Novel Method for Measuring the Heat Collection Rate and Heat Loss Coefficient of Water-in-Glass Evacuated Tube Solar Water Heaters Based on Artificial Neural Networks and Support Vector Machine

Abstract

:1. Introduction

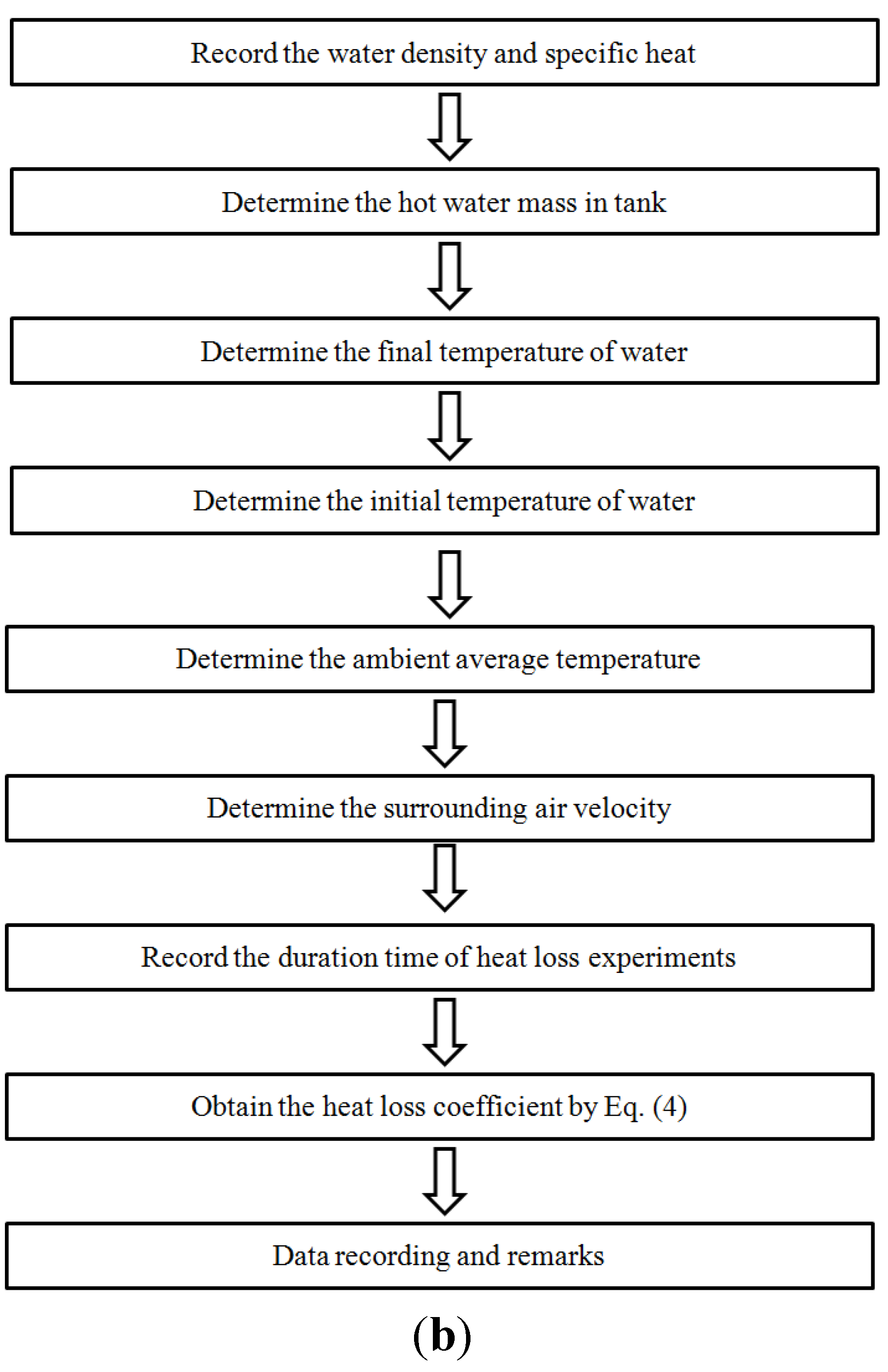

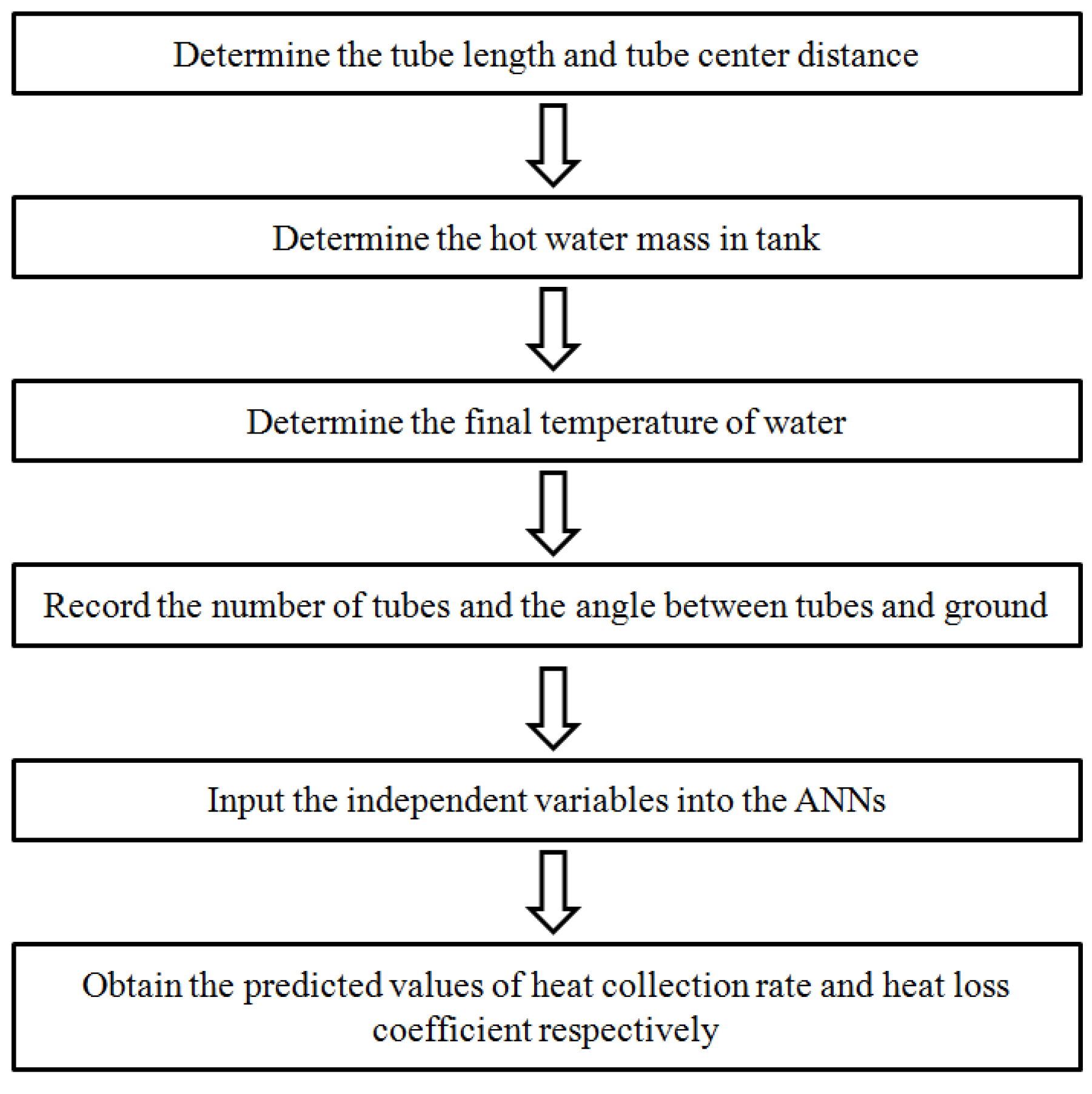

2. Materials and Methods

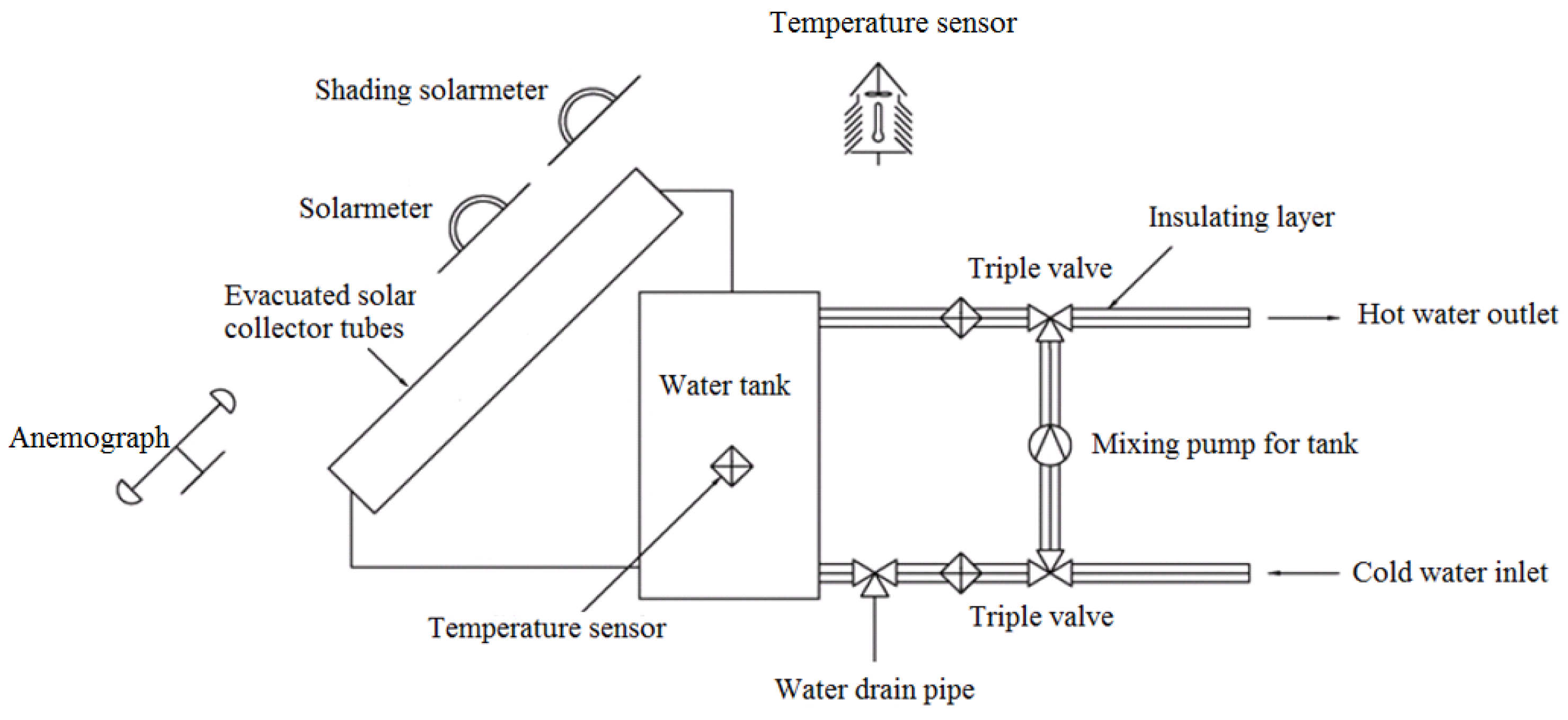

2.1. Experimental

| Parameters | Portable Test instruments | Accuracy | Picture |

|---|---|---|---|

| Final temperate of water | Digital thermoelectric thermometer | ±0.5% |  |

| Hot water mass in tank | Electric platform scale | ±1.0% |  |

| Diameter, tube center distance, tube length, collector area | Taper ZSH-3 | ±0.5% |  |

| Item | Tube Length (mm) | Number of Tubes | TCD (mm) | Tank Volume (kg) | Collector Area (m2) | Angle (°) | Final Temp. (°C) | HCR (MJ/m2) | HLC (W/(m3K)) |

|---|---|---|---|---|---|---|---|---|---|

| Maximum | 2200 | 64 | 151 | 403 | 8.24 | 85 | 62 | 11.3 | 13 |

| Minimum | 1600 | 5 | 60 | 70 | 1.27 | 30 | 46 | 6.7 | 8 |

| Range | 600 | 59 | 91 | 333 | 6.97 | 55 | 16 | 4.6 | 5 |

| Average | 1811 | 21 | 76.2 | 172 | 2.69 | 46 | 53 | 8.9 | 10 |

| Standard deviation | 87.8 | 5.8 | 5.11 | 47.0 | 0.73 | 3.89 | 2.0 | 0.48 | 0.77 |

