Flow Induced Vibration and Energy Extraction of an Equilateral Triangle Prism at Different System Damping Ratios

Abstract

:1. Introduction

2. Experimental Apparatus and Mathematical Model

2.1. Water Channel

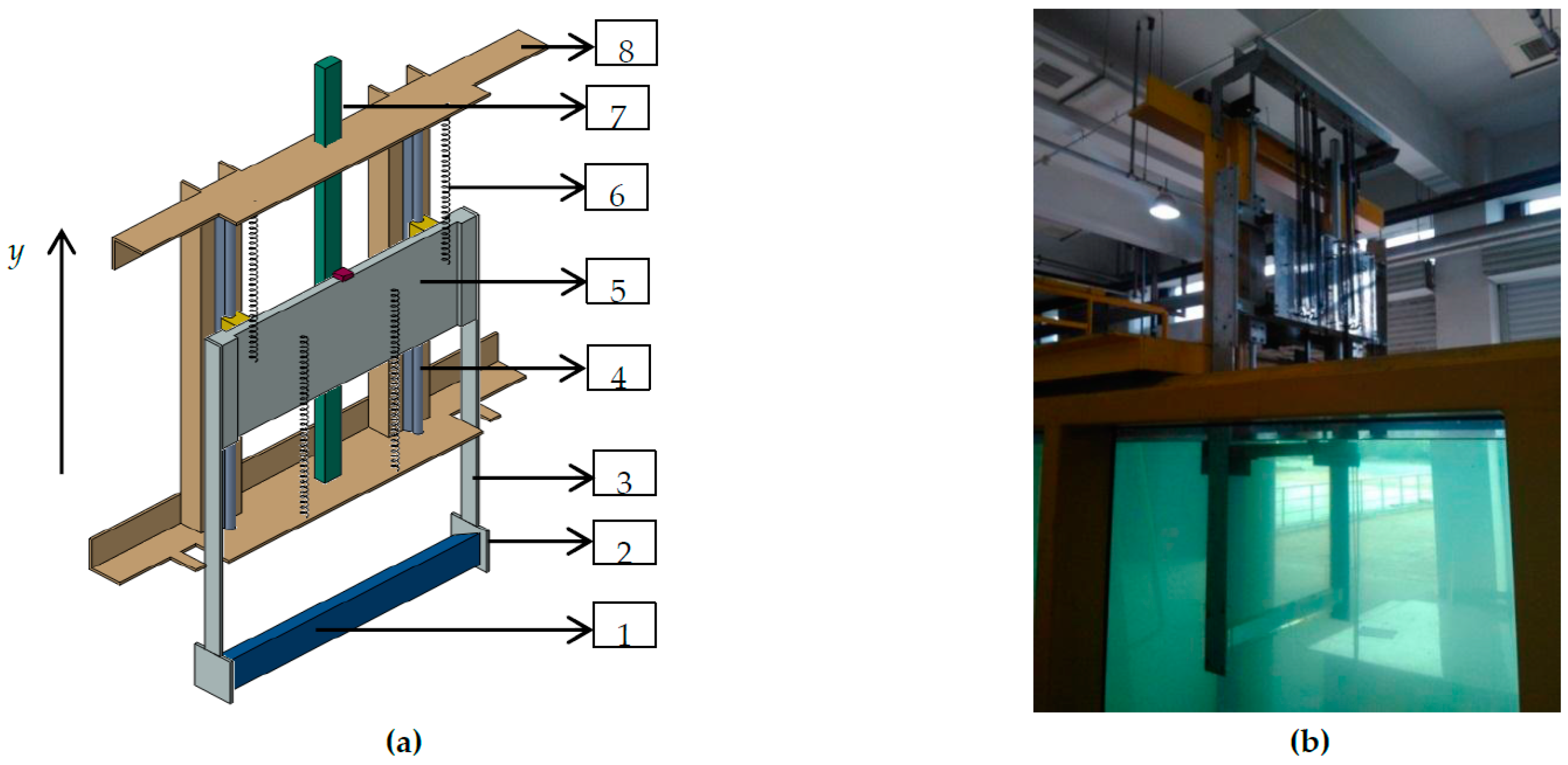

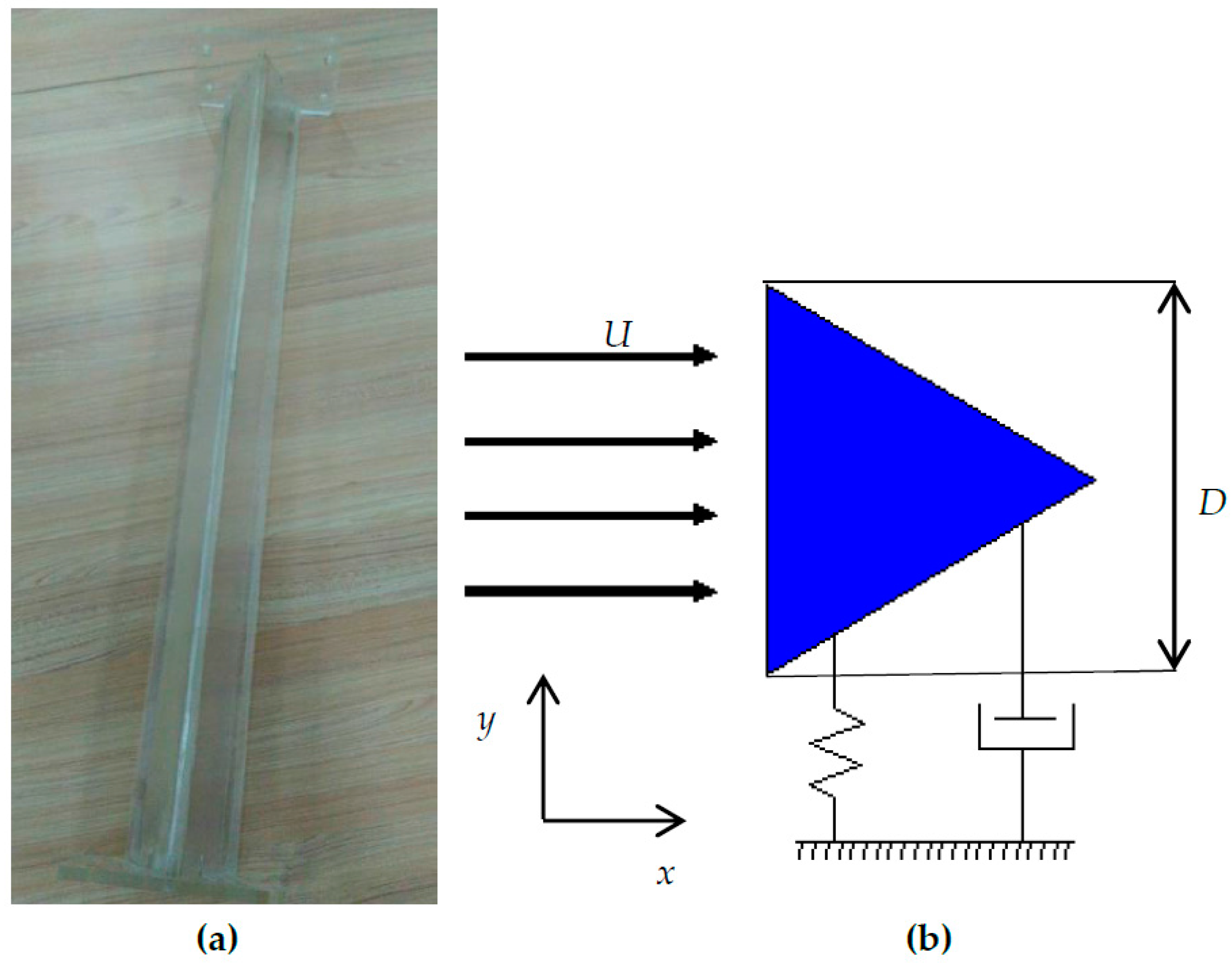

2.2. Vibration System

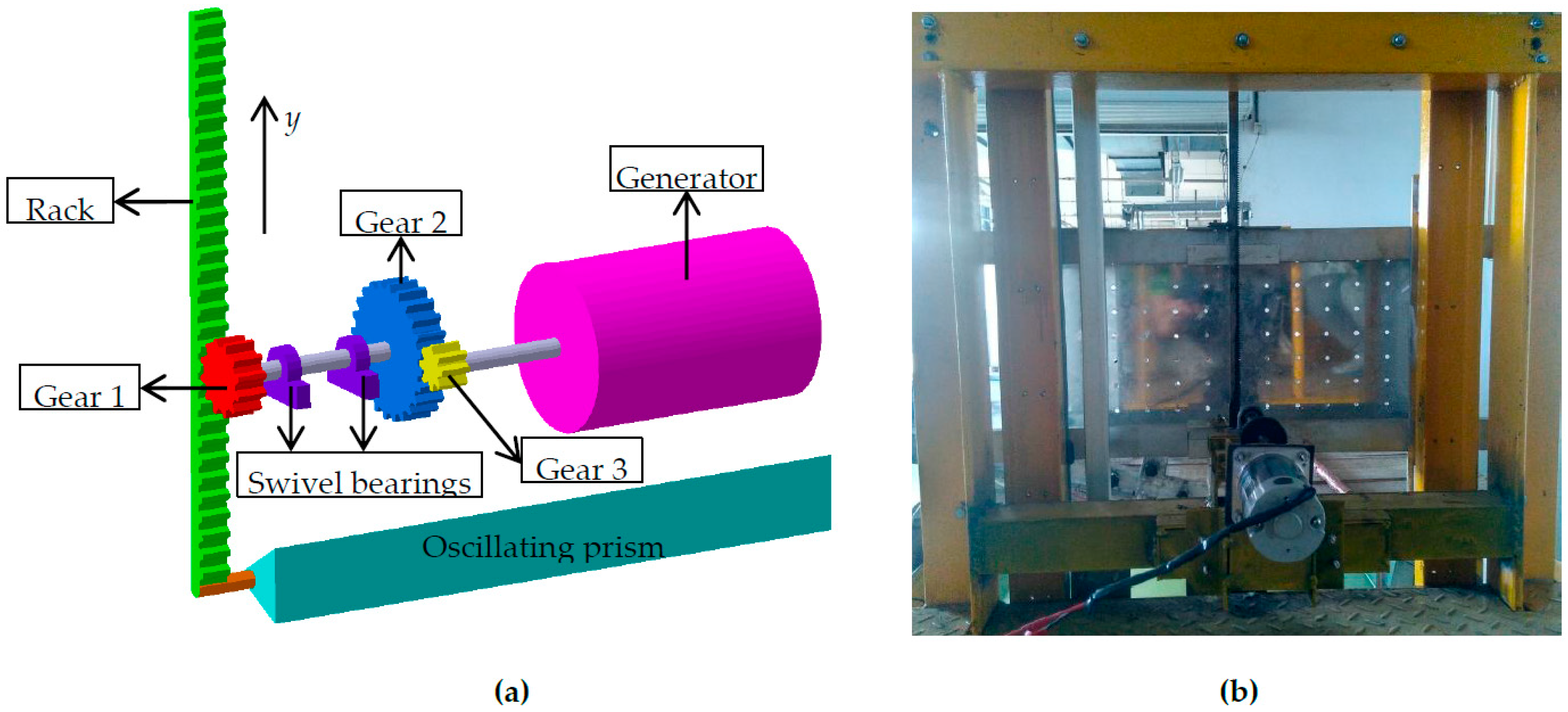

2.3. Power Take-off System

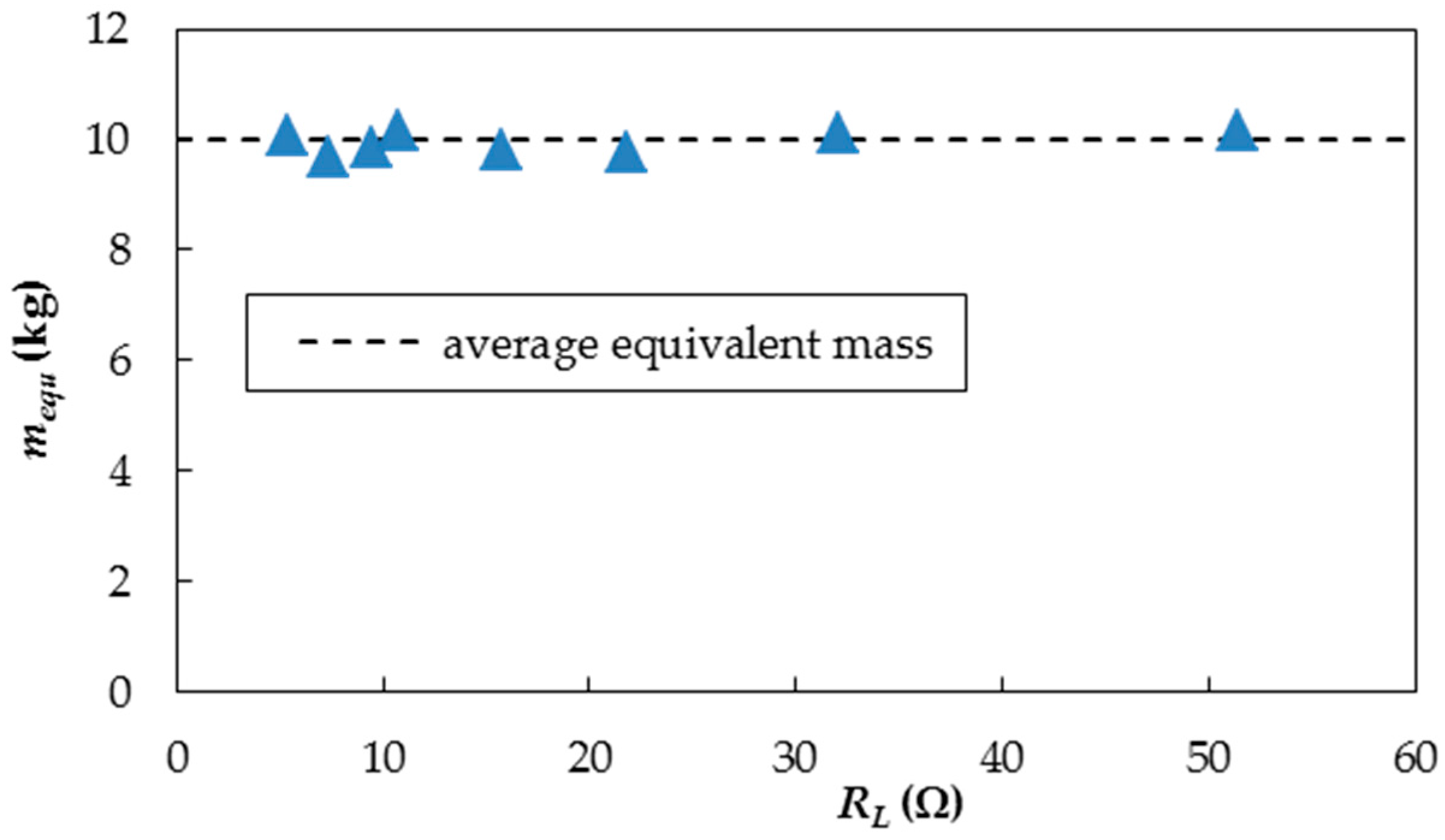

3. Free Decay Damping Experiment

4. Results and Discussion

4.1. Amplitude and Frequency Responses

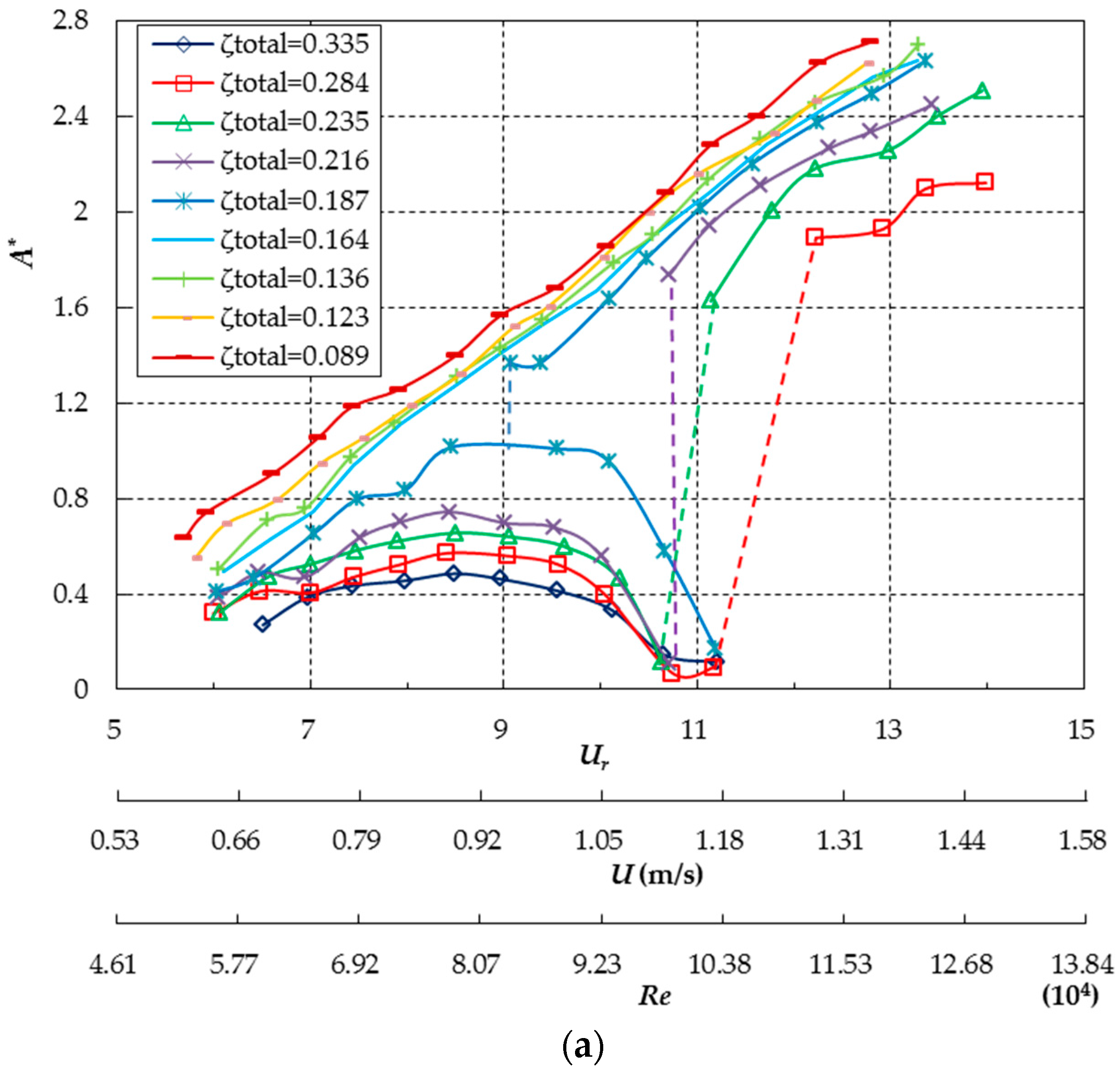

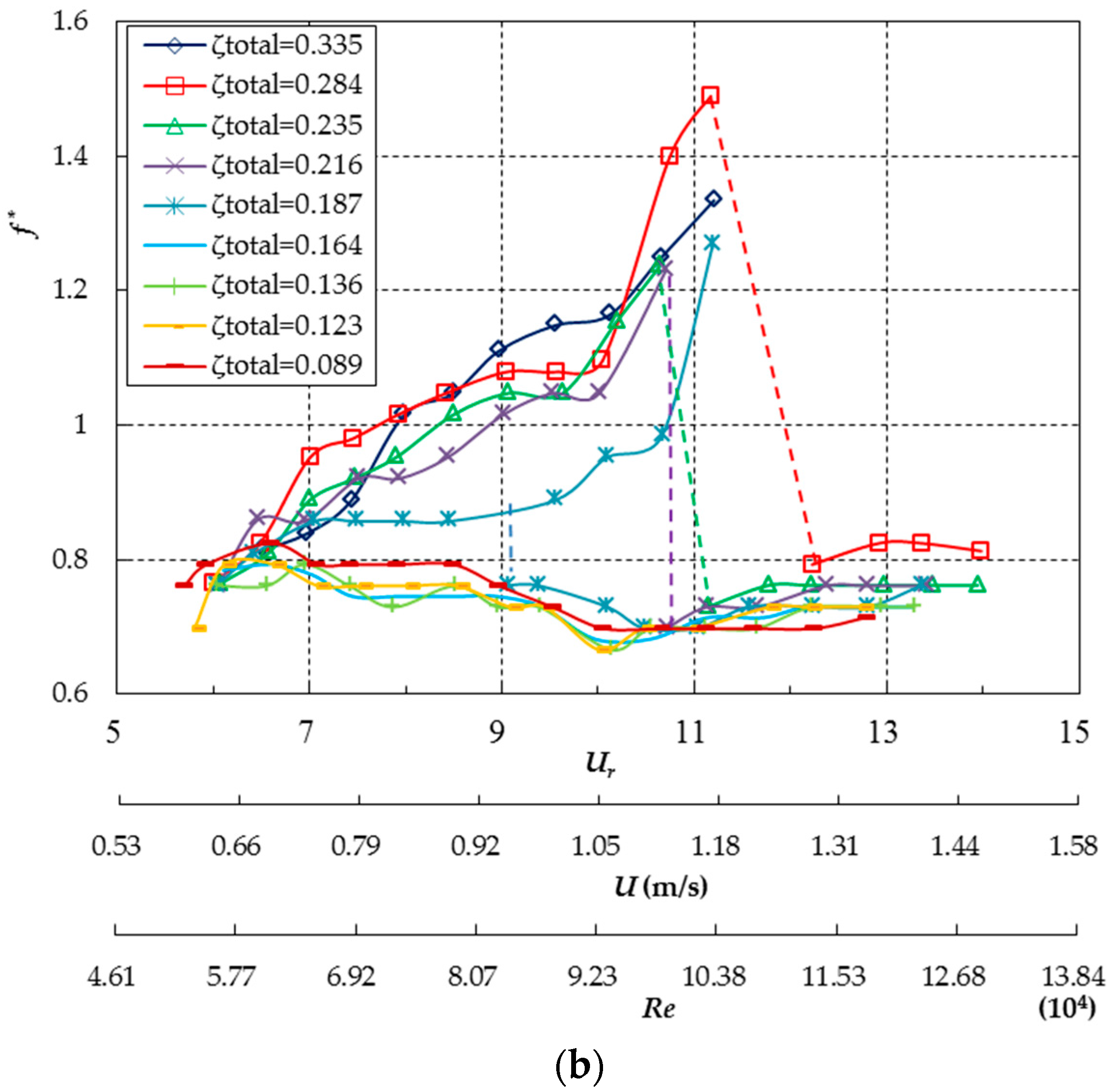

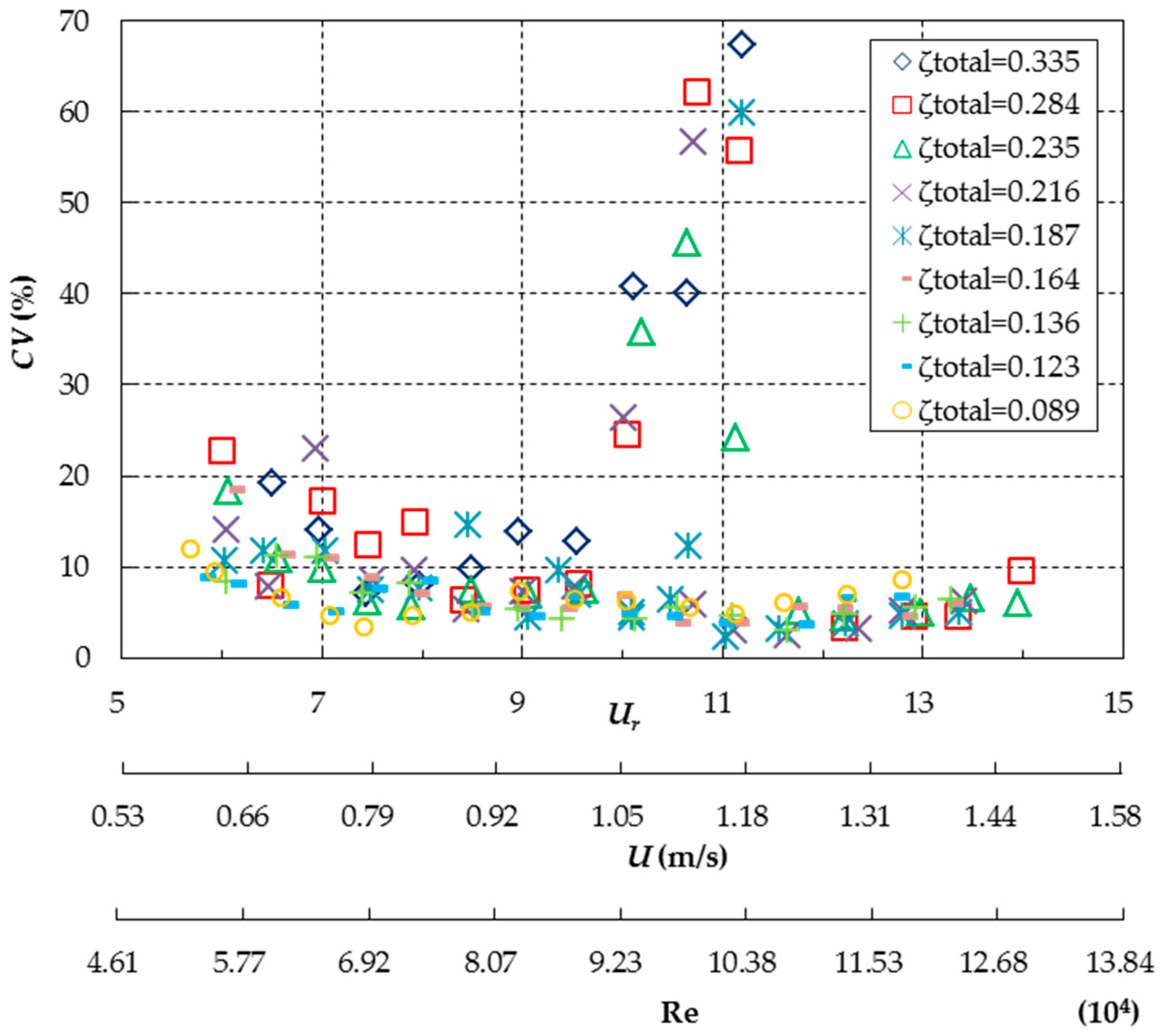

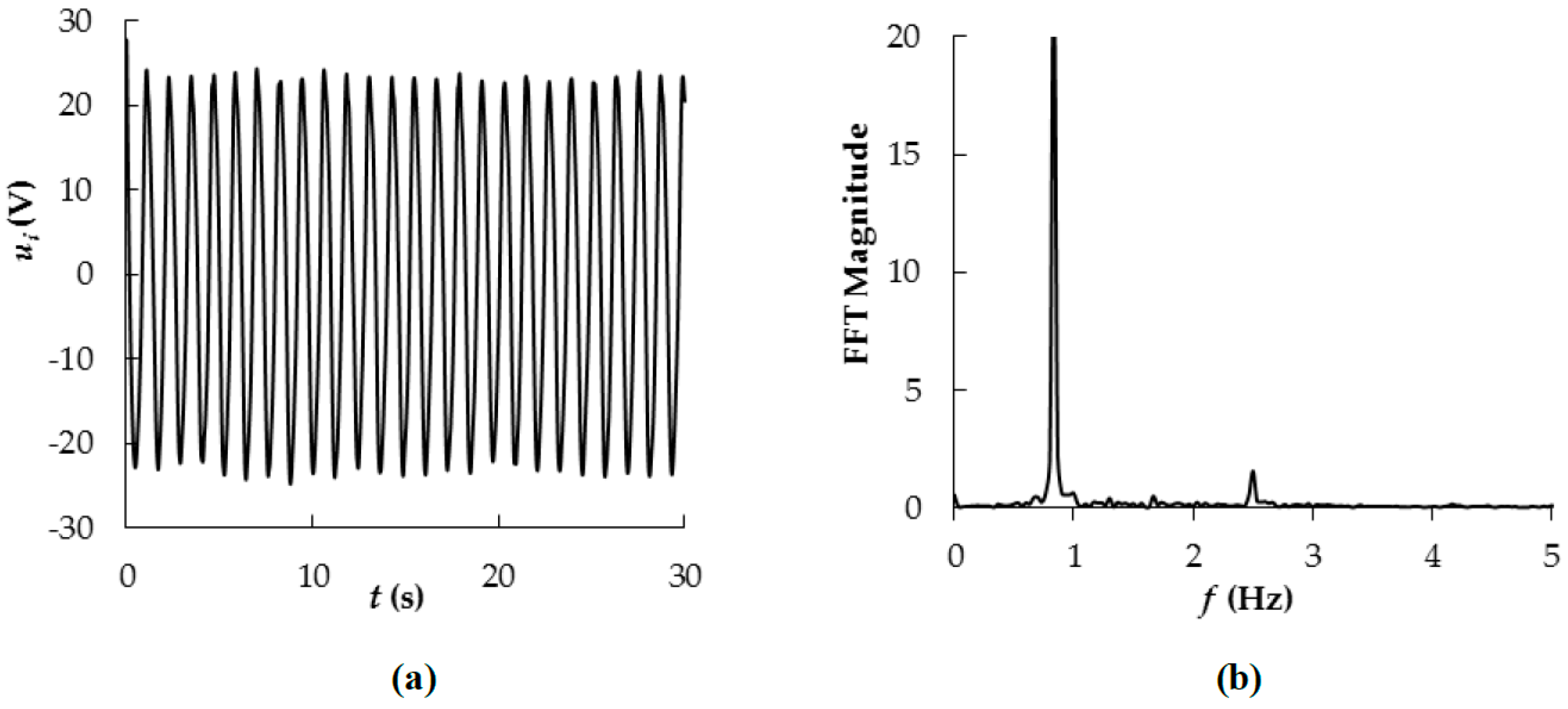

- SG. For ζtotal ≤ 0.164, A* monotonically increases with increasing Ur, and f* is less than 1 throughout the test Ur range revealing that the oscillation frequency is lower than the natural frequency of the vibration system in air. The FIV of the prism can be divided into four regions based on the amplitude and frequency responses: the vortex induced vibration (VIV) initial branch, the VIV upper branch, the transition