3.1. Structural and Morphological Characterization of Powder and Alloy Specimens

The MA-produced powder particles have an irregular shape, with diameter of 24 ± 20 µm and consist of single β-(Ti,Nb) phase. The broadening of the peaks in the XRD spectra at different stages of the ball-milling process (not shown here) suggests the formation of an ultrafine grain structure and an accumulation of strain in the lattice, which is typical for ball-milling related to severe mechanical deformation [

11]. The ball-milling process, the morphology and phase composition of the powder were discussed in detail in the previous work of the authors [

13]. Ball-milled powder was sieved to select particle sizes of 20–45 µm and its flowability was determined to be very good. Therefore, the MA-produced powder was found to be suitable for use in both SLM and hot pressing.

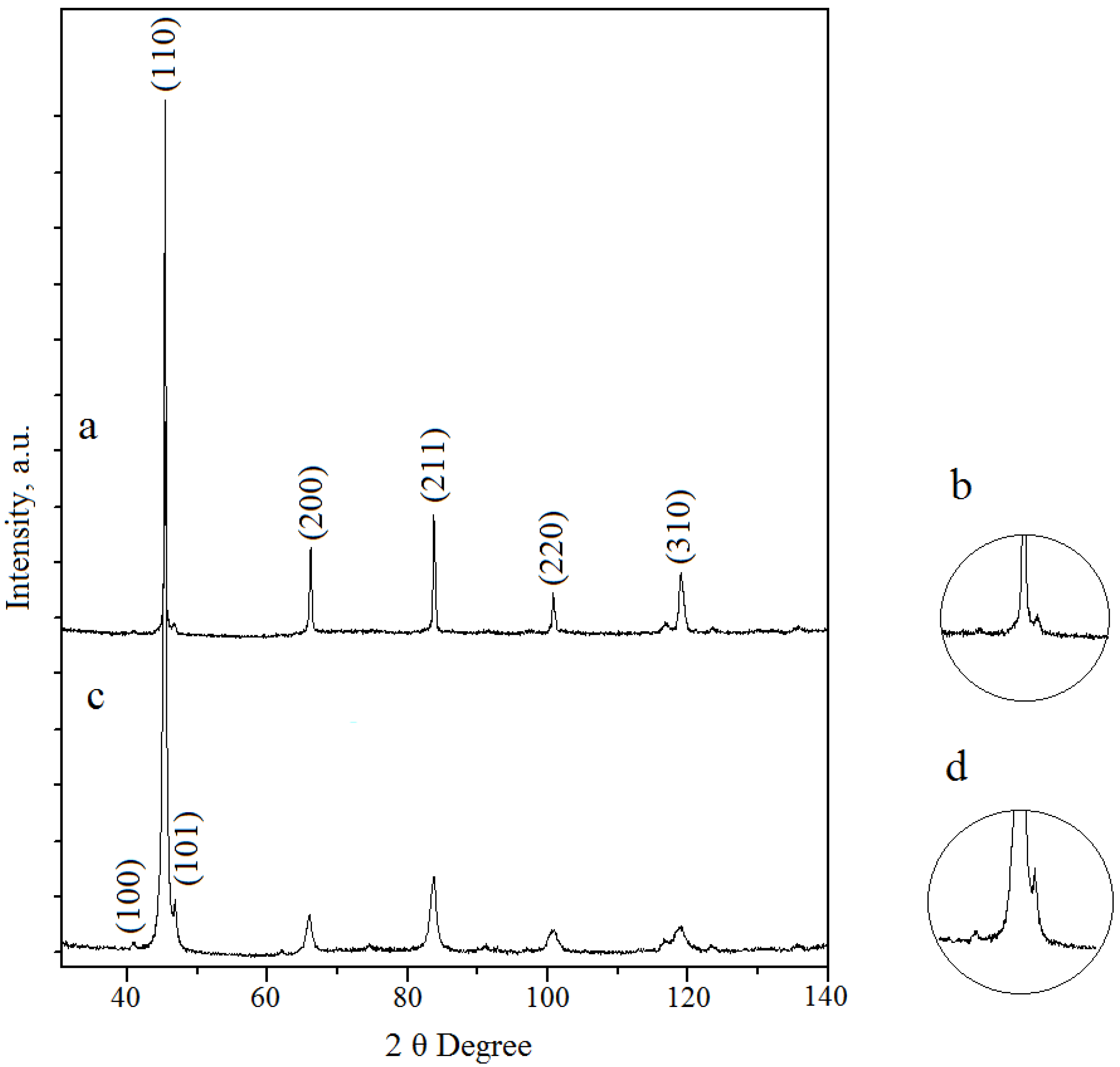

The XRD pattern taken from the cross-section of an SLM-fabricated cylinder is shown in

