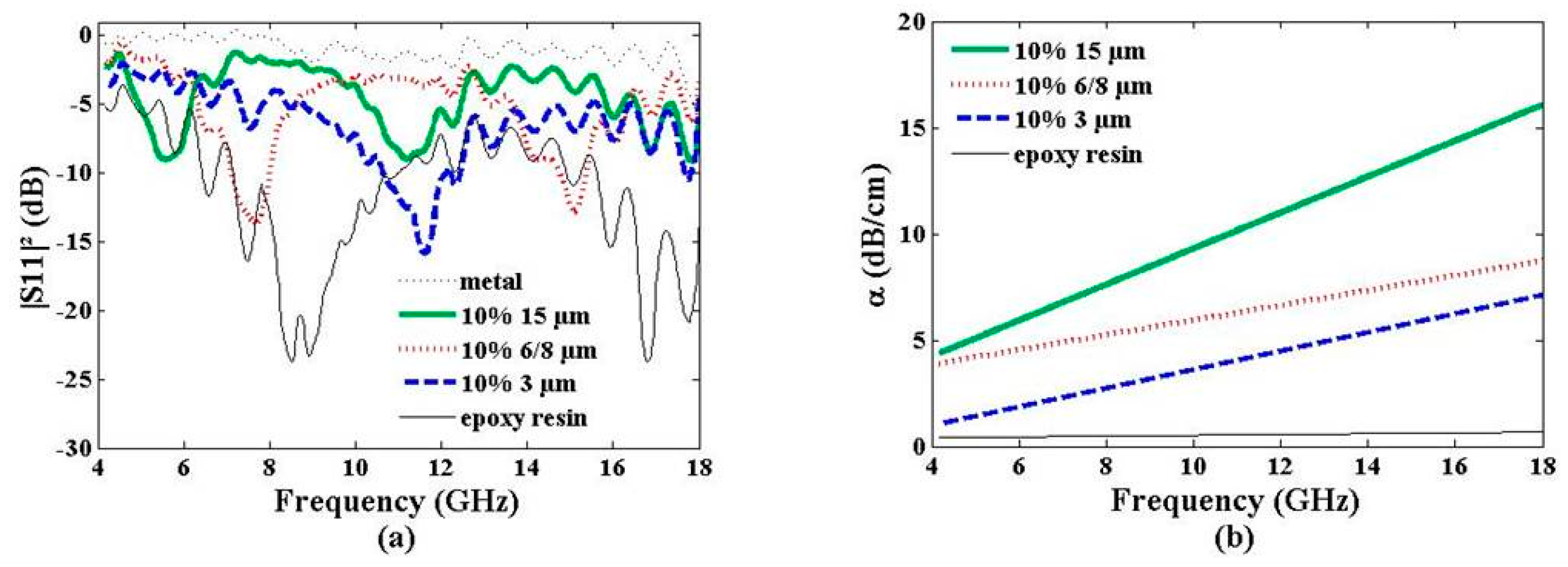

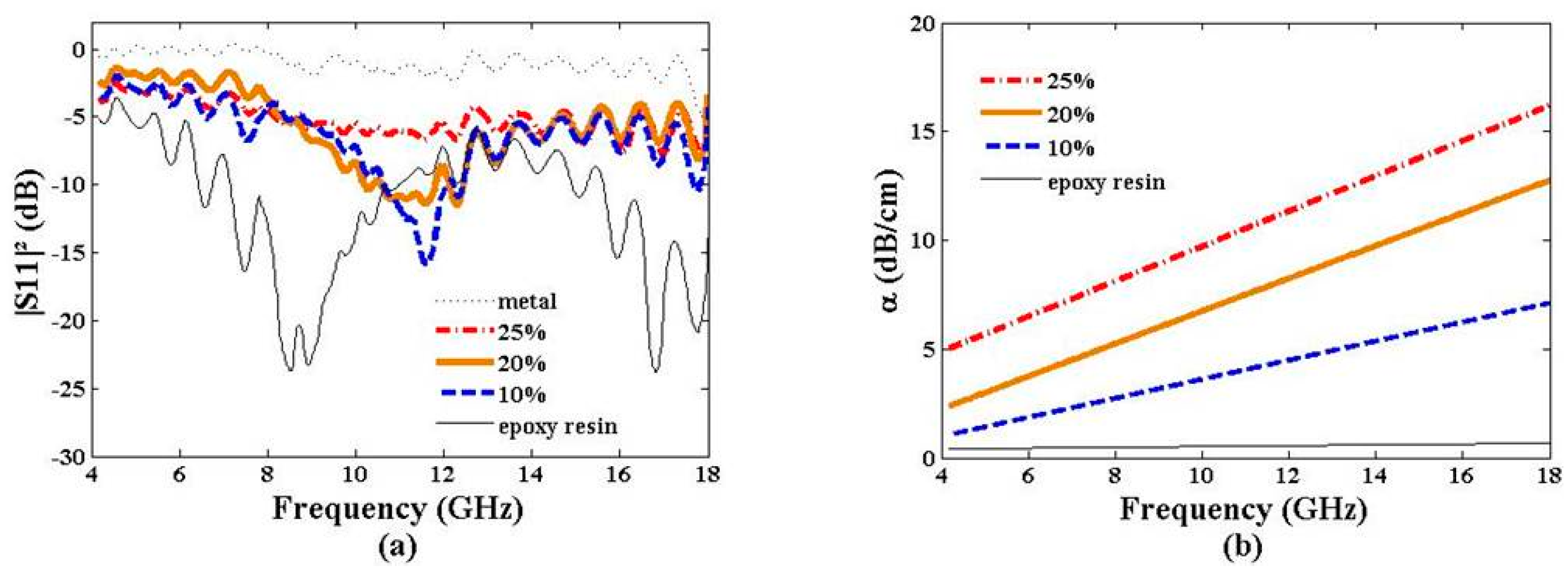

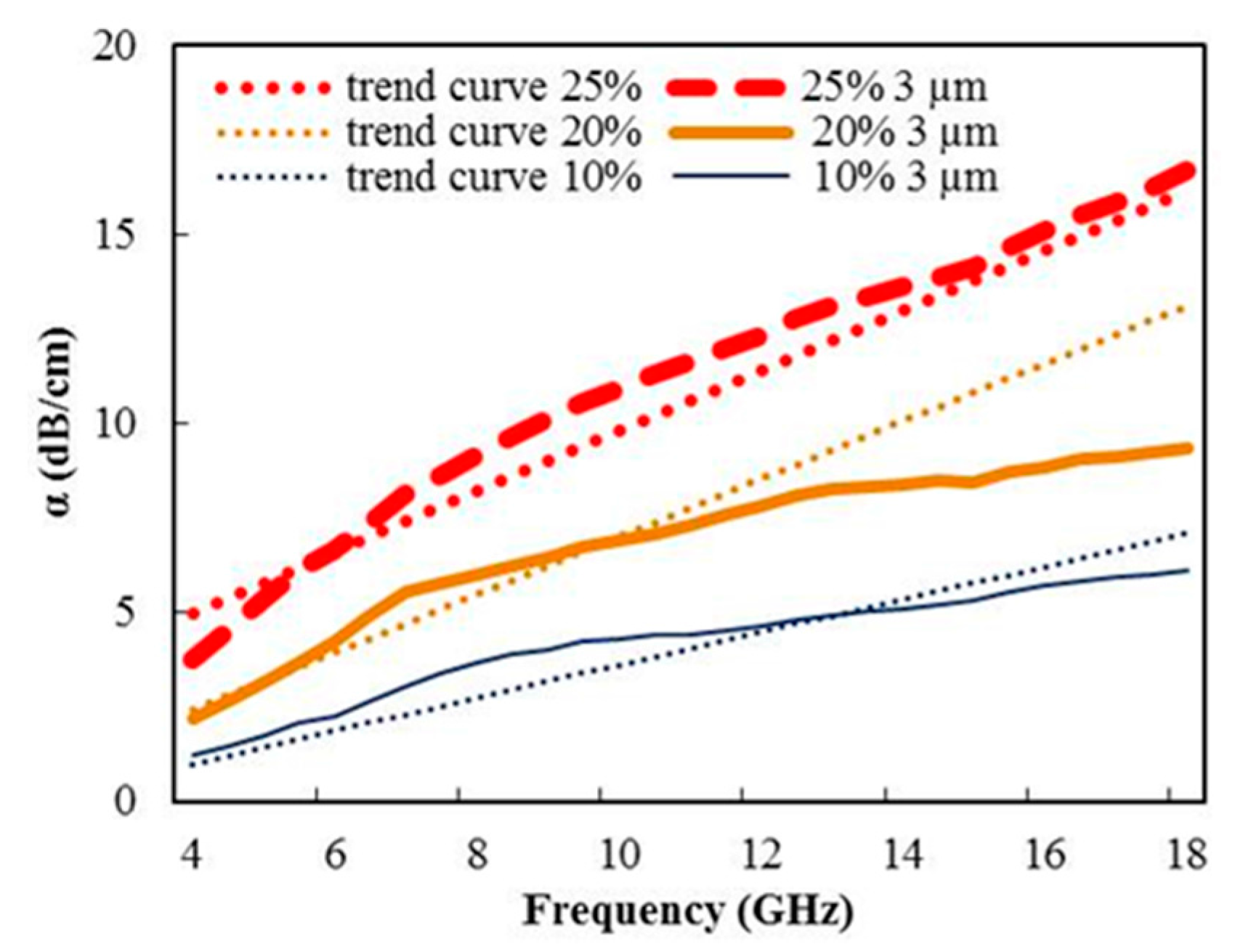

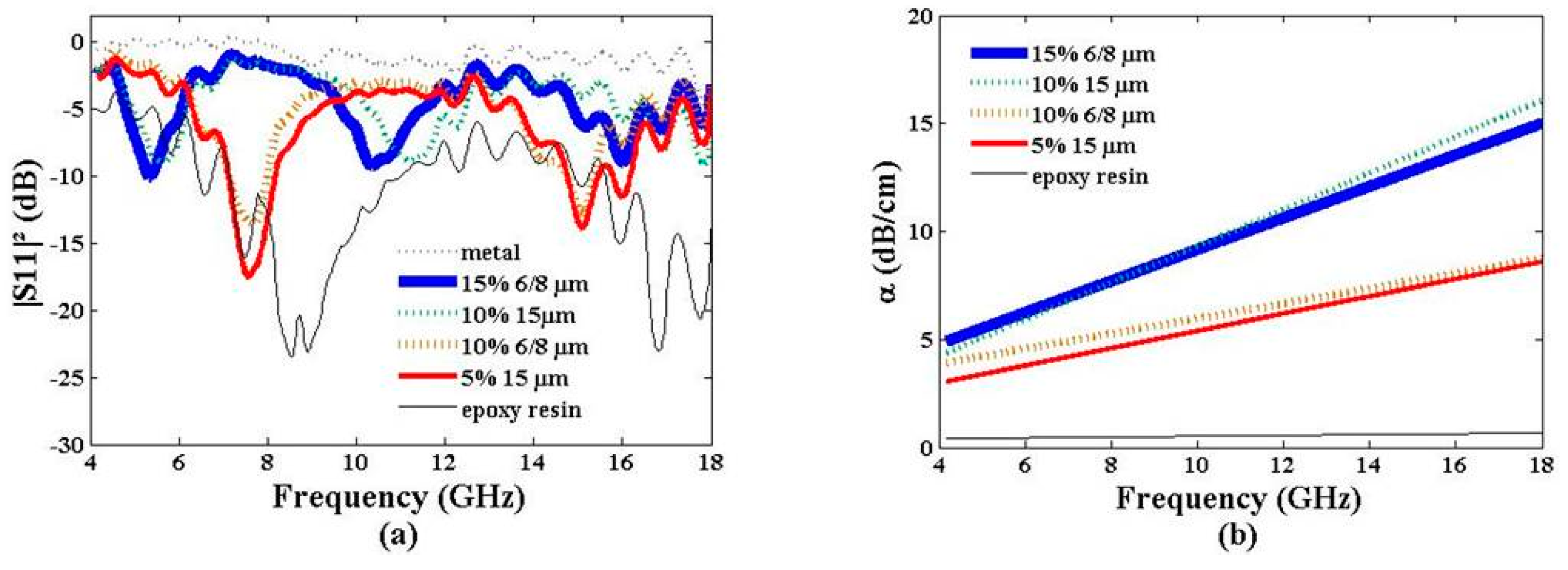

3.2. Electromagnetic Absorption

3.2.1. Influence of the Particle Size

3.2.2. Influence of the Weight Ratio

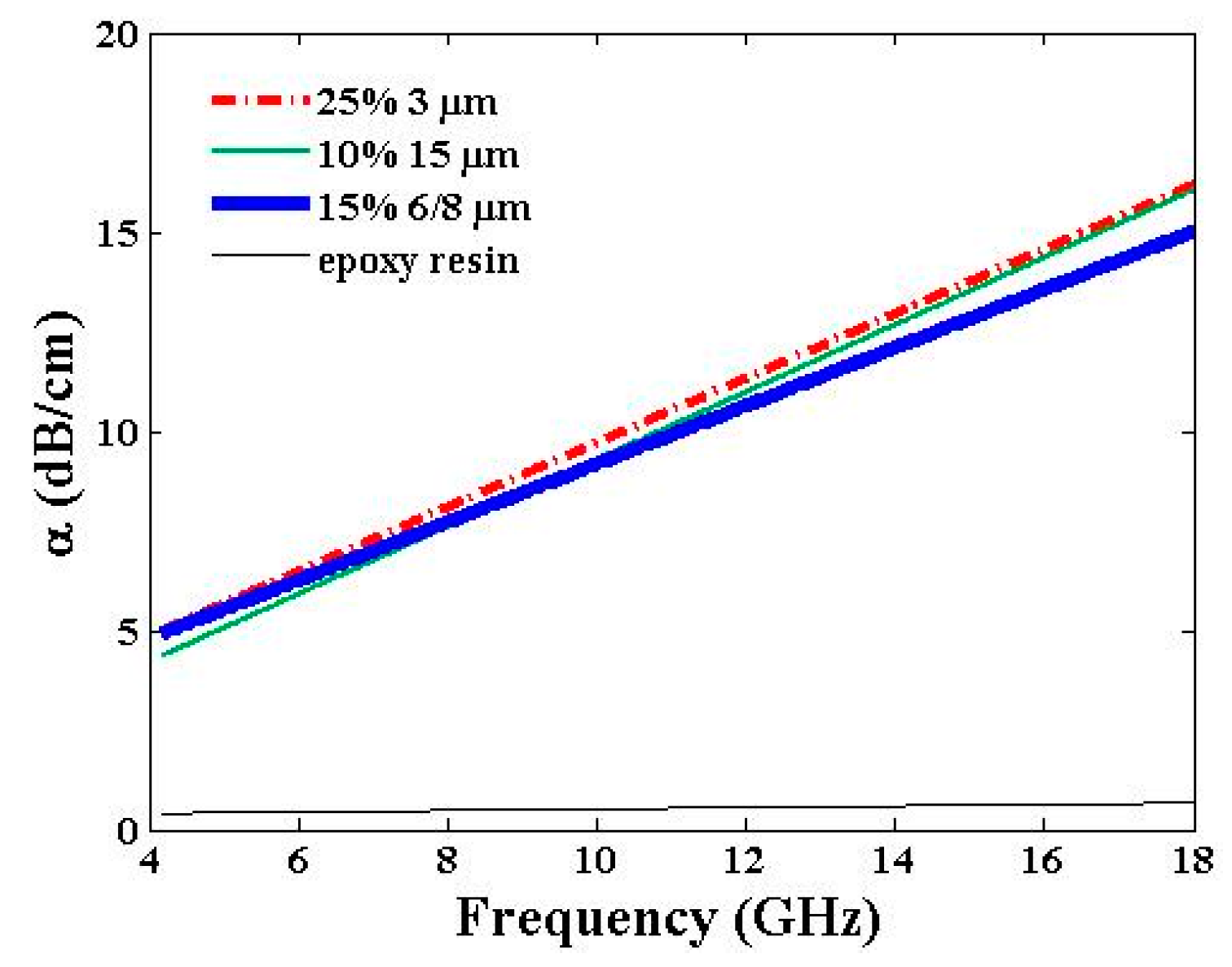

3.2.3. Particle Size and Weight Ratio Twofold Influence

