The Use of Flexible Ultrasound Transducers for the Detection of Laser-Induced Guided Waves on Curved Surfaces at Elevated Temperatures

Abstract

:1. Introduction

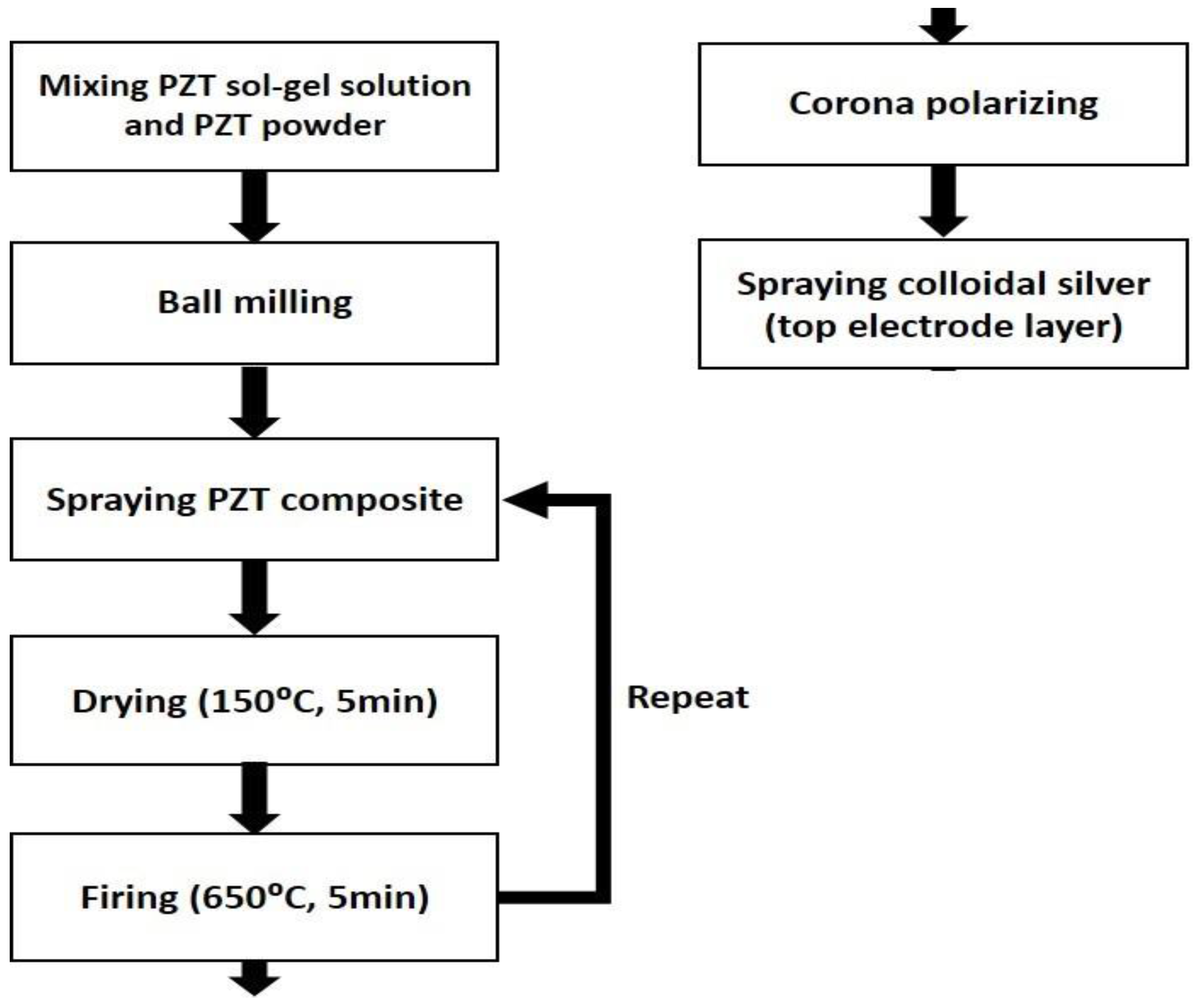

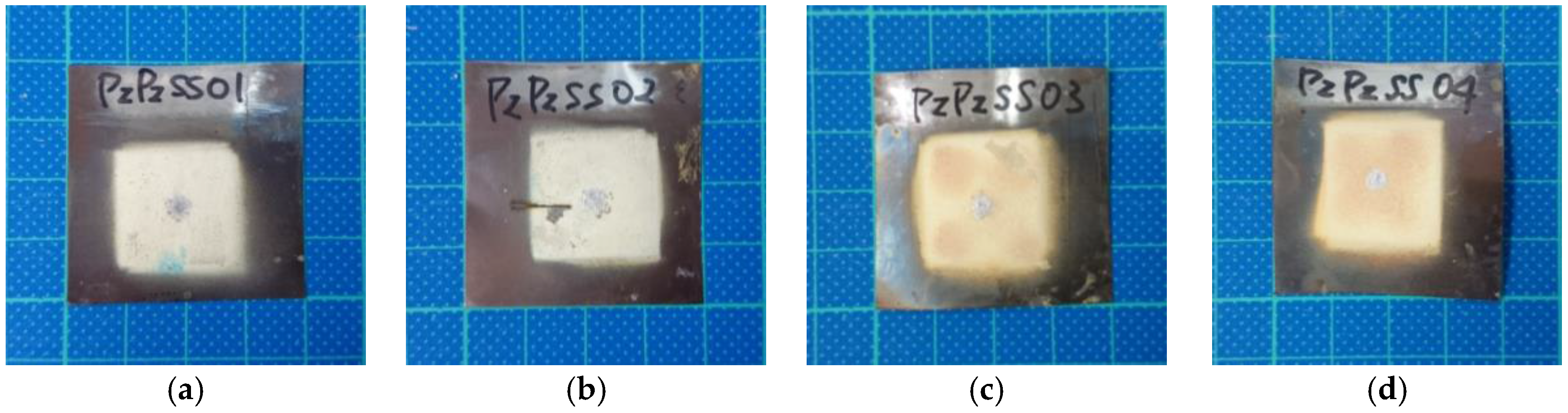

2. Flexible Ultrasound Transducer

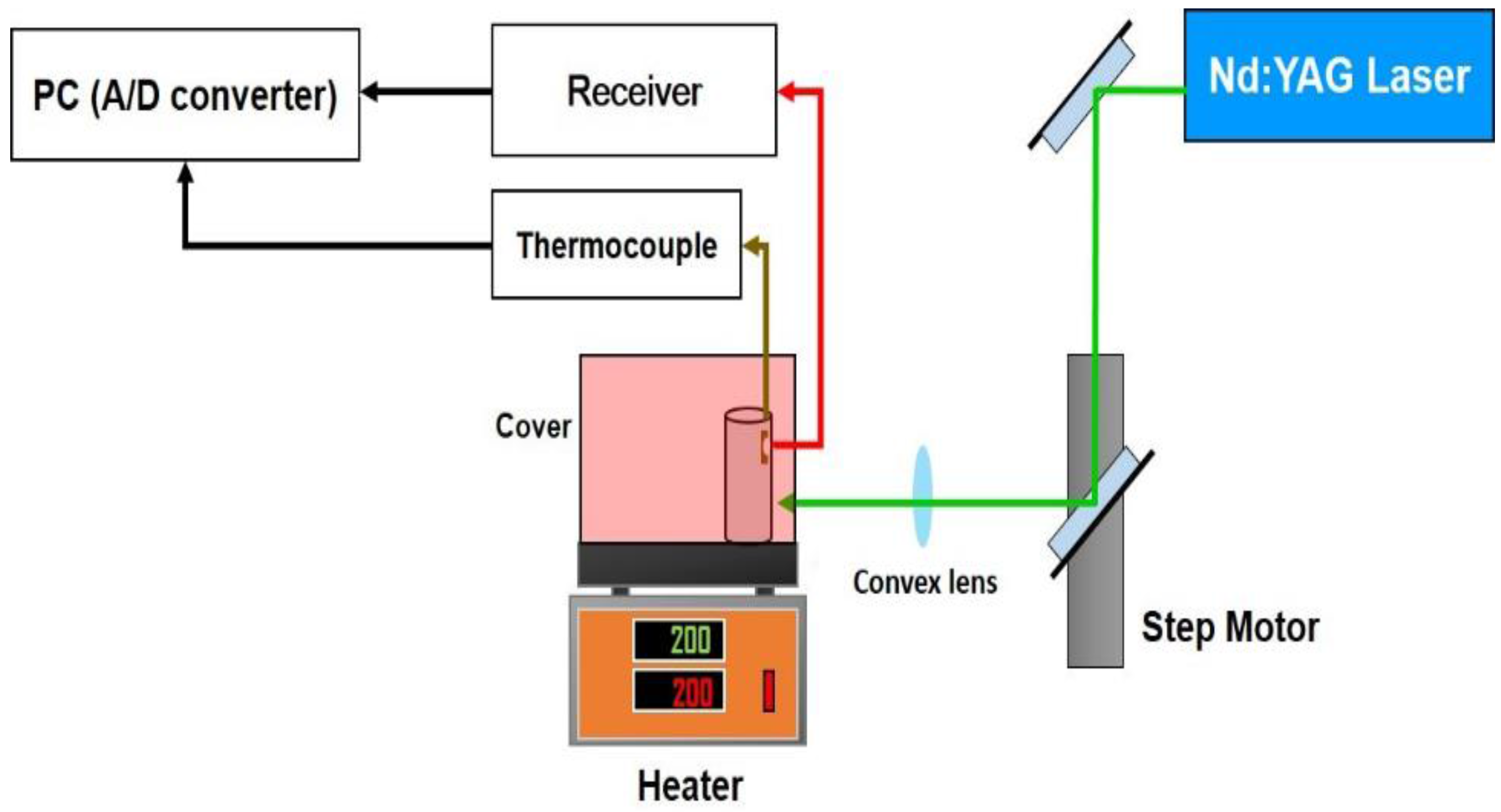

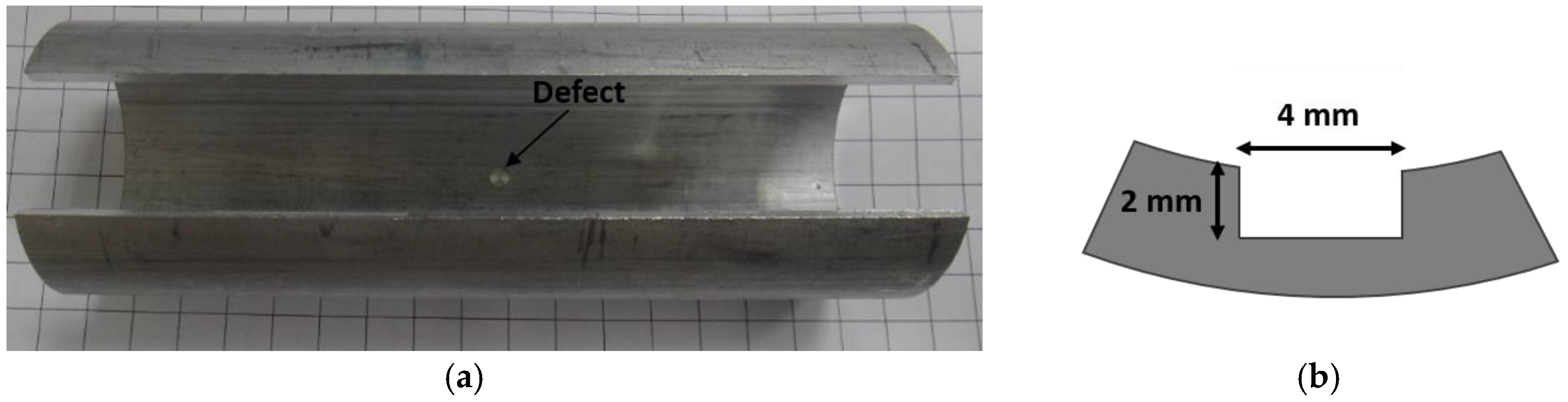

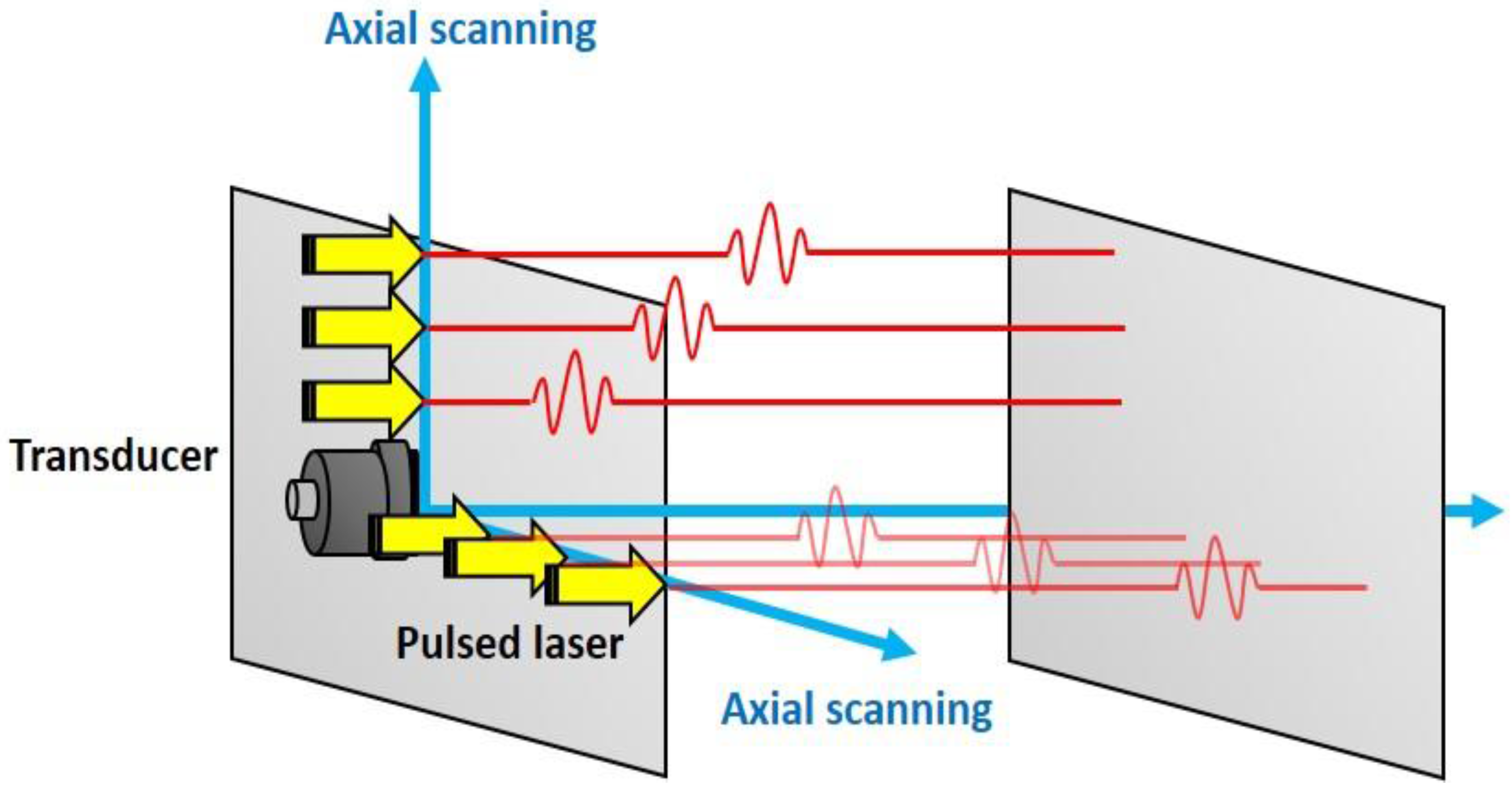

3. Laser Ultrasonic Technique (LUT) Tests

4. Laser Ultrasonic Imaging (LUI) Tests

5. Results and Discussion

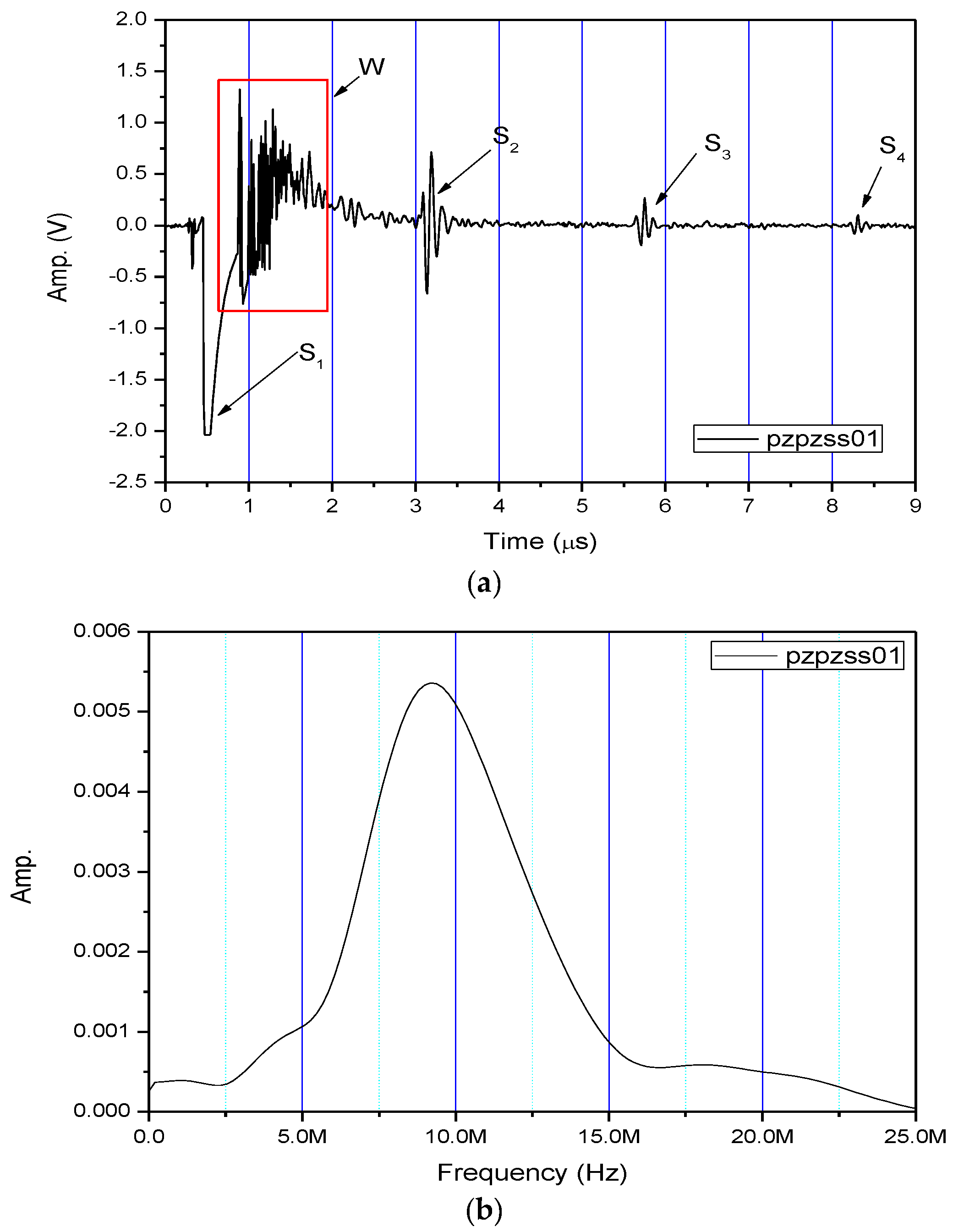

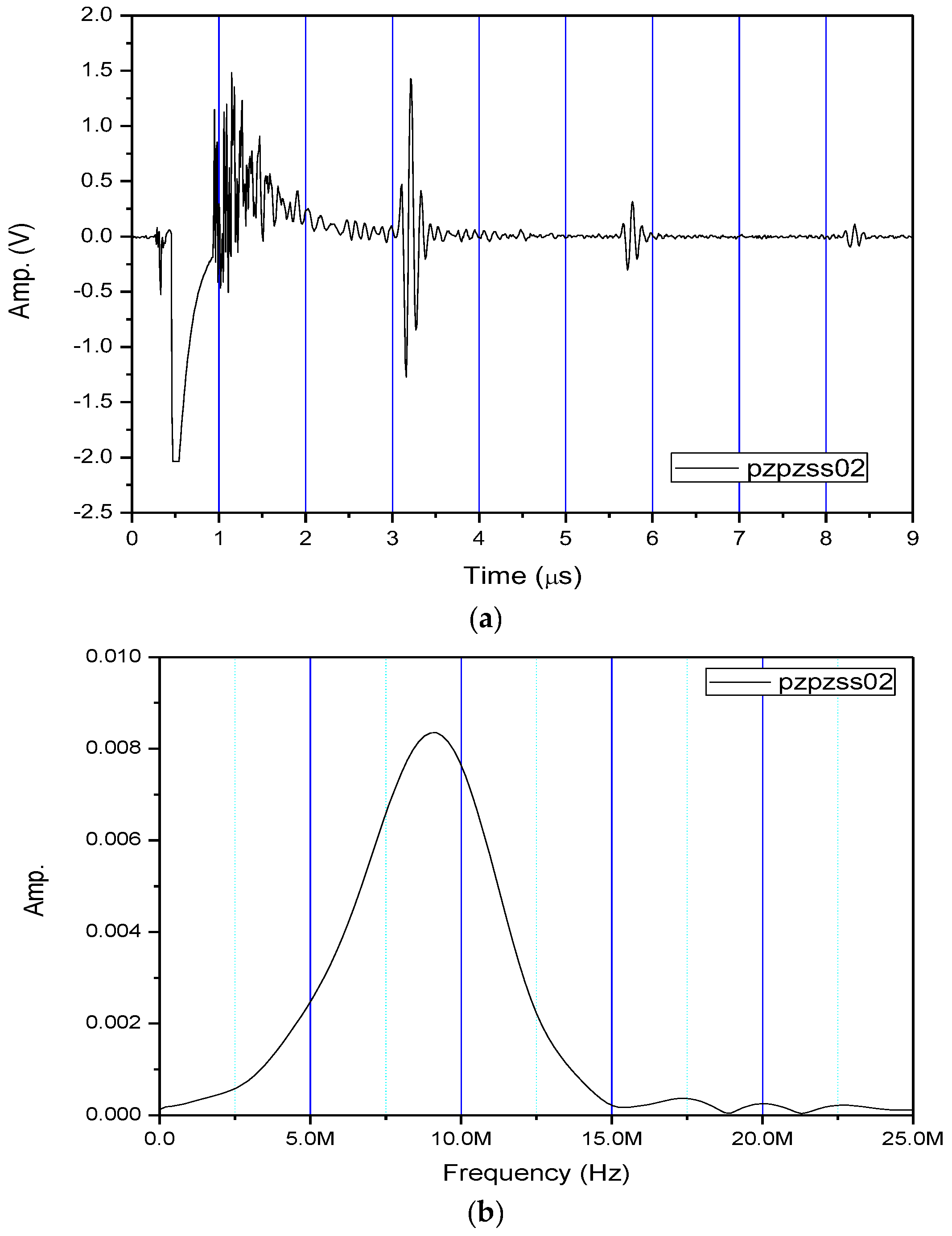

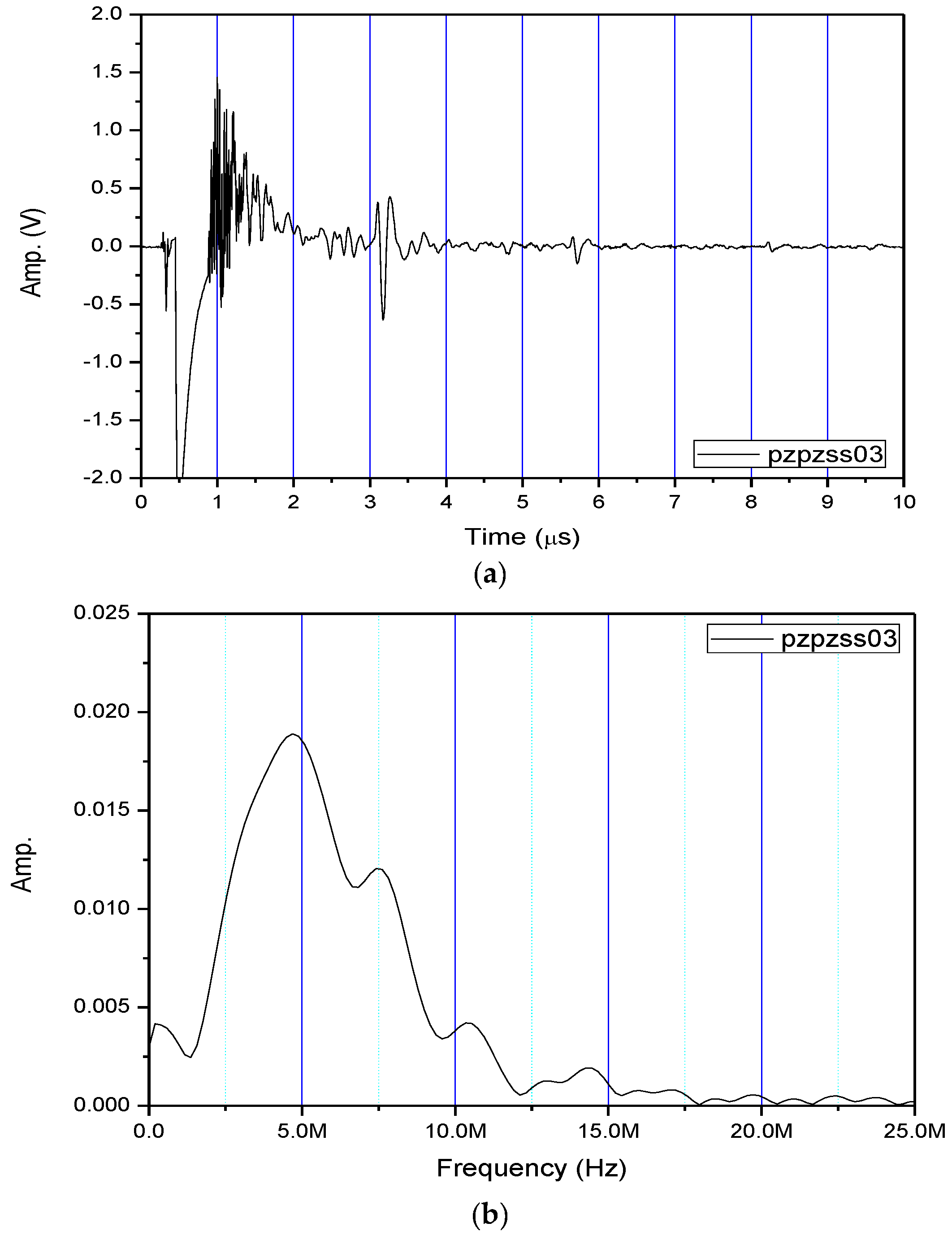

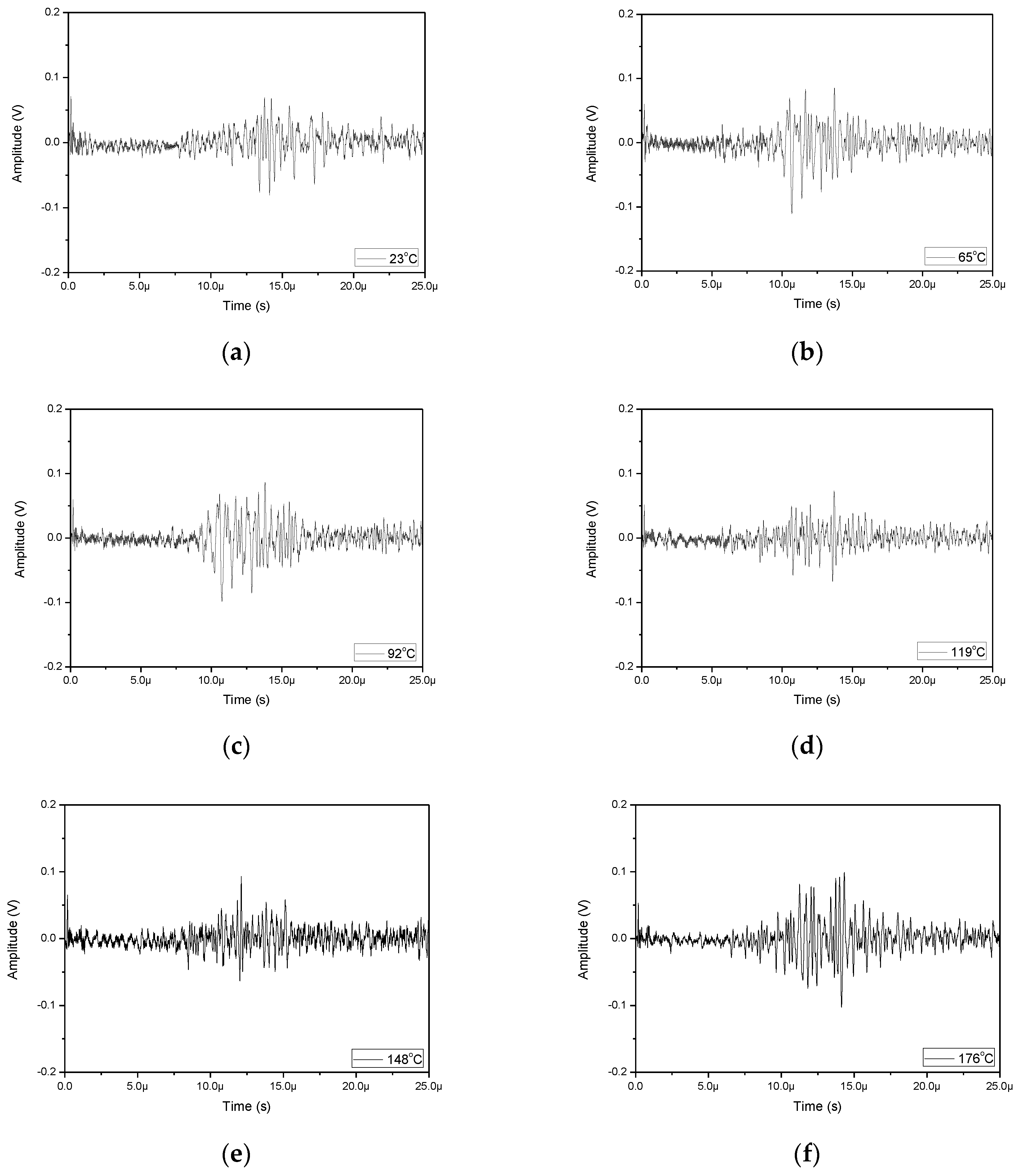

