Theoretical Research on Thermal Shock Resistance of Ultra-High Temperature Ceramics Focusing on the Adjustment of Stress Reduction Factor

Abstract

:1. Introduction

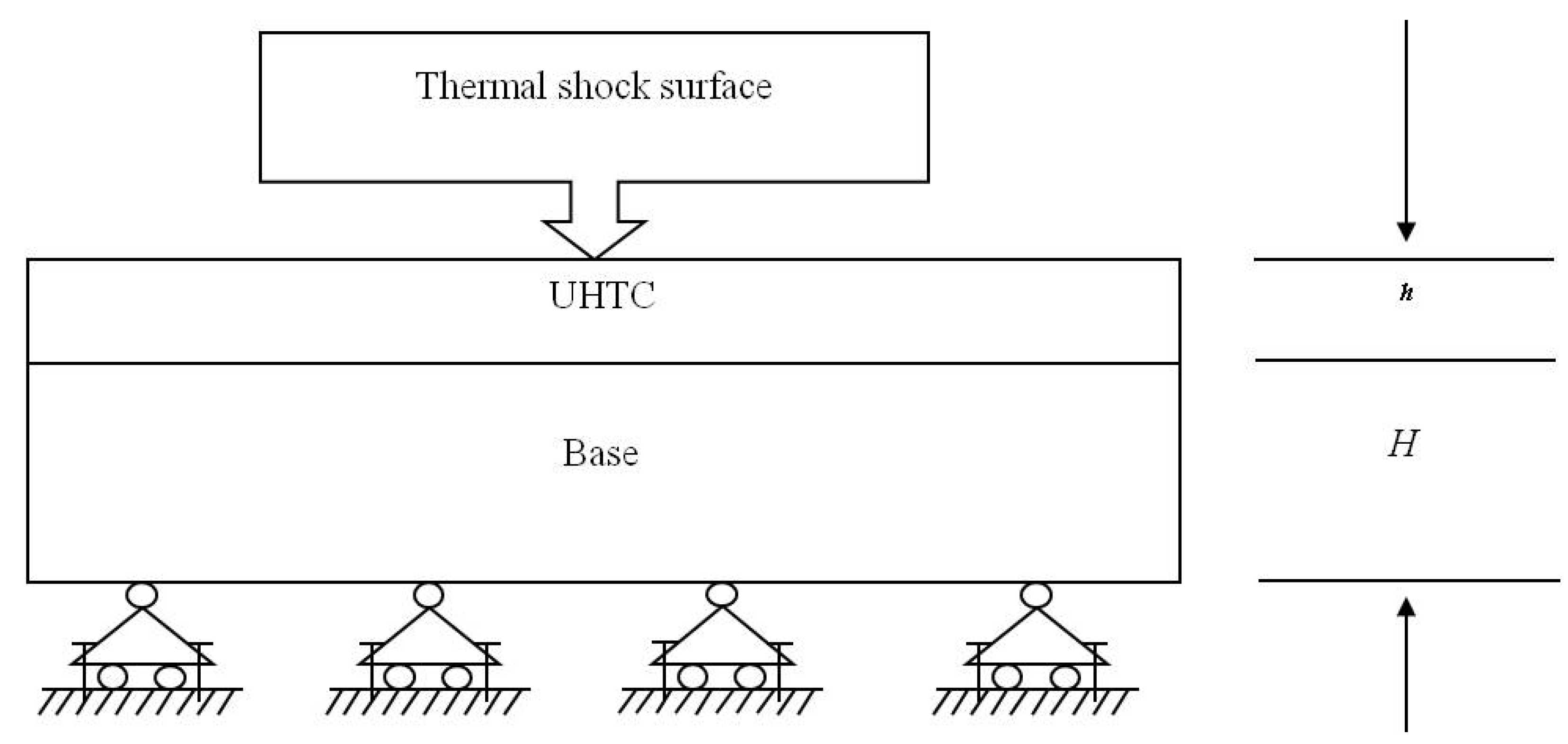

2. Derivation of the Theoretical Model

- The model is a two well-bonded plate, which doesn’t consider the interface damage.

- The upper is the UHTC plate, and the lower is the matrix base. These two plates are assumed to have the same plane geometry size for the convenience of theoretical model derivation.

- There is no heat exchange between the UHTC plate and the matrix base, and the temperature of the matrix base is constant, being equal to the predefined room temperature field of 25 °C.

- The plate is continuous, homogenous, isotropic, elastic and submits to small deformation hypothesis.