Figure 1a,b. Phase analysis reveals that the sample consists mainly of β-phase and a small amount of a minor phase, which might be either α or α′′-phase. Martensitic α′′-phase fractions (orthorhombic structure, space group

Cmcm) have been identified in some studies in Ti–Nb alloys which were rapidly quenched from the β-phase region [

14]. The presence of an α′′-phase was also suggested by TEM studies and may be attributed to oxygen impurities in the ball-milled powder together with the limited cooling provided during SLM, which triggers its precipitation.

The XRD pattern taken from the cross-section of a hot-pressed cylinder is shown in

Figure 1c,d. Both a main β-phase and a minor α-phase are identifiable. The amount of α-phase was evaluated as 11% ± 5% by the Le Bail method [

15]. The appearance of α-phase can be mainly attributed to a slow cooling rate as the samples had to be cooled inside of the hot press chamber. After slow cooling, the presence of the ω phase precipitates (hexagonal structure, space group

P6/

mmm) is also possible because, according to the literature data ω-phase precipitates may form during a slow quenching from the β-phase region or during isothermal aging [

14]. The presence of the ω-phase is hard to detect from the XRD patterns but it was confirmed by TEM studies in a previous work [

13].

Figure 1.

X-ray diffractometer (XRD) patterns of (a) sample made by selective laser melting (SLM) of Ti–40Nb ball-milled powder and (b) a higher resolution of its (101) peak; (c) sample made by hot-pressing of Ti–40Nb ball-milled powder and (d) a higher resolution of its (101) peak.

Figure 1.

X-ray diffractometer (XRD) patterns of (a) sample made by selective laser melting (SLM) of Ti–40Nb ball-milled powder and (b) a higher resolution of its (101) peak; (c) sample made by hot-pressing of Ti–40Nb ball-milled powder and (d) a higher resolution of its (101) peak.

TEM examination of selected regions of an SLM cylinder revealed precipitates with plate-like morphology embedded inside the metastable β-phase matrix (

Figure 2). The bright-field (BF) TEM image (

Figure 2a) shows a region with an area of about 9 µm

2 vertically intersected by precipitates arranged along a line. Additional single precipitates can be found uniformly distributed on both sides of this line. The long dimension of the precipitates ranged from 50 to 450 nm whereas the thickness was 10–20 nm (

Figure 2b) which represents a typical group of precipitates with a few of them oriented edge-on. Electron diffraction patterns using an electron beam with diameter of

ca. 40 nm centered on one of the precipitates with the β-phase matrix oriented in [100] zone axis, exhibited additional weak reflexes (

Figure 2c). Judging by their positions, they may be caused by either diffusional α- or by martensitic α′′-phase in [

] or [100] orientation, respectively. However, due to the combination of high cooling rates that occur during the SLM process, in conjunction with sluggish diffusional kinetics of the Ti–Nb system [

14], it is postulated that the second phase particles are of martensitic α′′-type.

The β-phase matrix on both sides of the line of precipitates is oriented identically, no misorientation could be detected by recording selected area electron diffraction (SAED) patterns from both areas (

Figure 2d). During SLM, small-scale pools are created by the laser, which scans across the powder. Consequently, part of the already consolidated material below the powder layer is also melted. This can result in epitaxial growth of grains across the SLM layers in the build direction [

16]. However, it may be assumed that the atoms in the solidified material are not arranged perfectly but various types of structural defects on the atomic scale will be created due to high cooling rates and strong temperature gradients. This will be especially true for the outermost layers of atoms inside a single melt pool, which are closest to the liquid-solid interface between the melt and the substrate where solidification occurs first. Therefore, defect-rich layers will form at the melt-pool boundaries and will be present in the solidified material. The defects thus trapped will act as nucleation centers for the formation of secondary-phase particles during further cooling, thereby giving rise to non-homogeneous precipitate arrangements such as observed in the present work arrangements (

Figure 2a).

