1. Introduction

Mining is first and foremost a source of mineral commodities that all countries find essential for maintaining their economies and improving their standards of living. Mined materials are needed to construct roads and hospitals, to build automobiles and houses, to make computers and satellites, to generate electricity, and to provide many other goods and services [

1]. Both energy consumption within the mining industry and energy prices, are rising and thus there increased need to reduce consumption, and improve primary energy utilization to maintain competitiveness within the mining sector by reducing input costs. Generally, energy supply security and reduced emissions can be achieved through [

2]: (1) improvement in energy efficiency; (2) energy savings; (3) higher proportion of renewable energy in supply systems; and (4) process-wide integration.

Given the significance of energy costs in operating expenses, efficiency of energy production and use must be improved in the energy-intensive mining sector [

3]. Governments and mining associations recognize the importance of improving energy efficiency, and are working together to implement more energy-efficient technologies. Energy efficiency makes sense for mining operations because it can reduce production cost while simultaneously realizing additional benefits including reduction in the greenhouse gas emissions. While not yet well utilized, process integration and polygeneration are promising tools which reach the double objective of increasing the efficiency of utilization of natural resources, and also of reducing the environmental impact [

4].

Polygeneration is a term used to describe a generalization of the cogeneration concept where two (co-generation) or more (poly-generation) energy services are simultaneously provided through use of highly-integrated energy systems. An immediate advantage of polygeneration is its thermodynamically efficient use of fuel. Polygeneration systems utilize otherwise wasted thermal energy, and can use it for space heating, industrial process needs, or as an energy source for another system component. This “cascading” use of energy is what distinguishes polygeneration systems from conventional separate electric and thermal energy systems (e.g., a powerplant and a low pressure boiler), and from simple heat recovery strategies [

5]. The deployment of polygeneration systems in mine sites aims at increasing the efficient use of natural resources by combining different technologies, process integration, and energy resources, an objective which may render mineral production operations compliant with the new energy management standard, ISO 50001 [

6].

Advantages of polygeneration systems have been demonstrated in the literature [

7,

8], as energy efficiency is associated with economic savings and sparing of the environment, as less fuel is consumed and consequently less pollution is generated. Such integrated energy systems could play an important role in the gap between fossil fuel-based energy systems and renewable energy-based systems. Polygeneration is a fully developed technology that has a long history of use in many types of industry, particularly in pulp and paper, petroleum and chemical industries, where there is a large demand for both heat and electricity at each site [

9]. In recent years, the greater availability and choice of suitable technology options means that polygeneration can become an attractive and practical business proposition.

In recent years, the analysis and design tools for energy systems and energy management have undergone development. In particular, the synthesis and design of energy systems for the industrial sector has become increasingly elaborate, with numerous possibilities for energy sources and technological options. This increase in complexity allows for more flexible systems but at the same time increases difficulties when designing the polygeneration system itself.

This paper reports on early work and concept development for Optimal Mine Site Energy Supply, where the specific requirements and constraints of mineral production operations are considered against methodologies that have been applied for other sectors and in other energy policy regimes. Through these extensions, the “most adequate” configurations of energy supply equipment that satisfice (as coined by Herbert Simon [

10]) the energy requirements of mine sites in different scenarios and conditions of constraint can be identified.

This paper also presents a critical review of precedent energy management practice in mineral operations, where the thrust has been independent deployment of beneficial technologies. The review indicates the additional benefits of energy supply systems for mine sites that concurrently meet all utilities.

2. Energy in Mineral Operations

South Africa’s Department of Minerals and Energy estimates that the mining industry uses 6% of all the energy consumed in South Africa. In Brazil, the largest single energy consumer is mining giant Vale, which accounts for around 4% of all energy used in the country. In the US State of Colorado, mining has been estimated to account for 18% of total industrial sector energy use, while overall in the US it is calculated that the mining industry uses 3% of industry energy [

11]. A secure and reliable supply of energy is thus critical for all mining operators to meet their production requirements. For most, energy constitutes a major operating expense and its generation and distribution requires substantial capital investment. To minimize costs, it is important to recognize that energy is a controllable operating cost [

12].

Canada is one of the world’s leading mining countries and ranks among the largest producers of minerals and metals [

13]. Mines, quarries, and primary metal and mineral manufacturing facilities (the mining sector) are distributed across every province and territory [

14]. Industrial energy prices increased 58% for electricity and 310% for heavy fuel oil in Canada, from 1990 to 2008 [

15]; these increases partly illustrate the financial incentive for energy management which aims to allow companies to reduce economic risks resulting from rising energy costs balanced against a need for security of energy supply to ensure continuous production [

16]. Between 1990 and 2008, total energy use in Canada has risen by 25.7%, with the mining industry increasing its energy consumption by 137.7% in the same period [

15].

It has been reported [

17] that the metal mining industry in the United States has the potential to reduce energy consumption by about 61% from current practice to the best-estimated practical minimum energy consumption. This reduction was made up of a 21% reduction by implementing best practices and a 40% reduction from research and development that improves energy efficiency of mining and mineral processing technologies. Governments, especially in countries with large mining sectors, are imposing standards for energy efficiency. Australia’s miners are obliged to comply with the Equipment Energy Efficiency program for energy efficiency. In South Africa, the DME set a target in 2007 for the mining industry to reduce energy demand by 15% by 2015 [

11]. In China, a vigorous program was launched in 2004 aimed at reducing energy intensity by 20% over the period between 2006 and 2010 [

18].

