A Portable Dynamic Laser Speckle System for Sensing Long-Term Changes Caused by Treatments in Painting Conservation

Abstract

:1. Introduction

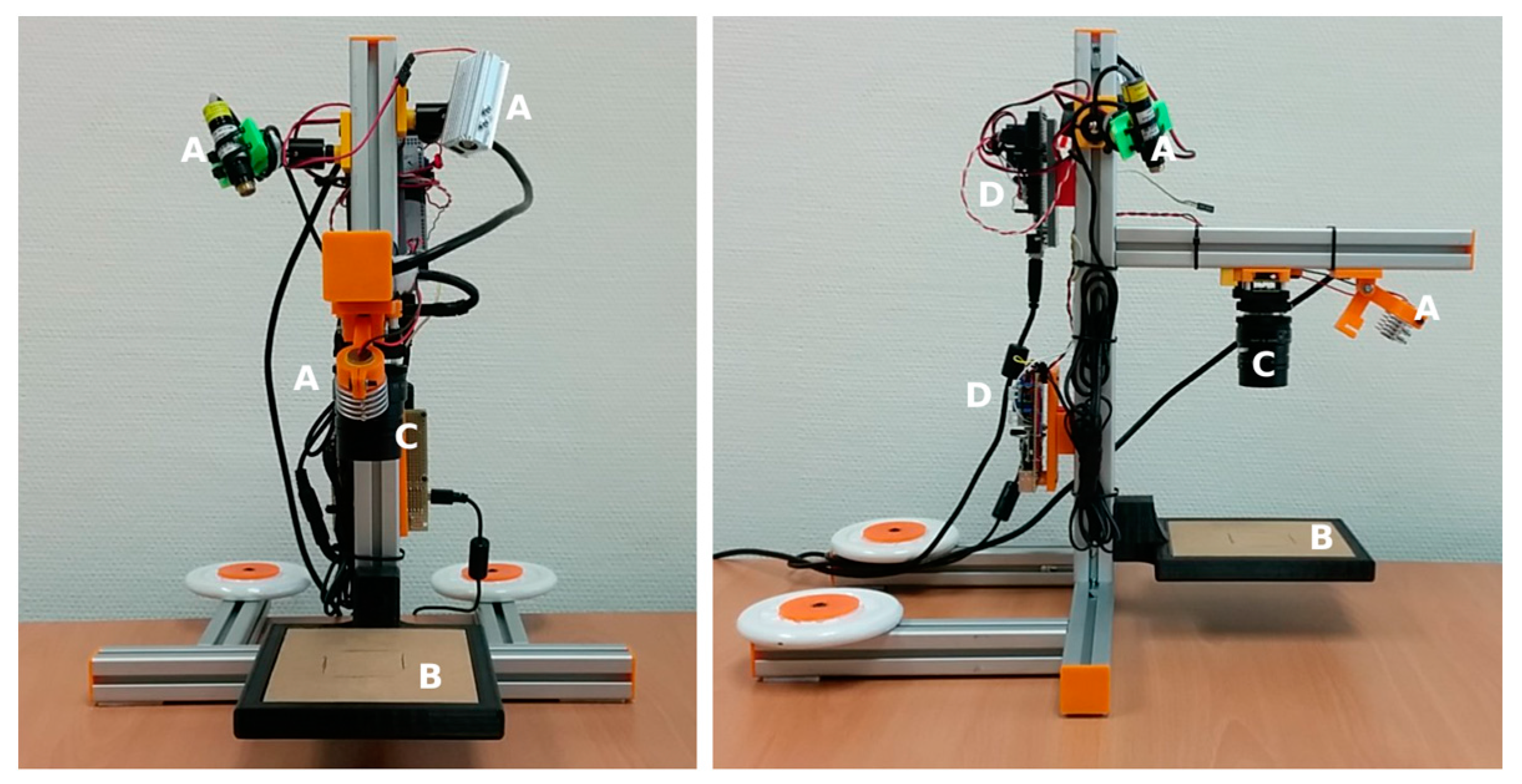

2. Design and Control of Portable System

2.1. Structural Design

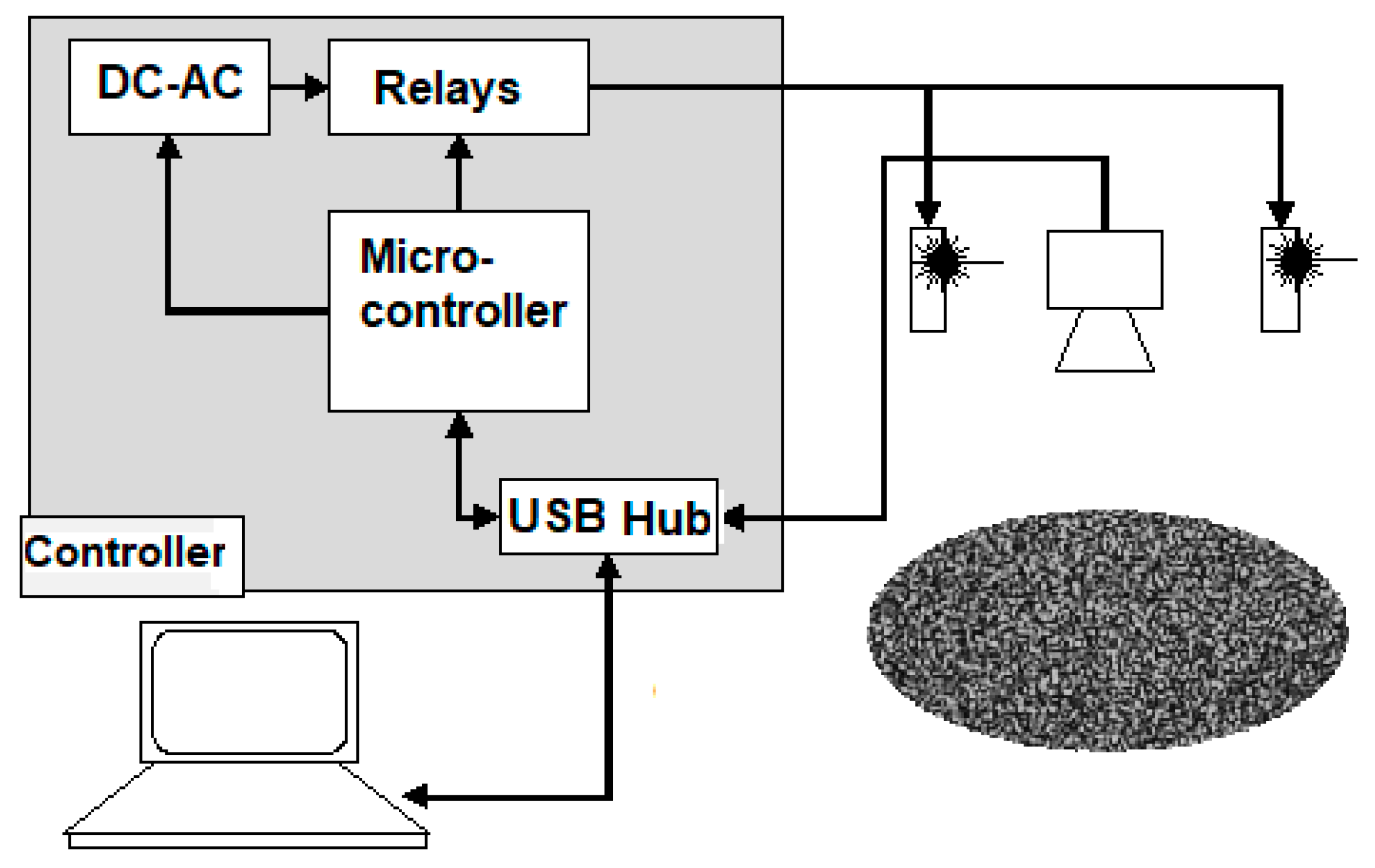

2.2. Electronic Design

3. Materials and Methods

3.1. Specimen

- -

- commercial acrylic resin varnish (Titan retouching varnish, INDUSTRIAS TITAN S.A., Barcelona, Spain, diluted in aliphatic and aromatic hydrocarbons).

- -

