Microstructure Evolution and Mechanical Properties Improvement in Liquid-Phase-Sintered Hydroxyapatite by Laser Sintering

Abstract

:1. Introduction

2. Results and Discussion

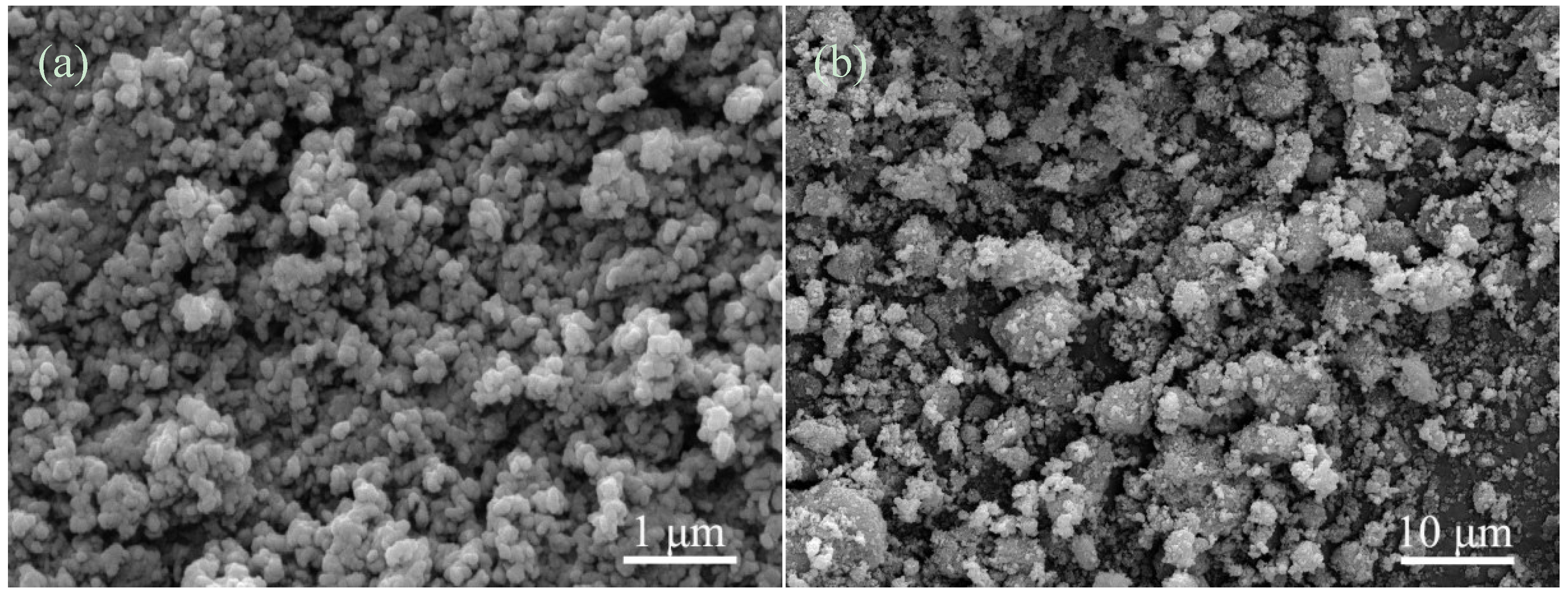

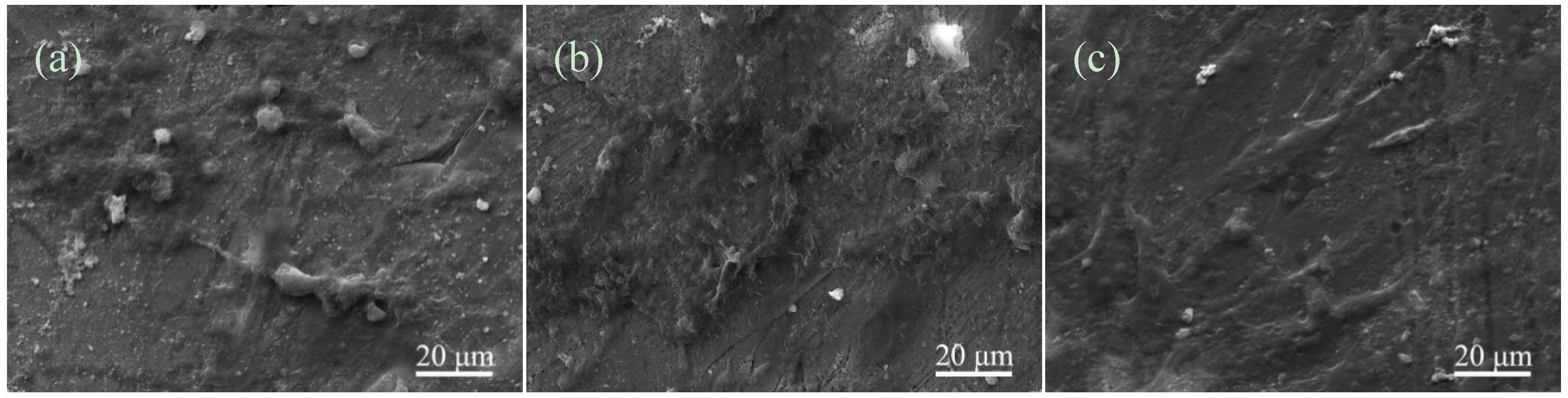

2.1. Microstructural Analysis

2.2. Mechanical Characterization

2.3. SBF Study

2.4. Cell Culture

3. Experimental Section

3.1. Materials and Method

| Parameters | Spot Diameter (mm) | Scan Spacing (mm) | Laser Power (W) | Scan Speed (mm/min) | Layer Thickness (mm) |

|---|---|---|---|---|---|

| Value | 1.0 | 2.0 | 6 | 100 | 0.1–0.2 |

3.2. Microstructural Analysis

3.3. Mechanical Characterization

3.4. SBF Study

| Ions | Ions Concentration (mmol·L−1) | |||||||

|---|---|---|---|---|---|---|---|---|

| Na+ | K+ | Ca2+ | Mg2+ | Cl− | HPO42− | HCO3− | SO42− | |

| Blood plasma | 142.0 | 5.0 | 2.5 | 1.5 | 103.0 | 1.0 | 27.0 | 0.5 |

| SBF | 142.0 | 5.0 | 2.5 | 1.5 | 147.8 | 1.0 | 4.2 | 0.5 |

3.5. Cell Culture

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Soucacos, P.N.; Kokkalis, Z.T.; Piagkou, M.; Johnsonb, E.O. Vascularized bone grafts for the management of skeletal defects in orthopaedic trauma and reconstructive surgery. Injury 2013, 44, S70–S75. [Google Scholar] [CrossRef] [PubMed]

- Schlickewei, W.; Schlickewei, C. The use of bone substitutes in the treatment of bone defects–The clinical view and history. Macromol. Symp. Aug. 2007, 253, 10–23. [Google Scholar] [CrossRef]

- Shi, Y.; Niedzinski, J.R.; Samaniego, A.; Bogdansky, S.; Atkinson, B.L. Adipose-derived stem cells combined with a demineralized cancellous bone substrate for bone regeneration. Tissue Eng. Part A 2012, 18, 1313–1321. [Google Scholar] [CrossRef] [PubMed]

