A Survey of Condition Monitoring and Fault Diagnosis toward Integrated O&M for Wind Turbines

Abstract

:1. Introduction

1.1. Background

1.2. Overview of the Survey

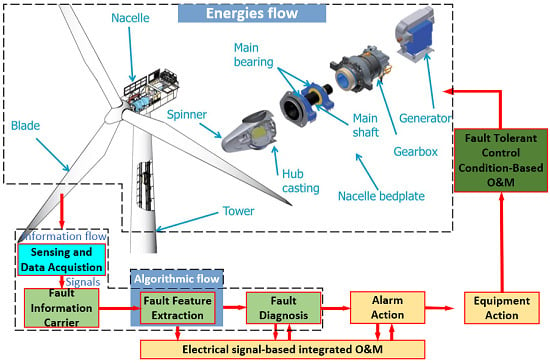

2. WT Component

3. WT Energy Flow

3.1. Wind Energy Subset

3.1.1. Blade

3.1.2. Pitch System and Yaw System

3.1.3. Tower

3.2. Mechanical Energy Subset

3.2.1. Shaft

3.2.2. Gearbox

3.3. Electrical Energy Subset

3.3.1. Generator

3.3.2. Power Electronic Device

4. WT Information Flow

4.1. Strain

4.2. Vibration

4.3. Torque

4.4. Temperature, Oil, and AE

5. WT Algorithm Flow

5.1. FFT and Wavelet Transform

5.2. Order Tracking (OT)

5.3. Artificial Intelligence (AI)

6. Wind Farm Integrated O&M System Based on Electrical Signal

6.1. Theory Analysis

6.2. Experimental Setup

7. Conclusions and Discussion

- Wind farms are generally located in remote areas with harsh environments. WTs have complex structures, and nacelle is difficult to access. The high failure rates of WTs call for more advanced techniques for CMFD of WTs.

- The purpose of WTs is to realize the conversion of wind energy to mechanical energy and then to electrical energy by energy flow. In order to better control and monitor the WT, the acquisition of information flow based on sensors is indispensable. In order to improve SNR of information flow, algorithm flow is essential.

- The CMFD based on electrical signals can use the signals acquired by the control system to realize sensorless CMFD of WTs and integration of control system and fault diagnosis, which is the direction of future efforts.

Author Contributions

Funding

Conflicts of Interest

References

- Sawyer, S.; Liming, Q.; Fried, L. Global Wind Report—Annual Market Update 2017. Available online: https://www.researchgate.net/publication/324966225_GLOBAL_WIND_REPORT_-_Annual_Market_Update_2017 (accessed on 4 May 2018).

- Ryan, W.; Mark, B. Wind Technologies Market Report. 2017. Available online: https://www.energy.gov/sites/prod/files/2018/08/f54/2017_wind_technologies_market_report_8.15.18.v2.pdf (accessed on 20 August 2018).

- Schlechtingen, M.; Santos, I.F.; Achiche, S. Wind turbine condition monitoring based on SCADA data using normal behavior models. Part 1: System description. Appl. Soft Comput. 2013, 13, 259–270. [Google Scholar] [CrossRef]

- Schlechtingen, M.; Santos, I.F. Wind turbine condition monitoring based on SCADA data using normal behavior models. Part 2: Application examples. Appl. Soft Comput. 2014, 14, 447–460. [Google Scholar] [CrossRef]

- Matthews, P.C.; Chen, B.; Tavner, P.J. Automated on-line fault prognosis for wind turbine pitch systems using supervisory control and data acquisition. IET Renew. Power Gener. 2015, 9, 503–513. [Google Scholar]

- Qiao, W.; Lu, D. A Survey on Wind Turbine Condition Monitoring and Fault Diagnosis—Part I: Components and Subsystems. IEEE Trans. Ind. Electron. 2015, 62, 6536–6545. [Google Scholar] [CrossRef]

- Qiao, W.; Lu, D. A Survey on Wind Turbine Condition Monitoring and Fault Diagnosis—Part II: Signals and Signal Processing Methods. IEEE Trans. Ind. Electron. 2015, 62, 6546–6557. [Google Scholar] [CrossRef]

