Tilted Fiber Bragg Grating Sensor with Graphene Oxide Coating for Humidity Sensing

Abstract

:1. Introduction

2. Working Principle of the Graphene Oxide Humidity Sensor

3. Experiment

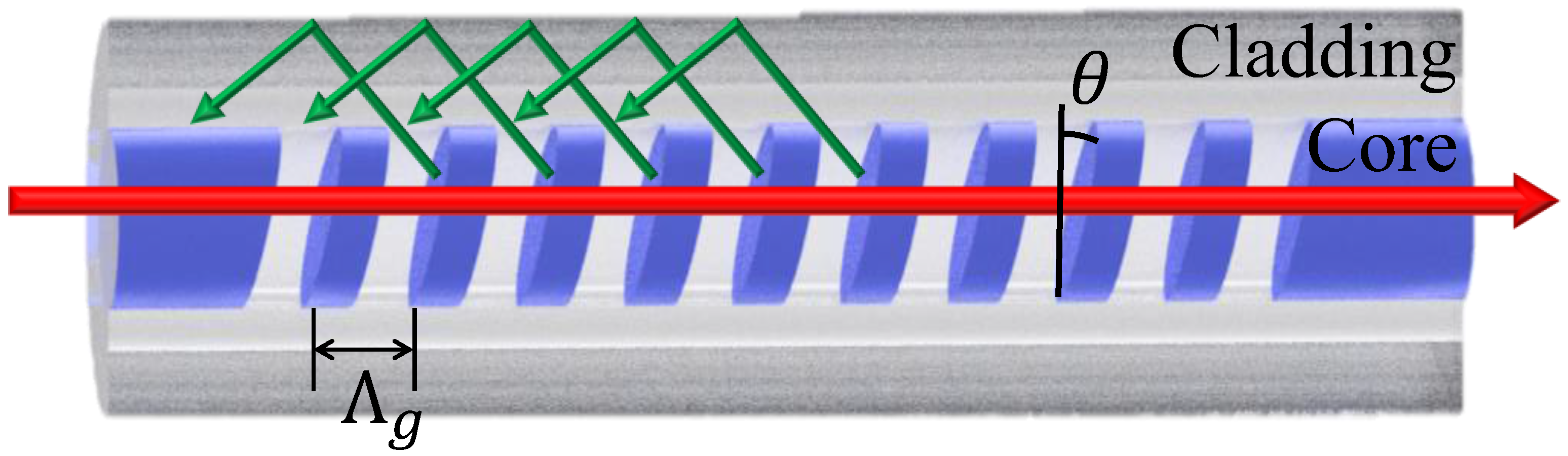

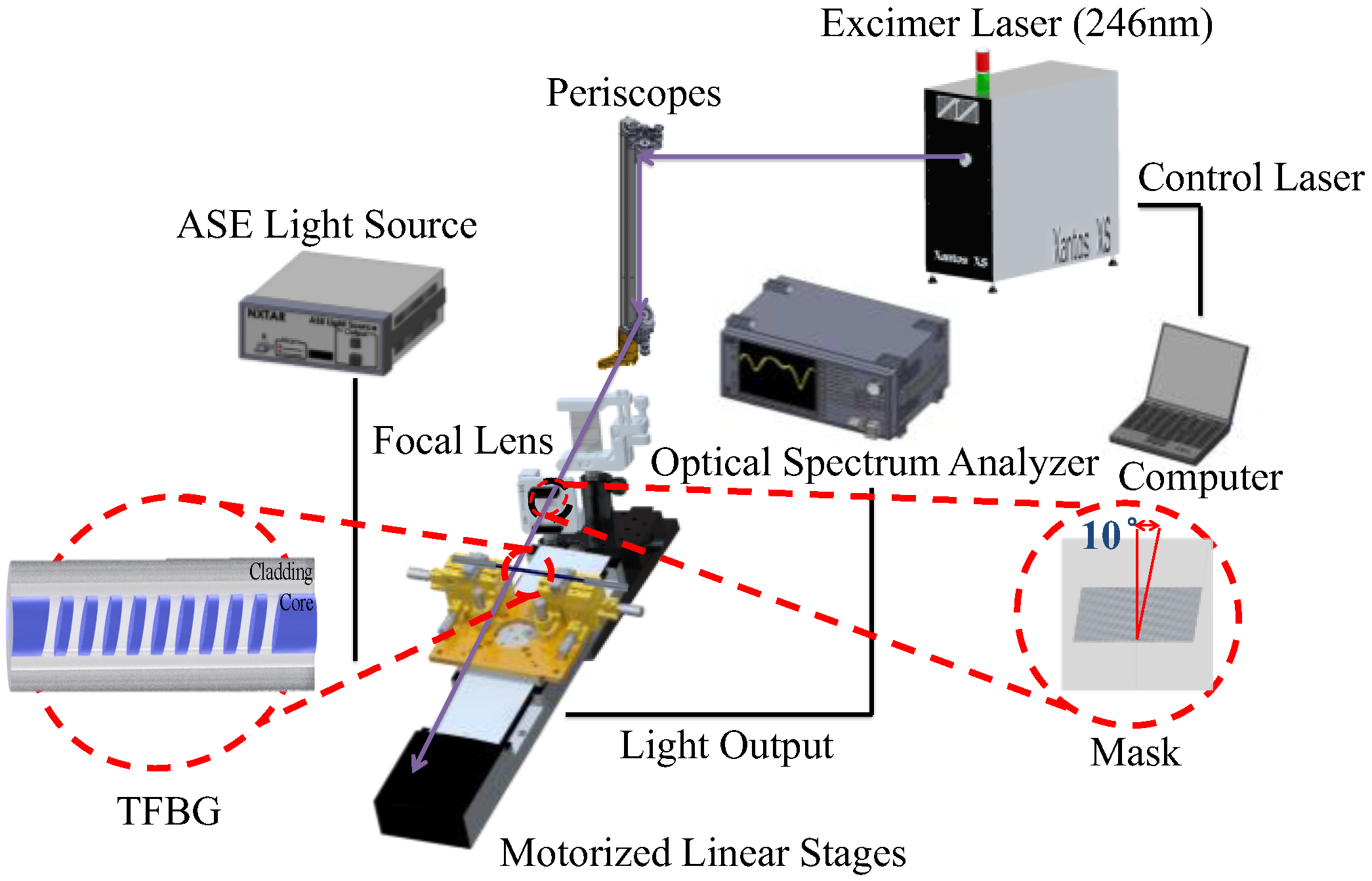