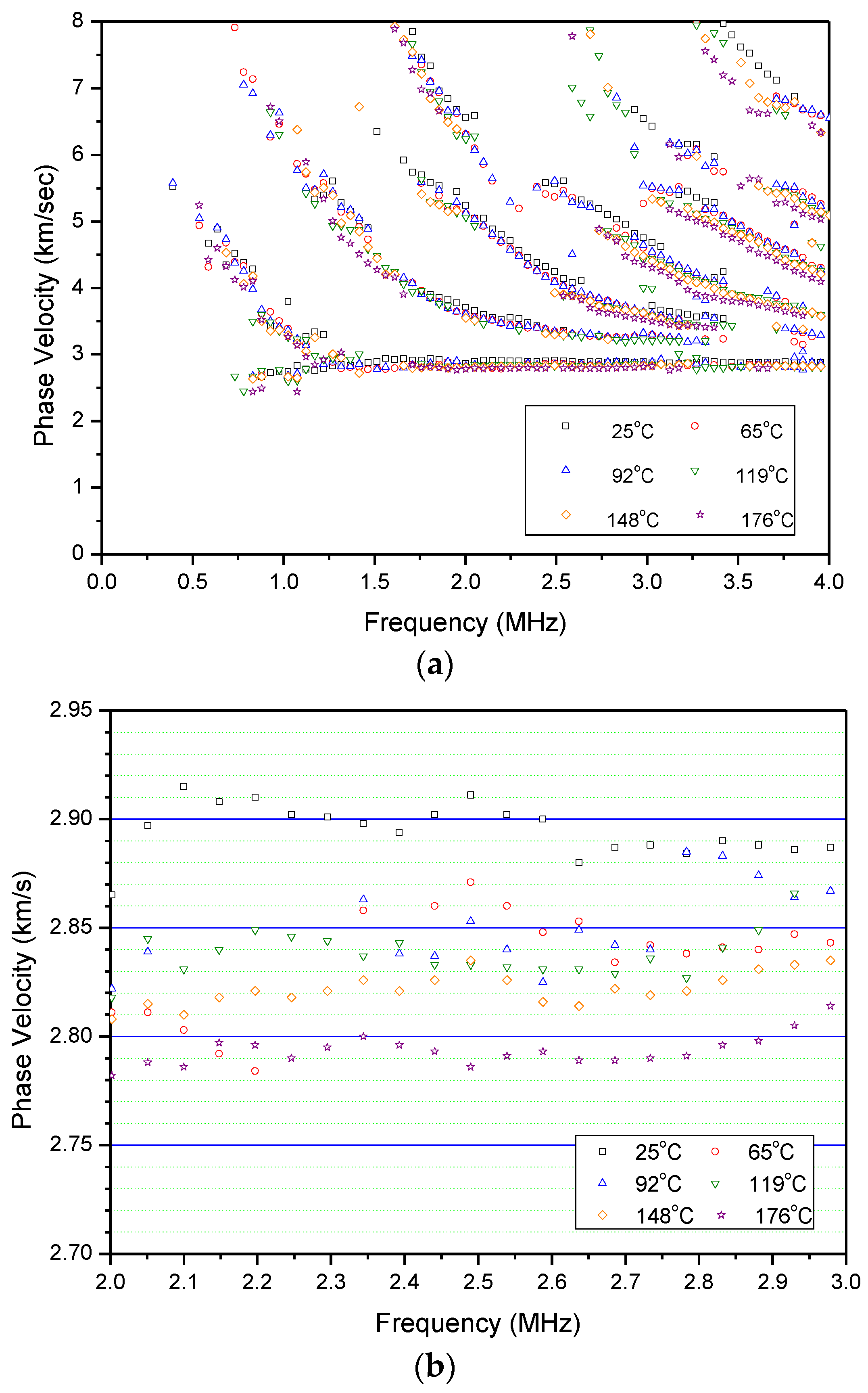

5.1. LUT Testing Results

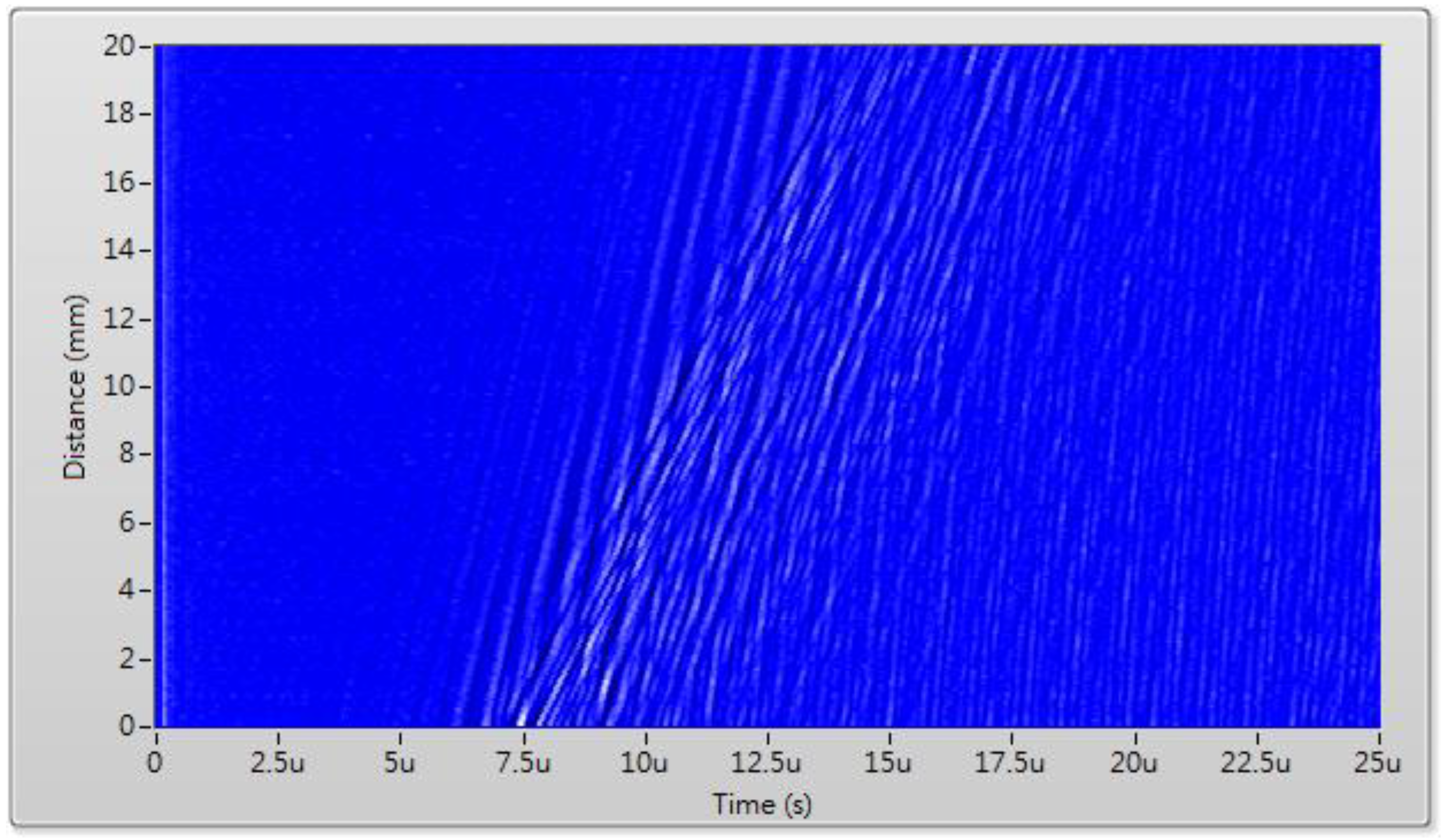

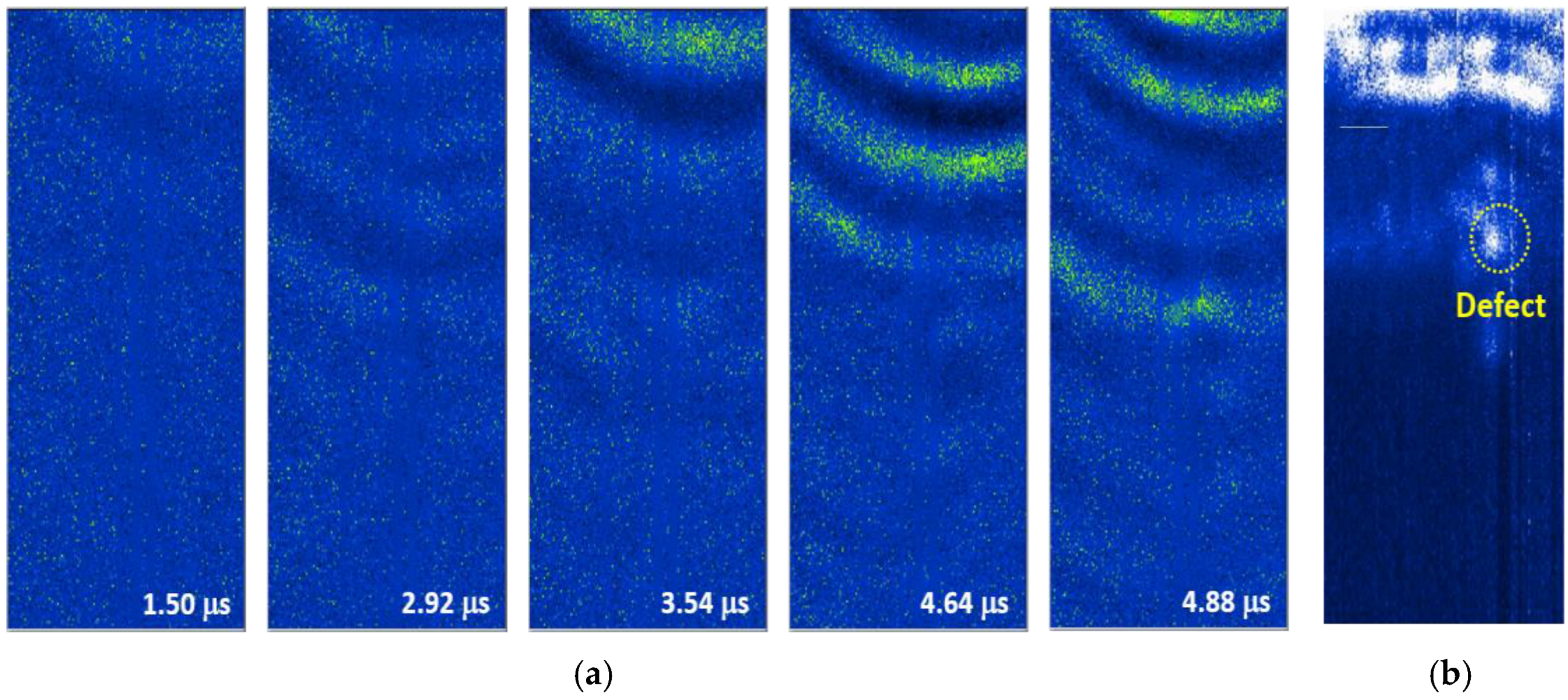

5.2. LUI Testing Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kažys, R.; Voleišis, A.; Voleišienė, B. High temperature ultrasonic transducers: Review. Ultragarsas Ultrasound 2008, 63, 7–17. [Google Scholar]

- Damjanovic, D. Materials for high-temperature piezoelectric transducers. Curr. Opin. Solid State Mater. Sci. 1998, 3, 469–473. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, F. Piezoelectric materials for high temperature sensors. J. Am. Ceram. Soc. 2011, 94, 3153–3170. [Google Scholar] [CrossRef]