2.1. Heating Thermal Shock Conditions

2.2. Cooling Thermal Shock Conditions

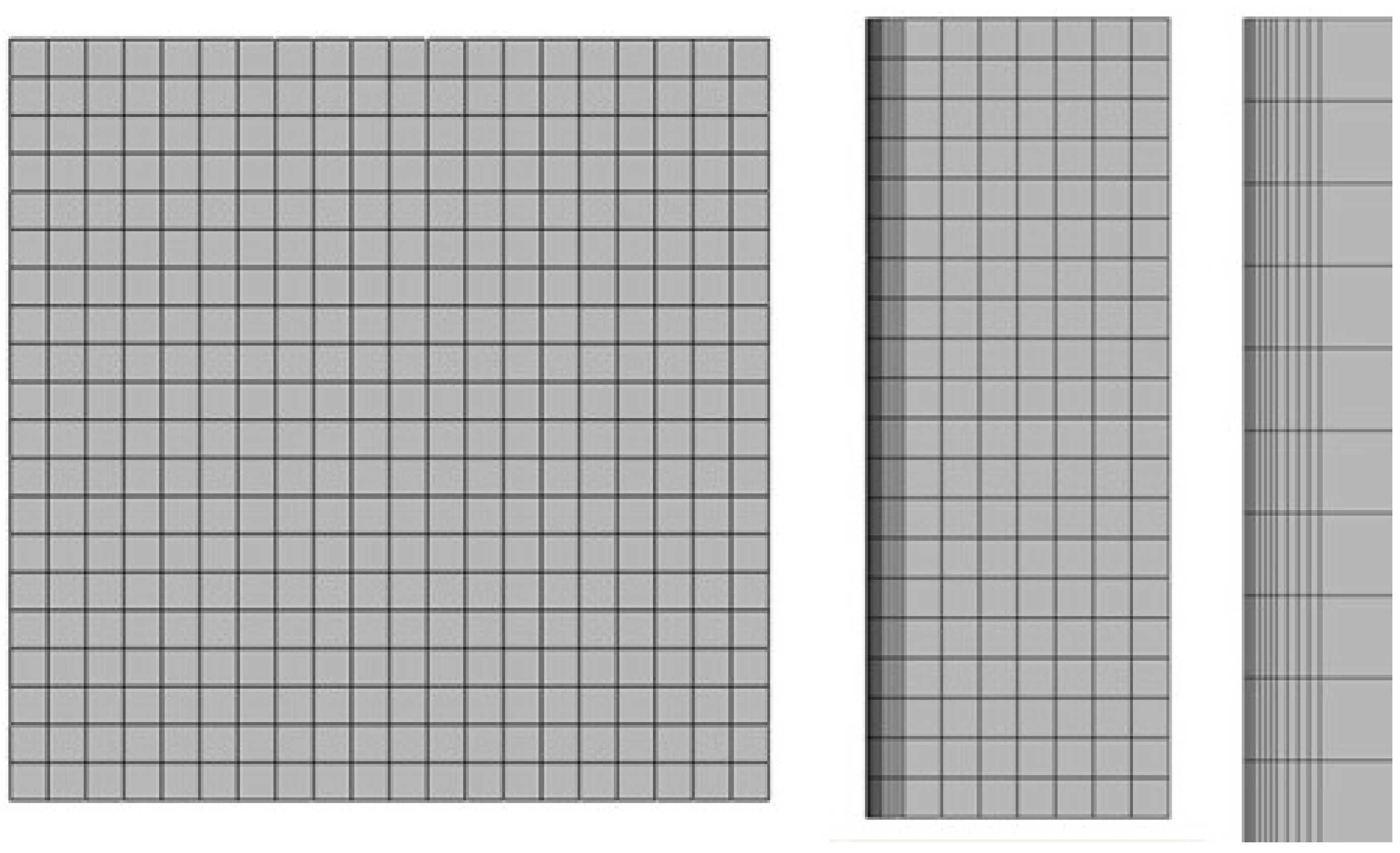

2.3. Finite Element Model

3. Results and Discussion

| Material parameter | Values and expressions |

|---|---|

| E(T) (GPa) | See Equation (4) |

| E0 (GPa) | 440.733 |

| B0, B1, B2 | 2.54, 1.9, 0.363 |

| (MPa) | 448 |

| 0.12 | |

| Tm (°C) | 3400 |

| Cp(T) [J/(kg·°C)] | 1532.8 + 1.635 × 10−1 × (T + 273.15) − 4.8086 × 107 × (T + 273.15)−2 |