branch from VIV to galloping, and the galloping branch. The transition from VIV to galloping is self-initiated, indicating the prism experiences SG. This is probably due to the fact that the amplitude in the VIV upper branch is high enough to induce galloping. In the VIV initial branch, f* increases with increasing Ur accompanied with a low A*. When the prism enter into the VIV upper branch, f* firstly decreases and then levels off at approximately 0.729 to 0.793. The VIV of the prism is driven by the imposed lift on the body from vortex shedding [1]. In the transition branch from VIV to galloping, f* declines sharply due to the coexistence of the driving mechanisms of oscillatory lift due to vortex shedding and instability inducing oscillatory lift due to shear layer motion in this transition region [6,11,12,21,22], and A*continues to increase with increasing Ur. As the prism response is in galloping branch, f* levels off at low values, and A* still exhibits an increasing trend. The maximum A* reaches 2.71 at Ur = 12.80 for ζtotal = 0.089. Note that A* = 2.71 is the maximum value limited by the conditions in present experiments. In addition, the maximum A* = 2.71 for the equilateral triangular prism exceeds the maximum A* = 1.90 for a single circular cylinder reported by Raghavan and Bernitsas [32]. Galloping oscillation of the prism is mainly driven by lift instability, while the effect of vortex shedding on the motion in this region is negligible [6]. The reduced velocity Ur along with the corresponding fluid velocity U and Reynolds number Re for the onsets of the upper, lower and transition branches are listed in Table 4. The results show that higher ζtotal promotes the oscillation response mode to change at higher Ur, U and Re for ζtotal ≤ 0.164.

- HG1. For the case ζtotal = 0.187, without a given threshold initial displacement, the prism can only experience VIV, which is consistent with the response of a smooth circular cylinder consisting of an initial branch followed by an upper branch and ending in desynchronization branch [32]. At reduced velocity in the range of 6.03 ≤ Ur ≤ 7.04, the amplitude ratio A* and the frequency ratio f* are small and increase rapidly with Ur indicating the oscillation response of