3.1. Processing and Fabrication of TFBG

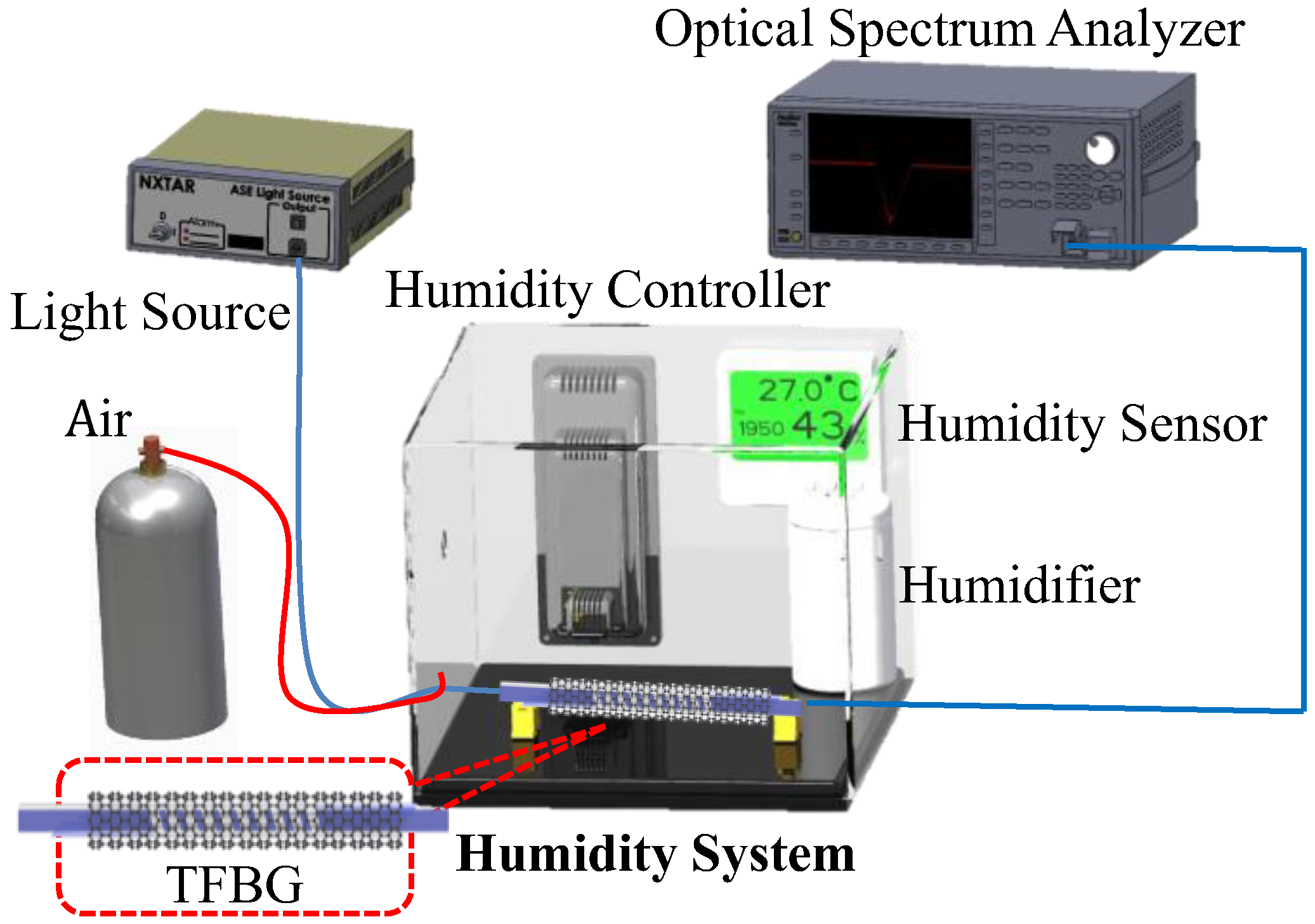

3.2. The Setup of the Humidity Sensing Experiment

4. Results and Discussion

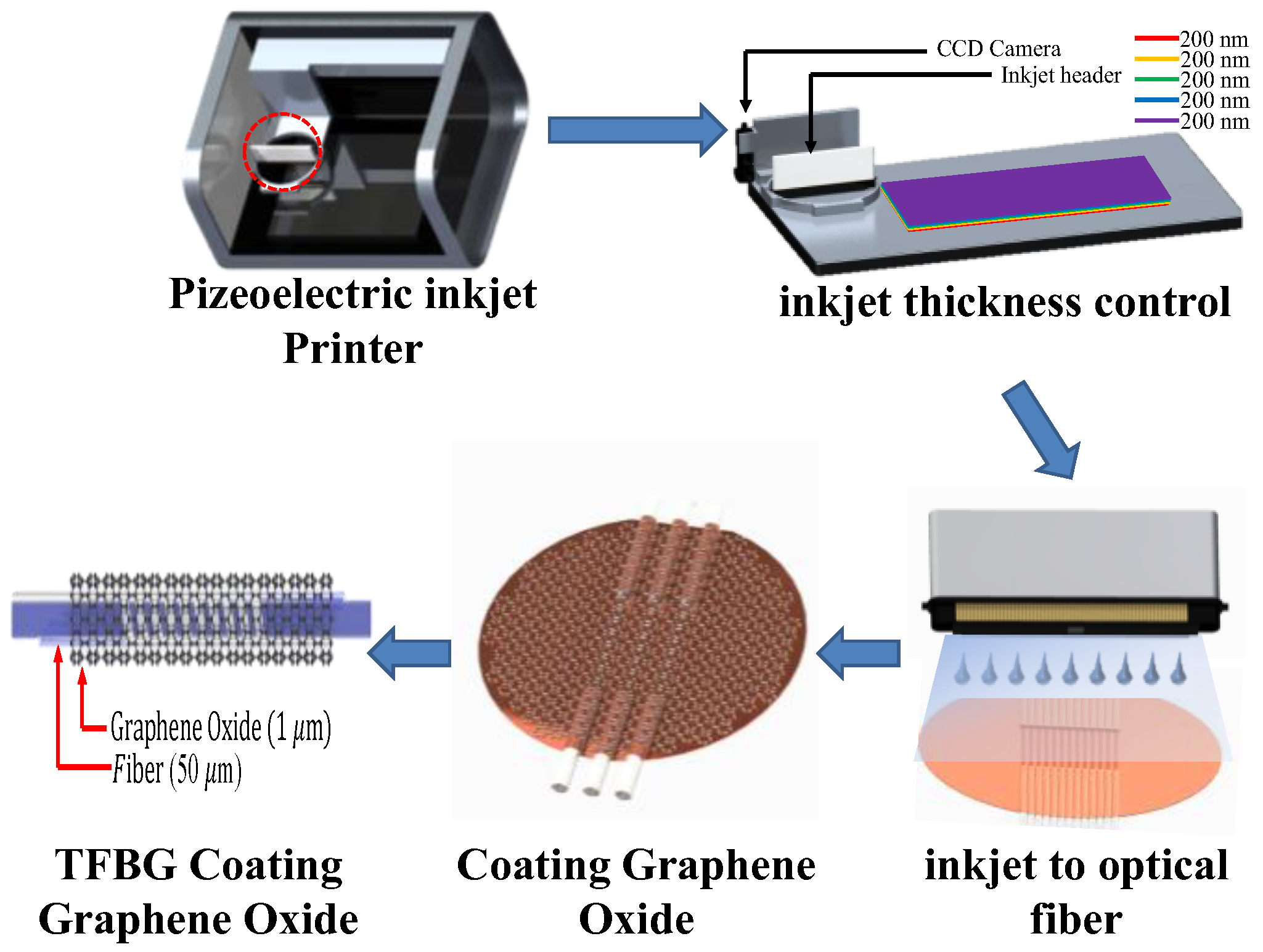

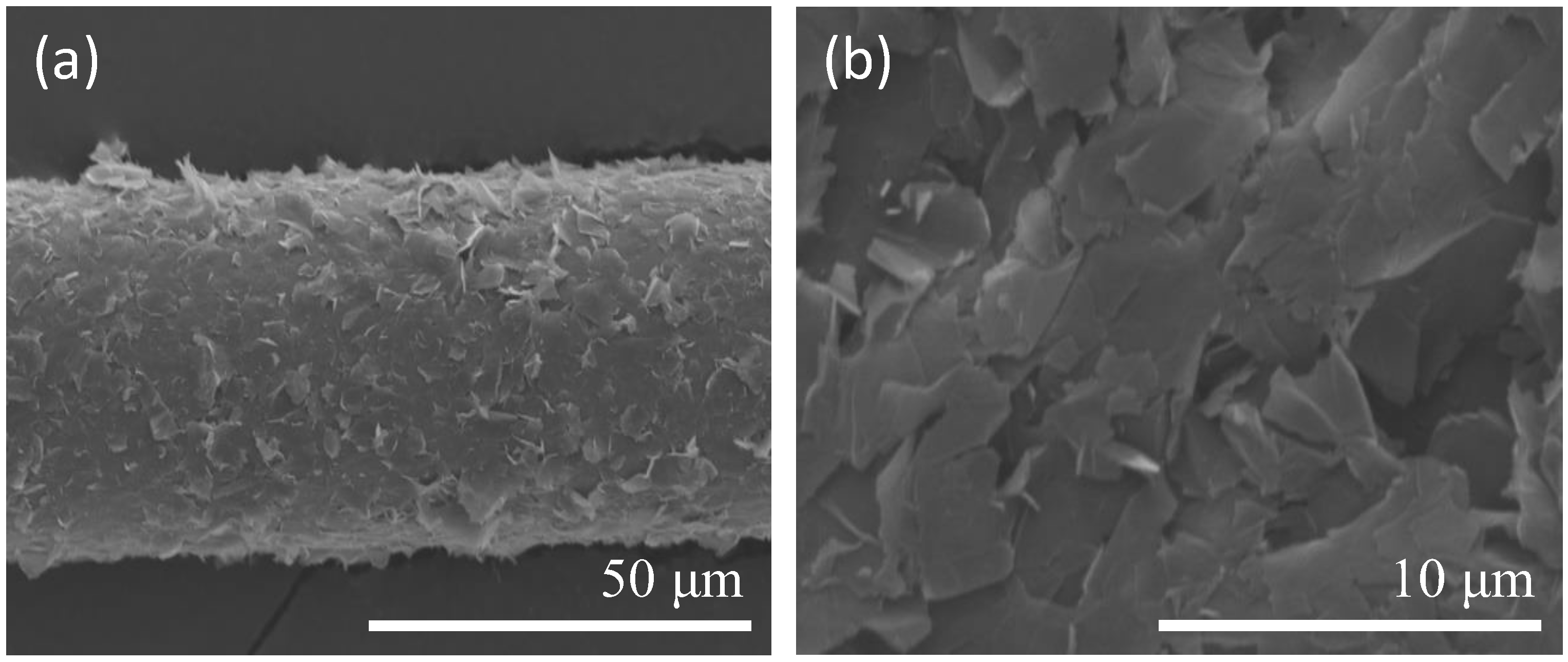