| k [W/(m·°C)] | −8.3455 × lnT + 127.68 |

| Α (°C−1) | (2lnT − 5) × 10−6 |

| Material parameters | Values | Values | Values |

|---|---|---|---|

| T (°C) | 1300 | 965 | 1132.5 |

| h (m) | 0.007 | 0.007 | 0.007 |

| [W /(m2·°C)] | 2 × 104 | 2 × 104 | 2 × 104 |

| ρ (kg/m3) | 1.05 × 104 | 1.05 × 104 | 1.05 × 104 |

| k [W/(m·°C)] | 67.84 | 70.33 | 68.99 |

| Cp(T) [J/(kg·°C)] | 1.771 × 103 | 1.704 × 103 | 1.738 × 103 |

| β | 2.06 | 1.99 | 2.03 |

| F0 | 0.125 | 0.134 | 0.129 |

| C | 0.1551 | 0.1583 | 0.1565 |

| Plate thickness: h(m) | C |

|---|---|

| 0.007 | 0.16 |

| 0.014 | 0.11 |

| 0.021 | 0.084 |

| 0.028 | 0.07 |

| 0.035 | 0.06 |

| 0.042 | 0.05 |

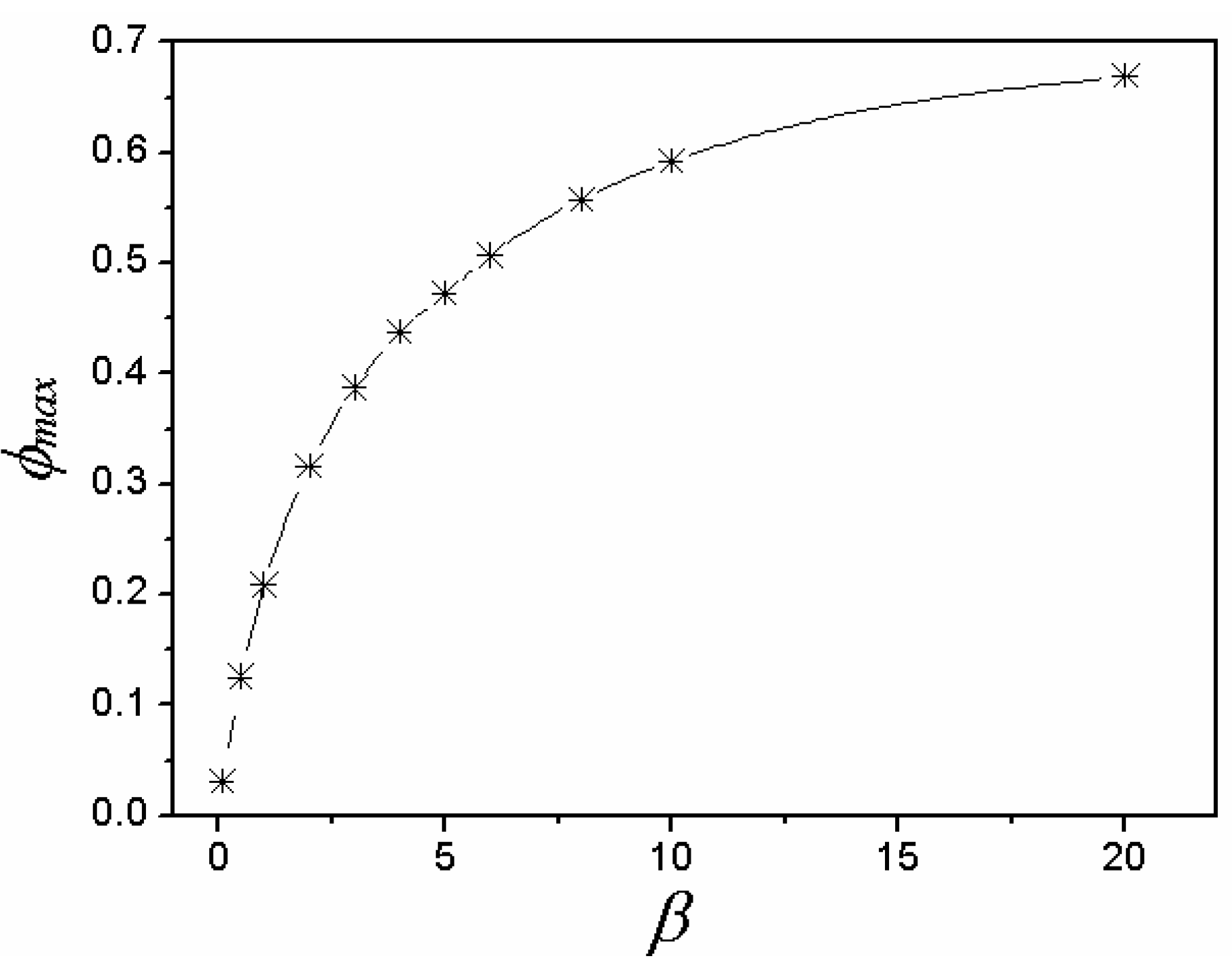

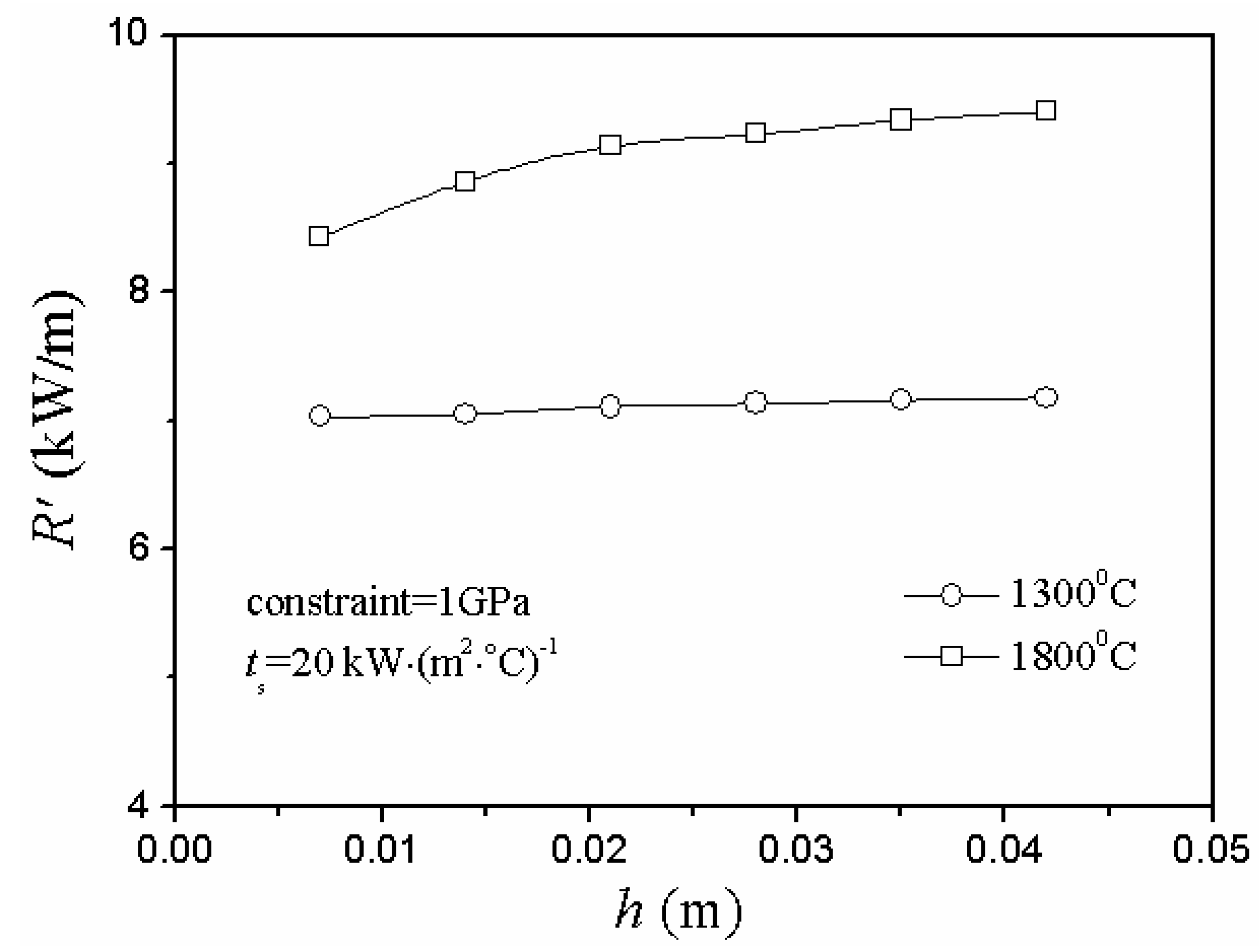

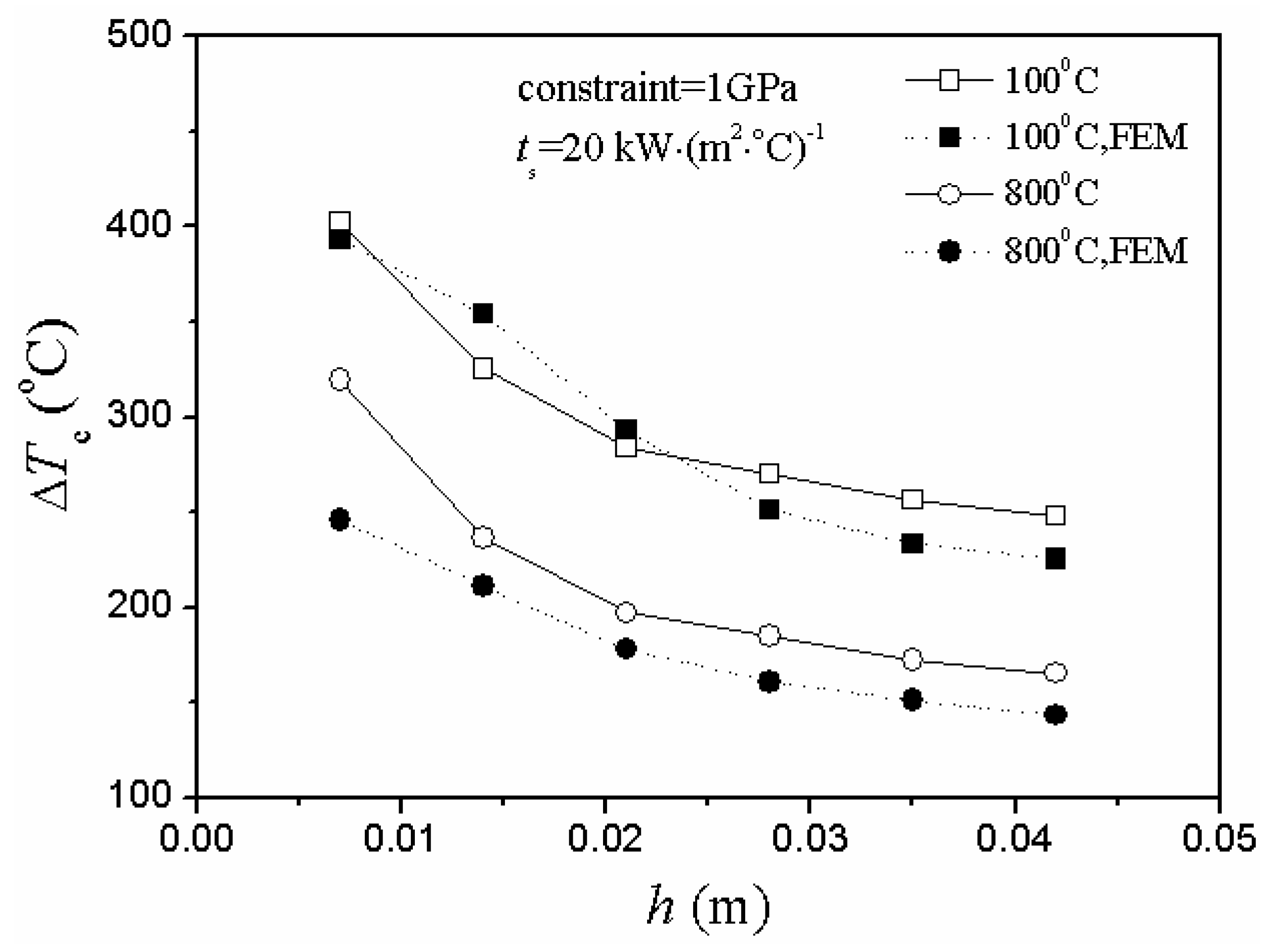

