Effect of Air Staging Ratios on the Burning Rate and Emissions in an Underfeed Fixed-Bed Biomass Combustor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fuels

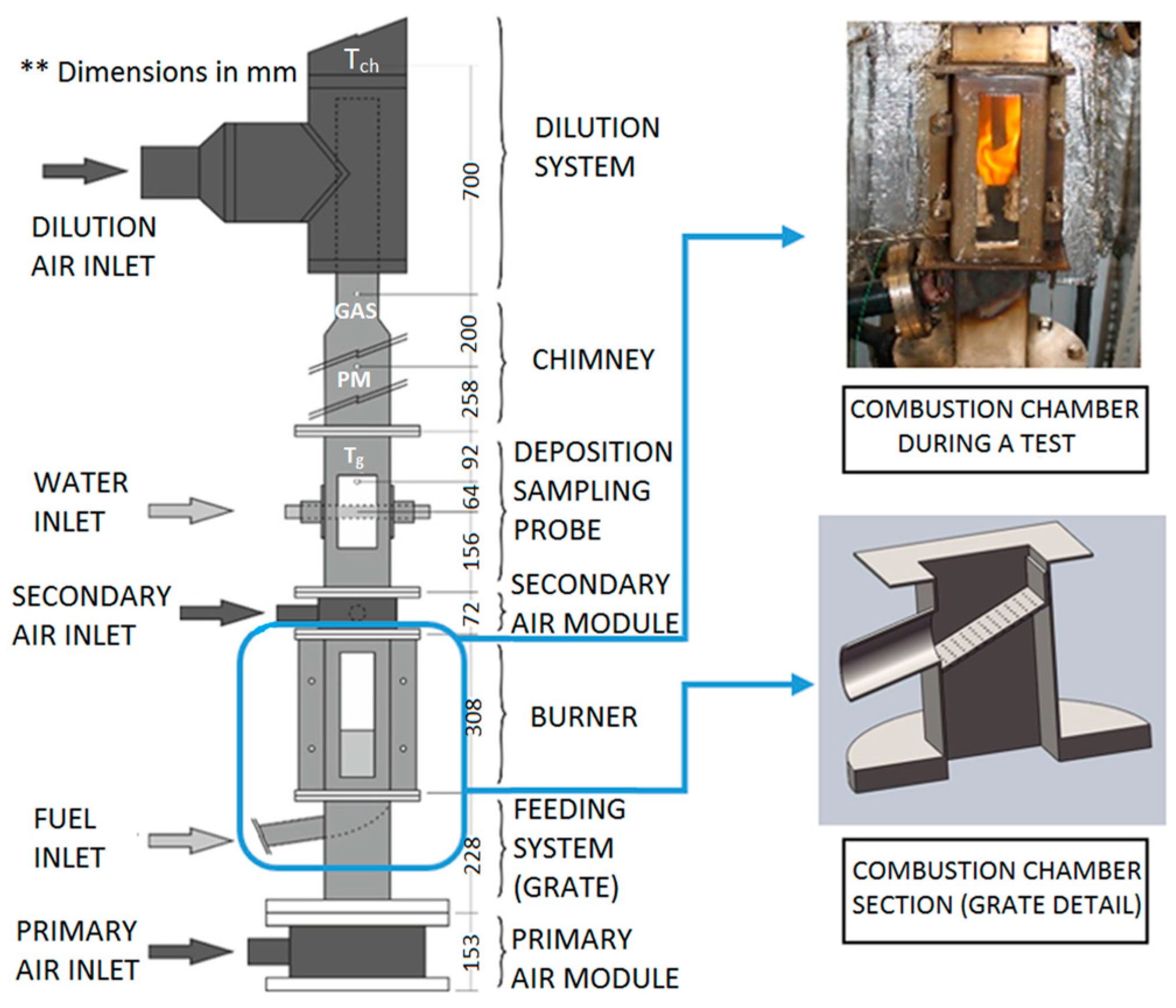

2.2. Description of the Pilot Plant

2.3. Experimental Methodology

3. Results and Discussion

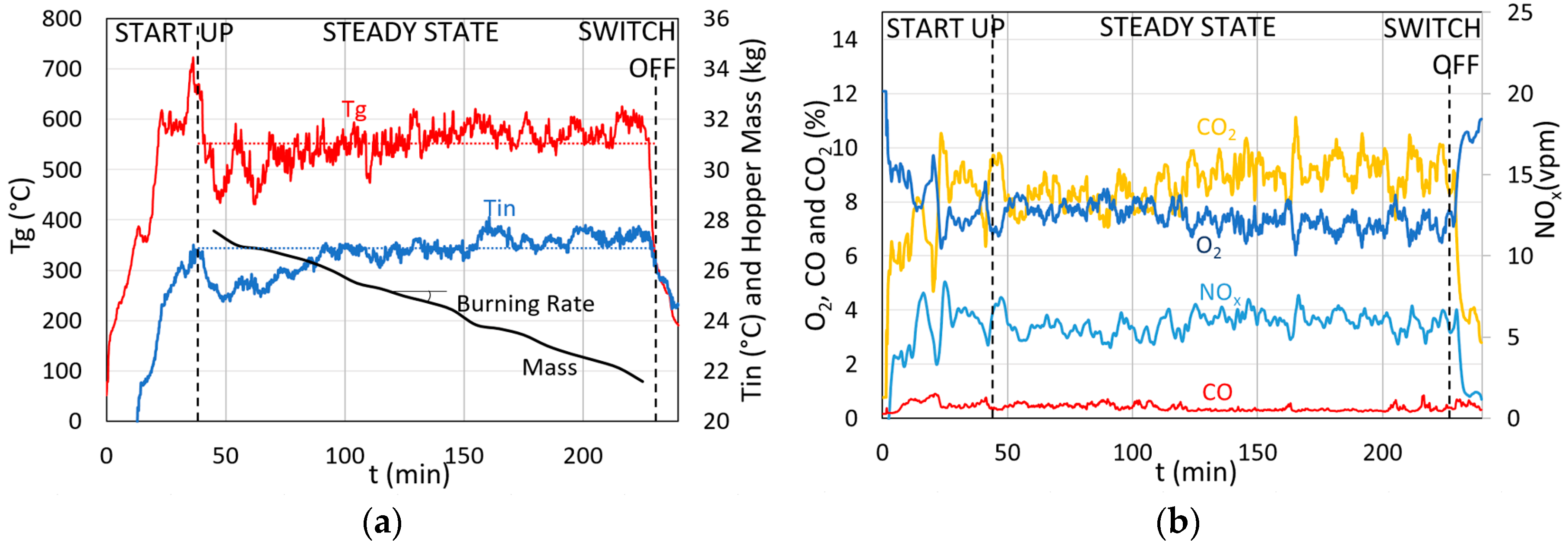

3.1. Plant Stability and Repeatability