- Zhao, M.; Jiang, D.; Li, S. Research on fault mechanism of icing of wind turbine blades. In Proceedings of the World Non-grid-connected Wind Power & Energy Conference, Nanjing, China, 24–26 September 2009. [Google Scholar]

- Ramlau, R.; Niebsch, J. Imbalance Estimation without Test Masses for Wind Turbines. J. Sol. Energy Eng. 2009, 131, 011010. [Google Scholar] [CrossRef]

- Kusnick, J.; Adams, D.E.; Griffith, D.T. Wind turbine rotor imbalance detection using nacelle and blade measurements. Wind Energy 2015, 18, 267–276. [Google Scholar] [CrossRef]

- Niebsch, J.; Ramlau, R.; Nguyen, T.T. Mass and Aerodynamic Imbalance Estimates of Wind Turbines. Energies 2010, 3, 696–710. [Google Scholar] [CrossRef] [Green Version]

- Gardels, D.J.; Qiao, W.; Gong, X. Simulation studies on imbalance faults of wind turbines. In Proceedings of the Power & Energy Society General Meeting, Providence, RI, USA, 25–29 July 2010. [Google Scholar]

- Caselitz, P.; Giebhardt, J. Rotor Condition Monitoring for Improved Operational Safety of Offshore Wind Energy Converters. J. Sol. Energy Eng. 2005, 127, 445–447. [Google Scholar] [CrossRef]

- Gong, X.; Qiao, W. Simulation investigation of wind turbine imbalance faults. In Proceedings of the International Conference on Power System Technology, Hangzhou, China, 24–28 October 2010. [Google Scholar]

- Rubert, T.; Perry, M.; Fusiek, G. Field demonstration of real-time wind turbine foundation strain monitoring. Sensors 2018, 18, 97. [Google Scholar] [CrossRef] [PubMed]

- Arsenault, T.J.; Achuthan, A.; Marzocca, P. Development of a FBG based distributed strain sensor system for wind turbine structural health monitoring. Smart Mater. Struct. 2013, 22, 075027. [Google Scholar] [CrossRef]

- Kusiak, A.; Verma, A. A data-driven approach for monitoring blade pitch faults in wind turbines. IEEE Trans. Sustain. Energy 2011, 2, 87–96. [Google Scholar] [CrossRef]

- Lu, D.; Zhang, P. MCSA-based Fault Diagnosis Technology for Motor Drivetrains. In Proceedings of the 2018 IEEE International Power Electronics and Application Conference and Exposition (PEAC), Shenzhen, China, 4–7 November 2018. [Google Scholar]

- Gill, S.; Stephen, B.; Galloway, S. Wind Turbine Condition Assessment through Power Curve Copula Modeling. IEEE Trans. Sustain. Energy 2012, 3, 94–101. [Google Scholar] [CrossRef]

- Guo, P.; Xu, M.; Bai, N. Wind turbine tower vibration modeling and monitoring driven by SCADA data. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2013, 33, 128–135. [Google Scholar]

- Benedetti, M.; Fontanari, V.; Zonta, D. Structural health monitoring of wind towers: Remote damage detection using strain sensors. Smart Mater. Struct. 2011, 20, 055009. [Google Scholar] [CrossRef]

- Bang, H.J.; Kim, H.I.; Lee, K.S. Measurement of strain and bending deflection of a wind turbine tower using arrayed FBG sensors. Int. J. Precis. Eng. Manuf. 2012, 13, 2121–2126. [Google Scholar] [CrossRef]

- Soua, S.; Van Lieshout, P.; Perera, A. Determination of the combined vibrational and acoustic emission signature of a wind turbine gearbox and generator shaft in service as a pre-requisite for effective condition monitoring. Renew. Energy 2013, 51, 175–181. [Google Scholar] [CrossRef] [Green Version]

- Wilkinson, M.R.; Spinato, F.; Tavner, P.J. Condition Monitoring of Generators & Other Subassemblies in Wind Turbine Drive Trains. In Proceedings of the IEEE International Symposium on Diagnostics for Electric Machines, Cracow, Poland, 6–8 September 2007. [Google Scholar]

- Eftekharnejad, B.; Addali, A.; Mba, D. Shaft crack diagnostics in a gearbox. Appl. Acoust. 2012, 73, 723–733. [Google Scholar] [CrossRef]

