Comparison of Reactive and Non-Reactive Spark Plasma Sintering Routes for the Fabrication of Monolithic and Composite Ultra High Temperature Ceramics (UHTC) Materials

Abstract

:1. Introduction

| System type | Composition | References |

|---|---|---|

| Monolithic | ZrB2 | [21,22,23,24] |

| HfB2 | [8,11,18] | |

| TaB2 | [20] | |

| ZrC | [25] | |

| TaC | [26,27,28,29] | |

| Binary | ZrB2–SiC | [19,30,31,32,33,34,35,36,37] |

| ZrB2–MoSi2 | [10] | |

| ZrB2–ZrC | [38,3940] | |

| ZrB2–CNT | [37] | |

| ZrB2–graphene | [41] | |

| ZrC–SiC | [42,43] | |

| ZrC–MoSi2 | [44] | |

| ZrC–TiC | [45] | |

| HfB2–SiC | [8,46,47,48] | |

| HfB2–MoSi2 | [49] | |

| HfB2–TaSi2 | [11] | |

| HfC–MoSi2 | [50] | |

| TaB2–SiC | [51] | |

| TaC–TaB2 | [52] | |

| TaC–SiC | [53] | |

| Ternary | ZrB2–ZrC–SiC | [16,54,55,56,57] |

| HfB2–HfC–SiC | [48] | |

| TaB2–TaC–SiC | [58] |

2. Experimental Section

3. Results and Discussion

3.1. Monolithic Systems

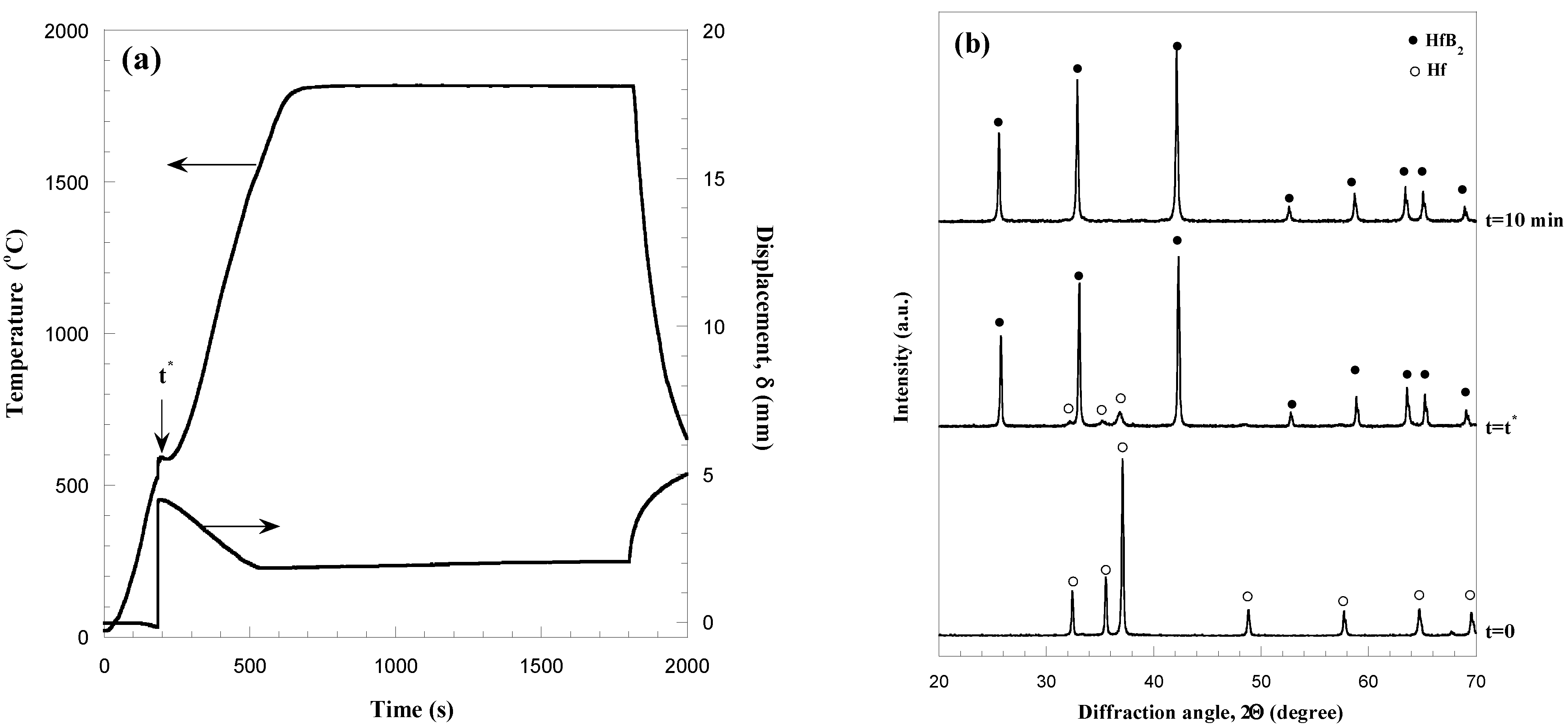

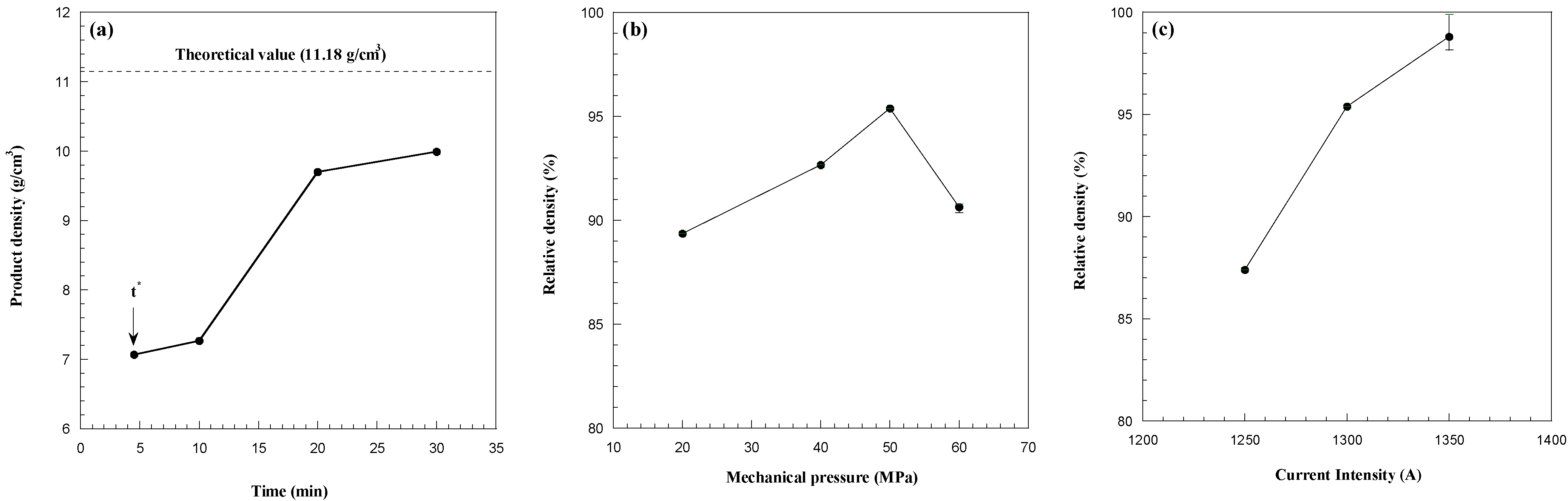

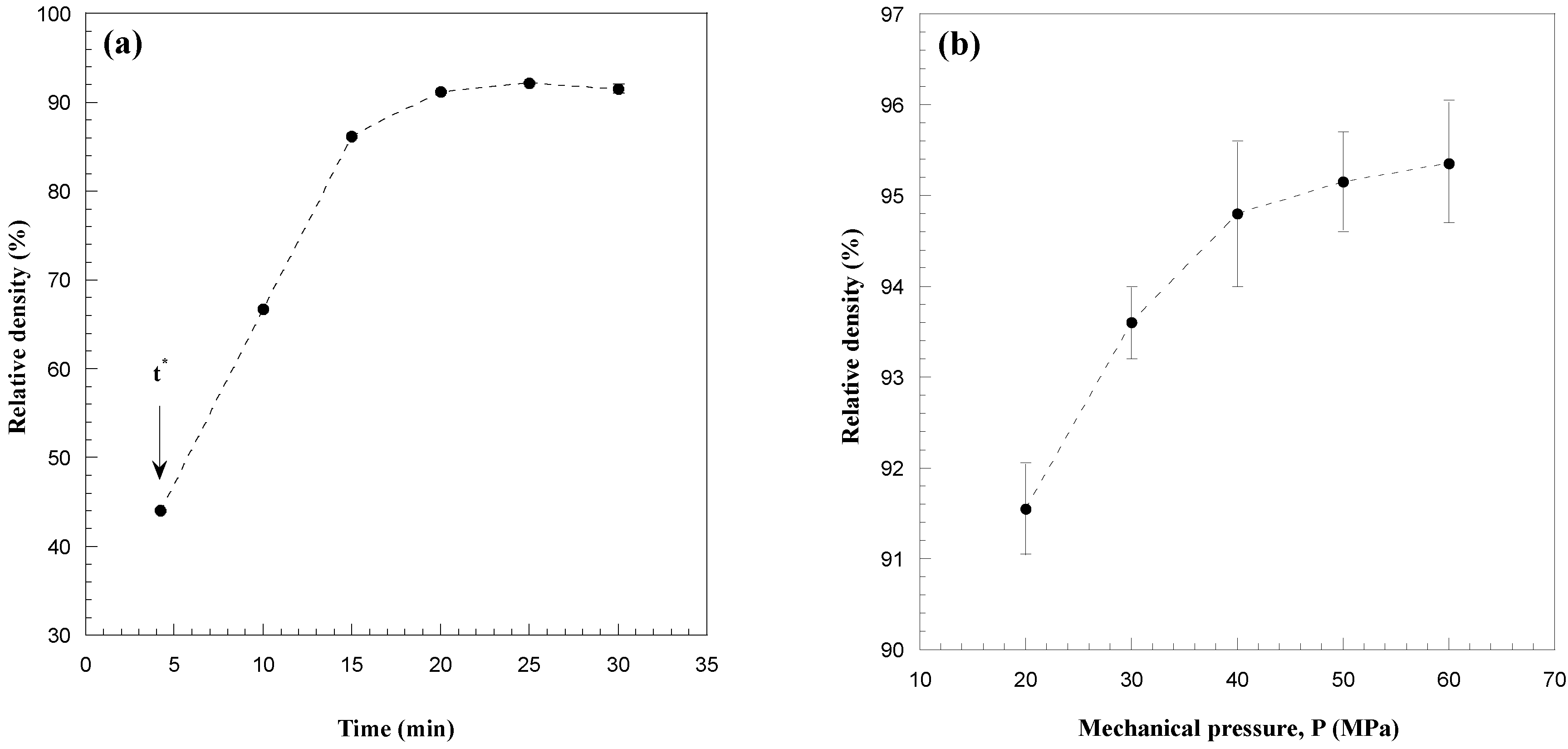

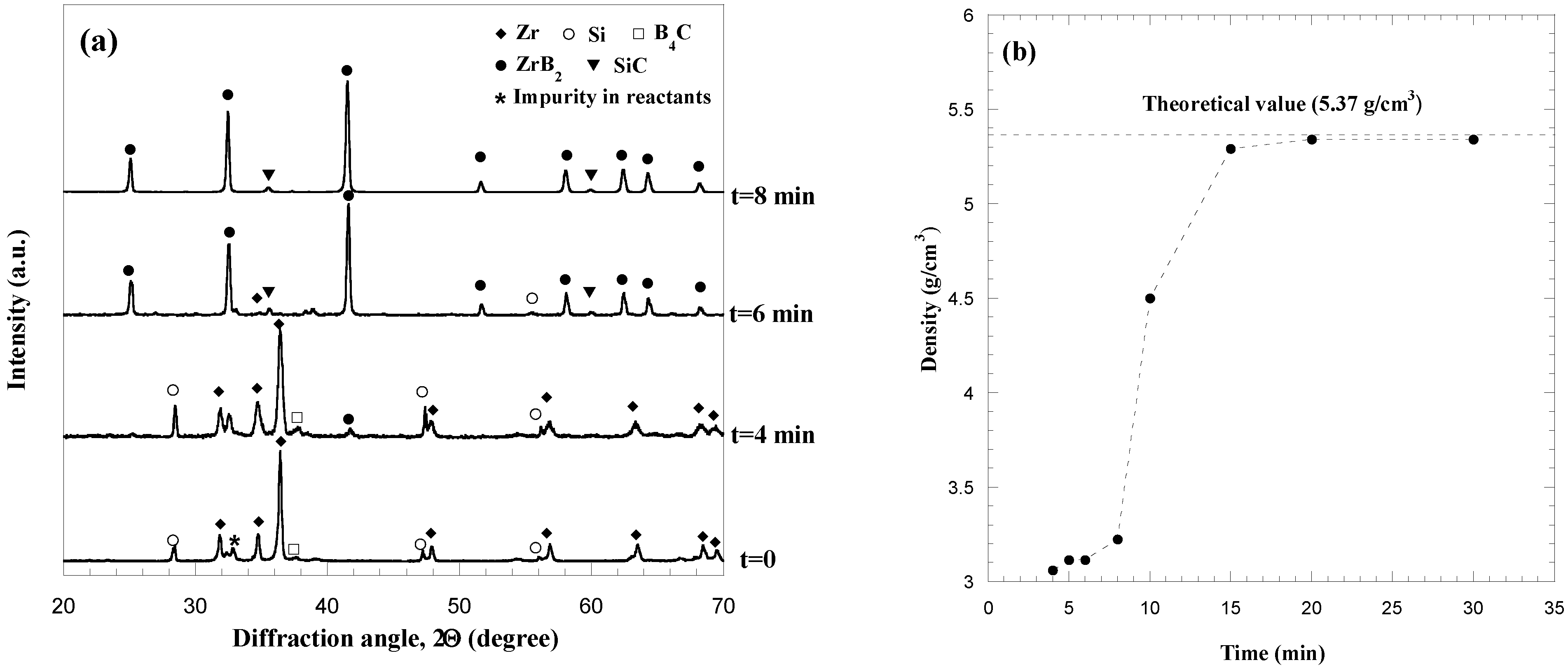

3.1.1. HfB2

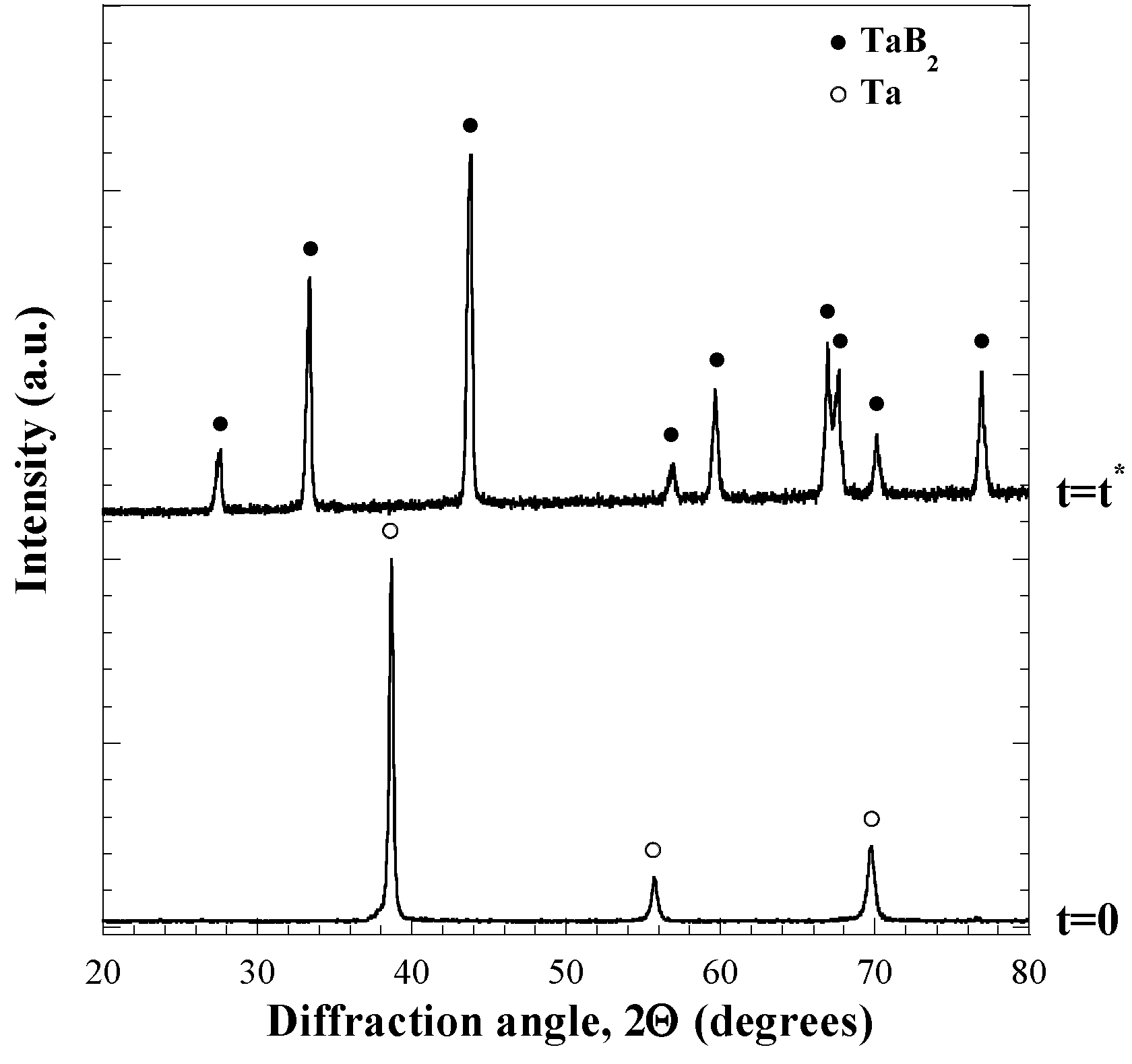

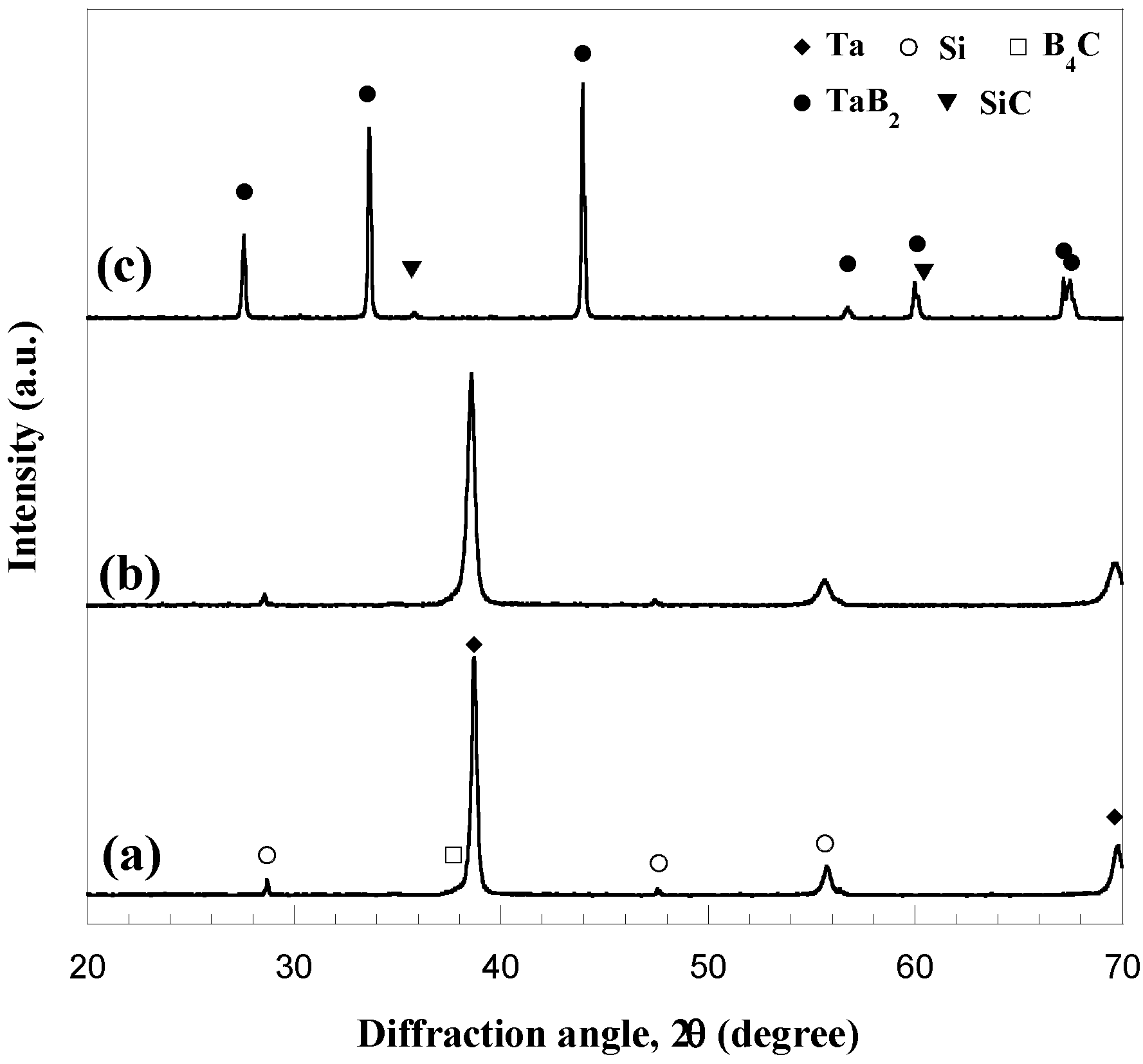

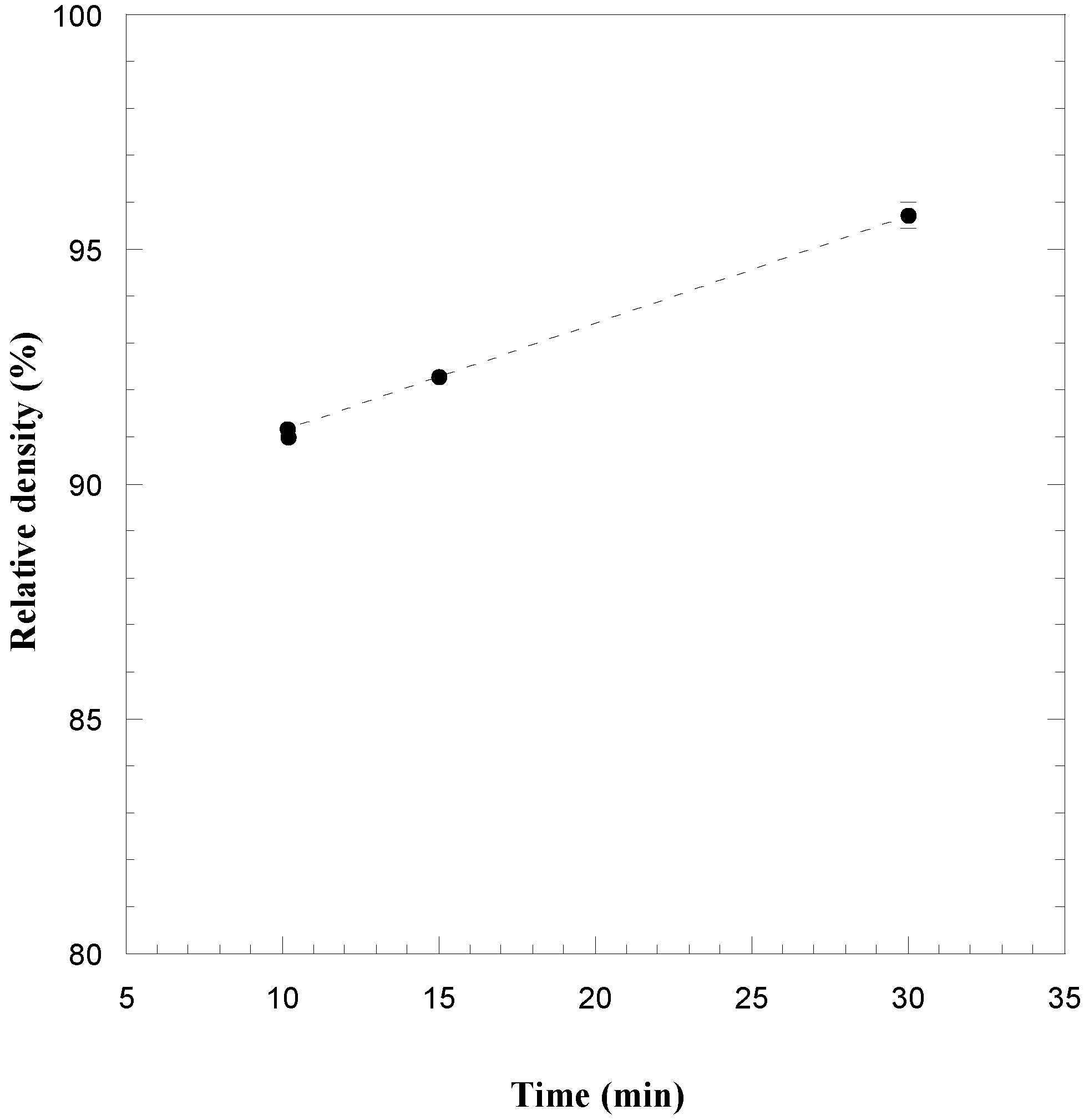

3.1.2. TaB2

3.2. Binary Systems

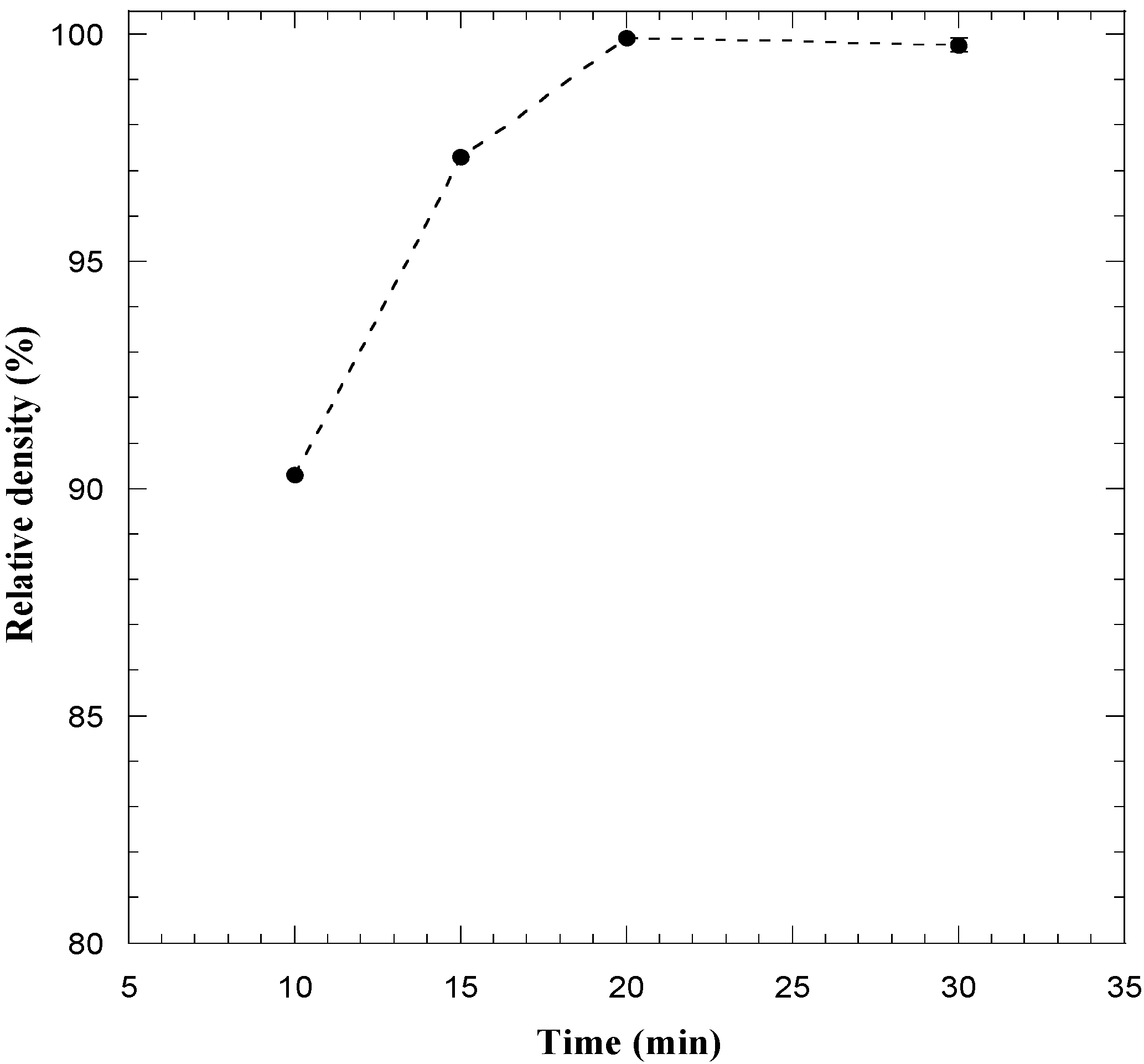

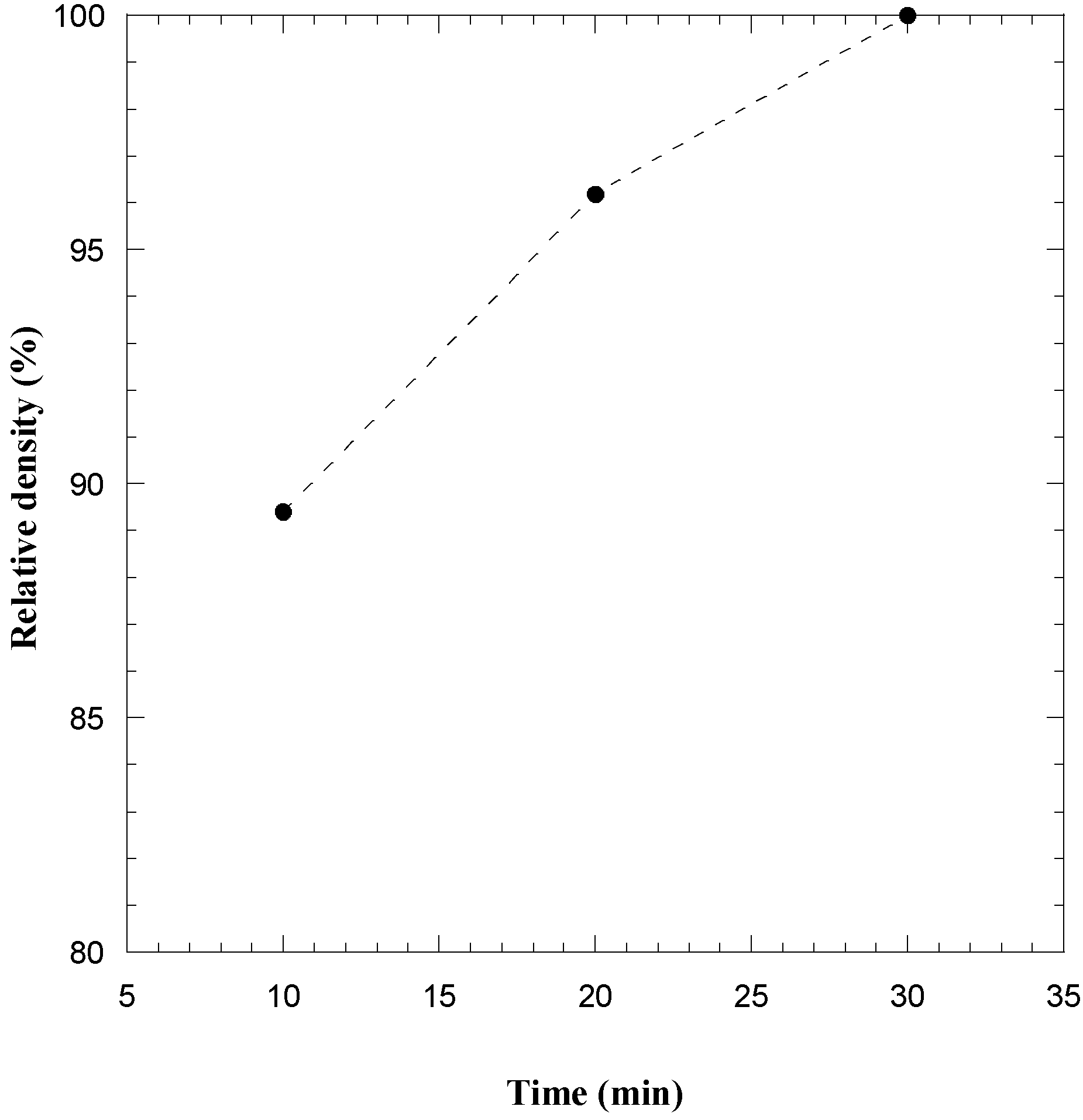

3.2.1. ZrB2–SiC

3.2.2. HfB2–SiC

3.2.3. TaB2–SiC

4. Conclusions