3.2. Influence of Air Configuration

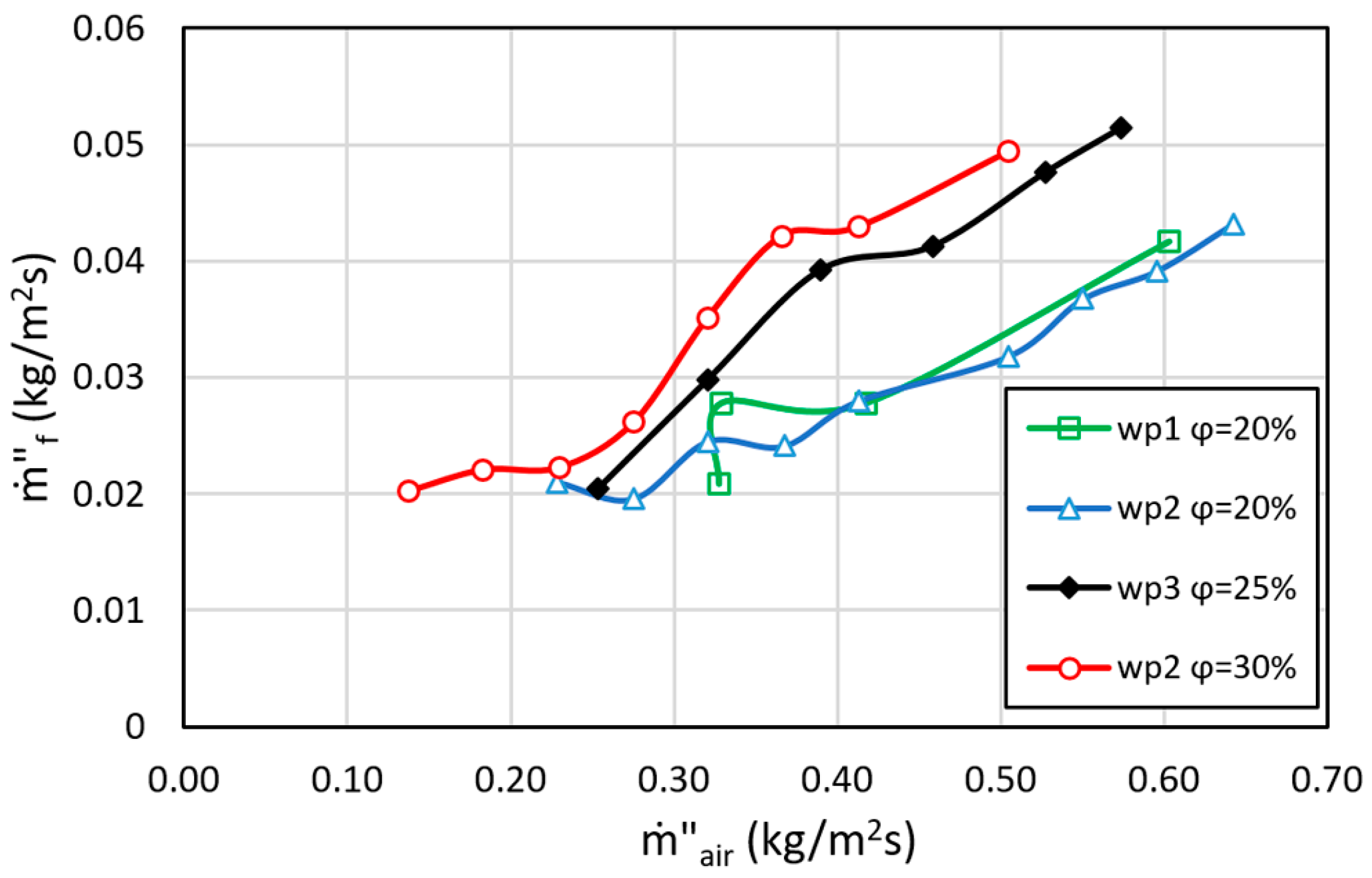

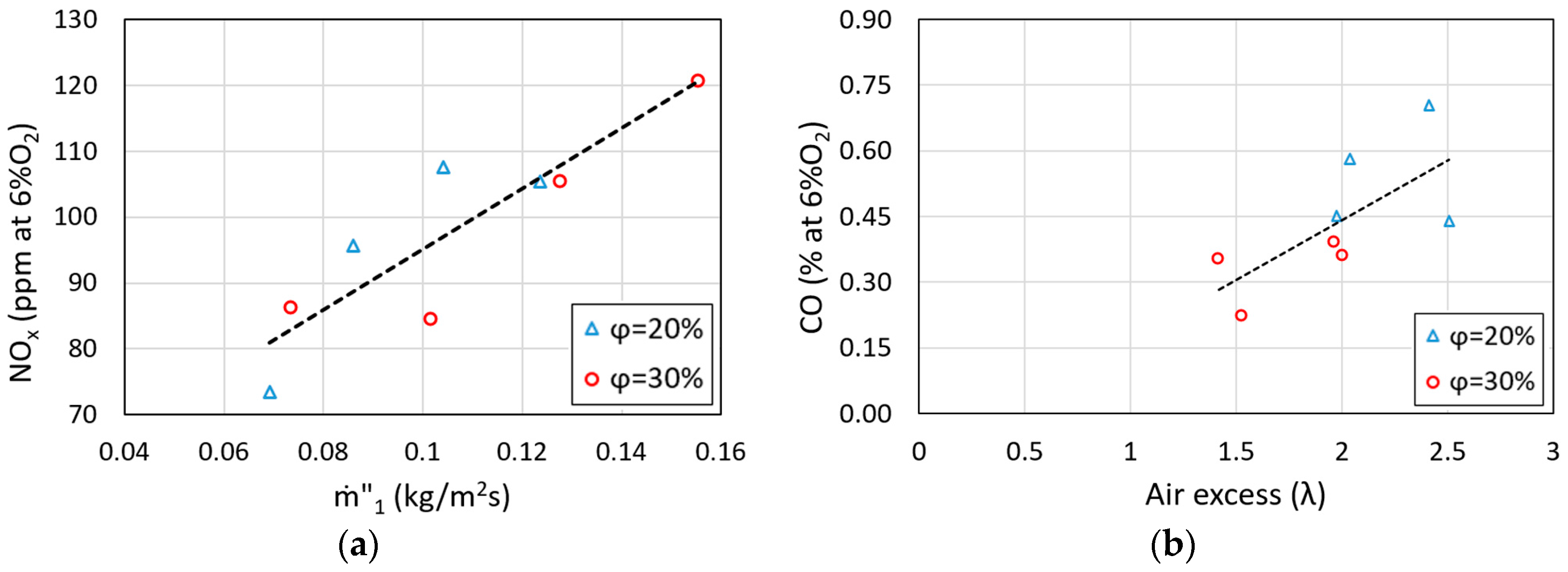

3.3. Emissions

4. Conclusions

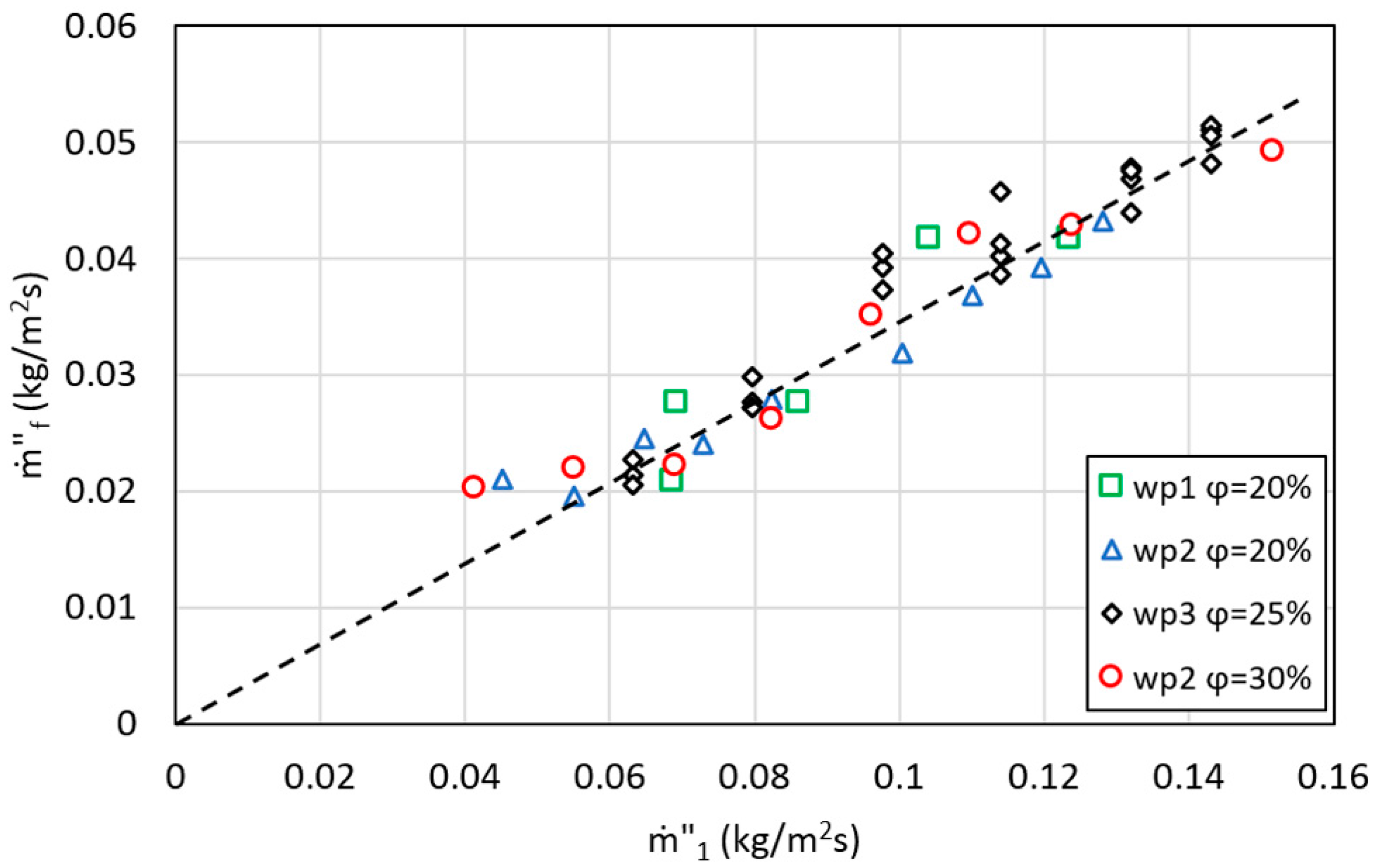

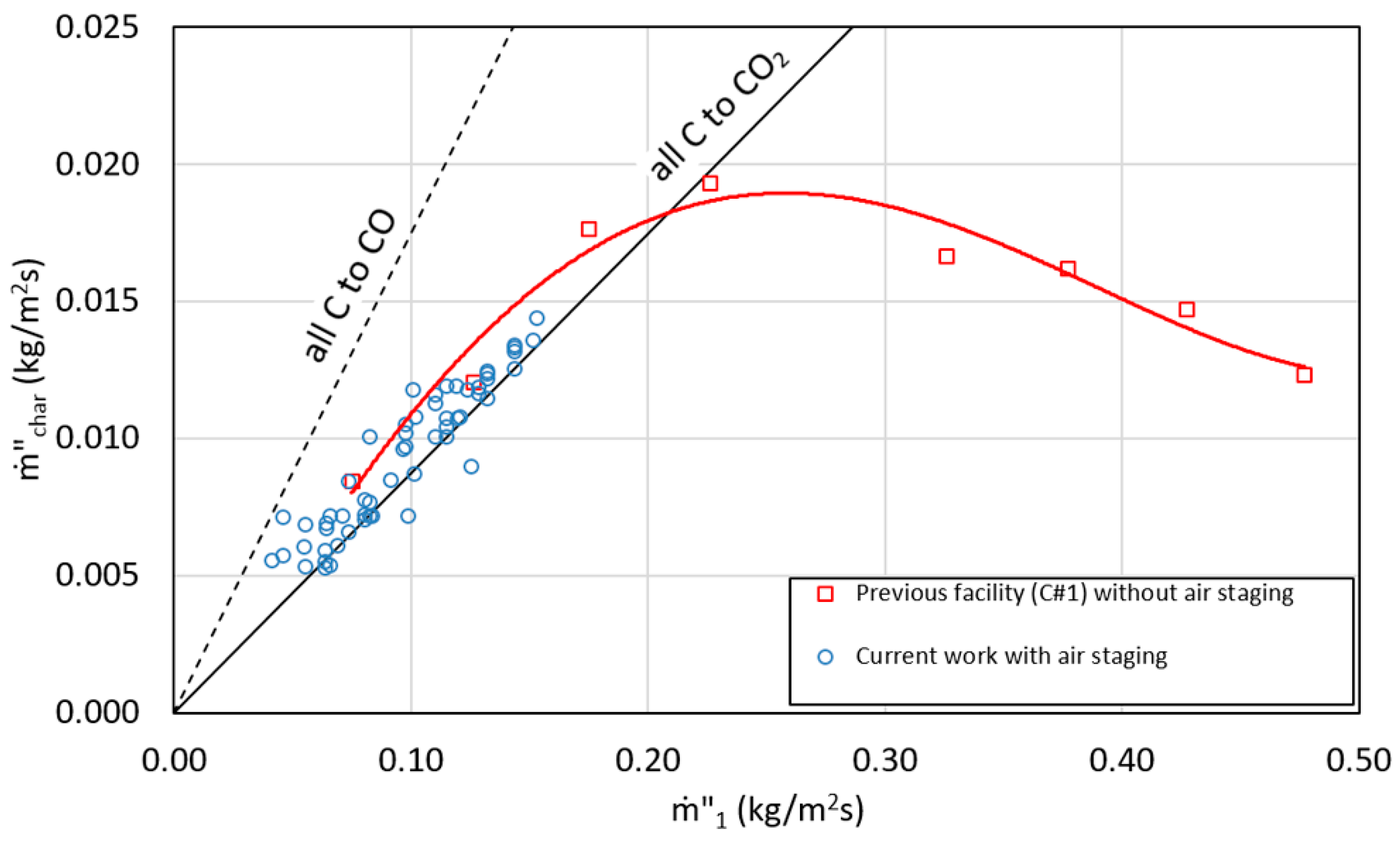

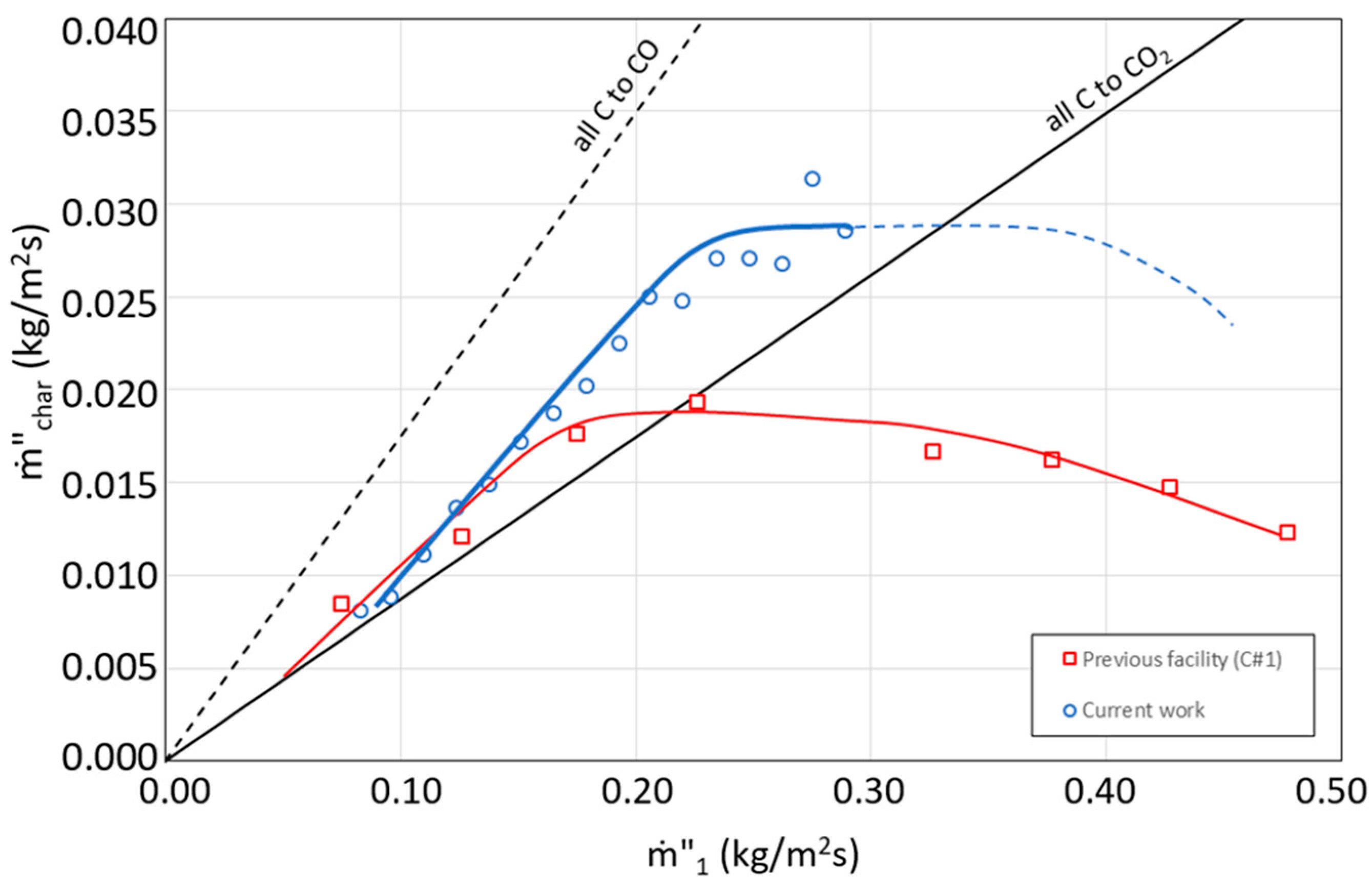

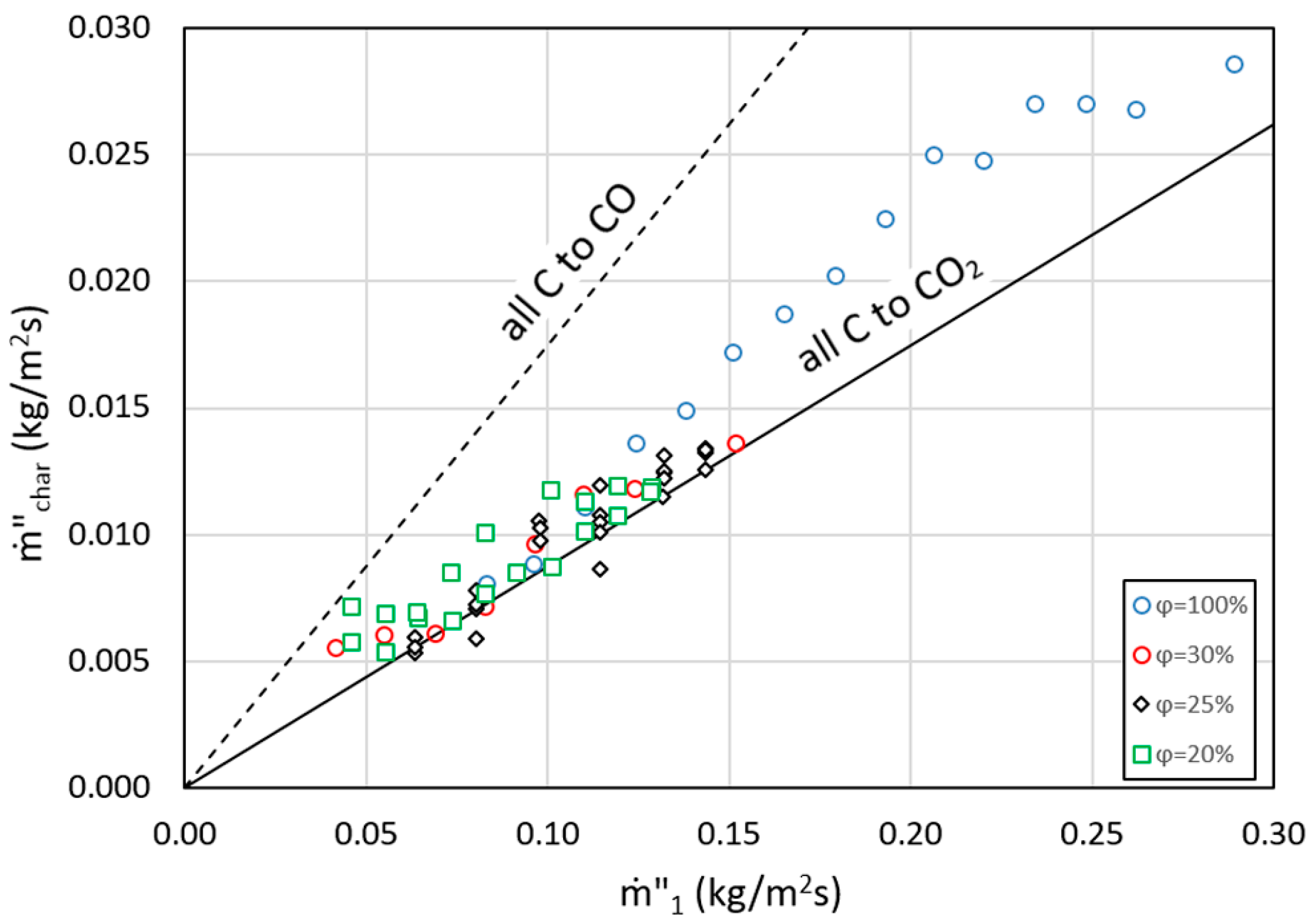

- The effect of air staging and total airflow in the burning (reaction) rate was