Low Power Near Field Communication Methods for RFID Applications of SIM Cards

Abstract

:1. Introduction

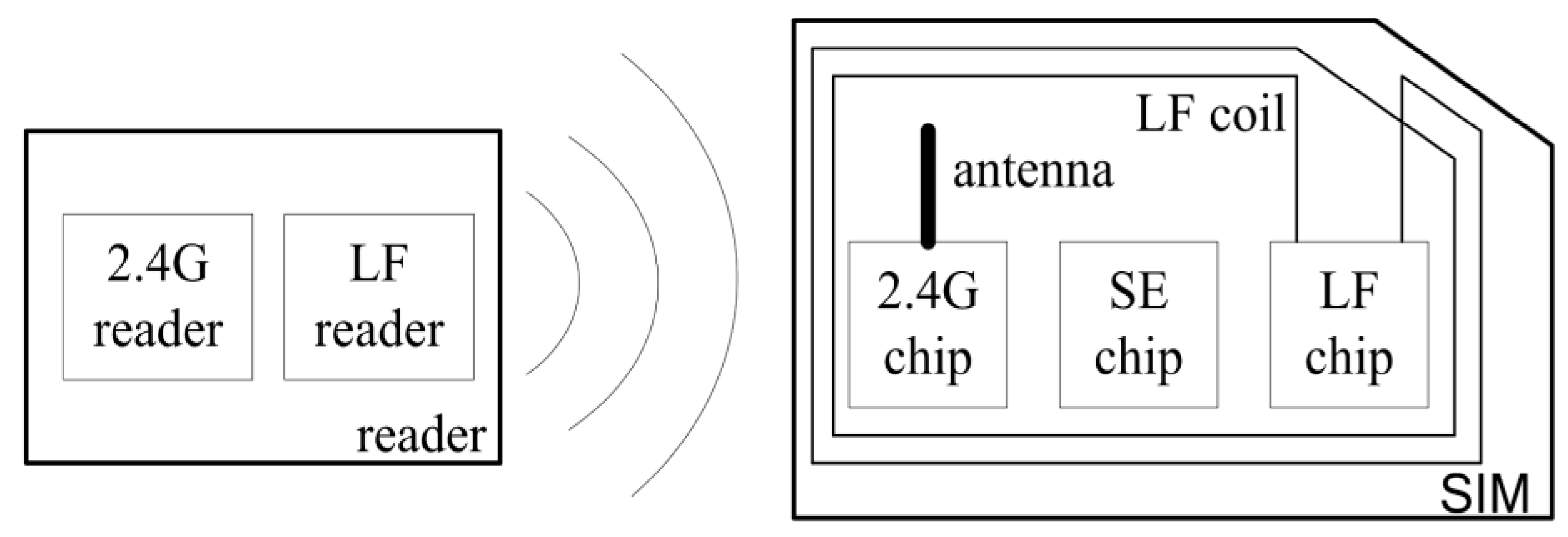

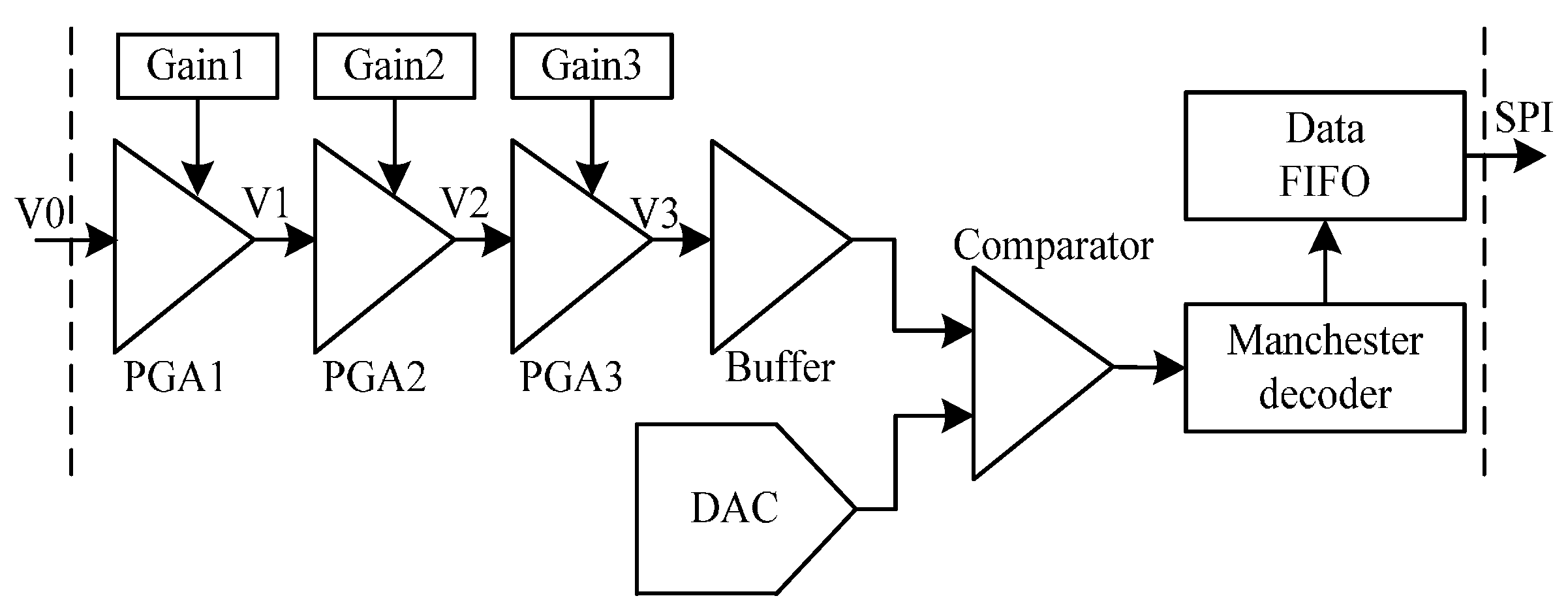

2. An Improved RFID SIM Structure

- (1)

- First, the 2.45 GHz RF chip sleeps with about 1 µA current, and the LF reader sends 2 kHz signals;

- (2)

- Secondly, the LF chip determines whether or not a card approaches, receives the LF data, and wakes up the 2.45 GHz chip;

- (3)

- Finally, the 2.45 GHz chip requests the reader to suspend the transmission of LF signals and handles 2.45 GHz transactions.

