Development of Natural Gas Fired Combined Cycle Plant for Tri-Generation of Power, Cooling and Clean Water Using Waste Heat Recovery: Techno-Economic Analysis

Abstract

:1. Introduction

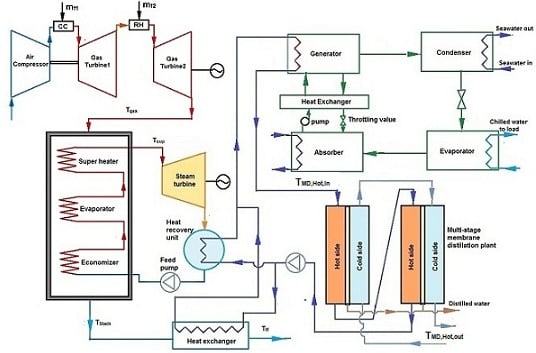

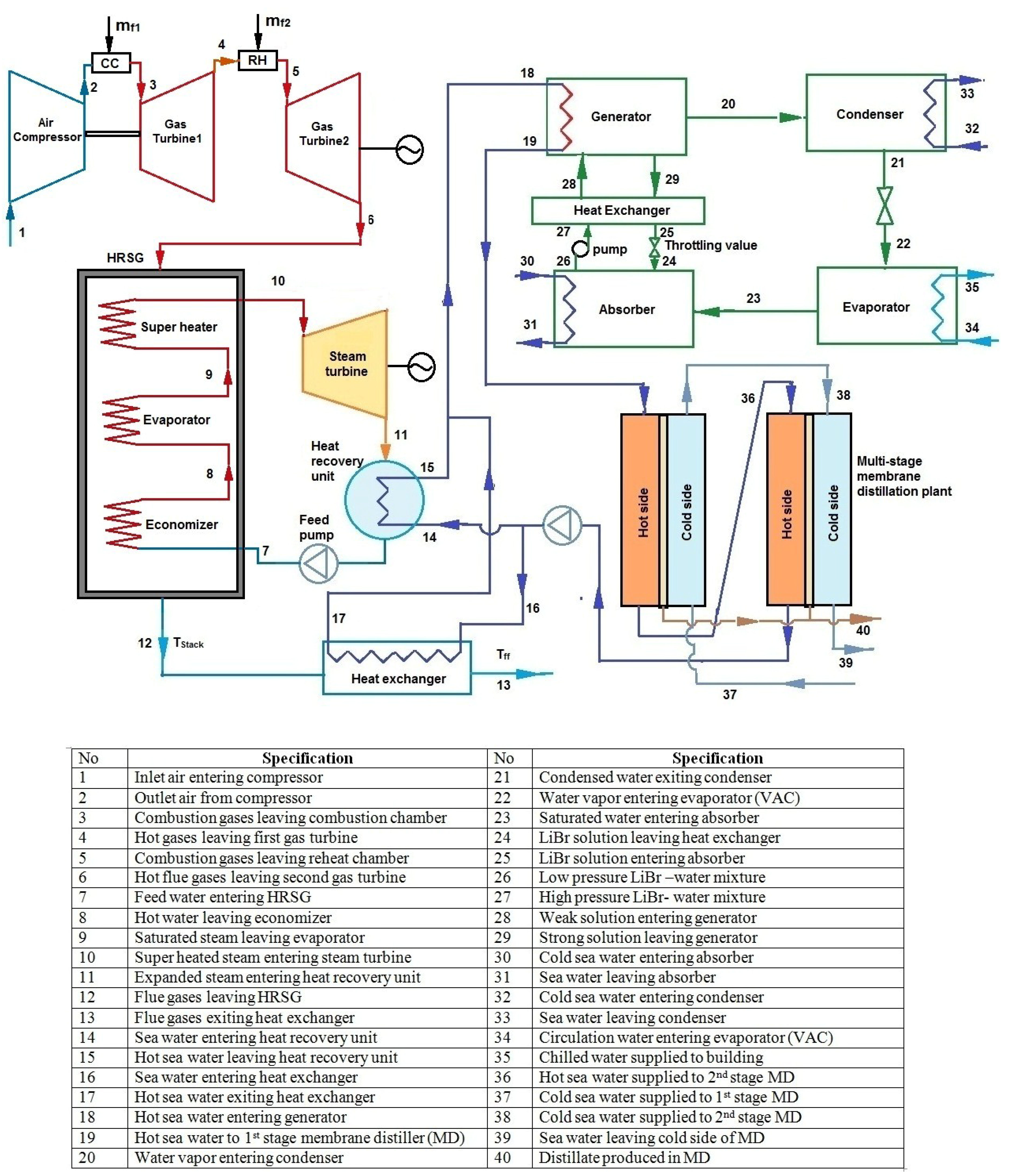

2. System Description

3. System Modeling

3.1. Brayton Cycle

3.2. Steam Cycle

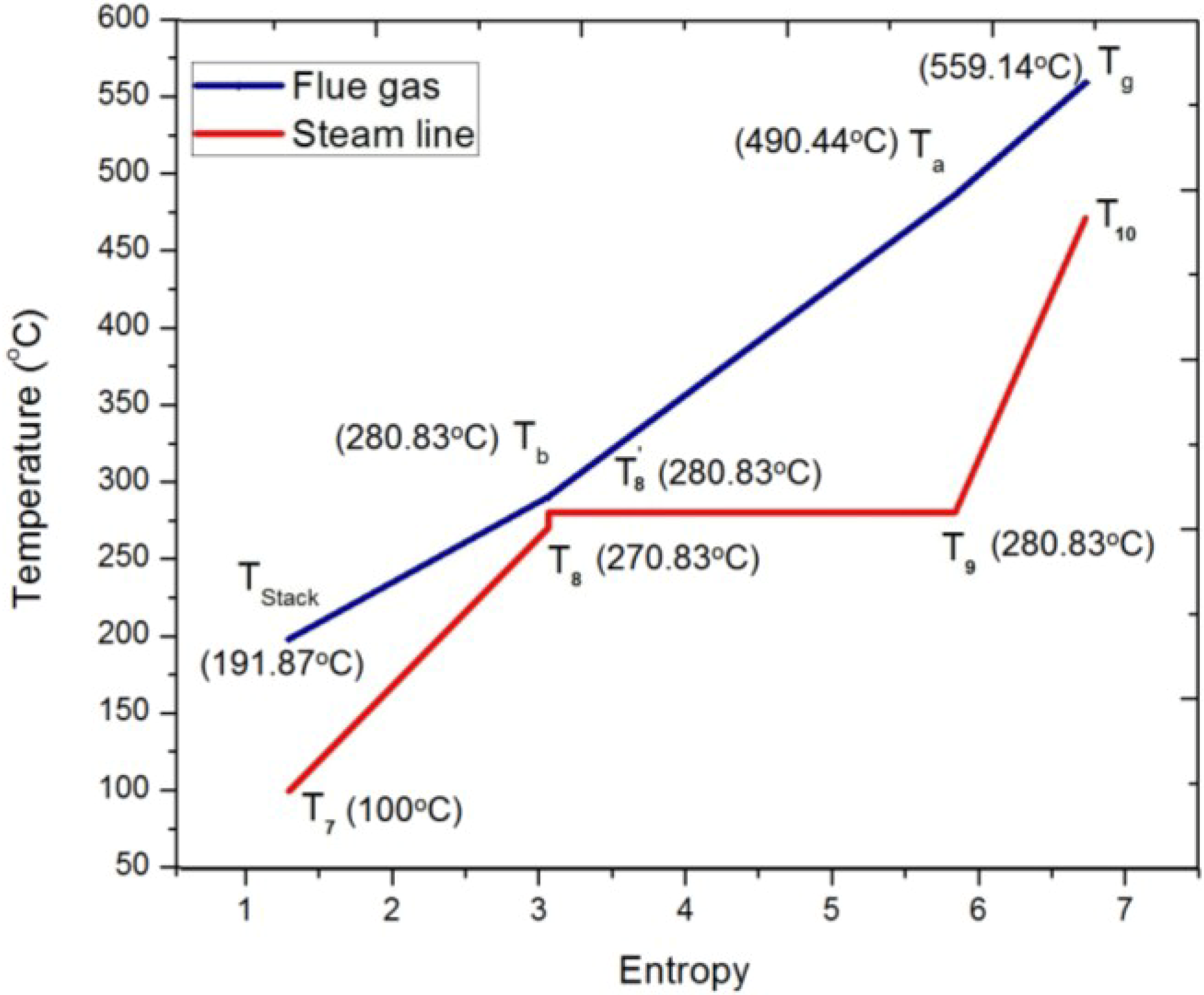

3.2.1. Heat Recovery Steam Generator (HRSG)

3.2.2. Steam Turbine

3.2.3. Heat Recovery System

3.3. Absorption Chiller

3.4. Membrane Distillation

| No. | Specification | Value |

|---|---|---|

| 1 | Membrane area | 2.8 m2 |

| 2 | Porosity (ф) | 0.8 |

| 3 | Membrane thickness (b) | 0.2 mm |

| 4 | Air gap width (L) | 1 mm |

| 5 | Height of the module | 730 mm |

| 6 | Width of the module | 630 mm |

| 7 | Thickness of the module | 175 mm |

