3.2.1. Composition of Corrosion Products

The compositions of corrosion products depends on the alkalinity degree, the oxygen supply, and the moisture content [

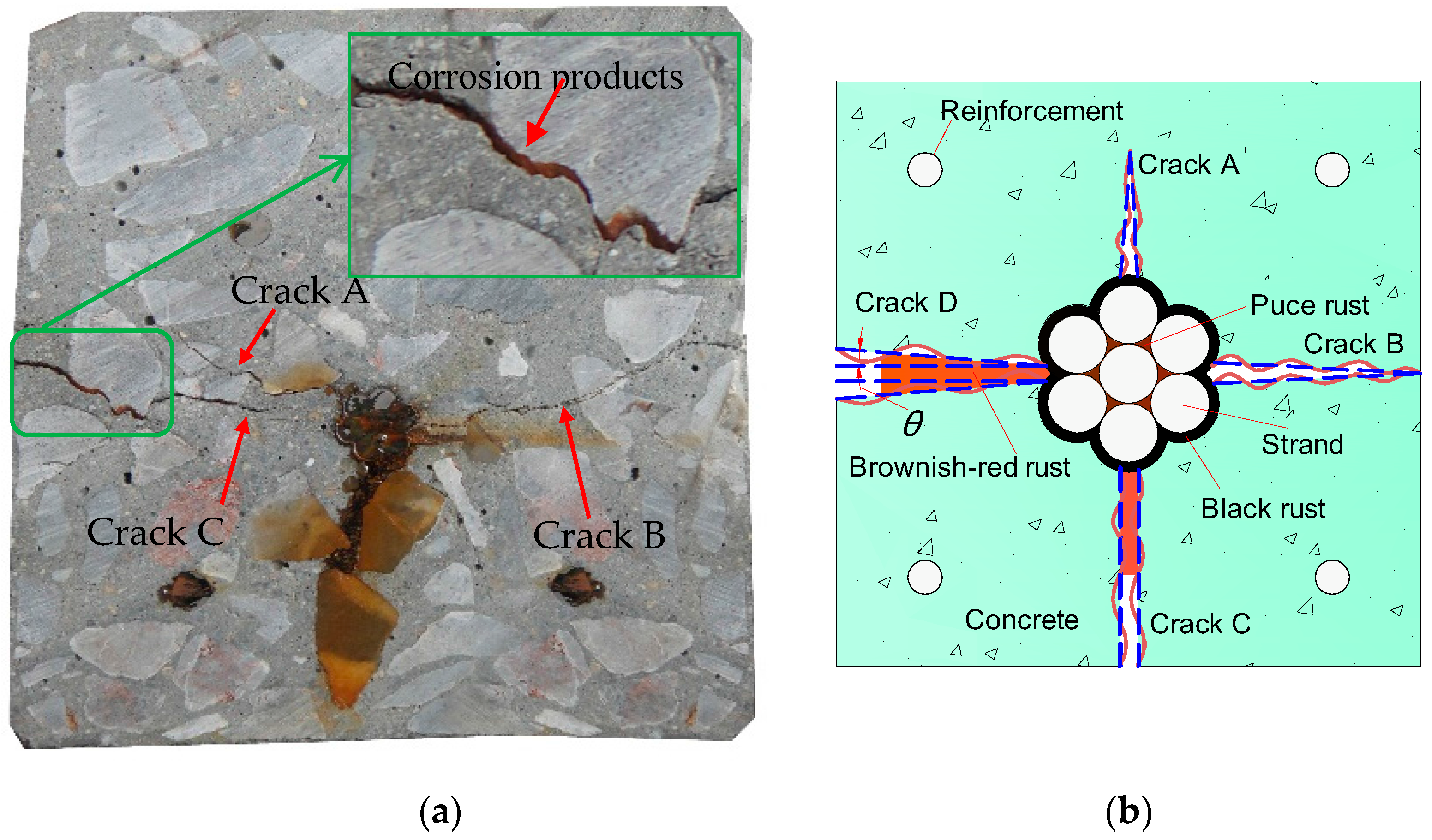

41]. Corrosion products also exhibit various colors at different regions in the present study. Three colors of corrosion products were observed: black, brownish-red, and puce.

Figure 11 shows the black rust at the strand-concrete interface. The cover prevents the oxygen from reaching the strand-concrete interface. For the reaction with some oxygen, the main compositions of corrosion products are ferrous oxide (FeO) and ferroferric oxide (Fe

3O

4) [

13,

17]. The colors of FeO and Fe

3O

4 are black. FeO is unstable and can easily become Fe

3O

4 in air. Therefore, Fe

3O

4 is considered as the primarily composition of black rust.