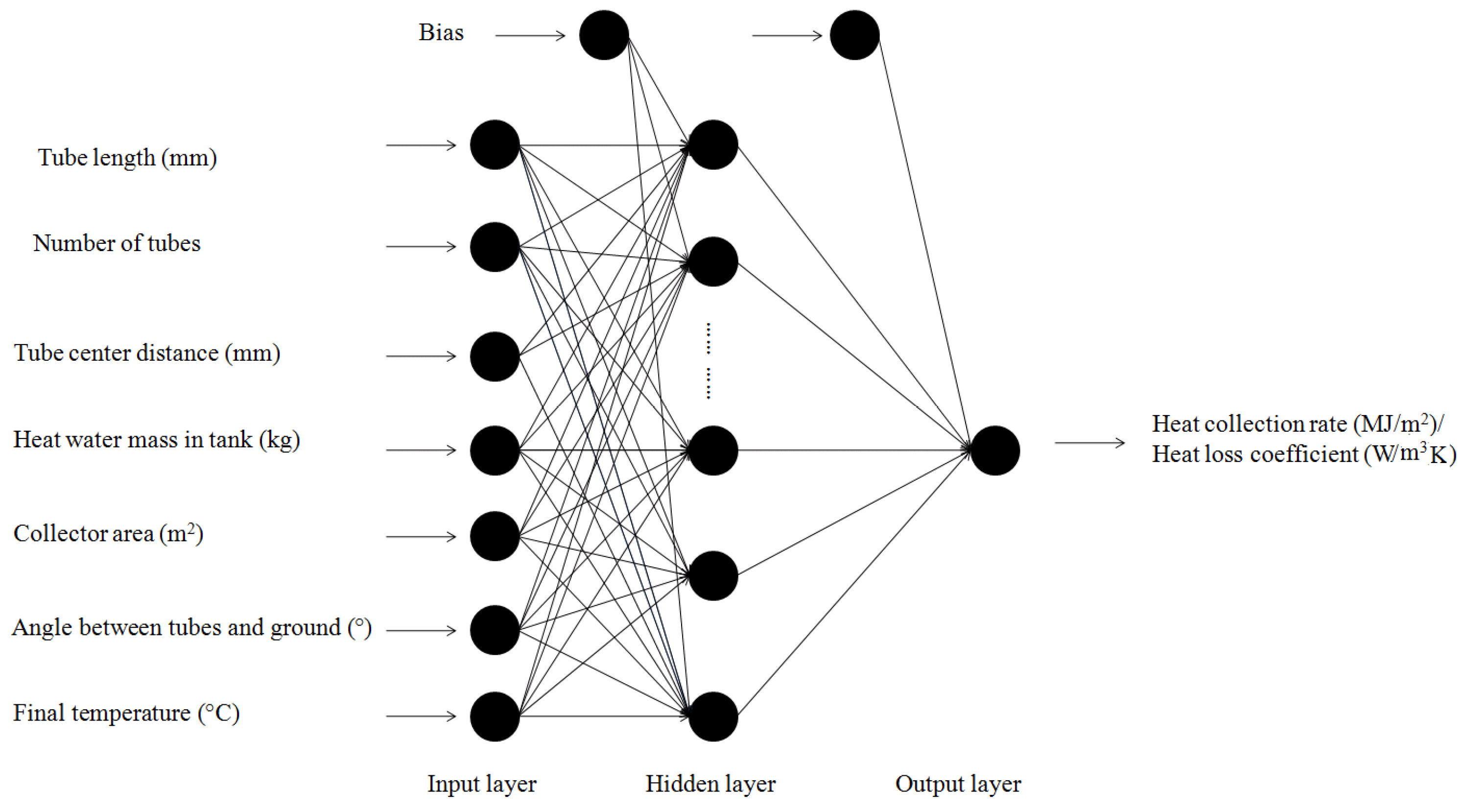

2.2. Artificial Neural Networks (ANNs)

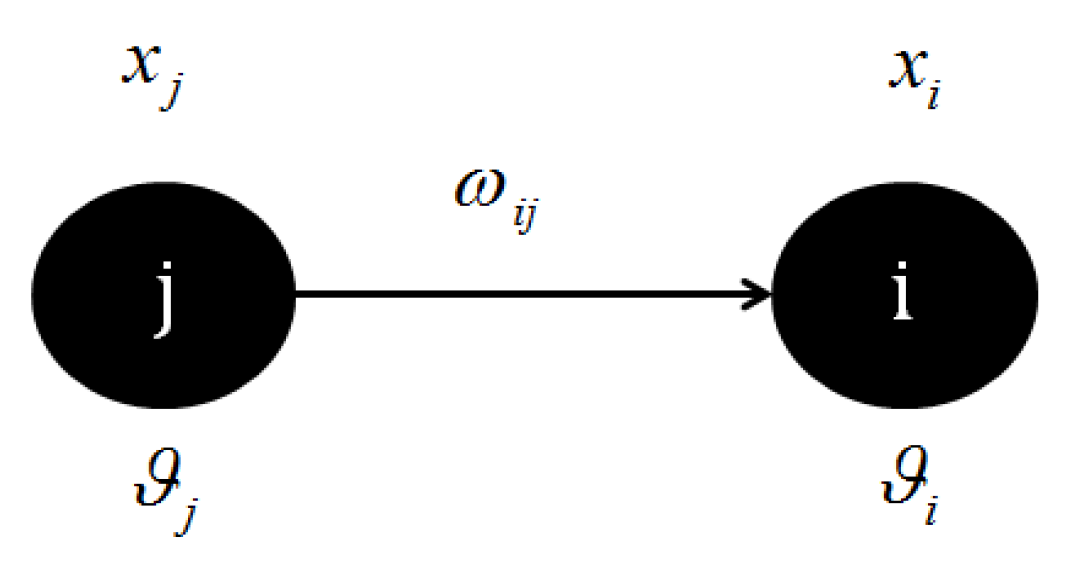

2.2.1. Multilayer Feed-Forward Neural Networks (MLFNs)

2.2.2. General Regression Neural Network (GRNN)

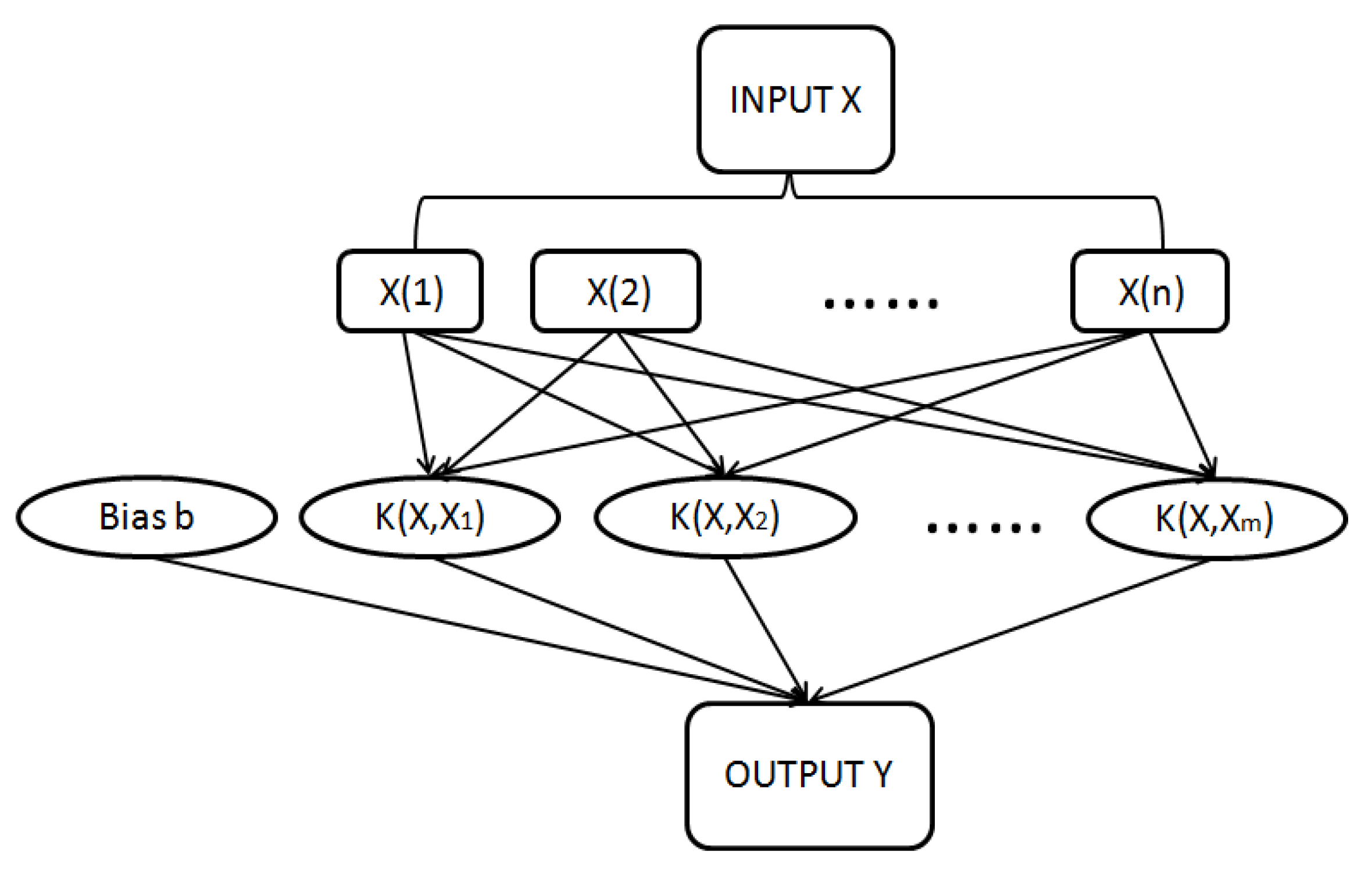

2.3. Support Vector Machine (SVM)

3. Results and Discussion

3.1. Model Development

| Model Type | Mean RMS Error in Testing | Mean Training Time | Mean Prediction Accuracy (30% tolerance) | Mean Prediction Accuracy (20% tolerance) | Mean Prediction Accuracy (10% tolerance) |

|---|---|---|---|---|---|

| SVM | 0.29 | 0:00:10 | 100% | 99.85% | 95.11% |

| GRNN | 0.33 | 0:00:14 | 100% | 99.82% | 94.42% |

| MLFN (2 Nodes) | 0.17 | 0:05:57 | 100% | 99.96% | 97.08% |

| MLFN (3 Nodes) | 0.15 | 0:07:12 | 100% | 100% | 98.33% |

| MLFN (4 Nodes) | 0.15 | 0:08:35 | 100% | 100% | 97.21% |

| MLFN (5 Nodes) | 0.17 | 0:10:03 | 100% | 99.96% | 97.03% |

| MLFN (6 Nodes) | 0.17 | 0:11:23 | 100% | 99.96% | 96.89% |

| MLFN (7 Nodes) | 0.15 | 0:13:39 | 100% | 100% | 97.31% |