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Bolotin, K.I.; Sikes, K.J.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H.L. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef]

- Rani, A.; Nam, S.; Ah Oh, K.; Park, M. Electrical conductivity of chemically reduced graphene powders under compression. Carbon Lett. 2010, 11, 90–95. [Google Scholar] [CrossRef]

- Hong, S.K.; Kim, K.Y.; Kim, T.Y.; Kim, J.H.; Park, S.W.; Kim, J.H.; Cho, K.J. Electromagnetic interference shielding effectiveness of monolayer graphene. Nanotechnology 2012, 23, 455704. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Han, X.; Xu, P.; Zhang, X.; Du, Y.; Hu, S.; Wang, J.; Wang, X. The electromagnetic property of chemically reduced graphene oxide and its application as microwave absorbing material. Appl. Phys. Lett. 2011, 98, 072906. [Google Scholar] [CrossRef]

- Zang, H.B.; Yan, Q.; Zheng, W.G.; He, Z.; Yu, Z.Z. Tough graphene-polymer microcellular foams for electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2011, 3, 918–924. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Wang, T.; Wen, B.; Lu, M.; Xu, Z.; Zhu, C.; Chen, Y.; Xue, X.; Sun, C.; Cao, M. Graphene/polyaniline nanorod arrays: Synthesis and excellent electromagnetic absorption properties. J. Mater. Chem. 2012, 22, 21679–21685. [Google Scholar] [CrossRef]

