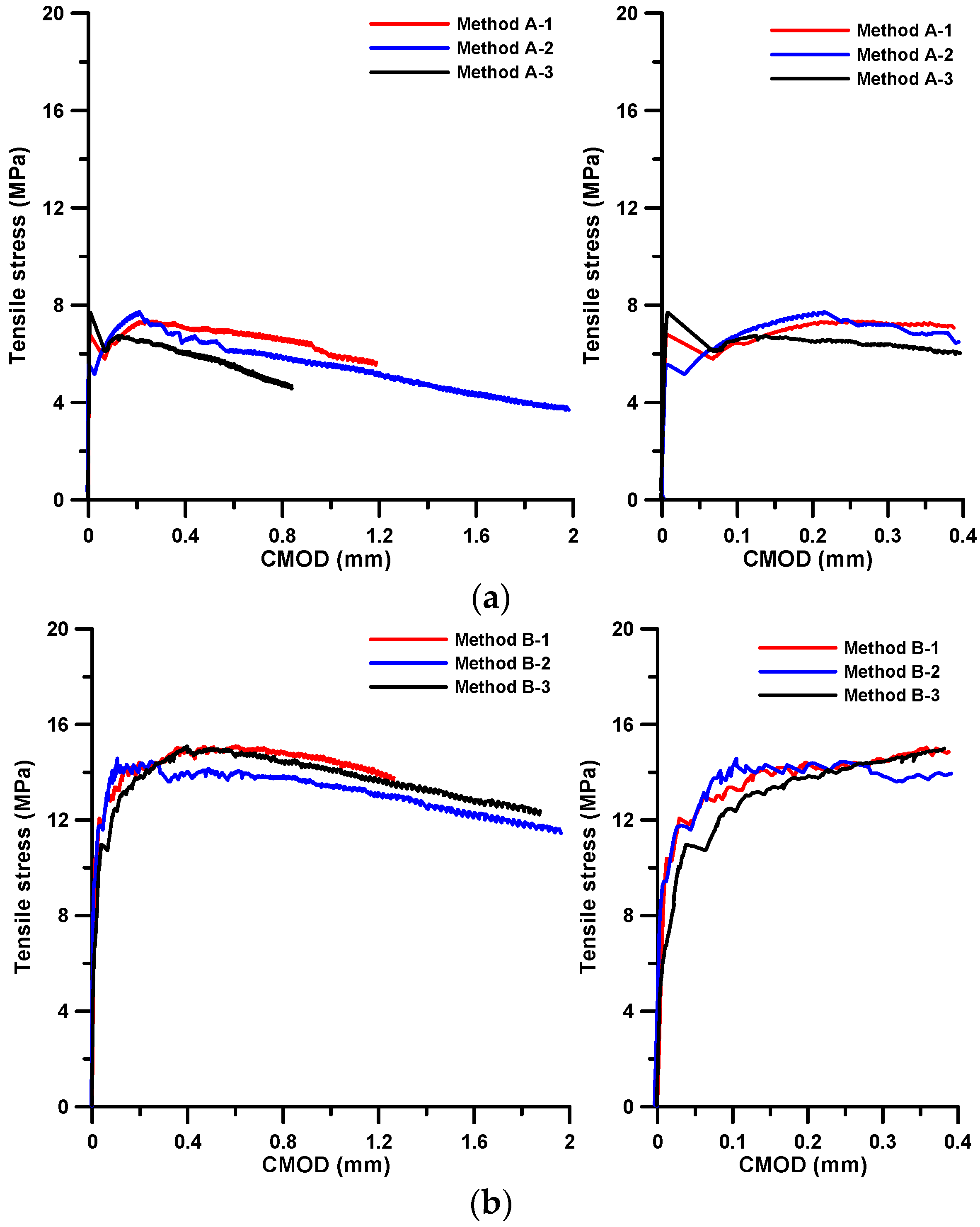

3.1. Methodology

Once a crack forms in a fiber-reinforced cementitious composite, the matrix barely resists an external load at the cracked plane and most of the applied load is supported by the fibers. That is, its tensile behavior is determined absolutely by the pullout behaviors of the fibers embedded in the matrix.