Energy management is the judicious and effective use of energy to maximize profits (and minimize costs) and enhance competitive positions [

19], while meeting energy demand when and where it is needed (the energy utility). This can be achieved by adjusting and optimizing energy systems and procedures so as to reduce energy requirements per unit of output while maintaining or reducing total costs of producing the output from these systems [

20].

Energy management activities are often categorized into supply side management or demand side management activities. As mineral production businesses are frequently vertically integrated businesses that hold their own generation [

21] and/or transmission [

22] and/or distribution assets, as well as maintaining control of their own demand centers, both sides of the energy system (supply and demand) are of concern in energy management practice.

Demand Side Management (DSM) can be defined [

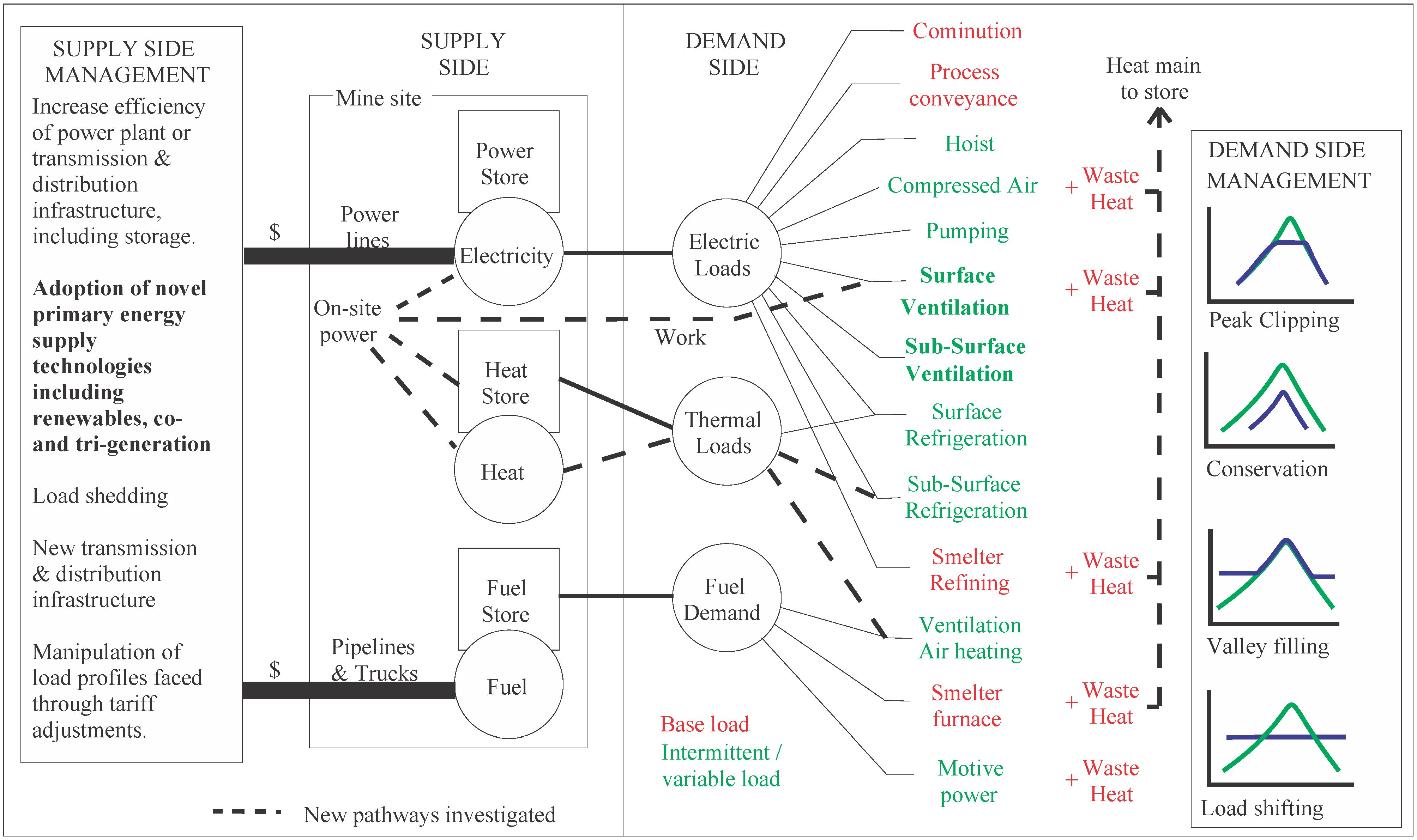

23] as the planning, implementation, and monitoring of distribution network utility activities designed to influence customer use of electricity in ways that will produce desired changes in the load shape. The goal of DSM is to smooth out peaks and valleys in energy demand to make better use of energy resources and defer the need to build new power plants. There are four broad categories of load-shape DSM objectives: peak clipping, strategic conservation, valley filling, and load shifting, as illustrated in the extreme right side of

Figure 1. In

Figure 1, sources of demand running continuously are shown in red, variable or intermittent loads are shown in green and those that may change from base load to intermittent loads are emboldened. Activities in the framework that are new are shown in dashed lines.