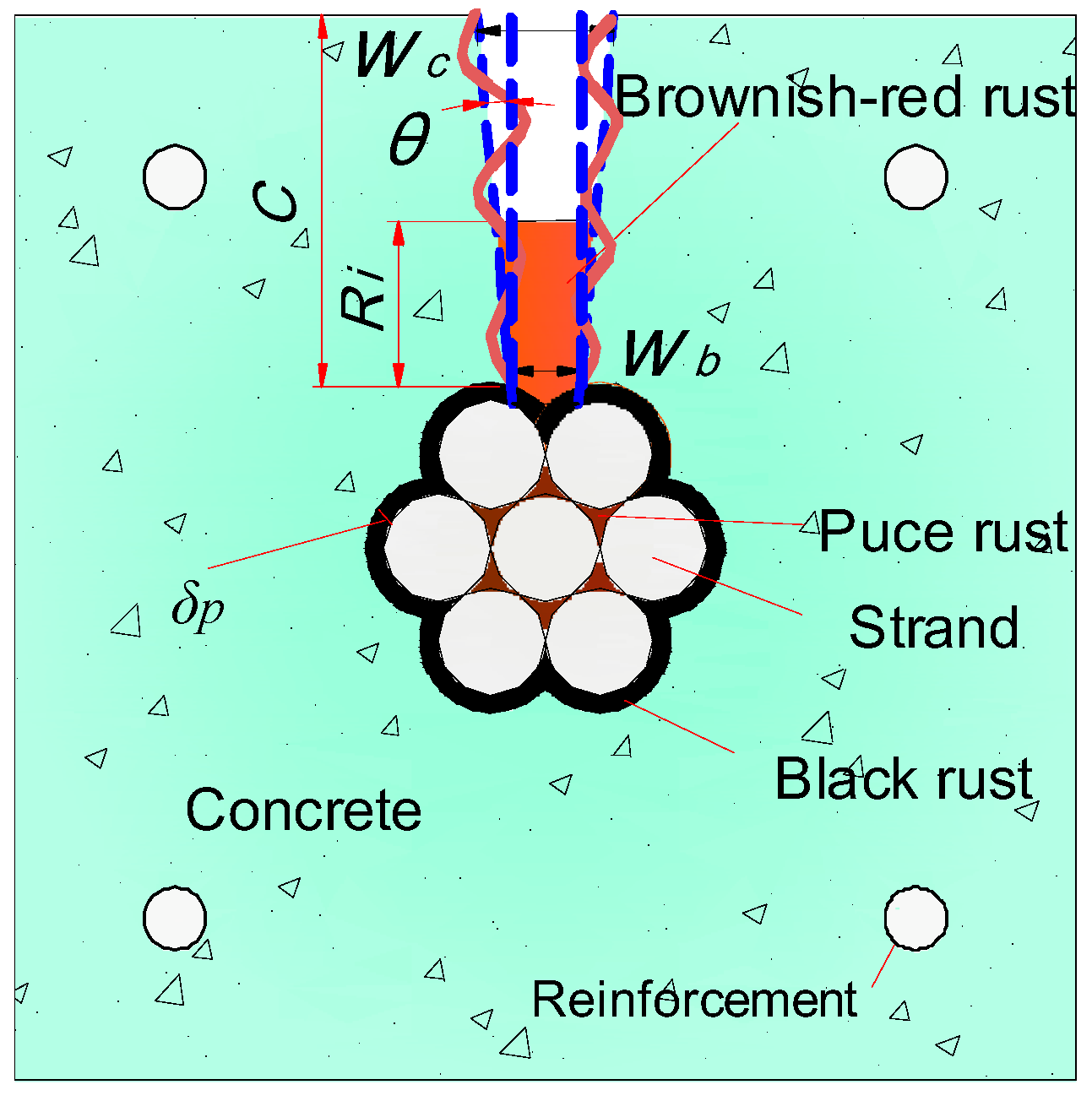

Figure 12 shows the brownish-red rust in cracks. Cracks provide a path for oxygen to the inner concrete. The oxygen supply is sufficient in cracks. The color of iron oxide (Fe

2O

3) is brownish-red, and Fe

2O

3 is regarded as the main composition of the brownish-red rust [

13].