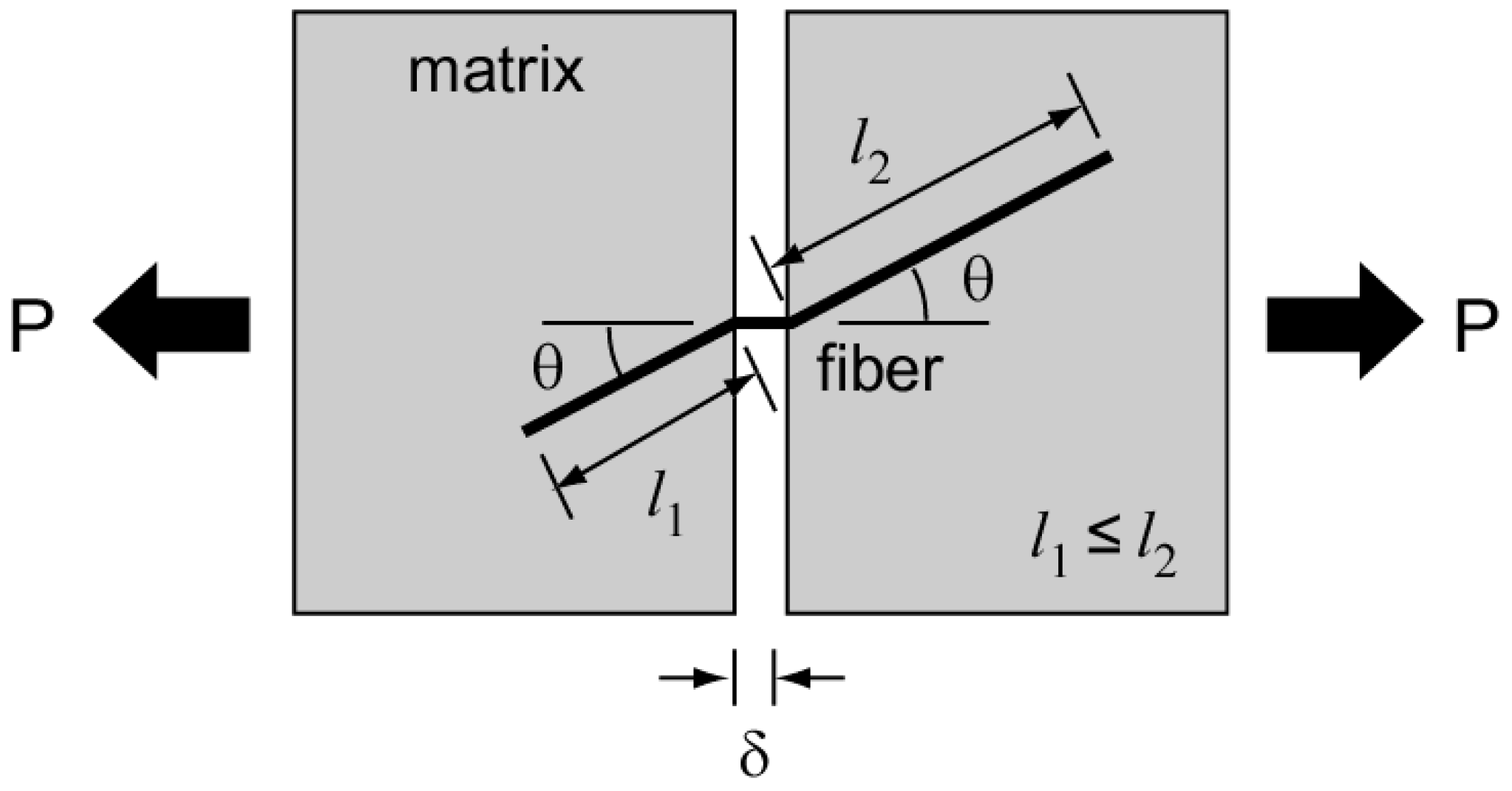

A large number of fibers can be found across the cracked plane, and each fiber has its own embedded length and inclined angle from the cracked plane. Let us consider a single fiber embedded in a matrix across a crack plane with an inclined angle (

θ), as depicted in

Figure 4. For convenience, the embedded length (

le) is defined as the length of the shorter segment of the fiber when it is divided into two embedded segments due to cracking. It is therefore less than

lf/2. It is well known that both the embedded length and inclined angle of the fiber have a strong influence on the pullout resistance, and the pullout force is also dependent on its pullout displacement or crack opening displacement on the cracked plane. Therefore, the bridging force of a single fiber shown in

Figure 4 is given by a function of the inclined angle of the fiber (

θ), the embedded length of the fiber (

le), and the crack opening displacement (

δ), which is therefore denoted as

P(

θ,

le,

δ). The fiber bridging stress of the composites after cracking, in which all the fibers placed with an embedded length and an inclination across the cracked plane are considered, can be calculated by the following equation [

41]:

where

p(

θ) and

p(

le) are the probability density functions for

θ and

le, respectively. These two functions can be expressed by sin

θ and 2/

lf in particular for the three-dimensional random distribution of the fibers.

lf and

df denote the length and diameter of the fiber, respectively.

Lee et al. [

42] proposed a predictive model for the pullout behavior of an inclined steel fiber in a UHPCC matrix. The model they suggested in their work was applied for the pullout resistance of a single fiber. The bridging force of a single fiber,

P(

θ,

le,

δ), can be obtained from the pullout resistance by assuming that (1) the crack width is equal to twice the slip deformation in the pullout behavior when the fiber is perfectly bonded and partially debonded; and (2) after the fiber is fully debonded, the crack width deformation is the same as the slip deformation because the shorter fiber only undergoes frictional slip deformation after debonding and is finally pulled out. More details of the function

P(

θ,

le,

δ) can be found in [

18]. In addition, in order to consider the inconsistency of the bond condition between that in their pullout test and in the composites, a correction factor (

Fc) was introduced and multiplied by the pullout resistance. A value of 1.25 was applied as this factor in an earlier study [

18] and it can be changed according to the mix condition and the characteristics of the fiber used.

The post-cracking behavior of a composite can be defined as the combination of the resistance provided by the fibers and the matrix. Therefore, in order to establish the post-cracking behavior, a mathematical model for the resistance of the matrix should also be introduced in addition to fiber bridging. The typical tension softening behavior of concrete after cracking can be expressed by a linear, bilinear, or exponential curve. The tension softening curve of UHPCC in this study was assumed to be an exponential function [

43]:

where

ft is the tensile strength (MPa),

w is the cracking opening (mm), and

c is a constant that can be determined experimentally and is theoretically equal to

ft/

GF.

3.2. Determination of Probability Density Distribution of Fiber Orientation

To derive the tensile bridging behavior of the fibers by Equation (1), considering the effect of the fiber orientation distribution, it is essential to determine the probability density function for the orientation of the fibers embedded in the composites. If the orientation distribution of the fibers embedded in the composites is measured directly, the measured distribution instead of the function can be applied for the term p(θ) in Equation (1).