Figure 1.

Preliminary framework for energy management activities in an underground mine [

3].

Figure 1.

Preliminary framework for energy management activities in an underground mine [

3].

Supply-side management (SSM) refers to actions taken to ensure the generation, transmission and distribution of energy are conducted efficiently [

24]. Effective SSM actions will usually increase the efficiency with which demand centers are supplied, allowing installed generating capacity to provide electricity at lower cost (permitting lower prices to be offered to consumers) and reducing environmental emissions per unit of end-use electricity provided. Exemplary SSM activities are illustrated on the extreme left side of

Figure 1, but could extend to emissions trading, construction of primary energy storage and distribution facilities [

3].

The potential economic benefits of a high energy consumption intensity for mineral production (see for example [

25]) lead to consideration of local (mine site) elements of supply side energy management. One example of supply side energy management is the adoption of energy supply technologies including renewable energy and polygeneration. As heat has not yet been considered for the mining sector in an integrated manner, polygeneration is of great interest for the sector. Renewables and polygeneration options are the new pathways that are subject to the current investigations.

3. Polygeneration Technology

The increase in energy utilization efficiency is, without doubt, the main advantage of producing different energy services (heat, coolth [

26], and electricity) in one installation from the same energy source. Furthermore, polygeneration schemes can generate many configurations and thus allow for ample design flexibility that accommodates specific regional conditions [

27]. However, choosing the correct size and design of a polygeneration system is a key factor for the success of the project: undersized systems do not realize the profit of exploiting the whole polygeneration potential of the site, and if the system is oversized low or negative primary energy savings may be obtained [

28].

In the case that the energy supply system has already been built, the optimization procedure will encompass only the operational strategy. However, if external conditions change (energy demands, utility prices,

etc.), a retrofit adopting additional equipment is added to the existing system (the configuration of which then comprises a constraint on optimization). For new systems, in addition to the optimal dispatch of energy supply plant the optimal system configuration must also be identified (essentially the specification of equipment in rating and number) [

29,

30].

A general thermoeconomic framework has been established [

31,

32,

33,

34,

35] to identify optimal combinations of energy conversion and delivery technologies, as well as operating rules for systems installed in tertiary sector buildings. A reference/conventional system for production of electricity, heating and coolth to attend the demands of a building is shown in

Figure 2, where all electricity is purchased from a utility company owned electricity distribution grid to either meet the electricity demand directly or produce cooling in mechanical chillers driven by electrical motors, and heating demand is produced by a natural gas boiler. The aforementioned framework, described as an energy superstructure [

31], is shown in

Figure 3, containing all technology alternatives that may be adopted (but not their ratings or numbers). D, S, P and W refer to, respectively, demand, sale, purchase and waste (loss) of a utility. Within

Figure 2 and

Figure 3, the horizontal or vertical lines essentially represent physical distribution systems into which the technologies indicated can feed in energy of a specific form. Site loads for energy in that specific form (a specific energy utility) are supplied from that distribution system, including further energy conversion technologies that convert the supplied utility into another form (which in turn supplies another distribution required by the site loads).

Figure 2.

Reference system.

Figure 2.

Reference system.

Figure 3.

Superstructure of an energy supply system for a building.

Figure 3.

Superstructure of an energy supply system for a building.

5. Characteristic Challenges of OMSES

Mining operations in Northern Canada can also face a particular energy challenge given the lack of grid (electric and gas) capacity and limited infrastructure. In addition, it is typical for underground mines to require progressively more energy to access and extract the minerals as operations mine deeper. Deep mines (nominally >2,000 m) acquire substantial cooling loads as they age, and meeting such important energy demands is becoming economically and technically important.

Opportunities for savings offered by adoption of polygeneration have not been investigated in depth previously for the specific cases of mine sites, possibly for the following reasons: (1) wide variety of technology options for the provision of energy services; (2) temporal variations (diurnal, seasonal and inter-annual) in energy prices; (3) temporal variations (diurnal, seasonal) in climate; (4) temporal variation (diurnal, seasonal and inter-annual) in energy demand; and (5) institutional inertia, and conservatism in mine design for mines.