| MLFN (8 Nodes) | 0.19 | 0:14:35 | 100% | 99.89% | 96.54% |

| MLFN (9 Nodes) | 0.15 | 0:15:45 | 100% | 100% | 97.18% |

| MLFN (10 Nodes) | 0.15 | 0:17:56 | 100% | 100% | 97.62% |

| MLFN (11 Nodes) | 0.15 | 0:19:10 | 100% | 100% | 97.19% |

| MLFN (12 Nodes) | 0.14 | 0:20:47 | 100% | 100% | 98.57% |

| MLFN (13 Nodes) | 0.16 | 0:21:51 | 100% | 99.96% | 97.01% |

| MLFN (14 Nodes) | 0.15 | 0:23:12 | 100% | 100% | 97.31% |

| MLFN (15 Nodes) | 0.17 | 0:24:19 | 100% | 99.96% | 96.92% |

| MLFN (16 Nodes) | 0.19 | 0:26:05 | 100% | 99.89% | 96.43% |

| MLFN (17 Nodes) | 0.16 | 0:29:05 | 100% | 100% | 95.72% |

| MLFN (18 Nodes) | 0.23 | 0:28:50 | 100% | 99.82% | 96.33% |

| MLFN (19 Nodes) | 0.19 | 0:30:20 | 100% | 99.89% | 96.57% |

| MLFN (20 Nodes) | 0.2 | 0:32:26 | 100% | 99.89% | 95.92% |

| ... | ... | ... | ... | ... | ... |

| MLFN (39 Nodes) | 0.22 | 1:07:44 | 100% | 99.85% | 95.41% |

| Model Type | Mean RMS Error in Testing | Mean Training Time | Mean Prediction Accuracy (30% tolerance) | Mean Prediction Accuracy (20% tolerance) | Mean Prediction Accuracy (10% tolerance) |