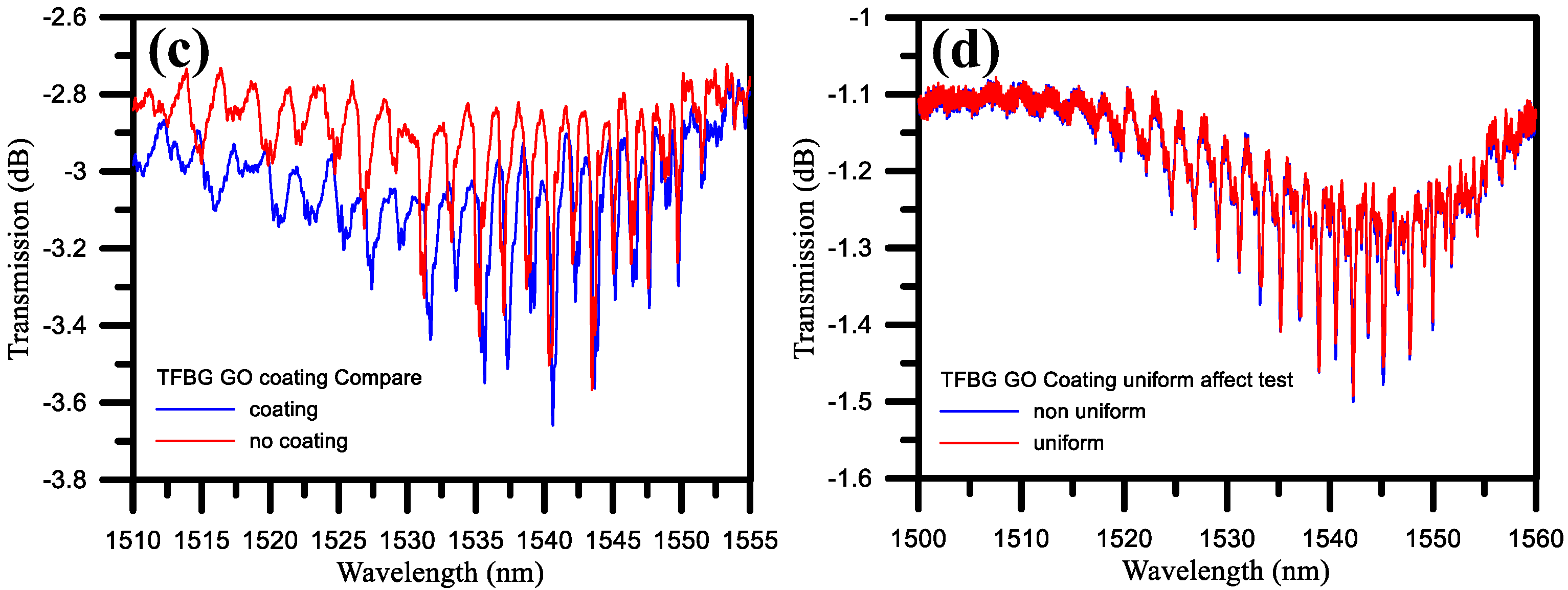

4.1. Graphene Oxide Film Coating

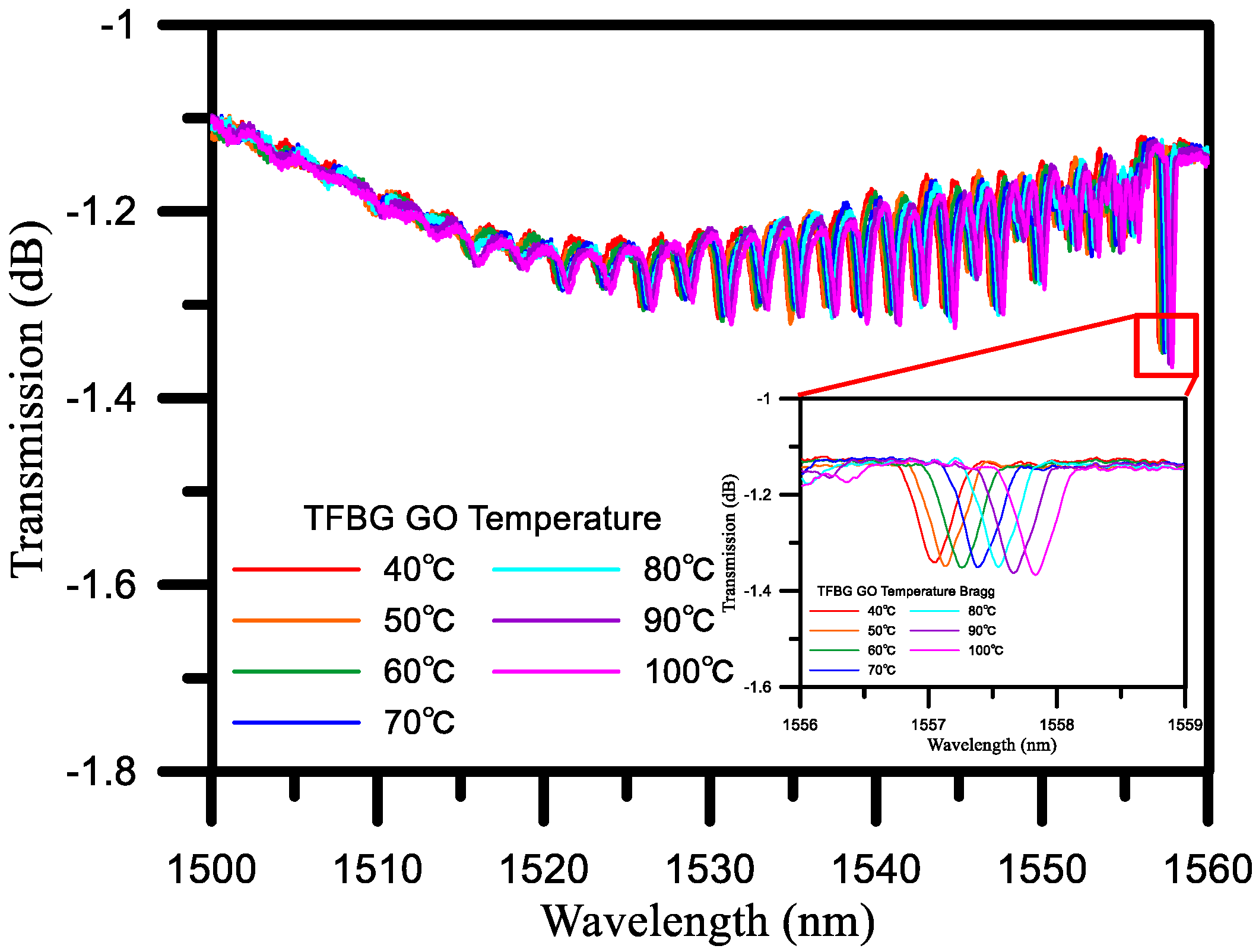

4.2. Temperature Response of the TFBG Sensor

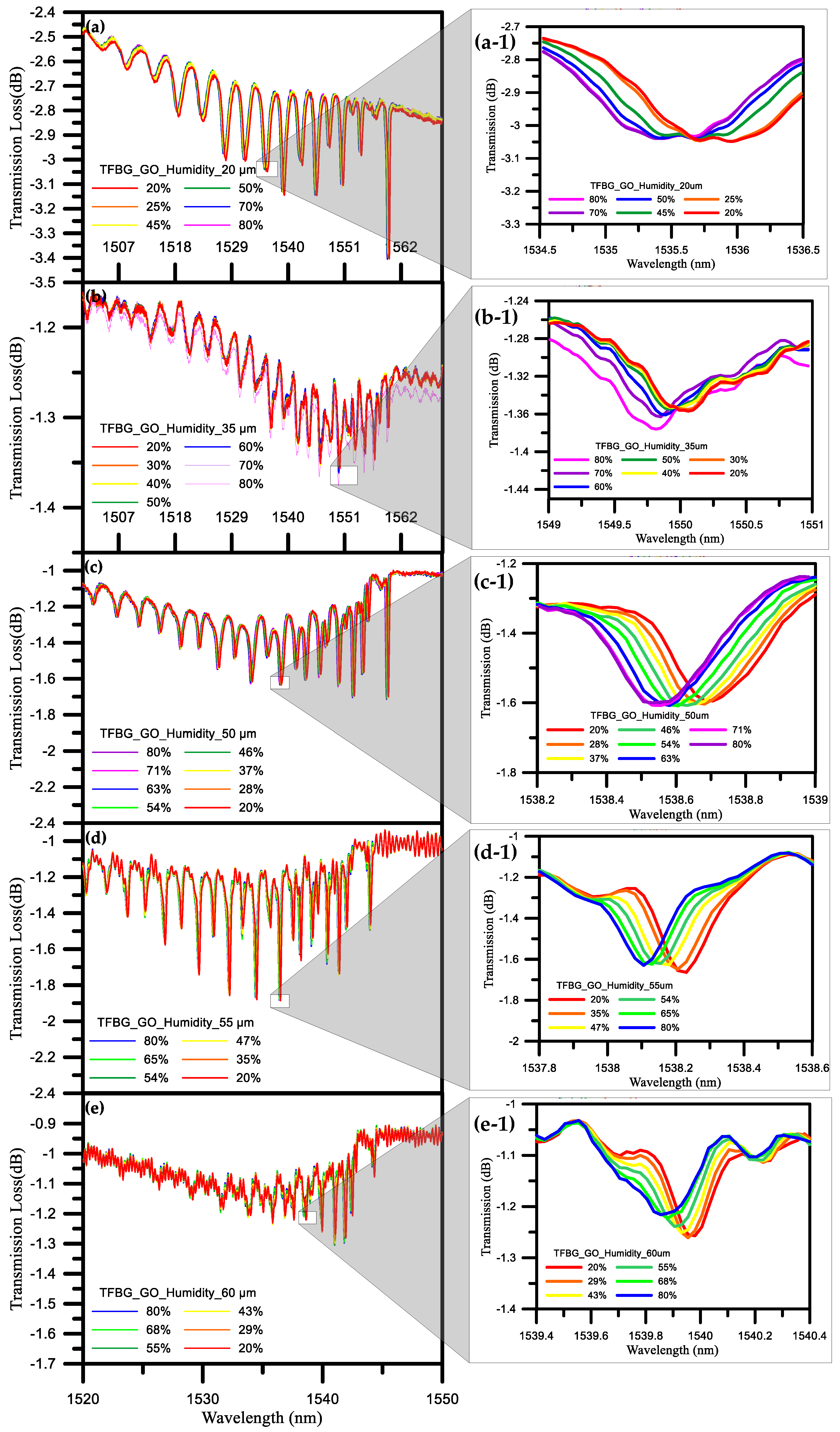

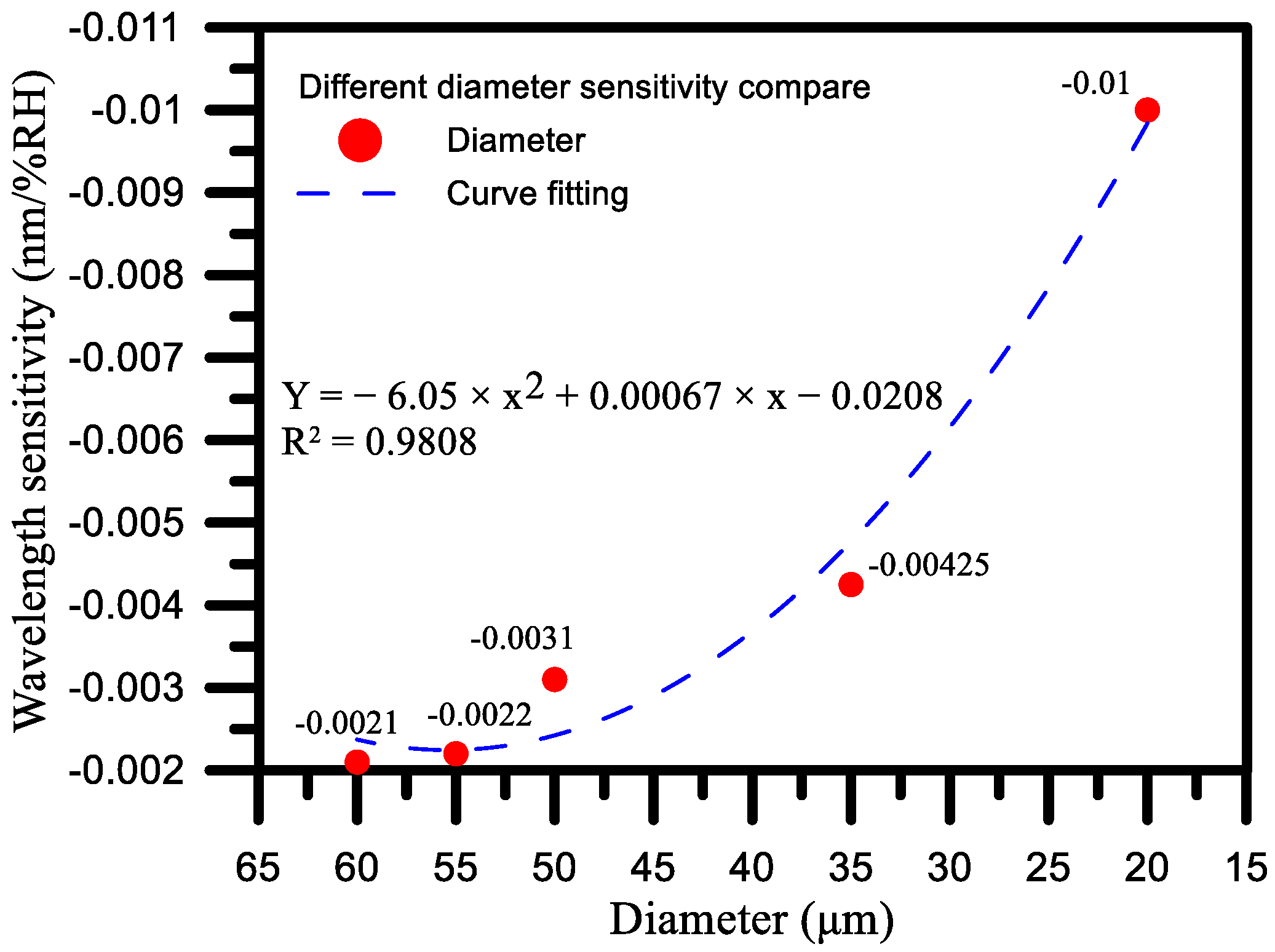

4.3. Comparison of Different Diameters