Figure 2.

(a) Bright field transmission electron microscopy (BF-TEM) image of sample made by SLM of Ti–40Nb ball-milled powder showing the precipitates embedded in the β matrix. The orientation of β to the left and to the right of the vertical line of precipitates is identical; (b) Close up of a group of precipitates, some of them viewed edge-on. Their thickness varied between 10 and 20 nm; (c) Nano beam diffraction pattern recorded in [100]β zone axis with the beam positioned on a single precipitate. The arrows mark reflexes not attributable to β; (d) Selected area electron diffraction (SAED)-pattern of the β matrix demonstrating the diffuse streaking along <110>β reciprocal lattice directions; (e) Intensity profile of the rectangular area marked in (b) illustrating the intensity maxima centered between β reflexes along <110>β reciprocal lattice directions.

Figure 2.

(a) Bright field transmission electron microscopy (BF-TEM) image of sample made by SLM of Ti–40Nb ball-milled powder showing the precipitates embedded in the β matrix. The orientation of β to the left and to the right of the vertical line of precipitates is identical; (b) Close up of a group of precipitates, some of them viewed edge-on. Their thickness varied between 10 and 20 nm; (c) Nano beam diffraction pattern recorded in [100]β zone axis with the beam positioned on a single precipitate. The arrows mark reflexes not attributable to β; (d) Selected area electron diffraction (SAED)-pattern of the β matrix demonstrating the diffuse streaking along <110>β reciprocal lattice directions; (e) Intensity profile of the rectangular area marked in (b) illustrating the intensity maxima centered between β reflexes along <110>β reciprocal lattice directions.

Diffuse reciprocal lattice streakings are commonly observed in β-stabilized Ti alloys, the origin of which lies in structural instabilities inherent to the β-type

bcc lattice. An SAED pattern corresponding to a circular area with diameter of 770 nm of the β-phase matrix oriented along [100]

β is presented in

Figure 2d. In addition to the strong principal β-reflections, streaks of diffuse intensity were observed along <110> directions of the β reciprocal lattice. The intensity profile in

Figure 2e of the rectangular region marked in the SAED-pattern (

Figure 2b) clearly demonstrates that the diffuse intensities along the <110>

β reciprocal lattice directions form maxima at ½ positions between the principal β-phase Bragg reflections. Tahara

et al. [

17] and Nii

et al. [

18] reported similar streaking effects in the metastable β-phase matrix of Ti–Nb alloys with small oxygen (O) additions of about0.3 wt % (

ca. 1 at %) These workers [

17,

18] concluded that the diffuse intensities arise from transversal {110}

β<1

10>

β lattice modulations caused by local stress fields around O atoms randomly distributed on octahedral interstices in the bcc host lattice. Atom shuffles of the same type are necessary to form the martensitic α′′ structure (orthorhombic,

Cmcm) from the parent β

bcc lattice. The O level of the initial powder used for this study (0.38 wt %) was similar to levels in the alloys studied by Tahara

et al. [

17]. Based on their results [

17], it is suggested that the diffuse intensities along <110>

β directions in reciprocal space observed in the present work are caused by {110}

β<1

10>

β atom shuffles caused by strain fields around interstitial oxygen atoms.