analyzed. When low primary airflows are used, similar reaction rates were measured, regardless of whether the plant is working only with primary or air staging. For higher primary airflows, the reaction rate, bed devolatilization and thermal power rise up. Using only primary airflows, the combustion is poorer and the values move closer to the incomplete combustion (sub-stoichiometric regimen) while using air staging the burning rate and gas temperature grew almost proportionally following the char stoichiometric line.

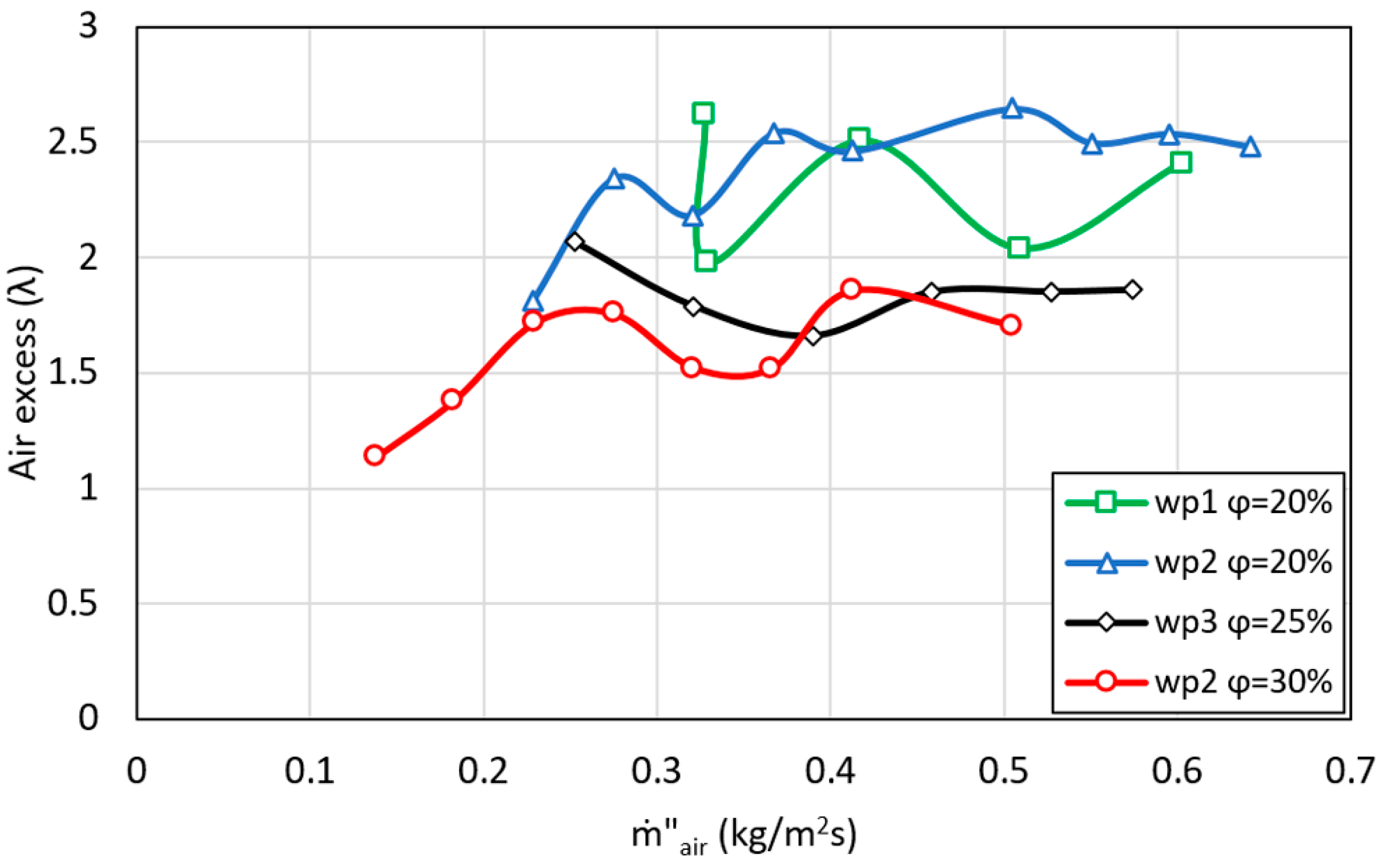

- An increase in the total amount of primary air supplied enhance the burning rate with an almost constant air excess ratio (λ). This ratio varies depending on the air staging, but it normally moves between 1.5 and 2.5.