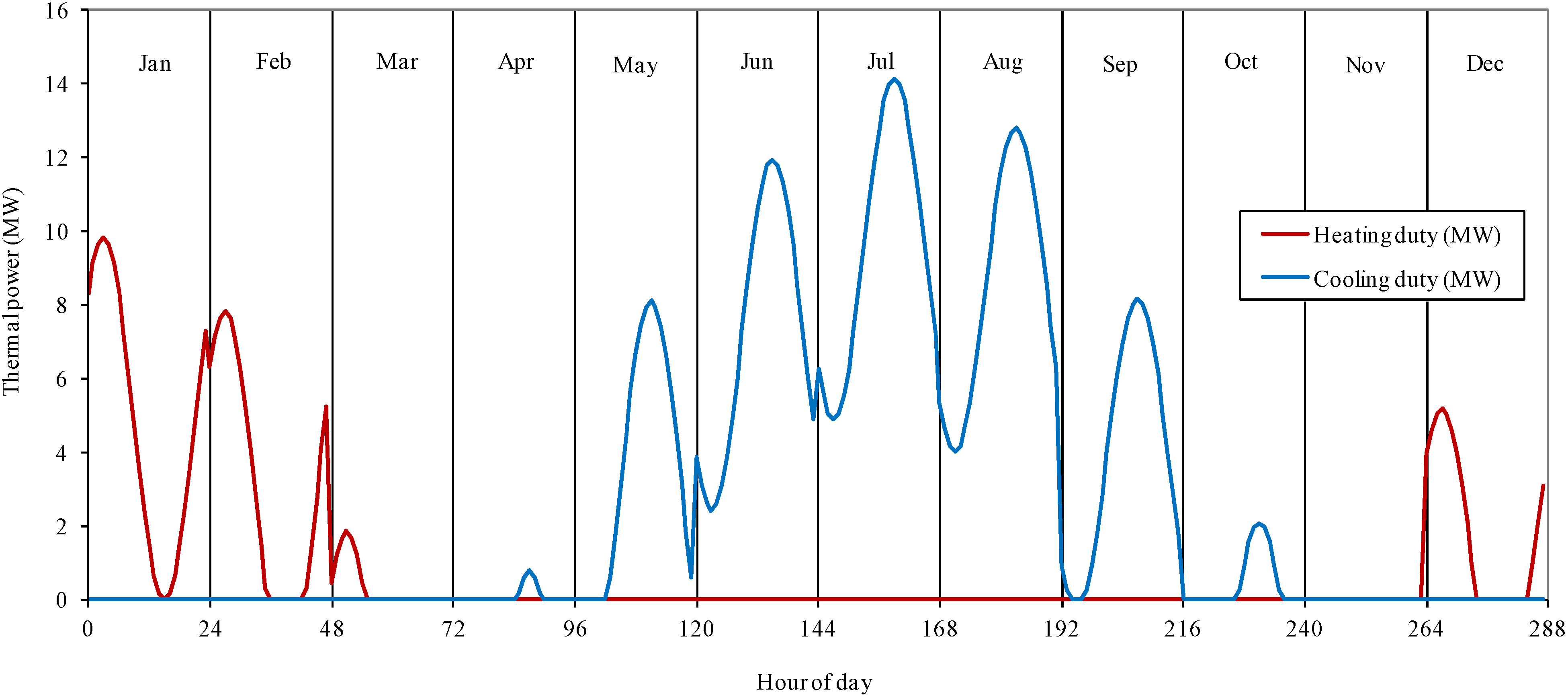

Diurnal, seasonal and inter-annual variability of thermal loads in the mining sector in Canada increase the complexity of generic energy supply systems and solutions of high sophistication are required for operation to be economically attractive. Mine air heating and cooling loads are seasonally complementary (see

Figure 5). The timing of the highest cooling loads in summer seasons, if serviced by a mechanical chiller system, is at odds with electricity tariff peak times.

In

Figure 5, thermal demand profile projections are illustrated for a study period of one year, distributed as 12 days, each day taken as typical for each month and divided into 24 hourly periods (at 2,500 m depth, base temperatures were: for heating = 18 °C; for cooling = 30 °C).

Applying optimization techniques to the problem of mine-site energy supply presents some unique challenges: variability of energy loads which will always remain variable, but may be highly predictable (e.g., those due to winding and groundwater pumping activity in the case of electricity), the need to produce from deeper, hotter levels, as in Canadian climates with extreme climatic variation, and in remote areas with no connection to the electric or gas grids. These characteristics are not seen as insurmountable and offer potential for innovation as indicated below.

7. An Example Application

A simple case study is considered to prove and illustrate the validity and usefulness of the proposed methodology. Real electricity data is available from a process plant, along with estimated heat (space heating plus sanitary hot water), coolth and electricity demands for mine office and dormitory buildings (accommodating approximately 400 employees). The monthly-average ambient temperature was used to calculate the monthly heat/coolth/electricity demand distribution and also the hourly ambient temperature and degree-days [

40] of the office and dormitory buildings. Real demands for diesel from mobile equipment were available and were introduced into the optimization model.

The annual energy demands for the mine operation were: 2,356 MWh for heat, 354 MWh for coolth, 119,730 MWh for electricity and 102,667 MWh of diesel. One operational year was considered in the study, divided into 12 representative days (one day per month, as no significant difference was identified between weekdays and weekends), subdivided into 24 hours.

