Bio-based Films from Linter Cellulose and Its Acetates: Formation and Properties

Abstract

:1. Introduction

2. Results and Discussion

2.1. Properties of Linter Cellulose

2.2. Characterization of Cellulose Acetates

| Molar ratio Ac2O/AGU | DS | Sample code |

|---|---|---|

| 1.5 | 0.8 | Ac0.8 |

| 5.0 | 1.5 | Ac1.5 |

| 9.0 | 2.1 | Ac2.1 |

| 12.0 | 2.9 | Ac2.9 |

2.3. Characterization of Cellulose, Cellulose Acetate and Bio-Based Cellulose Acetate/Cellulose Films

| Acetate (DS) | Acetate (wt %) | Cellulose (wt %) | Sample Code |

|---|---|---|---|

| 0.8 | 100 | 0 | FAc0.8 |

| 95 | 5 | FAc0.8Cell5 | |

| 90 | 10 | FAc0.8Cell10 | |

| 85 | 15 | FAc0.8Cell15 | |

| 1.5 | 100 | 0 | FAc1.5 |

| 95 | 5 | FAc1.5Cell5 | |

| 90 | 10 | FAc1.5Cell10 | |

| 85 | 15 | FAc1.5Cell15 | |

| 2.1 | 100 | 0 | FAc2.1 |

| 95 | 5 | FAc2.1Cell5 | |

| 90 | 10 | FAc2.1Cell10 | |

| 85 | 15 | FAc2.1Cell15 | |

| 2.9 | 100 | 0 | FAc2.9 |

| 95 | 5 | FAc2.9Cell5 | |

| 90 | 10 | Fac2.9Cell10 | |

| 85 | 15 | FAc2.9Cell15 |

2.3.1. Elemental Analysis and Atomic Absorption

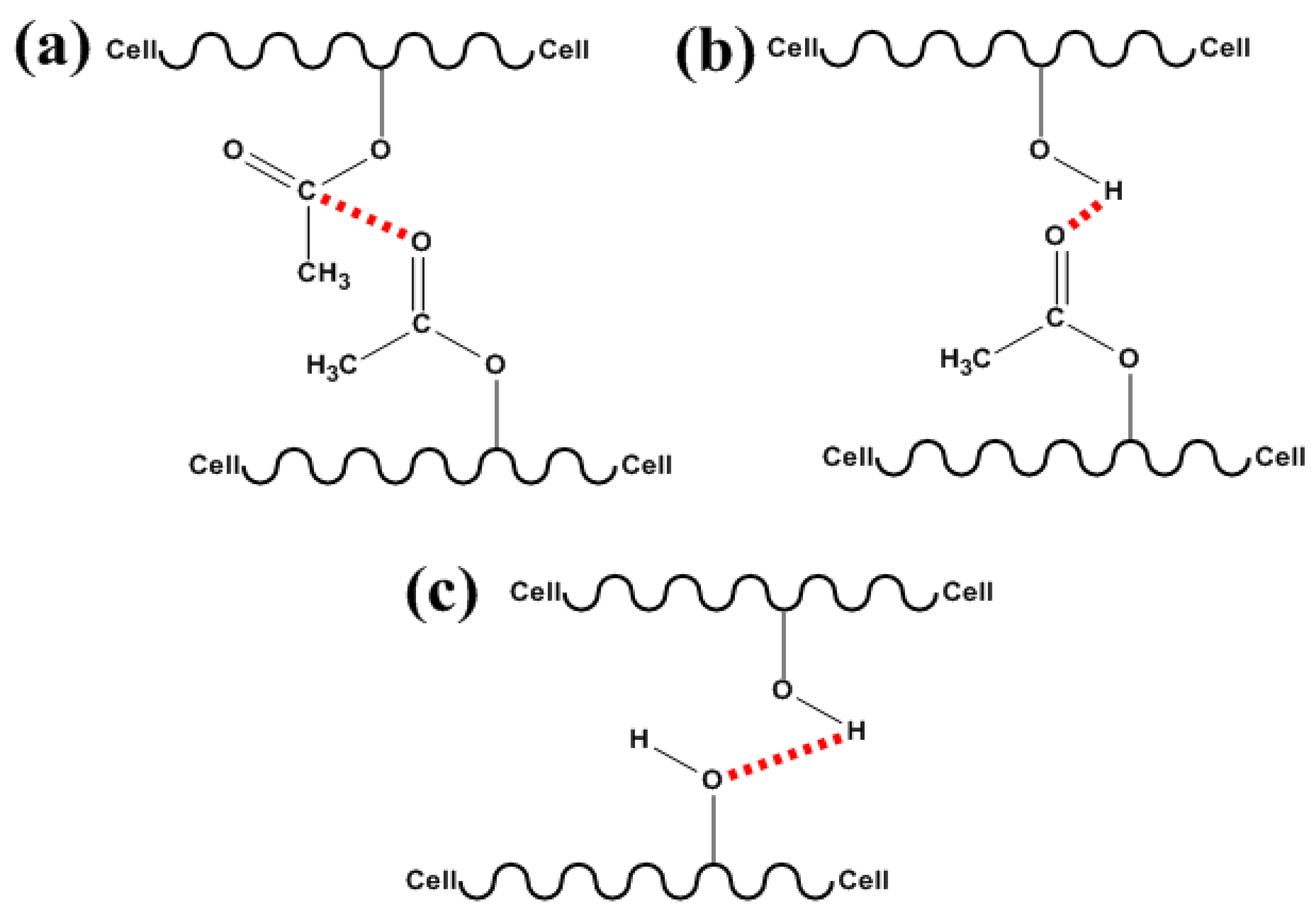

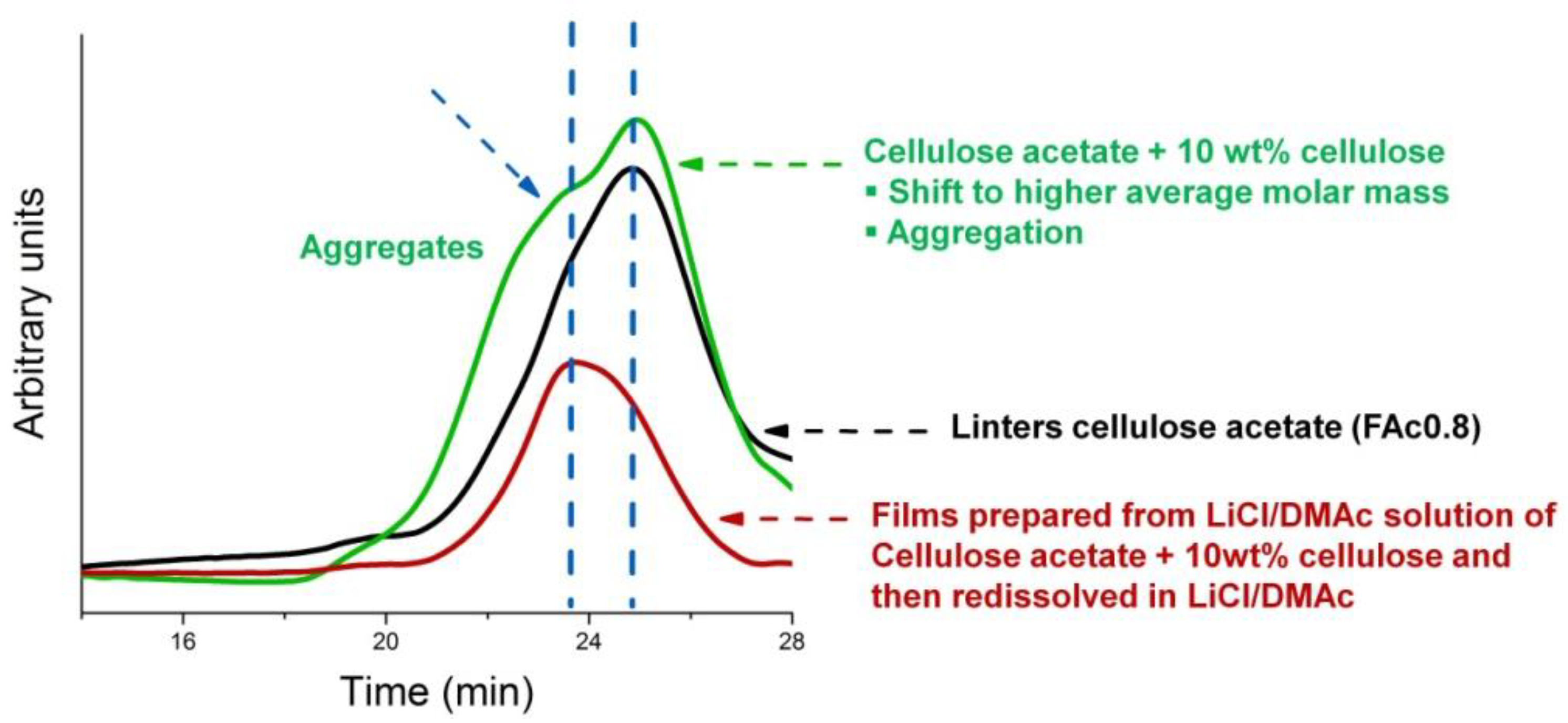

2.3.2. Size-Exclusion Chromatography (SEC) of DS 0.8 acetate (Ac0.8), Mixed or not Mixed with Cellulose, and of the Film FAc0.8Cell10 (Redissolved in LiCl/DMAc)

