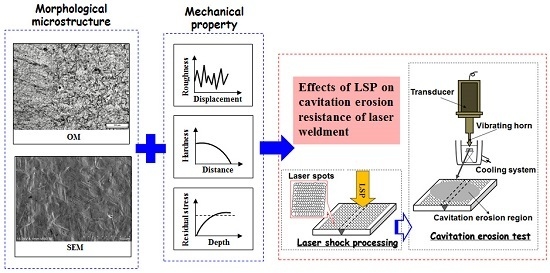

Effects of Laser Shock Processing on Morphologies and Mechanical Properties of ANSI 304 Stainless Steel Weldments Subjected to Cavitation Erosion

Abstract

:1. Introduction

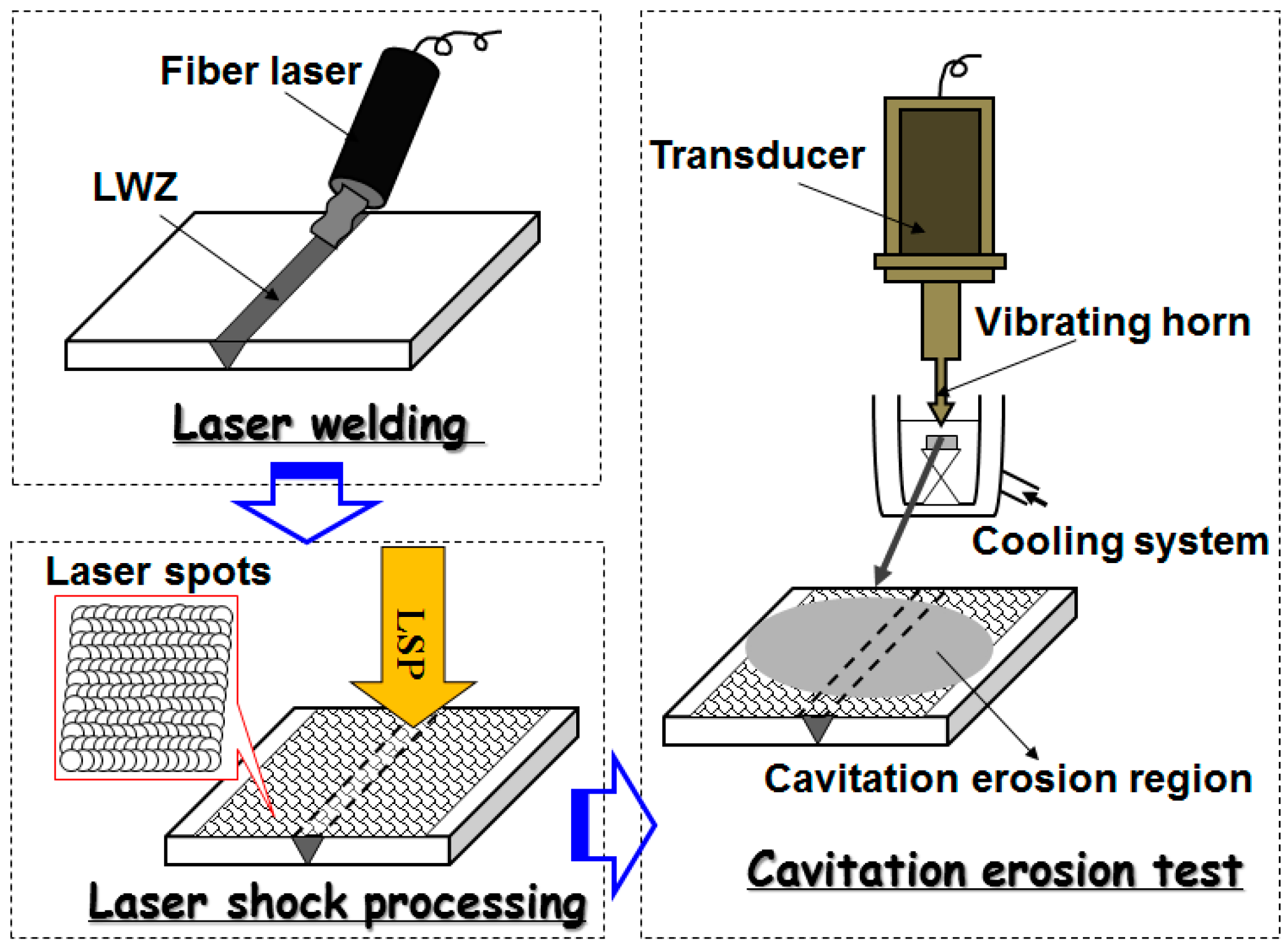

2. Materials and Methods

2.1. Materials and Laser Welding Procedure

2.2. Laser Shock Processing Experiment

2.3. Cavitation Erosion Experiment

2.4. Morphological Observation

2.5. Test Exposure to Ultrasound Cavitation Ageing

2.6. Surface Roughness, Micro-Hardness, and Residual Stress Measurement

3. Results and Discussion

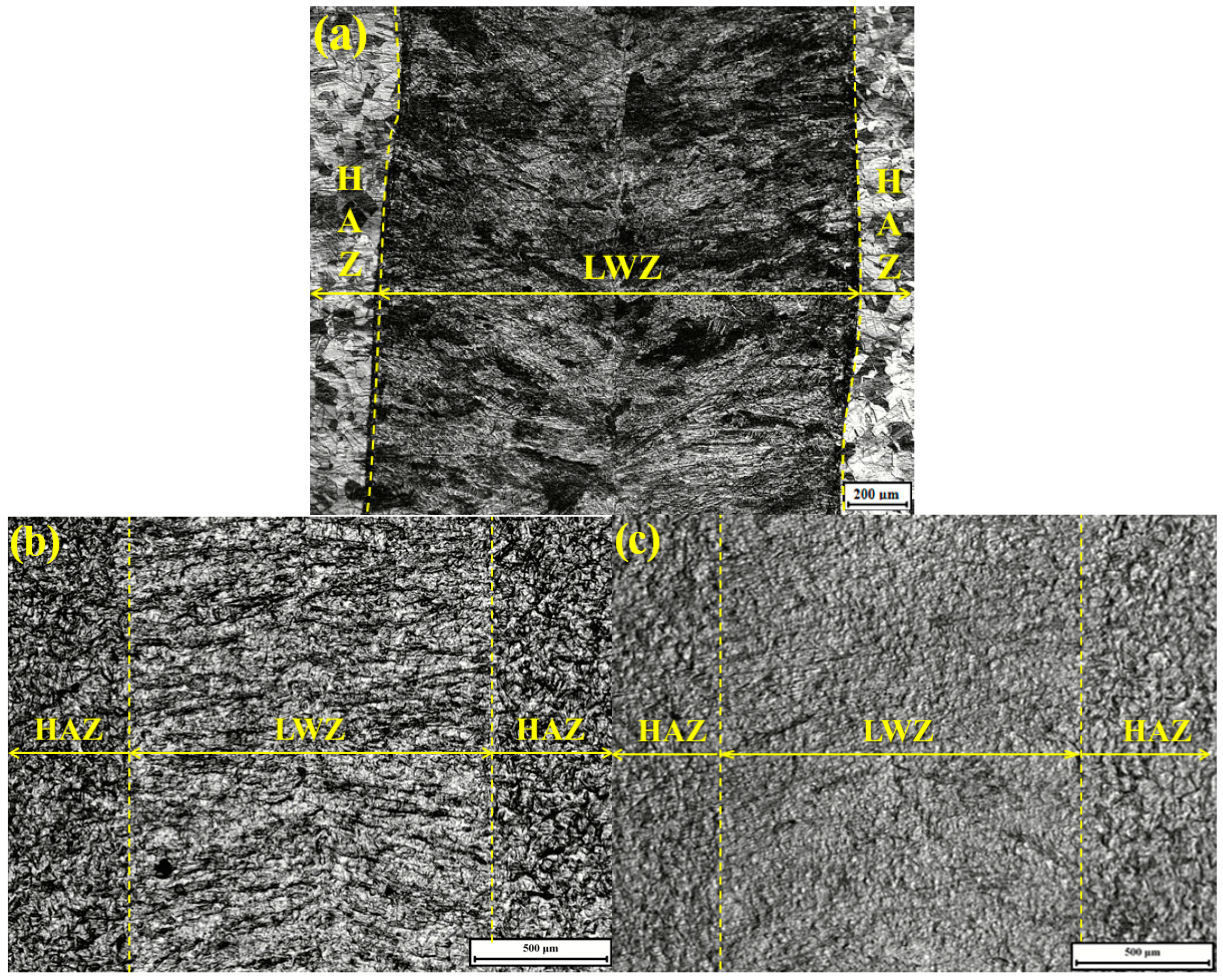

3.1. Surface Morphologies Observed under Different Ways and Magnifications

3.1.1. Morphological Observation by OM

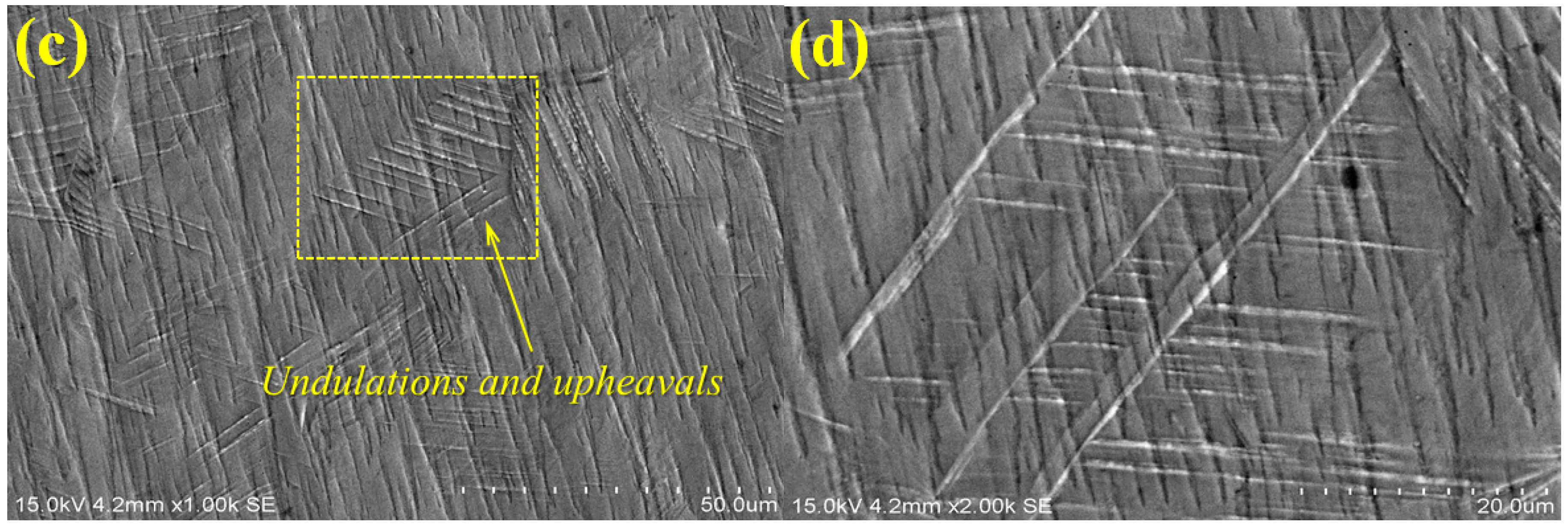

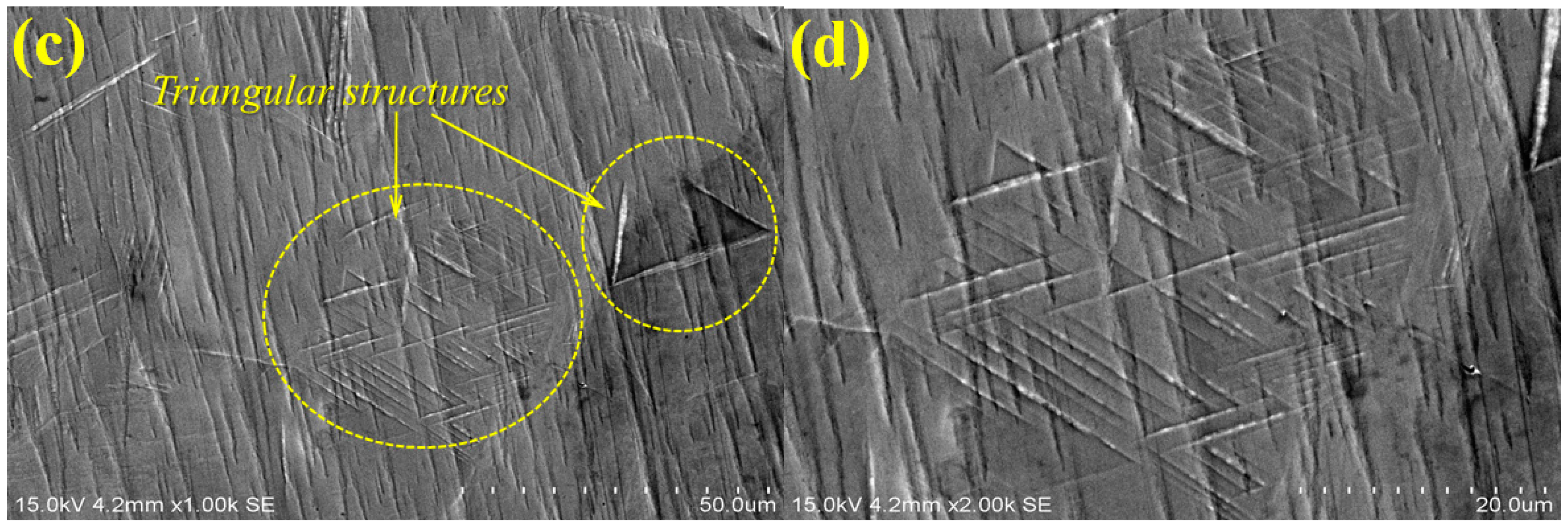