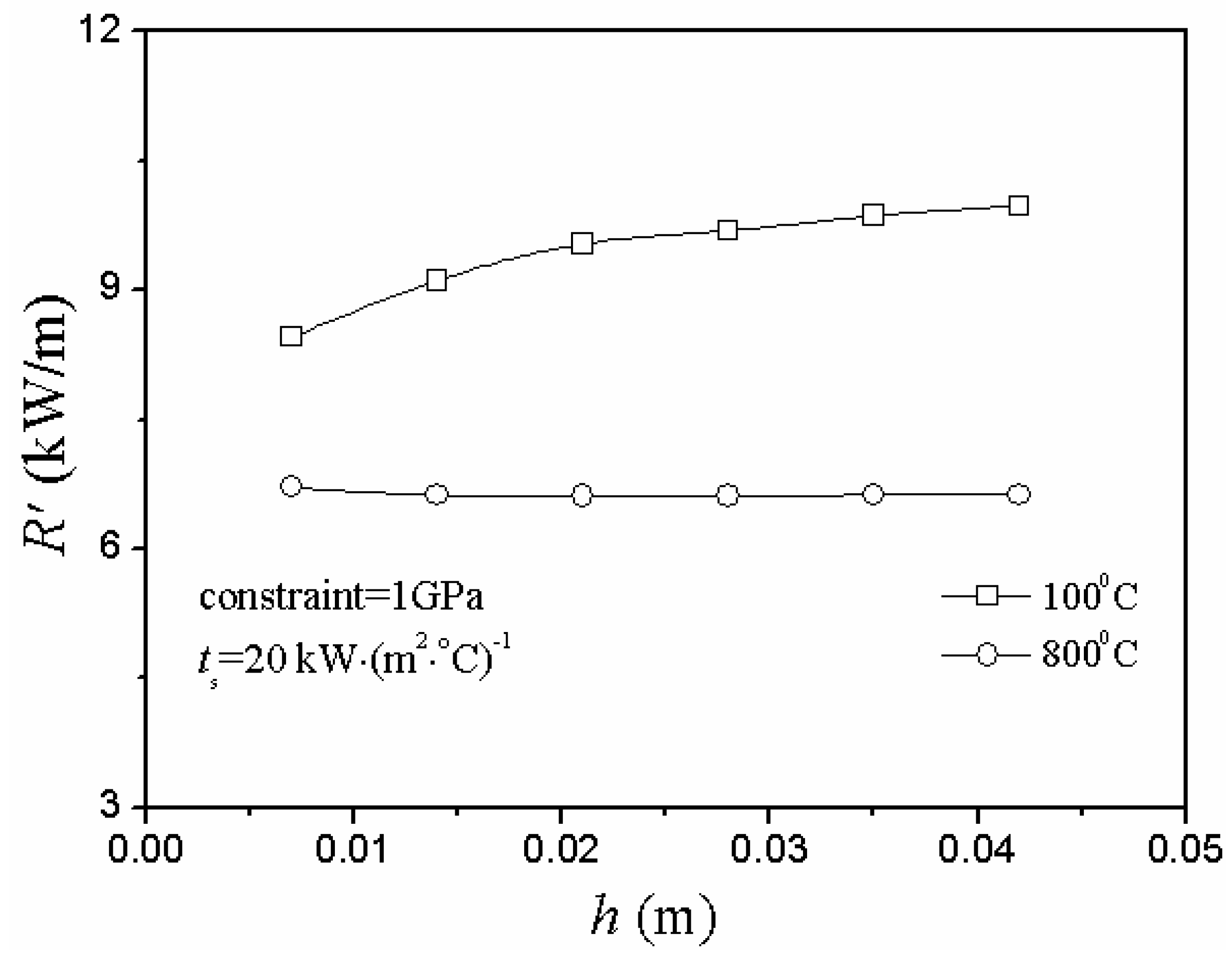

3.1. Adjustment of Stress Reduction Factor

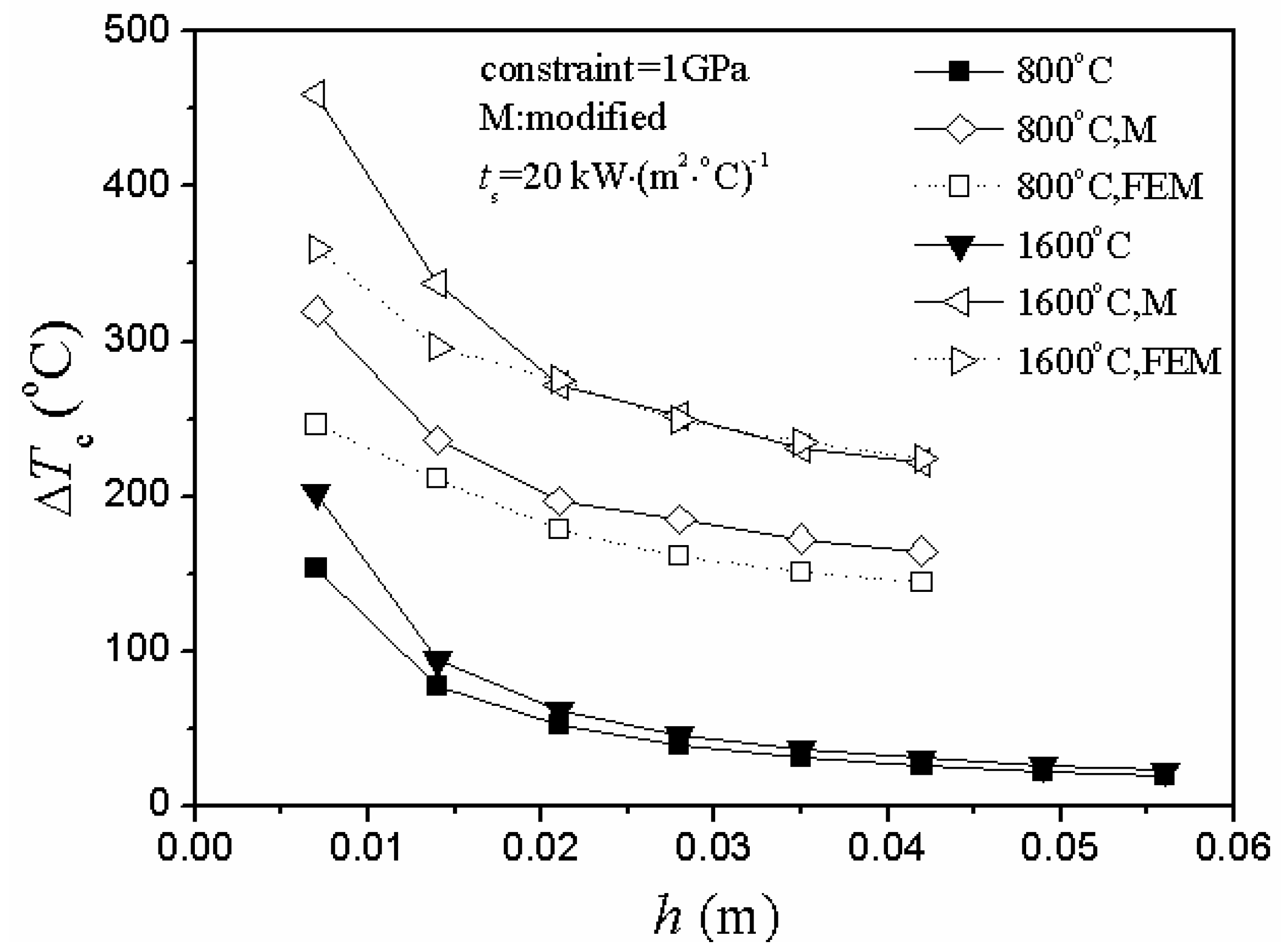

- As the plate thickness increased, the critical rupture temperature difference gradually decreased and slowly approached zero.

- There was a big difference between the theoretical value and the numerical simulation value of the critical rupture temperature difference in the unmodified situation.

- The theoretical and simulation results shared the same trend in different thermal shock conditions, and the value range of the modified situation was more similar to the simulation value.

- As the plate thickness increased, the theoretical value of the critical rupture temperature difference gradually decreased and slowly approached a constant (nonzero). Besides, the difference between the theoretical and simulation results also gradually decreased, and the entire control results tended toward convergence.