the prism is in the VIV initial branch. For the reduced velocity Ur ranging from 7.04 to 10.09, A* displays a more gradually increase firstly and then levels off with Ur accompanied with an approximately constant in f*, which indicate the prism goes into the VIV upper branch. The VIV of the prism is suppressed significantly at Ur > 10.09 where A* declines rapidly with increasing Ur while f* continues to increase. The oscillation response of the prism is in the VIV desynchronization branch where f* is more than 1 indicating the response frequency of the prism is higher than the nature frequency of the vibration system in air. When the prism is given a threshold initial displacement of approximately 1.5D at Ur = 9.07, the prism enters into HG1 where the oscillation response jumps to the galloping branch from the VIV upper branch [12]. This threshold amplitude is given to the prism by manually pushing the prism. For an initial displacement of less than 1.5D, galloping was not initiated. In the HG1 branch, as shown in Figure 8, A* continues to increase with increasing Ur while f* remains around 0.75.

- HG2. For the cases of 0.216 ≤ ζtotal ≤ 0.284, the prism only undergoes VIV without an externally imposed initial threshold amplitude. And the VIV characteristics are consistent with the case of ζtotal = 0.187 except that f* in VIV upper branch for the cases of 0.216 ≤ ζtotal ≤ 0.284 increase with increasing Ur while f* exhibits lock-in for the case of ζtotal = 0.187. After the VIV of the prism is strongly suppressed, a given threshold initial displacement of approximately 1.5D can excite the prism to gallop. The prism experiences HG2 because the VIV and galloping regions are separated by almost complete suppression [12]. In the HG2 branch, A* monotonically increases with increasing Ur while f* levels off into approximately 0.73~0.82. Besides, Figure 8 presents that the Ur where galloping is initiated increases as ζtotal increases in all galloping modes including SG, HG1 and HG2.

- VIV. As ζtotal increases up to 0.335, only VIV is observed in the test velocity range (Ur = 15.22, U = 1.6 m/s). The response characteristics of A* and f* are consistent with those for the cases of 0.216 ≤ ζtotal ≤ 0.284 in the VIV modes.