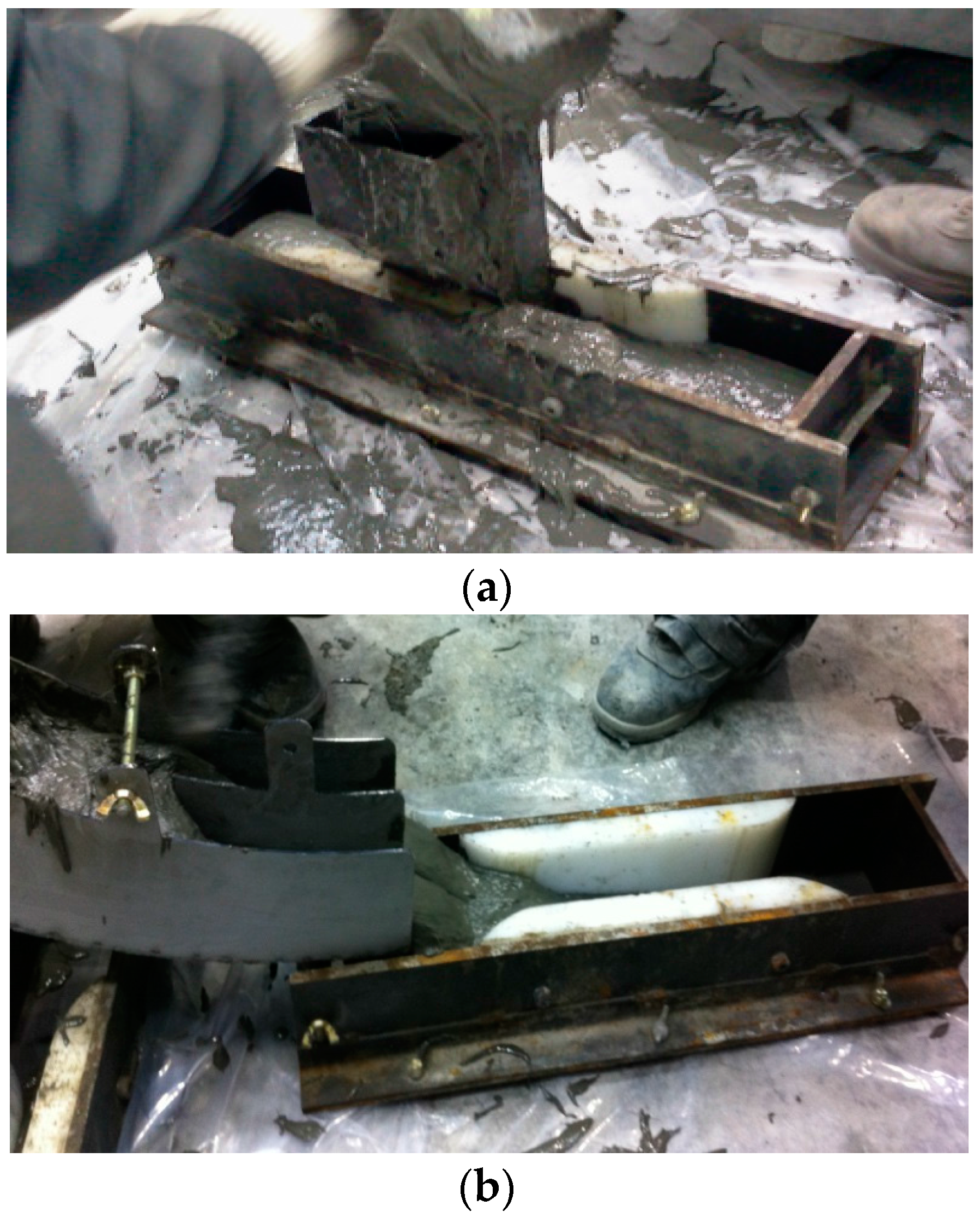

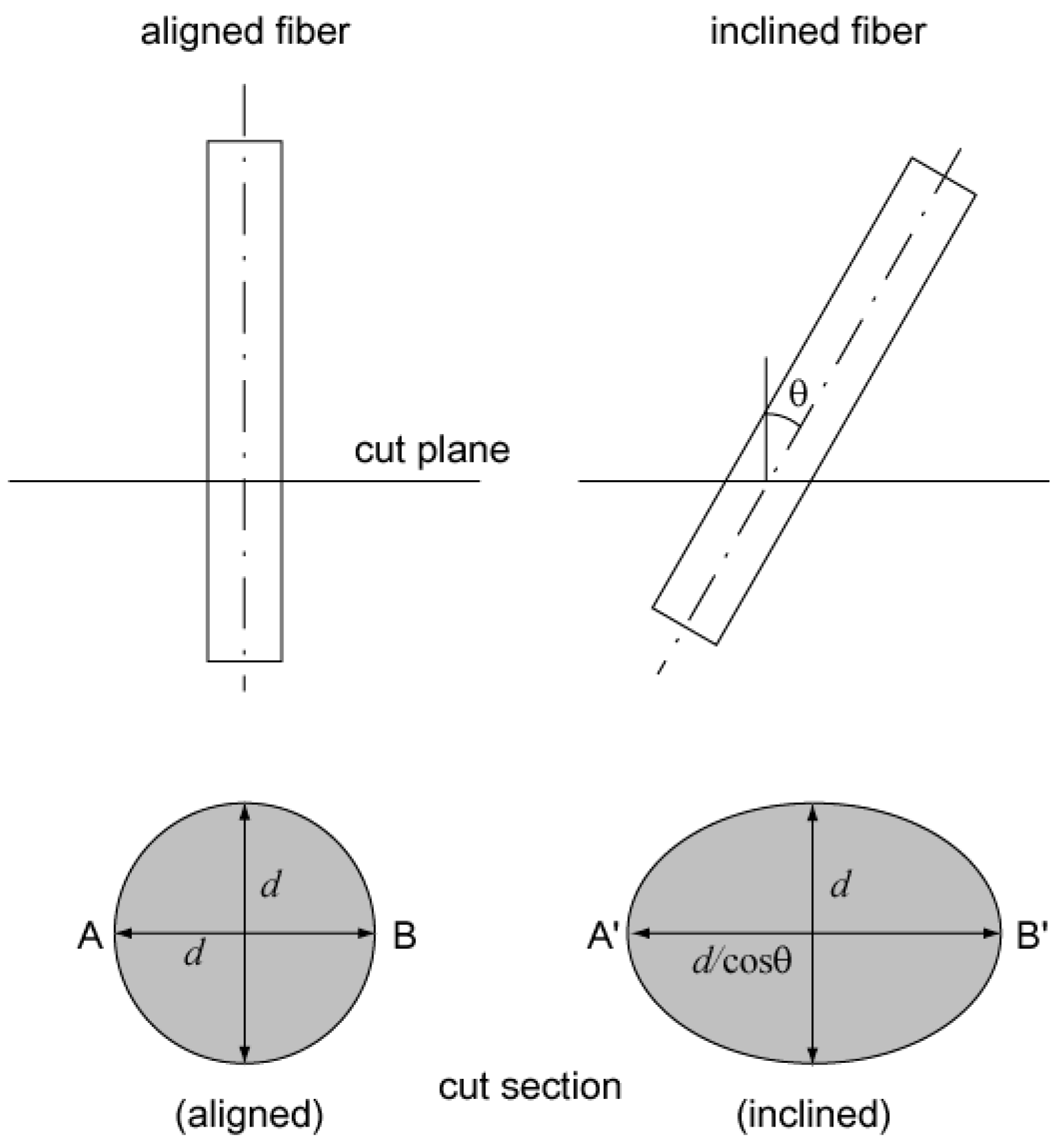

After finishing the direct tensile tests, the tested specimens were sawn along a plane as near as possible to the fractured plane with a localized crack and the cut sections were ground; an image of the cut section for each specimen was then taken by a digital camera. The fiber orientation distribution was then obtained using the image analysis technique. The number of total pixels constituting a fiber section was at least 80 in the image, and the pixel size of the fiber diameter was in the range of 10~14 pixels. In the process of detecting fibers through the thresholding algorithm in the image analysis, 80 pixels for an object’s area were applied for the threshold to distinguish the fibers from other objects. The method for calculating the orientation of an inclined fiber is explained by

Figure 5. Let us consider a fiber originally having a perfectly circular cross section. If it is laid at an inclined angle across a plane, the sectional geometry of the fiber on the plane becomes ellipsoidal and the ratio of the largest and smallest diameter in the ellipsoid is dependent on the inclination of the fiber. From

Figure 5, the inclined angle (

θ) of the fiber can be calculated using the following equation:

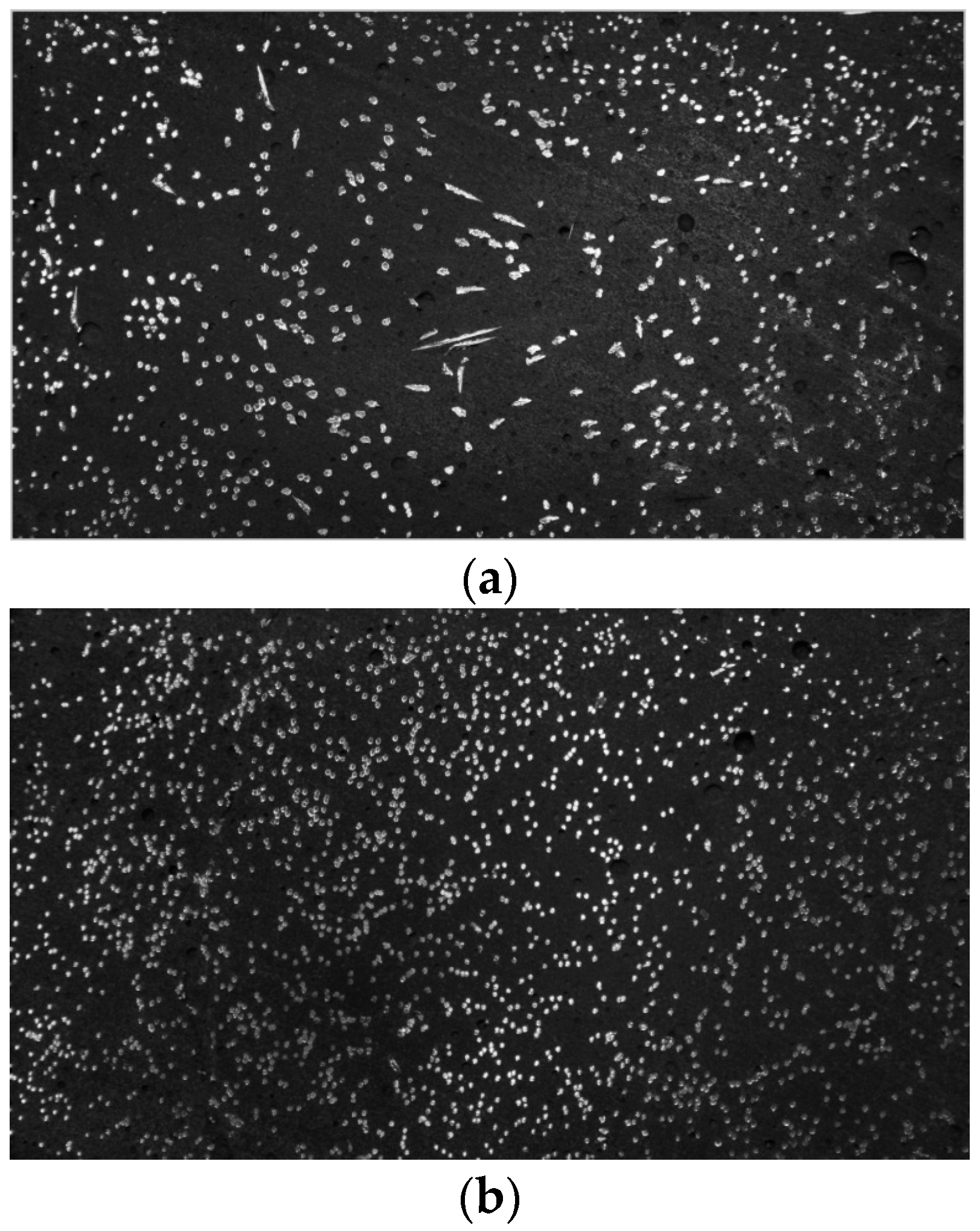

Figure 6 shows images of the sawn sections of the tested specimens. It can be easily seen that the number of fibers detected in the section image obtained from the specimen fabricated by Method B is much greater than in the Method A specimen. It can be also found that the fibers in the Method B section are mostly aligned in the direction normal to the plane, but Method A shows relatively fewer fibers as well as a higher percentage of fibers laid diagonally to the cut plane. This direct observation suggests that the differences in the fibers distributed in the cut section are closely related to the tensile behaviors of both cases.

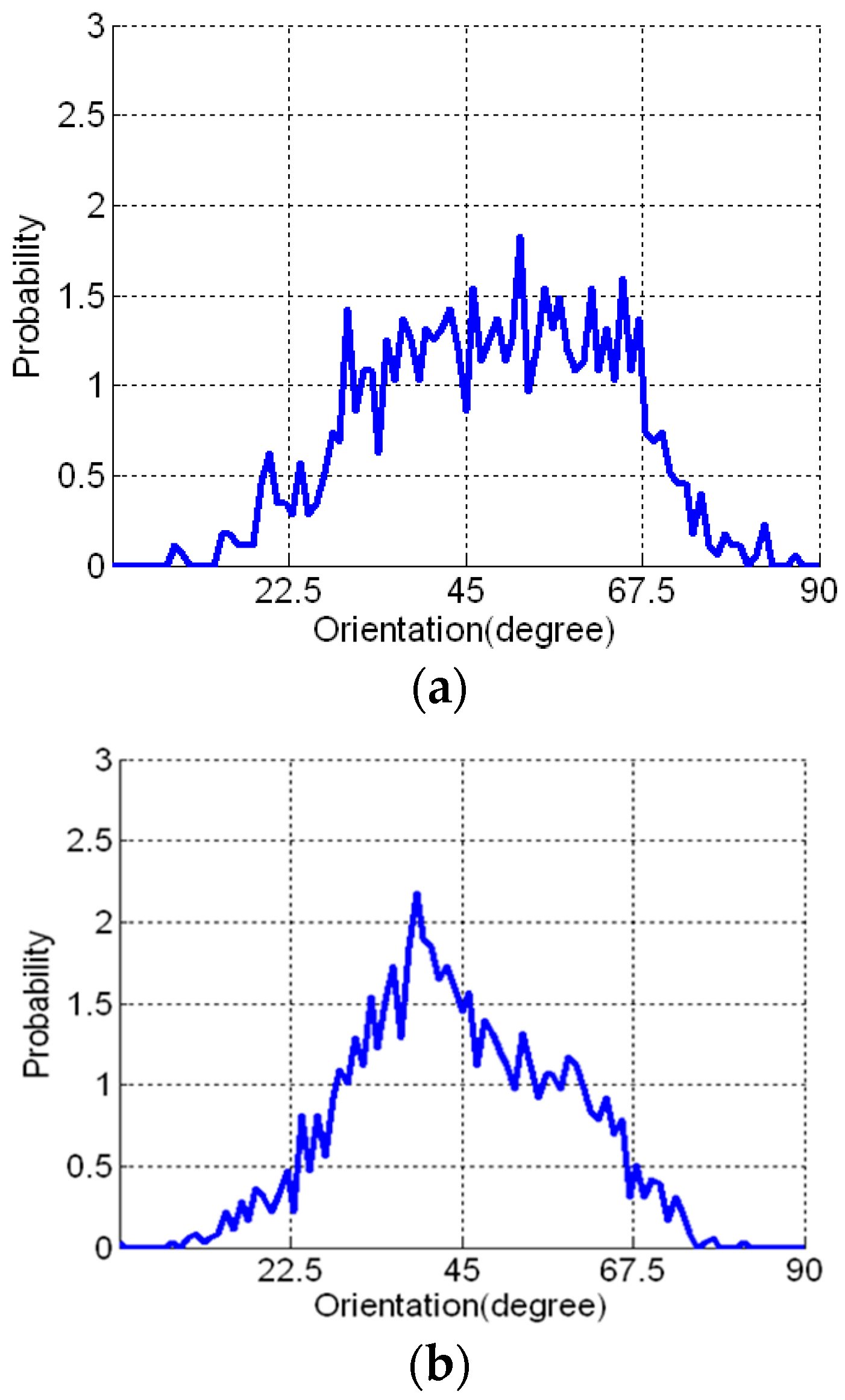

Table 4 presents the image analysis results. The average number of fibers calculated from the image analysis technique was 910 and 1872 for Methods A and B, respectively. The fiber orientation distribution for all detected fibers is given in