- cyclododecane: saturated and chemically stable cyclic hydrocarbon (C12H24). This chemical is applied in conservation treatments on a variety of surfaces as a temporary protector. It was used as a solution of 5 g in 10 mL of ligroin (an aliphatic hydrocarbon mixture).

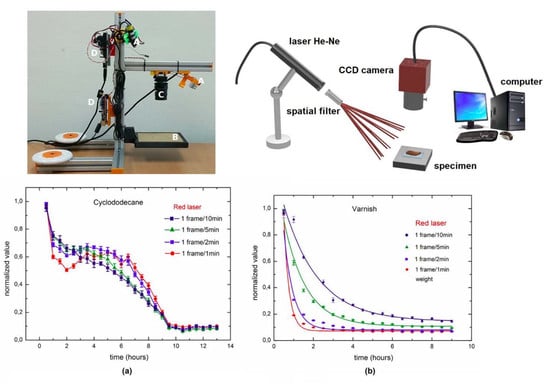

3.2. Experimental Setup Employed for Non-Portable Dynamic Laser Speckle

3.3. Protocol for Speckle Pattern Acquisition

- Set A: Capture of 20 images at 10 fps every minute (for fast dynamics).

- Sets B, C, D, E: Capture of {30, 15, 6, 3} images at {1 image every 1 min, 1 image every 2 min, 1 image every 5 min, 1 image every 10 min} every 30 min (for slow dynamics).