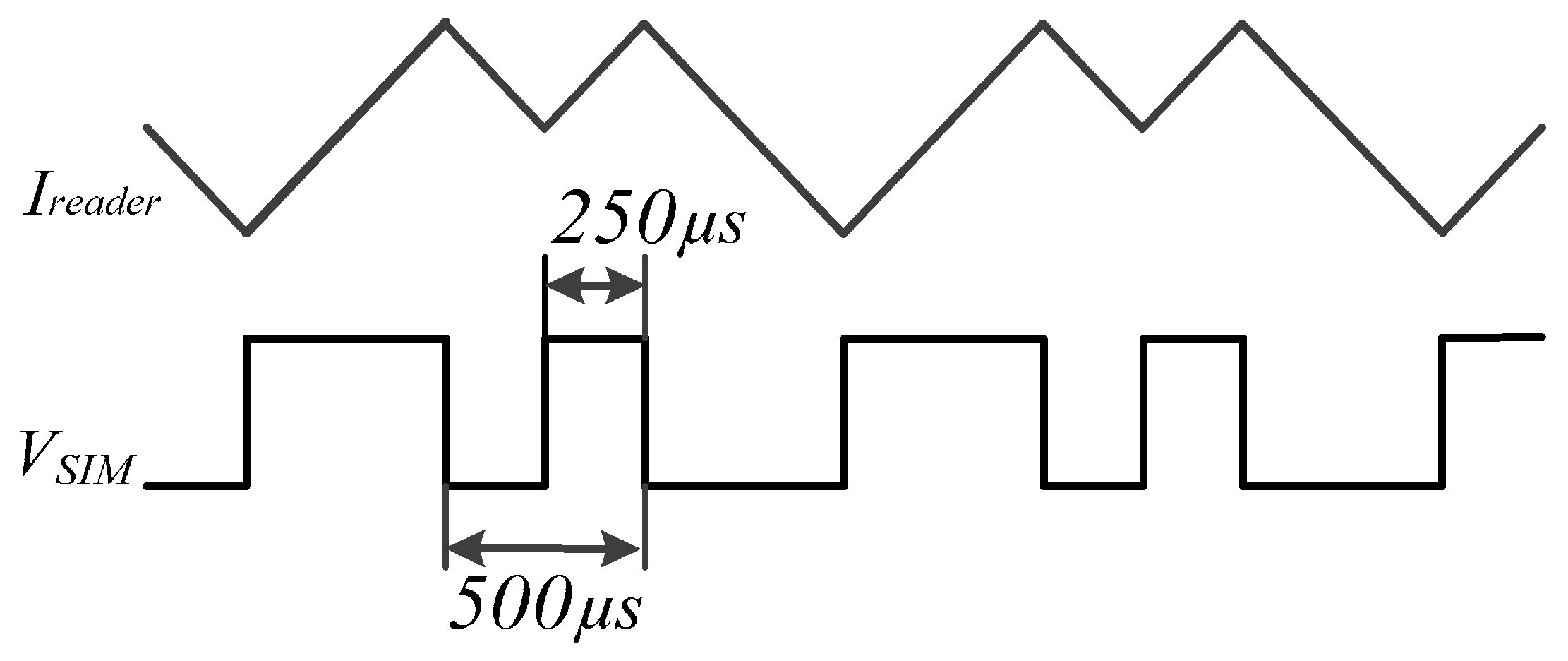

3. Low Frequency Data Transmission Model

4. Low Frequency Communication Implementation