3.1.2. Morphological Observation by SEM

3.2. Mechanical Properties Measured during Cavitation Erosion

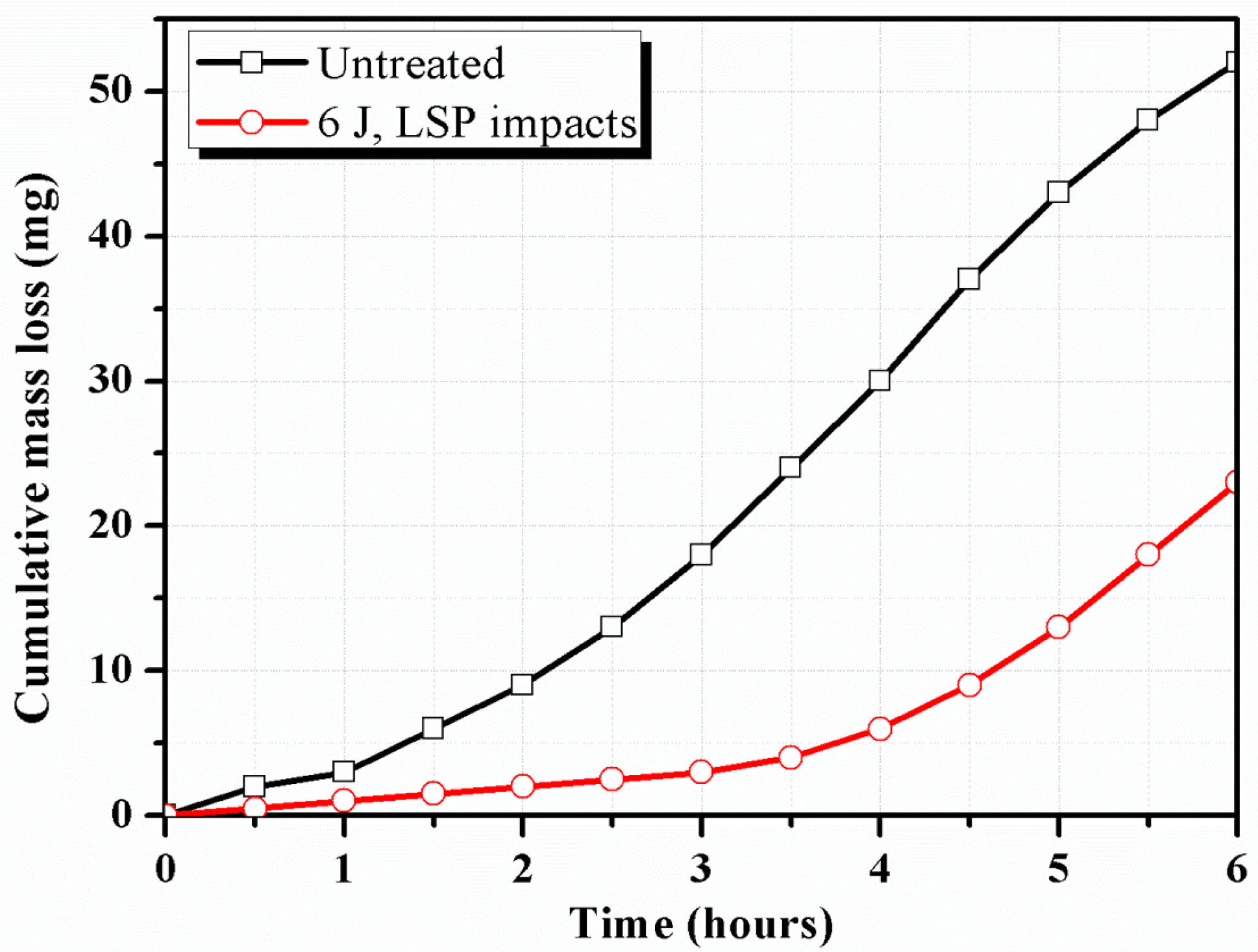

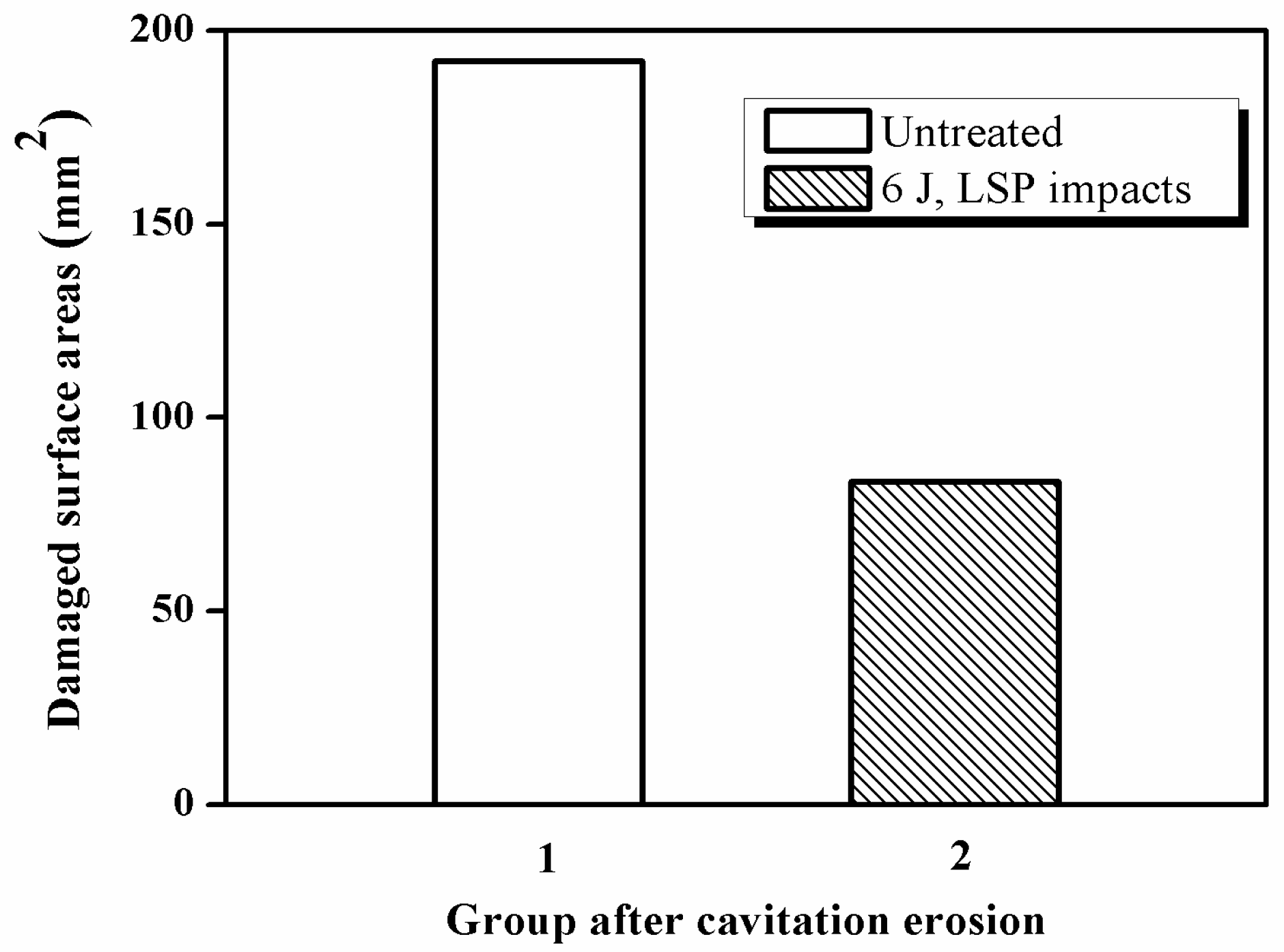

3.2.1. Measurement in the Development Process of Cavitation Erosion

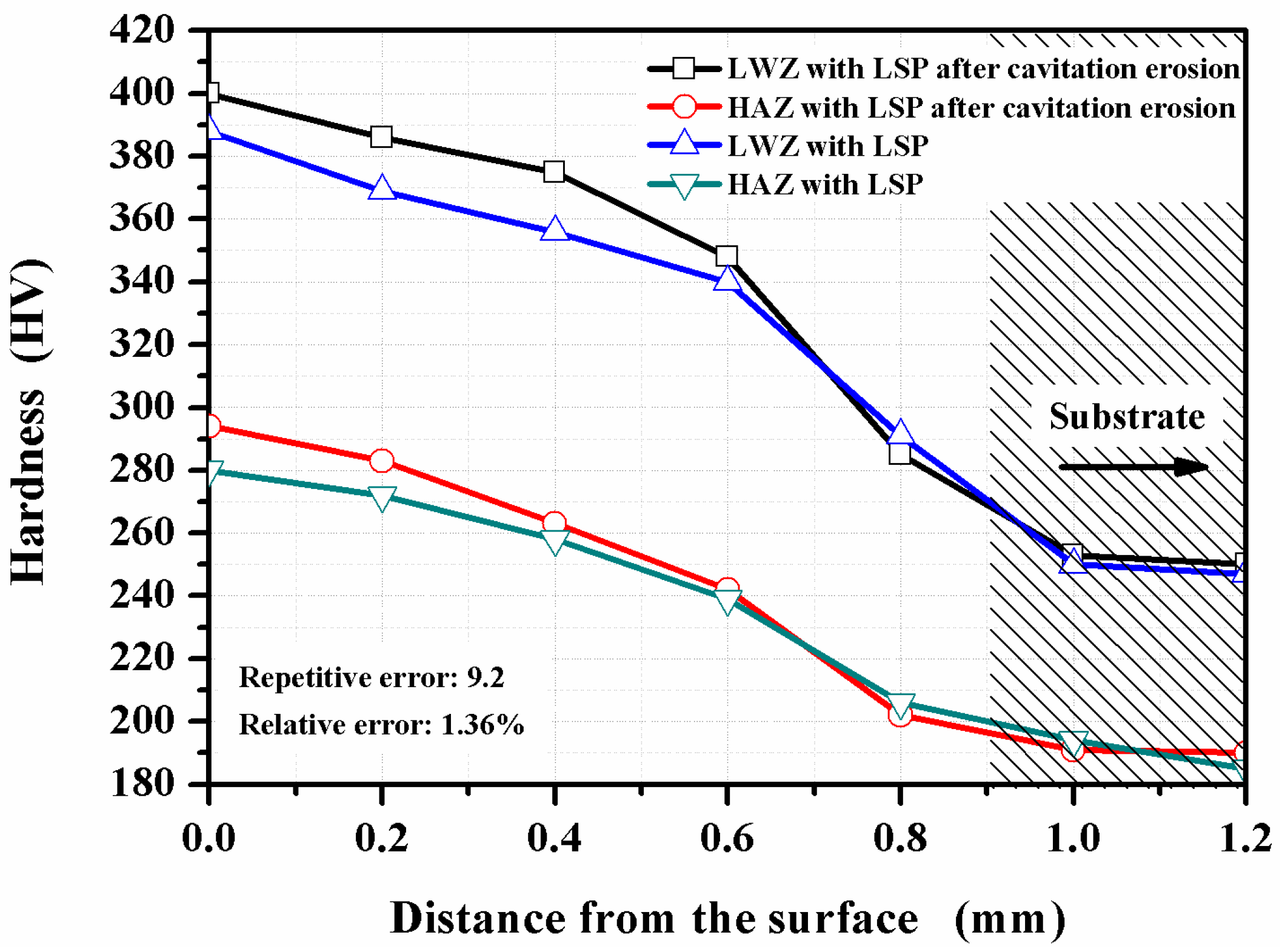

3.2.2. Surface Roughness, Micro-Hardness, and Residual Stress Analysis

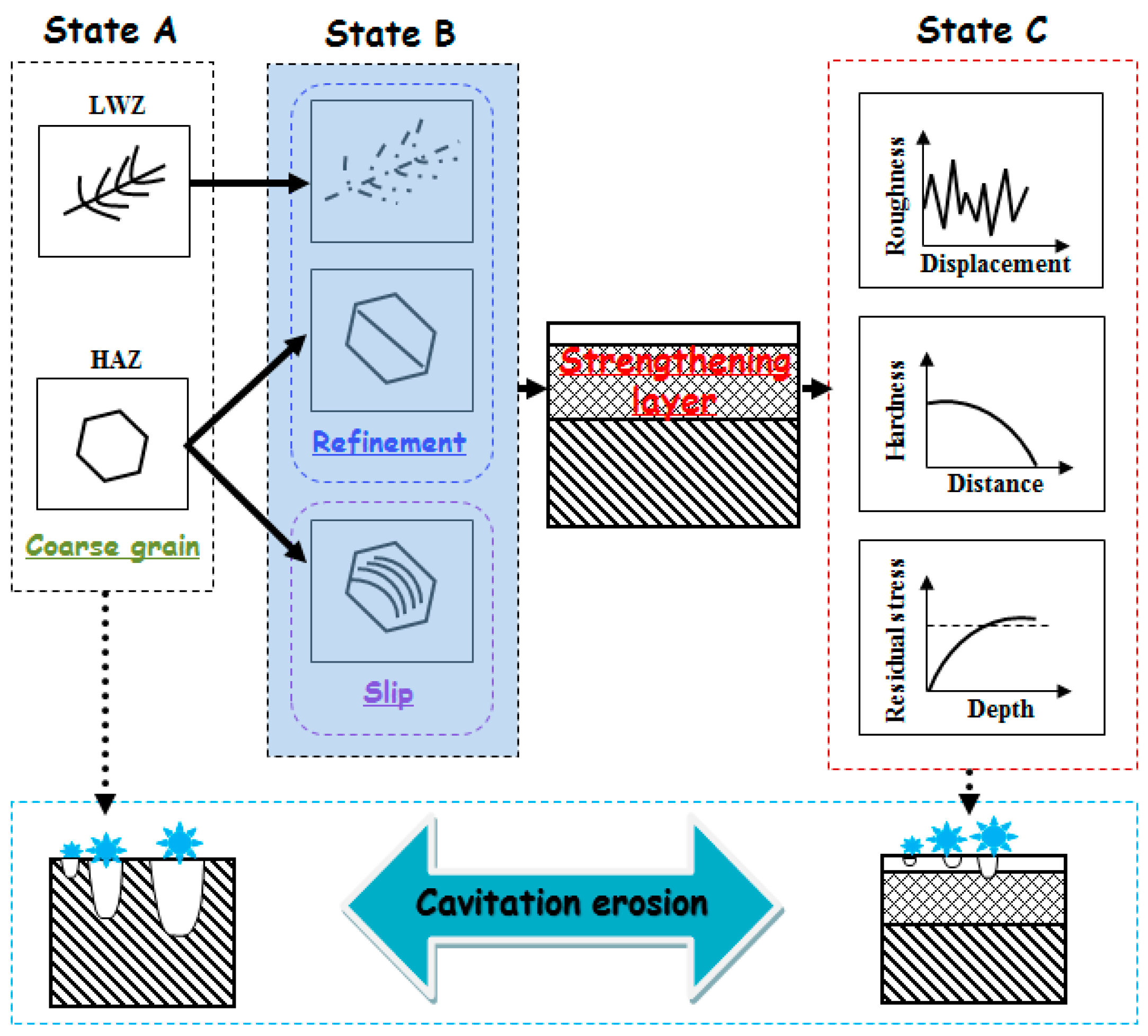

3.3. Strengthening Mechanism Explain of Cavitation Erosion Resistance during LSP

4. Conclusions

- (1)

- The surface morphologies of the samples are damaged after corrosion erosion. Those in the LWZ are different from that in the HAZ as demonstrated through the analysis of OM and SEM observations. Undulations and upheavals that present a dendrite structure occur on the surface of the LWZ, whereas common undulations and upheavals