|---|---|---|---|---|---|

| SVM | 0.73 | 0:00:10 | 100% | 98.81% | 82.31% |

| GRNN | 0.71 | 0:00:08 | 100% | 99.38% | 83.14% |

| MLFN (2 Nodes) | 0.75 | 0:05:47 | 100% | 98.44% | 81.43% |

| MLFN (3 Nodes) | 0.74 | 0:06:46 | 100% | 98.51% | 81.97% |

| MLFN (4 Nodes) | 0.78 | 0:08:22 | 100% | 98.17% | 80.69% |

| MLFN (5 Nodes) | 0.74 | 0:09:44 | 100% | 98.61% | 82.54% |

| MLFN (6 Nodes) | 0.73 | 0:10:56 | 100% | 98.76% | 82.63% |

| MLFN (7 Nodes) | 0.77 | 0:12:30 | 100% | 98.13% | 81.03% |

| MLFN (8 Nodes) | 0.76 | 0:14:07 | 100% | 98.44% | 81.64% |

| MLFN (9 Nodes) | 0.75 | 0:15:33 | 100% | 98.65% | 81.86% |

| MLFN (10 Nodes) | 0.76 | 0:17:02 | 100% | 98.43% | 81.55% |

| MLFN (11 Nodes) | 0.79 | 0:18:21 | 100% | 97.97% | 80.74% |

| MLFN (12 Nodes) | 0.9 | 0:19:37 | 100% | 93.32% | 75.14% |

| MLFN (13 Nodes) | 0.75 | 0:21:05 | 100% | 98.66% | 81.43% |

| MLFN (14 Nodes) | 0.78 | 0:22:38 | 100% | 98.04% | 81.03% |

| MLFN (15 Nodes) | 0.8 | 0:24:27 | 100% | 97.36% | 80.78% |

| MLFN (16 Nodes) | 0.73 | 0:25:31 | 100% | 98.35% | 82.22% |

| MLFN (17 Nodes) | 0.88 | 0:26:59 | 100% | 93.93% | 76.23% |

| MLFN (18 Nodes) | 0.8 | 0:28:30 | 100% | 96.41% | 80.67% |

| MLFN (19 Nodes) | 0.79 | 0:30:06 | 100% | 97.43% | 80.93% |

| MLFN (20 Nodes) | 0.88 | 0:31:25 | 100% | 93.86% | 76.61% |

| ... | ... | ... | ... | ... | ... |

| MLFN (39 Nodes) | 1.05 | 1:04:57 | 100% | 89.61% | 71.52% |

3.2. Model Analysis

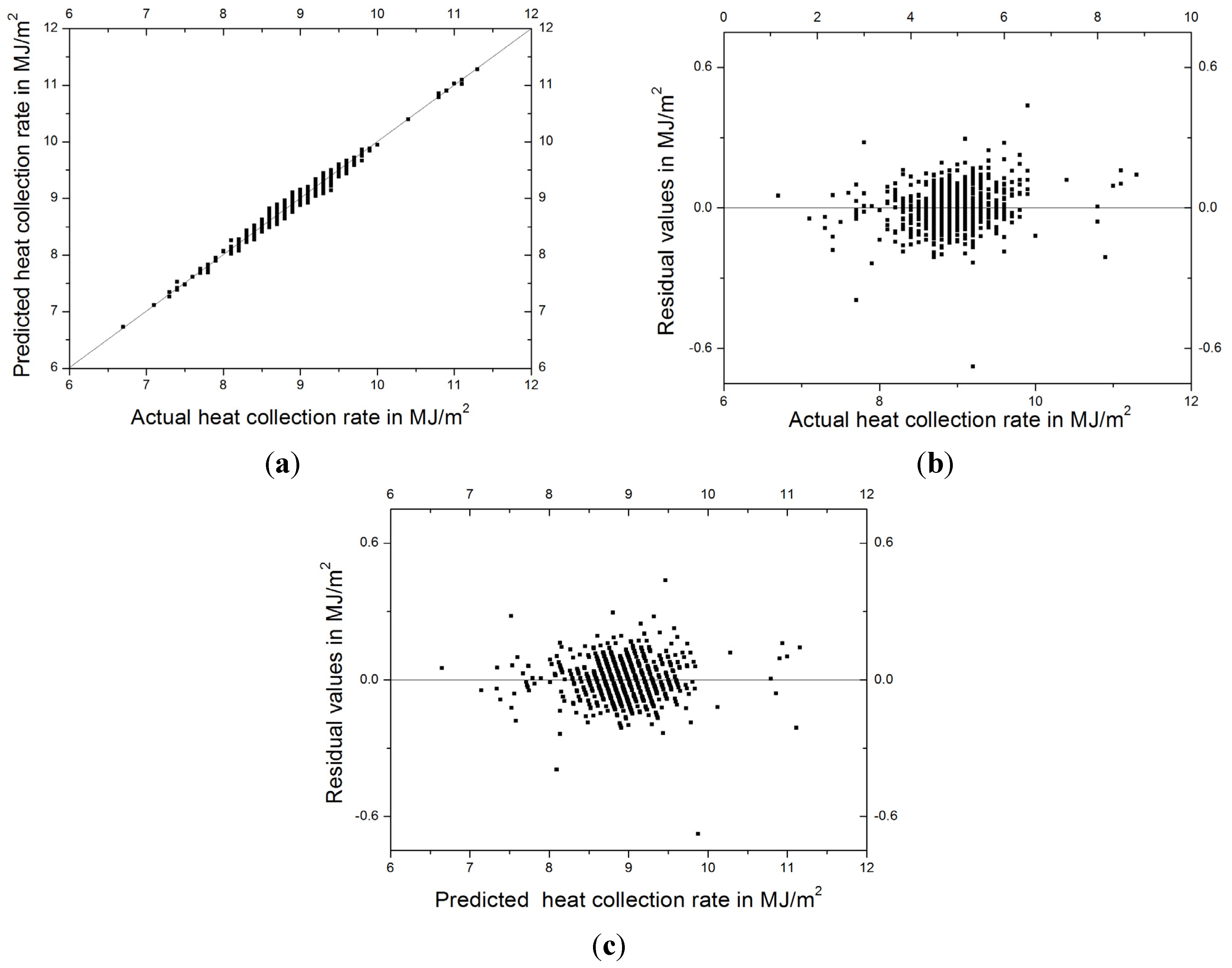

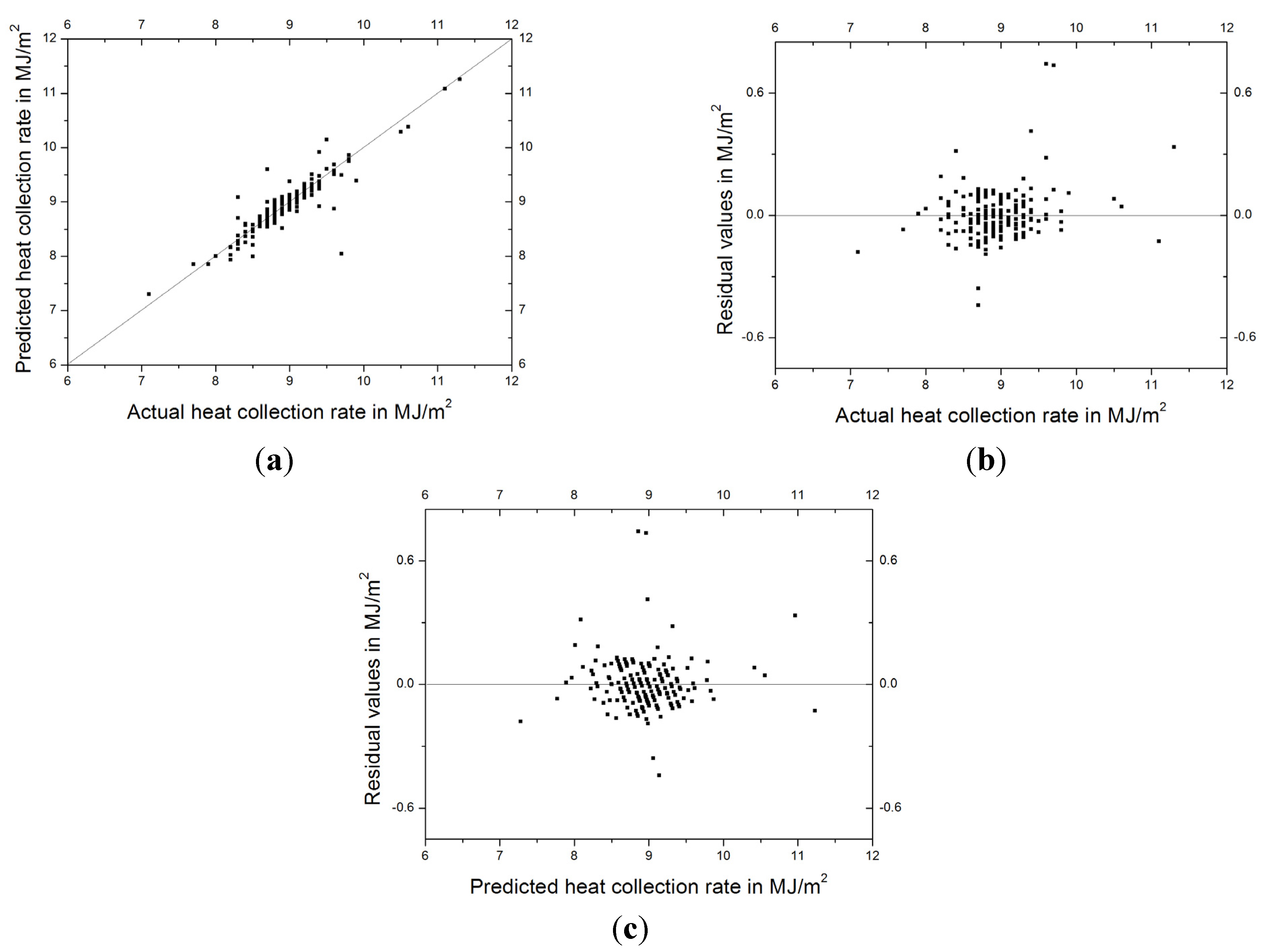

3.2.1. The MLFN-3 for Heat Collection Rate

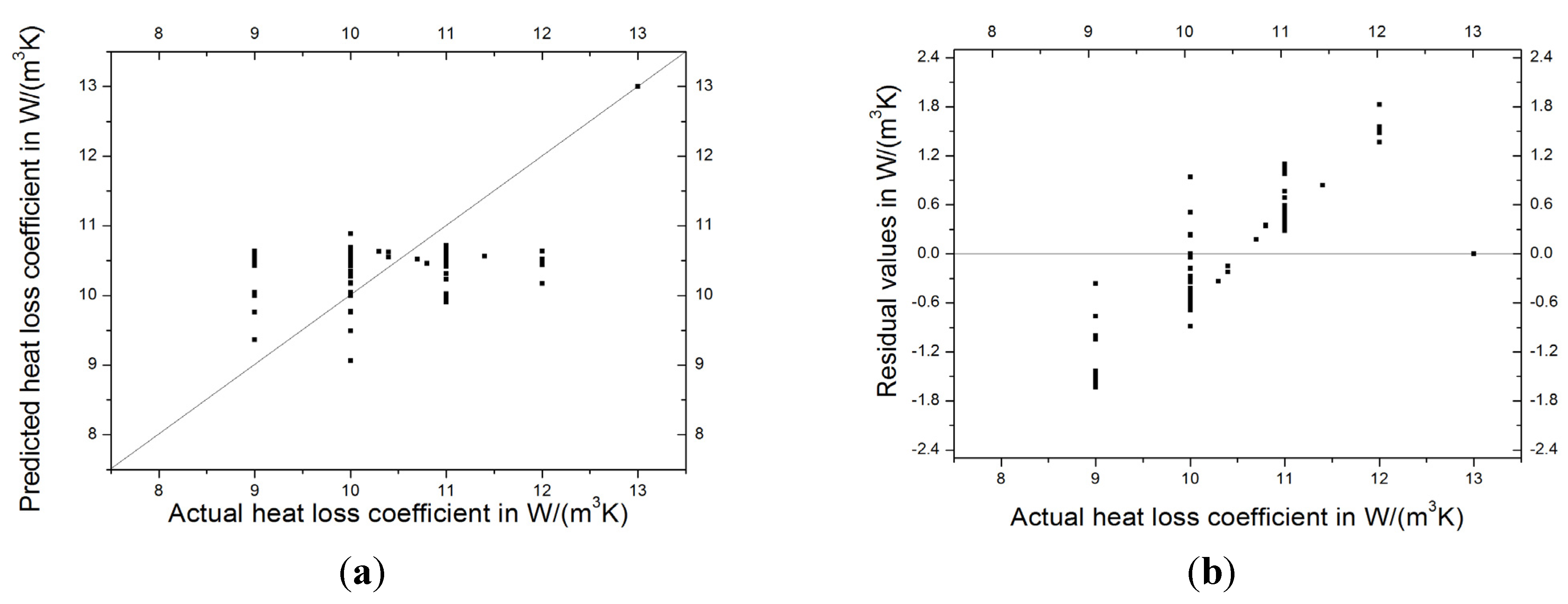

3.2.2. The GRNN for Heat Loss Coefficient

3.3. Robustness Analysis

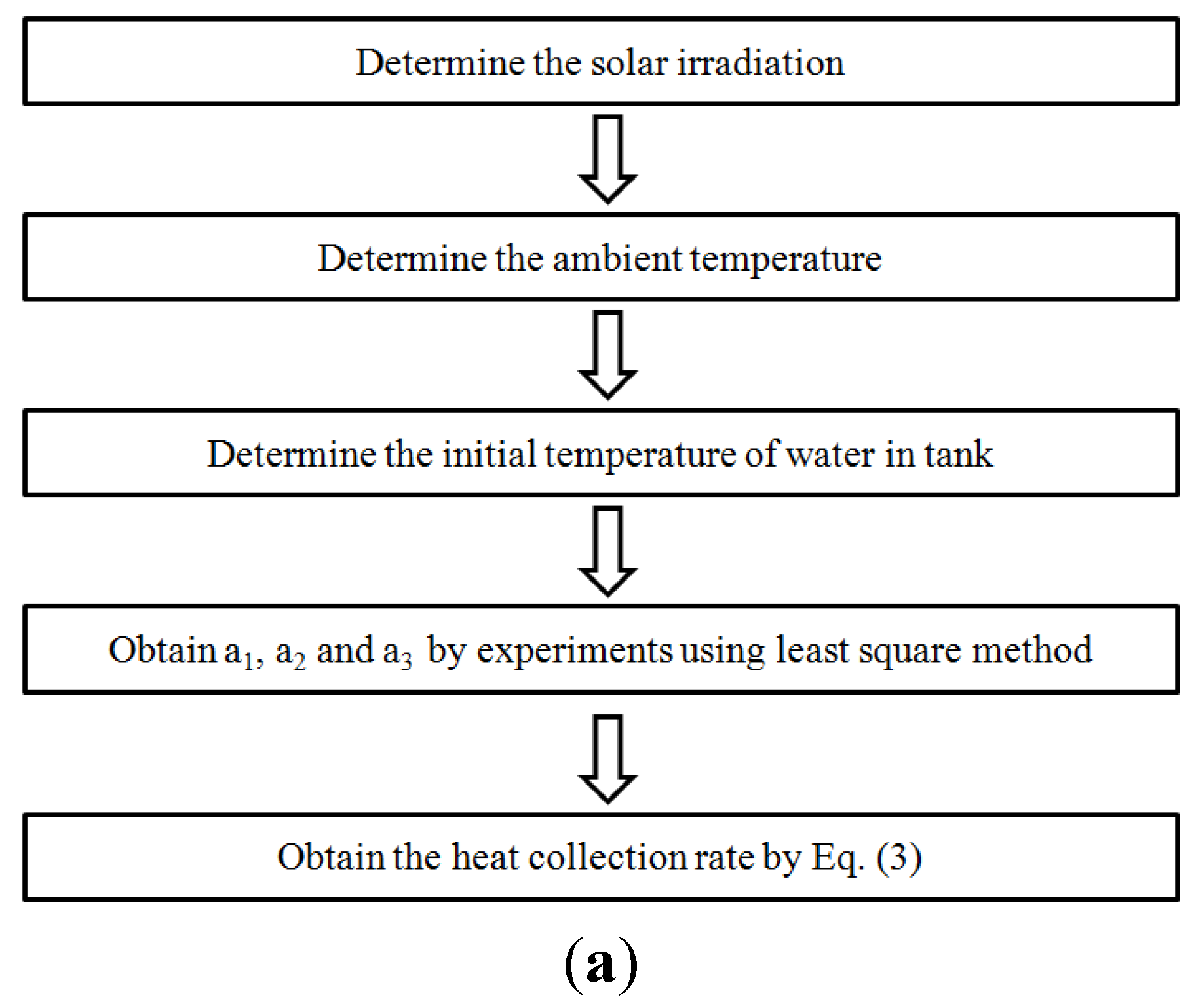

3.4. Comparison with Conventional Methods

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| H | the amount of solar radiation, MJ/m2 |

| ta | the ambient temperature, °C |

| ti | the initial temperature of water in tank, °C |

| S | the area of tubes, m2 |

| USL | the heat loss coefficient according to GB/T 19141, W/(m3K) |

| US | the heat loss coefficient to ISO 9459-2, W/K |

| ρw | the water density, kg/m3 |

| Cp,w | the specific heat of water, kJ/(kg °C) |

| Vs | the heat water mass in tank, kg |

| tis | the initial temperature of water, °C |

| tfs | the final temperature of water, °C |

| tas(av) | the ambient average temperature, °C |

| V | the volume of water, m3 |

