The Effect of Structural Design on Mechanical Properties and Cellular Response of Additive Manufactured Titanium Scaffolds

Abstract

:1. Introduction

2. Materials & Methods

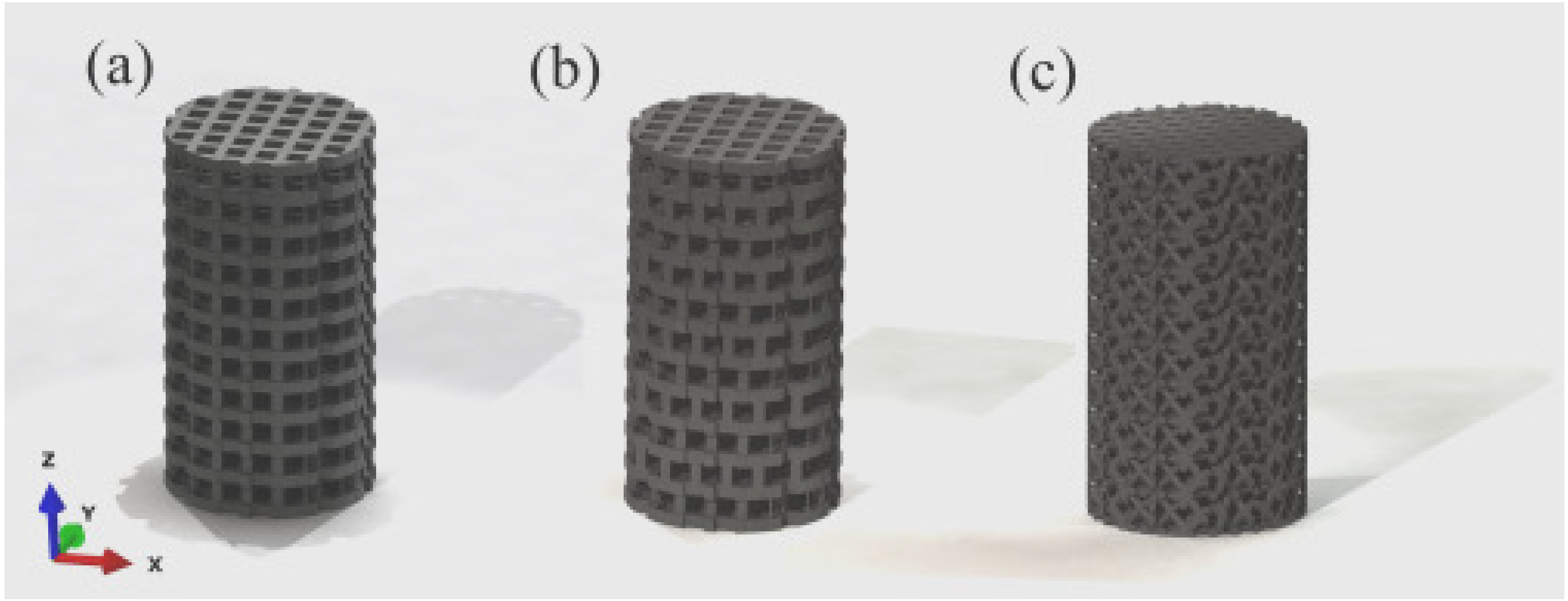

2.1. Generating the Open-Porous Scaffolds

2.2. Fabrication of the Scaffolds

2.3. Calculating Scaffold Porosity

2.4. Axial Compression Testing

2.5. Cell Seeding on SLM Scaffolds

