Compression Fracture of CFRP Laminates Containing Stress Intensifications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

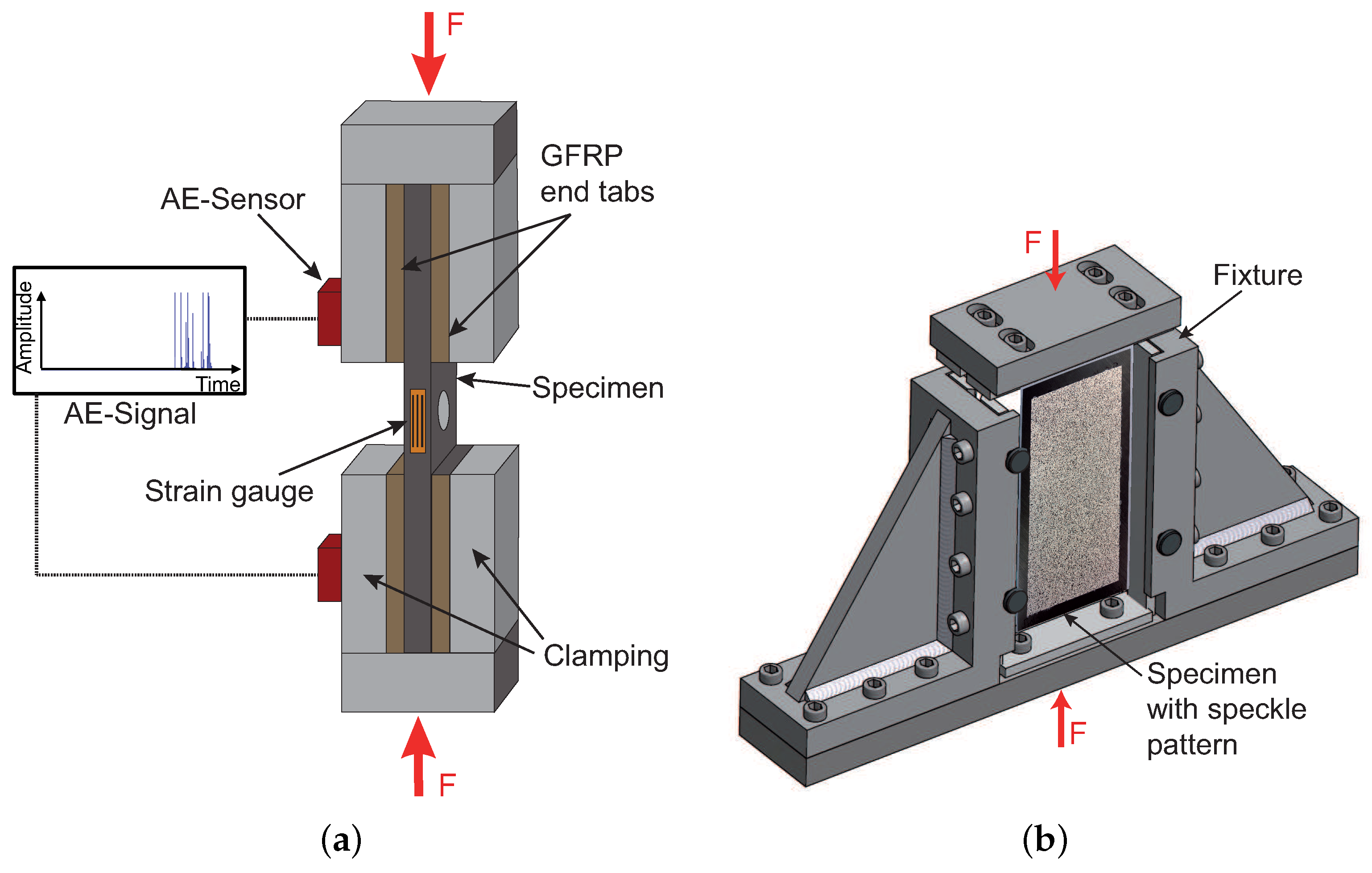

2.2. Compression Test Set-Up

3. Results

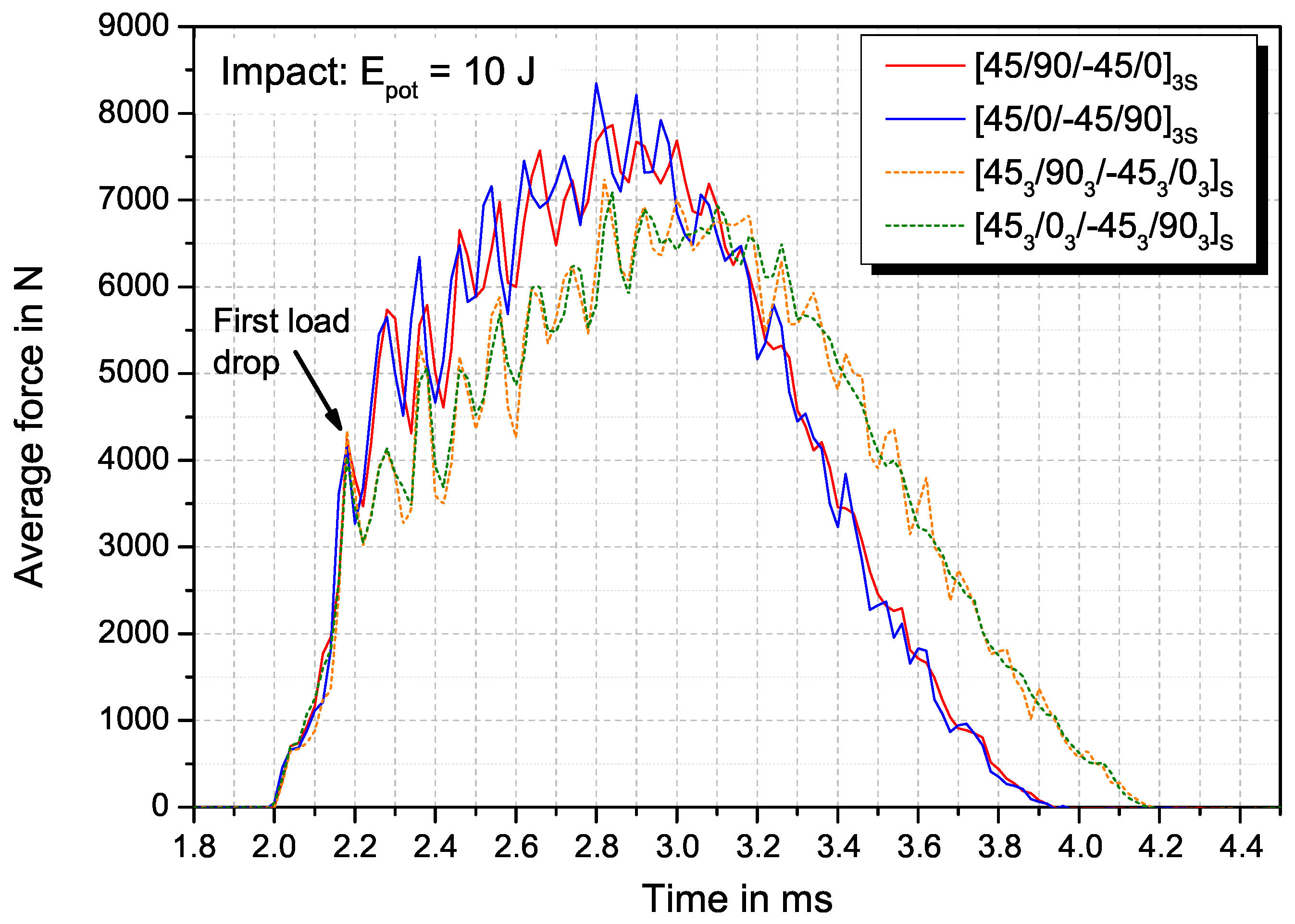

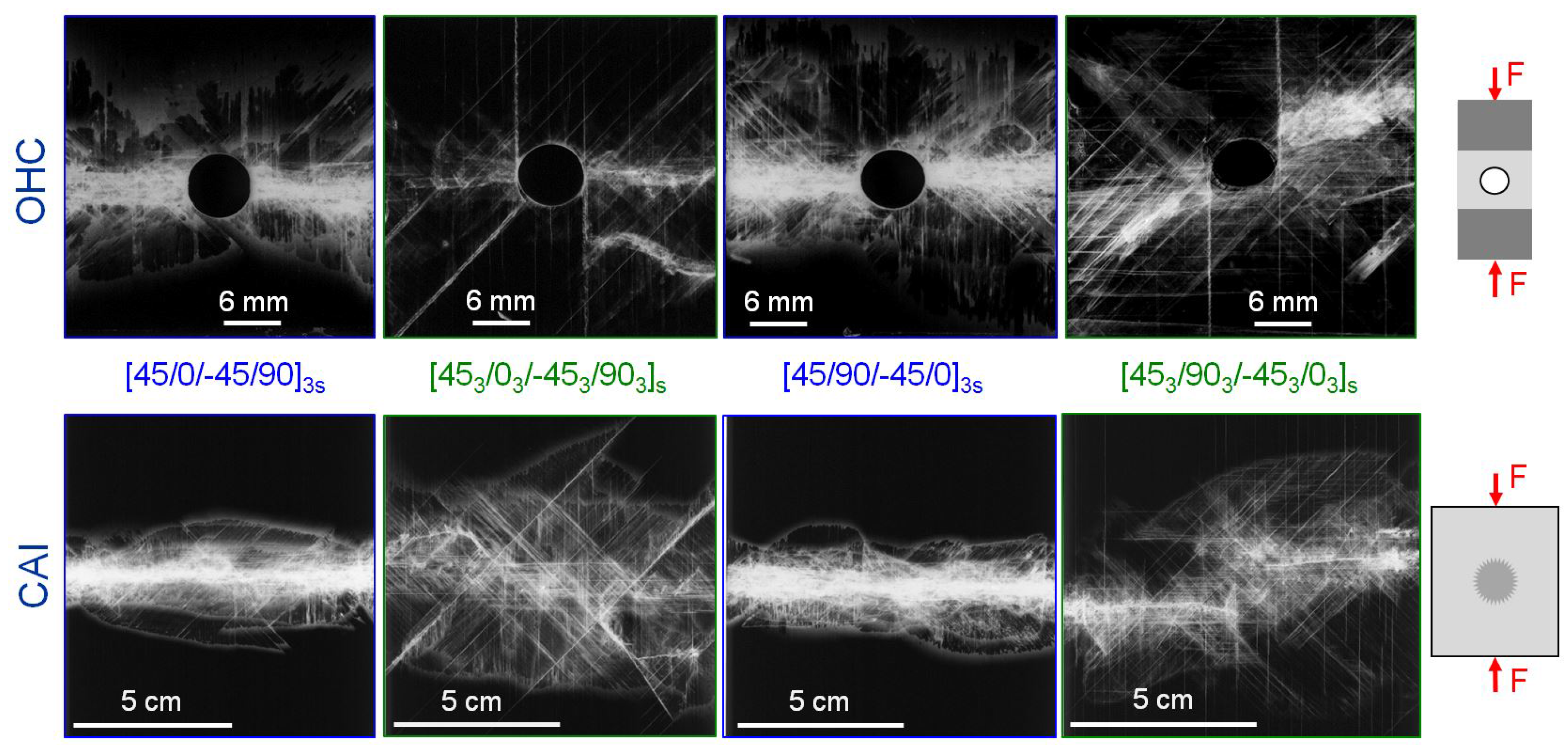