- Fothergill, J.R.; Willis, P.; Waywell, S. Development of high temperature ultrasonic transducers for under-sodium viewing applications. Br. J. Non Destr. Test. 1987, 31, 259–264. [Google Scholar]

- Schmarje, N.; Kirk, K.J.; Cochran, S. 1–3 Connectivity lithium niobate composites for high temperature operation. Ultrasonics 2007, 47, 15–22. [Google Scholar] [CrossRef] [PubMed]

- Baba, A.; Searfass, C.T.; Tittmann, B.R. High temperature ultrasonic transducer up to 1000 °C using lithium niobate single crystal. Appl. Phys. Lett. 2010, 97, 232901. [Google Scholar]

- Kirk, K.J.; Scheit, C.W.; Schmarje, N. High temperature acoustic emission tests using lithium niobate piezocomposite transducers. Insight Non Destr. Test. Cond. Monit. 2007, 49, 142–145. [Google Scholar] [CrossRef]

- Amini, M.H.; Sinclair, A.N.; Coyle, T.W. High Temperature Ultrasonic Transducer for Real-time Inspection. Phys. Procedia 2015, 70, 343–347. [Google Scholar] [CrossRef]

- Technologies, I.A. Developing Permanently Installed System for Ultrasonic Thickness Monitoring Based on HotSense® Technology; Ionix: Ipswich, UK, 2015. [Google Scholar]

- Dhuttia, A.; Tumina, S.A.; Mohimib, A.; Kostana, M.; Gana, T.H.; Balachandrana, W.; Selcuka, C. Development of low frequency high temperature ultrasonic transducers for in-service monitoring of pipework in power plants. Procedia Eng. 2016, 168, 983–986. [Google Scholar] [CrossRef]