2.6. In Vitro Characterization

3. Results

3.1. Scaffold Porosity

| Scaffold | Porosity | |

|---|---|---|

| CAD | AMS | |

| 1 | 70.3% | 70.2 ± 0.4% |

| 2 | 70.3% | 71.9 ± 0.2% |

| 3 | 70.7% | 68.7 ± 0.2% |

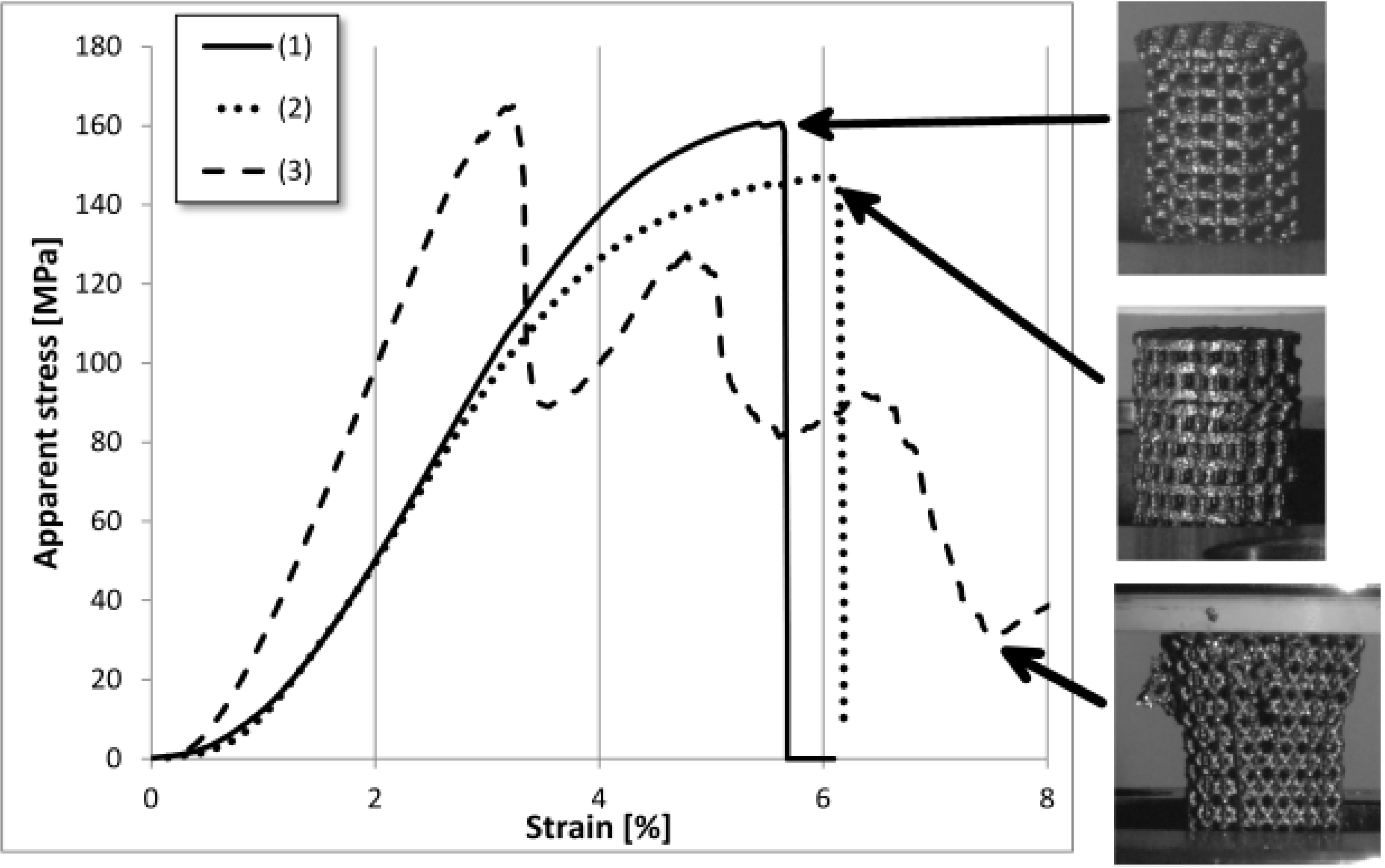

3.2. Mechanical Behavior

3.3. Mechanical Properties

| Scaffold design | Elastic modulus (GPa) | Ultimate compressive strength (MPa) | Ultimate compressive strain (%) |