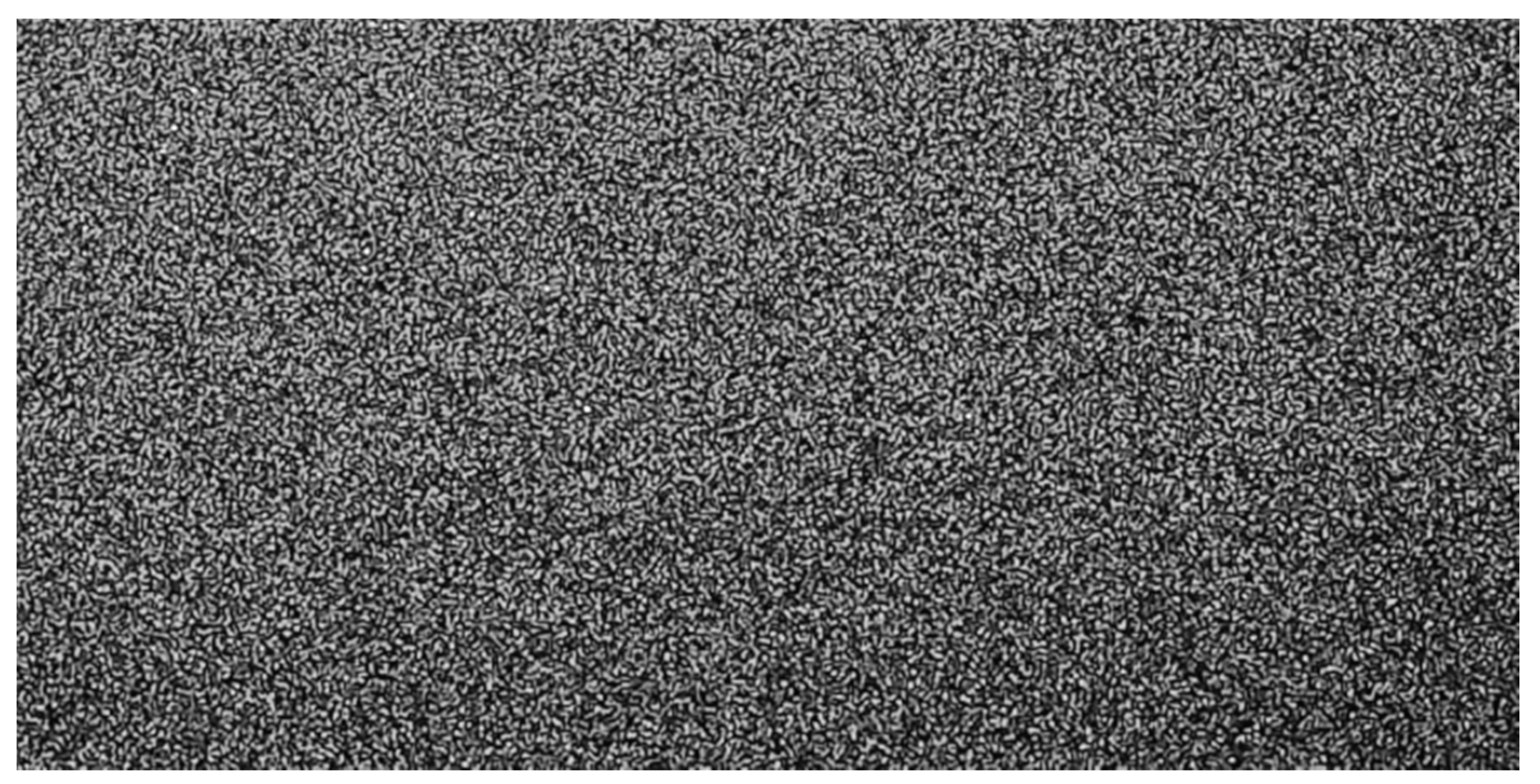

3.4. Methodology to Process Dynamic Speckle Images

4. Results

4.1. Validation of the Portable Device to Monitor Drying Processes in Painting Conservation

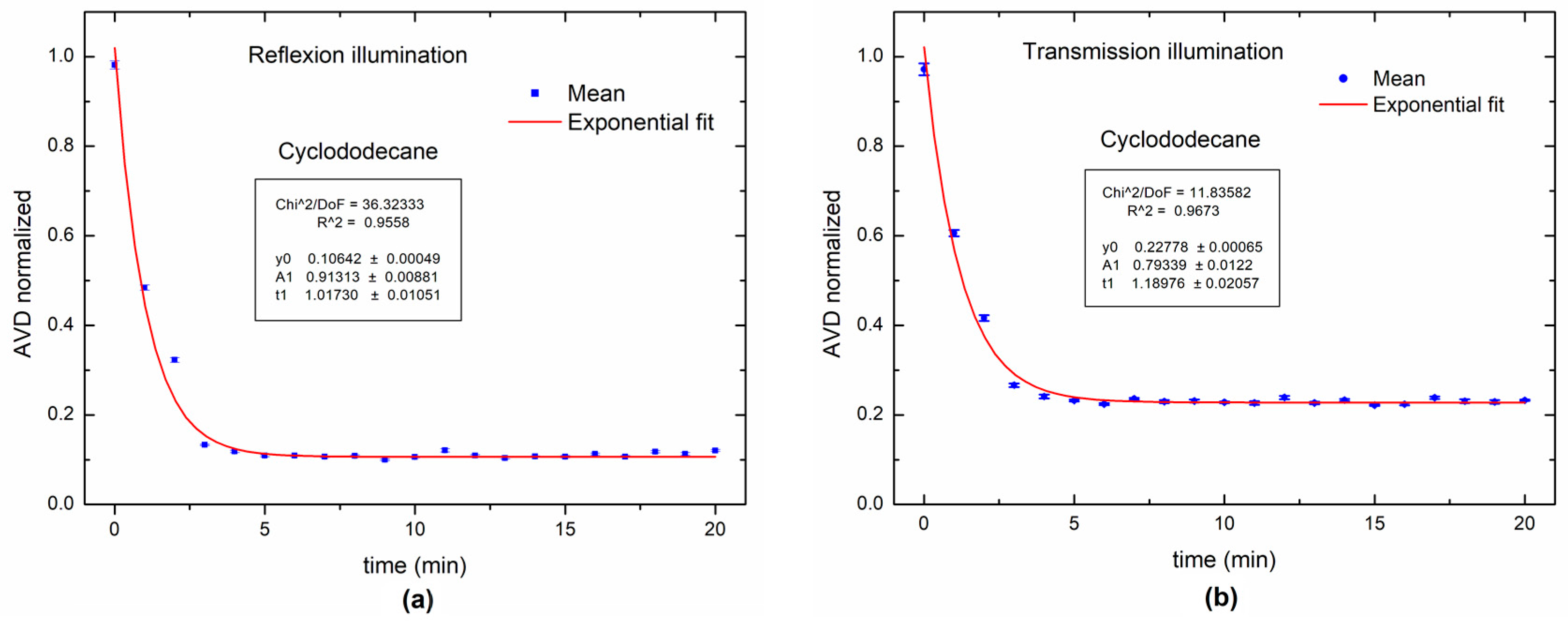

4.2. Comparison of Back and Forward Scattering Using the Portable Equipment

