Grafting Modification of the Reactive Core-Shell Particles to Enhance the Toughening Ability of Polylactide

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization of the RCS Particles

2.3. Blending and Molding Procedures

2.4. Mechanical Tests

2.5. Morphology Observation

2.6. DMA Test

2.7. DSC Test

3. Results and Discussion

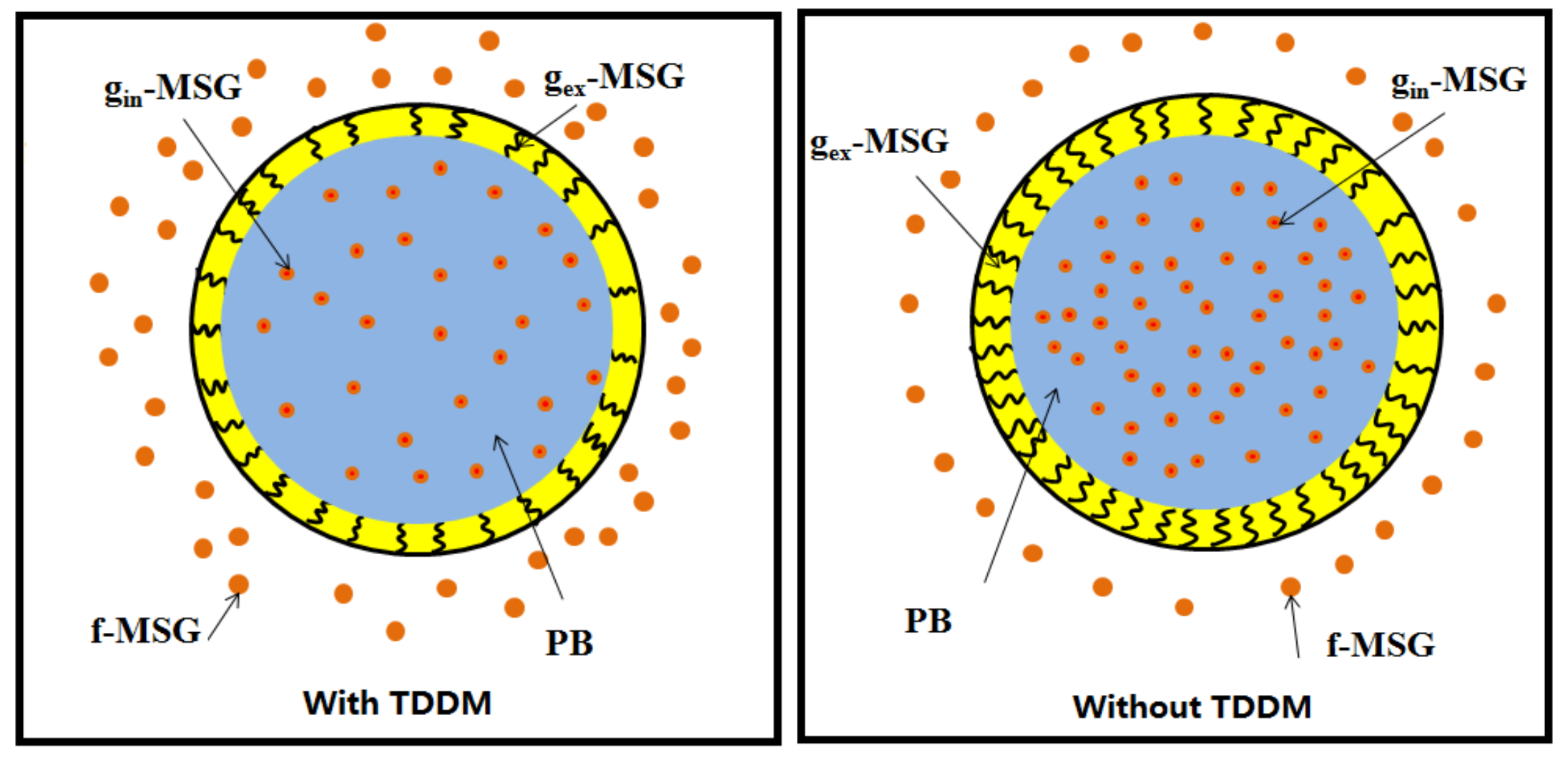

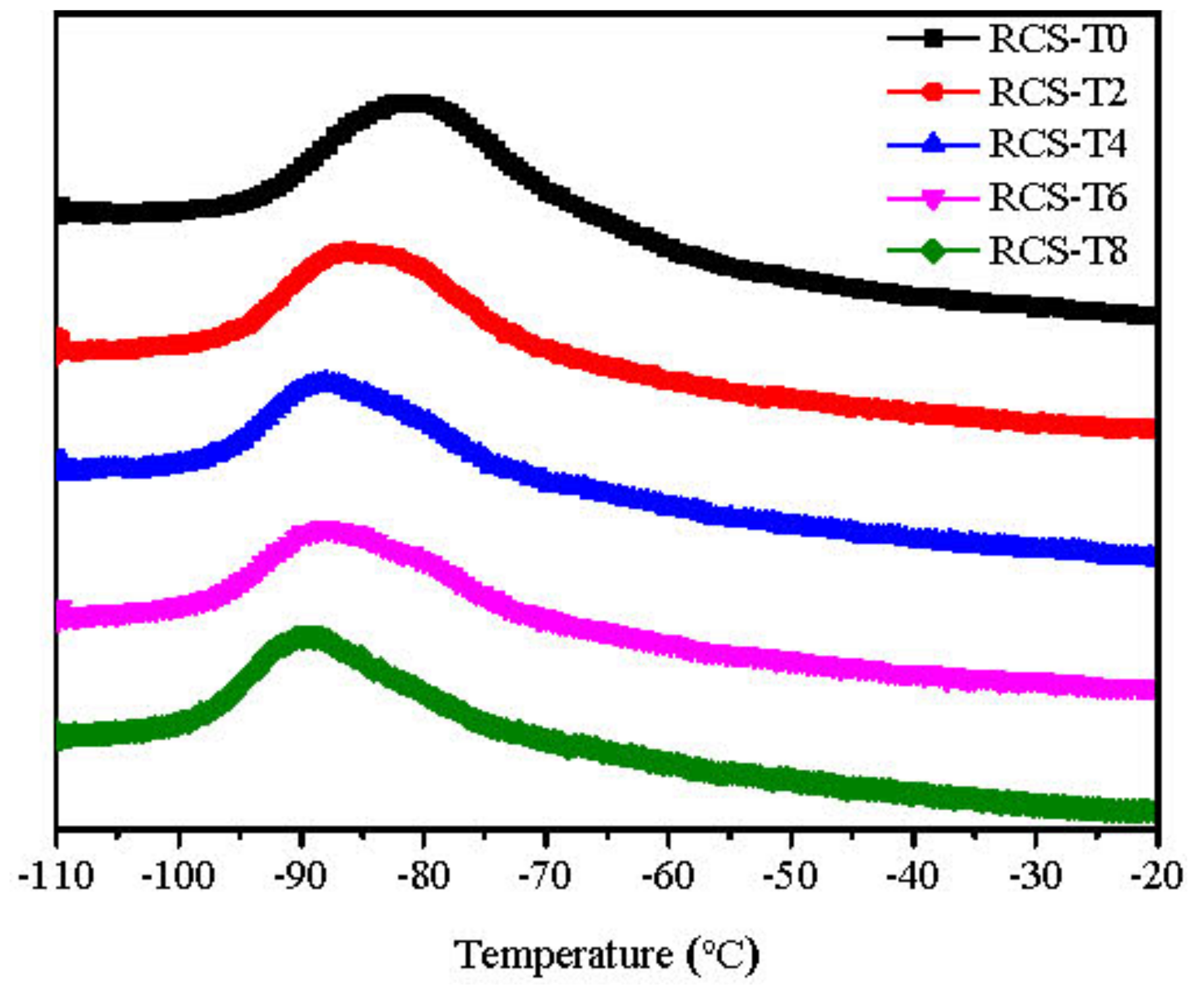

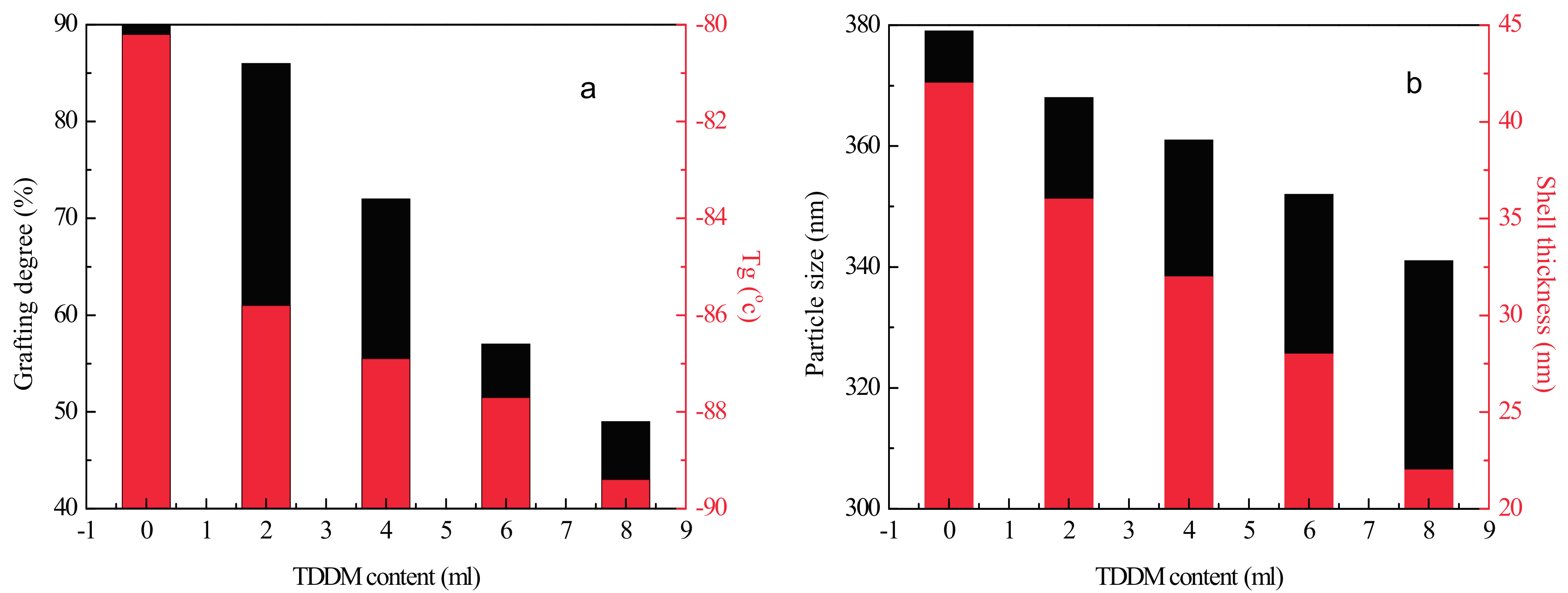

3.1. Properties of the Reactive Core-Shell Particles

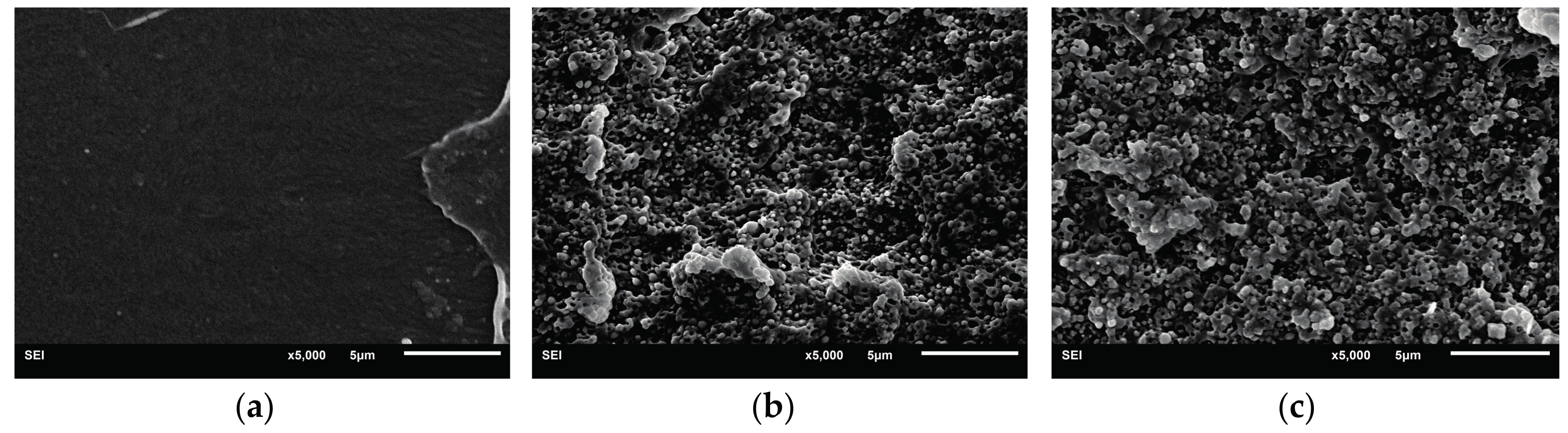

3.2. Dispersed Phase Morphology

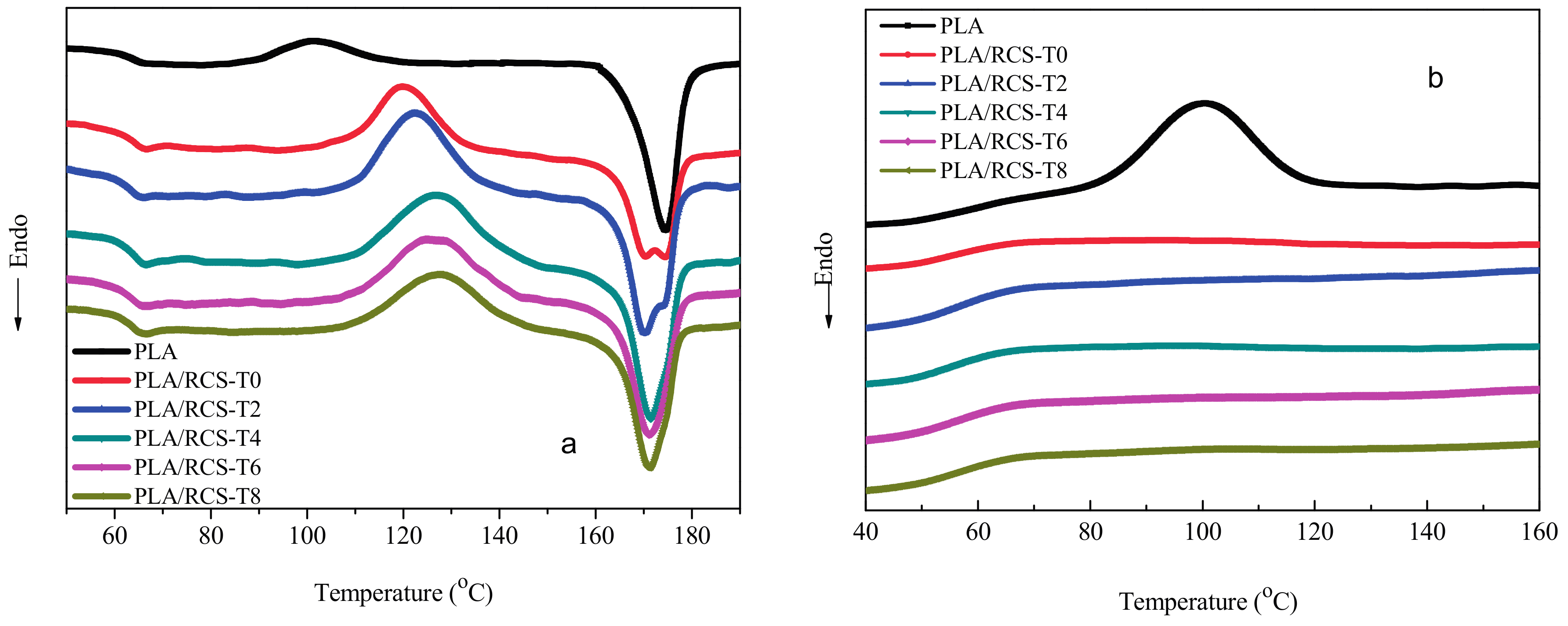