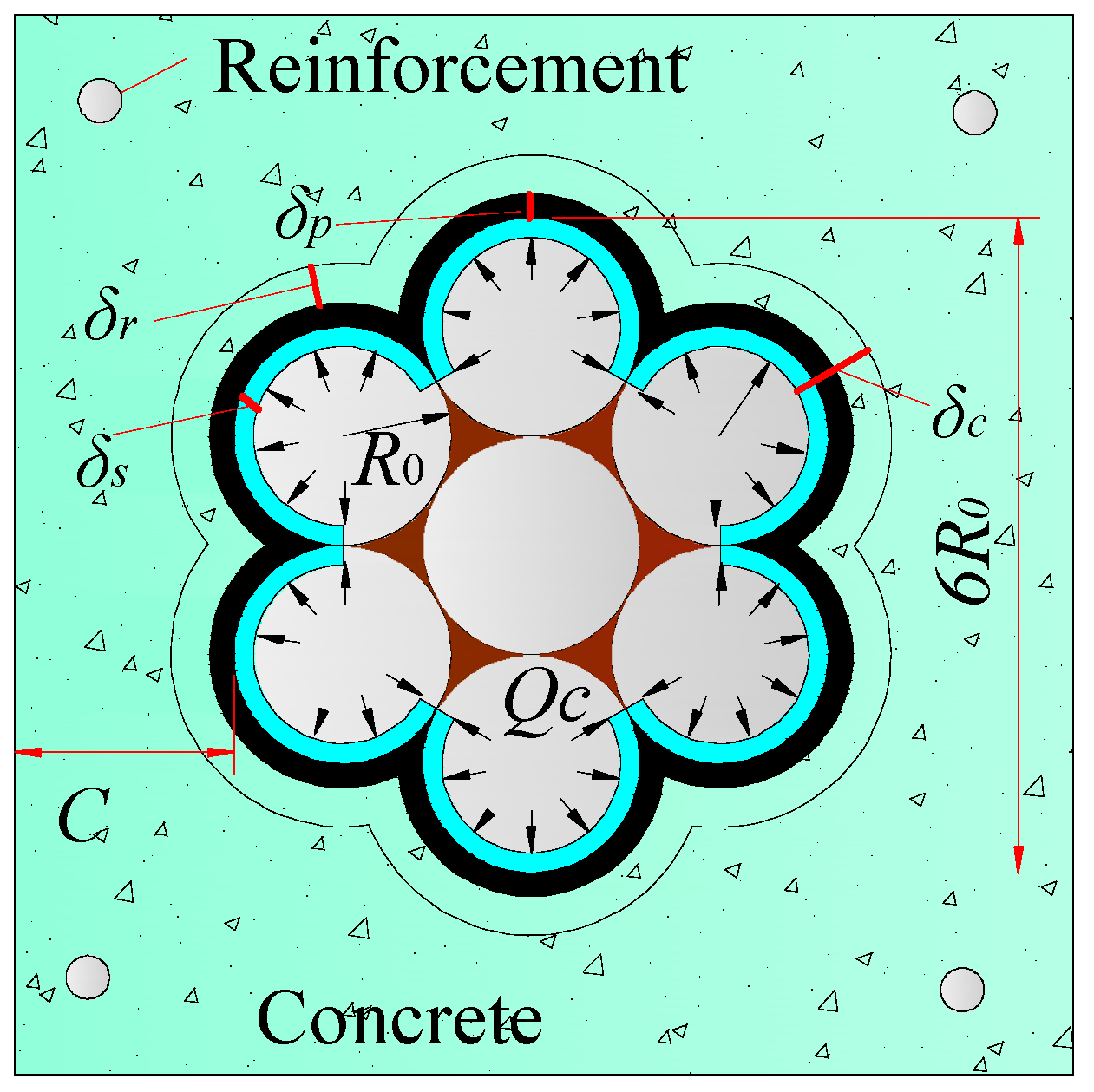

As

Figure 3 shows, the puce rust was found in the gaps between the core wire and outer wires. The oxygen can reach the gaps with the flow of aggressive liquid. The oxygen supply in the gaps may be lower than those in cracks, and higher than that at the strand-concrete interface. Therefore, the color of rust in the gaps is between the black and the brownish-red.