- Kobayashi, M.; Ken, C.K.; Bussiere, J.F.; Wu, K.T. High-temperature integrated and flexible ultrasonic transducers for nondestructive testing. NDT E Int. 2009, 42, 157–161. [Google Scholar] [CrossRef]

- Inoue, T.; Kobayashi, M. PbTiO3/Pb(Zr,Ti)O3 sol–gel composite for ultrasonic transducer applications. Jpn. J. Appl. Phys. 2014, 53, 07KC11. [Google Scholar] [CrossRef]

- Kobayashi, M.; Ono, Y.; Jen, C.K.; Chen, C.C. High-temperature piezoelectric film ultrasonic transducers by a sol-gel spray technique and their application to process monitoring of polymer injection molding. IEEE Sens. J. 2006, 6, 55–62. [Google Scholar] [CrossRef]

- Barrow, D.A.; Petroff, T.E.; Sayer, M. Method for Producing Thick Ceramic Films by a Sol Gel Coating Process. U.S. Patent 5,585,136, 17 December 1996. [Google Scholar]

- Kobayashi, M.; Jen, C.K.; Ono, Y.; Kruger, S. Lead-free thick piezoelectric films as miniature high temperature ultrasonic transducers. In Proceedings of the 2004 IEEE Ultrasonics Symposium, Montreal, QC, Canada, 23–27 August 2004. [Google Scholar]

- Kobayashi, M.; Jen, C.K.; Ono, Y.; Moisan, J.F. Integratable high temperature ultrasonic transducers for NDT of metals and industrial process monitoring. CINDE J. 2005, 26, 5–10. [Google Scholar]

- Kobayashi, M.; Jen, C.K.; Hui, R.; Yick, S.; Wu, K.T. Fabrication and characterization of thick film piezoelectric ultrasonic transducers. In Proceedings of the 2006 IEEE Ultrasonics Symposium, Vancouver, BC, Canada, 2–6 October 2006; Volume 14, pp. 816–819. [Google Scholar]

- Kobayashi, M.; Jen, C.K. Piezoelectric thick bismuth titanate/PZT composite film transducers for smart NDE of metals. Smart Mater. Struct. 2004, 13, 951–956. [Google Scholar] [CrossRef]

- Shih, J.L.; Kobayashi, M.; Jen, C.K. Flexible metallic ultrasonic transducers for structural health monitoring of pipes at high temperatures. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 2103–2110. [Google Scholar] [CrossRef] [PubMed]