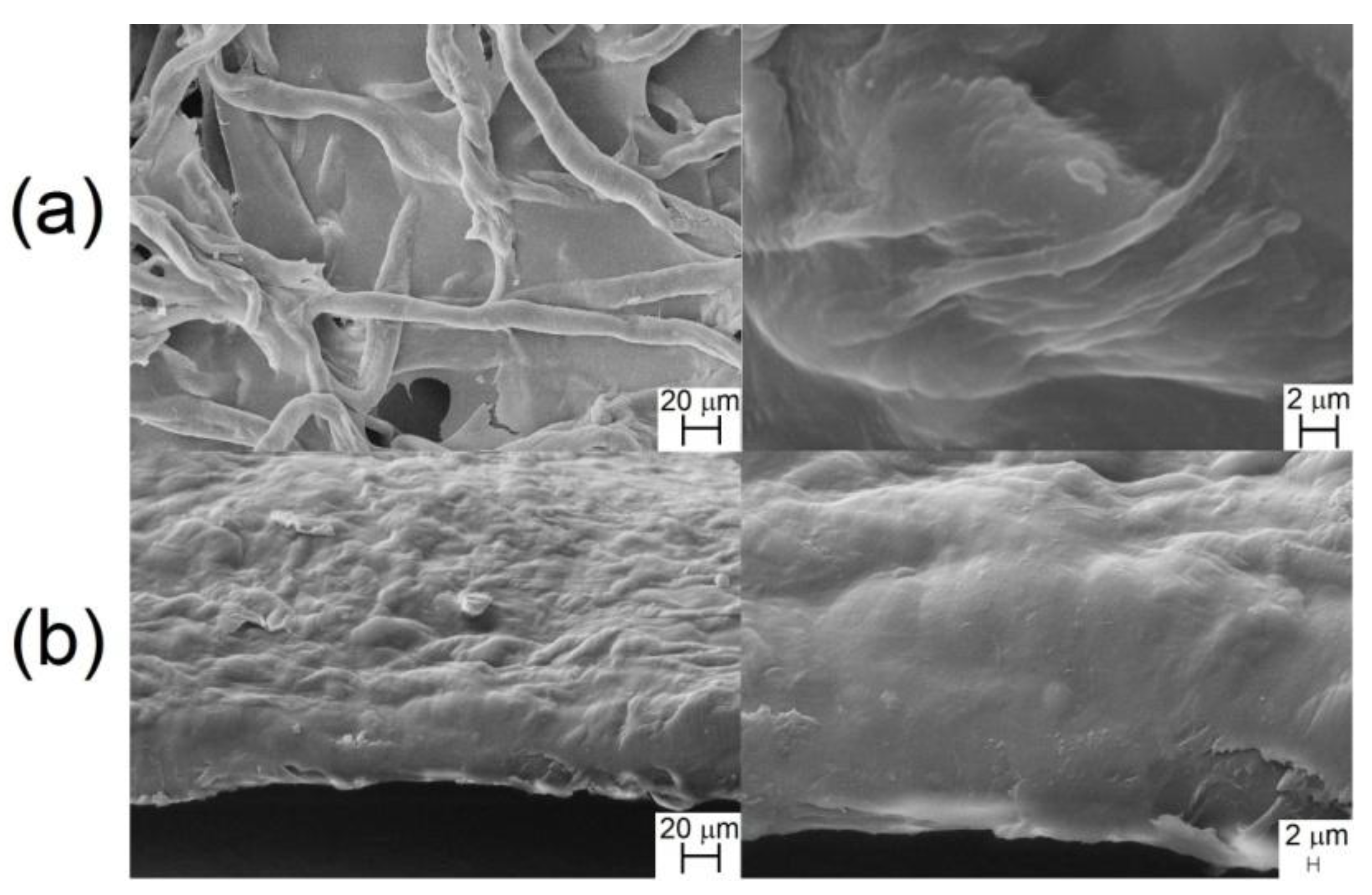

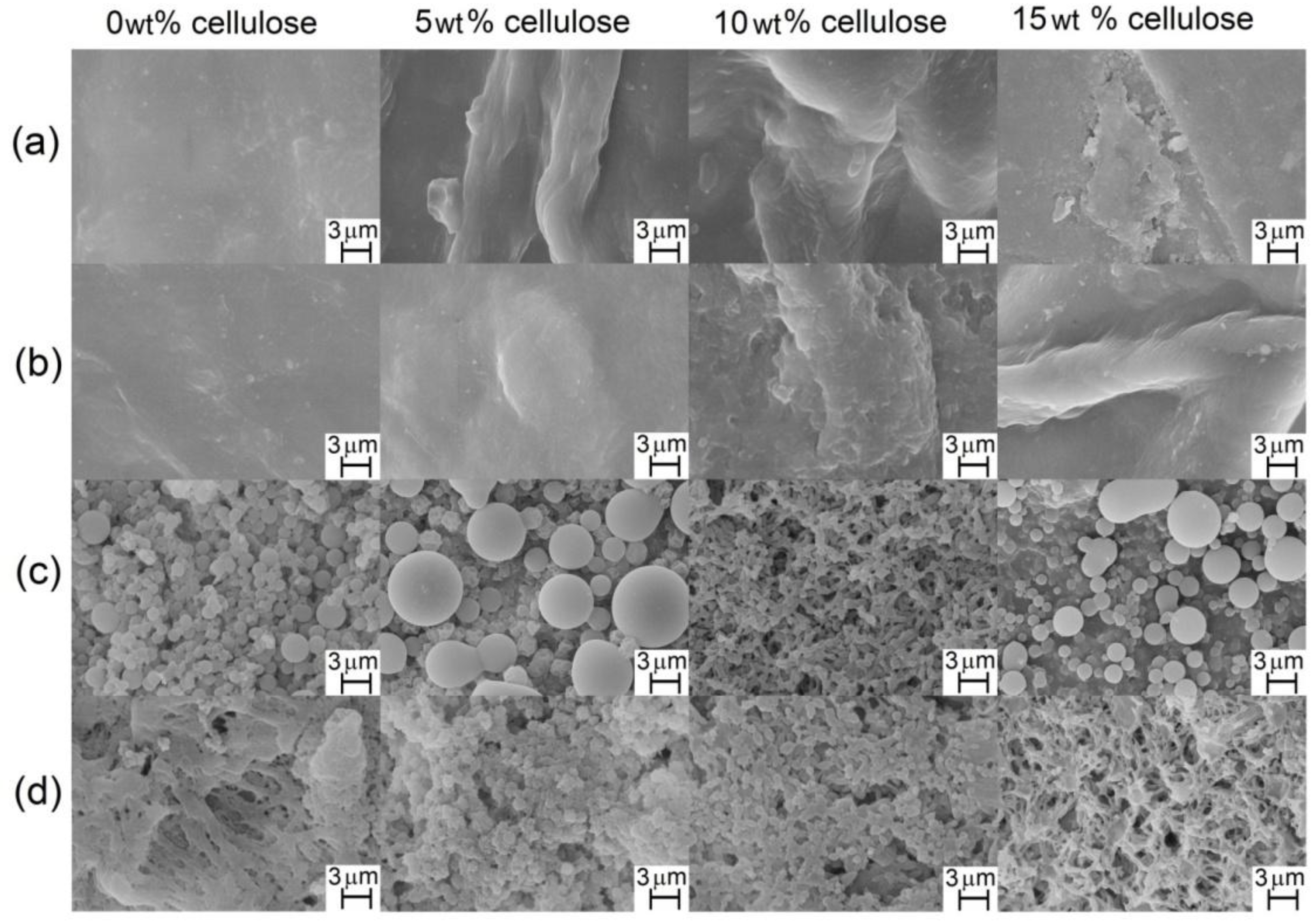

2.3.3. Morphological Surface Analyses

Scanning Electron Microscopy (SEM)