3.2. Limitations of the Applicable Range of the Second TSR Parameter

3.3. A Danger Region of Thermal Shock Initial Temperature

4. Conclusions

Acknowledgments

References

- Wang, C.R.; Yang, J.M.; Hoffman, W.P. Thermal stability of refractory carbide/boride composites. Mater. Chem. Phys. 2002, 74, 272–281. [Google Scholar] [CrossRef]

- Gasch, M.; Ellerby, D.; Irby, E.; Beckman, S.; Gusman, M.; Johnson, S. Processing properties and arc jet oxidation of hafnium diboride-silicon carbide ultra high temperature ceramics. J. Mater. Sci. 2004, 39, 5925–5937. [Google Scholar] [CrossRef]

- Opeka, M.M.; Talmy, I.G.; Eric, J.; Wuchina, E.J.; James, A.Z.; Causey, S.J. Mechanical, thermal and oxidation properties of refractory hafnium and zirconium compounds. J. Eur. Ceram. Soc. 1999, 19, 2405–2414. [Google Scholar] [CrossRef]

- Cheng, T.B.; Li, W.G.; Fang, D.N. Thermal shock resistance of ultra-high temperature ceramics under aerodynamic thermal environments. AIAA J. 2012, in press. [Google Scholar]

- Kingery, W.D. Factors affecting thermal stress resistance of ceramic materials. J. Am. Ceram. Soc. 1955, 38, 3–15. [Google Scholar] [CrossRef]

- Kingery, W.D.; Bowen, H.K.; Uhlmann, D.R. Introduction to ceramics, 2nd ed.; Wiley-Interscience: New York, NY, USA, 1976. [Google Scholar]

- Cheng, C.M. Resistance to thermal shock. J. Am. Rocket Soc. 1951, 21, 147–153. [Google Scholar] [CrossRef]

- Hasselman, D.P.H. Elastic energy at fracture and surface energy as design criteria for thermal shock. J. Am. Ceram. Soc. 1963, 46, 535–540. [Google Scholar] [CrossRef]

- Hasselman, D.P.H. Unified theory of thermal shock fracture initiation and crack propagation in brittle ceramics. J. Am. Ceram. Soc. 1969, 52, 600–604. [Google Scholar] [CrossRef]

- Han, J.C.; Wang, B.L. Thermal shock resistance of ceramics with temperature-dependent material properties at elevated temperature. Acta Mater. 2011, 59, 1373–1382. [Google Scholar] [CrossRef]

- Meng, S.H.; Liu, G.Q.; Guo, Y.; Xu, X.H.; Song, F. Mechanisms of thermal shock failure for ultra-high temperature ceramic. Mater. Des. 2009, 30, 2108–2112. [Google Scholar] [CrossRef]

- Jin, Z.H.; Batra, R.C. Thermal shock cracking in a metal-particle-reinforced ceramic matrix composite. Eng. Fract. Mech. 1999, 62, 339–350. [Google Scholar] [CrossRef]