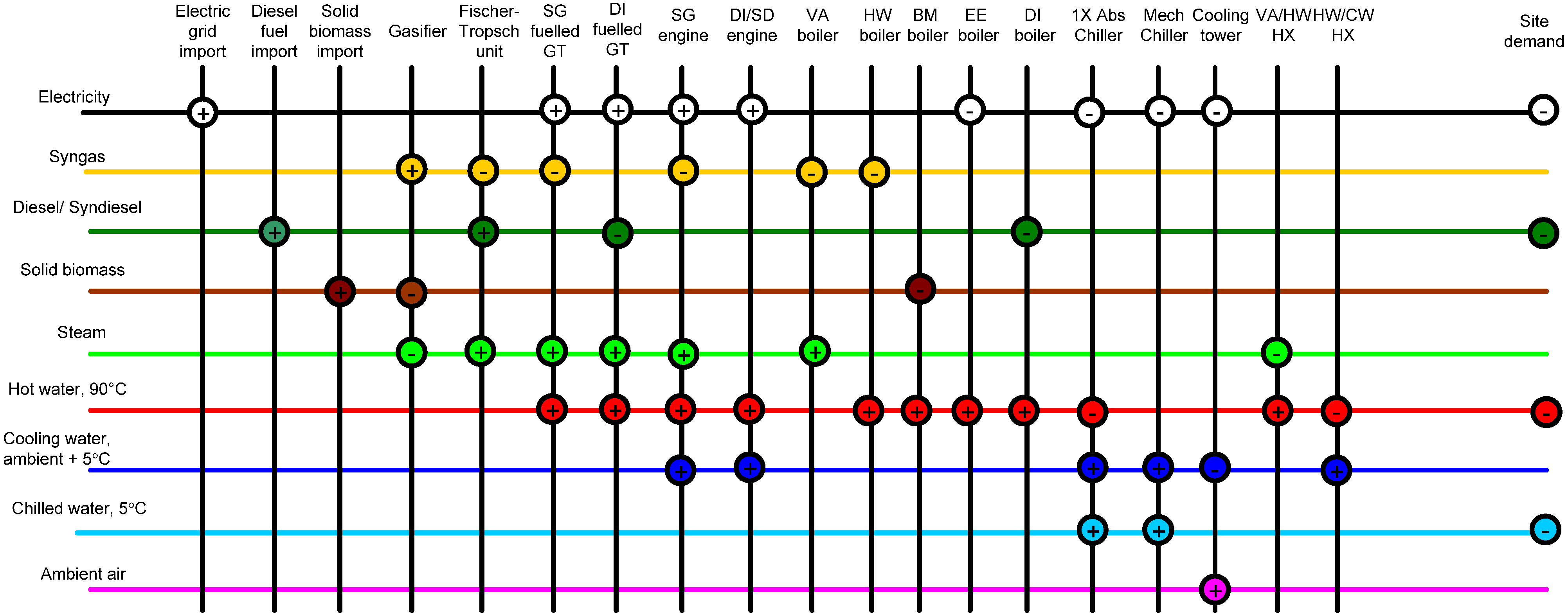

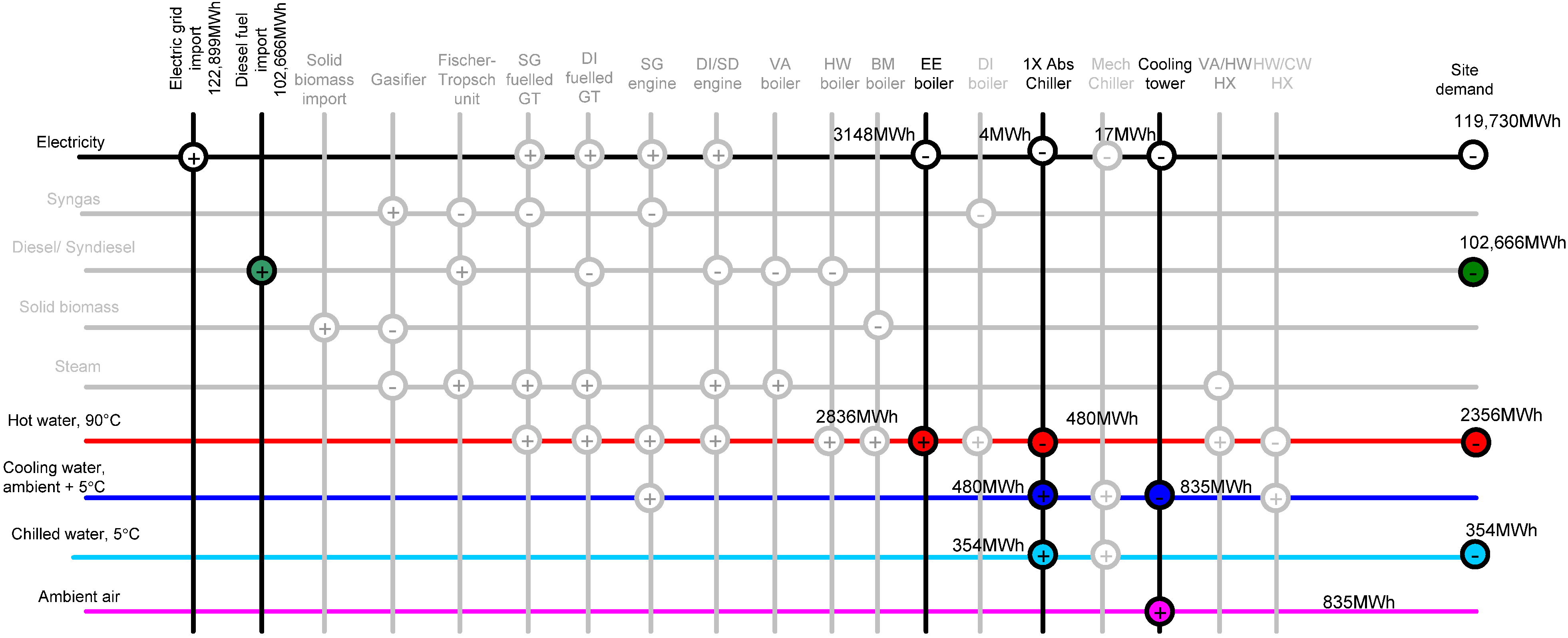

The extensions required development of a more generalized superstructure to describe the system and to visualize results, as shown in