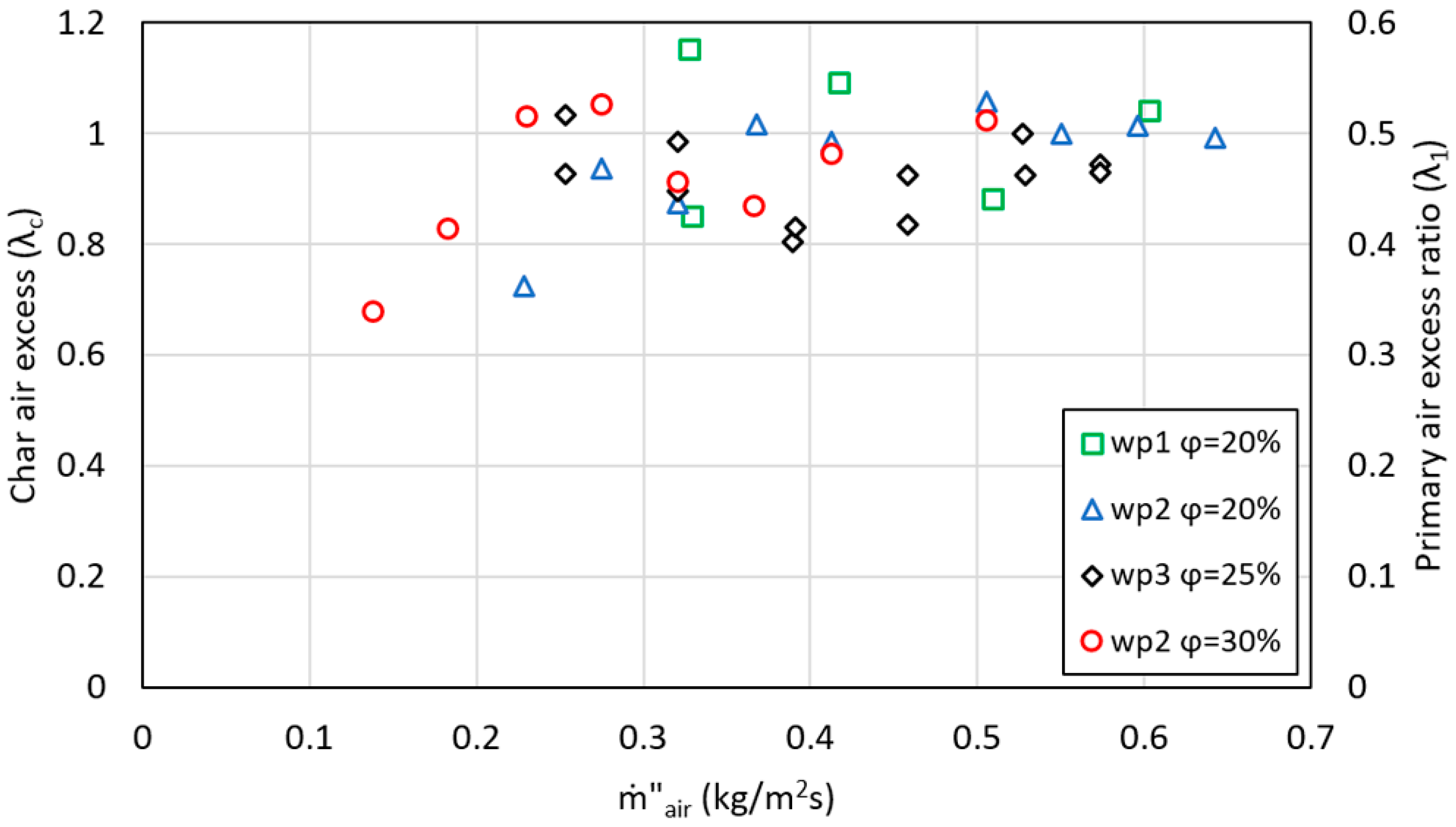

- Primary air excess ratio (λ1) between 0.4 and 0.55 as well as in-bed stoichiometric ratio (λC) close to one were experimentally measured as a consequence of the continuous oxygen-limited char combustion regime.

- The burning rates measured in this work are much higher when compare with reference data obtained in a batch combustor. The main explanation for this behavior is not only the effect of the air staging that enhances the reaction rate, but also the steady position of the ignition front due to the continuous feeding. In a batch combustor, as the ignition front travels along the tube there is an important heat dissipation. However, in the current facility, the combustion front is always steady in the same place owing to the continuously feeding system, increasing the temperature and thickness of the reaction front.