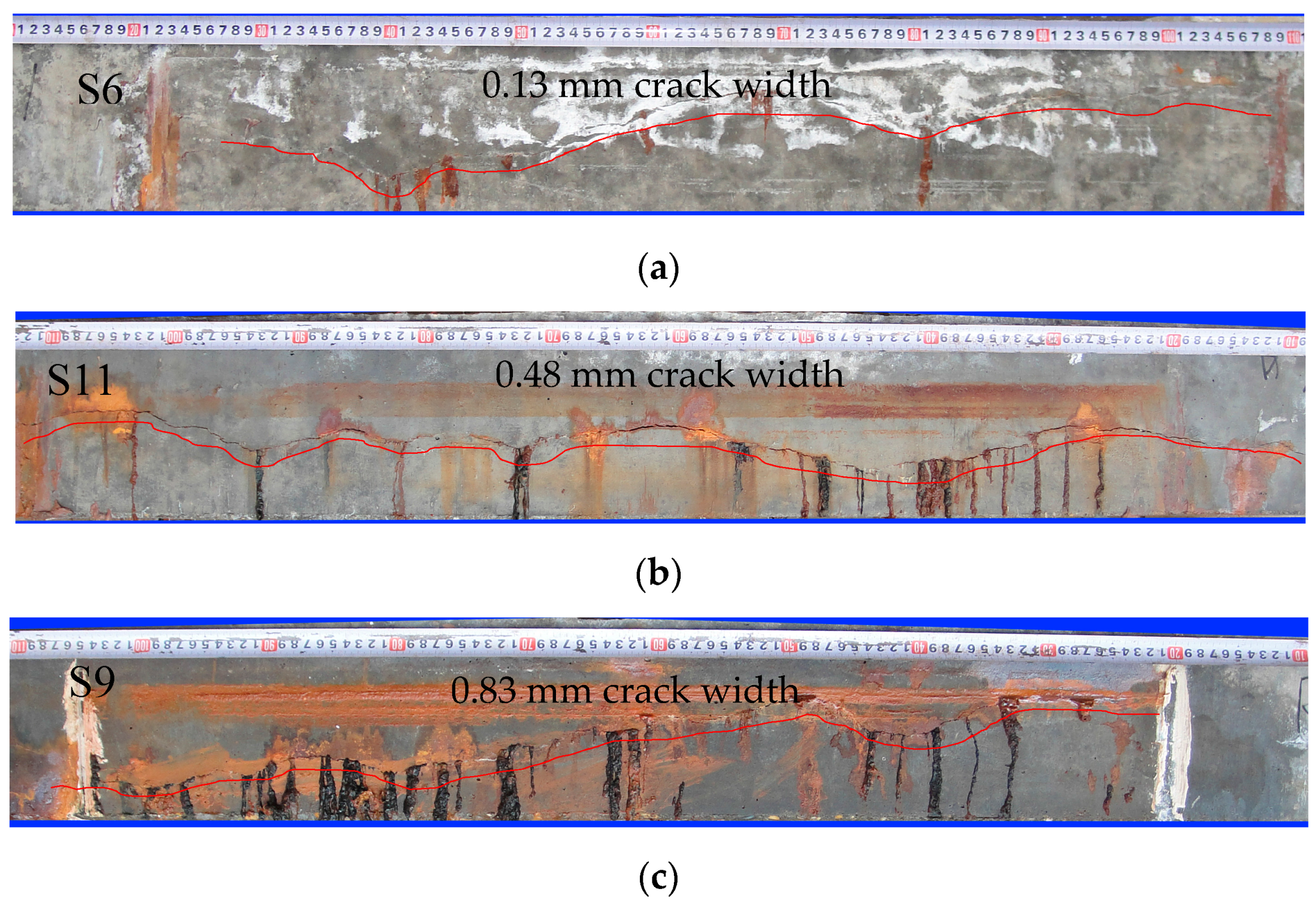

3.2.2. Filling of Corrosion Products

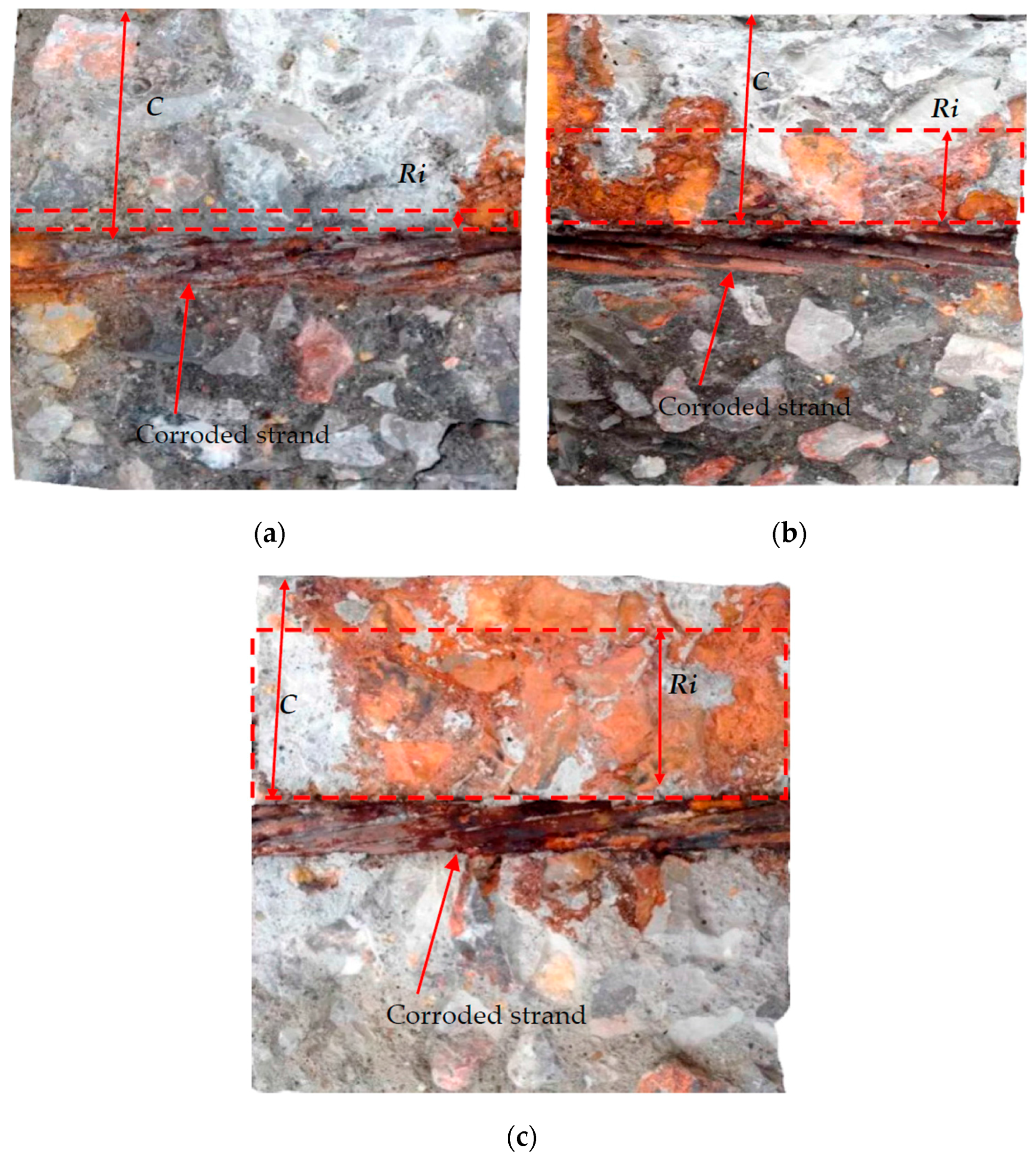

Some corrosion products were observed to flow out from the longitudinal cracks during the corrosion process. The slices were broken down to observe the filling of corrosion products in cracks.

Figure 12 shows the slices profiles of S6B, S9A, and S9C, respectively. Concrete slice profiles were broken down along the widest cracks. Corrosion products filled principally in the widest crack. In another small crack, a few corrosion products were found. The similar experimental observations were also found by Šavija et al. [

15]. In their study, the micro-computed X-ray tomography technique (CT-scanning) was used to monitor corrosion products formation during corrosion process. The scanning results showed that corrosion products principally penetrated into the widest crack, and few corrosion products were observed in other small cracks. This phenomenon is similar to the experimental observation obtained in the present study.

Figure 12 shows the profiles of concrete slices along the widest cracks. It should be noted that the upper part of the profile is the position of the widest crack and the bottom part is the broken surface obtained by the destruction method. As mentioned before, the corrosion products mainly filled in the widest cracks. The salt water can also immerse into the cracks. Therefore, the upper part is overlaid by the corrosion products and salt powders. Additionally, no aggregates can clearly be observed in that region. The bottom part, however, is a new surface. Very few, or no, corrosion products can be found, but the aggregates are clear in that region.

The filling of corrosion products depends on crack widths. The crack widths of the three slices in

Figure 12 are 0.08, 0.39, and 0.91 mm, respectively. The filling of corrosion products is slight in the narrow crack. Corrosion products principally fill in the wide crack. Corrosion products propagate with increasing crack width. The filling of corrosion products varies at different positions.

In the experimental testing, the volume of corrosion products is difficult to measure. Correspondingly, the filling depth of corrosion products is easy to obtain. Based on the geometric formula conversion, the volume of corrosion products can be obtained with the rust-filling depth. Therefore, the rust-filling depth was used to describe the rust-filling ratio in the experimental testing. The average rust-filling depth is used to represent the filling of corrosion products in the slice. The rust-filling ratio, defined as the ratio of average rust-filling depth to cover, is employed to reflect the filling of corrosion products:

where

is the rust-filling ratio;

is the average rust-filling depth; and

is the concrete cover.