appear on the surface of the HAZ. All these undulations and upheavals become shallower and sparser because of LSP. The degree of damage on the surface morphology is relieved by LSP.

- (2)

- Compared with the untreated samples after cavitation erosion, the cumulative mass loss, erosion rate, and damaged surface areas decrease through LSP, whereas the incubation period become longer for LSPed samples. The surface roughness decreases through LSP after cavitation erosion. The surface roughness in the LWZ is lower than that in the HAZ. The hardness value is at its highest on the surface through LSP. The cross-sectional hardness in the LWZ is higher than that in the HAZ for the samples. Moreover, the LSPed surface of the LWZ and HAZ is in a state of high-level compressive residual stress, and the absolute value in the LWZ is higher than that in the HAZ. Hence, cavitation erosion resistance can be improved because of the existence of compressive residual stress.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yong, X.Y.; Li, D.L.; Shen, H.J. Electrochemical responses to degradation of the surface layer nano–mechanical properties of stainless steels under cavitation. Mater. Chem. Phys. 2013, 139, 290–297. [Google Scholar] [CrossRef]

- Sergiienko, R.; Shibata, E.; Akase, Z.; Suwa, H.; Nakamura, T.; Shindo, D. Carbon encapsulated iron carbide nanoparticles synthesized in ethanol by an electric plasma discharge in an ultrasonic cavitation field. Mater. Chem. Phys. 2006, 98, 34–38. [Google Scholar] [CrossRef]

- Baek, J.H.; Kim, Y.P.; Kim, W.S.; Kho, Y.T. Fracture toughness and fatigue crack growth properties of the base metal and weld metal of a