- Goodridge, R.D.; Dalgarno, K.W.; Wood, D.J. Indirect selective laser sintering of an apatite-mullite glass-ceramic for potential use in bone replacement applications. Proc. Inst. Mech. Eng. H 2006, 220, 57–68. [Google Scholar] [CrossRef] [PubMed]

- Kaur, G.; Pandey, O.P.; Singh, K.; Homa, D.; Scott, B.; Pickrell, G. A review of bioactive glasses: Their structure, properties, fabrication and apatite formation. J. Biomed. Mater. Res. A 2014, 102, 254–274. [Google Scholar] [CrossRef]

- Martínez-Vázquez, F.J.; Pajares, A.; Guiberteau, F.; Miranda, P. Effect of polymer infiltration on the flexural behavior of β-tricalcium phosphate robocast scaffolds. Materials 2014, 7, 4001–4018. [Google Scholar] [CrossRef]

- Lawrence, B.J.; Madihally, S.V. Cell colonization in degradable 3D porous matrices. Cell Adhes. Migr. 2008, 2, 9–16. [Google Scholar] [CrossRef]

- Guan, S.; Zhang, X.L.; Lin, X.M.; Liu, T.Q.; Ma, X.H.; Cui, Z.F. Chitosan/gelatin porous scaffolds containing hyaluronic acid and heparan sulfate for neural tissue engineering. J. Biomater. Sci.-Polym. Ed. 2013, 24, 999–1014. [Google Scholar] [CrossRef] [PubMed]

- Murphy, C.M.; Haugh, M.G.; O’Brien, F.J. The effect of mean pore size on cell attachment, proliferation and migration in collagen–glycosaminoglycan scaffolds for bone tissue engineering. Biomaterials 2010, 31, 461–466. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Lee, J. Nanoscale hydroxyapatite particles for bone tissue engineering. Acta Biomater. 2011, 7, 2769–2781. [Google Scholar] [CrossRef] [PubMed]

- Sun, F.; Koh, K.; Ryu, S.C.; Han, D.W.; Lee, J. Biocompatibility of nanoscale hydroxyapatite-embedded chitosan films. Bull. Korean. Chem. Soc. 2012, 33, 3950–3956. [Google Scholar] [CrossRef]