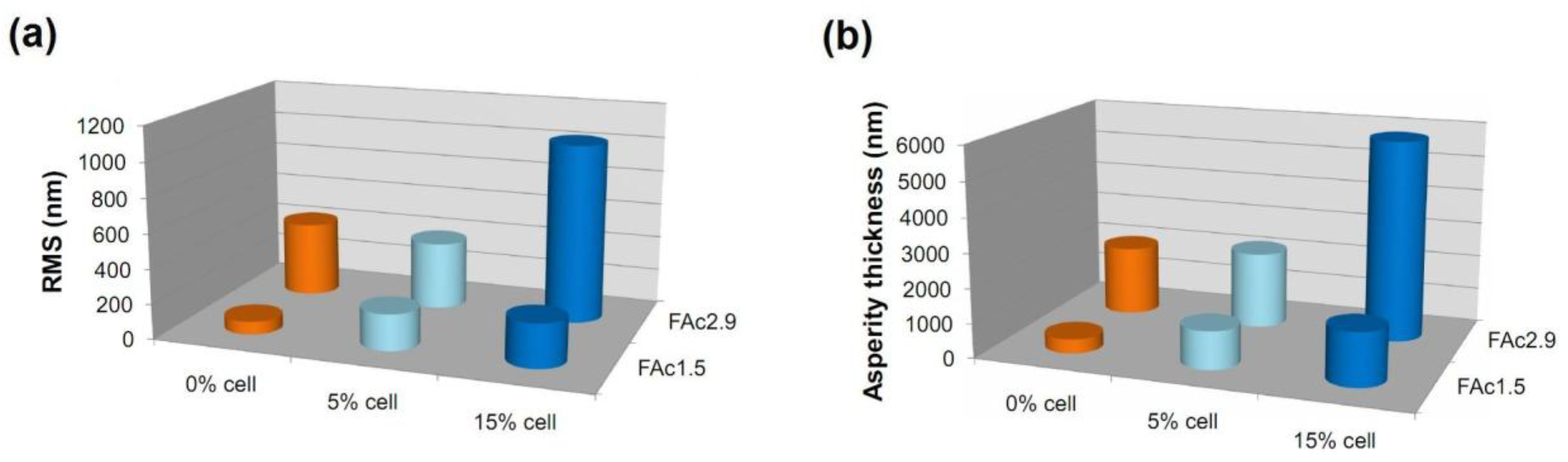

Atomic Force Microscopy (AFM)