type 304 stainless steel pipeline for LNG transmission. Int. J. Press. Vessels Pip. 2001, 78, 351–357. [Google Scholar] [CrossRef]

- Mukai, K.; Hoshino, K.; Fujioka, T. Tensile and fatigue properties of austenitic stainless steels at LNG temperature. Tetsu Hagane 1979, 65, 1756–1765. [Google Scholar]

- Lei, Y.C.; Feng, L.H.; Zhao, X.J. Cavitation erosion behavior of an austenitic stainless steel. J. Jiangsu Univ. Nat. Sci. Ed. 2006, 27, 241–244. [Google Scholar]

- Xu, G.F.; Qin, M.M.; Lei, Y.C.; Chen, X.Z. Cavitation erosion resistance of Fe-Cr-Ni-Co overlaying and remelting layer. Chin. J. Mater. Res. 2011, 25, 61–66. [Google Scholar]

- Ju, P.F.; Zuo, Y.; Tang, J.L.; Tang, Y.M.; Han, Z.Z. The characteristics of a Pd-Ni/Pd-Cu double coating on 316L stainless steel and the corrosion resistance in stirred boiling acetic and formic acids mixture. Mater. Chem. Phys. 2014, 144, 263–271. [Google Scholar] [CrossRef]

- Chang, J.T.; Yeh, C.H.; He, J.L.; Chen, K.C. Cavitation erosion and corrosion behavior of Ni–Al intermetallic coatings. Wear 2003, 255, 162–169. [Google Scholar] [CrossRef]

- Cui, C.Y.; Cui, X.G.; Zhao, Q.; Ren, X.D.; Zhou, J.Z.; Liu, Z.; Wang, Y.M. Simulation, microstructure and microhardness of the nano-SiC coating formed on Al surface via laser shock processing. Mater. Des. 2014, 62, 217–224. [Google Scholar] [CrossRef]

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Cui, C.Y.; Sun, G.F.; Zhou, J.Z.; Zhang, L.; You, J.; Chen, K.M.; Zhong, J.W. Grain refinement of LY2 aluminum alloy induced by ultra-high plastic strain during multiple laser shock processing impacts. Acta Mater. 2010, 58, 3984–3994. [Google Scholar] [CrossRef]