- Wang, Z.; Luo, J.; Zhao, G.L. Dielectric and microwave absorption properties of graphene nanoplatelet-epoxy composites. AIP Adv. 2014, 4, 017139. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Bao, C.; Song, L.; Xing, W.; Yuan, B.; Wilkie, C.A.; Huang, J.; Guo, Y.; Hu, Y. Preparation of graphene by pressurized oxidation and multiplex reduction and its polymer nanocomposites by masterbatch-based melt blending. J. Mater. Chem. 2012, 22, 6088–6096. [Google Scholar] [CrossRef]

- Zhang, K.; Li, D. Electromagnetic Theory for Microwaves and Optoelectronics; Springer Science & Business Media: Heidelberg, Germany, 2013. [Google Scholar]

- Griffiths, D.J. Introduction to Electrodynamics; Prentice Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Atwater, J.E.; Wheeler, R.R. Complex permittivities and dielectric relaxation of granular activated carbons at microwave frequencies between 0.2 and 26 GHz. Carbon 2003, 41, 1801–1807. [Google Scholar] [CrossRef]

- Giorcelli, M.; Savi, P.; Delogu, A.; Miscuglio, M.; Yahya, Y.M.H.; Tagliaferro, A. Microwave absorption properties in epoxy resin multi walled carbon nanotubes composites. In Proceedings of the International Conference on Electromagnetics in Advanced Applications (ICEAA), Torino, Italy, 9–13 September 2013; pp. 1139–1141.

- Savi, P.; Miscuglio, M.; Giorcelli, M.; Taglaferro, A. Analysis of microwave absorbing properties of epoxy MWCNT composites. Prog. Electromagn. Res. Lett. 2014, 44, 63–69. [Google Scholar] [CrossRef]

- Huang, Q.; Holland, T.B.; Mukherjee, A.K.; Chojnacki, E.; Liepe, M.; Malloy, M.; Tigner, M. Carbon nanotube RF absorbing materials. In Proceedings of the 14th International Conference on RF Superconductivity (SFR2009), Berlin, Germany, 20–25 September 2009; pp. 648–651.

- Chung, D.D.L. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Saxena, V.K.; Chandra, U. Microwave Synthesis: A Physical Concept. Available online: http://www.intechopen.com/books/microwave-heating/microwave-synthesis-a-physical-concept (accessed on 12 September 2016).

- Crane, C.A.; Pantoya, M.L.; Weeks, B.L.; Saed, M. The effect of particle size on microwave heating of metal and metal oxide powders. Powder Technol. 2014, 256, 113–117. [Google Scholar] [CrossRef]

- Balanis, C.A. Advanced Engineering Electromagnetics; Wiley, J., Ed.; Wiley: Chichester, UK, 2012. [Google Scholar]

| Sample Size (mm3) (Length × Width × Thickness) | Graphene Size (µm) | Weight Ratio (%) |

|---|---|---|

| 150 × 150 × 10 | 0 | 0 |

| 150 × 150 × 5 | 3 | 10/20/25 |

| 150 × 150 × 5 | 6–8 | 10/15 |

| 150 × 150 × 5 | 15 | 5/15 |

| Particle Size (µm) | Weight Ratio (%) | ε′ @10 GHz | tanδ @10 GHz | ε′ @18 GHz | tanδ @18 GHz |

|---|---|---|---|---|---|

| 6–8 | 10 | 10.6 | 0.14 | 10.2 | 0.11 |

| 15 | 5 | 9.5 | 0.15 | 9.2 | 0.10 |

| 6–8 | 15 | 18.5 | 0.18 | 17.8 | 0.18 |

| 15 | 10 | 20.4 | 0.18 | 20.4 | 0.16 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rubrice, K.; Castel, X.; Himdi, M.; Parneix, P. Dielectric Characteristics and Microwave Absorption of Graphene Composite Materials. Materials 2016, 9, 825. https://doi.org/10.3390/ma9100825

Rubrice K, Castel X, Himdi M, Parneix P. Dielectric Characteristics and Microwave Absorption of Graphene Composite Materials. Materials. 2016; 9(10):825. https://doi.org/10.3390/ma9100825

Chicago/Turabian StyleRubrice, Kevin, Xavier Castel, Mohamed Himdi, and Patrick Parneix. 2016. "Dielectric Characteristics and Microwave Absorption of Graphene Composite Materials" Materials 9, no. 10: 825. https://doi.org/10.3390/ma9100825