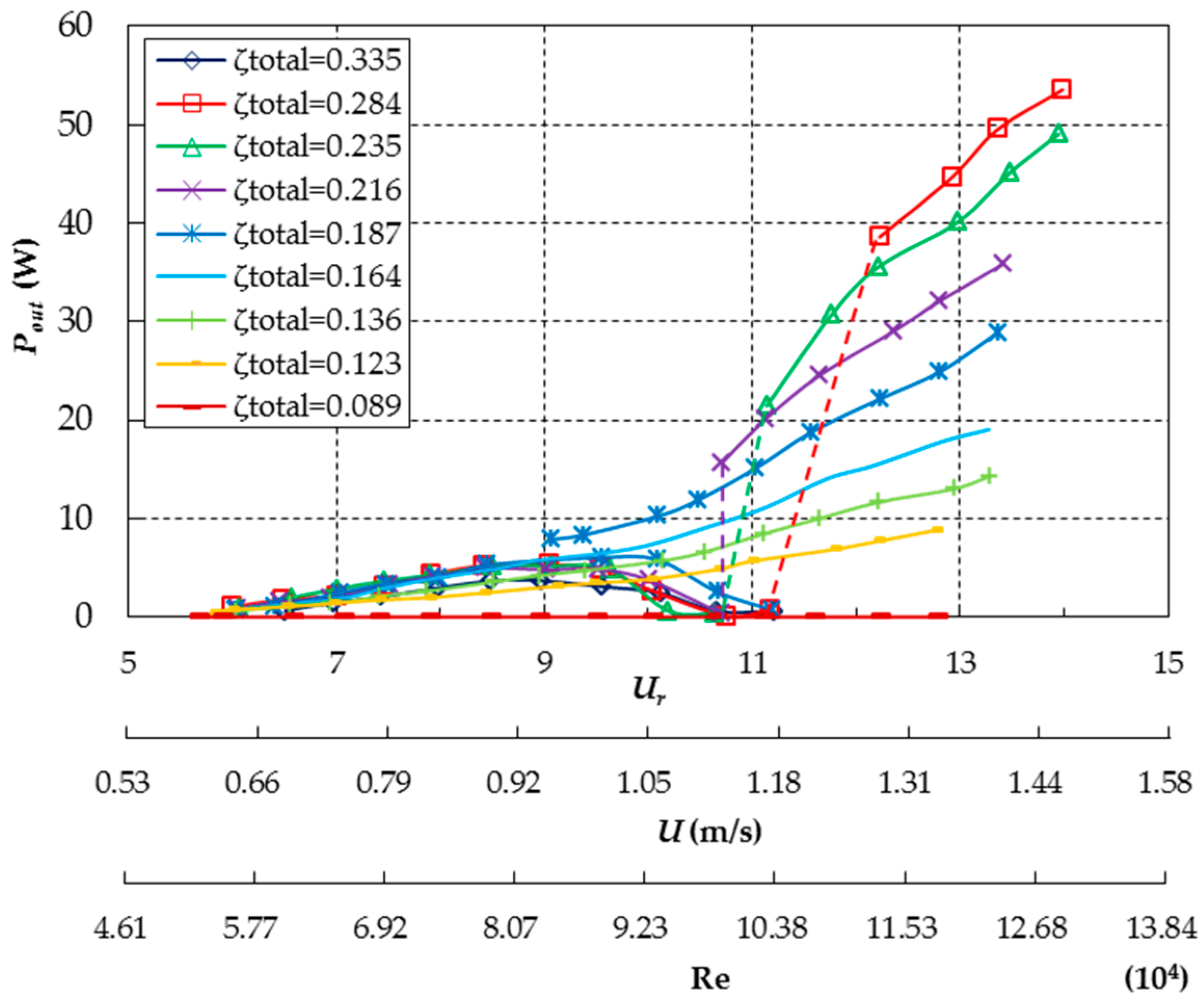

4.2. Energy Extraction

- For 0.089 < ζtotal ≤ 0.164, the prism experiences SG where the transition from VIV to galloping is self-initiated and the VIV desynchronization branch is absent. Pout monotonically increases with Ur throughout the range of test water velocities thus yielding the peak Pout at the maxmum Ur. Besides, Pout increases with increasing ζtotal in all FIV branches.

- For the case of 0.187 ≤ ζtotal ≤ 0.284, the prism undergoes HG excited by a given threshold initial displacement. Pout increases with increasing Ur in the VIV initial and upper branches while it is reduced with Ur when the prism goes in to the VIV desynchronization branch. Besides, higher ζtotal yields more harnessed power in the galloping branch.

- As ζtotal increases up to 0.335, the prism can only experience VIV because the system damping ratio is high enough to prevent the prism from galloping. Pout versus Ur in the VIV regions is similar to that for the case of 0.187 ≤ ζtotal ≤ 0.284.

5. Conclusions

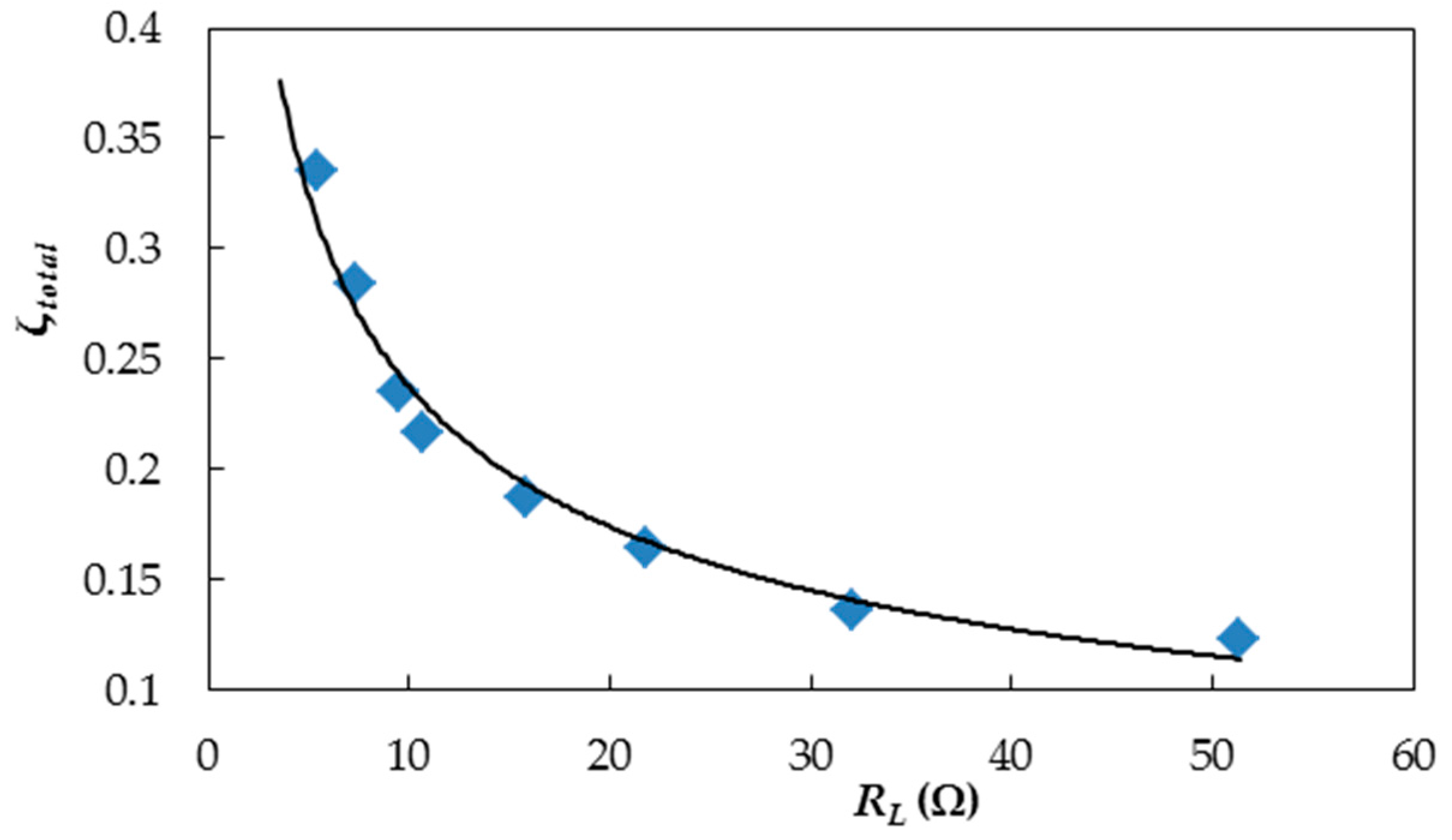

- The total oscillating mass of the vibration system includes the material mass mosc, and the equivalent mass mequ due to the rotation of the gears and rotor. Increasing load resistance RL can result in a decrease in the system damping coefficient thus decreasing the system damping ratio when the system stiffness and the total oscillating mass remain unchanged.