2.3.4. Crystallinity Index (Ic)

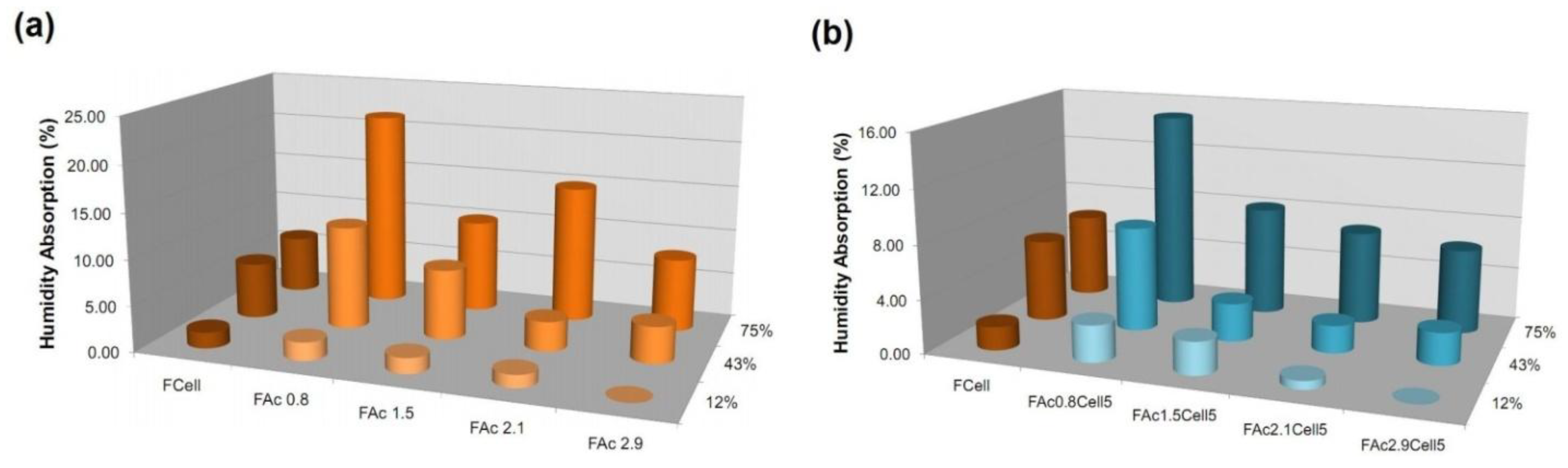

2.3.5. Humidity Absorption

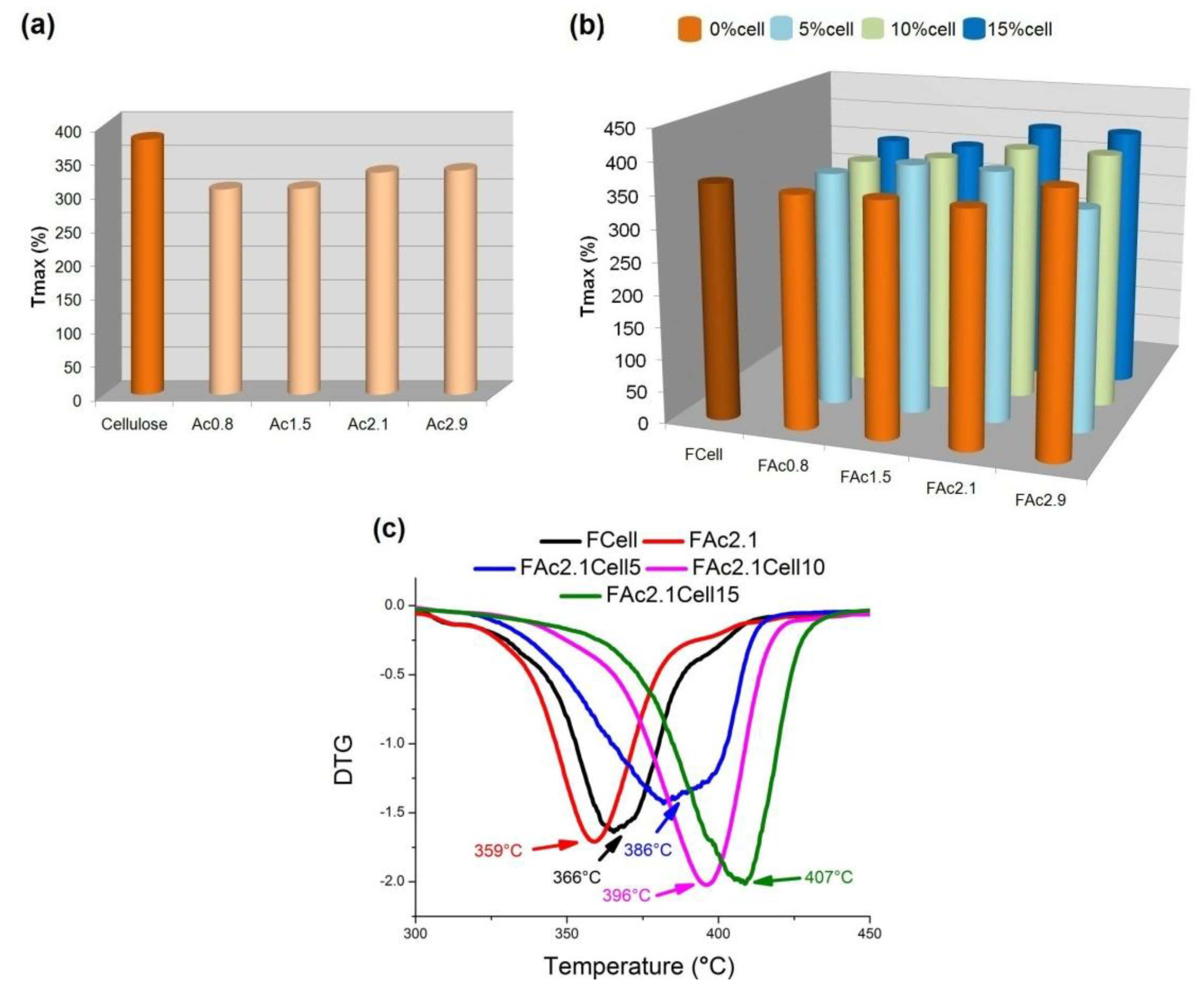

2.3.6. Thermogravimetric Analysis (TGA)

2.3.7. Tensile Properties

3. Experimental Section

3.1. Materials

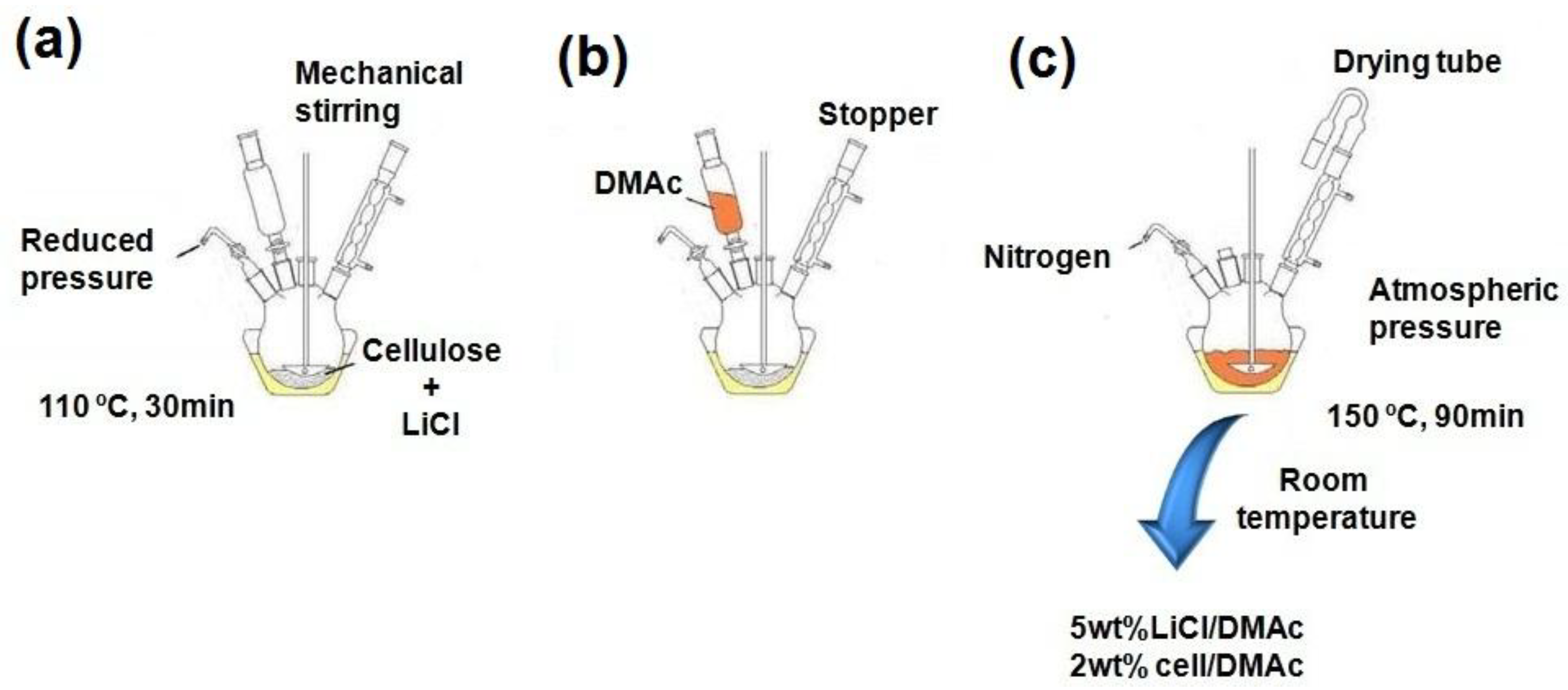

3.2. Cellulose Pre-Treatment

3.3. Dissolution and Acetylation of Cellulose

3.4. Characterization of Cellulose Acetates

3.4.1. Degree of Substitution (DS)

3.5. Elaboration of the Films

3.5.1. Cellulose Acetate Films

3.5.2. Cellulose Film

3.5.3. Cellulose Acetate/Cellulose Films

3.6. Characterization of Starting Materials and Cellulose Acetate/Cellulose Films

3.6.1. Crystallinity Index (Ic)

3.6.2. Thermogravimetric Analysis (TGA)

3.6.3. Elemental Analysis and Atomic Absorption

3.6.4. Determination of Molar Mass Distribution by Size-Exclusion Chromatography (SEC)

3.6.5. Morphological Analyses

Scanning Electron Microscopy (SEM)

Atomic Force Microscopy (AFM)

3.6.6. Humidity Absorption

3.6.7. Tensile Tests

4. Conclusions

Acknowledgments

References

- Silva, C.G.; Grelier, S.; Pichavant, F.; Frollini, E.; Castellan, A. Adding value to lignins isolated from sugarcane bagasse and Miscanthus. Ind. Crop. Prod. 2013, 42, 87–95. [Google Scholar] [CrossRef]

- Ramires, E.C.; Frollini, E. Tannin phenolic resins: Synthesis, characterization, and application as matrix in biobased composites reinforced with sisal fibers. Compos. Part B Eng. 2012, 43, 2851–2860. [Google Scholar] [CrossRef]