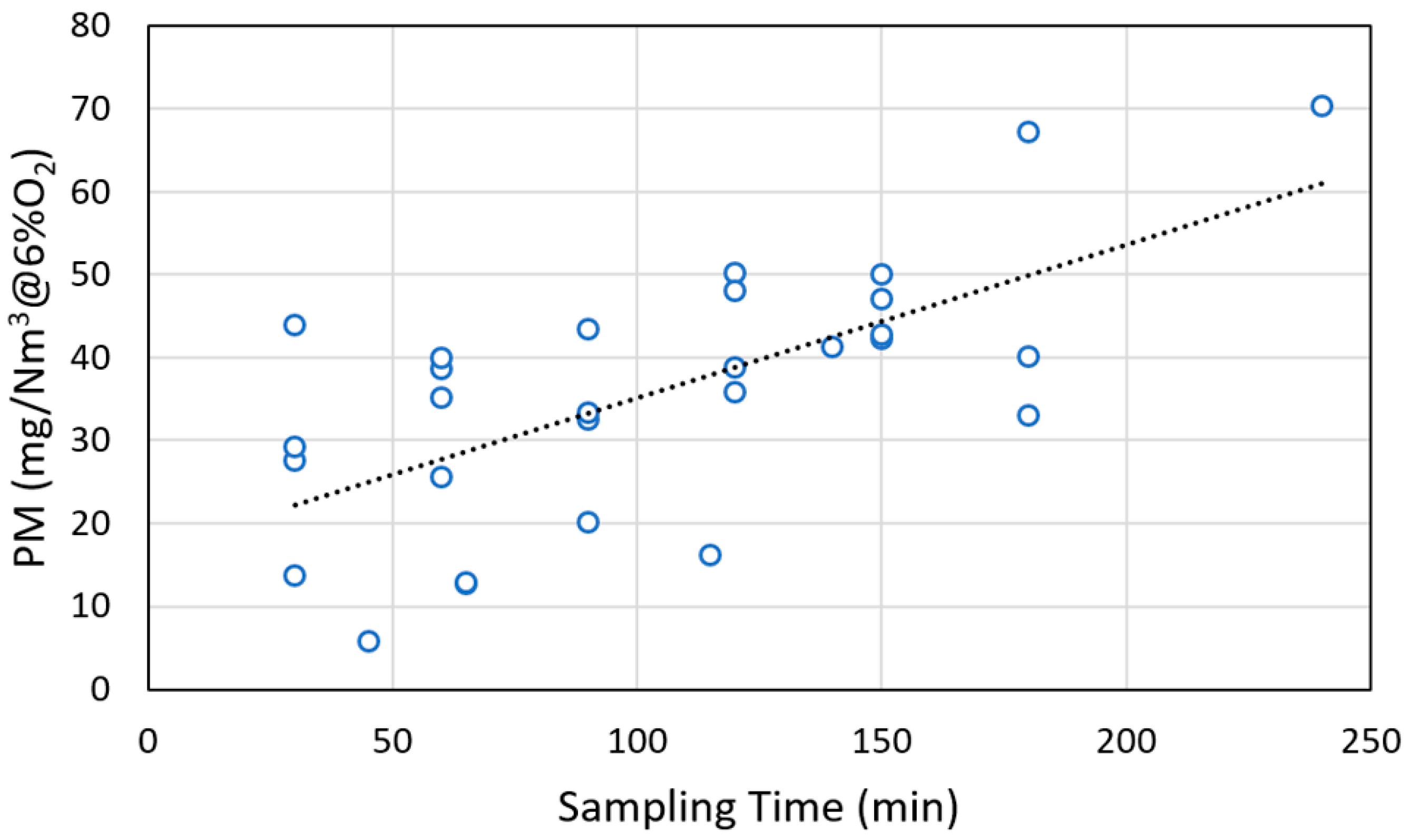

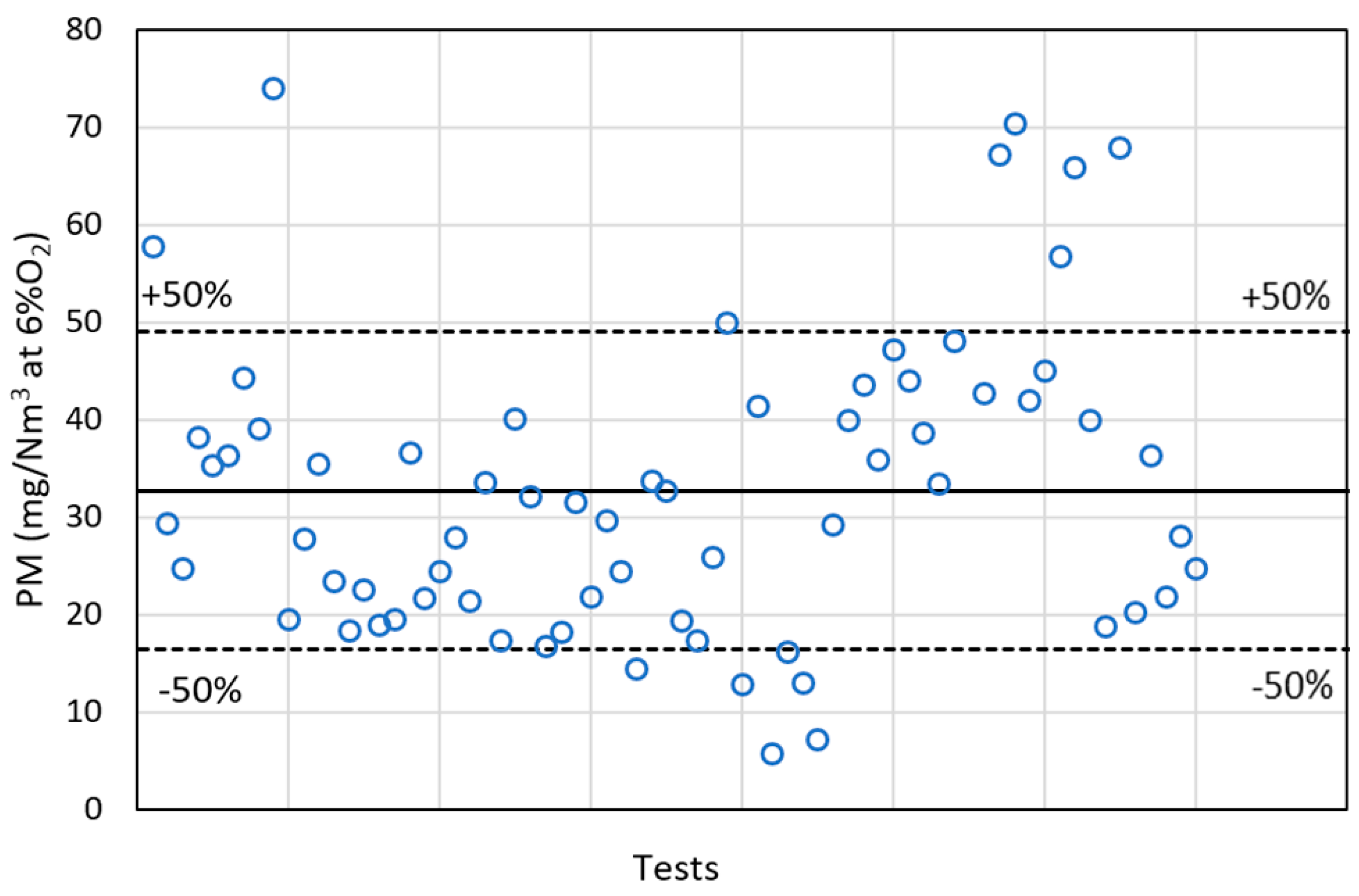

- The amount of particulate matter collected is a function of the sampling moment due to the ash accumulation in the combustion chamber.

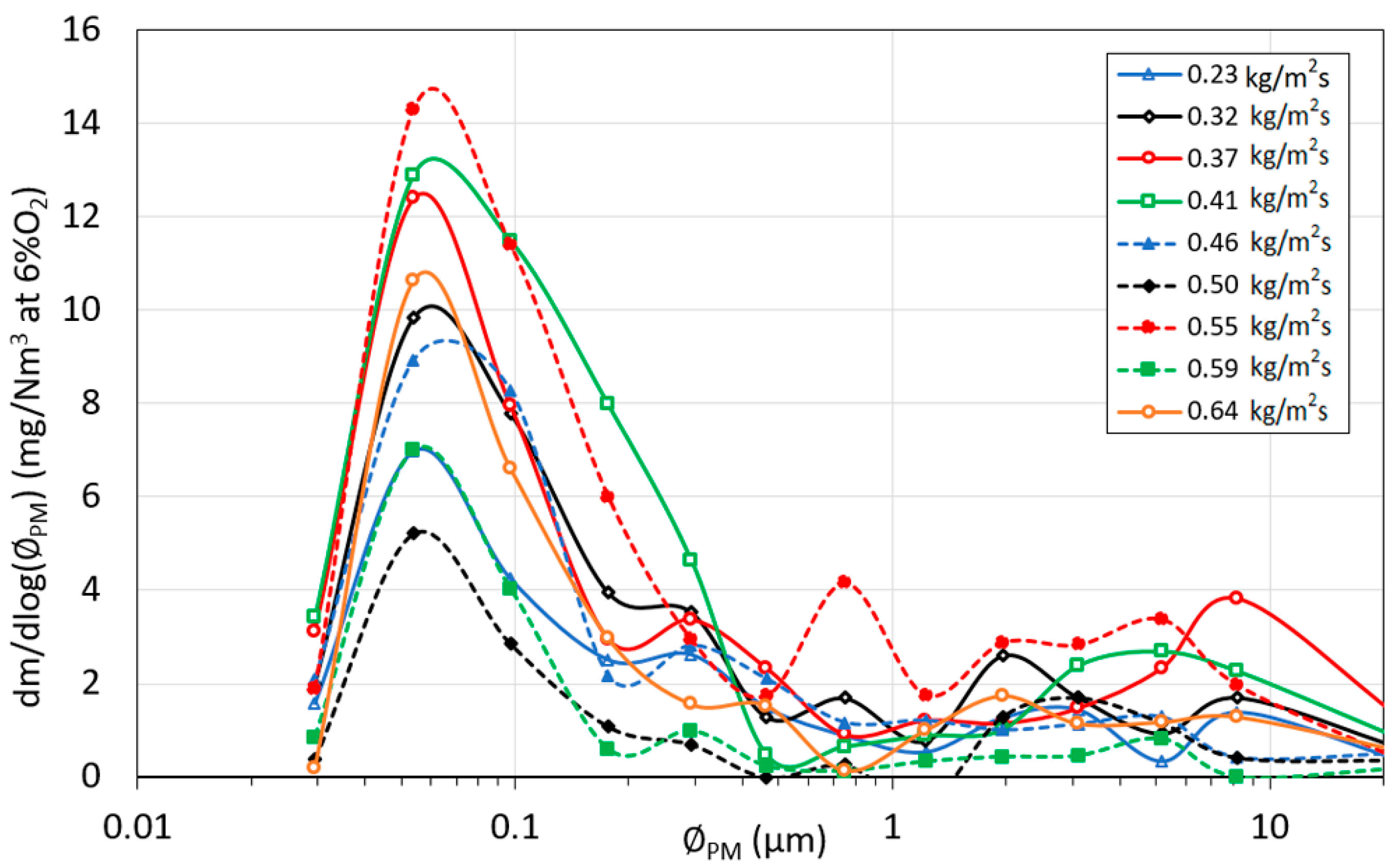

- Particle concentrations between 15 and 75 mg/Nm3 at 6% O2 were recorded with air staging in most of the cases. When only primary air is introduced, the concentration is increased, reaching values of up 360 mg/Nm3.