Figure 7,

Figure 8 and

Figure 9, where the possible technologies, available energy utilities and their interactions can be observed. A positive node denotes a technology that supplies the distribution. A negative node denotes a technology that consumes from the distribution. Within

Figure 7, the horizontal essentially represent physical distribution systems into which the technologies indicated (the vertical lines) can feed in or draw energy of a specific form. Site loads for energy in that specific form (a specific energy utility) are supplied from that distribution system, including further energy conversion technologies that convert the supplied utility into another form (which in turn may supply another utility distribution required by the site loads).

Figure 7.

Initial superstructure for example application illustrating all potential conversion pathways considered.

Figure 7.

Initial superstructure for example application illustrating all potential conversion pathways considered.

The available utilities for purchase were solid biomass (BM), electricity (EE), and diesel (DI). A natural gas grid is assumed not available at this location. A gasification unit to convert solid biomass into a combustible gas also introduced new thermal loads into the model [

41]. Gasified products could be utilized in a Fischer-Tropsch process to produce syndiesel [

42]. Diesel fuelled hydraulic excavators, haulage trucks well as static prime movers for electricity generation draw from the diesel utility. Energy consumption from mobile plant is thus assimilated into the polygeneration optimization model.

Other available utilities were syngas and syndiesel (SG, SD, respectively), steam (VA, 180 °C), hot water (HW, 90 °C), cooling water (CW, t

0 + 5 °C), ambient air (AA, t

0 °C), and chilled water (CO, 5 °C). In

Figure 7, GT denotes gas turbine and HX denotes heat exchanger.

Table 1 shows the equipment selected for inclusion in the superstructure, along with the production coefficients normalized to the main product of the equipment (indicated in bold). The capital cost of the equipment and nominal power are also included in

Table 1. The lifetime of the system was considered to be 20 years and the discount rate, 10%. The price for electricity purchased from the grid or sold to the grid was CAD 100 per MWh. The price of imported diesel was taken to be CAD 130 per MWh, which is approximately equivalent to CAD 1.35 per litre, the consumer pump price prevailing at the time of writing. The price of purpose grown solid biomass was CAD 30 per MWh, which is approximately equivalent to CAD 135 per tonne (at 16 MJ/kg, dry) [

43]. There can be multiple units of each technology.

For the purposes of this illustrative example only, no environmental constraints were admitted into the formulation.

The example application was formulated precisely following the methodologies set out in detail in [

31]. The optimization process simultaneously identifies the optimal combination and number of technologies (selected from those listed in

Table 1) and the optimal policy for their operation. This means, for example, that the results of the optimization process may reveal the hourly amounts of biomass and diesel fuel that may need to be procured, or produced on-site, by the mine operator in order to secure the capacity to produce. This base case mine is assumed grid connected with any surplus electricity utility being exported so that it may be imported subsequently. The formulation thus allows the electric grid to behave as an energy store with unlimited storage capacity. Other than the absence of a threshold of energy stored, the formulation to consider storage schemes for, for example, diesel, are similar. Referring to the nomenclature used in [

31] this threshold can be mathematically expressed as:

where CDIH(kd,kh) is the purchase of diesel at each day (kd) and hour (kh), and DILIMIT is a number which indicates the maximum purchase allowed for diesel at each day and hour. A different threshold could also be implemented by considering a fixed-capacity storage, which would be replenished only by winter road (in February, for example). Therefore the cumulative sum of the consumption from March to January, for example, should be lower than TLIMIT, where TLIMIT is the capacity of the storage tank.

As there were 68,000 decision variables, 101,000 non-negativity constraints and 43,000 technical constraints, it is not practical to report the results of the optimization process in detail. Instead, we report aggregated quantities found from the detailed results typically reflecting annual performance indicators and show only those utilities and technologies that are part of the optimal mine site energy supply. The configuration of the optimal base case solution is shown in

Figure 8, along with main energy flows.

Table 1.

Selected equipment and matrix of production coefficients.

Table 1.

Selected equipment and matrix of production coefficients.

| Equipment | Capital Cost (103 $) | Nominal Power (MW) | Biomass | Electricity | Syngas | Diesel | Steam | Hot Water | Cooling Water | Chilled Water | Ambient Air |