Figure 7, in which the difference in the distributions is distinguishable but not as much as expected. In addition, higher intensity of distribution around 45° was shown, especially for the casting Method B. Two major reasons can be suggested for such fiber orientation distribution, as shown in

Figure 7. First, according to hydrodynamics, most fibers subjected to shear flow are theoretically supposed to be aligned to the flow direction under the assumption that there is no interaction among fibers. The assumption may be applied for dilute suspensions of long rigid fibers and a composite with

is classified into this category.

means the aspect ratio, indicating the ratio of length to diameter of the fiber. Meanwhile, for semi-concentrated (

) or concentrated (

) suspensions, the interaction among fibers cannot be neglected and the rotational movement of fibers is restricted in some degree [

44]. The composites dealt with in this study have 2 vol % (fiber volume fraction) and therefore are classified into concentrated suspensions. The second is related to the error in calculating the orientation angle by image analysis, which is considerably dependent on the pixel size for expressing the fiber section. Lee et al. [

40] investigated the error of the measured orientation angle of an artificial fiber image according to the number of pixels in the diameter and demonstrated that the error increased as the orientation angle and the number of pixels in the diameter of the fiber decreased.

Table 5 presents the orientations calculated from fiber images with different orientation angle and the number of pixels in the study by Lee et al. [

40]. It can be seen that the lower fiber orientation as well as the lower number of pixels caused the higher error in the measured orientation. In particular, the orientation in the range of 15°~45° was calculated as 41.2°~49.8° when the number of pixels in the diameter of the fiber was 5. Therefore, considering the pixel size of the fiber diameter was in the range of 10~14 pixels in this study, it can be said that the lower resolution of the fiber images might cause significant errors in calculated orientation distribution in the range of 0°~45°, which resulted in the intensive distribution around 45°.

From the measured distribution, it is possible to calculate the fiber orientation coefficient (

), which is defined as [

45]

The calculated mean fiber orientation coefficient was 0.447 for Method A and 0.531 for Method B.

Generally, the number of discontinuous short fibers detected in a cut plane is dependent on the fiber orientation coefficient [

31]. A general equation for the number of fibers per unit area (

) is given by the following:

where

means the volume fraction of steel fibers in concrete,

indicates the cross-sectional area of a steel fiber, and

presents an orientation factor accounting for its effect on the number of fibers. This value is in the range of 0.41 to 0.81 [

31,

46], and is equal to 1 when all the fibers are aligned in one dimension.

The orientation factor, , can be estimated indirectly from the calculated using Equation (5). The estimated was 0.357 for Method A and 0.735 for Method B.

Li et al. [

41] proposed an equation for the fiber number in a unit area bridging the cracked plane, which was expressed as follows:

By comparing Equations (5) and (6), the orientation factor,

, can also be expressed as

With the measured orientation distribution,

p(

θ) for each case, the orientation factor can be calculated from Equation (7); the results are also listed in

Table 4. The orientation factor for Method A is 0.645 and 0.715 for Method B. Compared to the values calculated with the detected fiber number and Equation (5), both approaches, using Equation (5) or (7), produced similar results to the orientation factors for Method B. On the other hand, Equation (7) for Method A led to a much lower value than Equation (5). This means that the number of detected fibers for Method A is much smaller than the one expected theoretically.

In the case that all the fibers are aligned in one direction, both and are equal to 1. Considering the variation of the values for and with two different casting methods, it can be said that calculated from the number of detected fibers is a more sensitive indicator than and obtained theoretically from the measured fiber orientation distribution, to the variation in the fiber orientation distribution.

3.3. Estimation of Post-Cracking Tensile Behavior

As mentioned earlier, the post-cracking tensile behavior can be defined by superposing the tension softening curve of the matrix and the bridging curve of the fibers.

The bridging resistance of the fibers was obtained from Equation (1) by applying the measured probability density function for the fiber orientation for the two different casting methods. Each bridging resistance developed by 1 vol % of 16.3 mm fibers and 1 vol % of 19.5 mm fibers was first obtained, and the total bridging resistance by the combination of two types of fibers was obtained by superposition. The function for the 16.3 mm and 19.5 mm fibers was assumed to be the same. The probability

p(

le) in Equation (1) was assumed to be 2/

lf. It may not strictly follow the uniform distribution from 0 to

lf/2, but to our knowledge there is no feasible method to determine

p(

le). In the calculation, the model for the pullout resistance suggested by Lee et al. [

42] was modified slightly to fit the experimental data. The values employed in this study for the parameters in the model were listed in

Table 6. Two parameters (

γ and

n) describing the slip coefficient for the ascending branch of the pullout behavior were only adjusted to fit the experimental data. According to the analysis based on the model, the slip deformation at the peak pullout load for a fiber with an inclined angle is larger for longer fibers considering the difference in the bond stress distribution along the interface between fiber and matrix at the peak load. The correction factor (

Fc) in Equation (1) introduced for considering the variation due to the difference in the bond condition had a value of 1.2 in the analysis.

Once each bridging stress–crack width curve of the two types of fibers laid across the cracked plane is obtained, the tensile bridging behavior developed by incorporating the two kinds of fibers can be plotted by superposing each bridging curve for both fibers.

The tensile bridging behavior for a representative specimen of each case was obtained. The specimen that had a median value and the value closest to the average for most of the parameters listed in

Table 3 was selected as representative for each case.