- Yang, Y.H.; Liu, C.H.; Liang, Y.H.; Lin, F.H.; Wu, K.C.W. Hollow mesoporous hydroxyapatite nanoparticles (hmHANPs) with enhanced drug loading and pH-responsive release properties for intracellular drug delivery. J. Mater. Chem. B 2013, 1, 2447–2450. [Google Scholar] [CrossRef]

- Wu, K.C.W.; Yang, Y.H.; Liang, Y.H.; Chen, H.Y.; Sung, E.; Yamauchi, Y.; Lin, F.H. Facile synthesis of hollow mesoporous hydroxyapatite nanoparticles for intracellular bio-imaging. Curr. Nanosci. 2011, 7, 926–931. [Google Scholar] [CrossRef]

- Li, Z.; Wen, T.; Su, Y.; Wei, X.; He, C.; Wang, D. Hollow hydroxyapatite spheres fabrication with three-dimensional hydrogel template. Cryst. Eng. Comm. 2014, 16, 4202–4209. [Google Scholar] [CrossRef]

- Bastakoti, B.P.; Hsu, Y.C.; Liao, S.H.; Wu, K.C.W.; Inoue, M.; Yusa, S.I.; Yamauchi, Y. Inorganic–organic hybrid nanoparticles with biocompatible calcium phosphate thin shells for fluorescence enhancement. Chem. Asian J. 2013, 8, 1301–1305. [Google Scholar] [CrossRef] [PubMed]

- Chevalier, J.; Gremillard, L. Ceramics for medical applications: A picture for the next 20 years. J. Eur. Ceram. Soc. 2009, 29, 1245–1255. [Google Scholar] [CrossRef]

- Lin, K.; Chen, L.; Chang, J. Fabrication of dense hydroxyapatite nanobioceramics with enhanced mechanical properties via two-step sintering process. Int. J. Appl. Ceram. Technol. 2012, 9, 479–485. [Google Scholar] [CrossRef]

- Reves, B.T.; Jennings, J.A.; Bumgardner, J.D.; Haggard, W.O. Osteoinductivity assessment of BMP-2 loaded composite chitosan-nano-hydroxyapatite scaffolds in a rat muscle pouch. Materials 2011, 4, 1360–1374. [Google Scholar] [CrossRef]

- Tripathi, G.; Basu, B. A porous hydroxyapatite scaffold for bone tissue engineering: Physico-mechanical and biological evaluations. Ceram. Int. 2012, 38, 341–349. [Google Scholar] [CrossRef]

- Duan, B.; Wang, M. Selective laser sintering and its application in biomedical engineering. MRS Bull. 2011, 36, 998–1005. [Google Scholar] [CrossRef] [Green Version]

- Sandler, N.; Lammens, R.F. Pneumatic dry granulation: Potential to improve roller compaction technology in drug manufacture. Expert Opin. Drug Del. 2011, 8, 225–236. [Google Scholar] [CrossRef]

- Bouslama, N.; Chevalier, Y.; Bouaziz, J.; Ayed, F.B. Influence of the sintering temperature on Young’s modulus and the shear modulus of tricalcium phosphate–fluorapatite composites evaluated by ultrasound techniques. Mater. Chem. Phys. 2013, 141, 289–297. [Google Scholar] [CrossRef]

- Lupulescu, A.; Glicksman, M.E. Diffusion-limited crystal growth in silicate systems: Similarity with high-pressure liquid-phase sintering. J. Cryst. Growth 2000, 211, 49–61. [Google Scholar] [CrossRef]

- Wei, W.; Chen, K.; Ge, G. Strongly coupled nanorod vertical arrays for plasmonic sensing. Adv. Mater. 2013, 25, 3863–3868. [Google Scholar] [CrossRef] [PubMed]

- Hotta, M.; Hojo, J. Inhibition of grain growth in liquid-phase sintered SiC ceramics by AlN additive and spark plasma sintering. J. Eur. Ceram. Soc. 2010, 30, 2117–2122. [Google Scholar] [CrossRef]

- Liu, D.; Zhuang, J.; Shuai, C.; Peng, S. Mechanical properties’ improvement of a tricalcium phosphate scaffold with poly-L-lactic acid in selective laser sintering. Biofabrication 2013, 5, 025005. [Google Scholar] [CrossRef]

- Batra, U.; Kapoor, S.; Sharma, J.D. Nano-Hydroxyapatite/Fluoridated and Unfluoridated Bioactive Glass Composites: Structural Analysis and Bioactivity Evaluation. In Proceedings of the International Conference on Advances in Condensed and Nano Materials (ICACNM-2011), Chandigarh, India, 23–26 February 2011; AIP Publishing: New York, NY, USA, 2011; Volume 1393, pp. 271–272. [Google Scholar]