- Abusaad, S.; Benghozzi, A.; Smith, A. The Detection of Shaft Misalignments Using Motor Current Signals from a Sensorless Variable Speed Drive. Mech. Mach. Sci. 2014, 23, 173–182. [Google Scholar]

- Nie, M.; Wang, L. Review of Condition Monitoring and Fault Diagnosis Technologies for Wind Turbine Gearbox. Procedia CIRP 2013, 11, 287–290. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Qiu, Y.; Crabtree, C.J. Monitoring wind turbine gearboxes. Wind Energy 2013, 16, 728–740. [Google Scholar] [CrossRef]

- Sheng, S. Wind Turbine Gearbox Condition Monitoring Round Robin Study—Vibration Analysis. Off. Sci. Tech. Inf. Tech. Rep. 2012, 68, 856–860. [Google Scholar]

- Zhong, X.Y.; Zeng, L.C.; Zhao, C.H. Research of Condition Monitoring and Fault Diagnosis Techniques for Wind Turbine Gearbox. Appl. Mech. Mater. 2012, 197, 206–210. [Google Scholar] [CrossRef]

- Qin, H.W.; Cao, F.C.; Fan, Q.Y. Use of AE Testing Data for Condition Monitoring in Wind Turbine Gearbox. Adv. Mater. Res. 2014, 1070, 1893–1897. [Google Scholar] [CrossRef]

- Bell, R.N.; Mcwilliams, D.W.; O’Donnell, P. Report of Large Motor Reliability Survey of Industrial and Commercial Installations, Part I. IEEE Trans. Ind. Appl. 1985, 4, 853–864. [Google Scholar]

- Bell, R.N.; Mcwilliams, D.W.; O’Donnell, P. Report of Large Motor Reliability Survey of Industrial and Commercial Installations, Part II. IEEE Trans. Ind. Appl. 1985, 4, 865–872. [Google Scholar]

- Bell, R.N.; Mcwilliams, D.W.; O’Donnell, P. Report of Large Motor Reliability Survey of Industrial and Commercial Installations, Part III. IEEE Trans. Ind. Appl. 1987, 23, 153–158. [Google Scholar]

- Albrecht, P.F.; Appiarius, J.C.; Mccoy, R.M. Assessment of the Reliability of Motors in Utility Applications —Updated. IEEE Trans. Energy Convers. 1986, 1, 39–46. [Google Scholar] [CrossRef]

- Zhang, P.; Du, Y.; Habetler, T.G. A Survey of Condition Monitoring and Protection Methods for Medium-Voltage Induction Motors. IEEE Trans. Ind. Appl. 2011, 47, 34–46. [Google Scholar] [CrossRef]

- Zarei, J.; Poshtan, J. Bearing fault detection using wavelet packet transform of induction motor stator current. Tribol. Int. 2007, 40, 763–769. [Google Scholar] [CrossRef]

- Chen, J.; Pan, J.; Li, Z. Generator bearing fault diagnosis for wind turbine via empirical wavelet transform using measured vibration signals. Renew. Energy 2016, 89, 80–92. [Google Scholar] [CrossRef]

- Wang, J.; Peng, Y.; Qiao, W. Current-Aided Order Tracking of Vibration Signals for Bearing Fault Diagnosis of Direct-Drive Wind Turbines. IEEE Trans. Ind. Electron. 2016, 63, 6336–6346. [Google Scholar] [CrossRef]

- Yang, B.; Liu, R.; Chen, X. Fault Diagnosis for Wind Turbine Generator Bearing via Sparse Representation and Shift-invariant K-SVD. IEEE Trans. Ind. Inform. 2017, 13, 1321–1331. [Google Scholar] [CrossRef]

- Amirat, Y.; Choqueuse, V.; Benbouzid, M. EEMD-based wind turbine bearing failure detection using the generator stator current homopolar component. Mech. Syst. Signal Process. 2013, 41, 667–678. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Zhao, Y.; Jia, W. Fault diagnosis based on current signature analysis for stator winding of Doubly Fed Induction Generator in wind turbine. In Proceedings of the International Symposium on Electrical Insulating Materials, Niigata, Japan, 1–5 June 2014. [Google Scholar]