3.3. DSC Analysis

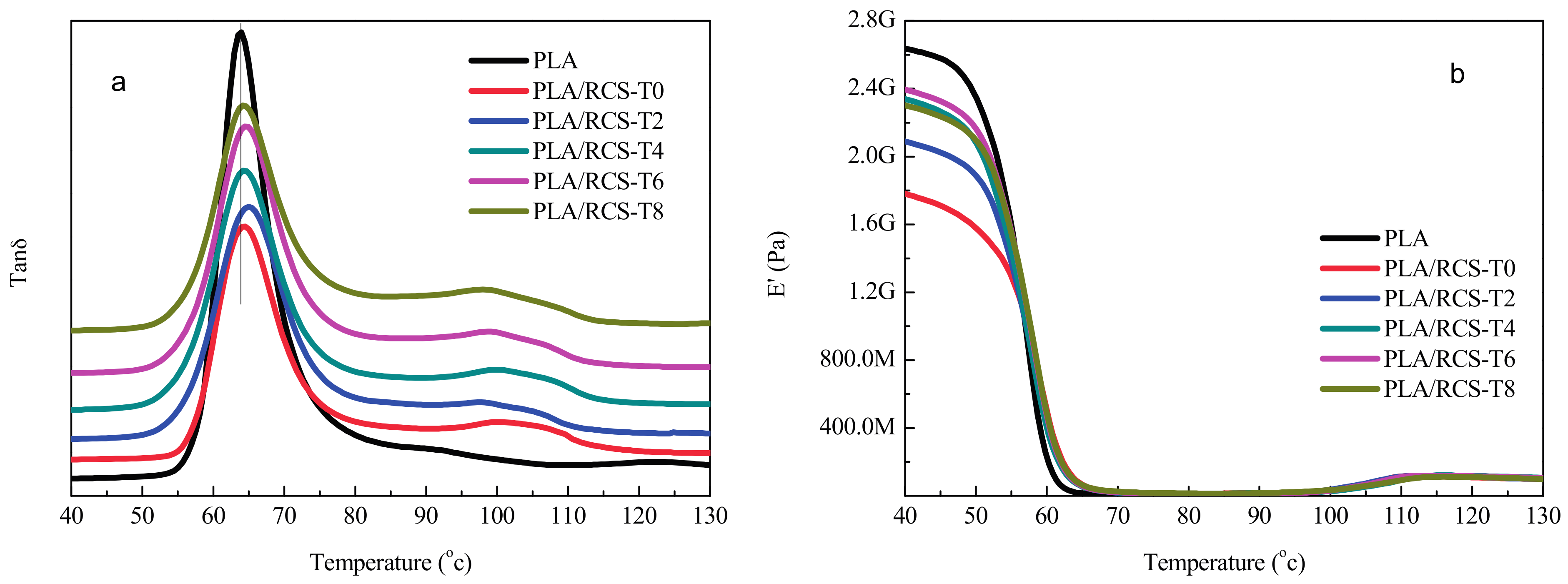

3.4. Dynamic Mechanical Properties

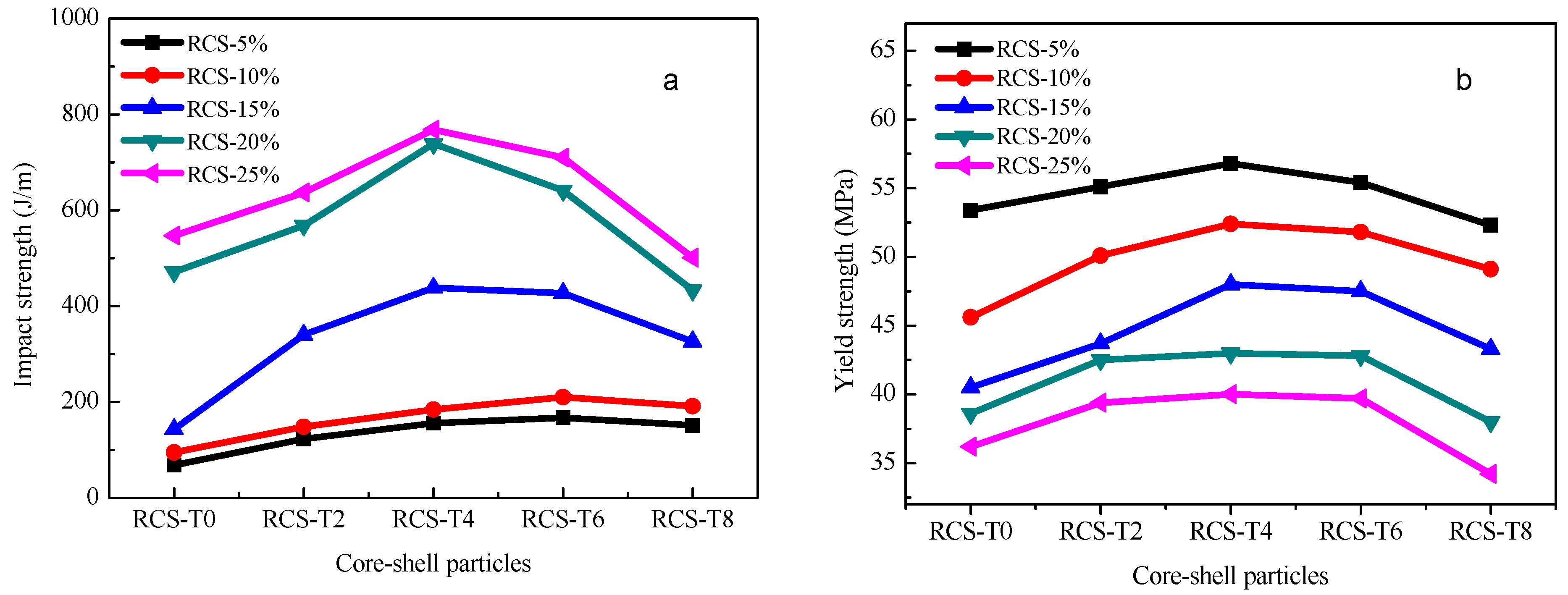

3.5. Mechanical Properties

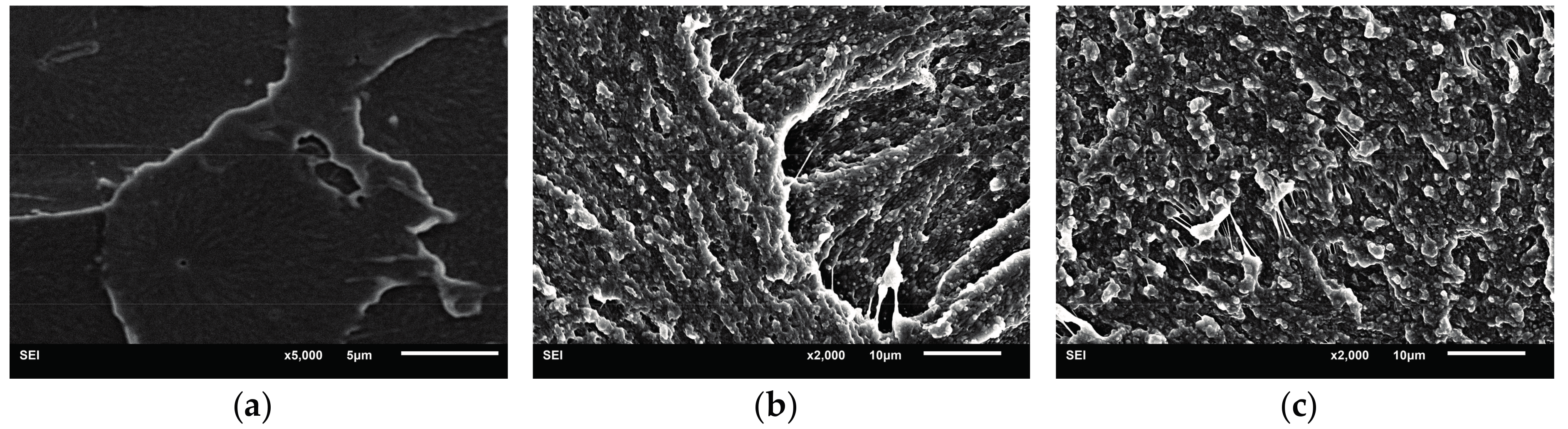

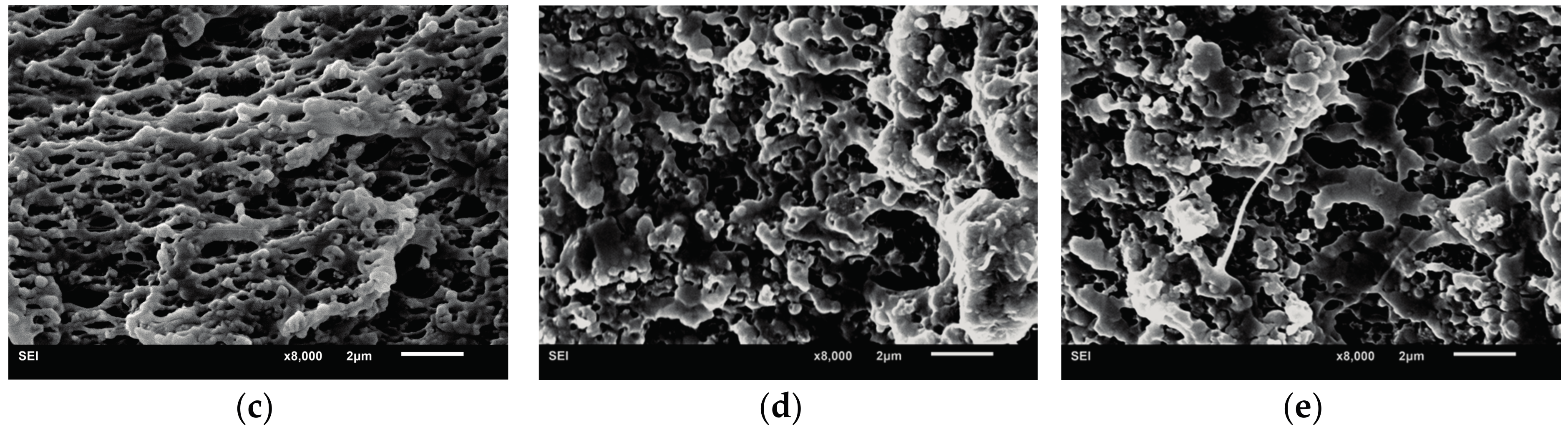

3.6. Fracture Mechanism

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Slomkowski, S.; Penczek, S.; Duda, A. Polylactides—An overview. Polym. Adv. Technol. 2014, 25, 436–447. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Muiruri, J.K.; Liu, S.L.; Teo, W.S.; Kong, J.; He, C. Highly biodegradable and tough polylactic acid–cellulose nanocrystal composite. ACS Sustain. Chem. Eng. 2017, 5, 3929–3937. [Google Scholar] [CrossRef]

- Gao, H.H.; Qiang, T. Fracture Surface Morphology and impact strength of cellulose/PLA composites. Materials 2017, 10, 624. [Google Scholar] [CrossRef] [PubMed]

- Balakrishnan, H.; Hassan, A.; Imran, M.; Wahit, M.U. Toughening of Polylactic Acid Nanocomposites: A Short Review. Polym.-Plast. Technol. Eng. 2012, 51, 175–192. [Google Scholar] [CrossRef]

- Sun, Y.; He, C.B. Synthesis, stereocomplex crystallization, morphology and mechanical property of poly(lactide)-carbon nanotube nanocomposites. RSC Adv. 2013, 3, 2219–2226. [Google Scholar] [CrossRef]