- The galloping of the prism presents, in turn, the soft galloping (SG), the hard galloping 1 (HG1) and the hard galloping 2 (HG2) with increasing ζtotal. For ζtotal ≤ 0.164, the prism experiences SG where the transition from VIV to galloping is self-initiated. The FIV of the prism can be divided into four regions: the VIV initial and upper branches, the transition branch from VIV to galloping, and the galloping branch. For the case of ζtotal = 0.187, the prism only experiences VIV without an externally imposed initial threshold amplitude. The response of the prism consists of an initial branch followed by an upper branch and ending in a desynchronization branch. When the prism is given a threshold initial displacement of approximately 1.5D at Ur = 9.07, the prism enters into HG1 from the VIV upper branch. For the cases of 0.216 ≤ ζtotal ≤ 0.284, after the VIV of the prism is strongly suppressed, a given threshold initial displacement of approximately 1.5D can excite the prism to HG2. Higher ζtotal promotes the galloping to start at higher Ur, U and Re. In addition, as ζtotal increases up to 0.335, only VIV is observed in the test velocity range. For all ζtotal cases, A* decreases with increasing ζtotal, and the maximum A* reaches 2.71 at Ur = 12.80 for ζtotal = 0.089.

- The galloping characteristics of the equilateral triangle cylinder, including significant amplitude responses in an extremely large range of flow velocities, the excellent vibration stationarity, and steady vibration frequencies, are beneficial for improving energy conversion.

- The prism can extract hydraulic energy for Ur > 5.80 (U > 0.610 m/s, Re > 5.36 × 104). The harnessed power Pout and the energy conversion efficiency ηout increase with increasing ζsystem in the galloping zone. The maximum Pout and ηout reach 53.56 W and 40.44%, respectively. In addition, the ηout of the prism exceeds the efficiencies of the smooth circular cylinder and the PTC circular cylinder. The optimal system damping ratio for extracting energy is the maximum system damping ratio that the prism can overcome to experience stable galloping.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| D | Side length of the cross section |

| L | Length of the prism |

| mosc | Oscillating material mass |

| Mosc | Total oscillating mass |

| md | Displaced fluid mass |

| M* | Mass ratio of the vibration system |

| K | System spring stiffness |

| ζtotal | Total damping ratio |

| fn,air | Natural frequency in air |

| U | Fluid velocity |

| Ur | Reduced fluid velocity |

| A | Maximum amplitude |

| A* | Maximum amplitude ratio |

| fosc | Response frequency |

| f* | Frequency ratio |

| Vi | Linear velocity of Gear i |

| Vg | Linear velocity of the generator rotor |

| ri | Radius of Gear i |

| rg | Radius of the generator rotor |

| ci | Damping coefficient due to friction on Gear i |

| cg | Damping coefficient due to friction on rotor |

| Angular velocity of Gear i | |

| Angular velocity of the rotor | |

| Angular acceleration of the ith wheel | |

| Angular acceleration of the rotor | |

| Fy | Force exerted by the fluid on the body |

| E | Induced voltage of the generator |

| B | Magnetic flux density |

| I | Induced current |

| l | Length of the wire cutting the a magnetic field |

| Fmag | Electromotive force |

| Tmag | Electromotive force torque |

| Ji | Rotational inertia of the ith wheel |

| Jg | Rotational inertia of the rotor |

| R0 | Generator inner resistance |

| RL | load resistance |

| mequ | Equivalent mass |

| ctotal | Total system damping coefficient |

| cstructure | Friction damping coefficient on bearings |

| ctra | Transmission damping coefficient |

| cgen | Generator damping coefficient |

| charn | Damping coefficient due to the load resistance |

| Pout | Output power |

| ηout | Energy conversion efficiency |

References

- Blevins, R.D. Flow-Induced Vibration, 3rd ed.; Van Nostrand Reinhold: New York, NY, USA, 1990. [Google Scholar]

- Williamson, C.H.K.; Govardhan, R. Vortex-induced vibrations. Annu. Rev. Fluid Mech. 2004, 36, 413–455. [Google Scholar] [CrossRef]

- Williamsona, C.H.K.; Govardhanb, R. A brief review of recent results in vortex-induced vibrations. J. Wind Eng. Ind. Aerodyn. 2008, 96, 713–735. [Google Scholar] [CrossRef]

- Parkinson, G.V.; Sullivan, P.P. Galloping response of towers. J. Wind Eng. Ind. Aerodyn. 1979, 4, 253–260. [Google Scholar] [CrossRef]

- Bokaian, A.R.; Geoola, F. Hydroelastic instabilities of square cylinders. J. Sound Vib. 1984, 92, 117–141. [Google Scholar] [CrossRef]

- Ding, L.; Zhang, L.; Wu, C.M. Flow induced motion and energy harvesting of bluff bodies with different cross sections. Energy Convers. Manag. 2015, 91, 416–426. [Google Scholar] [CrossRef]

- Xu, F.; Ou, J.; Xiao, Y. CFD Numerical Simulation of Flow-induced Vibration with Different Cross-section Cylinders. J. Eng. Mech. 2009, 26, 7–15. (In Chinese) [Google Scholar]

- Alonso, G.; Meseguer, J. A parametric study of the galloping stability of two dimensional triangular cross-section bodies. J. Wind Eng. Ind. Aerodyn. 2006, 94, 241–253. [Google Scholar] [CrossRef]

- Bernitsas, M.M.; Raghavan, K.; Ben-Simon, Y. Vivace (vortex induced vibration aquatic clean energy): A new concept in generation of clean and renewable energy from fluid flow. J. Offshore Mech. Arct. Eng. Trans. ASME 2008, 130, 619–637. [Google Scholar] [CrossRef]

- Bernitsas, M.M.; Ben-Simon, Y.; Raghavan, K. The VIVACE converter: Model tests at high damping and Reynolds number around 105. J. Offshore Mech. Arct. Eng. Trans. ASME 2009, 131, 403–410. [Google Scholar]

- Chang, C.C.; Kumar, R.A.; Bernitsas, M.M. VIV and galloping of single circular cylinder with surface roughness at 3.0 × 104 ≤ Re ≤ 1.2 × 105. Ocean Eng. 2011, 38, 1713–1732. [Google Scholar] [CrossRef]

- Park, H.; Kumar, R.A.; Bernitsas, M.M. Enhancement of flow-induced motion of rigid circular cylinder on springs by localized surface roughness at 3.0 × 104 ≤ Re ≤ 1.2 × 105. Ocean Eng. 2013, 72, 403–415. [Google Scholar] [CrossRef]

- Ding, L. Research on Flow Induced Motion of Multiple Circular Cylinders with Passive Turbulence Control. Ph.D. Thesis, Chongqing University, Chongqing, China, 2013. [Google Scholar]

- Kluger, J.M.; Moon, F.C.; Rand, R.H. Shape optimization of a blunt body Vibro-wind galloping oscillator. J. Fluid Struct. 2013, 40, 185–200. [Google Scholar] [CrossRef]

- Sorribes-Palmer, F.; Sanz-Andres, A. Optimization of energy extraction in transverse galloping. J. Fluid Struct. 2013, 4, 124–144. [Google Scholar] [CrossRef]

- Luo, S.C.; Chew, Y.T.; Ng, Y.T. Hysteresis phenomenon in the galloping oscillation of a square cylinder. J. Fluid Struct. 2003, 18, 103–118. [Google Scholar] [CrossRef]

- Ruecheweyh, H.; Hortmanns, M.; Schnakenberg, C. Vortex-excited vibrations and galloping of slender elements. J. Wind Eng. Ind. Aerodyn. 1996, 65, 347–352. [Google Scholar] [CrossRef]