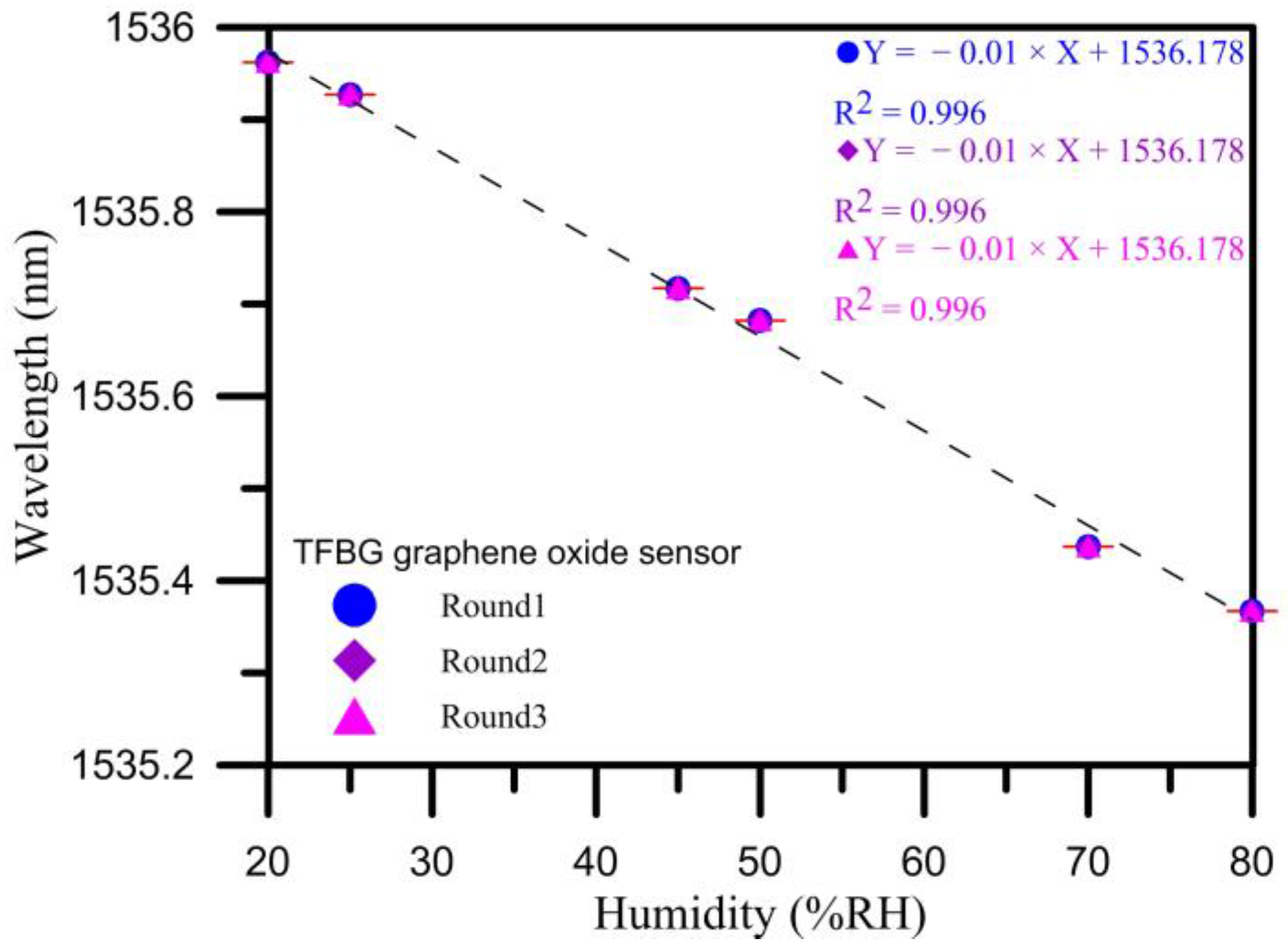

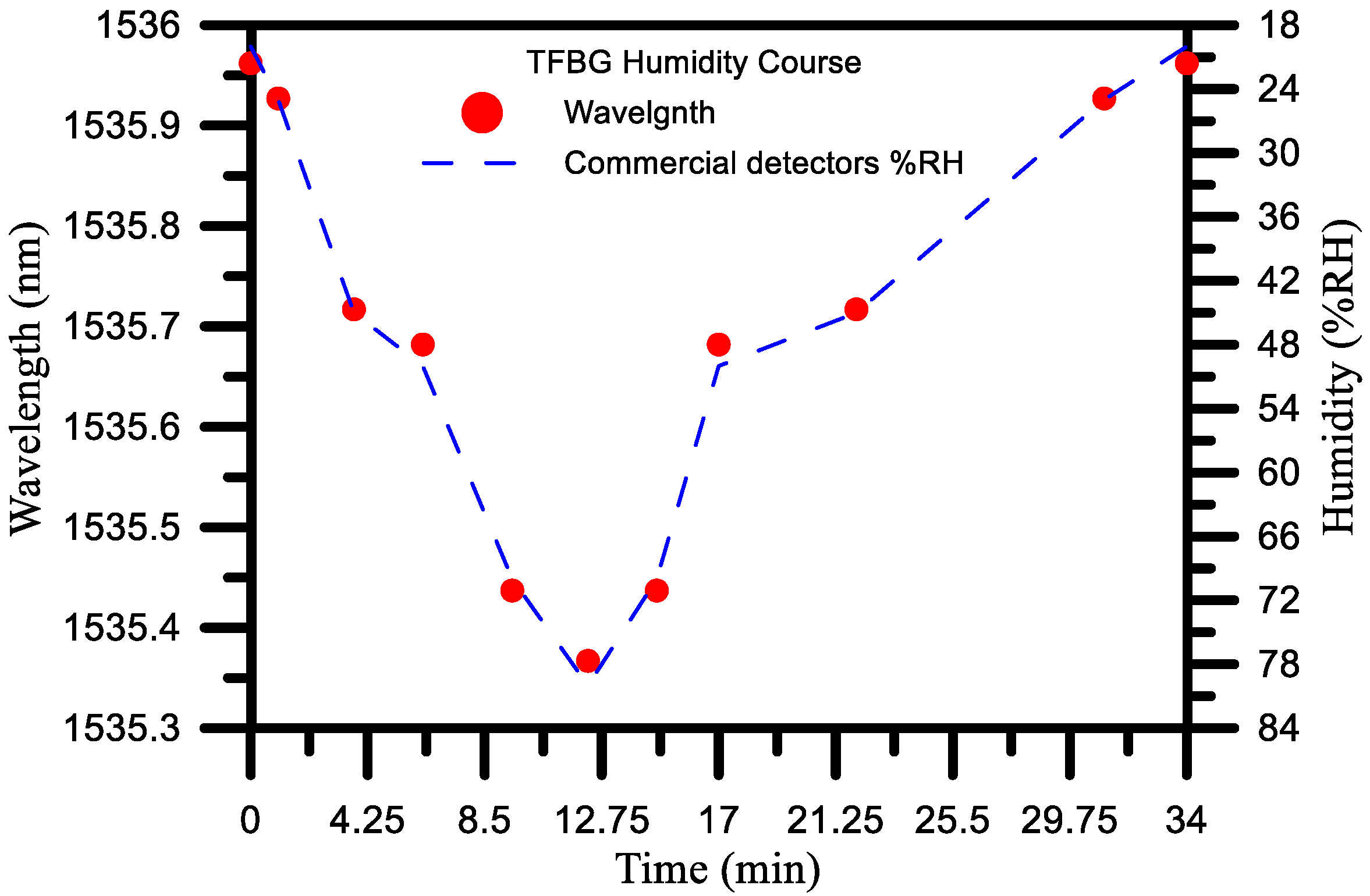

4.4. Analysis and Discussion of Humidification and Dehumidification

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wu, C.; Wu, C.; Chiang, C. A ZnO Nanoparticle-Coated Long Period Fiber Grating as a Carbon Dioxide Gas Sensor. Invention 2016, 1, 21. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, C.; Chiang, C. A Small U-Shaped Bending-Induced Interference Optical Fiber Sensor for the Measurement of Glucose Solutions. Sensors 2016, 16, 1460. [Google Scholar] [CrossRef] [PubMed]

- Woyessa, G.; Fasano, A.; Markos, C.; Rasmussen, H.K.; Bang, O. Low Loss Polycarbonate Polymer Optical Fiber for High Temperature FBG Humidity Sensing. IEEE Photon. Technol. Lett. 2017, 29, 575–578. [Google Scholar] [CrossRef]

- Woyessa, G.; Nielsen, K.; Stefani, A.; Markos, C.; Bang, O. Temperature insensitive hysteresis free highly sensitive polymer optical fiber Bragg grating humidity sensor. Opt. Express 2016, 24, 1206–1213. [Google Scholar] [CrossRef] [PubMed]