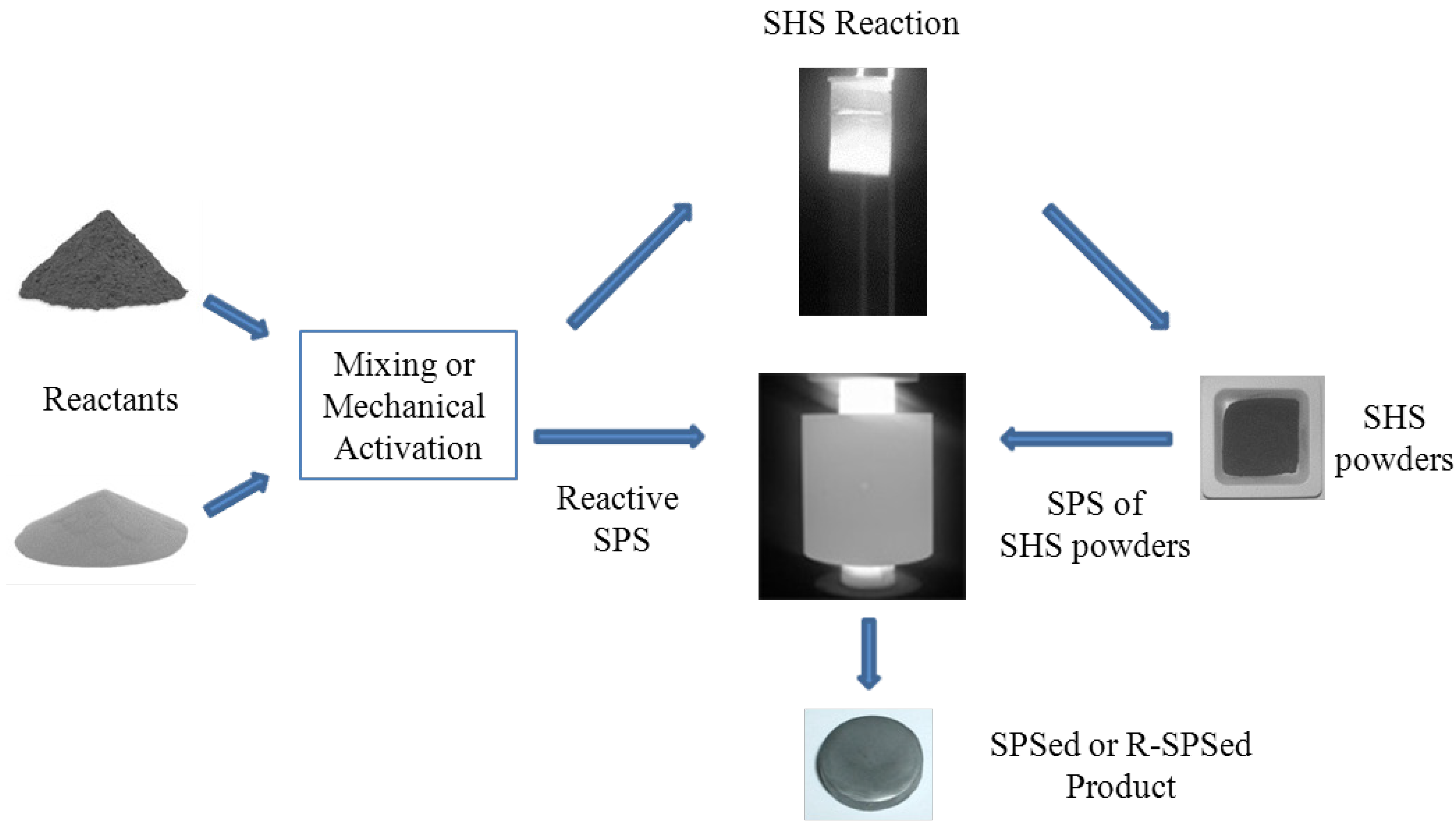

- (a)

- Reactive sintering, where the in situ synthesis and consolidation of the material was performed in one processing step starting from appropriate reaction promoters

- (b)

- Classical sintering, where the ceramic powders to be sintered by SPS were first synthesized by SHS using the same reactants as stated in (a)

Acknowledgments

References

- Rapp, R. Materials for Extreme environments. Mater. Today 2006, 9, 6. [Google Scholar]

- Fahrenholtz, W.G.; Hilmas, G.E.; Talmy, I.G.; Zaykoski, J.A. Refractory diborides of zirconium and hafnium. J. Am. Ceram. Soc. 2007, 90, 1347–1364. [Google Scholar] [CrossRef]

- Sonber, J.K.; Suri, A.K. Synthesis and consolidation of zirconium diboride: Review. Adv. Appl. Ceram. 2011, 110, 321–334. [Google Scholar] [CrossRef]

