Improvement in Fatigue Performance of Aluminium Alloy Welded Joints by Laser Shock Peening in a Dynamic Strain Aging Temperature Regime

Abstract

:1. Introduction

2. Materials and Methods

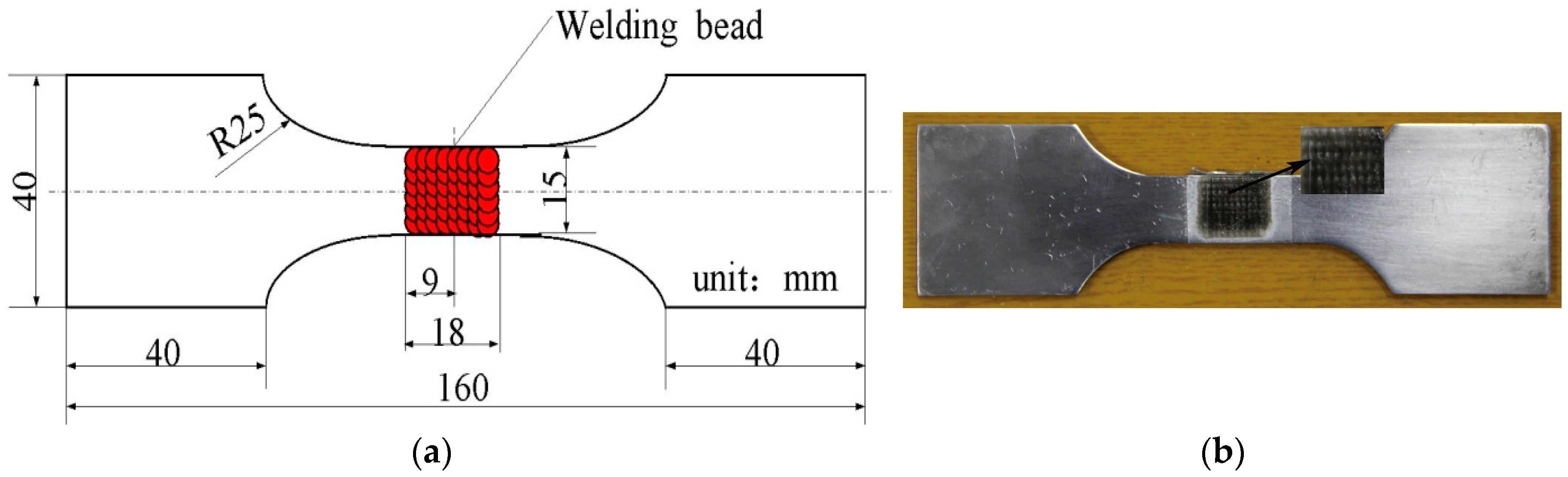

2.1. Experimental Material and Samples

2.2. LSP Assisted by DSA Experiment

2.3. Measurements and Microstructural Observations

3. Results and Discussion