- Sun, Y.; He, C. Biodegradable “core-shell” rubber nanoparticles and their toughening of poly (lactides). Macromolecules 2013, 46, 9625–9633. [Google Scholar] [CrossRef]

- Bai, H.; Bai, D.; Xiu, H.; Liu, H.; Zhang, Q.; Wang, K.; Deng, H.; Chen, F.; Fu, Q.; Chiu, F.-C. Towards high-performance poly (Llactide)/elastomer blends with tunable interfacial adhesion and matrix crystallization via constructing stereocomplex crystallites at the interface. RSC Adv. 2014, 4, 49374–49385. [Google Scholar] [CrossRef]

- Brzeziński, M.; Biela, T. Polylactide nanocomposites with functionalized carbon nanotubes and their stereocomplexes: A focused review. Mater. Lett. 2014, 121, 244–250. [Google Scholar] [CrossRef]

- Raquez, J.-M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Zeng, J.; Li, K.; Du, A. Compatibilization strategies in poly(lacticacid)-based blends. RSC Adv. 2015, 5, 32546–32565. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J. Research progress in toughening modification of poly(lactic acid). J. Polym. Sci. Part B: Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Anderson, K.S.; Schreck, K.M.; Hillmyer, M.A. Toughening polylactide. Polym. Rev. 2008, 48, 85–108. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Kulinski, Z.; Piorkowska, E. Crystallization, structure and properties of plasticized poly(l-lactide). Polymer 2005, 46, 10290–10300. [Google Scholar] [CrossRef]

- Ozkoc, G.; Kemaloglu, S. Morphology, biodegradability, mechanical, and thermal properties of nanocomposite films based on PLA and plasticized PLA. J. Appl. Polym. Sci. 2009, 114, 2481–2487. [Google Scholar] [CrossRef]

- Kulinski, Z.; Piorkowska, E.; Gadzinowska, A.K.; Stasiak, M. Plasticization of Poly(l-lactide) with Poly(propylene glycol). Biomacromolecules 2006, 47, 7178–7188. [Google Scholar] [CrossRef] [PubMed]

- Ge, H.H.; Yang, F.; Hao, Y.P.; Wu, G.F.; Zhang, H.L.; Dong, L.S. Thermal, Mechanical, and Rheological Properties of Plasticized Poly(L-lactic acid). J. Appl. Polym. Sci. 2013, 127, 2832–2839. [Google Scholar] [CrossRef]

- Odent, J.; Leclere, P.; Raquez, J.; Dubois, P. Toughening of polylactide by tailoring phase-morphology with P [CL-co-LA] random copolyesters as biodegradable impact modifiers. Eur. Polym. J. 2013, 49, 914–922. [Google Scholar] [CrossRef]

- Odent, J.; Raquez, J.; Duquesne, E.; Dubois, P. Random aliphatic copolyesters as new biodegradable impact modifiers for polylactide materials. Eur. Polym. J. 2012, 48, 331–340. [Google Scholar] [CrossRef]

- Peponi, L.; Navarro-Baena, I.; Báez, J.E.; Kenny, J.M.; Marcos-Fernández, A. Effect of the molecular weight on the crystallinity of PCL-b-PLLA diblock copolymers. Polymer 2012, 53, 4561–4568. [Google Scholar] [CrossRef]

- Oyama, H.T. Super-tough poly(lactic acid) materials: Reactive blending with ethylene copolymer. Polymer 2009, 50, 747–751. [Google Scholar] [CrossRef]

- Su, Z.; Li, Q.; Liu, Y.; Hu, G.; Wu, C. Compatibility and phase structure of binary blends of poly(lactic acid) and glycidyl methacrylate grafted poly(ethylene octane). Eur. Polym. J. 2009, 45, 2428–2433. [Google Scholar] [CrossRef]

- Kang, H.; Hu, X.; Li, M.; Zhang, L.; Wu, Y.; Ning, N.; Tian, M. Novel biobased thermoplastic elastomer consisting of synthetic polyester elastomer and polylactide by in situ dynamical crosslinking method. RSC Adv. 2015, 5, 23498–23507. [Google Scholar] [CrossRef]

- Ojijo, V.; Ray, S.S.; Sadiku, R. Toughening of biodegradable polylactide/poly(butylene succinate-co-adipate) blends via in situ reactive compatibilization. ACS Appl. Mater. Interfaces 2013, 5, 4266–4276. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Zhang, Y.; Wu, D.D.; Li, Z.L.; Zhang, H.L.; Dong, L.S.; Sun, S.L.; Deng, Y.J.; Zhang, H.X. The effect of core-shell ratio of acrylic impact modifier on toughening PLA. Adv. Polym. Technol. 2015. [Google Scholar] [CrossRef]