- Hmon, P.; Santi, F.; Schnoerringer, B. Influence of free stream turbulence on the movement-induced vibrations of an elongated rectangular cylinder in cross flow. J. Wind Eng. Ind. Aerodyn. 2011, 89, 1383–1395. [Google Scholar] [CrossRef]

- Tamura, T.; Itoh, Y. Unstable aerodynamic phenomena of a rectangular cylinder with critical section. J. Wind Eng. Ind. Aerodyn. 1999, 83, 121–133. [Google Scholar] [CrossRef]

- Li, Q.S.; Fang, J.Q.; Geary, A.P. Evaluation of 2D coupled galloping oscillations of slender structures. Comput. Struct. 1998, 6, 513–523. [Google Scholar] [CrossRef]

- Nemes, A.; Zhao, J.; Lo Jacono, D.; Sheridan, J. The interaction between flow induced vibration mechanisms of a square cylinder with varying angles of attack. J. Fluid Mech. 2012, 710, 102–130. [Google Scholar] [CrossRef]

- Barrero-Gil, A.; Fernandez-Arroyo, P. Maximum vortex-induced vibrations of a square prism. Wind Struct. 2013, 16, 341–354. [Google Scholar] [CrossRef]

- Johansson, S.H.; Davidson, L.; Olsson, E. Numerical simulation of vortex shedding past triangular cylinders at high Reynolds number using a k-ε turbulence model. Int. J. Numer. Methods Fluid 1993, 16, 859–878. [Google Scholar] [CrossRef]

- Camarri, S.; Salvetti, M.V.; Buresti, G. Large-eddy simulation of the flow around a triangular prism with moderate aspect-ratio. J. Wind Eng. Ind. Aerodyn. 2006, 94, 309–322. [Google Scholar] [CrossRef]

- Iungo, G.V.; Buresti, G. Experimental investigation on the aerodynamic loads and wake flow features of low aspect-ratio triangular prisms at different wind directions. J. Fluid Struct. 2009, 25, 1119–1135. [Google Scholar] [CrossRef]

- Alonso, G.; Sanz-Lobera, A.; Meseguer, J. Hysteresis phenomena in transverse galloping of triangular cross-section bodies. J. Fluid Mech. 2012, 33, 243–251. [Google Scholar] [CrossRef]

- Alonso, G.; Meseguer, J.; Pérez-Grande, I. Galloping instabilities of two dimensional triangular cross-section bodies. Exp. Fluids 2005, 38, 789–795. [Google Scholar] [CrossRef]

- Alonso, G.; Meseguer, J.; Pérez-Grande, I. Galloping stability of triangular cross sectional bodies: A systematic approach. J. Wind Eng. Ind. Aerodyn. 2007, 95, 928–940. [Google Scholar] [CrossRef]

- Norberg, C. Fluctuating lift on a circular cylinder: Review and new measurements. J. Fluids Struct. 2003, 17, 57–96. [Google Scholar] [CrossRef]

- Szepessy, S.; Bearman, P.W. Aspect Ratio and End Plate Effects on Vortex Shedding From a Circular Cylinder. J. Fluid Mech. 1992, 234, 191–218. [Google Scholar] [CrossRef]

- Szepessy, S. On the Control of Circular Cylinder Flow by End Plates. Eur. J. Mech. B Fluids 1993, 12, 217–244. [Google Scholar]

- Raghavan, K.; Bernitsas, M.M. Experimental investigation of Reynolds number effect on vortex induced vibration of rigid circular cylinder on elastic supports. Ocean Eng. 2011, 38, 719–731. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, G.B.; Liu, F. Experimental investigation on the flow induced vibration of an equilateral triangle prism in Water. Appl. Ocean Res. 2016, 61, 92–100. [Google Scholar] [CrossRef]

| Part No. | Description |

|---|---|

| 1 | Equilateral triangle prism |

| 2 | Endplates |

| 3 | Side strut used for connecting the prism and connection structure |

| 4 | Linear bearings playing a role in limiting the system to vibration in the vertical direction |

| 5 | Connection structure used for connecting side struts, linear bearings and a power take-off system |

| 6 | Tension springs |

| 7 | Displacement transducer |

| 8 | Steel frame used for fixing linear bearings, tension springs, displacement transducer and generator |

| Side Length of the Cross Section D | Length of the Prism L | Aspect Ratio of the Prism α = L/D | Displaced Fluid Mass md | Oscillating Material Mass mosc |

|---|---|---|---|---|

| 0.1 m | 0.9 m | 9 | 7.07 kg | 30.04 kg |

| RL (Ω) | ζtotal | fn,air (Hz) | ctotal (N·s·m−1) | cgen + charn (N·s·m−1) | Mosc (kg) |

|---|---|---|---|---|---|

| 5.39 | 0.335 | 1.042 | 122.759 | 90.351 | 27.366 |

| 7.33 | 0.284 | 1.049 | 104.012 | 71.604 | 26.983 |

| 9.48 | 0.235 | 1.045 | 85.915 | 53.507 | 27.164 |

| 10.7 | 0.216 | 1.042 | 79.200 | 46.792 | 27.441 |

| 15.81 | 0.187 | 1.052 | 68.464 | 36.056 | 27.111 |

| 21.82 | 0.164 | 1.056 | 60.199 | 27.791 | 27.072 |

| 32.05 | 0.136 | 1.056 | 49.959 | 17.551 | 27.394 |

| 51.37 | 0.123 | 1.056 | 44.960 | 12.552 | 27.457 |

| ∞ (O/C) | 0.089 | 1.058 | 32.408 | 0 | 27.583 |

| ζtotal | Onset of VIV Upper Branch | Onset of Transition Branch | Onset of Galloping Branch | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ur | U (m/s) | Re | Ur | U (m/s) | Re | Ur | U (m/s) | Re | |

| 0.089 | 6.60 | 0.694 | 60935 | 8.49 | 0.893 | 78386 | 10.06 | 1.057 | 92786 |

| 0.123 | 6.63 | 0.697 | 61215 | 8.54 | 0.897 | 78776 | 10.47 | 1.101 | 96643 |

| 0.136 | 6.65 | 0.730 | 64122 | 9.39 | 0.987 | 86662 | 10.54 | 1.108 | 97295 |

| 0.164 | 7.03 | 0.739 | 64857 | 9.45 | 0.990 | 86956 | 11.13 | 1.170 | 102709 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Liu, F.; Lian, J.; Yan, X.; Ren, Q. Flow Induced Vibration and Energy Extraction of an Equilateral Triangle Prism at Different System Damping Ratios. Energies 2016, 9, 938. https://doi.org/10.3390/en9110938

Zhang J, Liu F, Lian J, Yan X, Ren Q. Flow Induced Vibration and Energy Extraction of an Equilateral Triangle Prism at Different System Damping Ratios. Energies. 2016; 9(11):938. https://doi.org/10.3390/en9110938

Chicago/Turabian StyleZhang, Jun, Fang Liu, Jijian Lian, Xiang Yan, and Quanchao Ren. 2016. "Flow Induced Vibration and Energy Extraction of an Equilateral Triangle Prism at Different System Damping Ratios" Energies 9, no. 11: 938. https://doi.org/10.3390/en9110938

APA StyleZhang, J., Liu, F., Lian, J., Yan, X., & Ren, Q. (2016). Flow Induced Vibration and Energy Extraction of an Equilateral Triangle Prism at Different System Damping Ratios. Energies, 9(11), 938. https://doi.org/10.3390/en9110938