- Oktar, F.N.; Agathopoulos, S.; Ozyegin, L.S.; Gunduz, O.; Demirkol, N.; Bozkurt, Y.; Salman, S. Mechanical properties of bovine hydroxyapatite (BHA) composites doped with SiO2, MgO, Al2O3, and ZrO2. J. Mater. Sci.: Mater. Med. 2007, 18, 2137–2143. [Google Scholar] [CrossRef]

- Bellucci, D.; Cannillo, V.; Sola, A. A new highly bioactive composite for scaffold applications: A feasibility study. Materials 2011, 4, 339–354. [Google Scholar] [CrossRef]

- Nath, S.; Biswas, K.; Wang, K.; Bordia, R.K.; Basu, B. Sintering, phase stability, and properties of calcium phosphate-mullite composites. J. Am. Ceram. Soc. 2010, 93, 1639–1649. [Google Scholar]

- Bose, S.; Tarafder, S.; Banerjee, S.S.; Davies, N.M.; Bandyopadhyay, A. Understanding in vivo response and mechanical property variation in MgO, SrO and SiO2 doped β-TCP. Bone 2011, 48, 1282–1290. [Google Scholar] [CrossRef] [PubMed]

- German, R.M.; Suri, P.; Park, S.J. Review: Liquid phase sintering. J. Mater. Sci. 2009, 44, 1–39. [Google Scholar] [CrossRef]

- Borrero-López, O.; Ortiz, A.L.; Guiberteau, F.; Padture, N.P. Effect of liquid-phase content on the contact-mechanical properties of liquid-phase-sintered α-SiC. J. Eur. Ceram. Soc. 2007, 27, 2521–2527. [Google Scholar] [CrossRef]

- Bhatt, H.A.; Kalita, S.J. Influence of oxide-based sintering additives on densification and mechanical behavior of tricalcium phosphate (TCP). J. Mater. Sci.: Mater. Med. 2007, 18, 883–893. [Google Scholar] [CrossRef]

- Ribeiro, C.; Rigo, E.C.S.; Sepúlveda, P.; Bressiani, J.C.; Bressiani, A.H.A. Formation of calcium phosphate layer on ceramics with different reactivities. Mater. Sci. Eng. C 2004, 24, 631–636. [Google Scholar] [CrossRef]

- Shuai, C.J.; Feng, P.; Gao, C.D.; Zhou, Y.; Peng, S.P. Simulation of temperature field during the laser sintering process of nano-hydroxyapatite powder. Adv. Mater. Res. 2011, 314, 626–629. [Google Scholar] [CrossRef]

- Veljovic, D.; Palcevskis, E.; Zalite, I.; Petrovic, R.; Janackovic, D. Two-step microwave sintering-A promising technique for the processing of nanostructured bioceramics. Mater. Lett. 2013, 93, 251–253. [Google Scholar] [CrossRef]

- Kaur, G.; Pickrell, G.; Kimsawatde, G.; Homa, D.; Allbee, H.A.; Sriranganathan, N. Synthesis, cytotoxicity, and hydroxyapatite formation in 27-Tris-SBF for sol-gel based CaO-P2O5-SiO2-B2O3-ZnO bioactive glasses. Sci. Rep. 2014, 4, 4392. [Google Scholar] [CrossRef] [PubMed]

- Kokubo, T.; Kushitani, H.; Sakka, S.; Kitsugi, T.; Yamamuro, T. Solutions able to reproduce in vivo surface-structure changes in bioactive glass-ceramic A-W3. J. Biomed. Mater. Res. 1990, 24, 721–734. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, S.; Feng, P.; Gao, C.; Xiao, T.; Yu, K.; Shuai, C.; Peng, S. Microstructure Evolution and Mechanical Properties Improvement in Liquid-Phase-Sintered Hydroxyapatite by Laser Sintering. Materials 2015, 8, 1162-1175. https://doi.org/10.3390/ma8031162

Duan S, Feng P, Gao C, Xiao T, Yu K, Shuai C, Peng S. Microstructure Evolution and Mechanical Properties Improvement in Liquid-Phase-Sintered Hydroxyapatite by Laser Sintering. Materials. 2015; 8(3):1162-1175. https://doi.org/10.3390/ma8031162

Chicago/Turabian StyleDuan, Songlin, Pei Feng, Chengde Gao, Tao Xiao, Kun Yu, Cijun Shuai, and Shuping Peng. 2015. "Microstructure Evolution and Mechanical Properties Improvement in Liquid-Phase-Sintered Hydroxyapatite by Laser Sintering" Materials 8, no. 3: 1162-1175. https://doi.org/10.3390/ma8031162