|---|---|---|---|

| 1 | 5.1 ± 0.3 | 155 ± 7 | 5.22 ± 0.34 |

| 2 | 3.7 ± 0.2 | 145 ± 2 | 6.70 ± 0.56 |

| 3 | 6.7 ± 0.3 | 164 ± 6 | 3.45 ± 0.50 |

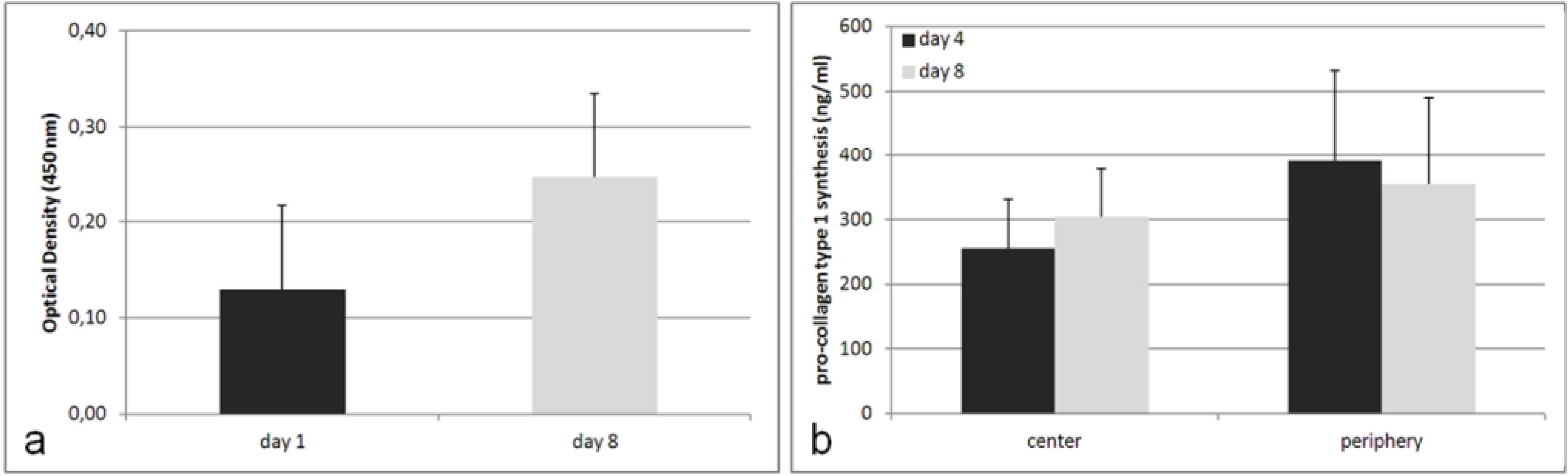

3.4. In Vitro Properties

4. Discussion

5. Conclusions

References

- De Coster, T.A.; Gehlert, R.J.; Mikola, E.A.; Pirela-Cruz, M.A. Management of posttraumatic segmental bone defects. J. Am. Acad. Orthop. Surg. 2004, 12, 28–38. [Google Scholar] [PubMed]

- Attias, N.; Lehman, R.E.; Bodell, L.S.; Lindsey, R.W. Surgical management of a long segmental defect of the humerus using a cylindrical titanium mesh cage and plates: A case report. J. Orthop. Trauma 2005, 19, 211–216. [Google Scholar] [CrossRef] [PubMed]

- Schieker, M.; Mutschler, W. Bridging posttraumatic bony defects. Established and new methods. Unfallchirurg 2006, 109, 715–732. [Google Scholar] [CrossRef] [PubMed]

- Dumont, C.E.; Exner, U.G. Reconstruction of large diaphyseal defects of the femur and the tibia with autologous bone. Eur. J. Trauma Emerg. Surg. 2009, 35, 17–25. [Google Scholar] [CrossRef]

- Niedhart, C.; Pingsmann, A.; Jurgens, C.; Marr, A.; Blatt, R.; Niethard, F.U. Complications after harvesting of autologous bone from the ventral and dorsal iliac crest—A prospective, controlled study. Z. Orthop. Grenzgeb. 2003, 141, 481–486. [Google Scholar] [CrossRef]

- Younger, E.M.; Chapman, M.W. Morbidity at bone graft donor sites. J. Orthop. Trauma 1989, 3, 192–195. [Google Scholar] [CrossRef] [PubMed]

- Hutmacher, D.W.; Schantz, J.T.; Lam, C.X.; Tan, K.C.; Lim, T.C. State of the art and future directions of scaffold-based bone engineering from a biomaterials perspective. J. Tissue Eng. Regen. Med. 2007, 1, 245–260. [Google Scholar] [CrossRef] [PubMed]

- Reichert, J.C.; Wullschleger, M.E.; Cipitria, A.; Lienau, J.; Cheng, T.K.; Schutz, M.A.; Duda, G.N.; Noth, U.; Eulert, J.; Hutmacher, D.W. Custom-made composite scaffolds for segmental defect repair in long bones. Int. Orthop. 201 2011, 35, 1229–1236. [Google Scholar] [CrossRef]

- Mueller, U.; Imwinkelried, T.; Horst, M.; Sievers, M.; Graf-Hausner, U. Do human osteoblasts grow into open-porous titanium? Eur. Cells Mater. 2006, 11, 8–15. [Google Scholar]

- Antonialli, A.I.S.; Bolfarini, C. Numerical evaluation of reduction of stress shielding in laser coated hip prostheses. Mater. Res. 2011, 14, 331–334. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M. Titanium-based biomaterials for preventing stress shielding between implant devices and bone. Int. J. Biomater. 2011, 2011, 1–10. [Google Scholar] [CrossRef]