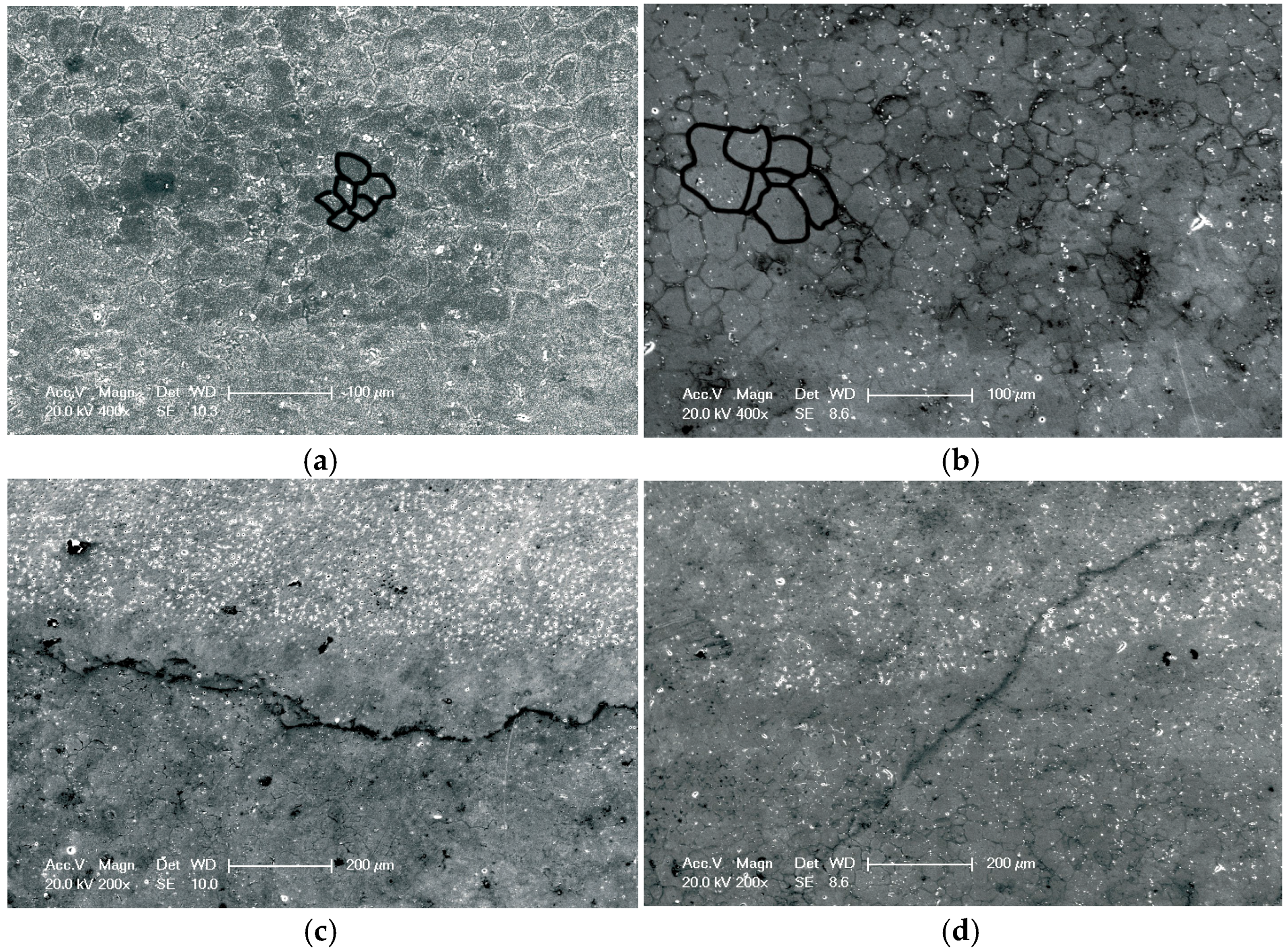

3.1. Microstructural Characteristics

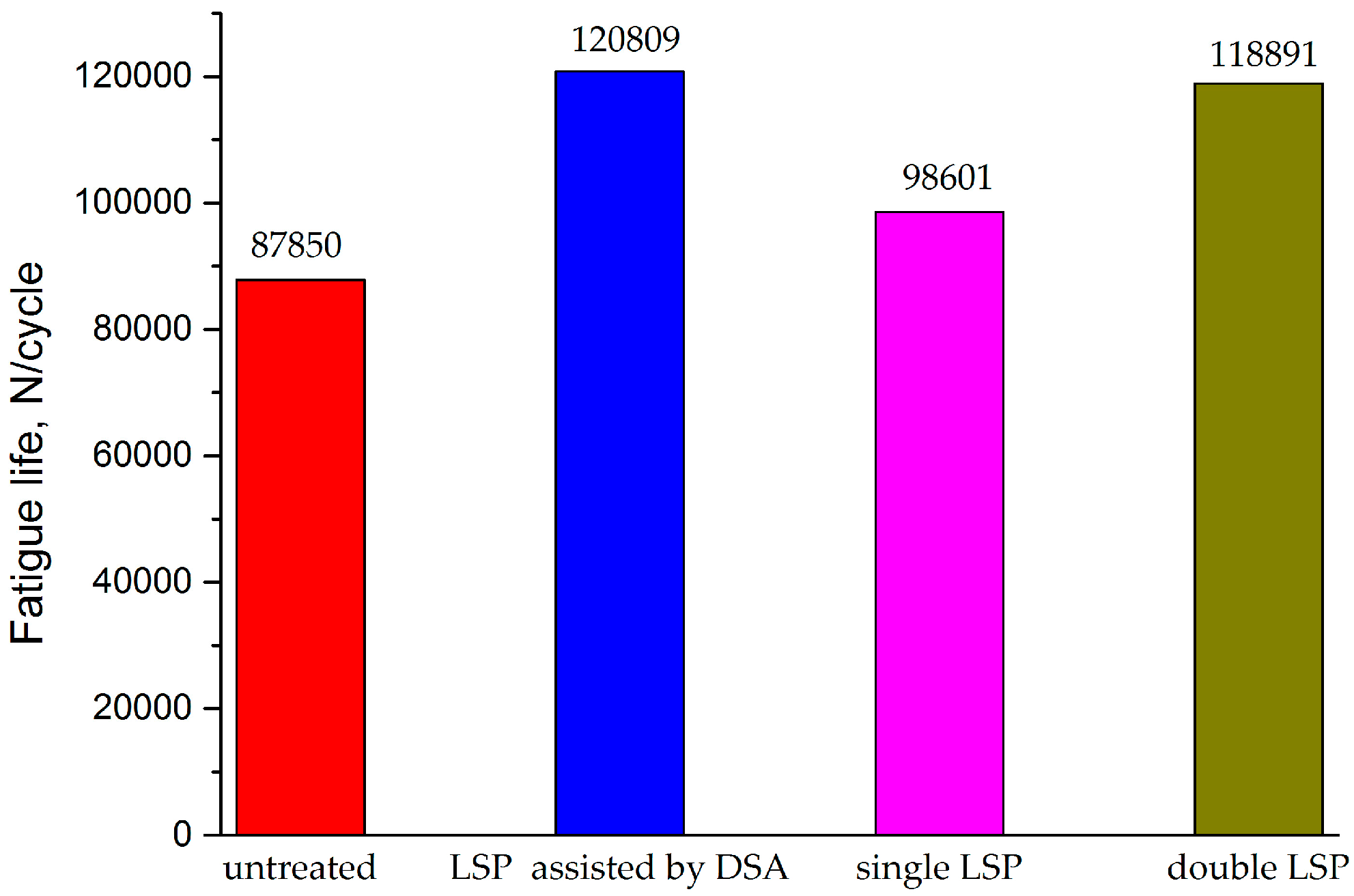

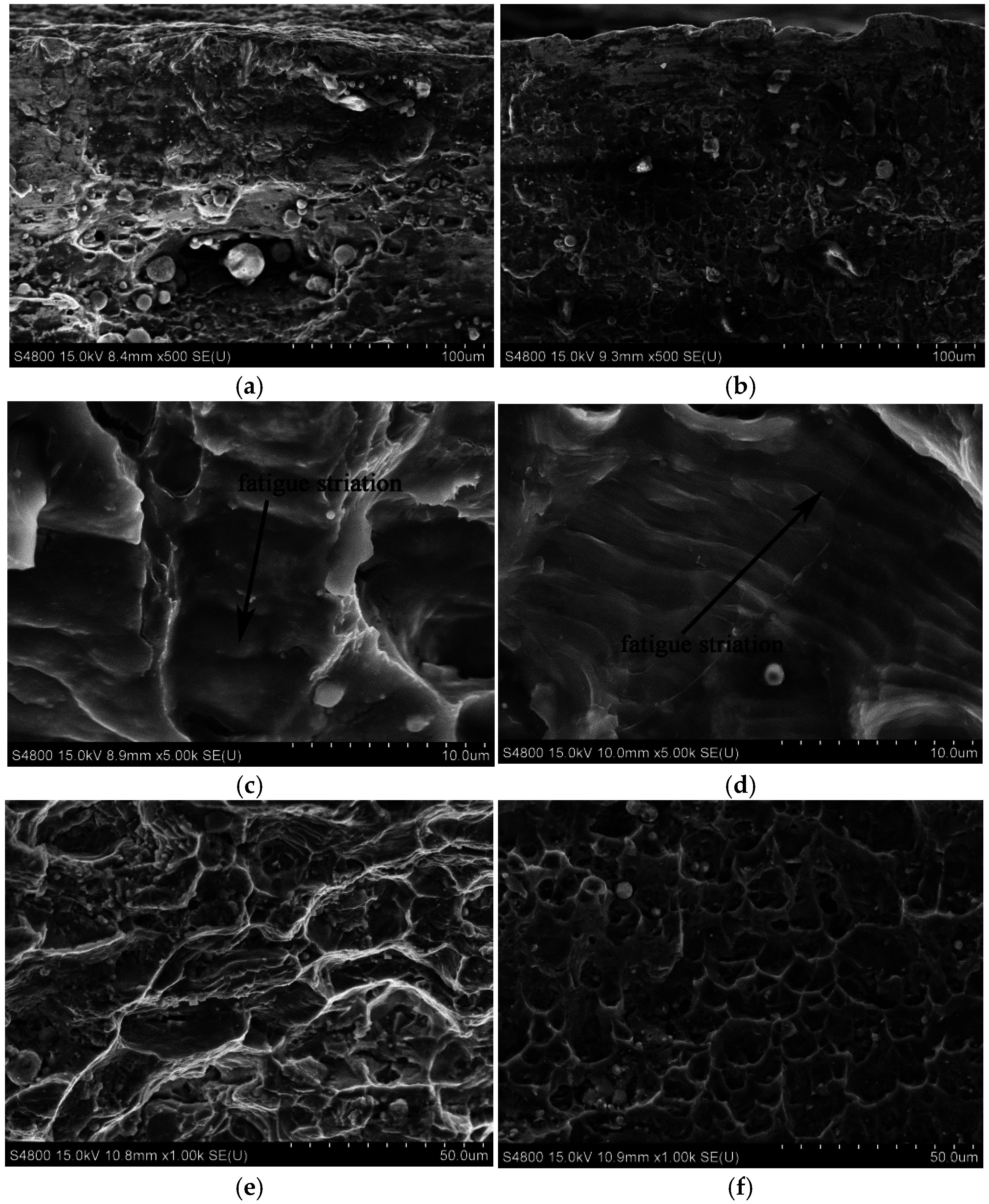

3.2. Tensile Fatigue Performance

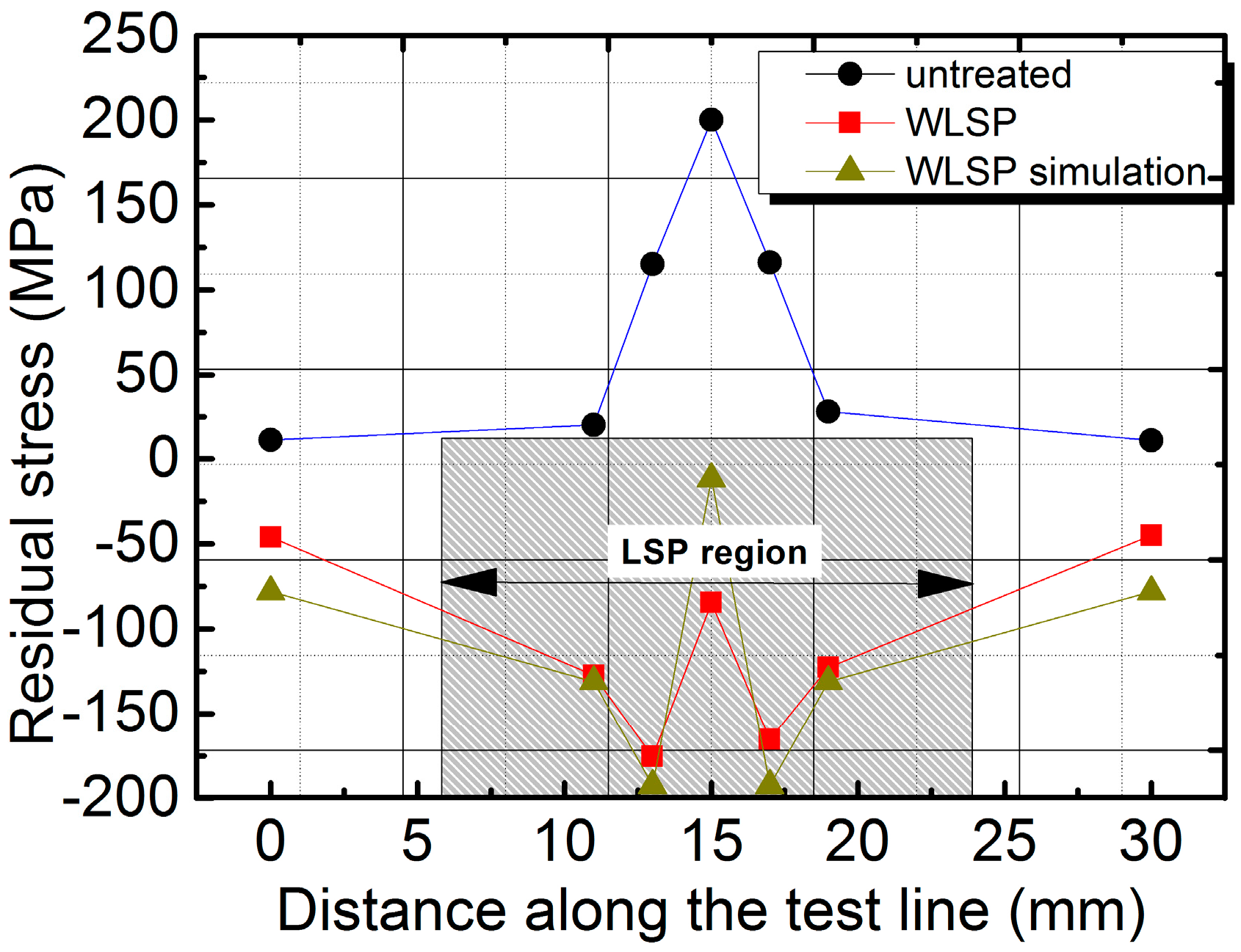

3.3. Surface Residual Stress

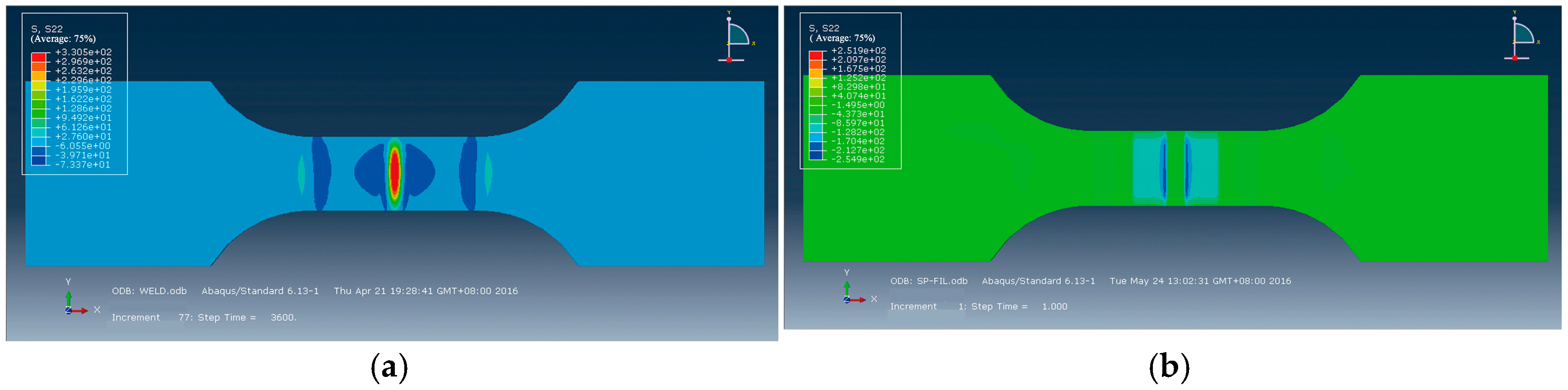

3.4. Numerical Analysis of Residual Stress

- (1)

- A minor amount of residual stress might be released as the residual stresses in the specimens, after being treated using LSP assisted by DSA, were not tested sufficiently quickly.

- (2)

- Explicit finite element analysis used in the simulation of the specimens treated using LSP assisted by DSA can generate cumulative errors and the preset parameters, including stepload, might have deviated slightly from the relevant experimental values.

- (3)

- The test results may have been subject to a certain amount of random error.

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kastensson, Å. Developing lightweight concepts in the automotive industry: Taking on the environmental challenge with the SåNätt project. J. Clean. Prod. 2014, 66, 337–346. [Google Scholar] [CrossRef]

- Vidal, C.; Infante, V. Fatigue behavior of friction stir-welded joints repaired by grinding. J. Mater. Eng. Perform. 2014, 23, 1340–1349. [Google Scholar] [CrossRef]

- Vidal, C.; Infante, V. Optimization of FS welding parameters for improving mechanical behavior of AA2024-T351 joints based on Taguchi method. J. Mater. Eng. Perform. 2013, 22, 2261–2270. [Google Scholar] [CrossRef]