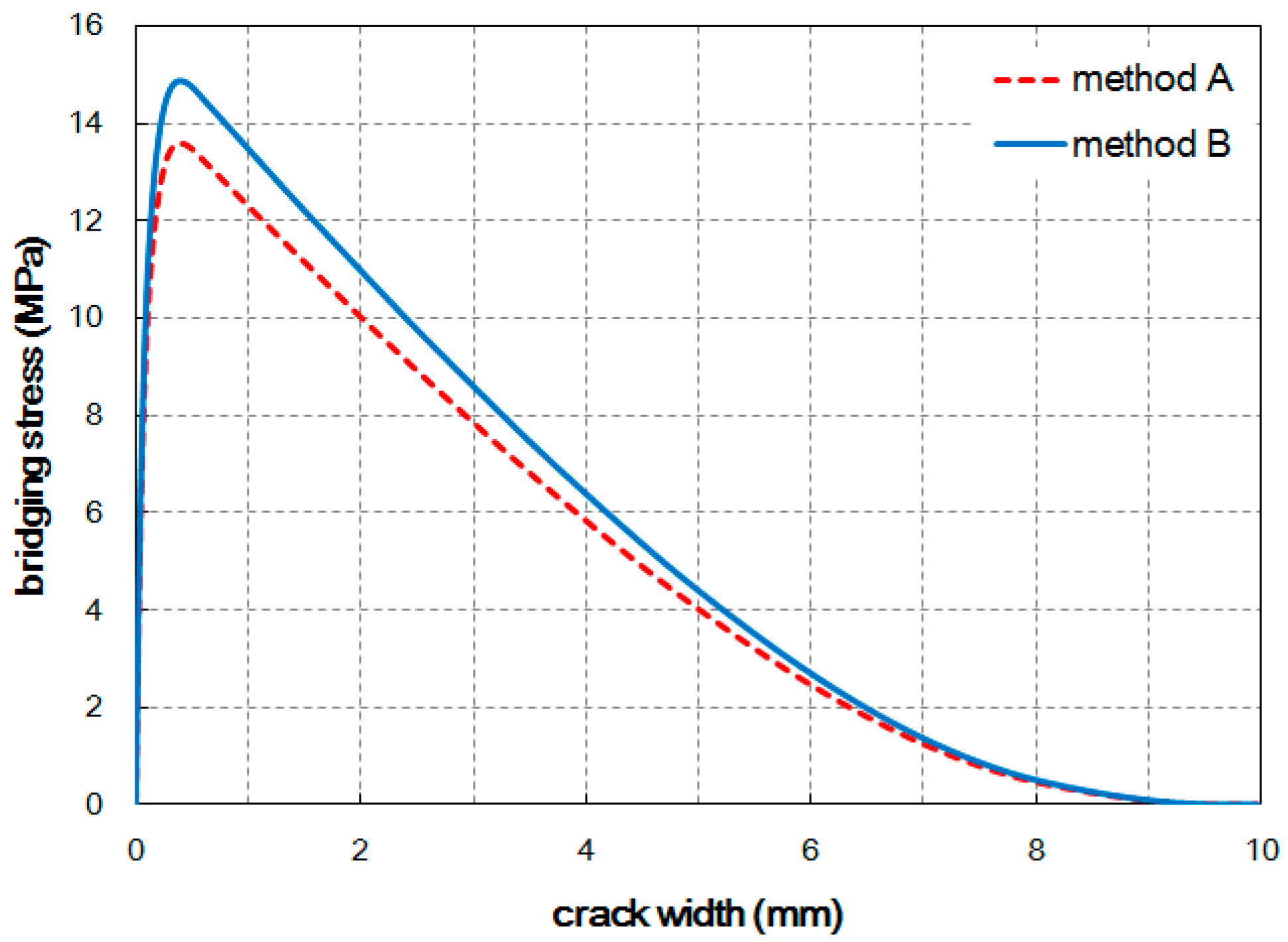

Figure 8 shows the estimated tensile bridging behaviors. The maximum bridging stress for Method A and Method B was 13.6 MPa and 14.9 MPa, respectively. Some difference in the tensile bridging behaviors, due to the difference in the fiber orientation distribution, can be seen. However, compared with the tensile strengths obtained from experiment, the difference is much smaller. This means that the fiber orientation distribution measured from the image analysis does not completely represent the influence of the placing method, and the fiber distribution and consequent tensile behavior vary according to the placing method.

In addition, the calculated maximum bridging stress for Method A was overestimated considerably. This seems to be closely related to the number of detected fibers. The theoretically estimated number of fibers per unit area (0.715 ×) was similar to the measured one (0.735 ×) for the case of Method B, whereas Method A resulted in a huge difference between the theoretically estimated number of fibers per unit area (0.644 ×) and the measured one (0.357 ×). This is believed to have been caused by several factors, including the inaccuracy in calculating the inclined angle of the highly inclined fibers, due to the limited number of pixels in the image used in the image analysis technique, and the consequent inaccuracy in the fiber orientation distribution, p(θ).