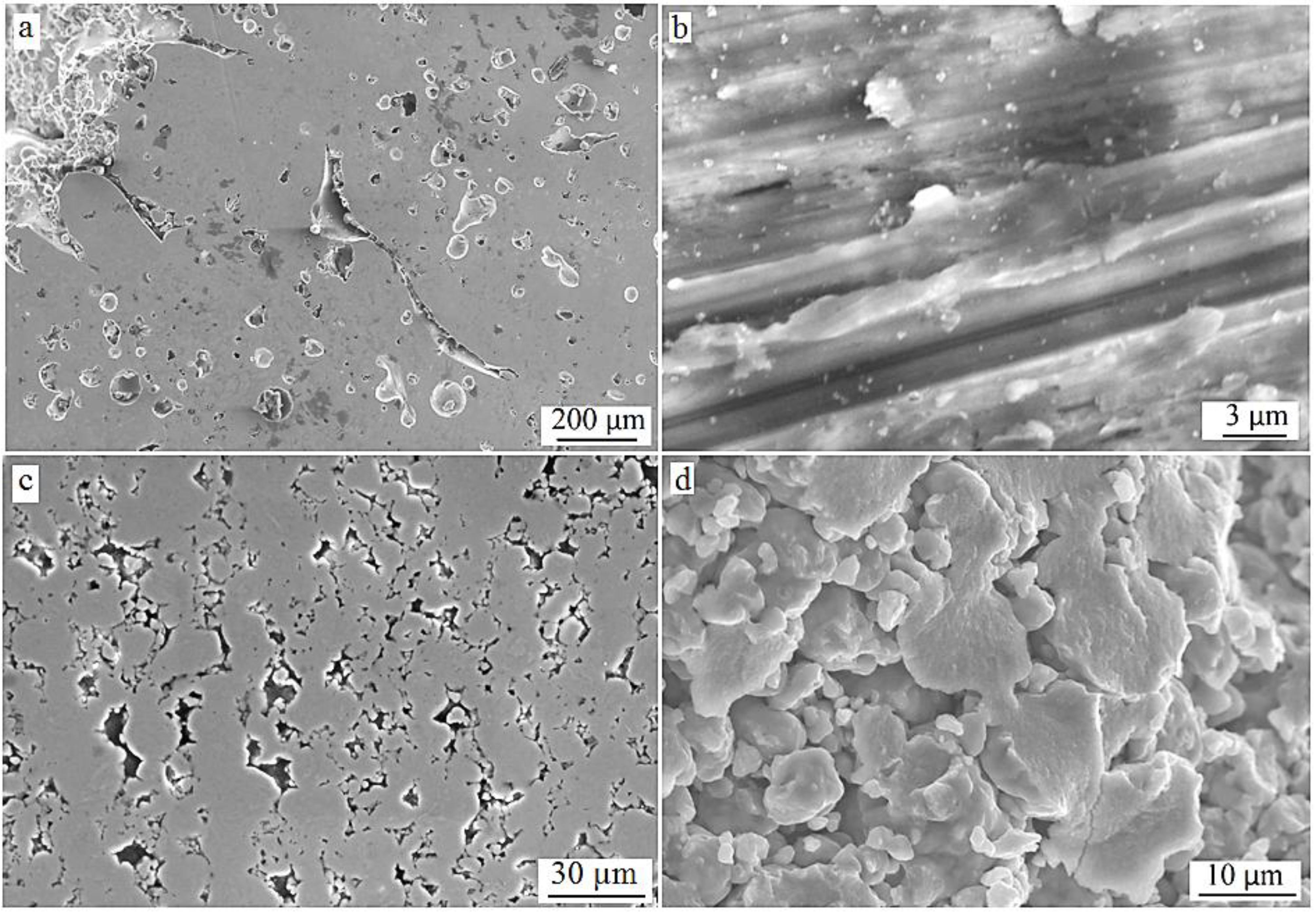

The microstructure of a typical cross-section of an SLM-fabricated cylinder is presented in

Figure 3. The width of individual metal layers in these samples was found to be around ≈100 µm. There are two types of pores detectable in the image in

Figure 3a: the elongated pores with a thickness of around 10 µm (formed by the incomplete connection between the molten layers) and small spherical-shaped pores of dimensions of 20–200 µm. The elongated pores are the consequence of the layer-by-layer approach in the SLM process and are typical for SLM fabricated alloys [

16]. These pores may result from the scan track instabilities or sphereodisation of the liquid melt pool. The spherical pores have a relatively large size and form a high porosity level of the alloy. The reason for the formation of these spherical pores can be that the mechanical alloying yields irregular alloy particles with higher contamination levels of O, C, N [

11]. Therefore, the particles have a more pronounced oxide layer on their surface than gas-atomized alloy particles. This can act as a thermal barrier for the local melting process during SLM and, thus, leads to formation of a high-porosity level.

In the hot-pressed cylinders , the pores were small and of irregular shapes since they were formed by the gaps between sintered powder particles [

12] (

Figure 3c,d). The powder particles are interconnected with each other via metal necks formed during the sintering. During hot pressing, the pressure from the punch was transported from one particle to another, deforming them and compacting the powder. The deformation in the contact points of the powder particles is elastic but, with growing pressure, causes plastic yield of the metal extending the contact points to contact areas [

19].