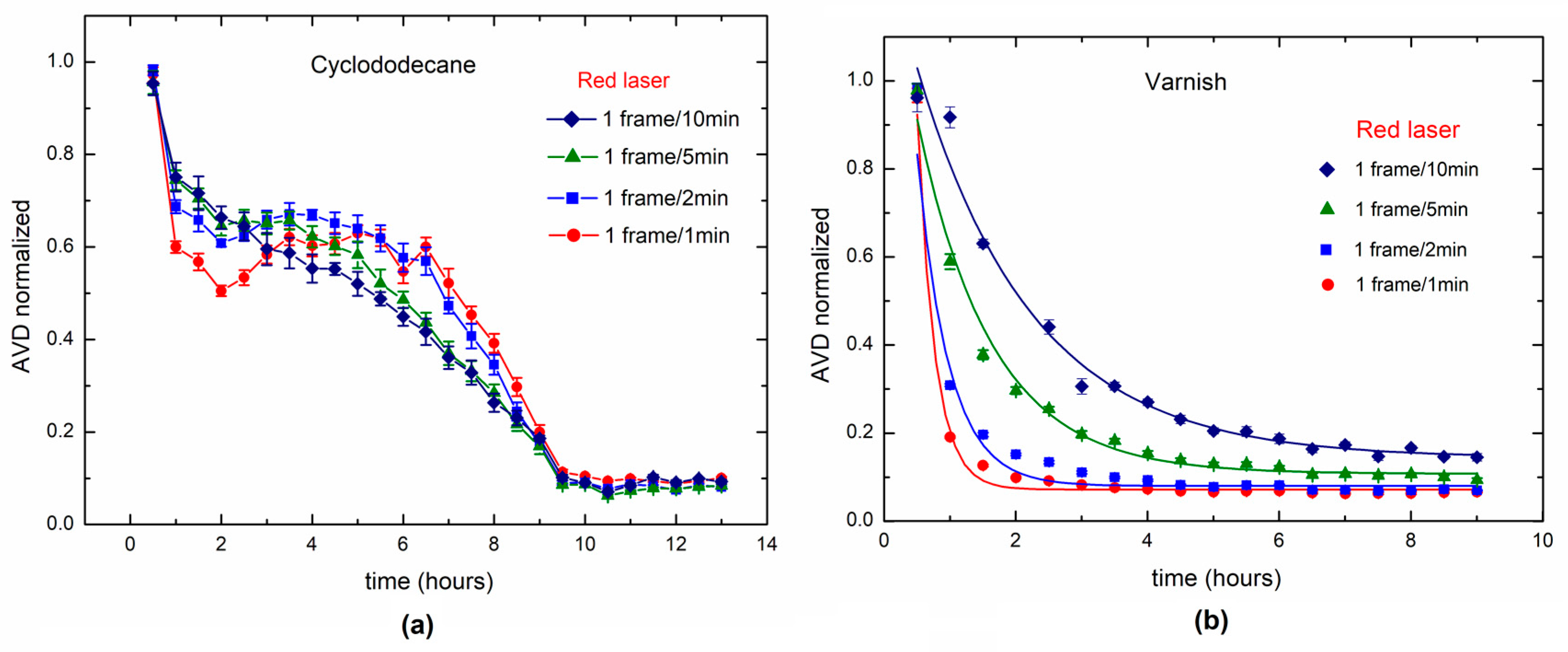

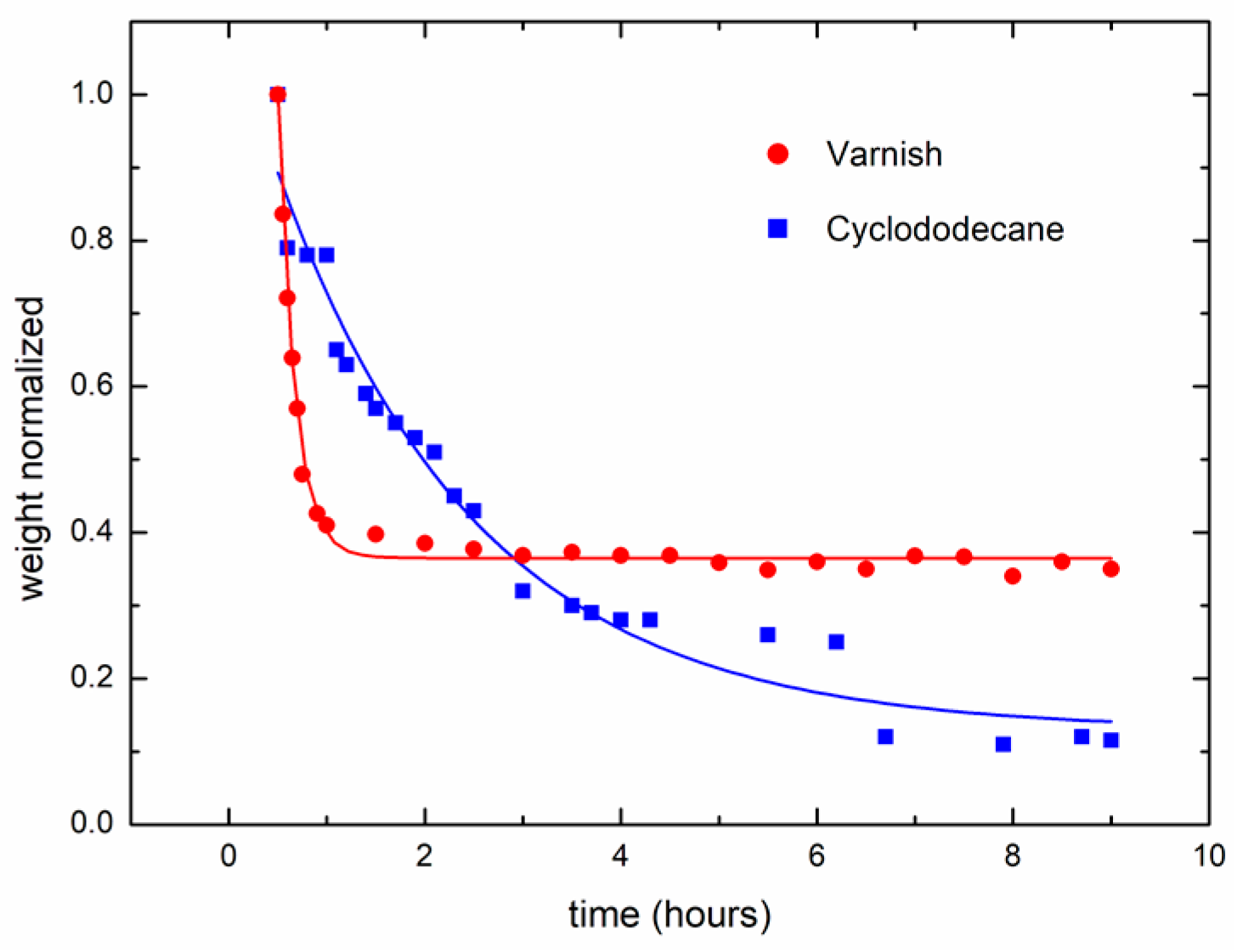

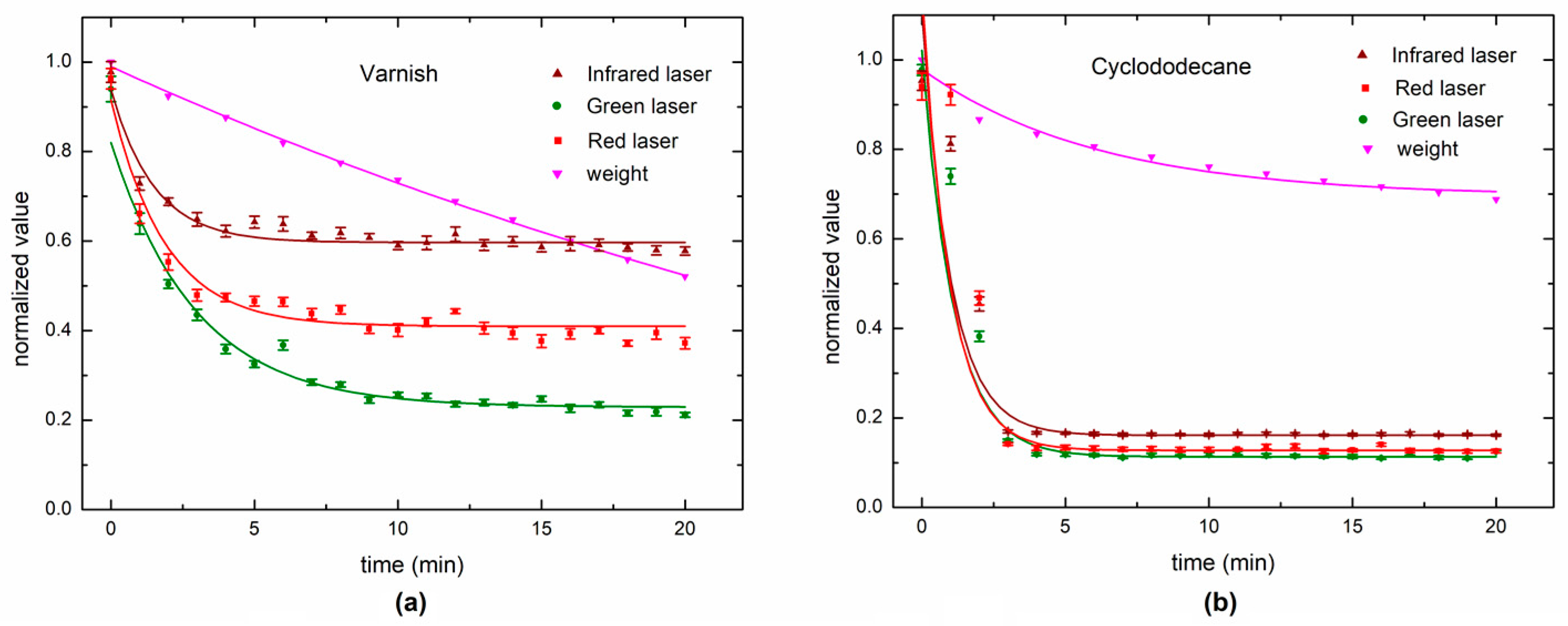

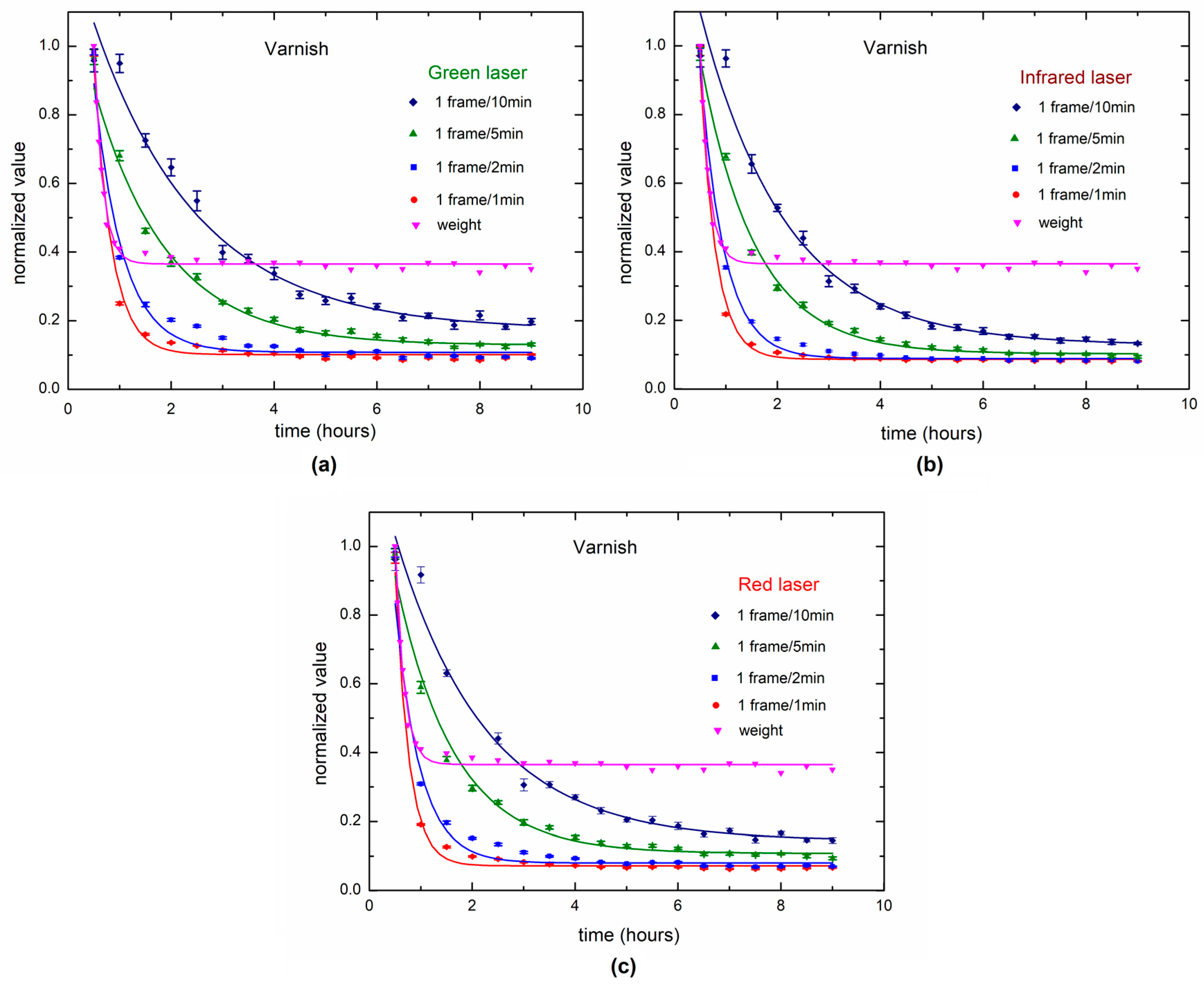

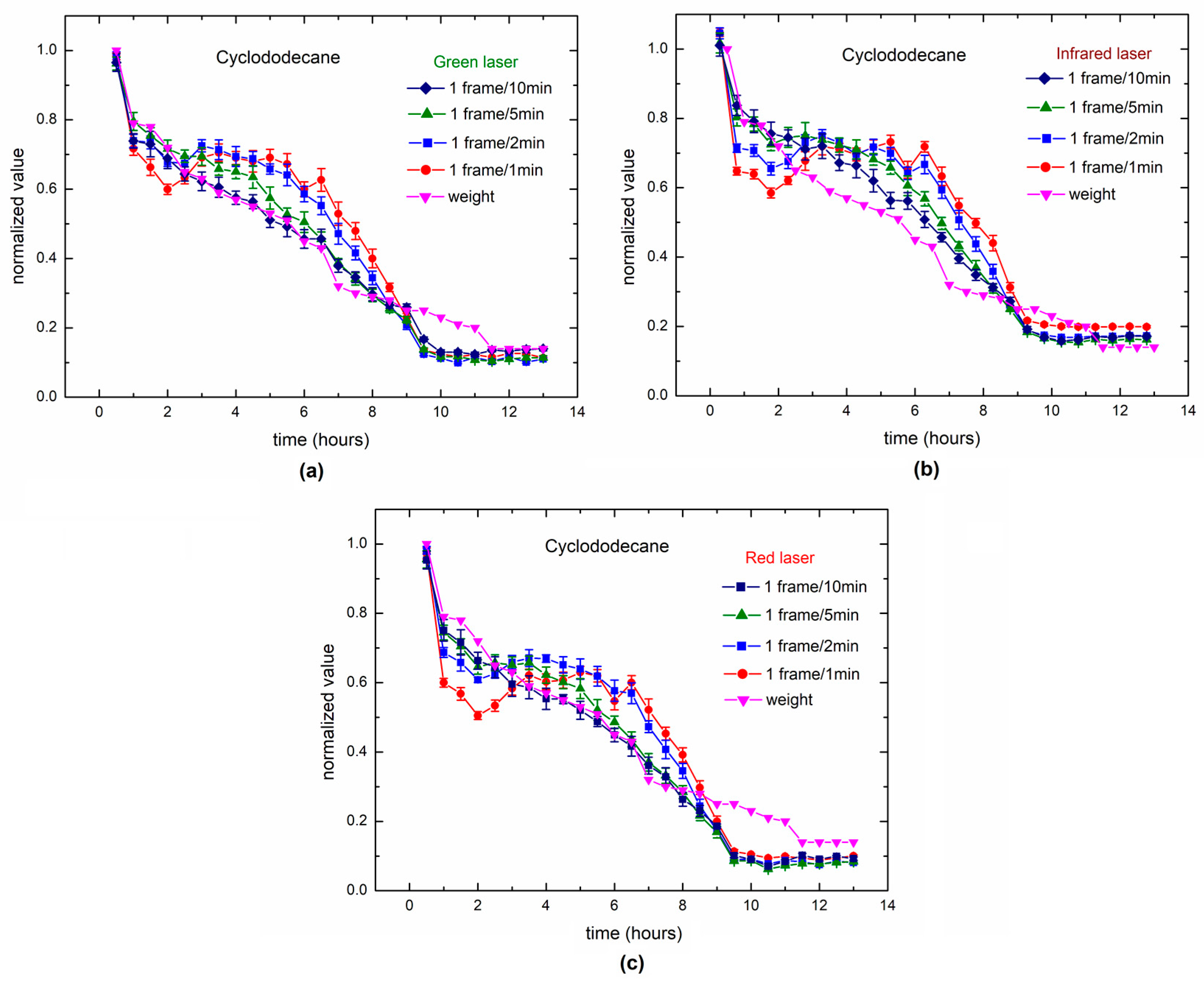

4.3. Third Experiment: Changes in Time Rate Using Different Lasers Compared to Weight

5. Discussion

5.1. Validation of the Portable Device for Monitor Drying Processes during Painting Conservation

5.2. Comparison of Back and Forward Scattering Using the Portable Equipment

5.3. Third Experiment: Changes in Time Rate Using Different Lasers Relative to Weight

6. Conclusions

Acknowledgments

Author contributions

Conflicts of interest

References

- Schnars, U.; Falldorf, C.; Watson, J.; Jüptner, W. Digital Holography and Wavefront Sensing; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Kim, M.K. Principles and techniques of digital holographic microscopy. SPIE Rev. 2010, 1, 018005. [Google Scholar] [CrossRef]