3.1. Impact Damage

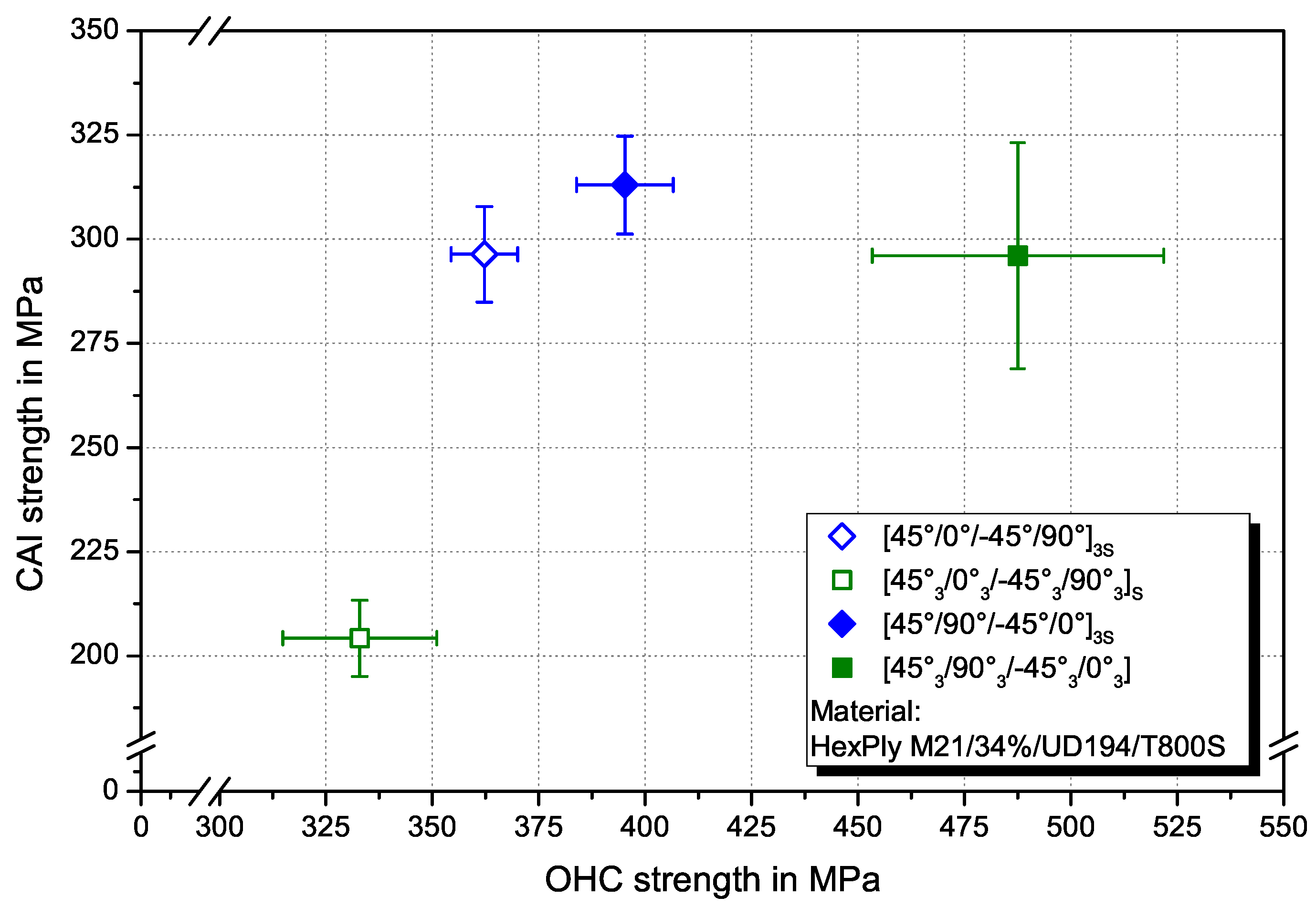

3.2. Compression Tests

Interrupted Open-Hole Compression Tests

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AE | Acoustic emission |

| CAI | Compression after impact |

| CFRP | Carbon fibre reinforced plastic |

| DIC | Digital image correlation |

| CPT | Cured ply thickness |

| OHC | Open-hole compression |

| QI | Quasi-isotropic |

| SEM | Scanning electron microscopy |

| UNC | Unnotched Compression |

| US | Ultrasonic |

References

- Rosen, B.W. Mechanics of composite strengthening. In American Society for Metals: Seminar on Fiber Composite Materials; American Society for Metals (ASM): Philadelphia, PA, USA, 1964; pp. 37–75. [Google Scholar]

- Moran, P.M.; Liu, X.H.; Shih, C.F. Kink band formation and band broadening in fiber composites under compressive loading. Acta Metall. Mater. 1995, 43, 2943–2958. [Google Scholar] [CrossRef]