- Patil, C.; Patil, H.; Patil, H. Experimental investigation of hardness of FSW and TIG joints of aluminium alloys of AA7075 and AA6061. Frat. Integr. Strutt. 2016, 37, 325–332. [Google Scholar]

- Liu, H.; Fujii, H.; Maeda, M.; Nogi, K. Tensile Properties and Fracture Locations of Friction-Stir Welded Joints of 6061-T6 Aluminum Alloy. J. Mater. Sci. Lett. 2003, 22, 1061–1063. [Google Scholar] [CrossRef]

- Hatamleh, O.; Mishra, R.S.; Oliveras, O. Peening effects on mechanical properties in friction stir welded AA 2195 at elevated and cryogenic temperatures. Mater. Des. 2009, 30, 3165–3173. [Google Scholar] [CrossRef]

- Hatamleh, O.; Preet, M.S.; Hamid, G. Corrosion susceptibility of peened friction stir welded 7075 aluminum alloy joints. Corros. Sci. 2009, 1, 135–143. [Google Scholar] [CrossRef]

- Zhang, Y.K.; Zhang, L.; Luo, K.Y.; Sun, G.F.; Lu, J.Z.; Dai, F.Z.; Zhong, J.W. Effects of laser shock processing on mechanical properties of laser welded ANSI 304 stainless steel joint. Chin. J. Mech. Eng. 2012, 2, 285–292. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, K.Y.; Lu, J.Z.; Zhang, Y.K.; Dai, F.Z.; Zhong, J.W. Effects of laser shock processing with different shocked paths on mechanical properties of laser welded ANSI 304 stainless steel joint. Mater. Sci. Eng. A 2011, 13–14, 4652–4657. [Google Scholar] [CrossRef]

- Huang, S.; Zhou, J.Z.; Sheng, J.; Lu, J.Z.; Sun, G.F.; Meng, X.K.; Zuo, L.D.; Ruan, H.Y.; Chen, H.S. Effects of laser energy on fatigue crack growth properties of 6061-T6 aluminum alloy subjected to multiple laser peening. Eng. Fract. Mech. 2013, 99, 87–100. [Google Scholar] [CrossRef]

- Huang, S.; Zhou, J.Z.; Sheng, J.; Luo, K.Y.; Lu, J.Z.; Xu, Z.C.; Meng, X.K. Effects of laser peening with different coverage areas on fatigue crack growth properties of 6061-T6 aluminum alloy. Int. J. Fatigue 2013, 47, 292–299. [Google Scholar] [CrossRef]

- Su, C.; Zhou, J.Z.; Sheng, J.; Huang, S.; Meng, X.K. Strengthening effect analysis of laser shock processing on aluminum alloy welded joint process. Procedia Eng. 2015, 130, 524–530. [Google Scholar] [CrossRef]

- Montross, C.S.; Wei, T.; Ye, L.; Clark, G.; Mai, Y.W. Laser shock processing and its effects on microstructure and properties of metal alloys: A review. Int. J. Fatigue 2002, 10, 1021–1036. [Google Scholar] [CrossRef]

- Ballard, P.; Fournier, J.; Fabbro, R.; Frelat, J. Residual stresses induced by laser-shocks. J. Phys. IV 1991, 1, C3-487–C3-494. [Google Scholar] [CrossRef]

- Juijerm, P.; Altenberger, I.; Scholtes, B. Fatigue and residual stress relaxation of deep rolled differently aged aluminium alloy AA6110. Mater. Sci. Eng. A 2006, 426, 4–10. [Google Scholar] [CrossRef]

- Dalaei, K.; Karlsson, B.; Svensson, L.E. Stability of residual stresses created by shot peening of pearlitic steel and their influence on fatigue behaviour. Procedia Eng. 2010, 2, 613–622. [Google Scholar] [CrossRef]

- Cui, C.Y.; Gu, Y.F.; Yuan, Y.; Harada, H. Dynamic strain aging in a new Ni–Co base superalloy. Scr. Mater. 2011, 6, 502–505. [Google Scholar] [CrossRef]

- Austin, R.A.; Mcdowell, D.L. A dislocation-based constitutive model for viscoplastic deformation of FCC metals at very high strain rates. Int. J. Plast. 2011, 1, 1–24. [Google Scholar] [CrossRef]

- Liao, Y.L.; Ye, C.; Kim, B.J.; Suslov, S.; Stach, E.A.; Cheng, G.J. Nucleation of highly dense nanoscale precipitates based on warm laser shock peening. J. Appl. Phys. 2010, 108, 063518. [Google Scholar] [CrossRef]