- Chen, X.Z.; Wang, J.J.; Fang, Y.Y.; Madigan, B.; Xu, G.F.; Zhou, J.Z. Investigation of microstructures and residual stresses in laser peened incoloy 800H weldments. Opt. Laser Technol. 2014, 57, 159–164. [Google Scholar] [CrossRef]

- Yang, D.H.; Zhang, X.S. The friction and wear of metals modified by a continuous wave CO2 laser. Surf. Coat. Technol. 1994, 63, 43–48. [Google Scholar]

- Shadangi, Y.; Chattopadhyay, K.; Rai, S.B.; Singh, V. Effect of laser shock peening on microstructure, mechanical properties and corrosion behavior of interstitial free steel. Surf. Coat. Technol. 2015, 280, 216–224. [Google Scholar] [CrossRef]

- Zhang, Y.K.; You, J.; Lu, J.Z.; Cui, C.Y.; Jiang, Y.F.; Ren, X.D. Effects of laser shock processing on stress corrosion cracking susceptibility of AZ31B magnesium alloy. Surf. Coat. Technol. 2010, 204, 3947–3953. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, K.Y.; Lu, J.Z.; Zhang, Y.K.; Dai, F.Z.; Zhong, J.W. Effects of laser shock processing with different shocked paths on mechanical properties of laser welded ANSI 304 stainless steel joint. Mater. Sci. Eng. A 2011, 528, 4652–4657. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, J.Z.; Zhang, Y.K.; Luo, K.Y.; Zhong, J.W.; Cui, C.Y.; Kong, D.J.; Guan, H.B.; Qian, X.M. Effects of different shocked paths on fatigue property of 7050−T7451 aluminum alloy during two−sided laser shock processing. Mater. Des. 2011, 32, 480–486. [Google Scholar] [CrossRef]

- Luo, K.Y.; Yao, H.X.; Dai, F.Z.; Lu, J.Z. Surface textural features and its formation process of AISI 304 stainless steel subjected to massive LSP impacts. Opt. Laser Eng. 2014, 55, 136–142. [Google Scholar] [CrossRef]

- Dai, F.Z.; Zhou, J.Z.; Lu, J.Z.; Luo, X.M. A technique to decrease surface roughness in overlapping laser shock peening. Appl. Surf. Sci. 2016, 370, 501–507. [Google Scholar] [CrossRef]

- Das, A.; Kotadia, H.R. Effect of high-intensity ultrasonic irradiation on the modification of solidification microstructure in a Si-rich hypoeutectic Al–Si alloy. Mater. Chem. Phys. 2011, 125, 853–859. [Google Scholar] [CrossRef]

- Hattori, S.; Ishikura, R.; Zhang, Q.L. Construction of database on cavitation erosion and analyses of carbon steel data. Wear 2004, 257, 1022–1029. [Google Scholar] [CrossRef]

- Lu, J.Z.; Zhong, J.S.; Luo, K.Y.; Zhang, L.; Qi, H.; Luo, M.; Xu, X.J.; Zhou, J.Z. Strain rate correspondence of fracture surface features and tensile properties in AISI304 stainless steel under different LSP impact time. Surf. Coat. Technol. 2013, 221, 88–93. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.K.; Lu, J.Z.; Dai, F.Z.; Feng, A.X.; Luo, K.Y.; Zhong, J.S.; Wang, Q.W.; Luo, M.; Qi, H. Effects of laser shock processing on electrochemical corrosion resistance of ANSI 304 stainless steel weldments after cavitation erosion. Corros. Sci. 2013, 66, 5–13. [Google Scholar] [CrossRef]

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Sun, G.F.; Gu, Y.Y.; Zhou, J.Z.; Ren, X.D.; Zhang, X.C.; Zhang, L.F.; Chen, K.M.; et al. Grain refinement mechanism of multiple laser shock processing impacts on ANSI 304 stainless steel. Acta Mater. 2010, 58, 5354–5362. [Google Scholar] [CrossRef]

- Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; G32-09; ASTM: West Conshohocken, PA, USA, 2009.

- Li, X.Y.; Yan, Y.G.; Ma, L.; Xu, Z.M.; Li, J.G. Cavitation erosion and corrosion behavior of copper−manganese−aluminum alloy weldment. Mater. Sci. Eng. A 2004, 382, 82–89. [Google Scholar] [CrossRef]

- Kwok, C.T.; Lo, K.H.; Chan, W.K.; Cheng, F.T.; Man, H.C. Effect of laser surface melting on intergranular corrosion behaviour of aged austenitic and duplex stainless steels. Corros. Sci. 2011, 53, 1581–1591. [Google Scholar] [CrossRef]

- Li, H.B.; Cui, Z.D.; Li, Z.Y.; Zhu, S.L.; Yang, X.J. Surface modification by gas nitriding for improving cavitation erosion resistance of CP−Ti. Appl. Surf. Sci. 2014, 298, 164–170. [Google Scholar] [CrossRef]

- Hattori, S.; Itoh, T. Cavitation erosion resistance of plastics. Wear 2011, 271, 1103–1108. [Google Scholar] [CrossRef]

- Stronge, W.J. Accuracy of bounds of plastic deformation for dynamically loaded plates and shells. Int. J. Mech. Sci. 1985, 27, 97–104. [Google Scholar] [CrossRef]