3.5. Energy Efficiency

4. Results and Discussion

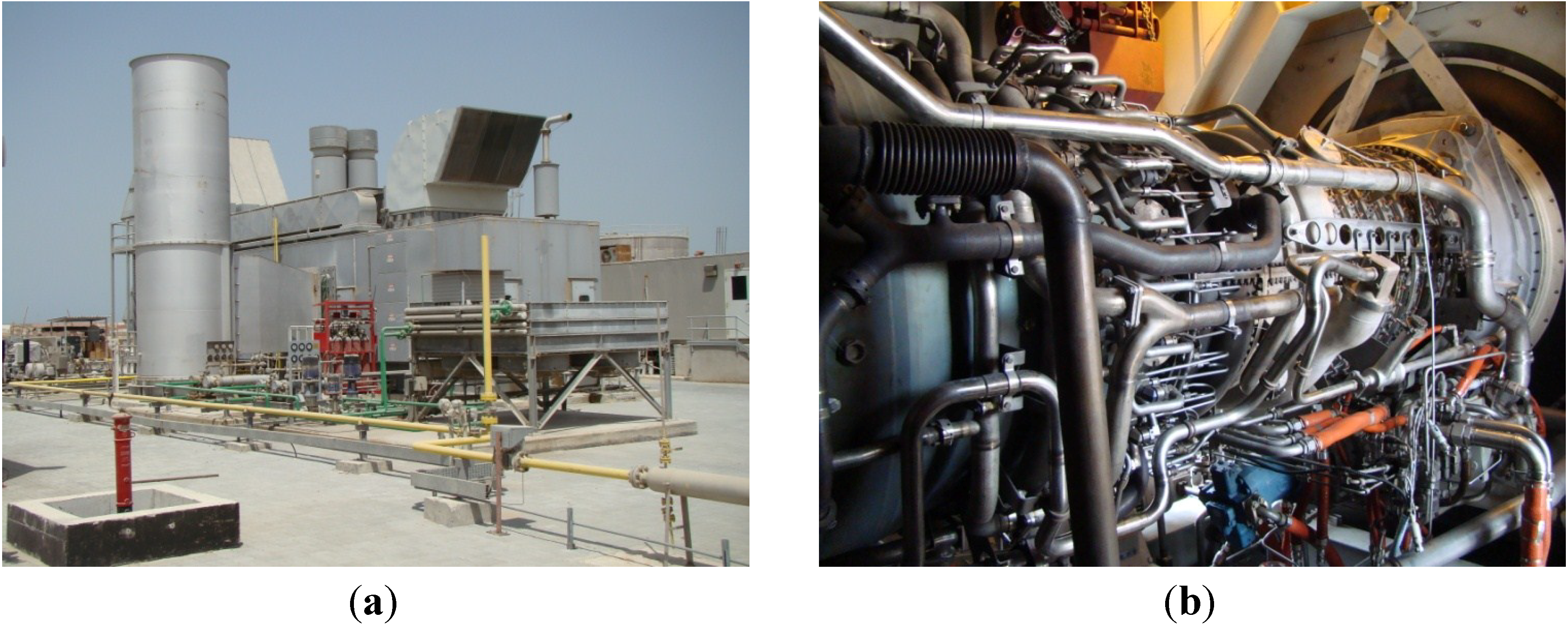

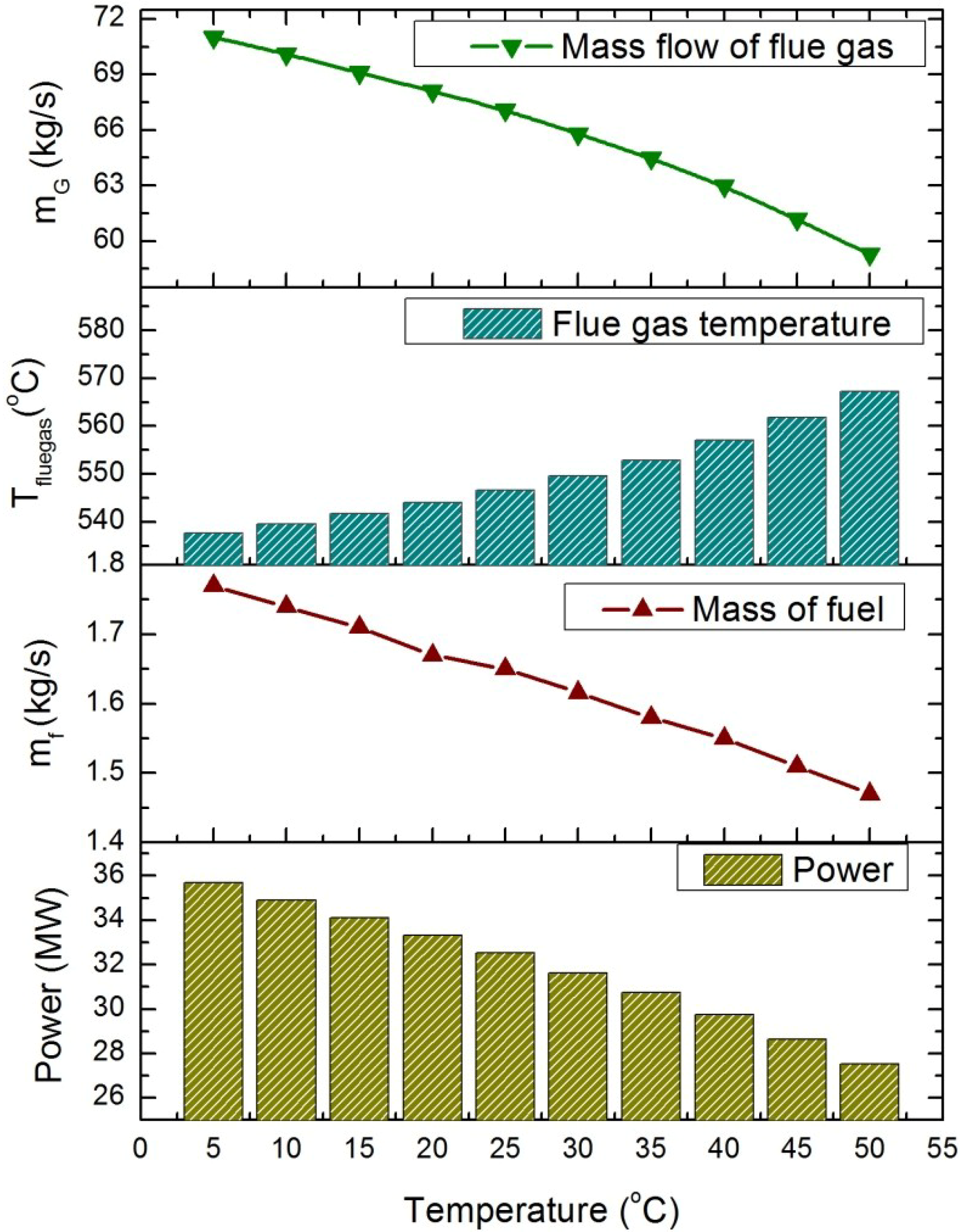

4.1. Brayton Cycle

| Description | Parameters |

|---|---|

| Gas turbine model (GE-manufacturer) | Model: LM2500 PE, Avio, Italy |

| Gas turbine inlet temperature | 824 °C |

| Mean intake air temperature | 35 °C |

| Mean exhaust gas flow | 64.1 kg/s |

| Mean exhaust gas temperature | 550 °C |

| Lower Heating Value | 47,000 kJ/kg |

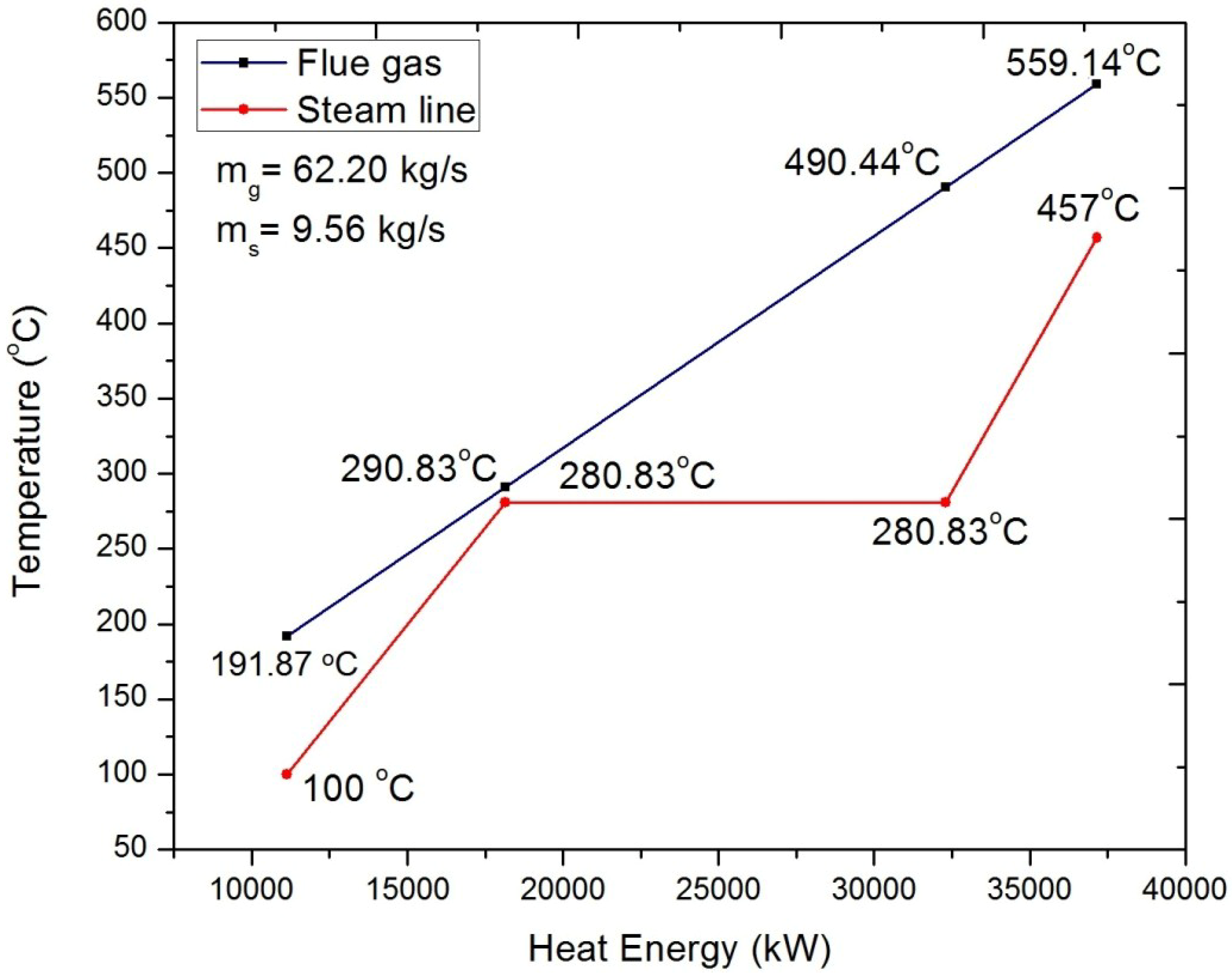

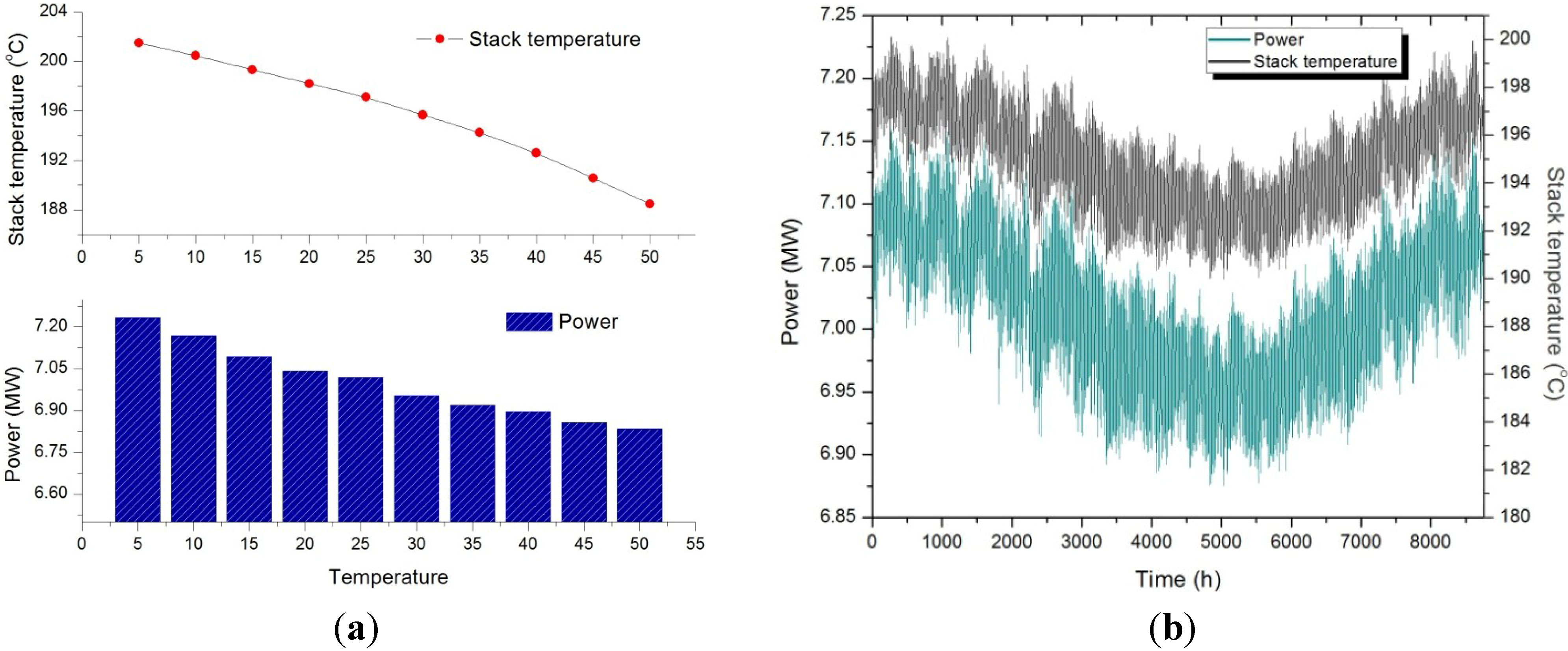

4.2. Steam Cycle

| No. | Description | Parameters |

|---|---|---|

| 1 | Steam turbine model (Siemens) | SST-100 |

| 2 | Power output | 8.5 MW |

| 3 | Inlet steam pressure | Up to 65 bar |

| 4 | Inlet steam temperature | Up to 480 °C |

| 5 | Condensing pressure | 1 bar |