- Tripp, W.C.; Davis, H.H.; Graham, H.C. Effect of a SiC Addition on the oxidation of ZrB2. Am. Ceram. Soc. Bull. 1973, 52, 612–616. [Google Scholar]

- Monteverde, F.; Bellosi, A. Oxidation of ZrB2-based ceramics in dry air. J. Electrochem. Soc. 2003, 150, B552–B559. [Google Scholar] [CrossRef]

- Wu, W.W.; Zhang, G.J.; Kan, Y.M.; Wang, P.L. Reactive hot pressing of ZrB2–SiC–ZrC Ultra high-temperature ceramics at 1800 °C. J. Am. Ceram. Soc. 2006, 89, 2967–2969. [Google Scholar]

- Monteverde, F.; Scatteia, L. Resistance to thermal shock and to oxidation of metal diborides-SiC ceramics for aerospace application. J. Am. Ceram. Soc. 2007, 90, 1130–1138. [Google Scholar] [CrossRef]

- Musa, C.; Orrù, R.; Sciti, D.; Silvestroni, L.; Cao, G. Synthesis, consolidation and characterization of monolithic and SiC whiskers reinforced HfB2 ceramics. J. Eur. Ceram. Soc. 2013, 33, 603–614. [Google Scholar] [CrossRef]

- Monteverde, F.; Bellosi, A. Effect of the addition of silicon nitride on sintering behaviour and microstructure of zirconium diboride. Scripta Mater. 2002, 46, 223–228. [Google Scholar] [CrossRef]

- Balbo, A.; Sciti, D. Spark Plasma Sintering and hot pressing of ZrB2–MoSi2 under high-temperature ceramics. Mater. Sci. Eng. A 2008, 475, 108–112. [Google Scholar] [CrossRef]

- Sciti, D.; Bonnefont, G.; Fantozzi, G.; Silvestroni, L. Spark plasma sintering of HfB2 with low additions of silicides of molybdenum and tantalum. J. Eur. Ceram. Soc. 2010, 30, 3253–3258. [Google Scholar] [CrossRef]

- Munir, Z.A.; Anselmi-Tamburini, U. Self-propagating exothermic reactions: The synthesis of high-temperature materials by combustion. Mater. Sci. Rep. 1989, 3, 277–365. [Google Scholar] [CrossRef]

- Varma, A.; Rogachev, A.S.; Mukasyan, A.S.; Hwang, S. Combustion synthesis of advanced materials: Principles and applications. Adv. Chem. Eng. 1998, 24, 79–226. [Google Scholar]

- Cincotti, A.; Licheri, R.; Locci, A.M.; Orrù, R.; Cao, G. A review on combustion synthesis of novel materials: Recent experimental and modeling results. J. Chem. Technol. Biotechnol. 2003, 78, 122–127. [Google Scholar] [CrossRef]