- The characteristic size obtained for the PM was 0.05–0.1 μm. As with the total concentration, this size does not seem to vary significantly with the air conditions (total airflow or staging ratios). At the very least, the variations are lower than the measurement uncertainty for this study.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Primary air mass flow (kg/m2s) | |

| Secondary air mass flow (kg/m2s) | |

| Total air mass flow ( + ) (kg/m2s) | |

| Fuel burning rate (kg/m2s) | |

| Char/carbon burning rate (kg/m2s) | |

| AFR | Particle air to fuel stoichiometric ratio (kg of dry air per kg of fuel burnt) |

| AFRC | Char air to fuel stoichiometric ratio (kg of dry air per kg of carbon burnt) |

| Tch | Chimney/Stack gas temperature (°C) |

| Tg | Gas temperature (°C) |

| Tin | Water inlet temperature (°C) |

Greek Symbols

| λ | Air excess (total air-fuel equivalence ratio) |

| λ1 | Primary air excess (primary air-fuel equivalence ratio) |

| λC | Char air excess (primary air-char equivalence ratio) |

| φ | Air staging ratio (/) |

| ØPM | Particulate matter representative size (μm) |

Abbreviation

| DLPI | Dekati Low Pressure Impactor |

| PM | Particulate Matter (mg/Nm3) |

| SEM/EDS | Scanning Electron Microscopy/Energy Dispersive Spectroscopy |

| wp | wood pellet |

References

- Michopoulos, A.; Skoulou, V.; Voulgari, V.; Tsikaloudaki, A.; Kyriakis, N. The exploitation of biomass for building space heating in Greece: Energy, environmental and economic considerations. Energy Convers. Manag. 2014, 78, 276–285. [Google Scholar] [CrossRef]

- Tchapda, A.H.; Pisupati, S.V. A review of thermal co-conversion of coal and biomass/waste. Energies 2014, 7, 1098–1148. [Google Scholar] [CrossRef]

- Wiinikka, H.; Gebart, R. Critical parameters for particle emissions in small-scale fixed-bed combustion of wood pellets. Energy Fuels 2004, 18, 897–907. [Google Scholar] [CrossRef]

- Wiinikka, H.; Gebart, R.; Boman, C.; Boström, D.; Nordin, A.; Öhman, M. High-temperature aerosol formation in wood pellets flames: Spatially resolved measurements. Combust. Flame 2006, 147, 278–293. [Google Scholar] [CrossRef]

- Wiinikka, H.; Gebart, R. Experimental investigations of the influence from different operating conditions on the particle emissions from a small-scale pellets combustor. Biomass Bioenergy 2004, 27, 645–652. [Google Scholar] [CrossRef]

- Yang, Y.; Sharifi, V.; Swithenbank, J. Effect of air flow rate and fuel moisture on the burning behaviours of biomass and simulated municipal solid wastes in packed beds. Fuel 2004, 83, 1553–1562. [Google Scholar] [CrossRef]

- Porteiro, J.; Patiño, D.; Collazo, J.; Granada, E.; Moran, J.; Miguez, J. Experimental analysis of the ignition front propagation of several biomass fuels in a fixed-bed combustor. Fuel 2010, 89, 26–35. [Google Scholar] [CrossRef]

- Porteiro, J.; Patiño, D.; Moran, J.; Granada, E. Study of a fixed-bed biomass combustor: Influential parameters on ignition front propagation using parametric analysis. Energy Fuels 2010, 24, 3890–3897. [Google Scholar] [CrossRef]

- Buchmayr, M.; Gruber, J.; Hargassner, M.; Hochenauer, C. Experimental investigation of the primary combustion zone during staged combustion of wood-chips in a commercial small-scale boiler. Biomass Bioenergy 2015, 81, 356–363. [Google Scholar] [CrossRef]

- Fernandes, U.; Costa, M. Formation of fine particulate matter in a domestic pellet-fired boiler. Energy Fuels 2013, 27, 1081–1092. [Google Scholar] [CrossRef]

- Fernandes, U.; Costa, M. Particle emissions from a domestic pellets-fired boiler. Fuel Process. Technol. 2012, 103, 51–56. [Google Scholar] [CrossRef]

- Ozgen, S.; Cernuschi, S.; Giugliano, M. Experimental evaluation of particle number emissions from wood combustion in a closed fireplace. Biomass Bioenergy 2013, 50, 65–74. [Google Scholar] [CrossRef]

- Murasawa, N.; Koseki, H. Investigation of Heat Generation from Biomass Fuels. Energies 2015, 8, 5143–5158. [Google Scholar] [CrossRef]

- Boman, C.; Pettersson, E.R.; Westerholm, R.; Boström, D.; Nordin, A. Stove performance and emission characteristics in residential wood log and pellet combustion, Part 1: Pellet stoves. Energy Fuels 2011, 25, 307–314. [Google Scholar] [CrossRef]

- Wiinikka, H.; Gebart, R.; Boman, C.; Boström, D.; Öhman, M. Influence of fuel ash composition on high temperature aerosol formation in fixed bed combustion of woody biomass pellets. Fuel 2007, 86, 181–193. [Google Scholar] [CrossRef]

- Ryu, C.; Yang, Y.B.; Khor, A.; Yates, N.E.; Sharifi, V.N.; Swithenbank, J. Effect of fuel properties on biomass combustion: Part I. Experiments—Fuel type, equivalence ratio and particle size. Fuel 2006, 85, 1039–1046. [Google Scholar] [CrossRef]

- Tarelho, L.A.C.; Neves, D.S.F.; Matos, M.A.A. Forest biomass waste combustion in a pilot-scale bubbling fluidised bed combustor. Biomass Bioenergy 2011, 35, 1511–1523. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, J.; Preto, F.; Zhu, J.; Xu, C. Ash deposition in biomass combustion or co-firing for power/heat generation. Energies 2012, 5, 5171–5189. [Google Scholar] [CrossRef]

- Ryu, C.; Phan, A.N.; Sharifi, V.N.; Swithenbank, J. Combustion of textile residues in a packed bed. Exp. Therm. Fluid Sci. 2007, 31, 887–895. [Google Scholar] [CrossRef]

- Zhao, W.; Li, Z.; Wang, D.; Zhu, Q.; Sun, R.; Meng, B.; Zhao, G. Combustion characteristics of different parts of corn straw and NO formation in a fixed bed. Bioresour. Technol. 2008, 99, 2956–2963. [Google Scholar] [CrossRef] [PubMed]

- Gómez, M.; Porteiro, J.; Patiño, D.; Míguez, J. Fast-solving thermally thick model of biomass particles embedded in a CFD code for the simulation of fixed-bed burners. Energy Convers. Manag. 2015, 105, 30–44. [Google Scholar] [CrossRef]

- Febrero, L.; Granada, E.; Pérez, C.; Patiño, D.; Arce, E. Characterisation and comparison of biomass ashes with different thermal histories using tg-dsc. J. Therm. Anal. Calorim. 2014, 118, 669–680. [Google Scholar] [CrossRef]

- Rogaume, T.; Auzanneau, M.; Jabouille, F.; Goudeau, J.; Torero, J. The effects of different airflows on the formation of pollutants during waste incineration. Fuel 2002, 81, 2277–2288. [Google Scholar] [CrossRef]

- Khodaei, H.; Al-Abdeli, Y.M.; Guzzomi, F.; Yeoh, G.H. An overview of processes and considerations in the modelling of fixed-bed biomass combustion. Energy 2015, 88, 946–972. [Google Scholar] [CrossRef]

- Horttanainen, M.; Saastamoinen, J.; Sarkomaa, P. Operational limits of ignition front propagation against airflow in packed beds of different wood fuels. Energy Fuels 2002, 16, 676–686. [Google Scholar] [CrossRef]

- Nicholls, P. Underfeed Combustion, Effect of Preheat, and Distribution of Ash in Fuel Beds; United states Government Printing Office: Washington, DC, USA, 1934.