| 6 | Exhaust area | 0.22 m2 |

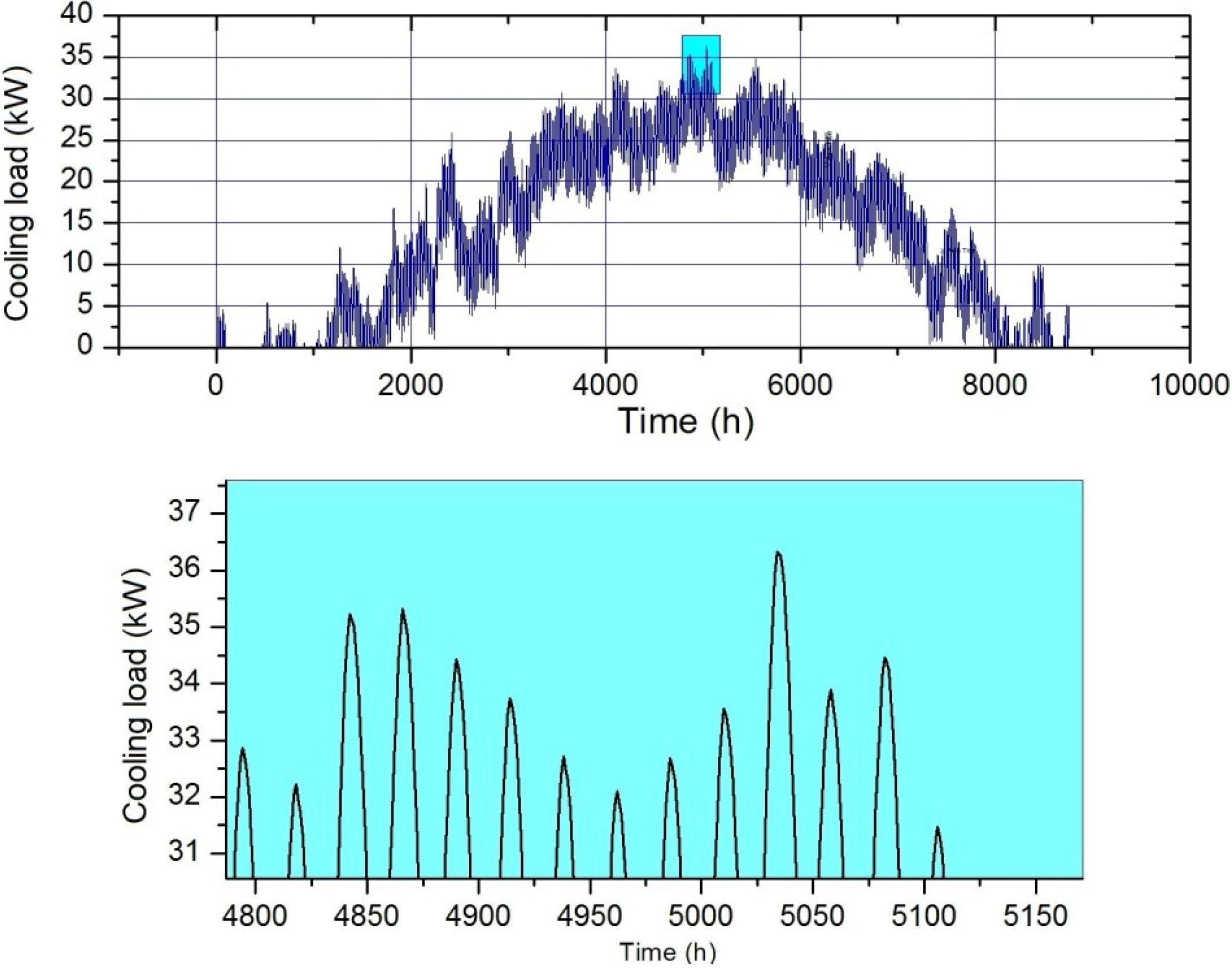

4.3. Absorption Chiller

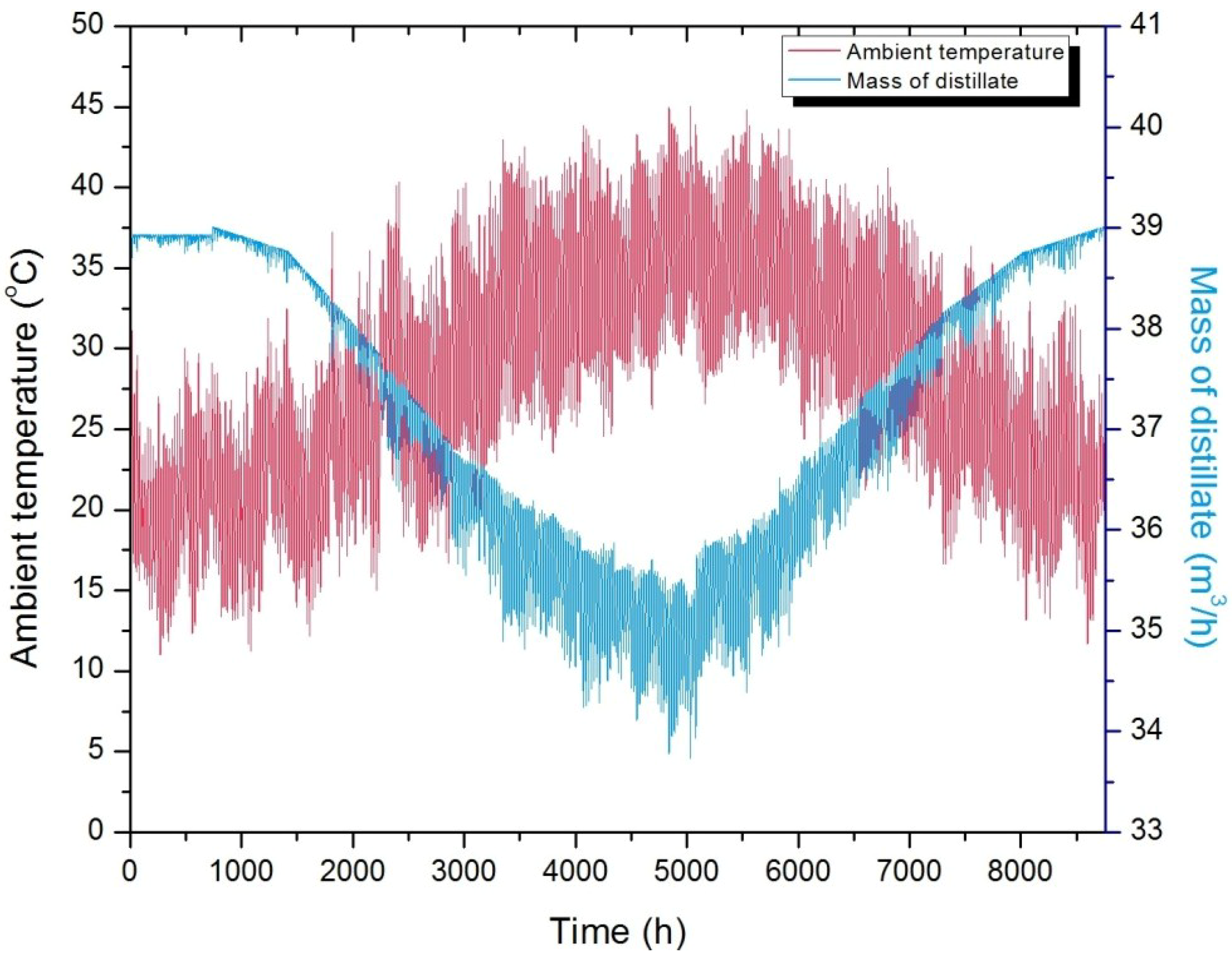

4.4. Membrane Distillation

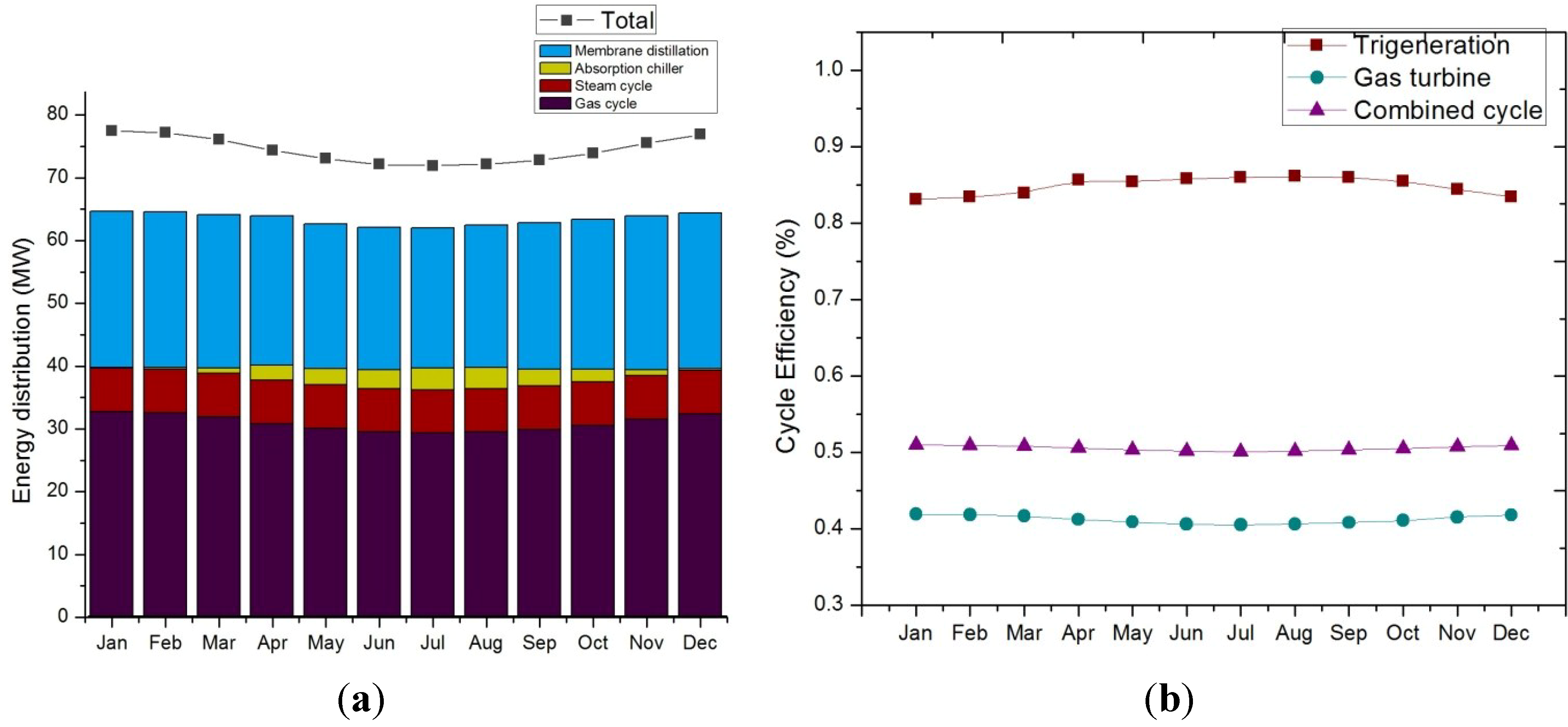

4.5. Energy Efficiency

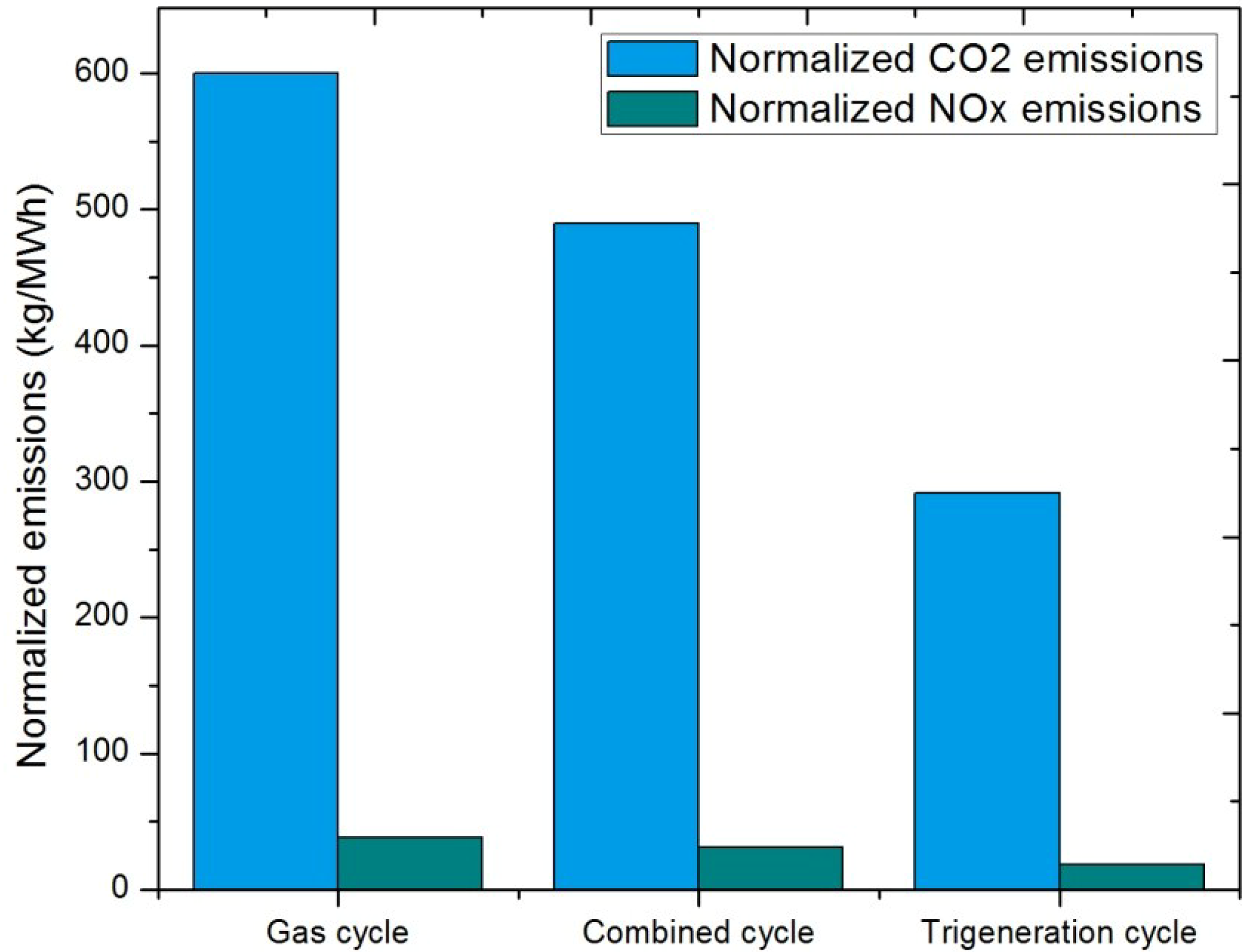

4.6. Emission Analysis

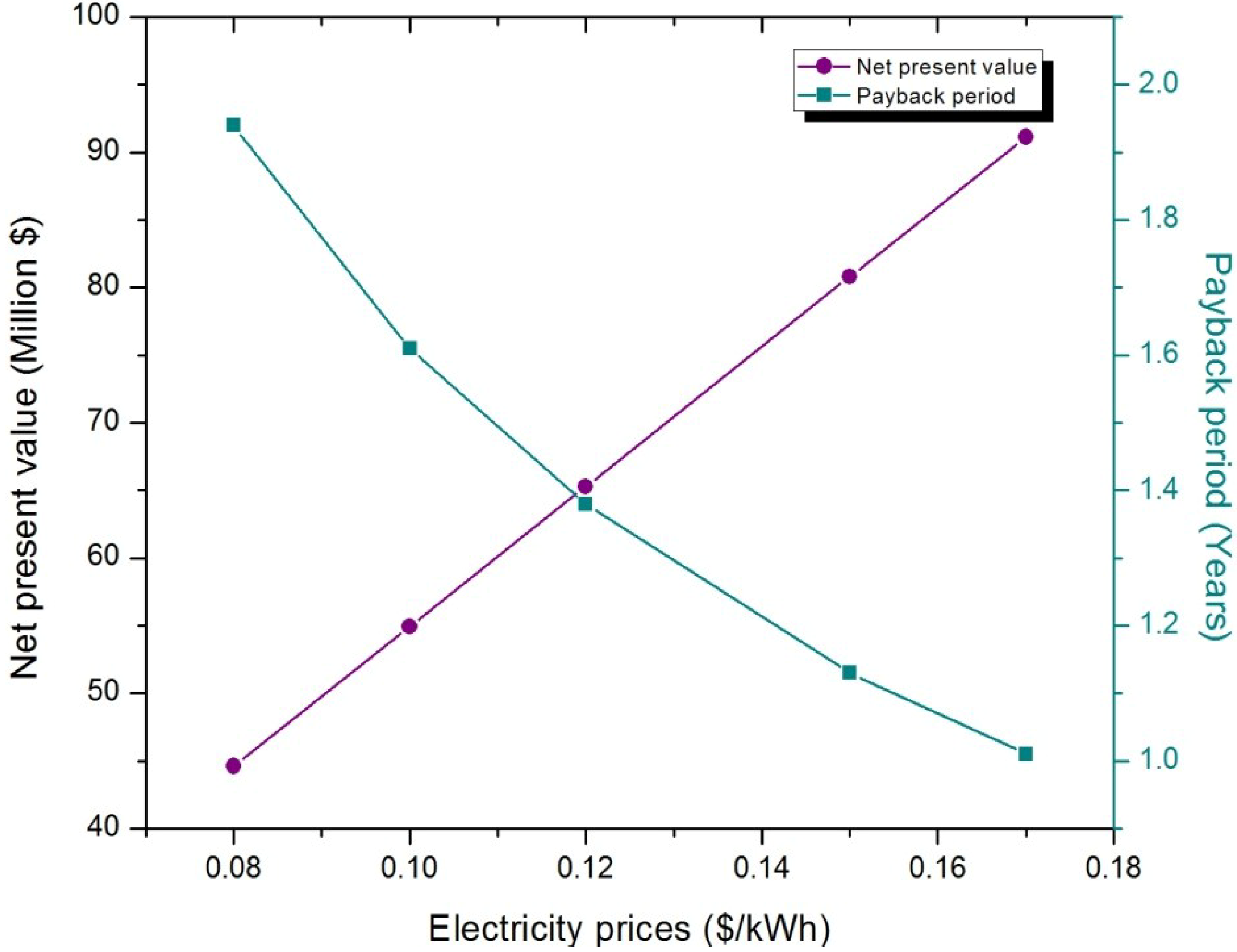

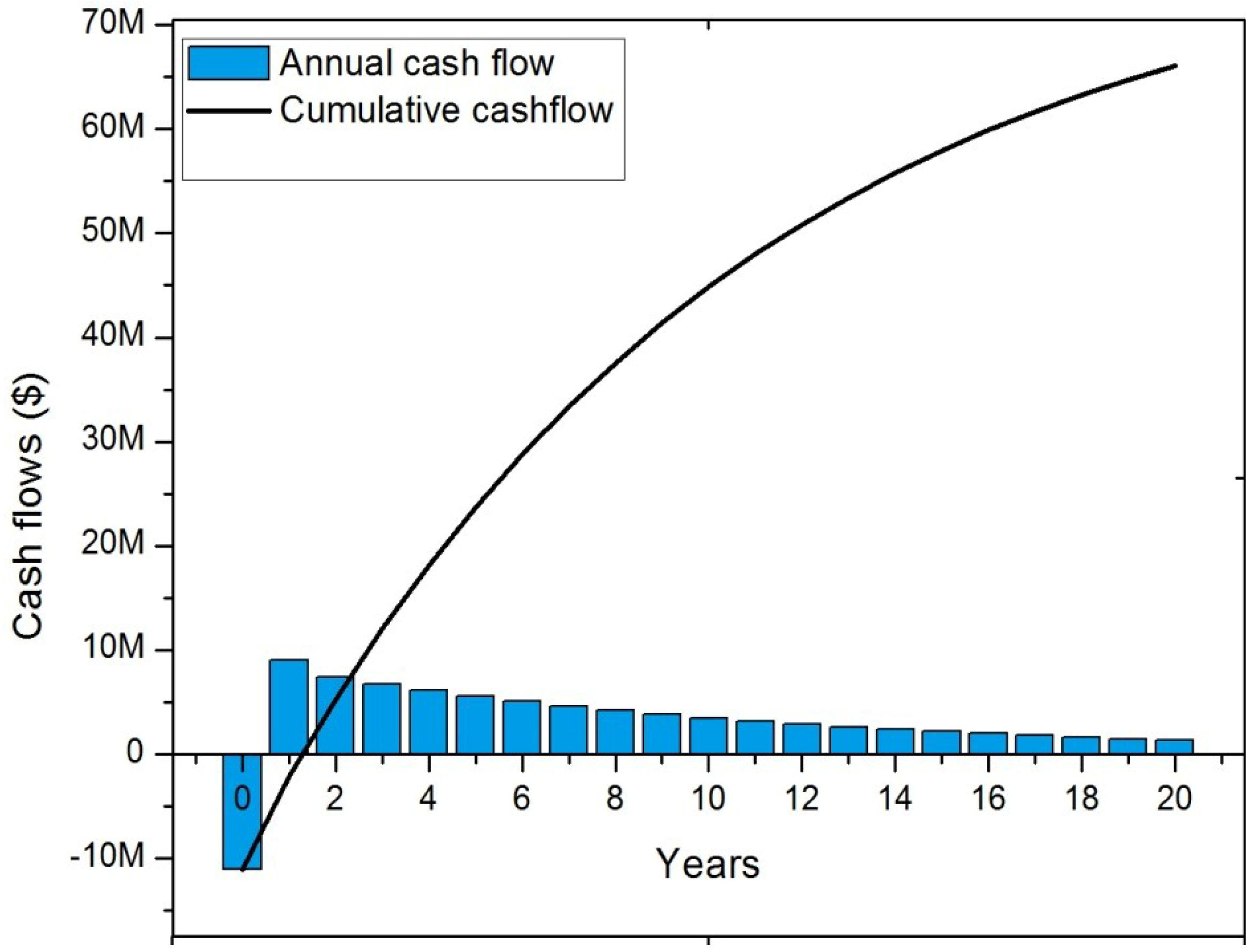

4.7. Economic Analysis

| Component | Abbreviation | Value |

|---|---|---|

| Heat recovery steam generator [23] | CHRSG | Equation (33) |

| Steam turbine [23] | CST | Equation (37) |

| Heat recovery unit [24] | CHRS | $2,000/m2 |

| Feed water pump (Steam cycle) [25] | CST,PUMP | 881Wp0.4 |

| Membrane distillation unit [26] | CAGMD | $1,375/unit |

| Membrane replacement cost [24] | CMD,R | 15% of CAGMD |

| Feed pump (Heat recovery) [25] | CHRS,PUMP | 881Wp0.4 |