The porosity (pT) for the SLM-fabricated cylinders was 17% ± 1% (median = 17.0%; variance: 0.4%), which is in good agreement with the value obtained using density determined by simply dividing the mass of the cylinder by its volume. As seen in

Figure 3a, the porosity is mainly formed by spherical pores, which result from the gas uptake by the powder during the ball milling process. These big spherical pores and such a relatively high porosity are not typical for alloys fabricated using SLM from gas-atomized powders. The relative density of Ti alloys fabricated using gas-atomized powder and SLM is of the order of 99% [

12,

20,

21]. For hot-pressed cylinders, the size of the micropores and pT were 3–12 µm and 3% ± 0.4% (median = 3.0%; variance = 0.06%), respectively. pT for SLM-fabricated cylinders was significantly higher than that for hot-pressed cylinders (

p = 0.01).

Figure 3.

Scanning electron microscope (SEM) images of cross-sections of (a) sample made by SLM of Ti–40Nb ball-milled powder and (b) its higher resolution image; (c) sample made by hot-pressing of Ti–40Nb ball-milled powder and (d) its higher resolution image.

Figure 3.

Scanning electron microscope (SEM) images of cross-sections of (a) sample made by SLM of Ti–40Nb ball-milled powder and (b) its higher resolution image; (c) sample made by hot-pressing of Ti–40Nb ball-milled powder and (d) its higher resolution image.