- Shah, D.; Nandi, S.; Neti, P. Stator-Interturn-Fault Detection of Doubly Fed Induction Generators Using Rotor-Current and Search-Coil-Voltage Signature Analysis. IEEE Trans. Ind. Appl. 2008, 45, 1831–1842. [Google Scholar] [CrossRef]

- Abadi, M.B.; Cruz, S.M.A.; Gonçalves, A.P. Inter-turn fault detection in doubly-fed induction generators for wind turbine applications using the stator reactive power analysis. In Proceedings of the Renewable Power Generation Conference (RPG 2014), Naples, Italy, 24–25 September 2014. [Google Scholar]

- Zaher, A.; Mcarthur, S.D.J.; Infield, D.G. Online wind turbine fault detection through automated SCADA data analysis. Wind Energy 2009, 12, 574–593. [Google Scholar] [CrossRef]

- Ma, K.; Yang, Y.; Wang, H.; Blaabjerg, F. Design for reliability of power electronics in renewable energy systems. In Use, Operation and Maintenance of Renewable Energy Systems; Springer: Cham, Switzerland, 2014; pp. 295–338. [Google Scholar]

- Lu, B.; Sharma, S.K. A Literature Review of IGBT Fault Diagnostic and Protection Methods for Power Inverters. IEEE Trans. Ind. Appl. 2009, 45, 1770–1777. [Google Scholar]

- Avenas, Y.; Dupont, L.; Baker, N. Condition Monitoring: A Decade of Proposed Techniques. IEEE Ind. Electron. Mag. 2015, 9, 22–36. [Google Scholar] [CrossRef]

- Yang, S.; Xiang, D.; Bryant., A. Condition Monitoring for Device Reliability in Power Electronic Converters: A Review. IEEE Trans. Power Electron. 2010, 25, 2734–2752. [Google Scholar] [CrossRef]

- Xue, S.; Quan, Z.; Jian, L. Reliability evaluation for the DC-link capacitor considering mission profiles in wind power converter. In Proceedings of the IEEE International Conference on High Voltage Engineering & Application, Chengdu, China, 19–22 September 2016. [Google Scholar]

- Boettcher, M.; Reese, J.; Fuchs, F.W. Reliability comparison of fault-tolerant 3L-NPC based converter topologies for application in wind turbine systems. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013. [Google Scholar]

- Ghimire, P.; de Vega, A.R.; Beczkowski, S. Improving power converter reliability: Online monitoring of high-power IGBT modules. IEEE Ind. Electron. Mag. 2014, 8, 40–50. [Google Scholar] [CrossRef]

- Patil, N.; Das, D.; Goebel, K. Identification of failure precursor parameters for Insulated Gate Bipolar Transistors (IGBTs). In Proceedings of the International Conference on Prognostics & Health Management, Denver, CO, USA, 6–9 October 2008. [Google Scholar]

- Yang, L.; Agyakwa, P.A.; Johnson, C.M. Physics-of-Failure Lifetime Prediction Models for Wire Bond Interconnects in Power Electronic Modules. IEEE Trans. Device Mater. Reliab. 2013, 13, 9–17. [Google Scholar] [CrossRef]

- Xiang, D.; Ran, L.; Tavner, P. Condition monitoring power module solder fatigue using inverter harmonic identification. IEEE Trans. Power Electron. 2011, 27, 235–247. [Google Scholar] [CrossRef]

- Siegel, D.; Zhao, W.; Lapira, E. A comparative study on vibration-based condition monitoring algorithms for wind turbine drive trains. Wind Energy 2014, 17, 695–714. [Google Scholar] [CrossRef]

- Igba, J.; Alemzadeh, K.; Durugbo, C. Analysing RMS and peak values of vibration signals for condition monitoring of wind turbine gearboxes. Renew. Energy 2016, 91, 90–106. [Google Scholar] [CrossRef] [Green Version]

- Joshuva, A.; Sugumaran, V. A data driven approach for condition monitoring of wind turbine blade using vibration signals through best-first tree algorithm and functional trees algorithm: A comparative study. ISA Trans. 2017, 67, 160–172. [Google Scholar] [CrossRef] [PubMed]

- Abouhnik, A.A. An Investigation into Vibration Based Techniques for Wind Turbine Blades Condition Monitoring; Manchester Metropolitan University: Manchester, UK, 2014. [Google Scholar]