- Mishra, S.K.; Das, S.; Pathak, L.C. Defect structures in zirconium diboride powder prepared by self-propagating high-temperature synthesis. Mater. Sci. Eng. A 2004, 364, 249–255. [Google Scholar] [CrossRef]

- Licheri, R.; Orrù, R.; Musa, C.; Cao, G. Combination of SHS and SPS techniques for fabrication of fully dense ZrB2–ZrC–SiC composites. Mater. Lett. 2008, 62, 432–435. [Google Scholar] [CrossRef]

- Orrù, R.; Licheri, R.; Locci, A.M.; Cincotti, A.; Cao, G. Consolidation/synthesis of materials by electric current activated/assisted sintering. Mater. Sci. Eng. R 2009, 63, 127–287. [Google Scholar] [CrossRef]

- Anselmi-Tamburini, U.; Kodera, Y.; Gasch, M.; Unuvar, C.; Munir, Z.A.; Ohyanagi, M.; Johnson, S.M. Synthesis and characterization of dense ultra-high temperature thermal protection materials produced by field activation through spark plasma sintering (SPS): I. Hafnium diboride. J. Mater. Sci. 2006, 41, 3097–3104. [Google Scholar] [CrossRef]

- Licheri, R.; Orrù, R.; Locci, A.M.; Cao, G. Efficient synthesis/sintering routes to obtain fully dense ZrB2–SiC Ultra-High-Temperature Ceramics (UHTCs). Ind. Eng. Chem. Res. 2007, 46, 9087–9096. [Google Scholar] [CrossRef]

- Musa, C.; Orrù, R.; Licheri, R.; Cao, G. Spark Plasma Synthesis and Densification of TaB2 by Pulsed Electric Current Sintering. Mater. Lett. 2011, 65, 3080–3082. [Google Scholar] [CrossRef]

- Liu, H.T.; Zhang, G.J. Reactive synthesis of ZrB2-based ultra high temperature ceramics. J. Korean Cer. Soc. 2012, 49, 308–317. [Google Scholar] [CrossRef]

- Thompson, M.; Fahrenholtz, W.G.; Hilmas, G. Effect of starting particle size and oxygen content on densification of ZrB2. J. Am. Ceram. Soc. 2011, 94, 429–435. [Google Scholar] [CrossRef]

- Zamora, V.; Ortiz, A.L.; Guiberteau, F.; Nygren, M. Spark-plasma sintering of ZrB2 ultra-high-temperature ceramics at lower temperature via nanoscale crystal refinement. J. Eur. Ceram. Soc. 2012, 32, 2529–2536. [Google Scholar] [CrossRef]

- Yuan, H.; Li, J.; Shen, Q.; Zhang, L. Preparation and thermal conductivity characterization of ZrB2 porous ceramics fabricated by spark plasma sintering. Inter. J. Refract. Met. H. 2013, 36, 225–231. [Google Scholar] [CrossRef]

- Núñez-González, B.; Ortiz, A.L.; Guiberteau, F.; Nygren, M. Improvement of the spark-plasma-sintering kinetics of ZrC by high-energy ball-milling. J. Am. Ceram. Soc. 2012, 95, 453–456. [Google Scholar] [CrossRef]

- Limeng, L.; Feng, Y.; Yu, Z.; Zhiguo, Z. Microstructure and mechanical properties of spark plasma sintered TaC0.7 ceramics. J. Am. Ceram. Soc. 2010, 93, 2945–2947. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Musaramthota, V.; Lahiri, D.; Singh, V.; Seal, S.; Agarwal, A. Spark plasma sintered tantalum carbide: Effect of pressure and nano-boron carbide addition on microstructure and mechanical properties. Mater. Sci. Eng. A 2011, 528, 1287–1295. [Google Scholar] [CrossRef]

- Liu, L.; Ye, F.; Zhou, Y. New route to densify tantalum carbide at 1400 °C by spark plasma sintering. Mater. Sci. Eng. A 2011, 528, 4710–4714. [Google Scholar] [CrossRef]

- Lahiri, D.; Khaleghi, E.; Bakshi, S.R.; Li, W.; Olevsky, E.A.; Agarwal, A. Graphene-induced strengthening in spark plasma sintered tantalum carbide-nanotube composite. Scripta Mater. 2013, 68, 285–288. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.A.; Yao, X.; Fang, D. Processing and mechanical properties of zirconium diboride-based ceramics prepared by spark plasma sintering. J. Am. Ceram. Soc. 2007, 90, 1992–1997. [Google Scholar] [CrossRef]

- Wu, W.W.; Zhang, G.J.; Kan, Y.M.; Wang, P.L.; Vanmeensel, K.; Vleugels, J.; van der Biest, O. Synthesis and microstructural features of ZrB2–SiC-based composites by reactive spark plasma sintering and reactive hot pressing. Scripta Mater. 2007, 57, 317–320. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, L.; Du, S.; Liu, C.; Han, J.; Han, W. Spark plasma sintering and hot pressing of ZrB2–SiCw ultra-high temperature ceramics. J. Alloy. Compd. 2008, 466, 241–245. [Google Scholar] [CrossRef]

- Akin, I.; Hotta, M.; Sahin, F.C.; Yucel, O.; Goller, G.; Goto, T. Microstructure and densification of ZrB2–SiC composites prepared by spark plasma sintering. J. Eur. Ceram. Soc. 2009, 29, 2379–2385. [Google Scholar] [CrossRef]

- Hu, C.; Sakka, Y.; Tanaka, H.; Nishimura, T.; Guo, S.; Grasso, S. Microstructure and properties of ZrB2–SiC composites prepared by spark plasma sintering using TaSi2 as sintering additive. J. Eur. Ceram. Soc. 2010, 30, 2625–2631. [Google Scholar] [CrossRef]

- Guicciardi, S.; Silvestroni, L.; Nygren, M.; Sciti, D. Microstructure and toughening mechanisms in spark plasma-sintered ZrB2 ceramics reinforced by SiC whiskers or SiC-chopped fibers. J. Am. Ceram. Soc. 2010, 93, 2384–2391. [Google Scholar] [CrossRef]

- Ran, S.; van der Biest, O.; Vleugels, J. ZrB2–SiC composites prepared by reactive pulsed electric current sintering. J. Eur. Ceram. Soc. 2010, 30, 2633–2642. [Google Scholar] [CrossRef]

- Yadhukulakrishnan, G.B.; Rahman, A.; Karumuri, S.; Stackpoole, M.M.; Kalkan, A.K.; Singh, R.P.; Harimkar, S.P. Spark plasma sintering of silicon carbide and multi-walled carbon nanotube reinforced zirconium diboride ceramic composite. Mater. Sci. Eng. A 2012, 552, 125–133. [Google Scholar] [CrossRef]