Before corrosion products full fill cracks, concrete cover would have cracked. From the experimental testing, corrosion products cannot fully fill cracks, even with severe cracking. The rust-filling ratio is defined as the ratio of the average rust-filling depth to the cover. Therefore, the rust-filling ratio is less than 1.0.

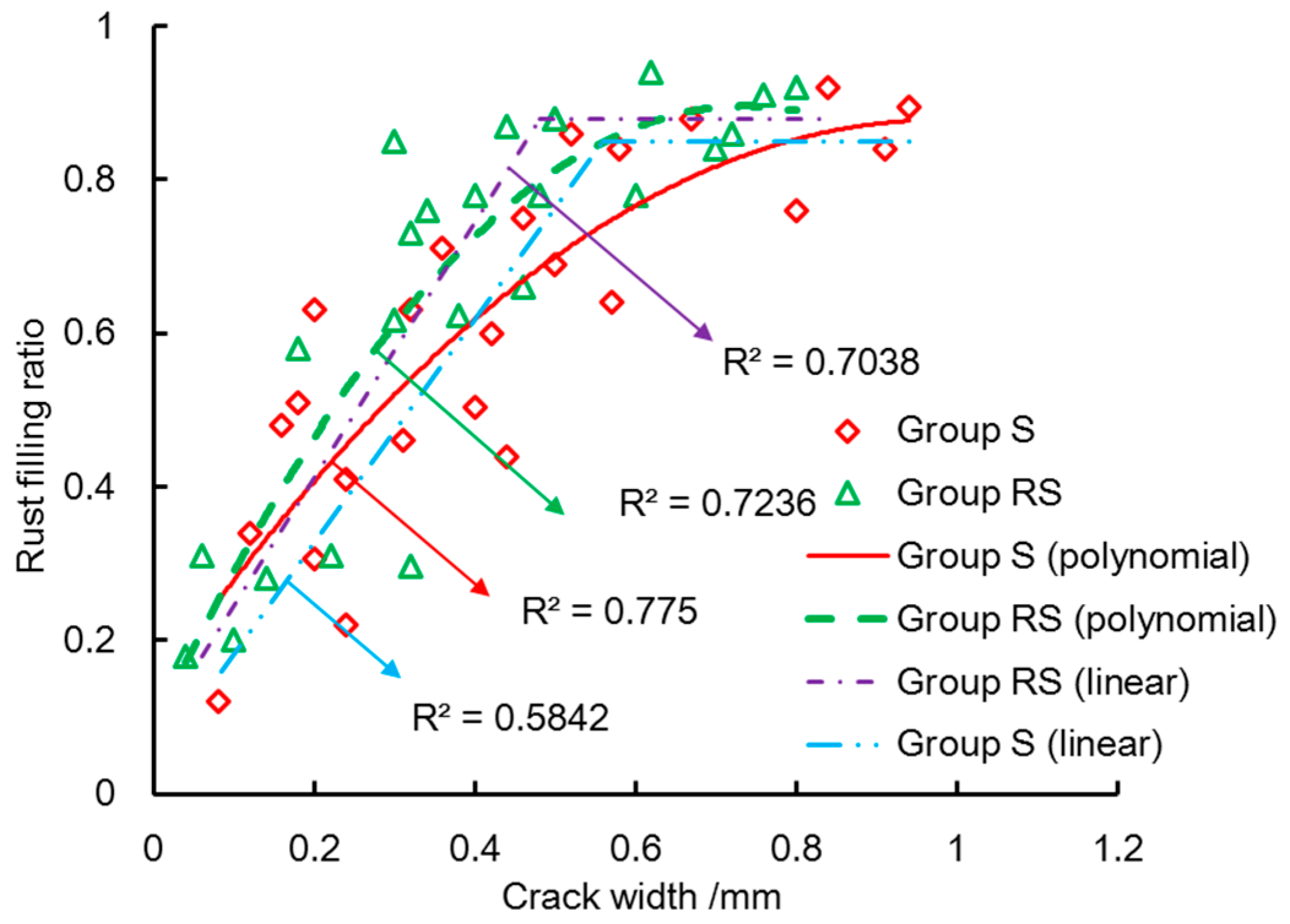

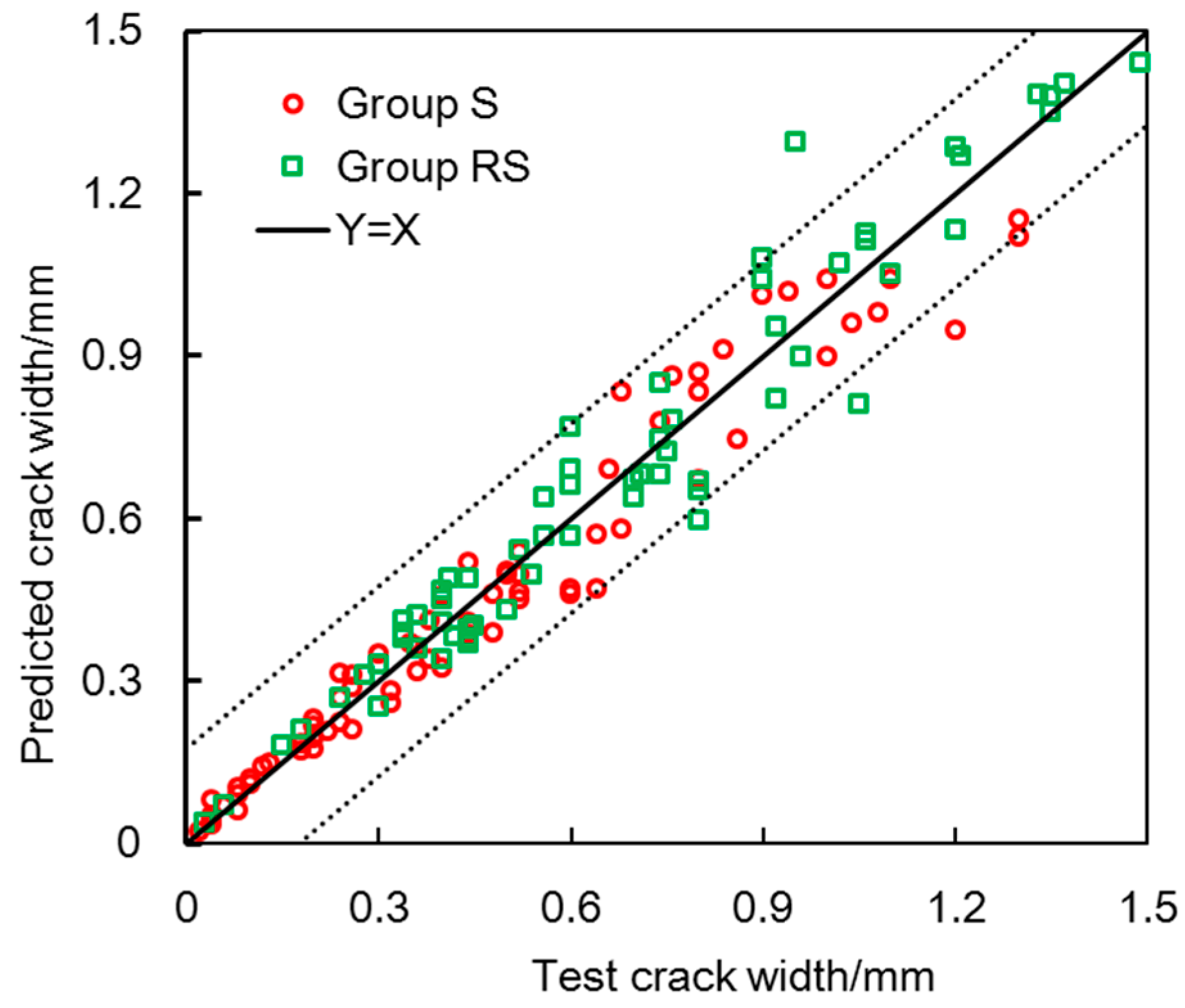

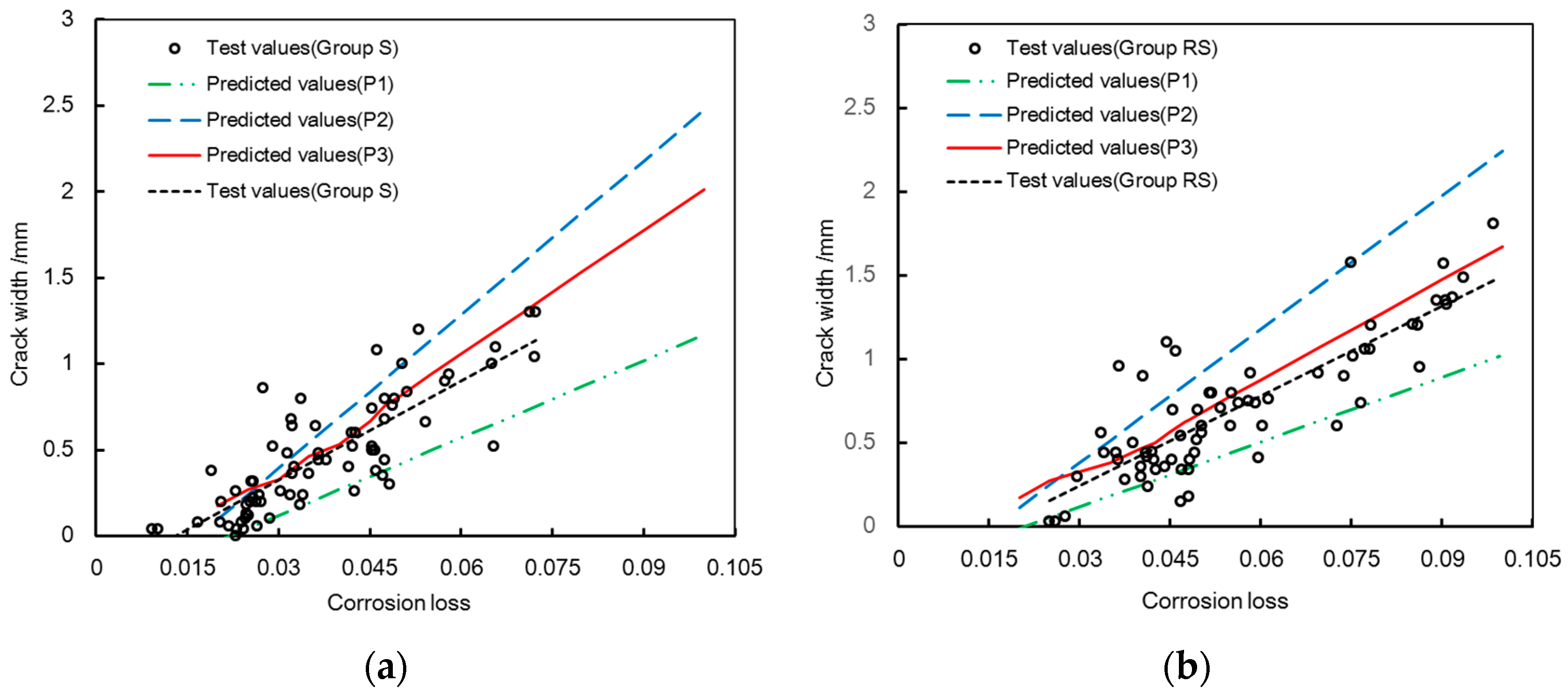

Figure 13 shows the linear regression and polynomial regression of rust-filling ratio and crack width. The rust-filling ratio increases with increasing crack width until a critical value. After that, the rust-filling ratio can be taken as a constant. This constant is less than one and considered as the maximum rust-filling ratio in the present study. The maximum rust-filling ratios of group S and group RS are 0.85 and 0.88, respectively. The critical widths of maximum rust-filling ratio are 0.79 mm and 0.63 mm in group S and group RS, respectively.

As