|---|

| Gasifier | 3000 | 3.0 | 1.54 | | 1 | | 0.06 | | | | |

| Fischer-Tropsch unit | 4000 | 3.0 | | | 1.25 | 1 | 0.60 | | | | |

| Gas turbine | 4000 | 3.6 | | 1 | 3.03 | | 0.59 | 0.66 | | | |

| Diesel turbine | 4000 | 3.6 | | 1 | | 3.00 | 0.60 | 0.60 | | | |

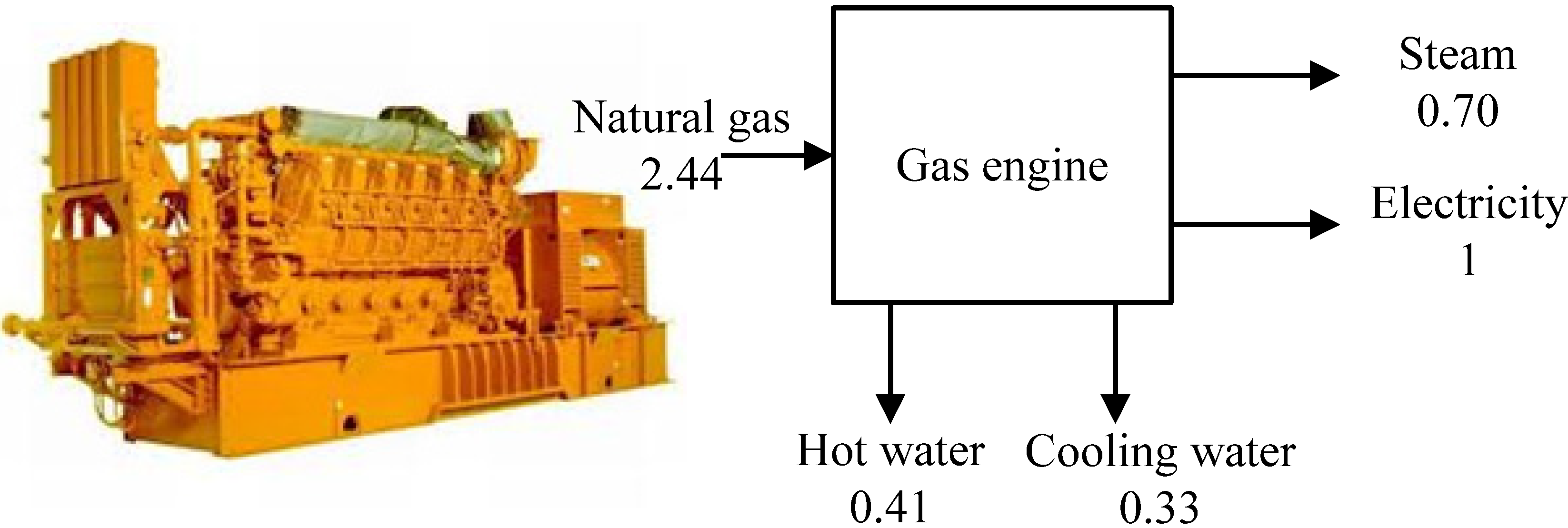

| Gas engine | 3600 | 3.6 | | 1 | 2.44 | | 0.70 | 0.41 | 0.33 | | |

| Diesel engine | 4400 | 4.4 | | 1 | | 2.27 | | 0.80 | 0.20 | | |

| Steam boiler | 144 | 3.0 | | | 1.18 | | 1 | | | | |

| Hot Water Boiler | 150 | 3.9 | | | 1.22 | | | 1 | | | |

| Biomass boiler | 492 | 3.5 | 1.25 | | 0.06 | | | 1 | | | |

| Electric boiler | 144 | 3.0 | | 1.11 | | | | 1 | | | |

| Diesel boiler | 170 | 3.8 | | | | 1.25 | | 1 | | | |

| 1X Abs Chiller | 280 | 1.5 | | 0.01 | | | | 1.36 | 2.36 | 1 | |

| Mechanical Chiller | 680 | 2.7 | | 0.21 | | | | | 1.21 | 1 | |

| Cooling Tower | 185 | 7.4 | | 0.02 | | | | | 1 | | 1 |

| Steam-Hot W HX | 50 | 5.0 | | | | | 1.1 | 1 | | | |

| Hot W-Cool W HX | 35 | 5.0 | | | | | | 1.1 | 1 | | |

Figure 8.

Optimal base case solution, displaying technologies installed and main annual energy flows. The annuitized capital cost is 140,070 CAD, and the annualized operation cost is 25,636,444 CAD.

Figure 8.

Optimal base case solution, displaying technologies installed and main annual energy flows. The annuitized capital cost is 140,070 CAD, and the annualized operation cost is 25,636,444 CAD.

The optimal base case solution installs one electric boiler, one single effect absorption chiller and one cooling tower. The heat from the electric boiler covers the heat demand and also the coolth demand through the absorption chiller. The cooling tower is used to evacuate all the cooling water heat from the chiller. The annuitized capital cost of the optimal base case solution is 140,070 CAD, and the annualized operation cost is 25,636,444 CAD.