| ∆τ | the duration time of heat loss coefficient experiments, s |

| qs | the heat collection rate, MJ/m2 |

the predicted value, MJ/m2 or W/(m3K) | |

the actual value, MJ/m2 or W/(m3K) | |

the number of tested samples, no unit | |

the number of tested samples, no unit | |

| a1, a2, a3 | the regression coefficients, no unit |

| SWH | solar water heater |

| ANNs | artificial neural networks |

| SVM | support vector machine |

| MLFN | multilayer feed-forward neural network |

| GRNN | general regression neural network |

| RMS | root mean square |

References

- Mekhilef, S.; Saidur, R.; Safari, A. A review on solar energy use in industries. Renew. Sustain. Energy Rev. 2011, 15, 1777–1790. [Google Scholar] [CrossRef]

- Kalogirou, S. The potential of solar industrial process heat applications. Appl. Energy 2003, 76, 337–361. [Google Scholar] [CrossRef]

- Morrison, G.L.; Tran, N.H.; McKenzie, D.R.; Onley, I.C.; Harding, G.L.; Collins, R.E. Long term performance of evacuated tubular solar water heaters in Sydney, Australia. Sol. Energy 1984, 32, 785–791. [Google Scholar] [CrossRef]

- Shah, L.J.; Furbo, S. Theoretical flow investigations of an all glass evacuated tubular collector. Sol. Energy 2007, 81, 822–888. [Google Scholar] [CrossRef]

- Liu, Z.H.; Hu, R.L.; Lu, L.; Zhao, F.; Xiao, H.S. Thermal performance of an open thermosyphon using nanofluid for evacuated tubular high temperature air solar collector. Energy Convers. Manag. 2013, 73, 135–143. [Google Scholar] [CrossRef]

- Tang, R.S.; Li, Z.M.; Xia, C.F.; Lan, Q. Assessment of uncertainty in heat loss coefficient of all glass evacuated solar tubes testing. Energy Convers. Manag. 2006, 47, 60–67. [Google Scholar] [CrossRef]

- Liu, Y.M.; Chung, K.M.; Chang, K.C.; Lee, T.S. Performance of thermosyphon solar water heaters in series. Energies 2012, 5, 3266–3278. [Google Scholar] [CrossRef]

- Morrison, G.L.; Budihardjo, I.; Behnia, M. Water-in-glass evacuated tube solar water heaters. Sol. Energy 2014, 76, 135–140. [Google Scholar] [CrossRef]

- Pei, G.; Li, G.; Zhou, X.; Ji, J.; Su, Y. Comparative experimental analysis of the thermal performance of evacuated tube solar water heater systems with and without a mini-compound parabolic concentrating (CPC) reflector (C < 1). Energies 2012, 5, 911–924. [Google Scholar]

- Lin, W.M.; Chang, K.C.; Liu, Y.M.; Chung, K.M. Field surveys of non-residential solar water heating systems in Taiwan. Energies 2012, 5, 258–269. [Google Scholar] [CrossRef]