| Absorption chiller [27] | CAC | $400/kW |

| Hydraulics [26] | CHYD | 5% of component costs |

| Installation cost [26] | CI | 5% of component costs |

| Interest rate | i | 10% |

| Life time of the project | n | 20 years |

| Cost of electricity | CF | $0.12/kW·h |

| No. | Parameters | Values |

|---|---|---|

| 1 | Investment cost | $11,079,548 |

| 2 | Operating and maintenance cost | $443,494 |

| 3 | Annual benefits | $9,413,460 |

| 4 | Payback period | 1.38 years |

| 5 | Net present value | $66,102,281 |

| Parameters | Value | Total benefits |

|---|---|---|

| Electricity production | $0.12/kW·h | $7,289,423.73 |

| Cooling benefits | $0.10/kW·h | $1,582,854.46 |

| Cooling demand charges | $42.3/kW·year | $211,500.00 |

| Water production cost | $1/m3 | $329,681.90 |

5. Conclusions

- The absorption chiller plant can provide district cooling for 124 duplex houses with a production capacity of 4600 kW during peak requirements;

- The production capacity of membrane distillation plant varies between 33 and 37 m3/h based on daily cooling requirements and ambient temperature;

- The normalized CO2 emission per MW·h is reduced to 291 kg/MW·h from an actual scenario of 600 kg/MW·h by implementation of the waste heat recovery system;

- In terms of economy, the system has a rapid payback period of 1.38 years with a cumulative saving of $66 million.

Nomenclature

| A | Area (m2) |

| AGMD | Air gap membrane distillation |

| B | Benefits ($) |

| CP | Specific heat capacity (kJ/kg·K) |

| CCHP | Combined cooling, heat and power |

| CHP | Combined heat and power cycle |

| E | Energy flux (kJ) |

| NPV | Net present value ($) |

| GHG | Greenhouse gases |