- Li, J.P.; Wijn, J.R.; van Blitterswijk, C.A.; de Groot, K. Comparison of porous Ti6Al4V made by sponge replication and directly 3D fiber deposition and cancellous bone. Key Eng. Mater. 2007, 330–332, 999–1002. [Google Scholar] [CrossRef]

- Karageorgiou, V.; Kaplan, D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials 2005, 26, 5474–5491. [Google Scholar] [CrossRef] [PubMed]

- Ryan, G.; Pandit, A.; Apatsidis, D.P. Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials 2006, 27, 2651–2670. [Google Scholar] [CrossRef] [PubMed]

- Takemoto, M.; Fujibayashi, S.; Neo, M.; Suzuki, J.; Kokubo, T.; Nakamura, T. Mechanical properties and osteoconductivity of porous bioactive titanium. Biomaterials 2005, 26, 6014–6023. [Google Scholar] [CrossRef] [PubMed]

- Spoerke, E.D.; Murray, N.G.; Li, H.; Brinson, L.C.; Dunand, D.C.; Stupp, S.I. A bioactive titanium foam scaffold for bone repair. Acta Biomater. 2005, 1, 523–533. [Google Scholar] [CrossRef] [PubMed]

- Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of titanium alloys fabricated using rapid prototyping technologies—Electron beam melting and laser beam melting. Materials 2011, 4, 1776–1792. [Google Scholar] [CrossRef]

- Ponader, S.; von Wilmowsky, C.; Widenmayer, M.; Lutz, R.; Heinl, P.; Koerner, C.; Singer, R.F.; Nkenke, E.; Neukam, F.W.; Schlegel, K.A. In vivo performance of selective electron beam-melted Ti-6Al-4V structures. J. Biomed. Mater. Res. A 2010, 92, 56–62. [Google Scholar] [CrossRef] [PubMed]

- Li, J.P.; Habibovic, P.; van den Doel, M.; Wilson, C.E.; de Wijn, J.R.; van Blitterswijk, C.A.; de Groot, K. Bone ingrowth in porous titanium implants produced by 3D fiber deposition. Biomaterials 2007, 28, 2810–2820. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Lopez, H.; Martinez, E.; Machado, B.I.; Hernandez, D.H.; Martinez, L.; Lopez, M.I.; Wicker, R.B.; Bracke, J. Next-generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays. Phil. Trans. Roy. Soc. A Math. Phys. Eng. Sci. 2010, 368, 1999–2032. [Google Scholar] [CrossRef]

- Harrysson, O.L.A.; CansiZoglu, O.; Marcellin-Little, D.J.; Cormier, D.R.; West, H.A. Direct metal fabrication of titanium implants with tailored materials and mechanical properties using electron beam melting technology. Mater. Sci. Eng. C Biomim. Supramol. Syst. 2008, 28, 366–373. [Google Scholar] [CrossRef]

- Chahine, G.; Koike, M.; Okabe, T.; Smith, P.; Kovacevic, R. The design and production of Ti-6Al-4V ELI customized dental implants. JOM 2008, 60, 50–55. [Google Scholar] [CrossRef]

- Mangano, C.; de Rosa, A.; Desiderio, V.; d'Aquino, R.; Piattelli, A.; de Francesco, F.; Tirino, V.; Mangano, F.; Papaccio, G. The osteoblastic differentiation of dental pulp stem cells and bone formation on different titanium surface textures. Biomaterials 2010, 31, 3543–3551. [Google Scholar] [CrossRef] [PubMed]

- Parthasarathy, J.; Starly, B.; Raman, S.; Christensen, A. Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM). J. Mech. Behav. Biomed. Mater. 2010, 3, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Gibson, L.J.; Ashby, M.F. mechanics of three-dimensional cellular materials. Proc. R Soc. Lond. Ser. A 1982, 382, 43–59. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.T.; Zhang, W.G.; Li, Y.C. Fabrication and compressive properties of Ti6Al4V implant with honeycomb-like structure for biomedical applications. Rapid Prototyping J. 2010, 16, 44–49. [Google Scholar] [CrossRef]

- Fassina, L.; Saino, E.; Visai, L.; Magenes, G. Electromagnetically enhanced coating of a sintered titanium grid with human SAOS-2 osteoblasts and extracellular matrix. In Proceedings of 30th Annual International Conference of the IEEE, Vancouver, Canada, 20–25 August 2008.