- Wang, S.Q.; Zhang, D.K.; Hu, N.N.; Zhang, J.L. Effect of Stress Ratio and Loading Frequency on the Corrosion Fatigue Behavior of Smooth Steel Wire in Different Solutions. Materials 2016, 9, 750. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.P.; Zhang, J.F.; Zheng, Y.G.; Qin, Y.J.; Lin, J.R. Ultrasonic cavitation erosion of high−velocity oxygen−fuel (HVOF) sprayed near−nanostructured WC−10Co−4Cr coating in NaCl solution. Ultrason. Sonochem. 2015, 26, 87–92. [Google Scholar] [CrossRef] [PubMed]

- Mordyuk, B.N.; Milman, Y.V.; Iefimov, M.O.; Prokopenko, G.I.; Silberschmidt, V.V.; Danylenko, M.I.; Kotko, A.V. Characterization of ultrasonically peened and laser-shock peened surface layers of AISI 321 stainless steel. Surf. Coat. Technol. 2008, 202, 4875–4883. [Google Scholar] [CrossRef]

- Brunatto, S.F.; Allenstein, A.N.; Allenstein, C.L.M.; Buschinelli, A.J.A. Cavitation erosion behaviour of niobium. Wear 2012, 274–275, 220–228. [Google Scholar] [CrossRef]

- Chiu, K.Y.; Cheng, F.T.; Man, H.C. Evolution of surface roughness of some metallic materials in cavitation erosion. Ultrasonics 2005, 43, 713–716. [Google Scholar] [CrossRef] [PubMed]

- Krella, A.K. Cavitation erosion resistance of Ti/TiN multilayer coatings. Surf. Coat. Technol. 2013, 228, 115–123. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, J.Z.; Luo, K.Y.; Feng, A.X.; Dai, F.Z.; Zhong, J.S.; Luo, M.; Zhang, Y.K. Residual stress, micro−hardness and tensile properties of ANSI 304 stainless steel thick sheet by fiber laser welding. Mater. Sci. Eng. A 2013, 561, 136–144. [Google Scholar] [CrossRef]

- Hajian, M.; Abdollah-zadeh, A.; Rezaei-Nejad, S.S.; Assadi, H.; Hadavi, S.M.M.; Chung, K.; Shokouhimehr, M. Improvement in cavitation erosion resistance of AISI 316L stainless steel by friction stir processing. Appl. Surf. Sci. 2014, 308, 184–192. [Google Scholar] [CrossRef]

- Jeng, C.A.; Huang, J.L.; Lee, S.Y.; Hwang, B.H. Erosion damage and surface residual stress of Cr3C2/Al2O3 composite. Mater. Chem. Phys. 2003, 78, 278–287. [Google Scholar] [CrossRef]

- Sano, Y.; Obata, M.; Kubo, T.; Mukai, N.; Yoda, M.; Masaki, K.; Ochi, Y. Retardation of crack initiation and growth in austenitic stainless steels by laser peening without protective coating. Mater. Sci. Eng. A 2006, 417, 334–340. [Google Scholar] [CrossRef]

- Yoo, M.H.; Agnew, S.R.; Morris, J.R.; Ho, K.M. Non−basal slip systems in HCP metals and alloys: Source mechanisms. Mater. Sci. Eng. A 2001, 321, 87–92. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, J.Z.; Zhang, Y.K.; Luo, K.Y.; Dai, F.Z.; Cui, C.Y.; Qian, X.M.; Zhong, J.W. Effects of processing parameters on the fatigue properties of LY2 aluminum alloy subjected to laser shock processing. Chin. Opt. Lett. 2011, 9. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | S | P |

|---|---|---|---|---|---|---|

| ≤0.08 | ≤1.0 | ≤2.0 | 18.0−20.0 | 8.0−10.0 | ≤0.03 | ≤0.035 |

| Laser Type | Laser Power P (kW) | Welding Speed V (mm·s–1) | Defocusing Distance Δf (mm) |

|---|---|---|---|

| Fiber laser | 4 | 30 | −3 |

| Diameter of Vibrating Horn (mm) | Frequency (kHz) | Peak-to-Peak Amplitude (µm) | Temperature (°C) | Total Testing Time (h) |

|---|---|---|---|---|

| 12 | 19−21 | 50 | 20 | At least 6 |

| Sample | Ra (μm) | |

|---|---|---|

| LWZ | HAZ | |

| Before cavitation erosion | 0.02 | 0.02 |

| Without LSP after cavitation erosion | 1.26 | 1.37 |

| 6 J, LSP after cavitation erosion | 0.68 | 0.89 |

| Caption | The Value of Surface Residual Stress (MPa) | |

|---|---|---|

| LWZ | HAZ | |

| Untreated | −5 | 21 |

| 6 J, LSP impacts | −402 | −335 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Lu, J.-Z.; Zhang, Y.-K.; Ma, H.-L.; Luo, K.-Y.; Dai, F.-Z. Effects of Laser Shock Processing on Morphologies and Mechanical Properties of ANSI 304 Stainless Steel Weldments Subjected to Cavitation Erosion. Materials 2017, 10, 292. https://doi.org/10.3390/ma10030292

Zhang L, Lu J-Z, Zhang Y-K, Ma H-L, Luo K-Y, Dai F-Z. Effects of Laser Shock Processing on Morphologies and Mechanical Properties of ANSI 304 Stainless Steel Weldments Subjected to Cavitation Erosion. Materials. 2017; 10(3):292. https://doi.org/10.3390/ma10030292

Chicago/Turabian StyleZhang, Lei, Jin-Zhong Lu, Yong-Kang Zhang, Hai-Le Ma, Kai-Yu Luo, and Feng-Ze Dai. 2017. "Effects of Laser Shock Processing on Morphologies and Mechanical Properties of ANSI 304 Stainless Steel Weldments Subjected to Cavitation Erosion" Materials 10, no. 3: 292. https://doi.org/10.3390/ma10030292