- Çomaklı, K.; Çakır, U.; Kaya, M.; Bakirci, K. The relation of collector and storage tank size in solar heating systems. Energy Convers. Manag. 2012, 63, 112–117. [Google Scholar] [CrossRef]

- Govind, N.K.; Shireesh, B.K.; Satanu, B. Optimization of solar water heating system through water replenishment. Energy Convers. Manag. 2009, 50, 837–846. [Google Scholar]

- Tang, R.; Gao, W.; Yu, Y.; Chen, H. Optimal tilt-angles of all-glass evacuated tube solar collectors. Energy 2009, 34, 1387–1395. [Google Scholar] [CrossRef]

- Wang, P.Y.; Guan, H.Y.; Liu, Z.H.; Wang, G.S.; Zhao, F.; Xiao, H.S. High temperature collecting performance of a new all-glass evacuated tubular solar air heater with U-shaped tube heat exchanger. Energy Convers. Manag. 2014, 77, 315–323. [Google Scholar] [CrossRef]

- Porras-Prieto, C.J.; Mazarrón, F.R.; DelosMozos, V.; García, J.L. Influence of required tank water temperature on the energy performance and water withdrawal potential of a solar water heating system equipped with a heat pipe evacuated tube collector. Sol. Energy 2014, 110, 365–677. [Google Scholar] [CrossRef]

- Zhang, X.; You, S.; Xu, W.; Wang, M.; He, T.; Zheng, X. Experimental investigation of the higher coefficient of thermal performance for water-in-glass evacuated tube solar water heaters in China. Energy Convers. Manag. 2014, 78, 386–392. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Panteliou, S.; Dentsoras, A. Modelling of solar domestic water-heating systems using artificial neural-networks. Sol. Energy 1999, 65, 335–342. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Prediction of flat-plate collector performance parameters using artificial neural network. Sol. Energy 2006, 80, 248–259. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Mathioulakis, E.; Belessiotis, V. Artificial neural networks for the performance prediction of large solar systems. Renew. Energy 2014, 63, 90–97. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Panteliou, S. Thermosiphon solar domestic water heating systems long-term performance prediction using artificial neural networks. Sol. Energy 2000, 69, 163–174. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Neocleous, C.; Schizas, C. Artificial neural networks for modelling the starting-up of a solar steam generator. Appl. Energy 1998, 60, 89–100. [Google Scholar] [CrossRef]