- Yokota, M.; Kawakami, T.; Kimoto, Y.; Yamaguchi, I. Drying process in a solvent-based paint analyzed by phase-shifting digital holography and an estimation of time for tack free. Appl. Opt. 2011, 50, 5834–5841. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, I.; Ida, T.; Yokota, M.; Kobayashi, K. Monitoring of Paint Drying Process by Phase-Shifting Digital Holography. In Adaptive Optics: Analysis and Methods/Computational Optical Sensing and Imaging/Information Photonics/Signal Recovery and Synthesis Topical Meetings on CD-ROM, Paper DWC2; Optical Society of America: Washington, DC, USA, 2007. [Google Scholar] [CrossRef]

- Krzemień, L.; Łukomski, M.; Kijowska, A.; Mierzejewska, B. Combining digital speckle pattern interferometry with shearography in a new instrument to characterize surface delamination in museum artefacts. J. Cult. Herit. 2015, 16, 544–550. [Google Scholar] [CrossRef]

- Lasyk, L.; Lukomski, M.; Bratasz, L. Simple digital speckle pattern interferometer (DSPI) for investigation of art objects. Opt. Appl. 2011, 41, 688–700. [Google Scholar]

- Trumpy, G.; Conover, D.; Simonot, L.; Thoury, M.; Picollo, M.; Delaney, J.K. Experimental study on merits of virtual cleaning of paintings with aged Varnish. Opt. Express 2015, 23, 33836–33848. [Google Scholar] [CrossRef] [PubMed]

- Reifsnyder, J.M. A note on a traditional technique of Varnish application for paintings on panel. Stud. Conserv. 1996, 41, 120–122. [Google Scholar] [CrossRef]

- Caley, T. Aspects of Varnishes and the Cleaning of Oil Paintings Before 1700. Stud. Conserv. 1990, 35, 70–72. [Google Scholar] [CrossRef]

- Brückle, I.; Thornton, J.; Nichols, K.; Strickler, G. Cyclododecane: Technical Note on Some Uses in Paper and Objects Conservation. J. Am. Inst. Conserv. 1999, 38, 162–175. [Google Scholar] [CrossRef]

- Rowe, S.; Rozeik, C. The uses of cyclododecane in conservation. Stud. Conserv. 2008, 53, 17–31. [Google Scholar] [CrossRef]

- Maish, J.P.; Risser, E. A case study in the use of cyclododecane and latex rubber in the molding of marble. J. Am. Inst. Conserv. 2002, 41, 127–137. [Google Scholar] [CrossRef]

- Lenk, R.S.; Fellers, J.F.; White, J.L. Comparative Study of Polyamides from Bisacid A2. Polym. J. 1977, 9, 9–17. [Google Scholar] [CrossRef]

- Koleske, J.V. Paint and Coating Testing Manual, 15th ed.; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Carvalho, P.H.A.; Barreto, J.B.; Braga, R.A., Jr.; Rabelo, G.F. Motility parameters assessment of bovine frozen semen by biospeckle laser (BSL) system. Biosyst. Eng. 2009, 102, 31–35. [Google Scholar] [CrossRef]

- Richards, L.M.; Kazmi, S.M.S.; Davis, J.L.; Olin, K.E.; Dunn, A.K. Low-cost laser speckle contrast imaging of blood flow using a webcam. Biomed. Opt. Express 2013, 4, 2269–2283. [Google Scholar] [CrossRef] [PubMed]

- Ganilova, Y.A.; Ulyanov, S.S. A study of blood flow in microvessels using biospeckle dynamics. Biophysics 2006, 51, 299–304. [Google Scholar] [CrossRef]

- Murialdo, S.E.; Sendra, G.H.; Passoni, L.I.; Arizaga, R.; Gonzalez, J.F.; Rabal, H.; Trivi, M. Analysis of bacterial chemotactic response using dynamic laser speckle. J. Biomed. Opt. 2009, 14, 064015. [Google Scholar] [CrossRef] [PubMed]

- González-Peña, R.J.; Braga, J.; Roberto, A.; Cibrián, R.M.; Salvador-Palmer, R.; Gil-Benso, R.; Miguel, T.S. Monitoring of the action of drugs in melanoma cells by dynamic laser speckle. J. Biomed. Opt. 2014, 19, 057008. [Google Scholar] [CrossRef] [PubMed]

- Arizaga, R.; Grumel, E.E.; Cap, N.; Trivi, M.; Amalvy, J.I.; Yepes, B.; Ricaurte, G. Following the drying of spray paints using space and time contrast of dynamic speckle. JCT Res. 2006, 3, 295–299. [Google Scholar] [CrossRef]

- Faccia, P.A.; Pardini, O.R.; Amalvy, J.I.; Cap, N.; Grumel, E.E.; Arizaga, R.; Trivi, M. Differentiation of the drying time of paints by dynamic speckle interferometry. Prog. Org. Coat. 2009, 64, 350–355. [Google Scholar] [CrossRef]

- Mavilio, A.; Fernández, M.; Trivi, M.; Rabal, H.; Arizaga, R. Characterization of a paint drying process through granulometric analysis of speckle dynamic patterns. Signal Process. 2010, 90, 1623–1630. [Google Scholar] [CrossRef]

- Budini, N.; Mulone, C.; Balducci, N.; Vincitorio, F.M.; López, A.J.; Ramil, A. Characterization of drying paint coatings by dynamic speckle and holographic interferometry measurements. Appl. Opt. 2016, 55, 4706–4712. [Google Scholar] [CrossRef] [PubMed]