| K | Thermal conductivity (W/m·K) |

| LHV | Lower heating value |

| MENA | Middle East and North Africa |

| P | Power capacity (kW) |

| PB | Payback period (years) |

| Q | Heat energy (kJ) |

| S | Entropy (kJ/kg·K) |

| U | Overall heat transfer coefficient |

| X | Mole fraction of water vapor |

| ACH | Air changes per hour |

| B | Membrane thickness (mm) |

| C | Cost ($) |

| CC | Combustion chamber |

| CCCWP | Combined cooling, clean water and power |

| COP | Coefficient of performance |

| HRSG | Heat recovery steam generator |

| I | Interest rate (%) |

| H | Enthalpy (kJ/kg) |

| L | Air gap width (mm) |

| M | Mass flow (kg/h) |

mass flow rate (kg/s) | |

| P | Partial pressure of vapor |

| Pr | Pressure (bar) |

| RH | Reheat chamber |

| T | Temperature (°C) |

| VAC | Vapor absorption chiller |

Greek Letters

| ∆T | Change in temperature |

| λL | Latent heat of evaporation |

| Γ | Specific heat ratio |

| Ф | Porosity |

| Η | Efficiency |

Subscripts

| A | Air |

| C | Cold side |

| Ch | Chilled water |

| F | Fuel |

| Gen | Generator |

| H | Hot side |

| LMTD | Logarithmic mean temperature difference |

| RH | Reheat chamber |

| ST | Steam turbine |

| T | Thermal |

| Ac | Absorption chiller |

| Cc | Combustion chamber |

| Dis | Distillate |

| G | Gas |

| GT | Gas turbine |

| HRS | Heat recovery system |

| MD | Membrane distillation |

| Stack | Stack temperature |

| SW | Seawater |

| Tri | Tri-generation |

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kong, X.Q.; Wang, R.Z.; Huang, X.H. Energy optimization model for a CCHP system with available gas turbines. Appl. Therm. Eng. 2005, 80, 377–391. [Google Scholar] [CrossRef]