Figure 13 shows, the rust-filling ratio increases faster in the specimens with stirrups than that in the specimens without stirrups. The volume of corrosion products can be obtained with the crack width and rust-filling ratio. In the similar corrosion loss, the volumes of corrosion products in Group S and Group RS are the same. The stirrups can bear the tangential stress and decrease the crack width, which would lead to the large rust-filling ratio.

The discreteness of correlation between the rust-filling ratio and crack width may be attributed to the measurement uncertainty of crack width and corrosion loss. As

Figure 13 shows, the fitting precision of polynomial regression is larger than that of linear regression. The polynomial regression was used to describe the relation between crack width and rust-filling ratio in the present study. Two regressed curves of the rust-filling ratio are proposed for the both groups as follows:

where

and

are the rust-filling ratios of group S and group RS, respectively; and

and

are the crack widths of group S and group RS, respectively.

The specimens in the present study were immersed in the saline solution and accelerated by the electrochemical corrosion. The rust-filling ratio obtained in this situation may be different from that in natural corrosion. The longer corrosion time can induce the higher corrosion degree, which would lead to the larger crack width and the deeper rust-filling depth.

It should be pointed out that cover depth, crack extension, corrosion rate, and corrosion environment are size-dependent and can affect the filling of corrosion products. The different concrete covers might induce the various filling extent of corrosion products. In the practical engineering structure, the cover ranges from 30 to 50 mm based on the design code [

32]. In the present testing, the cover of 30 mm was used to investigate the filling of corrosion products in cracks. Different corrosion rate may lead to the various filling extent of corrosion products. The rust-filling ratio obtained in the electrochemical corrosion may be different from that in natural corrosion. More studies on the filling of corrosion products in cracks are required.