- Lecoeuche, S.; Lalot, S. Prediction of the daily performance of solar collectors. Int. Commun. Heat Mass Transf. 2005, 32, 603–611. [Google Scholar] [CrossRef]

- Specification of Domestic Solar Water Heating Systems; GB/T 19141; Standard Press: Beijing, China, 2011. (In Chinese)

- Hugo, A.; Zmeureanu, R. Residential solar-based seasonal thermal storage systems in cold climates: Building envelope and thermal storage. Energies 2012, 5, 3972–3985. [Google Scholar] [CrossRef]

- Wang, F.; Mi, Z.; Su, S.; Zhao, H. Short-term solar irradiance forecasting model based on artificial neural network using statistical feature parameters. Energies 2012, 5, 1355–1370. [Google Scholar] [CrossRef]

- Kandananond, K. Forecasting electricity demand in Thailand with an artificial neural network approach. Energies 2011, 4, 1246–1257. [Google Scholar] [CrossRef]

- Rashidi, M.M.; Ali, M.; Freidoonimehr, N.; Nazari, F. Parametric analysis and optimization of entropy generation in unsteady MHD flow over a stretching rotating disk using artificial neural network and particle swarm optimization algorithm. Energy 2013, 55, 497–510. [Google Scholar] [CrossRef]

- Svozil, D.; Kvasnicka, V.; Pospichal, J. Introduction to multi-layer feed-forward neural networks. Chemom. Intell. Lab. Syst. 1997, 39, 43–62. [Google Scholar] [CrossRef]

- Johansson, E.M.; Dowla, F.U.; Goodman, D.M. Backpropagation learning for multilayer feed-forward neural networks using the conjugate gradient method. Int. J. Neural Syst. 1991, 2, 291–301. [Google Scholar] [CrossRef]

- Guo, Z.; Zhao, W.; Lu, H.; Wang, J. Multi-step forecasting for wind speed using a modified EMD-based artificial neural network model. Renew. Energy 2012, 37, 241–249. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Applications of artificial neural-networks for energy systems. Appl. Energy 2000, 67, 17–35. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Artificial neural networks in renewable energy systems applications: A review. Renew. Sustain. Energy Rev. 2001, 5, 373–401. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Sencan, A. Artificial Intelligence Techniques in Solar Energy Applications. Available online: http://www.intechopen.com/articles/show/title/artificial-intelligence-techniques-in-solar-energy-applications (accessed on 17 August 2015).

- Specht, D.F. A general regression neural network. IEEE. Trans. Neural. Netw. 1991, 2, 568–576. [Google Scholar] [CrossRef] [PubMed]

- Kandirmaz, H.M.; Kaba, K.; Avci, M. Estimation of monthly sunshine duration in Turkey using artificial neural networks. Int. J. Photoenergy 2014, 14, 9–10. [Google Scholar] [CrossRef]

- Deng, N.; Tian, Y.; Zhang, C. Support Vector Machines: Optimization Based Theory, Algorithms, and Extensions, 2nd ed.; Chapman & Hall/CRC: Boca Raton, FL, USA, 2012; pp. 154–162. [Google Scholar]

- Zhong, X.; Li, J.; Dou, H.; Deng, S.; Wang, G.; Jiang, Y.; Yan, F. Fuzzy nonlinear proximal support vector machine for land extraction based on remote sensing image. PLoS ONE 2013, 8, 694–698. [Google Scholar] [CrossRef]

- Jian, L.; Weikang, K.; Jiangbo, S.; Ke, W.; Weikui, W.; Weipu, Z.; Zhoumo, Z. Determination of corrosion types from electrochemical noise by artificial neural networks. Int. J. Electrochem. Sci. 2013, 8, 2365–2377. [Google Scholar]

- Kim, D.W.; Lee, K.; Lee, D.; Lee, K.H. A kernel-based subtractive clustering method. Pattern Recognit. Lett. 2005, 26, 879–891. [Google Scholar] [CrossRef]

- Fan, R.E.; Chang, K.W.; Hsieh, C.J.; Wang, X.R.; Lin, C.J. LIBLINEAR: A library for large linear classification. J. Mach. Learn. Res. 2008, 9, 1871–1874. [Google Scholar]

- Guo, Q.; Liu, Y. ModEco: An integrated software package for ecological niche modeling. Ecography 2010, 33, 637–642. [Google Scholar] [CrossRef]

- Vouk, D.; Malus, D.; Halkijevic, I. Neural networks in economic analyses of wastewater systems. Expert Syst. Appl. 2011, 38, 10031–10035. [Google Scholar] [CrossRef]

- Saadah, L.M.; Chedid, F.D.; Sohail, M.R.; Nazzal, Y.M.; Al-Kaabi, M.R.; Rahmani, A.Y. Palivizumab prophylaxis during nosocomial outbreaks of respiratory syncytial virus in a neonatal intensive care unit: Predicting effectiveness with an artificial neural network model. Pharmacother. J. Hum. Pharmacol. Drug Ther. 2014, 34, 251–259. [Google Scholar] [CrossRef] [PubMed]

- Goh, Y.M.; Binte Sa’adon, N.F. Cognitive Factors Influencing Safety Behavior at Height: A Multimethod Exploratory Study. J. Constr. Eng. Manag. 2015, 9, 107–112. [Google Scholar] [CrossRef]

- Solar Heating—Domestic Water Heating Systems—Part 2: Outdoor Test Methods for System Performance Characterization and Yearly Performance Prediction of Solar-Only Systems; ISO 9459-2; ISO: Geneva, Switzerland, 1995.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Li, H.; Zhang, X.; Jin, G.; Cheng, K. Novel Method for Measuring the Heat Collection Rate and Heat Loss Coefficient of Water-in-Glass Evacuated Tube Solar Water Heaters Based on Artificial Neural Networks and Support Vector Machine. Energies 2015, 8, 8814-8834. https://doi.org/10.3390/en8088814

Liu Z, Li H, Zhang X, Jin G, Cheng K. Novel Method for Measuring the Heat Collection Rate and Heat Loss Coefficient of Water-in-Glass Evacuated Tube Solar Water Heaters Based on Artificial Neural Networks and Support Vector Machine. Energies. 2015; 8(8):8814-8834. https://doi.org/10.3390/en8088814

Chicago/Turabian StyleLiu, Zhijian, Hao Li, Xinyu Zhang, Guangya Jin, and Kewei Cheng. 2015. "Novel Method for Measuring the Heat Collection Rate and Heat Loss Coefficient of Water-in-Glass Evacuated Tube Solar Water Heaters Based on Artificial Neural Networks and Support Vector Machine" Energies 8, no. 8: 8814-8834. https://doi.org/10.3390/en8088814