- Yang, W.; Court, R.; Tavner, P.J. Bivariate empirical mode decomposition and its contribution to wind turbine condition monitoring. J. Sound Vib. 2011, 330, 3766–3782. [Google Scholar] [CrossRef]

- Perišić, N.; Kirkegaard, P.H.; Pedersen, B.J. Cost-effective shaft torque observer for condition monitoring of wind turbines. Wind Energy 2015, 18, 1–19. [Google Scholar] [CrossRef]

- Gong, X. Online Nonintrusive Condition Monitoring and Fault Detection for Wind Turbines; University of Nebraska Lincoln: Lincoln, Nebraska, 2012. [Google Scholar]

- Guo, P.; Infield, D.; Yang, X. Wind Turbine Generator Condition-Monitoring Using Temperature Trend Analysis. IEEE Trans. Sustain. Energy 2011, 3, 124–133. [Google Scholar] [CrossRef]

- Garcia, M.C.; Sanz-Bobi, M.A.; Pico, J.D. SIMAP: Intelligent System for Predictive Maintenance: Application to the health condition monitoring of a wind turbine gearbox. Comput. Ind. 2006, 57, 552–568. [Google Scholar] [CrossRef]

- Abdusamad, K.B.; Gao, D.W.; Muljadi, E. A condition monitoring system for wind turbine generator temperature by applying multiple linear regression model. In Proceedings of the North American Power Symposium, Manhattan, KS, USA, 22–24 September 2013. [Google Scholar]

- Tonks, O.; Wang, Q. The detection of wind turbine shaft misalignment using temperature monitoring. CIRP J. Manuf. Sci. Technol. 2017, 17, 71–79. [Google Scholar] [CrossRef] [Green Version]

- Cheng, S.; Du, Y.; Restrepo, J.A. A Nonintrusive Thermal Monitoring Method for Induction Motors Fed by Closed-Loop Inverter Drives. IEEE Trans. Power Electron. 2012, 27, 4122–4131. [Google Scholar] [CrossRef]

- Wu, X.; Li, Y.; Li, F. Adaptive Estimation-Based Leakage Detection for a Wind Turbine Hydraulic Pitching System. IEEE-ASME Trans. Mechatron. 2015, 17, 907–914. [Google Scholar] [CrossRef]

- Coronado, D.; Kupferschmidt, C. Assessment and Validation of Oil Sensor Systems for On-line Oil Condition Monitoring of Wind Turbine Gearboxes. Procedia Technol. 2014, 15, 748–755. [Google Scholar] [CrossRef]

- Sheng, S. Monitoring of Wind Turbine Gearbox Condition through Oil and Wear Debris Analysis: A Full-Scale Testing Perspective. Tribol. Trans. 2015, 59, 149–162. [Google Scholar] [CrossRef]

- Zhu, J.; Yoon, J.M.; He, D. Online particle-contaminated lubrication oil condition monitoring and remaining useful life prediction for wind turbines. Wind Energy 2015, 18, 1131–1149. [Google Scholar] [CrossRef]

- Cooley, J.W. An Algorithm for the machine calculation of complex Fourier series. Math. Comput. 1965, 19, 297–301. [Google Scholar] [CrossRef]

- Bodla, M.K.; Malik, S.M.; Rasheed, M.T. Logistic regression and feature extraction based fault diagnosis of main bearing of wind turbines. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), Hefei, China, 5–7 June 2016. [Google Scholar]

- Ibrahim, R.; Watson, S.J. Advanced Algorithms for Wind Turbine Condition Monitoring and Fault Diagnosis. In Proceedings of the Windeurope Summit, Hamburg, Germany, 27–29 September 2016. [Google Scholar]

- Lee, J.K.; Park, J.Y.; Oh, K.Y. Transformation algorithm of wind turbine blade moment signals for blade condition monitoring. Renew. Energy 2015, 79, 209–218. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Wilkinson, M. Condition monitoring and fault diagnosis of a wind turbine with a synchronous generator using wavelet transforms. In Proceedings of the 2008 4th IET Conference on Power Electronics, Machines and Drives, York, UK, 2–4 April 2008. [Google Scholar]