- Khan, K.H.; Rasul, M.G.; Khan, M.M.K. Energy conservation in buildings: Cogeneration and cogeneration coupled with thermal-energy storage. Appl. Therm. Eng. 2004, 77, 15–34. [Google Scholar] [CrossRef]

- Havelsky, V. Energetic efficiency of cogeneration system for combined heat, cold and power production. Int. J. Refrig. 1999, 22, 479–485. [Google Scholar] [CrossRef]

- Bilgen, E. Exergetic and engineering analyses of gas turbine based cogeneration systems. Energy 2000, 25, 1215–1229. [Google Scholar] [CrossRef]

- Huangfu, Y.; Wu, J.Y.; Wang, R.Z.; Kong, X.Q.; Wei, B.H. Evaluation and analysis of novel micro-scale combined cooling, heating and power (MCCHP) system. Energy Convers. Manag. 2007, 48, 1703–1709. [Google Scholar] [CrossRef]

- Liu, M.; Shi, Y.; Fang, F. Combined cooling, heating and power systems: A survey. Renew. Sustain. Energy Rev. 2014, 35, 1–22. [Google Scholar] [CrossRef]

- Ahmadi, P.; Dincer, I.; Rosen, M.A. Exergo-environmental analysis of an integrated organic Rankine cycle for trigeneration. Energy Convers. Manag. 2012, 64, 447–453. [Google Scholar] [CrossRef]

- Khaliq, A. Exergy analysis of gas turbine trigeneration system for combined production of power heat and refrigeration. Int. J. Refrig. 2009, 32, 534–545. [Google Scholar] [CrossRef]

- Ahmadi, P.; Rosen, M.A.; Dincer, I. Greenhouse gas emission and exergo-environmental analyses of a trigeneration energy system. Int. J. Greenh. Gas Control 2011, 5, 1540–1549. [Google Scholar] [CrossRef]

- Temir, G.; Bilge, D. Thermoeconomic analysis of a trigeneration system. Appl. Therm. Eng. 2004, 24, 2689–2699. [Google Scholar] [CrossRef]

- Sun, Z.G. Energy efficiency and economic feasibility analysis of cogeneration system driven by gas engine. Energy Build. 2008, 40, 126–130. [Google Scholar] [CrossRef]

- Hussain, H.J. Development of a Hybrid Powerplant for Kuwait: The Simultaneous Production of Power, Fresh Water and Cooling. Ph.D. Thesis, Cranfield University, Shrivenham, UK, 2010. [Google Scholar]

- Calise, F.; d’Accadia, M.D.; Piacentino, A. A novel solar trigeneration system integrating PVT (photovoltaic/thermal collectors) and SW (Seawater) desalination: Dynamic simulation and economic assessment. Energy 2014, 67, 129–148. [Google Scholar] [CrossRef]

- Kullab, A.; Martin, A. Membrane distillation and applications for water purification in thermal cogeneration plants. Sep. Purif. Technol. 2011, 76, 231–237. [Google Scholar] [CrossRef]

- Liu, C. Polygeneration of Electricity, Heat and Ultrapure Water for the Semiconductor Industry. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2004. [Google Scholar]

- Kullab, A. Desalination using Membrane Distillation: Experimental and Numerical study. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2011. [Google Scholar]

- Burrieza, E.G.; Blanco, J.; Zaragoza, G.; Alarcón, D.C.; Palenzuela, P.; Ibarra, M.; Gerjak, W. Experimental analysis of an air gap membrane distillation solar desalination pilot plant system. J. Membr. Sci. 2011, 379, 386–396. [Google Scholar] [CrossRef]

- RAK Property Services. Available online: http://www.rakps.com (accessed on 2 June 2014).

- Data Sheet of Test Results—GE Energy; Al-Hamra Gas Turbine Powerplant: Ras Al Khaimah, UAE, Unpublished work; 2014.

- Technical Specification of Steam Turbine SST-100. Available online: http://www.energy.siemens.com (accessed on 25 April 2014).

- International Energy Agency (IEA) STATISTICS 2012. CO2 Emissions from Fuel Combustion. Available online: http://www.iea.org (accessed on 5 May 2014).

- Greenhouse Gas Inventory for Abu Dhabi Emirate: Inventory Results Executive Summary; Environment Agency—Abu Dhabi: Abu Dhabi, UAE, 2012.

- Roosen, P.; Uhlenbruck, S.; Lucas, K. Pareto optimization of a combined cycle power system as a decision support tool for trading off investment vs. operating cost. Int. J. Therm. Sci. 2003, 42, 553–560. [Google Scholar] [CrossRef]

- Al-Obaidani, S.; Curcio, E.; Macedonio, F.; Profio, G.D.; Al-Hinai, H.; Drioli, E. Potential of membrane distillation in seawater desalination: Thermal efficiency, sensitivity and cost estimation. J. Membr. Sci. 2008, 323, 85–98. [Google Scholar] [CrossRef]

- Alili, A.A.; Islam, M.D.; Kubo, I.; Hwang, Y.; Radermacher, R. Modeling of a solar powered absorption cycle for Abu Dhabi. Appl. Energy 2012, 93, 160–167. [Google Scholar] [CrossRef]

- Performance and Cost Estimations of Final Industrial Size of MEDESOL-2 Technology 2010; University of La Laguna: Canary Islands, Spain, 2010.

- Lazzarin, R.M. Solar cooling: PV or thermal? A thermodynamic and economic analysis. Int. J. Refrig. 2014, 39, 38–47. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohan, G.; Dahal, S.; Kumar, U.; Martin, A.; Kayal, H. Development of Natural Gas Fired Combined Cycle Plant for Tri-Generation of Power, Cooling and Clean Water Using Waste Heat Recovery: Techno-Economic Analysis. Energies 2014, 7, 6358-6381. https://doi.org/10.3390/en7106358

Mohan G, Dahal S, Kumar U, Martin A, Kayal H. Development of Natural Gas Fired Combined Cycle Plant for Tri-Generation of Power, Cooling and Clean Water Using Waste Heat Recovery: Techno-Economic Analysis. Energies. 2014; 7(10):6358-6381. https://doi.org/10.3390/en7106358

Chicago/Turabian StyleMohan, Gowtham, Sujata Dahal, Uday Kumar, Andrew Martin, and Hamid Kayal. 2014. "Development of Natural Gas Fired Combined Cycle Plant for Tri-Generation of Power, Cooling and Clean Water Using Waste Heat Recovery: Techno-Economic Analysis" Energies 7, no. 10: 6358-6381. https://doi.org/10.3390/en7106358