- Shim, S.H.; Niihara, K.; Auh, K.H.; Shim, K.B. Crystallographic orientation of ZrB2–ZrC composites manufactured by the spark plasma sintering method. J. Micros. 2002, 205, 238–244. [Google Scholar] [CrossRef]

- Kim, K.H.; Shim, K.B. The effect of lanthanum on the fabrication of ZrB2–ZrC composites by spark plasma sintering. Mater. Charact. 2003, 50, 31–37. [Google Scholar] [CrossRef]

- Tsuchida, T.; Yamamoto, S. MA-SHS and SPS of ZrB2–ZrC composites. Solid State Ion. 2004, 172, 215–216. [Google Scholar] [CrossRef]

- Yadhukulakrishnan, G.B.; Karumuri, S.; Rahman, A.; Singh, R.P.; Kaan Kalkan, A.; Harimkar, S.P. Spark plasma sintering of graphene reinforced zirconium diboride ultra-high temperature ceramic composites. Ceram. Int. 2013. [Google Scholar] [CrossRef]

- Zhao, L.; Jia, D.; Duan, X.; Yang, Z.; Zhou, Y. Low temperature sintering of ZrC–SiC composite. J. Alloy. Compd. 2011, 509, 9816–9820. [Google Scholar] [CrossRef]

- Sagdic, S.; Akin, I.; Sahin, F.; Yücel, O.; Goller, G. Mechanical properties of spark plasma sintered ZrC–SiC composites. TMS Annu. Meet. 2012, 1, 569–575. [Google Scholar]

- Sciti, D.; Guicciardi, S.; Nygren, M. Spark plasma sintering and mechanical behaviour of ZrC-based composites. Scripta Mater. 2008, 59, 638–641. [Google Scholar] [CrossRef]

- Acicbe, R.B.; Goller, G. Densification behavior and mechanical properties of spark plasma-sintered ZrC–TiC and ZrC–TiC–CNT composites. J. Mater. Sci. 2013, 48, 2388–2393. [Google Scholar] [CrossRef]

- Monteverde, F.; Melandri, C.; Guicciardi, S. Microstructure and mechanical properties of an HfB2 + 30 vol % SiC composite consolidated by spark plasma sintering. Mater. Chem. Phys. 2006, 100, 513–519. [Google Scholar] [CrossRef]

- Gasch, M.; Johnson, S.; Marschall, J. Thermal conductivity characterization of hafnium diboride-based ultra-high-temperature ceramics. J. Am. Ceram. Soc. 2008, 91, 1423–1432. [Google Scholar] [CrossRef]

- Licheri, R.; Orrù, R.; Musa, C.; Locci, A.M.; Cao, G. Consolidation via spark plasma sintering of HfB2/SiC and HfB2/HfC/SiC composite powders obtained by self-propagating high-temperature synthesis. J. Alloy Compd. 2009, 478, 572–578. [Google Scholar] [CrossRef]

- Sciti, D.; Silvestroni, L.; Bellosi, A. Fabrication and properties of HfB2–MoSi2 composites produced by hot pressing and spark plasma sintering. J. Mater. Res. 2006, 21, 1460–1466. [Google Scholar] [CrossRef]

- Sciti, D.; Guicciardi, S.; Nygren, M. Densification and mechanical behavior of HfC and HfB2 fabricated by spark plasma sintering. J. Am. Ceram. Soc. 2008, 91, 1433–1440. [Google Scholar] [CrossRef]

- Licheri, R.; Orrù, R.; Musa, C.; Cao, G. Synthesis, densification and characterization of TaB2–SiC composites. Ceram. Int. 2010, 36, 937–941. [Google Scholar] [CrossRef]

- Liu, L.; Ye, F.; He, X.; Zhou, Y. Densification process of TaC/TaB2 composite in spark plasma sintering. Mater. Chem. Phys. 2011, 126, 459–462. [Google Scholar] [CrossRef]

- Liu, H.; Liu, L.; Ye, F.; Zhang, Z.; Zhou, Y. Microstructure and mechanical properties of the spark plasma sintered TaC/SiC composites: Effects of sintering temperatures. J. Eur. Ceram. Soc. 2012, 32, 3617–3625. [Google Scholar] [CrossRef]

- Medri, V.; Monteverde, F.; Balbo, A.; Bellosi, A. Comparison of ZrB2–ZrC–SiC composites fabricated by spark plasma sintering and hot-pressing. Adv. Eng. Mater. 2005, 7, 159–163. [Google Scholar] [CrossRef]

- Guo, S.; Kagawa, Y.; Nishimura, T.; Tanaka, H. Elastic properties of spark plasma sintered (SPSed) ZrB2–ZrC–SiC composites. Ceram. Int. 2008, 34, 1811–1817. [Google Scholar] [CrossRef]

- Snyder, A.; Quach, D.; Groza, J.R.; Fisher, T.; Hodson, S.; Stanciu, L.A. Spark Plasma Sintering of ZrB2–SiC–ZrC ultra-high temperature ceramics at 1800 °C. Mater. Sci. Eng. A 2011, 528, 6079–6082. [Google Scholar] [CrossRef]

- Snyder, A.; Bo, Z.; Hodson, S.; Fisher, T.; Stanciu, L. The effect of heating rate and composition on the properties of spark plasma sintered zirconium diboride based composites. Mater. Sci. Eng. A 2012, 538, 98–102. [Google Scholar] [CrossRef]

- Licheri, R.; Orrù, R.; Musa, C.; Cao, G. Efficient technologies for the Fabrication of dense TaB2-based Ultra High Temperature Ceramics. ACS Appl. Mater. Interfaces 2010, 2, 2206–2212. [Google Scholar] [CrossRef]

- Matthews, F.L.; Rawlings, R. Composite Materials: Engineering and Science; Chapman & Hall: London, UK, 1994. [Google Scholar]

- Barin, I. Thermochemical Data of Pure Substances; Wiley-VHC: Weinheim, Germany, 1989. [Google Scholar]

- Yeh, C.L.; Chen, Y.L. An experimental study on self-propagating high-temperature synthesis in the Ta–B4C system. J. Alloy. Compd. 2009, 478, 163–167. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Orrù, R.; Cao, G. Comparison of Reactive and Non-Reactive Spark Plasma Sintering Routes for the Fabrication of Monolithic and Composite Ultra High Temperature Ceramics (UHTC) Materials. Materials 2013, 6, 1566-1583. https://doi.org/10.3390/ma6051566

Orrù R, Cao G. Comparison of Reactive and Non-Reactive Spark Plasma Sintering Routes for the Fabrication of Monolithic and Composite Ultra High Temperature Ceramics (UHTC) Materials. Materials. 2013; 6(5):1566-1583. https://doi.org/10.3390/ma6051566

Chicago/Turabian StyleOrrù, Roberto, and Giacomo Cao. 2013. "Comparison of Reactive and Non-Reactive Spark Plasma Sintering Routes for the Fabrication of Monolithic and Composite Ultra High Temperature Ceramics (UHTC) Materials" Materials 6, no. 5: 1566-1583. https://doi.org/10.3390/ma6051566