- Zhang, L.; Lang, Z.Q. Wavelet Energy Transmissibility Function and its Application to Wind Turbine Bearing Condition Monitoring. IEEE Trans. Sustain. Energy 2018, 9, 1833–1843. [Google Scholar] [CrossRef]

- Sapenabano, A.; Pinedasanchez, M.; PuchePanadero, R. Harmonic Order Tracking Analysis: A Novel Method for Fault Diagnosis in Induction Machines. IEEE Trans. Energy Convers. 2015, 30, 833–841. [Google Scholar] [CrossRef] [Green Version]

- Sapena-Bano, A.; Riera-Guasp, M.; Puche-Panadero, R. Harmonic Order Tracking Analysis: A Speed-Sensorless Method for Condition Monitoring of Wound Rotor Induction Generators. IEEE Trans. Ind. Appl. 2016, 52, 4719–4729. [Google Scholar] [CrossRef]

- Sapena-Bano, A.; Burriel-Valencia, J.; Pineda-Sanchez, M. The Harmonic Order Tracking Analysis Method for the Fault Diagnosis in Induction Motors under Time-Varying Conditions. IEEE Trans. Energy Convers. 2017, 32, 244–256. [Google Scholar] [CrossRef]

- Morshedizadeh, M. Condition Monitoring of Wind Turbines Using Intelligent Machine Learning Techniques; University of Hawai’i at Manoa: Honolulu, Hawaii, 2017. [Google Scholar]

- Ali, Y.H. Artificial Intelligence Application in Machine Condition Monitoring and Fault Diagnosis Artificial Intelligence-Emerging Trends and Applications; IntechOpen: Mosul, Iraq, 2018. [Google Scholar]

- Pattison, D.; Segovia Garcia, M.; Xie, W. Intelligent integrated maintenance for wind power generation. Wind Energy 2016, 19, 547–562. [Google Scholar] [CrossRef]

- Cheng, F.Z.; Qu, L.Y.; Qiao, W.; Hao, L. Enhanced Particle Filtering for Bearing Remaining Useful Life Prediction of Wind Turbine Drivetrain Gearboxes. IEEE Trans. Ind. Electron. 2019, 66, 4738–4748. [Google Scholar] [CrossRef]

- Durbhaka, G.K.; Selvaraj, B. Predictive maintenance for wind turbine diagnostics using vibration signal analysis based on collaborative recommendation approach. In Proceedings of the 2016 International Conference on Advances in Computing, Communications and Informatics (ICACCI), Jaipur, India, 21–24 September 2016. [Google Scholar]

- Lin, D.F.; Chen, P.H.; Williams, M. Measurement and Analysis of Current Signals for Gearbox Fault Recognition of Wind Turbine. Meas. Sci. Rev. 2013, 13, 89–93. [Google Scholar] [CrossRef]

- Gong, X.; Qiao, W. Bearing fault diagnosis for direct-drive wind turbines via current-demodulated signals. IEEE Trans. Ind. Electron. 2013, 60, 3419–3428. [Google Scholar] [CrossRef]

- Zhang, P.; Neti, P. Detection of Gearbox Bearing Defects Using Electrical Signature Analysis for Doubly Fed Wind Generators. IEEE Trans. Ind. Appl. 2014, 51, 2195–2200. [Google Scholar] [CrossRef]

| Major Components | IEEE-IAS % of Failures | EPRI % of Failures | Allianz % of Failures |

|---|---|---|---|

| Bearing related | 44 | 41 | 13 |

| Stator related | 26 | 36 | 66 |

| Rotor related | 8 | 9 | 13 |

| Others | 22 | 14 | 8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Lu, D. A Survey of Condition Monitoring and Fault Diagnosis toward Integrated O&M for Wind Turbines. Energies 2019, 12, 2801. https://doi.org/10.3390/en12142801

Zhang P, Lu D. A Survey of Condition Monitoring and Fault Diagnosis toward Integrated O&M for Wind Turbines. Energies. 2019; 12(14):2801. https://doi.org/10.3390/en12142801

Chicago/Turabian StyleZhang, Pinjia, and Delong Lu. 2019. "A Survey of Condition Monitoring and Fault Diagnosis toward Integrated O&M for Wind Turbines" Energies 12, no. 14: 2801. https://doi.org/10.3390/en12142801