- Katunzi, M. Biomass Conversion in Fixed Bed Experiments; Report Number WVT; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 2006; pp. 1–55. [Google Scholar]

- Zhou, H.; Jensen, A.; Glarborg, P.; Jensen, P.A.; Kavaliauskas, A. Numerical modeling of straw combustion in a fixed bed. Fuel 2005, 84, 389–403. [Google Scholar] [CrossRef]

- Van Blijderveen, M.; Gucho, E.M.; Bramer, E.A.; Brem, G. Spontaneous ignition of wood, char and RDF in a lab scale packed bed. Fuel 2010, 89, 2393–2404. [Google Scholar] [CrossRef]

- Razuan, R.; Chen, Q.; Finney, K.N.; Russell, N.V.; Sharifi, V.N.; Swithenbank, J. Combustion of oil palm stone in a pilot-scale fluidised bed reactor. Fuel Process. Technol. 2011, 92, 2219–2225. [Google Scholar] [CrossRef]

- Obaidullah, M.; Bram, S.; Verma, V.; De Ruyck, J. A review on particle emissions from small scale biomass combustion. Int. J. Renew. Energy Res. 2012, 2, 147–159. [Google Scholar]

- Sippula, O. Fine Particle Formation and Emissions in Biomass Combustion. Available online: http://www.atm.helsinki.fi/faar/reportseries/rs-108.pdf (accessed on 18 March 2010).

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Fine particulate emissions from modern Austrian small-scale biomass combustion plants. In Proceedings of the 15th European Biomass Conference & Exhibition, Berlin, Germany, 7–11 May 2007; pp. 1546–1557.

- Johansson, L.; Tullin, C.; Leckner, B.; Sjövall, P. Particle emissions from biomass combustion in small combustors. Biomass Bioenergy 2003, 25, 435–446. [Google Scholar] [CrossRef]

- Gaegauf, C.; Wieser, U.; Macquat, Y. Field investigation of nanoparticle emissions from various biomass combustion systems. In Proceedings of the International Seminar on Aerosol from Biomass Combustion, Zurich, Switzerland, 27 June 2001; pp. 81–85.

- Chen, Q.; Zhang, X.; Bradford, D.; Sharifi, V.; Swithenbank, J. Comparison of emission characteristics of small-scale heating systems using biomass instead of coal. Energy Fuels 2010, 24, 4255–4265. [Google Scholar] [CrossRef]

- Boman, C.; Nordin, A.; Boström, D.; Öhman, M. Characterization of inorganic particulate matter from residential combustion of pelletized biomass fuels. Energy Fuels 2004, 18, 338–348. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion and co-combustion of biomass: Fundamentals, technologies, and primary measures for emission reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Wierzbicka, A.; Lillieblad, L.; Pagels, J.; Strand, M.; Gudmundsson, A.; Gharibi, A.; Swietlicki, E.; Sanati, M.; Bohgard, M. Particle emissions from district heating units operating on three commonly used biofuels. Atmos. Environ. 2005, 39, 139–150. [Google Scholar] [CrossRef]

- Yang, Y.; Yamauchi, H.; Nasserzadeh, V.; Swithenbank, J. Effects of fuel devolatilisation on the combustion of wood chips and incineration of simulated municipal solid wastes in a packed bed. Fuel 2003, 82, 2205–2221. [Google Scholar] [CrossRef]

- Yang, Y.B.; Ryu, C.; Khor, A.; Sharifi, V.N.; Swithenbank, J. Fuel size effect on pinewood combustion in a packed bed. Fuel 2005, 84, 2026–2038. [Google Scholar] [CrossRef]

- Arromdee, P.; Kuprianov, V.I. Combustion of peanut shells in a cone-shaped bubbling fluidized-bed combustor using alumina as the bed material. Appl. Energy 2012, 97, 470–482. [Google Scholar] [CrossRef]

- Liu, H.; Chaney, J.; Li, J.; Sun, C. Control of NOx emissions of a domestic/small-scale biomass pellet boiler by air staging. Fuel 2013, 103, 792–798. [Google Scholar] [CrossRef]

- Ehrlich, C.; Noll, G.; Kalkoff, W. Determining PM-emission fractions (PM10, PM2.5, PM1.0) from small-scale combustion units and domestic stoves using different types of fuels including biofuels like wood pellets and energy grain. In Proceedings of the 18th Clean Air Society of Australia and New Zealand (CASANZ) Conference, Brisbane, Australia, 9–13 September 2007.

- Bäfver, L.S.; Leckner, B.; Tullin, C.; Berntsen, M. Particle emissions from pellets stoves and modern and old-type wood stoves. Biomass Bioenergy 2011, 35, 3648–3655. [Google Scholar] [CrossRef]

- Kelz, J.; Brunner, T.; Obernberger, I.; Jalava, P.; Hirvonen, M. PM emissions from old and modern biomass combustion systems and their health effects. In Proceedings of the 18th European Biomass Conference and Exhibition, Lyon, France, 3–7 May 2010.

- Krugly, E.; Martuzevicius, D.; Puida, E.; Buinevicius, K.; Stasiulaitiene, I.; Radziuniene, I.; Minikauskas, A.; Kliucininkas, L. Characterization of Gaseous-and Particle-Phase Emissions from the Combustion of Biomass-Residue-Derived Fuels in a Small Residential Boiler. Energy Fuels 2014, 28, 5057–5066. [Google Scholar] [CrossRef]

| Proximate Analysis 1 (% Weight) | |||

| wp1 | wp2 | wp3 | |

| Moisture | 6.85 | 6.60 | 5.81 |

| Volatile | 68.50 | 66.65 | 66.46 |

| Fixed carbon 2 | 24.24 | 25.75 | 24.60 |

| Ash | 0.41 | 1.00 | 3.13 |

| Ultimate Analysis 3 (% Weight) | |||

| C | 47.43 | 46.23 | 47.71 |

| H | 6.22 | 6.29 | 6.17 |

| N | 0.14 | 2.55 | 1.95 |

| O | 46.21 | 44.93 | 44.17 |

| Fuel | Number of Tests | Parameter | Relative Deviation % | Air Staging φ |

|---|---|---|---|---|

| wp1 | 9 | Burning rate | 6.1 | 20% |

| Gas temperature | 9.3 | |||

| 5 | Burning rate | 4.7 | 15% | |

| Gas temperature | 2.7 | |||

| 5 | Burning rate | 7.6 | 30% | |

| Gas temperature | 3.8 | |||

| wp2 | 17 | Burning rate | 10.3 | 20% |

| Gas temperature | 4.9 | |||

| wp3 | 46 | Burning rate | 10.4 | 25% |

| Gas temperature | 8.8 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Regueiro, A.; Patiño, D.; Porteiro, J.; Granada, E.; Míguez, J.L. Effect of Air Staging Ratios on the Burning Rate and Emissions in an Underfeed Fixed-Bed Biomass Combustor. Energies 2016, 9, 940. https://doi.org/10.3390/en9110940

Regueiro A, Patiño D, Porteiro J, Granada E, Míguez JL. Effect of Air Staging Ratios on the Burning Rate and Emissions in an Underfeed Fixed-Bed Biomass Combustor. Energies. 2016; 9(11):940. https://doi.org/10.3390/en9110940

Chicago/Turabian StyleRegueiro, Araceli, David Patiño, Jacobo Porteiro, Enrique Granada, and José Luis Míguez. 2016. "Effect of Air Staging Ratios on the Burning Rate and Emissions in an Underfeed Fixed-Bed Biomass Combustor" Energies 9, no. 11: 940. https://doi.org/10.3390/en9110940

APA StyleRegueiro, A., Patiño, D., Porteiro, J., Granada, E., & Míguez, J. L. (2016). Effect of Air Staging Ratios on the Burning Rate and Emissions in an Underfeed Fixed-Bed Biomass Combustor. Energies, 9(11), 940. https://doi.org/10.3390/en9110940