- Castro, D.O.; Ruvolo-Filho, A.; Frollini, E. Materials prepared from biopolyethylene and curaua fibers: Composites from biomass. Polym. Test. 2012, 31, 880–888. [Google Scholar] [CrossRef]

- Silva, C.G.; Oliveira, F.; Ramires, E.C.; Castellan, A.; Frollini, E. Composites from a forest biorefinery by-product and agrofibers: Lignosulfonate-Phenolic type matrices reinforced with sisal fibers. Tappi J. 2012, 11, 41–49. [Google Scholar]

- Cerrutti, B.M.; Souza, C.S.; Castellan, A.; Ruggiero, R.; Frollini, E. Carboxymethyl lignin as stabilizing agent in aqueous ceramic suspensions. Ind. Crop. Prod. 2012, 36, 108–115. [Google Scholar] [CrossRef]

- Cao, X.; Sun, S.; Peng, X.; Zhong, L.; Sun, R. Synthesis and characterization of cyanoethyl hemicelluloses and their hydrated products. Cellulose 2013, 20, 291–301. [Google Scholar] [CrossRef]

- Bujanovic, B.; Ralph, S.; Reiner, R.; Hirth, K.; Atalla, R. Polyoxometalates in oxidative delignification of chemical pulps: Effect on lignin. Materials 2010, 3, 1888–1903. [Google Scholar] [CrossRef]

- Pinto, R.J.B.; Neves, M.C.; Pascoal Neto, C.; Tito Trindade, T. Growth and chemical stability of copper nanostructures on cellulosic fibers. Eur. J. Inorg. Chem. 2012, 31, 5043–5049. [Google Scholar] [CrossRef]

- Foston, M.B.; Hubbell, C.A.; Ragauskas, A.J. Cellulose isolation methodology for NMR analysis of cellulose ultrastructure. Materials 2011, 4, 1985–2002. [Google Scholar] [CrossRef]

- De Paula, M.P.; Lacerda, T.M.; Zambon, M.D.; Frollini, E. Adding value to the Brazilian sisal: Acid hydrolysis of its pulp seeking production of sugars and materials. Cellulose 2012, 19, 975–992. [Google Scholar] [CrossRef]

- Lacerda, T.M.; de Paula, M.P.; Zambon, M.D.; Frollini, E. Saccharification of Brazilian sisal pulp: Evaluating the impact of mercerization on non-hydrolyzed pulp and hydrolysis products. Cellulose 2012, 19, 1–12. [Google Scholar] [CrossRef]

- Lacerda, T.M.; Zambon, M.D.; Frollini, E. Effect of acid concentration and pulp properties on hydrolysis reactions of mercerized sisal. Carbohydr. Polym. 2013, 93, 347–356. [Google Scholar] [CrossRef] [PubMed]

- Kaur, U.; Oberoi, H.S.; Bhargav, V.K.; Sharma-Shivappa, R.; Dhaliwal, S.S. Ethanol production rom alkali- and ozone-treated cotton stalks using thermotolerant Pichia kudriavzevii HOP-1. Ind. Crop. Prod. 2012, 37, 219–226. [Google Scholar] [CrossRef]

- Dutta, S.; De, S.; Alam, M.I.; Abu-Omar, M.M.; Saha, B. Direct conversion of cellulose and lignocellulosic biomass into chemicals and biofuel with metal chloride catalysts. J. Catal. 2012, 288, 8–15. [Google Scholar] [CrossRef]

- Mazzoli, R.; Lamberti, C.; Pessione, E. Engineering new metabolic capabilities in bacteria: Lessons from recombinant cellulolytic strategies. Trends Biotechnol. 2011, 30, 111–119. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, S.C.M.; Freire, C.S.R.; Silvestre, A.J.D.; Pascoal Neto, C.; Gandini, A. Novel materials based on chitosan and cellulose. Polym. Int. 2011, 60, 875–882. [Google Scholar] [CrossRef]

- Almeida, E.V.R.; Morgado, D.L.; Ramos, L.A.; Frollini, E. Sisal cellulose and its acetates: Generation of films and reinforcement in a one-pot process. Cellulose 2013, 20, 453–465. [Google Scholar] [CrossRef]

- Yang, Q.; Saito, T.; Isogai, A. Facile fabrication of transparent cellulose films with high water repellency and gas barrier properties. Cellulose 2012, 19, 1913–1921. [Google Scholar] [CrossRef]

- Trovatti, E.; Fernandes, S.C.M.; Rubatat, L.; da Silva Perez, D.; Freire, C.S.R.; Silvestre, A.J.D.; Pascoal Neto, C. Pullulan–nanofibrillated cellulose composite films with improved thermal and mechanical properties. Compos. Sci. Technol. 2012, 72, 1556–1561. [Google Scholar] [CrossRef]

- Peydecastaing, J.; Vaca-Garcia, C.; Borredon, E. Bi-acylation of cellulose: Determining the relative reactivities of the acetyl and fatty-acyl moieties. Cellulose 2011, 18, 1015–1021. [Google Scholar] [CrossRef] [Green Version]

- Athauda, T.J.; Ozer, R.R. Investigation of the effect of dual-size coatings on the hydrophobicity of cotton surface. Cellulose 2012, 19, 1031–1040. [Google Scholar] [CrossRef]

- Budimir, A.; Vukusic, S.B.; Flincec, S.G. Study of antimicrobial properties of cotton medical textiles treated with citric acid and dried/cured by microwaves. Cellulose 2012, 19, 289–296. [Google Scholar] [CrossRef]

- Cardoso, G.D.; Alves, P.L.C.A.; Severino, L.S.; Vale, L.S. Critical periods of weed control in naturally green colored cotton BRS Verde. Ind. Crop. Prod. 2011, 34, 1198–1202. [Google Scholar] [CrossRef]

- Nourbakhsh, S.; Ashjaran, A. Laser treatment of cotton fabric for durable antibacterial properties of silver nanoparticles. Materials 2012, 5, 1247–1257. [Google Scholar] [CrossRef]