- Zhang, X.H.; Xu, L.; Du, S.Y.; Han, W.B.; Han, J.C.; Liu, C.Y. Thermal shock behavior of SiC-whisker reinforced diboride ultra-high-temperature ceramics. Scripta Mater. 2008, 59, 55–88. [Google Scholar] [CrossRef]

- Li, W.G.; Cheng, T.B.; Li, D.Y.; Fang, D.N. Numerical simulation for thermal shock resistance of ultra-high temperature ceramics considering the effects of initial stress field. Adv. Mater. Sci. Eng. 2011, 2011. [Google Scholar] [CrossRef]

- Li, W.G.; Wang, R.Z.; Li, D.Y.; Fang, D.N. A model of temperature-dependent young’s modulus for ultra-high temperature ceramics. Phys. Res. Int. 2011, 2011, 1–3. [Google Scholar] [CrossRef]

- Li, W.G.; Yang, F.; Fang, D.N. The temperature-dependent strength model for ultra-high temperature ceramics. Acta Mech. Sinica 2010, 26, 235–239. [Google Scholar] [CrossRef]

- Li, W.G.; Fang, D.N. Thermal shock resistance of ultra-high temperature ceramics. Key Eng. Mater. 2008, 368–372, 1782–1784. [Google Scholar] [CrossRef]

- Green, D.J. Strength and engineering design. In An Introduction to the Mechanical Properties of Ceramics; Cambridge University Press: Cambridge, UK, 1998; pp. 275–280. [Google Scholar]

- Li, W.G.; Cheng, T.B.; Zhang, R.B.; Fang, D.N. Properties and appropriate conditions of stress reduction factor and thermal shock resistance parameters for ceramics. Appl. Math. Mech. 2012, 33, 1351–1360. [Google Scholar] [CrossRef]

- Manson, S.S. Behavior of materials under conditions of thermal stress. In NACA Technical Note 2933; National Advisory Committee for Aeronautics: Washington D.C., USA, 1953. [Google Scholar]

- Wuchina, E.J.; Opeka, M.M.; Causey, S.; Buesking, K.; Spain, J.; Cull, A.; Routbort, J.; Guitierrez-mora, F. Designing for ultrahigh-temperature applications: The mechanical and thermal properties of HfB2, HfCx, HfNx and αHf(N). J. Mater. Sci. 2004, 39, 5939–5949. [Google Scholar] [CrossRef]

- Lewis, D. Comparison of critical ΔTc values in thermal shock with the R parameter. J. Am. Ceram. Soc. 1980, 63, 713–714. [Google Scholar] [CrossRef]

- Becher, P.F.; Lewis, D., III; Garman, K.R.; Gonzalez, A.C. Thermal-shock resistance of ceramics-size and geometry-effects in quench tests. Am. Ceram. Soc. Bull. 1980, 59, 542–545. [Google Scholar]

- Collin, M.; Rowcliffe, D. Analysis and prediction of thermal shock in brittle materials. Acta Mater. 2000, 48, 1655–1665. [Google Scholar] [CrossRef]

- Manson, S.S. Thermal stresses: I. Mach. Des. 1958, 30, 114–120. [Google Scholar]

- Liang, J.; Wang, C.; Wang, Y.; Jing, L.; Luan, X. The influence of surface heat transfer conditions on thermal shock behavior of ZrB2-SiC-AlN ceramic composites. Scripta Mater. 2009, 61, 656–659. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Li, D.; Li, W.; Li, D.; Shi, Y.; Fang, D. Theoretical Research on Thermal Shock Resistance of Ultra-High Temperature Ceramics Focusing on the Adjustment of Stress Reduction Factor. Materials 2013, 6, 551-564. https://doi.org/10.3390/ma6020551

Li D, Li W, Li D, Shi Y, Fang D. Theoretical Research on Thermal Shock Resistance of Ultra-High Temperature Ceramics Focusing on the Adjustment of Stress Reduction Factor. Materials. 2013; 6(2):551-564. https://doi.org/10.3390/ma6020551

Chicago/Turabian StyleLi, Dengjian, Weiguo Li, Dingyu Li, Yushan Shi, and Daining Fang. 2013. "Theoretical Research on Thermal Shock Resistance of Ultra-High Temperature Ceramics Focusing on the Adjustment of Stress Reduction Factor" Materials 6, no. 2: 551-564. https://doi.org/10.3390/ma6020551

APA StyleLi, D., Li, W., Li, D., Shi, Y., & Fang, D. (2013). Theoretical Research on Thermal Shock Resistance of Ultra-High Temperature Ceramics Focusing on the Adjustment of Stress Reduction Factor. Materials, 6(2), 551-564. https://doi.org/10.3390/ma6020551