- Searfass, C.T.; Pheil, C.; Sinding, K.; Tittmann, B.R.; Baba, A.; Agrawal, D.K. Bismuth titanate fabricated by spray-on deposition and microwave sintering for high-temperature ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Eason, T.J.; Bond, L.J.; Lozev, M.G. Ultrasonic Sol-Gel Arrays for Monitoring High-Temperature Corrosion. In Proceedings of the 19th World Conference on Non-Destructive Testing 2016, Munichm, Germany, 13–17 June 2016. [Google Scholar]

- Kobayashi, M.; Jen, C.K.; Lévesque, D. Flexible ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 1478–1486. [Google Scholar] [CrossRef] [PubMed]

- Ouahabi, A.; Thomas, M.; Kobayashi, M.; Jen, C.K. Structural health monitoring of aerospace structures with sol-gel spray sensors. Key Eng. Mater. 2007, 347, 505–510. [Google Scholar] [CrossRef]

- Jen, C.K.; Wu, K.T.; Kobayashi, M.; Blouin, A. NDE using laser generated ultrasound and ultrasonic transducer receivers. In Proceedings of the 2008 IEEE Ultrasonics Symposium, Beijing, China, 2–5 November 2008; pp. 1516–1519. [Google Scholar]

- Di Scalea, F.L.; Bcrndl, T.P.; Spicer, J.U.; Djordjevic, B.B. Remote laser generation of narrow-band surface waves through optical fibers. IEEE Trans. Ultrason. Ferroelec. Freq. Control 1999, 46, 1551–1557. [Google Scholar] [CrossRef] [PubMed]

- Aindow, A.M.; Dewhurst, R.J.; Palmer, S.B. Laser-generation of directional surface acoustic wave pulses in metals. Opt. Commun. 1982, 42, 116–120. [Google Scholar] [CrossRef]

- Clorennec, D.; Royer, D.; Walaszek, H. Nondestructive Evaluation of Cylindrical Parts Using Laser Ultasonics. Ultrasonics 2002, 40, 783–789. [Google Scholar] [CrossRef]

- Shi, Y.; Wooh, S.; Orwat, M. Laserultrasonic Generation of Lamb Waves in the Reaction Rorce Range. Ultrasonics 2003, 41, 623–633. [Google Scholar] [CrossRef]

- Liu, I.-H.; Yang, C.-H. A novel procedure employing laser ultrasound technique and simplex algorism for the characterization of mechanical and geometrical properties in Zircaloy tubes with different levels of hydrogen charging. J. Nucl. Mater. 2011, 408, 96–101. [Google Scholar] [CrossRef]

- Yang, C.-H.; Tang, S.-W. Characterization of material properties in solid oxide fuel cells using a laser ultrasound technique. In Proceedings of the Symposium on Ultrasonic Electronics, Kyoto, Japan, 18–20 November 2009; pp. 1207–1210. [Google Scholar]

- Yeh, C.-H.; Yang, C.H.; Su, C.Y.; Hsiao, W.T. Laser ultrasound technique for material characterization of thermal sprayed nickel aluminum coatings in elevated temperature environment. J. Acoust. Soc. Am. 2012, 131, 3476. [Google Scholar] [CrossRef]

- Yashiro, S.; Takatsubo, J.; Toyama, N. An NDT technique for composite structure using visualized Lamd-wave propagation. Compos. Sci. Technol. 2007, 67, 3202–3208. [Google Scholar] [CrossRef]

- Lee, J.R.; Takatsubo, J.; Toyama, N.; Kang, D.H. Health monitoring of complex curved structures using an ultrasonic wavefield propagation imaging system. Meas. Sci. Technol. 2007, 18, 3816–3824. [Google Scholar] [CrossRef]

- Lee, J.R.; Jeong, H.; Ciang, C.C.; Yoon, D.J.; Lee, S.S. Application of ultrasonic wave propagation imaging method to automatic damage visualization of nuclear power plant pipeline. Nucl. Eng. Des. 2010, 240, 3513–3520. [Google Scholar] [CrossRef]

- Nishino, H.; Tanaka, T.; Yoshida, K.; Takasudo, J. Simultaneous measurement of the phase and group velocities of Lamb waves in a laser-generation based imaging method. Ultrasonic 2011, 20, 530–535. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.-H.; Liu, I.-H. Optical visualization of acoustic wave propagating along the wedge tip. In Proceedings of the Seventh International Symposium on Precision Engineering Measurements and Instrumentation, Lijiang, China, 7–11 August 2011. [Google Scholar]

- Wu, C.-H.; Yang, C.-H. Laser ultrasound technique for ray tracing investigation of Lamb wave tomography. In Proceedings of the Nondestructive Characterization for Composite Materials, Aerospace Engineering, Civil Infrastructure, and Homeland Security 2011, San Diego, CA, USA, 7–11 March 2011. [Google Scholar]

- Wu, C.-H.; Tseng, S.-P.; Yang, C.-H. A full-field mechanical property mapping reconstruction algorithm with quantitative laser ultrasound visualization system. In Proceedings of the 2012 IEEE Ultrasonics Symposium, Dresden, Germany, 7–10 October 2012. [Google Scholar]

- Zhou, Z.G.; Zhang, K.S.; Zhou, J.H.; Sun, G.G.; Wang, J. Application of laser ultrasonic technique for non-contact detection of structural surface-breaking cracks. Opt. Laser Technol. 2015, 73, 173–178. [Google Scholar] [CrossRef]

- Zeng, W.; Wang, H.T.; Tian, G.Y.; Wang, W. Detection of surface defects for longitudinal acoustic waves by a laser ultrasonic imaging technique. Opt. Int. J. Light Electron Opt. 2016, 127, 415–419. [Google Scholar] [CrossRef]

| Label | Film Thickness (μm) | Central Frequency (MHz) |

|---|---|---|

| PzPzss01 | 83 | 9.18 |

| PzPzss02 | 72 | 9.18 |

| PzPzss03 | 146 | 4.89 |

| PzPzss04 | 138 | 6.45 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.C.; Kobayashi, M.; Tanabe, M.; Yang, C.H. The Use of Flexible Ultrasound Transducers for the Detection of Laser-Induced Guided Waves on Curved Surfaces at Elevated Temperatures. Sensors 2017, 17, 1285. https://doi.org/10.3390/s17061285

Wu TC, Kobayashi M, Tanabe M, Yang CH. The Use of Flexible Ultrasound Transducers for the Detection of Laser-Induced Guided Waves on Curved Surfaces at Elevated Temperatures. Sensors. 2017; 17(6):1285. https://doi.org/10.3390/s17061285

Chicago/Turabian StyleWu, Tai Chieh, Makiko Kobayashi, Masayuki Tanabe, and Che Hua Yang. 2017. "The Use of Flexible Ultrasound Transducers for the Detection of Laser-Induced Guided Waves on Curved Surfaces at Elevated Temperatures" Sensors 17, no. 6: 1285. https://doi.org/10.3390/s17061285