- Song, X.; Chen, Y.; Xu, Y.; Wang, C. Study on Tough Blends of Polylactide and Acrylic Impact Modifier. BioResources 2014, 9, 1939–1952. [Google Scholar] [CrossRef]

- Zhang, H.L.; Liu, N.N.; Ran, X.H.; Han, C.Y.; Han, L.J.; Zhang, Y.G.; Dong, L.S. Toughening of polylactide by melt with methyl methacrylate-butadiene-styrene copolymer. J. Appl. Polym. Sci. 2012, 125, E550–E561. [Google Scholar] [CrossRef]

- Liang, H.Y.; Hao, Y.P.; Bian, J.J.; Zhang, H.L.; Dong, L.S.; Zhang, H.X. Assessment of miscibility, crystallization behavior, and toughening mechanism of polylactide/acrylate copolymer blends. Polym. Eng. Sci. 2015, 55, 386–396. [Google Scholar] [CrossRef]

- Hao, Y.P.; Liang, H.Y.; Bian, J.J.; Sun, S.L.; Zhang, H.L.; Dong, L.S. Toughening of polylactide with epoxy-functionalized methyl methacrylate-butadiene copolymer. Polym. Int. 2013, 63, 660–666. [Google Scholar] [CrossRef]

- Zhang, H.L.; Liang, H.Y.; Bian, J.J.; Hao, Y.P.; Han, L.J.; Wang, X.M.; Zhang, G.B.; Liu, S.R.; Dong, L.S. Influence of acrylic impact modifier on plasticized polylactide blown films. Polym. Int. 2014, 63, 1076–1084. [Google Scholar] [CrossRef]

- Li, W.; Wu, D.D.; Sun, S.L.; Wu, G.F.; Zhang, H.X.; Deng, Y.J.; Zhang, H.L.; Dong, L.S. Toughening of polylactide with epoxy-functionalized methyl methacrylate-butyl acrylate copolymer. Polym. Bull. 2014, 71, 2881–2902. [Google Scholar] [CrossRef]

- Wu, N.J.; Zhang, H. Toughening of poly(L-lactide) modified by a small amount of acrylonitrile-butadiene-styrene core-shell polymer. J. Appl. Polym. Sci. 2015, 132, 42554. [Google Scholar] [CrossRef]

- Sun, S.; Zhang, M.; Zhang, H.; Zhang, X. Polylactide toughening with epoxy-functionalized grafted acrylonitrile−butadiene−styrene particles. J. Appl. Polym. Sci. 2011, 122, 2992–2999. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J.; Wang, S.; Shen, D. Miscibility and phase structure of binary blends of polylactide and poly(methyl methacrylate). J. Polym. Sci. Part B: Polym. Phys. 2003, 41, 23–30. [Google Scholar] [CrossRef]

- Guo, Y.; Sun, S.; Zhang, H. Modification of the core-shell ratio to prepare PB-g-(MMA-co-St-co-GMA) particle-toughened poly(butylene terephthalate) and polycarbonate blends with balanced stiffness and toughness. RSC. Adv. 2014, 4, 58880–58887. [Google Scholar] [CrossRef]

- Pawlak, A.; Galeski, A.; Rozanski, A. Cavitation during deformation of semicrystalline polymers. Prog. Polym. Sci. 2014, 39, 921–958. [Google Scholar] [CrossRef]

| Designation Used Here | Polybutadiene (PB) Content (wt %) | Styrene/Methyl Methacrylate (St/MMA) (wt/wt) | Glycidyl Methacrylate (GMA) Content (wt %) | Tert-Dodecyl Mercaptan (TDDM) Content (mL/wt %) |

|---|---|---|---|---|

| RCS-T0 | 50 | 3/1 | 1 | 0/0 |

| RCS-T2 | 50 | 3/1 | 1 | 2/0.38 |

| RCS-T4 | 50 | 3/1 | 1 | 4/0.76 |

| RCS-T6 | 50 | 3/1 | 1 | 6/1.15 |

| RCS-T8 | 50 | 3/1 | 1 | 8/1.53 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Song, S.; Zhao, X.; Lv, X.; Sun, S. Grafting Modification of the Reactive Core-Shell Particles to Enhance the Toughening Ability of Polylactide. Materials 2017, 10, 957. https://doi.org/10.3390/ma10080957

Li Z, Song S, Zhao X, Lv X, Sun S. Grafting Modification of the Reactive Core-Shell Particles to Enhance the Toughening Ability of Polylactide. Materials. 2017; 10(8):957. https://doi.org/10.3390/ma10080957

Chicago/Turabian StyleLi, Zhaokun, Shixin Song, Xuanchen Zhao, Xue Lv, and Shulin Sun. 2017. "Grafting Modification of the Reactive Core-Shell Particles to Enhance the Toughening Ability of Polylactide" Materials 10, no. 8: 957. https://doi.org/10.3390/ma10080957