- Brunel, L.; Brun, A.; Snabre, P. Microstructure movements study by dynamic speckle analysis. Int. Soc. Opt. Photonics 2006, 6341, 634127. [Google Scholar] [CrossRef]

- Braga, R.A. Challenges to apply the biospeckle laser technique in the field. Chem. Eng. Trans. 2017, 58, 577–582. [Google Scholar] [CrossRef]

- Braga, R.A.; González-Peña, R.J. Accuracy in dynamic laser speckle: Optimum size of speckles for temporal and frequency analyses. Opt. Eng. 2016, 55, 121702. [Google Scholar] [CrossRef]

- Moreira, J.; Cardoso, R.R.; Braga, R.A. Quality test protocol to dynamic laser speckle analysis. Opt. Lasers Eng. 2014, 61, 8–13. [Google Scholar] [CrossRef]

- Ansari, M.Z.; Nirala, A.K. Biospeckle numerical assessment followed by speckle quality tests. Opt. Int. J. Light Electron Opt. 2016, 127, 5825–5833. [Google Scholar] [CrossRef]

- Rabal, H.J.; Braga, R.A., Jr. Dynamic Laser Speckle and Applications; CRC Press: Broken Sound Parkway NW, FL, USA, 2008; ISBN 978-1-4200-6016-4. [Google Scholar]

- Oulamara, A.; Tribillon, G.; Duvernoy, J. Biological Activity Measurement on Botanical Specimen Surfaces Using a Temporal Decorrelation Effect of Laser Speckle. J. Mod. Opt. 1989, 36, 165–179. [Google Scholar] [CrossRef]

- Braga, R.A.; Nobre, C.M.B.; Costa, A.G.; Sáfadi, T.; da Costa, F.M. Evaluation of activity through dynamic laser speckle using the absolute value of the differences. Opt. Commun. 2011, 284, 646–650. [Google Scholar] [CrossRef]

- Narita, T.; Beauvais, C.; Hébraud, P.; Lequeux, F. Dynamics of concentrated colloidal suspensions during drying–aging, rejuvenation and overaging. Eur. Phys. J. 2004, 14, 287–292. [Google Scholar] [CrossRef] [PubMed]

- Puspasari, I.; Talib, M.Z.M.; Daub, W.R.W.; Tasirin, S.M. Characteristic Drying Curve of Oil Palm Fibers. Int. J. Adv. Sci. Eng. Inf. Technol. 2014, 4, 20–24. [Google Scholar] [CrossRef]

- Bellagha, S.; Amami, E.; Farhat, A.; Kechaou, N. Drying kinetics and characteristic drying curve of lightly salted sardine (Sardinella aurita). Dry. Tech. 2020, 20, 1527–1538. [Google Scholar] [CrossRef]

- Trivi, M. Dynamic Speckle: Origin and Features. In Dynamic Laser Speckle and Applications; CRC Press: Broken Sound Parkway NW, FL, USA, 2008. [Google Scholar]

- Kooij, H.M.; Fokink, R.; Gucht, J.; Sprackel, J. Quantitative imaging of heterogeneous dynamics in drying and aging paints. Sci. Rep. 2016, 6, 34383. [Google Scholar] [CrossRef] [PubMed]

- Vaz, P.; Pereira, T.; Figueiras, E.; Correia, C.; Humeau-Heurtier, A.; Cardoso, J. Which wavelength is the best for arterial pulse waveform extraction using laser speckle imaging? Biomed. Signal Proc. Control 2016, 25, 188–195. [Google Scholar] [CrossRef] [Green Version]

| Green Laser | Infrared Laser | Red Laser | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| y0 | A1 | t1 | % | y0 | A1 | t1 | % | y0 | A1 | t1 | % | |

| 1 image/1 min | 0.10 | 0.84 | 0.35 | 91.5 | 0.09 | 0.83 | 0.31 | 94.0 | 0.07 | 0.85 | 0.53 | 89.6 |

| 1 image/2 min | 0.11 | 0.79 | 0.55 | 93.6 | 0.09 | 0.85 | 0.47 | 97.4 | 0.08 | 0.75 | 0.96 | 91.6 |

| 1 image/5 min | 0.13 | 0.75 | 1.41 | 98.4 | 0.10 | 0.86 | 1.07 | 98.9 | 0.11 | 0.80 | 2.26 | 97.7 |

| 1 image/10 min | 0.17 | 0.90 | 2.04 | 98.2 | 0.13 | 0.97 | 1.67 | 98.7 | 0.14 | 0.89 | 3.50 | 98.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez, A.J.; González-Peña, R.J.; Braga Jr., R.; Perles, Á.; Pérez–Marín, E.; García-Diego, F.J. A Portable Dynamic Laser Speckle System for Sensing Long-Term Changes Caused by Treatments in Painting Conservation. Sensors 2018, 18, 190. https://doi.org/10.3390/s18010190

Pérez AJ, González-Peña RJ, Braga Jr. R, Perles Á, Pérez–Marín E, García-Diego FJ. A Portable Dynamic Laser Speckle System for Sensing Long-Term Changes Caused by Treatments in Painting Conservation. Sensors. 2018; 18(1):190. https://doi.org/10.3390/s18010190

Chicago/Turabian StylePérez, Alberto J., Rolando J. González-Peña, Roberto Braga Jr., Ángel Perles, Eva Pérez–Marín, and Fernando J. García-Diego. 2018. "A Portable Dynamic Laser Speckle System for Sensing Long-Term Changes Caused by Treatments in Painting Conservation" Sensors 18, no. 1: 190. https://doi.org/10.3390/s18010190

APA StylePérez, A. J., González-Peña, R. J., Braga Jr., R., Perles, Á., Pérez–Marín, E., & García-Diego, F. J. (2018). A Portable Dynamic Laser Speckle System for Sensing Long-Term Changes Caused by Treatments in Painting Conservation. Sensors, 18(1), 190. https://doi.org/10.3390/s18010190