- Hollander, D.A.; von Walter, M.; Wirtz, T.; Sellei, R.; Schmidt-Rohlfing, B.; Paar, O.; Erli, H.J. Structural, mechanical and in vitro characterization of individually structured Ti-6Al-4V produced by direct laser forming. Biomaterials 2006, 27, 955–963. [Google Scholar] [CrossRef] [PubMed]

- Frosch, K.H.; Barvencik, F.; Lohmann, C.H.; Viereck, V.; Siggelkow, H.; Breme, J.; Dresing, K.; Sturmer, K.M. Migration, matrix production and lamellar bone formation of human osteoblast-like cells in porous titanium implants. Cells Tissues Organs 2002, 170, 214–227. [Google Scholar] [CrossRef] [PubMed]

- Warnke, P.H.; Douglas, T.; Wollny, P.; Sherry, E.; Steiner, M.; Galonska, S.; Becker, S.T.; Springer, I.N.; Wiltfang, J.; Sivananthan, S. Rapid prototyping: Porous titanium alloy scaffolds produced by selective laser melting for bone tissue engineering. Tissue Eng. Part C Methods 2009, 15, 115–124. [Google Scholar] [CrossRef] [PubMed]

- Jonitz, A.; Wieding, J.; Lochner, K.; Cornelsen, M.; Seitz, H.; Hansmann, D.; Bader, R. Migration capacity and viability of human primary osteoblasts in synthetic three-dimensional bone scaffolds made of tricalciumphosphate. Materials 2011, 4, 1249–1259. [Google Scholar] [CrossRef]

- Merle, C.; Streit, M.R.; Volz, C.; Pritsch, M.; Gotterbarm, T.; Aldinger, P.R. Bone remodeling around stable uncemented titanium stems during the second decade after total hip arthroplasty: A DXA study at 12 and 17 years. Osteoporos. Int. 2011, 22, 2879–2886. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, Y.; Nomura, N.; Hanada, S.; Kamakura, S.; Anada, T.; Fuji, T.; Honda, Y.; Masuda, T.; Sasaki, K.; Kokubun, S.; Suzuki, O. Osteoconductivity of porous titanium having young’s modulus similar to bone and surface modification by OCP. Key Eng. Mater. 2007, 330–332, 951–954. [Google Scholar] [CrossRef]

- Ohman, C.; Baleani, M.; Pani, C.; Taddei, F.; Alberghini, M.; Viceconti, M.; Manfrini, M. Compressive behaviour of child and adult cortical bone. Bone 2011, 49, 769–776. [Google Scholar] [CrossRef] [PubMed]

- Grimal, Q.; Haupert, S.; Mitton, D.; Vastel, L.; Laugier, P. Assessment of cortical bone elasticity and strength: Mechanical testing and ultrasound provide complementary data. Med. Eng. Phys. 2009, 31, 1140–1147. [Google Scholar] [CrossRef] [PubMed]

- Cahill, S.; Lohfeld, S.; McHugh, P.E. Finite element predictions compared to experimental results for the effective modulus of bone tissue engineering scaffolds fabricated by selective laser sintering. J. Mater. Sci. Mater. Med. 2009, 20, 1255–1262. [Google Scholar] [CrossRef] [PubMed]

- Frosch, K.H.; Barvencik, F.; Viereck, V.; Lohmann, C.H.; Dresing, K.; Breme, J.; Brunner, E.; Sturmer, K.M. Growth behavior, matrix production, and gene expression of human osteoblasts in defined cylindrical titanium channels. J. Biomed. Mater. Res. A 2004, 68, 325–334. [Google Scholar] [CrossRef] [PubMed]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wieding, J.; Jonitz, A.; Bader, R. The Effect of Structural Design on Mechanical Properties and Cellular Response of Additive Manufactured Titanium Scaffolds. Materials 2012, 5, 1336-1347. https://doi.org/10.3390/ma5081336

Wieding J, Jonitz A, Bader R. The Effect of Structural Design on Mechanical Properties and Cellular Response of Additive Manufactured Titanium Scaffolds. Materials. 2012; 5(8):1336-1347. https://doi.org/10.3390/ma5081336

Chicago/Turabian StyleWieding, Jan, Anika Jonitz, and Rainer Bader. 2012. "The Effect of Structural Design on Mechanical Properties and Cellular Response of Additive Manufactured Titanium Scaffolds" Materials 5, no. 8: 1336-1347. https://doi.org/10.3390/ma5081336