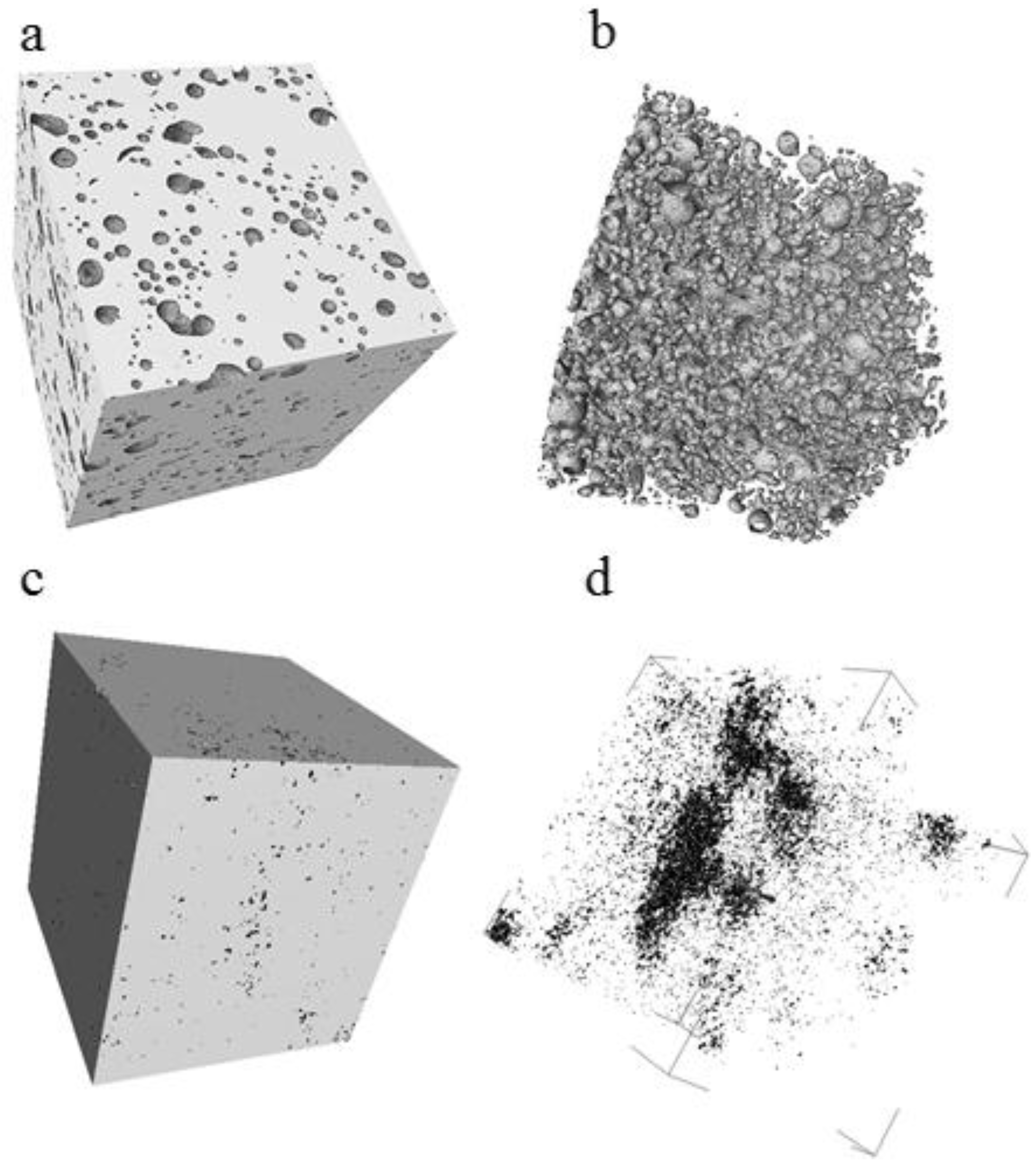

The reconstructed 3D image for an SLM-fabricated cylinder is shown in

Figure 4a. The pores are perfectly spherical, consistent with the SEM images and are clearly visible in

Figure 4b, which represents only pores (air) and no solid metal phase. The pores are homogeneously distributed all over the sample volume and are not interconnected. For the hot-pressed cylinders, the µCT studies of the hot-pressed sample (

Figure 4c,d) revealed that the porosity is homogeneously destributed all over the volume of the sample. The resolution of the µCT was 4 µm, so it is possible that not all the porosity is visible on the images. The porosity is not interconnected and the shape of the pores was found to be irregular, consistent with the results given in

Figure 3d.

Figure 4.

Micro-computed tomography (µCT) images of (a) sample made by SLM of Ti–40Nb ball-milled powder and (b) its inner porous architecture (from image analysis); (c) sample made by hot-pressing of Ti–40Nb ball-milled powder and (d) its inner porous architecture (from image analysis).

Figure 4.

Micro-computed tomography (µCT) images of (a) sample made by SLM of Ti–40Nb ball-milled powder and (b) its inner porous architecture (from image analysis); (c) sample made by hot-pressing of Ti–40Nb ball-milled powder and (d) its inner porous architecture (from image analysis).

3.2. Mechanical Testing

Typical stress-strain curves are presented in

Figure 5. UCS of the SLM-fabricated material (968 ± 8 MPa) (median = 964.5 MPa; variance = 58.4 MPa) was significantly lower than that for the hot-pressed material (1400 ± 19 MPa) (median = 1400 MPa; variance = 351 MPa) (

p = 0.01). Two reasons are postulated to account for this difference. One is to do with the difference in bonding between the alloy powder particles at the end of the two fabrication processes. The temperatures during the SLM process are so high that the metallic powder particles are almost completely molten, because this process involves full melting of the powder [

22]. This is a liquid state process that results in homogeneous alloy regions where no single powder particles are present (

Figure 3b). The alloy powder particles in a hot-pressed sample are sintered together by forming small necks as shown in (

Figure 3d). This is a consequence of the relatively low temperature of the hot-pressing process,

i.e., only 600 °C. This temperature is not high enough to completely melt the alloy powder particles. Besides that, the process time of 30 min eliminated grain growth and stress relaxation in the powder particles was eliminated during the process time (30 min) [

23].

Figure 5.

Stress-strain curves of (a) sample made by SLM of Ti–40Nb ball-milled powder and (b) sample made by hot-pressing of Ti–40Nb ball-milled powder.

Figure 5.

Stress-strain curves of (a) sample made by SLM of Ti–40Nb ball-milled powder and (b) sample made by hot-pressing of Ti–40Nb ball-milled powder.

The second reason for the significant difference in the strength between SLM processed and hot-pressed samples is the porosity. Porosity has a strong influence on the mechanical properties and strongly reduces the strength of an alloy [

5].

The Young’s modulus SLM-fabricated material (33 ± 2 GPa, median = 33.0 GPa; variance = 4.1 GPa) was significantly higher than that for the hot-pressed material (77.0 ± 3.1 GPa) (median 76.5 GPa; variance = 5.1 GPa) (p = 0.01). Two reasons are postulated to account for this difference.

First, the porosity of the hot-pressed material is very low so it cannot strongly reduce the stiffness of the alloy; Second, slow cooling of the cylinders inside of the press chamber lead to the formation of ω-phase, which has the highest elastic modulus among all the phases in the Ti–Nb system [

14].