- Poulsen, J.S.; Moran, P.M.; Shih, C.F.; Byskov, E. Kink band initiation and band broadening in clear wood under compressive loading. Mech. Mater. 1997, 25, 67–77. [Google Scholar] [CrossRef]

- Fleck, N.; Jelf, P.; Curtis, P. Compressive Failure of Laminated and Woven Composites: Compressive Failure of Laminated and Woven Composites. J. Compos. Technol. Res. 1995, 17, 212–220. [Google Scholar]

- Budiansky, B.; Fleck, N.A. Compressive failure of fibre composites. J. Mech. Phys. Solids 1993, 41, 183–211. [Google Scholar] [CrossRef]

- Budiansky, B.; Fleck, N.A.; Amazigo, J.C. On kink-band propagation in fiber composites. J. Mech. Phys. Solids 1998, 46, 1637–1653. [Google Scholar] [CrossRef]

- Gutkin, R.; Pinho, S.T.; Robinson, P.; Curtis, P. On the transition from shear-driven fibre compressive failure to fibre kinking in notched CFRP laminates under longitudinal compression. Compos. Sci. Technol. 2010, 70, 1223–1231. [Google Scholar] [CrossRef]

- Gutkin, R.; Pinho, S.T.; Robinson, P.; Curtis, P.T. Micro-mechanical modelling of shear-driven fibre compressive failure and of fibre kinking for failure envelope generation in CFRP laminates. Compos. Sci. Technol. 2010, 70, 1214–1222. [Google Scholar] [CrossRef]

- Liebig, W.V.; Leopold, C.; Schulte, K. Photoelastic study of stresses in the vicinity of a unique void in a fibre-reinforced model composite under compression. Compos. Sci. Technol. 2013, 84, 72–77. [Google Scholar] [CrossRef]

- Liebig, W.V.; Schulte, K.; Fiedler, B. Hierarchical analysis of the degradation of fibre-reinforced polymers under the presence of void imperfections. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2016, 374, 20150279. [Google Scholar] [CrossRef] [PubMed]

- Shams, S.S.; Elhajjar, R.F. Investigation into the effects of fiber waviness in standard notched composite specimens. CEAS Aeronaut. J. 2015, 6, 541–555. [Google Scholar] [CrossRef]

- Wisnom, M.R. Size effects in the testing of fibre-composite materials. Compos. Sci. Technol. 1999, 59, 1937–1957. [Google Scholar] [CrossRef]

- Soutis, C. Measurement of the static compressive strength of carbon-fibre/epoxy laminates. Compos. Sci. Technol. 1991, 42, 373–392. [Google Scholar] [CrossRef]

- Lee, J.; Soutis, C. Thickness effect on the compressive strength of T800/924C carbon fibre—Epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2005, 36, 213–227. [Google Scholar] [CrossRef]

- Lee, J.; Soutis, C. Measuring the notched compressive strength of composite laminates: Specimen size effects. Compos. Sci. Technol. 2008, 68, 2359–2366. [Google Scholar] [CrossRef]

- Soutis, C.; Lee, J. Scaling effects in notched carbon fibre/epoxy composites loaded in compression. J. Mater. Sci. 2008, 43, 6593–6598. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Hallett, S.R.; Soutis, C. Scaling Effects in Notched Composites. J. Compos. Mater. 2010, 44, 195–210. [Google Scholar] [CrossRef] [Green Version]

- Arteiro, A.; Catalanotti, G.; Melro, A.R.; Linde, P.; Camanho, P.P. Micro-mechanical analysis of the effect of ply thickness on the transverse compressive strength of polymer composites. Compos. Part A Appl. Sci. Manuf. 2015, 79, 127–137. [Google Scholar] [CrossRef]

- Flaggs, D.L.; Kural, M.H. Experimental Determination of the In Situ Transverse Lamina Strength in Graphite/Epoxy Laminates. J. Compos. Mater. 1982, 16, 103–116. [Google Scholar] [CrossRef]