- Alberto, N.; Tavares, C.; Domingues, M.F.; Correia, S.F.H.; Marques, C.; Antunes, P.; Pinto, J.L.; Ferreira, R.A.S.; Andre, P.S. Relative humidity sensing using micro-cavities produced by the catastrophic fuse effect. Opt. Quant. Electron. 2016, 48, 1–8. [Google Scholar] [CrossRef]

- Torres, D.; Elosua, C.; Villatoro, J.; Zubia, J.; Rothhardt, M.; Schuster, K.; Arregui, F. Photonic crystal fiber interferometer coated with a PAH/PAA nanolayer as humidity sensor. Sens. Actuators B Chem. 2017, 242, 1065–1072. [Google Scholar] [CrossRef]

- Urrutia, A.; Goicoechea, J.; Ricchiuti, A.L.; Barrera, D.; Sales, S.; Arregui, F.J. Simultaneous measurement of humidity and temperature based on a partially coated optical fiber long period grating. Sens. Actuators B Chem. 2016, 227, 135–141. [Google Scholar] [CrossRef]

- Ascorbe, J.; Corres, J.M.; Matias, I.R.; Arregui, F.J. High sensitivity humidity sensor based on cladding-etched optical fiber and lossy mode resonances. Sens. Actuators B Chem. 2016, 242, 7–16. [Google Scholar] [CrossRef]

- Alberto, N.J.; Marques, C.A.; Pinto, J.L.; Nogueira, R.N. Three-parameter optical fiber sensor based on a tilted fiber Bragg grating. Appl. Opt. 2010, 49, 6085–6091. [Google Scholar] [CrossRef]

- Huang, Y.; Zhu, W.; Li, Z.; Chen, G.; Chen, L.; Zhou, J.; Lin, H.; Guan, J.; Fang, W.; Liu, X.; et al. High-performance fibre-optic humidity sensor based on a side-polished fibre wavelength selectively coupled with graphene oxide film. Sens. Actuators B Chem. 2018, 255, 57–69. [Google Scholar] [CrossRef]

- Dissanayake, K.P.W.; Wu, W.; Nguyen, H.; Sun, T.; Grattan, K.T.V. Graphene oxide coated long period grating based fibre optic humidity sensor. In Proceedings of the 2017 25th Optical Fiber Sensors Conference (OFS), Jeju, Korea, 24–28 April 2017. [Google Scholar]

- Gao, R.; Lu, D.F.; Cheng, J.; Jiang, Y.; Jiang, L.; Qi, Z.-M. Humidity sensor based on power leakage at resonance wavelengths of a hollow core fiber coated with reduced graphene oxide. Sens. Actuators B Chem. 2016, 222, 618–624. [Google Scholar] [CrossRef]

- Dong, X.; Zhang, H.; Liu, B.; Miao, Y. Tilted fiber Bragg gratings: Principle and sensing applications. Photon. Sens. 2011, 1, 6–30. [Google Scholar] [CrossRef]

- Albert, J.; Shao, L.; Caucheteur, C. Tilted fiber Bragg grating sensors. Laser Photon. Rev. 2013, 7, 83–108. [Google Scholar] [CrossRef]

- Erdogan, T.; Sipe, J.E. Tilted fiber phase gratings. Opt. Soc. Am. A 1996, 13, 296–313. [Google Scholar] [CrossRef]

- Li, Y.; Froggatt, M.; Erdogan, T. Volume Current Method for Analysis of Tilted Fiber Gratings. J. Lightwave Technol. 2001, 19, 1580. [Google Scholar] [CrossRef]

- Feder, K.S.; Westbrook, P.S.; Ging, J.; Reyes, P.I.; Carver, G.E. In-Fiber Spectrometer Using Tilted Fiber Gratings. Photon. Technol. Lett. 2003, 15, 933–935. [Google Scholar] [CrossRef]

- Wang, L.; Fang, N.; Huang, Z. Polyimide-Coated Fiber Bragg Grating Sensors for Humidity Measurements; InTech Open Access: Rijeka, Croatia, 2012. [Google Scholar]

- Berrutia, G.; Consalesa, M.; Giordanob, M.; Sansoneb, L.; Petagnac, P.; Buontempod, S.; Breglioe, G.; Cusanoa, A. Radiation hard humidity sensors for high energy physics applications using polyimide-coated fiber Bragg gratings sensors. Sens. Actuators B Chem. 2013, 177, 94–102. [Google Scholar] [CrossRef]

- Montero, A.; Aldabaldetreku, G.; Durana, G.; Jorge, I.; de Ocáriz, I.S.; Zubia, J. Influence of Humidity on Fiber Bragg Grating Sensors. Adv. Mater. Sci. Eng. 2014. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, C.; Lou, W.; Shentu, F.; Zhong, C.; Dong, X.; Tong, L. Fiber optic relative humidity sensor based on the tilted fiber Bragg grating coated with graphene oxide. Appl. Phys. Lett. 2016, 109, 031107. [Google Scholar] [CrossRef]

- Naik, G.; Krishnaswamy, S. Room-Temperature Humidity Sensing Using Graphene Oxide Thin Films. Sci. Res. 2016. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiu, Y.-D.; Wu, C.-W.; Chiang, C.-C. Tilted Fiber Bragg Grating Sensor with Graphene Oxide Coating for Humidity Sensing. Sensors 2017, 17, 2129. https://doi.org/10.3390/s17092129

Chiu Y-D, Wu C-W, Chiang C-C. Tilted Fiber Bragg Grating Sensor with Graphene Oxide Coating for Humidity Sensing. Sensors. 2017; 17(9):2129. https://doi.org/10.3390/s17092129

Chicago/Turabian StyleChiu, Yung-Da, Chao-Wei Wu, and Chia-Chin Chiang. 2017. "Tilted Fiber Bragg Grating Sensor with Graphene Oxide Coating for Humidity Sensing" Sensors 17, no. 9: 2129. https://doi.org/10.3390/s17092129