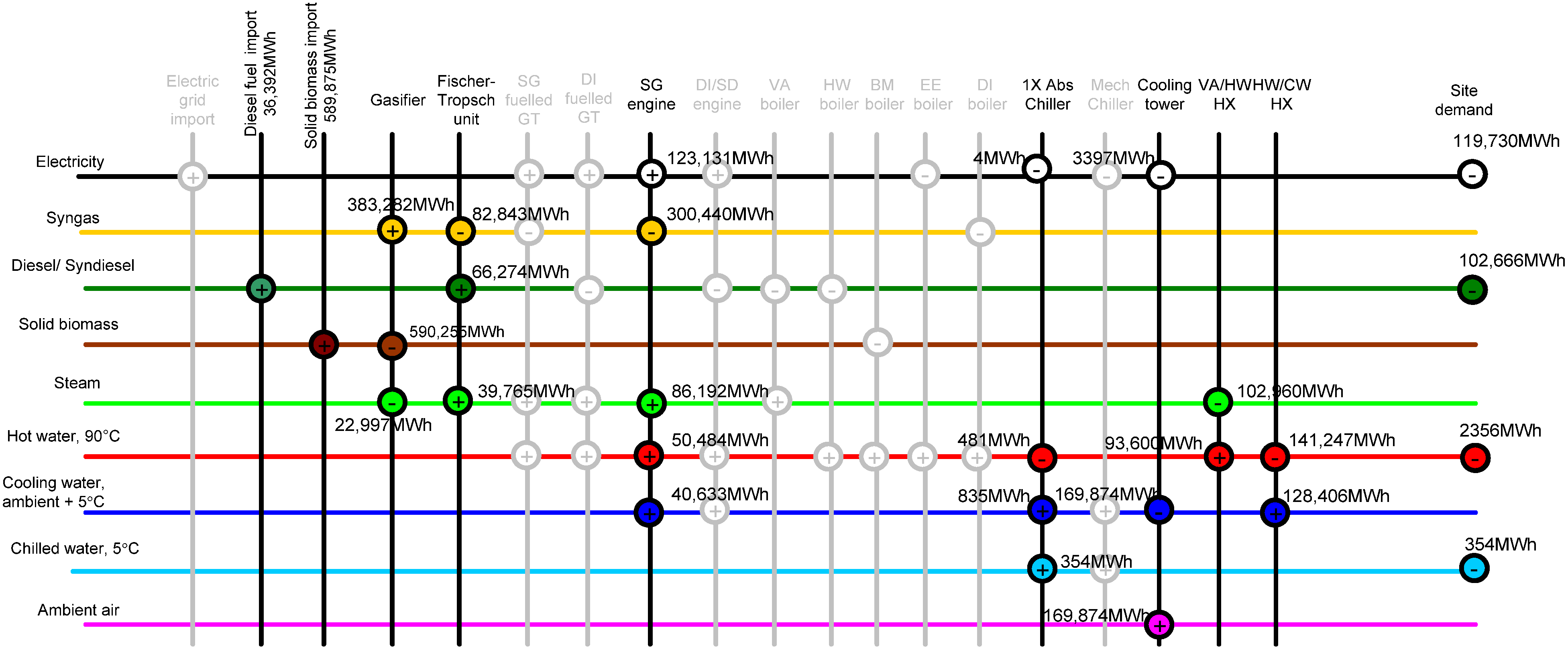

If, however, we consider the base case mine to be off-grid mine with the aforementioned technical and economic scenario, the optimal solution changes drastically. Preclusion of the possibility of purchasing electricity forces the system to change to the configuration shown in

Figure 9. Five syngas-fuelled engines are installed, along with one absorption chiller, 15 gasifiers and three Fischer-Tropsch units. Biomass is purchased to feed the gasifiers, which produce syngas to operate the gas engines and the Fischer-Tropsch units. In this case, the annuitized capital cost of the optimal solution is 17,508,750 CAD, and the annualized operating cost is 22,438,577 CAD. This solution presents an increase in annual cost of 55%, however had the base case mine been considered remote from the existing transmission and distribution electricity grid, the annuitized capital cost of extending high tension lines to the mine site would become relevant and would equalize the total annual costs of the off-grid mine at a break-even extension distance. The technologies and main energy flows of this re-optimized solution are shown in

Figure 9.

This formulation for optimal mine site energy supply may be used to investigate additional trade-offs. For the base case mine, an interesting analysis is to identify the diesel price at which there is a switch from direct diesel purchase to the installation of gasifiers + Fischer-Tropsch units for the production of syngas and syndiesel. A series of parametrically driven re-optimizations identified that when diesel prices almost double to 250 CAD/MWh, the optimal solution installs 4 gasifiers producing syngas to drive a gas engine and to fuel one Fischer-Tropsch unit.

Figure 9.

Off-grid optimal base case solution, showing technologies installed and main annual energy flows. The annuitized capital cost is 17,508,750 CAD, and the annualized operating cost is 22,438,577 CAD.

Figure 9.

Off-grid optimal base case solution, showing technologies installed and main annual energy flows. The annuitized capital cost is 17,508,750 CAD, and the annualized operating cost is 22,438,577 CAD.

It is also interesting to verify the biomass starting point for the installation of gasifiers. The price utilized in the model considers purpose-grown biomass and transportation. However, peat fuel—a biomass energy source—is abundant in Northern Ontario [

44]. In this case, the biomass procurement cost would be much reduced as the resource is close to, or on-site. At a price of 12 CAD/MWh for peat (equivalent to approximately 55 CAD/tonne), the re-optimized solution includes the purchase of biomass to feed gasifiers and then Fischer-Tropsch units.

As stated in the opening of the paper, this is work in progress, however the value of the optimal mine site energy supply formulation in decision support for mining operations has been clearly illustrated in these simple examples. The objective of this paper was to present the concept of developing energy supply solutions for mining operations in Canada, to reflect the challenges faced by the mining sector that must be overcome, and the extensions that will be implemented in order to achieve energy efficiency goals.