- Sihn, S.; Kim, R.Y.; Kawabe, K.; Tsai, S.W. Experimental studies of thin-ply laminated composites. Compos. Sci. Technol. 2007, 67, 996–1008. [Google Scholar] [CrossRef]

- Amacher, R.; Cugnoni, J.; Botsis, J.; Sorensen, L.; Smith, W.; Dransfeld, C. Thin ply composites: Experimental characterization and modeling of size-effects. Compos. Sci. Technol. 2014, 101, 121–132. [Google Scholar] [CrossRef]

- Pipes, R.B.; Pagano, N.J. Interlaminar Stresses in Composite Laminates Under Uniform Axial Extension. J. Compos. Mater. 1970, 4, 538–548. [Google Scholar] [CrossRef]

- Pagano, N.J.; Pipes, R.B. The Influence of Stacking Sequence on Laminate Strength. J. Compos. Mater. 1971, 5, 50–57. [Google Scholar] [CrossRef]

- Mittelstedt, C.; Becker, W. Free-Edge Effects in Composite Laminates. Appl. Mech. Rev. 2007, 60, 217–245. [Google Scholar] [CrossRef]

- Camanho, P.P.; Arteiro, A.; Turon, A.; Costa, J.; Guillamet, E.G. Structural integrity of thin-ply laminates. JEC Compos. Mag. 2012, 71, 91–92. [Google Scholar]

- Soutis, C.; Fleck, N.A.; Smith, P.A. Failure Prediction Technique for Compression Loaded Carbon Fibre-Epoxy Laminate with Open Holes. J. Compos. Mater. 1991, 25, 1476–1498. [Google Scholar] [CrossRef]

- Erçin, G.H.; Camanho, P.P.; Xavier, J.; Catalanotti, G.; Mahdi, S.; Linde, P. Size effects on the tensile and compressive failure of notched composite laminates. Compos. Struct. 2013, 96, 736–744. [Google Scholar] [CrossRef]

- Suemasu, H.; Takahashi, H.; Ishikawa, T. On failure mechanisms of composite laminates with an open hole subjected to compressive load. Compos. Sci. Technol. 2006, 66, 634–641. [Google Scholar] [CrossRef]

- Wang, J.; Callus, P.; Bannister, M. Experimental and numerical investigation of the tension and compression strength of un-notched and notched quasi-isotropic laminates. Compos. Struct. 2004, 64, 297–306. [Google Scholar] [CrossRef]

- Saito, H.; Morita, M.; Kawabe, K.; Kanesaki, M.; Takeuchi, H.; Tanaka, M.; Kimpara, I. Effect of ply-thickness on impact damage morphology in CFRP laminates. J. Reinf. Plast. Compos. 2011, 30, 1097–1106. [Google Scholar] [CrossRef]

- González, E.V.; Maimí, P.; Camanho, P.P.; Lopes, C.S.; Blanco, N. Effects of ply clustering in laminated composite plates under low-velocity impact loading. Compos. Sci. Technol. 2011, 71, 805–817. [Google Scholar] [CrossRef]

- González, E.V.; Maimí, P.; Camanho, P.P.; Turon, A.; Mayugo, J.A. Simulation of drop-weight impact and compression after impact tests on composite laminates. Compos. Struct. 2012, 94, 3364–3378. [Google Scholar] [CrossRef]

- Bull, D.J.; Spearing, S.M.; Sinclair, I. Observations of damage development from compression-after-impact experiments using ex situ micro-focus computed tomography. Compos. Sci. Technol. 2014, 97, 106–114. [Google Scholar] [CrossRef]

- Yokozeki, T.; Aoki, Y.; Ogasawara, T. Experimental characterization of strength and damage resistance properties of thin-ply carbon fiber/toughened epoxy laminates. Compos. Struct. 2008, 82, 382–389. [Google Scholar] [CrossRef]

- Greenhalgh, E.S.; Rogers, C.; Robinson, P. Fractographic observations on delamination growth and the subsequent migration through the laminate. Compos. Sci. Technol. 2009, 69, 2345–2351. [Google Scholar] [CrossRef]

- Airbus, S.A.S. AITM 1-0008: Fibre Reinforced Plastics—Determination of Plain, Open Hole and Filled Hole Compression Strength; Airbus SAS: Toulouse, France, 2004. [Google Scholar]