- Ramos, L.A.; Assaf, J.M.; El Seoud, O.A.; Frollini, E. Influence of supra-molecular structure and physico-chemical properties on the dissolution of celluloses in lithium chloride/N,N-dimethylacetamide solvent system. Biomacromolecules 2005, 6, 2638–2647. [Google Scholar] [CrossRef] [PubMed]

- Ramos, L.A.; Morgado, D.L.; El Seoud, O.A.; da Silva, V.C.; Frollini, E. Acetylation of cellulose in LiCl-N,N-dimethylacetamie: First report on the correlation between the reaction efficiency and the aggregation number of dissolved cellulose. Cellulose 2011, 18, 385–392. [Google Scholar] [CrossRef]

- Ramos, L.A.; Morgado, D.L.; Gessner, F.; Frollini, E.; El Seoud, O.A. A physical organic chemistry approach to dissolution of cellulose: Effects of cellulose mercerization on its properties and on the kinetics of its decrystallization. Arkivoc 2011, vii, 416–425. [Google Scholar] [CrossRef]

- De Paula, M.P.; Lacerda, T.M.; Frollini, E. Sisal cellulose acetates obtaines from heterogeneous reactions. Express Polym. Lett. 2008, 2, 423–428. [Google Scholar] [CrossRef]

- Almeida, E.V.R.; Frollini, E.; Castellan, A.; Coma, V. Chitosan, sisal cellulose, and biocomposite chitosan/sisal cellulose films prepared from thiourea/NaOH aqueous solution. Carbohydr. Polym. 2010, 80, 655–664. [Google Scholar] [CrossRef]

- Morgado, D.L.; Frollini, E.; Castellan, A.; Rosa, D.S.; Coma, V. Biobased films prepared from NaOH/thiourea aqueous solution of chitosan and linter cellulose. Cellulose 2011, 18, 699–712. [Google Scholar] [CrossRef]

- Gericke, M.; Fardim, P.; Heinze, T. Ionic liquids—Promising but challenging solvents for homogeneous derivatization of cellulose. Molecules 2012, 17, 7458–7502. [Google Scholar] [CrossRef] [PubMed]

- El Seoud, O.A.; Koschella, A.; Fidale, L.C.; Dorn, S.; Heinze, T. Applications of ionic liquids in carbohydrate chemistry: A window of opportunities. Biomacromolecules 2007, 8, 2629–2647. [Google Scholar] [CrossRef] [PubMed]

- Sathitsuksanoh, N.; Zhu, Z.; Zhang, Y.-H.P. Cellulose solvent-based pretreatment for corn stover and avicel: Concentrated phosphoric acid versus ionic liquid [BMIM]Cl. Cellulose 2012, 19, 1161–1172. [Google Scholar] [CrossRef]

- Nawaz, H.; Casarano, R.; El Seoud, O.A. First report on the kinetics of the uncatalyzed esterification of cellulose under homogeneous reaction conditions: A rationale for the effect of carboxylic acid anhydride chain-length on the degree of biopolymer substitution. Cellulose 2012, 19, 199–207. [Google Scholar] [CrossRef]

- Glasser, W.G.; Becker, U.; Todd, J.G. Novel cellulose derivatives. Part VI. Preparation and thermal analysis of two novel cellulose esters with fluorine-containing substituents. Carbohydr. Polym. 2000, 42, 393–400. [Google Scholar] [CrossRef]

- Raus, V.; Sturcova, A.; Dybal, J.; Slouf, M.; Vackova, T.; Salek, P.; Kobera, L.; Vlcek, P. Activation of cellulose by 1,4-dioxane for dissolution in N,N-dimethylacetamide/LiCl. Cellulose 2012, 19, 1893–1906. [Google Scholar] [CrossRef]

- Crepy, L.; Monchau, F.; Chai, F.; Raoul, G.; Hivart, P.; Hildebrand, H.F.; Martin, P.; Joly, N. Evaluation of a bio-based hydrophobic cellulose laurate film as biomaterial—Study on biodegradation and cytocompatibility. J. Biomed. Mater. Res. B 2012, 100B, 1000–1008. [Google Scholar]

- Liu, H.; Kar, N.; Edgar, K.J. Direct synthesis of cellulose adipate derivatives using adipic anhydride. Cellulose 2012, 19, 1279–1293. [Google Scholar] [CrossRef]

- Regiani, A.M.; Frollini, E.; Marson, G.A.; Arantes, G.M.; El Seoud, O.A. Some aspects of acylation of cellulose under homogeneous solution conditions. J. Polym. Sci. A Polym. Chem. 1999, 37, 1357–1363. [Google Scholar] [CrossRef]

- Chen, W.; Su, Y.; Zheng, L.; Wang, L.; Jiang, Z. The improvement of oil/water separation perfomance of cellulose acetate-graft-polyacrylonitrile membranes. J. Membr. Sci. 2009, 337, 98–105. [Google Scholar] [CrossRef]

- Ho, F.F.L.; Klosiewicz, D.W. Proton nuclear magnetic resonance spectrometry for determination of substituents and their distribution in carboxymethylcellulose. Anal. Chem. 2002, 52, 913–916. [Google Scholar] [CrossRef]

- Mohammadi, T.; Saljoughi, E. Effect of production conditions on morphology and permeability of asymmetric cellulose acetate membranes. Desalination 2009, 243, 1–7. [Google Scholar] [CrossRef]

- Amim, J., Jr.; Petri, D.F.S.; Maia, F.C.B.; Miranda, P.B. Ultrafhin cellulose ester films: Preparation, characterization and protein immobilization. Quim. Nova 2010, 33, 2064–2069. [Google Scholar] [CrossRef]

- Morgado, D.L.; Martins, V.C.A.; Plepis, A.M.G.; Frollini, E. Aggregation of cellulose acetates chains in LiCl/DMAc: Evaluation via viscometry. Polímeros 2011, 21, 143–145. [Google Scholar] [CrossRef]

- Edgar, K.J.; Arnold, K.M.; Blount, W.W.; Lawniczak, J.E.; Lowman, D.W. Synthesis and properties of cellulose acetates. Macromolecules 1995, 28, 4122–4128. [Google Scholar] [CrossRef]

- Ass, B.A.P.; Belgacem, M.N.; Frollini, E. Mercerized linter cellulose: Characterization and acetylation in N,N-dimethylacetamide/lithium chloride. Carbohydr. Polym. 2006, 63, 19–29. [Google Scholar] [CrossRef]