- Tani, G.; Orazi, L.; Fortunato, A.; Ascari, A.; Campana, G. Warm laser shock peening: New developments and process optimization. CIRP Ann. Manuf. Technol. 2011, 1, 219–222. [Google Scholar] [CrossRef]

- Ye, C.; Liao, Y.L.; Cheng, G.J. Warm laser shock peening driven nanostructures and their effects on fatigue performance in aluminum alloy 6160. Adv. Eng. Mater. 2010, 4, 291–297. [Google Scholar]

- Ye, C.; Suslov, S.; Kim, B.J.; Stach, E.A.; Cheng, G.J. Fatigue performance improvement in AISI 4140 steel by dynamic strain aging and dynamic precipitation during warm laser shock peening. Acta Mater. 2011, 3, 1014–1025. [Google Scholar] [CrossRef]

- Abdullahi, K.G.; Mamoun, M. Laser peening process and its impact on materials properties in comparison with shot peening and ultrasonic impact peening. Materials 2014, 7, 7925–7974. [Google Scholar]

- Withers, P.J.; Bhadeshia, H.K. Residual stress part 2—Nature and origins. Mater. Sci. Technol. 2001, 4, 366–375. [Google Scholar] [CrossRef]

- Non-Destructive Testing- Test Method for Residual Stress Analysis by X-ray Diffraction; EN 15305-2008; BSI Publications: London, UK, 2008.

- Standard Test Method for Verifying the Alignment of X-ray Diffraction Instrumentation for Residual Stress Measurement; E 915-10; ASTM: West Conshohocken, PA, USA, 2010.

- Raghavan, V. Al-Mg-Si (aluminum-magnesium-silicon). J. Ph. Equilib. Diffus. 2007, 2, 189–191. [Google Scholar] [CrossRef]

- Chukken, J.R.; Vasudevan, M.; Muthukumaran, S.; Kumar, R.R.; Chandrasekhar, N. Simulation of laser butt welding of AISI 316L stainless steel sheet using various heat sources and experimental validation. J. Mater. Process. Technol. 2015, 219, 48–59. [Google Scholar] [CrossRef]

- Fabbro, R.; Fournier, J.; Ballard, P.; Devaux, D.; Virmont, J. Physical study of laser-produced plasma in confined geometry. J. Appl. Phys. 1990, 2, 775–784. [Google Scholar] [CrossRef]

- Amarchinta, H.K.; Grandhi, R.V.; Clauer, A.H.; Langer, K.; Stargel, D.S. Simulation of residual stress induced by a laser peening process through inverse optimization of material models. J. Mater. Process. Technol. 2010, 14, 1997–2006. [Google Scholar] [CrossRef]

| Material | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 6061-T6 | 0.61 | 0.53 | 0.29 | 0.11 | 0.98 | 0.26 | 0.19 | 0.10 | Bal |

| ER4043 | 4.5~6.0 | ≤0.8 | ≤0.3 | ≤0.05 | ≤0.05 | – | ≤0.1 | ≤0.2 | Bal |

| Parameters | Value |

|---|---|

| Operation material | Nd:YAG |

| Wavelength/nm | <12 |

| Frequency/Hz | 1~5 |

| Power distribution | Flat |

| Pulse width/ns | <10 |

| Pulse power/J | <12 |

| Focus size, Φ/mm | 3~8 |

| Spot shape | Circle |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, C.; Zhou, J.; Meng, X.; Huang, S. Improvement in Fatigue Performance of Aluminium Alloy Welded Joints by Laser Shock Peening in a Dynamic Strain Aging Temperature Regime. Materials 2016, 9, 799. https://doi.org/10.3390/ma9100799

Su C, Zhou J, Meng X, Huang S. Improvement in Fatigue Performance of Aluminium Alloy Welded Joints by Laser Shock Peening in a Dynamic Strain Aging Temperature Regime. Materials. 2016; 9(10):799. https://doi.org/10.3390/ma9100799

Chicago/Turabian StyleSu, Chun, Jianzhong Zhou, Xiankai Meng, and Shu Huang. 2016. "Improvement in Fatigue Performance of Aluminium Alloy Welded Joints by Laser Shock Peening in a Dynamic Strain Aging Temperature Regime" Materials 9, no. 10: 799. https://doi.org/10.3390/ma9100799