- ASTM International. ASTM D7136 / D7136M-15: Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. ASTM D7137 / D7137M-12: Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- German Institute for Standardisation. DIN EN 3615:1999-04: Fibre Reinforced Plastics—Determination of the Conditions of Exposure to Humid Atmosphere and of Moisture Absorption (Withdrawn); German Institute for Standardisation: Berlin, Germany, 1999. [Google Scholar]

- Große, C.U.; Ohtsu, M. Acoustic Emission Testing: Basics for Research—Applications in Civil Engineering, 1st ed.; Springer: Berlin, Germany, 2008. [Google Scholar]

- The Japanese Society for Non-Destructive Inspection; Mizutani, Y. Practical Acoustic Emission Testing; Mizutani, Y., Ed.; Springer: Tokyo, Japan, 2016. [Google Scholar]

- Qing-Qing, N.; Eiichi, J. Acoustic emission and fracture of Carbon Fiber Reinforced Thermosoftening Plastic (CFRTP) materials under monotonous tensile loading. Eng. Fracture Mech. 1993, 45, 611–625. [Google Scholar] [CrossRef]

- Mizutani, Y.; Nagashima, K.; Takemoto, M.; Ono, K. Fracture mechanism characterization of cross-ply carbon-fiber composites using acoustic emission analysis. NDT E Int. 2000, 33, 101–110. [Google Scholar] [CrossRef]

- Liu, P.F.; Chu, J.K.; Liu, Y.L.; Zheng, J.Y. A study on the failure mechanisms of carbon fiber/epoxy composite laminates using acoustic emission. Mater. Des. 2012, 37, 228–235. [Google Scholar] [CrossRef]

- Kosmann, N.; Karsten, J.; Schuett, M.; Schulte, K.; Fiedler, B. Determining the effect of voids in GFRP on the damage behaviour under compression loading using acoustic emission. Compos. Part B Eng. 2015, 70, 184–188. [Google Scholar] [CrossRef]

- Hsu, N.; Breckenridge, R. Characterization and Calibration of Acoustic Emission Sensors. Mater. Eval. 1981, 39, 60–68. [Google Scholar]

| Parameter | Value |

|---|---|

| Frame rate/MHz | 5 |

| Preamp gain/dB | 40 |

| Threshold/dB | 45 |

| Hit definition time (HDT)/ | 200 |

| Hit lockout time (HLT)/ | 300 |

| Peak definition time (PDT)/ | 50 |

| Maximum hit duration/ | 100 |

| Contact time/ | ||||

| Max. contact force/ | ||||

| Induced energy/ | ||||

| Damage area/ |

| UNC strength/MPa | ||||

| UNC /% | ≈1.40 | ≈0.70 | ≈1.60 | ≈0.80 |

| OHC strength/MPa | ||||

| OHC /% | ≈0.70 | ≈0.60 | ≈0.77 | ≈0.50 |

| CAI strength/MPa |

| Thick ply | Inner ply | Thin ply | Outer ply |

|---|---|---|---|

| Shear failure | Shear failure of single fibre | ||

| in plane | out of plane | ||

| is changing | is constant | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leopold, C.; Schütt, M.; Liebig, W.V.; Philipkowski, T.; Kürten, J.; Schulte, K.; Fiedler, B. Compression Fracture of CFRP Laminates Containing Stress Intensifications. Materials 2017, 10, 1039. https://doi.org/10.3390/ma10091039

Leopold C, Schütt M, Liebig WV, Philipkowski T, Kürten J, Schulte K, Fiedler B. Compression Fracture of CFRP Laminates Containing Stress Intensifications. Materials. 2017; 10(9):1039. https://doi.org/10.3390/ma10091039

Chicago/Turabian StyleLeopold, Christian, Martin Schütt, Wilfried V. Liebig, Timo Philipkowski, Jonas Kürten, Karl Schulte, and Bodo Fiedler. 2017. "Compression Fracture of CFRP Laminates Containing Stress Intensifications" Materials 10, no. 9: 1039. https://doi.org/10.3390/ma10091039