- Ciacco, G.T.; Morgado, D.L.; Frollini, E.; Possidonio, S.; El Seoud, O.A. Some aspects of acetylation of untreated and mercerized sisal cellulose. J. Braz. Chem. Soc. 2010, 21, 71–77. [Google Scholar] [CrossRef] [Green Version]

- Morgado, D.L.; Frollini, E. Thermal decomposition of mercerized linter cellulose and its acetates obtained from a homogeneous reaction. Polímeros 2011, 21, 111–117. [Google Scholar] [CrossRef] [Green Version]

- Dort, I. On the possibility of quantitative evaluation of polymer-solvent interaction from the Huggins viscosity constant. Polymer 1988, 29, 490–499. [Google Scholar] [CrossRef]

- McCormick, C.L.; Nonaka, T.; Johnson, C.B. Water-soluble copolymers: 27 Synthesis and aqueous solution behavior of associative acrylamide/N-alkylacrylamide copolymers. Polymer 1988, 29, 731–738. [Google Scholar] [CrossRef]

- Roy, C.; Budtova, T.; Navard, P. Rheological properties and gelation of aqueous cellulose-NaOH solutions. Biomacromolecules 2003, 4, 259–264. [Google Scholar] [CrossRef] [PubMed]

- El Seoud, O.A.; Marson, G.A.; Ciacco, G.T.; Frollini, E. An efficient, one-pot acylation of cellulose under homogeneous reaction conditions. Macromol. Chem. Physic. 2000, 201, 882–889. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, X. Characteristics and degradation of chitosan/cellulose acetate microspheres with different model drugs. Front. Mater. Sci. China 2008, 2, 417–425. [Google Scholar] [CrossRef]

- Wang, F.; Yang, Y.; Zhang, X.; Zhu, X.; Chung, T.; Moochhala, S. Cellulose acetate membranes for transdermal delivery of scopolamine base. Mater. Sci. Eng. C 2002, 20, 93–100. [Google Scholar] [CrossRef]

- Meier, M.; Kanis, L.A.; Soldi, V. Characterization and drug-permeation profiles of microporous and dense cellulose acetate membranes: influence of plasticizer and pore forming agent. Int. J. Pharmaceut. 2004, 278, 99–110. [Google Scholar] [CrossRef]

- Marson, G.A.; El Seoud, O.A. A novel, efficient procedure for acylation of cellulose under homogeneous solution conditions. J. Appl. Polym. Sci. 1999, 74, 1355–1360. [Google Scholar] [CrossRef]

- Huang, M.-R.; Li, X.-G. Thermal degradation of cellulose and cellulose esters. J. Appl. Polym. Sci. 1998, 68, 293–304. [Google Scholar] [CrossRef]

- Li, X.G. High-Resolution thermogravimetry of cellulose esters. J. Appl. Polym. Sci. 1999, 71, 573–578. [Google Scholar] [CrossRef]

- Lawton, J.W. Effect of starch type on the properties of starch containing films. Carbohydr. Polym. 1996, 29, 203–208. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Wongchaiya, P. Effect of relative humidity on mechanical properties of blended chitosan methylcellulose film. Chiang Mai J. Sci. 2012, 39, 133–137. [Google Scholar]

- Srinivasa, P.C.; Ravi, R.; Tharanathan, R.N. Effect of storage conditions on the tensile properties of eco-friendly chitosan films by response surface methodology. J. Food Eng. 2007, 80, 184–189. [Google Scholar] [CrossRef]

- Cuq, B.; Gontard, N.; Aymard, C.; Guilbert, S. Relative humidity and temperature effects on mechanical and water vapor barrier properties of myofibrillar protein-based films. Polym. Gels Netw. 1997, 5, 1–15. [Google Scholar] [CrossRef]

- Chang, Y.P.; Cheah, P.B.; Seow, C.C. Plasticizing-antiplasticizing effects of water on physical properties of tapioca starch films in the glassy state. J. Food Sci. 2000, 65, 445–451. [Google Scholar] [CrossRef]

- Borges, J.P.; Godinho, M.H.; Martins, A.F.; Stamatialis, D.F.; de Pinho, M.N.; Belgacem, M.N. Tensile properties of cellulose fiber reinforced hydroxypropylcellulose films. Polym. Compos. 2004, 25, 102–110. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Wibowo, A.; Misra, M.; Drzal, L.T. Effect of process engineering on the performance of natural fiber reinforced cellulose acetate biocomposites. Compos. A Appl. Sci. Manuf. 2004, 35, 363–370. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Frone, A.M.; Ghiurea, M.; Spataru, C.I.; Radovici, C.; Iorga, M.D. Properties of Polymer Composites with Cellulose Microfibrils. In Advances in Composite Materials—Ecodesign and Analysis; InTech: Brahim Attaf, Croatia, 2001; pp. 103–122. [Google Scholar]

- Cheremisinoff, N.P. Evaporating and Drying Equipment. In Handbook of Chemical Processing Equipment; Butterworth-Heinemann: Woburn, MA, USA, 2000; pp. 94–161. [Google Scholar]

- American Society for Testing and Materials (ASTM). Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions, ASTM E 104–02. In Annual Book of ASTM Standard; ASTM: West Conshohocken, PA, 2003; Volume 11.03, pp. 1133–1137. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Morgado, D.L.; Rodrigues, B.V.M.; Almeida, E.V.R.; Seoud, O.A.E.; Frollini, E. Bio-based Films from Linter Cellulose and Its Acetates: Formation and Properties. Materials 2013, 6, 2410-2435. https://doi.org/10.3390/ma6062410

Morgado DL, Rodrigues BVM, Almeida EVR, Seoud OAE, Frollini E. Bio-based Films from Linter Cellulose and Its Acetates: Formation and Properties. Materials. 2013; 6(6):2410-2435. https://doi.org/10.3390/ma6062410

Chicago/Turabian StyleMorgado, Daniella L., Bruno V. M. Rodrigues, Erika V. R. Almeida, Omar A. El Seoud, and Elisabete Frollini. 2013. "Bio-based Films from Linter Cellulose and Its Acetates: Formation and Properties" Materials 6, no. 6: 2410-2435. https://doi.org/10.3390/ma6062410