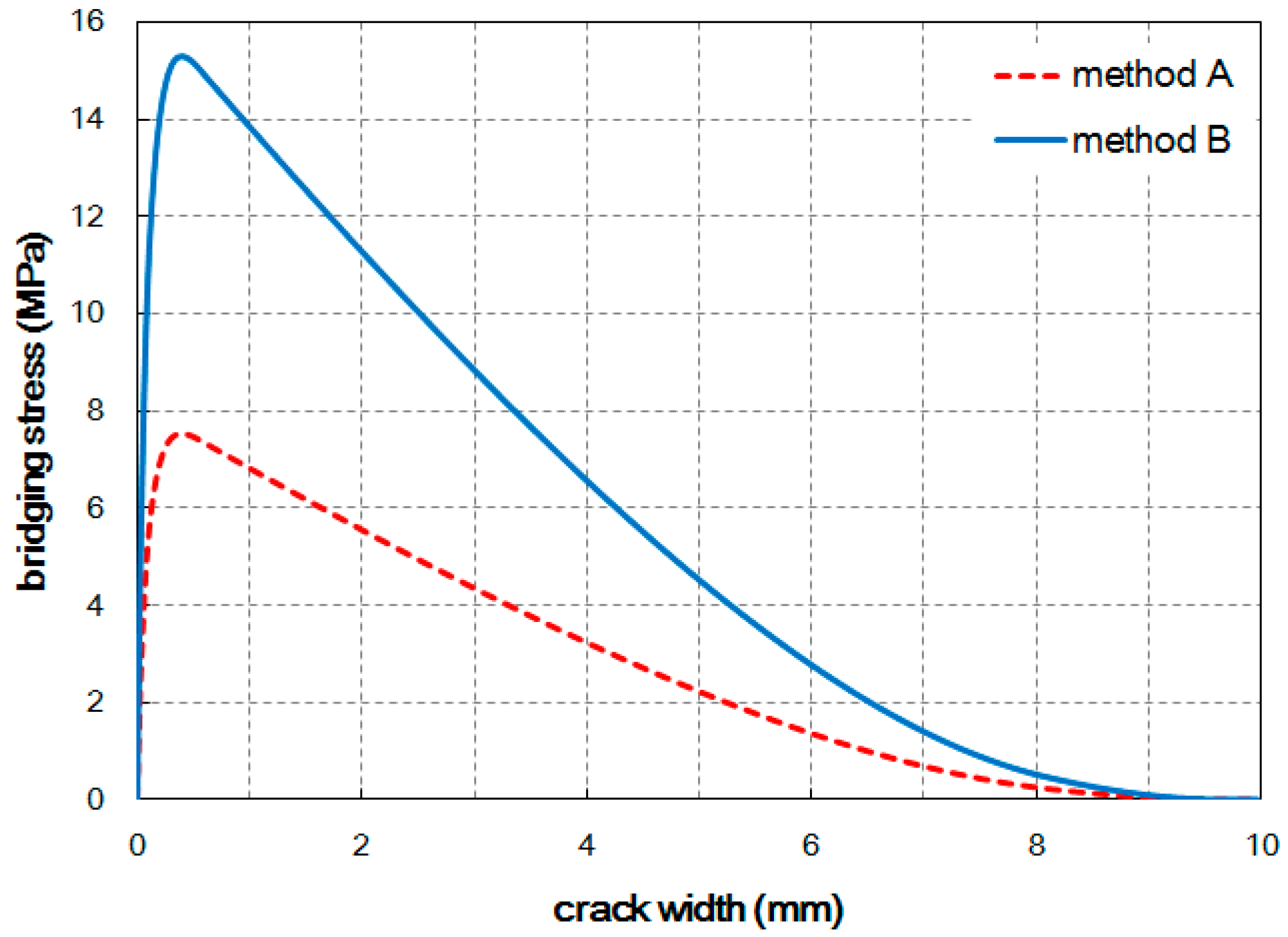

The number of fibers detected in an image is relatively accurate regardless of the image resolution, as explained previously. If the difference in the number of fibers is therefore considered when estimating the tensile bridging behavior, more reasonable results can be obtained. By multiplying Equation (1) by the ratio of the orientation factor (

) obtained from Equations (5) and (7), the tensile bridging behaviors can be modified; the results are plotted in

Figure 9. After modification, the maximum bridging stresses became similar to the measured tensile strengths for both cases. Therefore, the number of fibers placed across the cracked plane provides better tensile responses, similar to the measured tensile stress–CMOD curves.

The tension softening curve of the matrix needs to be defined to calculate the post-cracking tensile behavior of UHPCC. Kang and Kim [

21] introduced the concept of apparent tension softening curve and fracture energy in order to model the post-cracking tensile behavior of UHPCC by superposing the resistance of the bridging fibers and the tension softening of the matrix. In their research, it was shown that the post-cracking tensile resistance of cementitious matrix in a fiber-reinforced cementitious composite was much higher than its own tension softening curve. Therefore, when a much higher fracture energy than the intrinsic value for the tension softening curve was applied, the estimated behaviors became more consistent with the experimental results. It was also said that this apparent tension softening curve might be dependent on the fiber characteristics as well as the matrix properties. For the apparent tension softening curve of the matrix in this study, the tensile strength,

ft was assumed to be 6.68 for Method A and 7.55 for Method B, which were determined from the experimental results. The fracture energy,

GF, for determining

c was assumed to be 0.5 N/mm, which was determined under the consideration of the magnitude of the stress drop after first cracking and the corresponding crack width in the tensile behavior of UHPCC.

When the estimated tensile behaviors were compared with the experimental results, as shown in

Figure 10, the estimation results provided acceptable agreement with the measured tensile behaviors for both specimens fabricated with the two different casting methods. The slope in the softening branch, tensile hardening behavior after the first cracking, and tensile strength could be estimated properly. With regard to the crack width at the ultimate tensile stress, the simulated crack width was similar for the two cases but the experimental results presented a noticeable difference between the two cases. The crack width for Method B was larger than the value for Method A. This inconsistency may be ascribed to the inaccuracy of the assumed fiber pullout behavior according to the inclined angle. Especially for Method A, the overestimation of the pullout deformation of highly inclined fibers is thought to cause the difference between the simulated and measured values. If a more accurate model for the fiber pullout behavior according to the inclined angle is provided based on experiments, the prediction of the crack width at the ultimate tensile stress may also be improved.

Through the analysis and comparison with the experimental results for the post-cracking tensile behavior, the validity of the approach adopted in this study to simulate the post-cracking behavior of fiber-reinforced cementitious composites was proven.