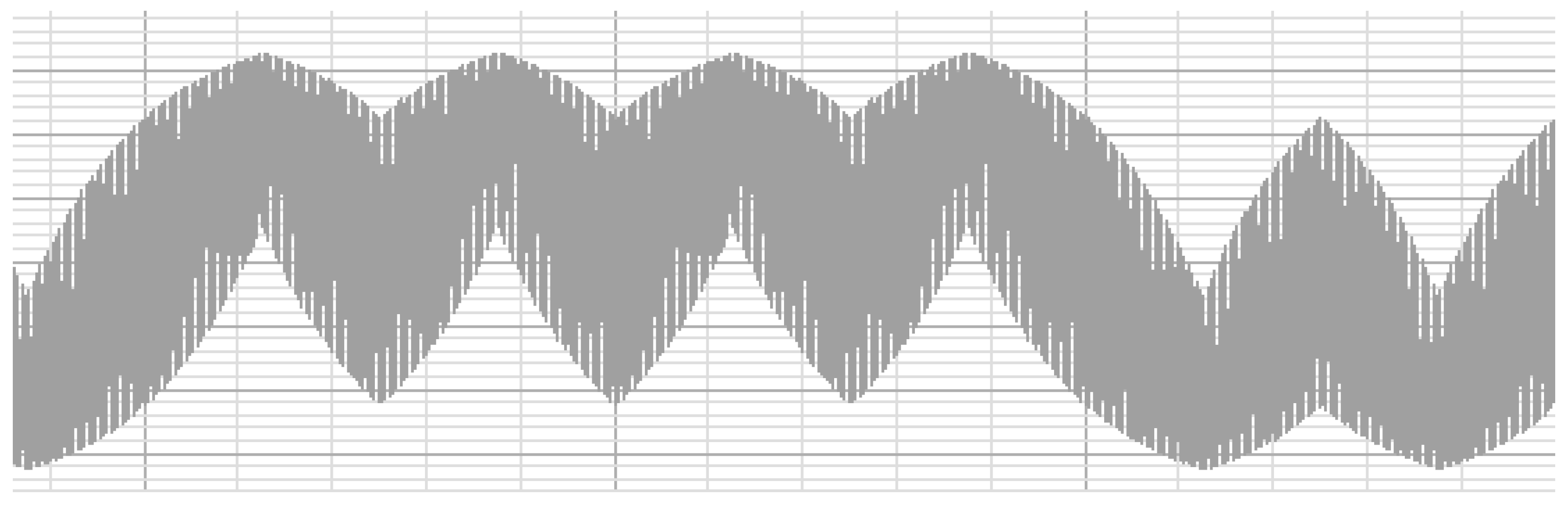

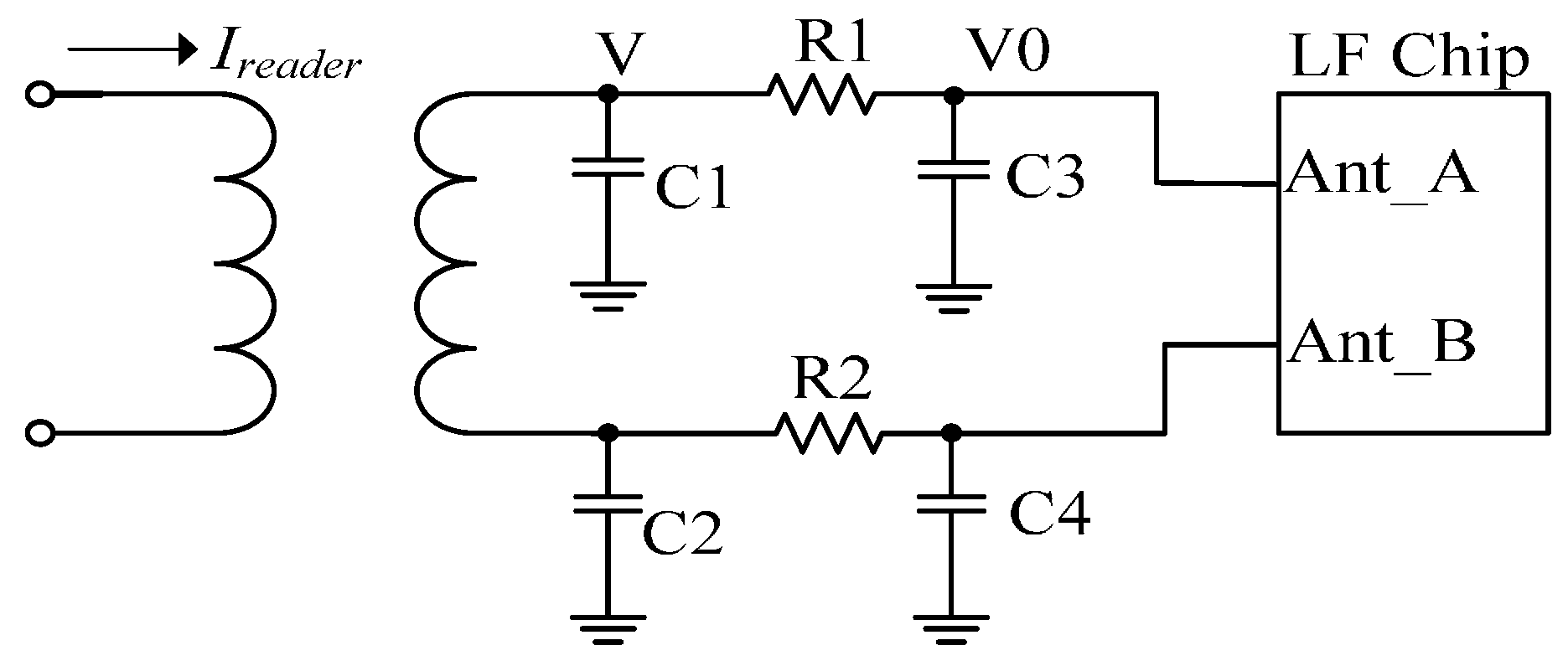

4.1. The Frontend Circuit Design

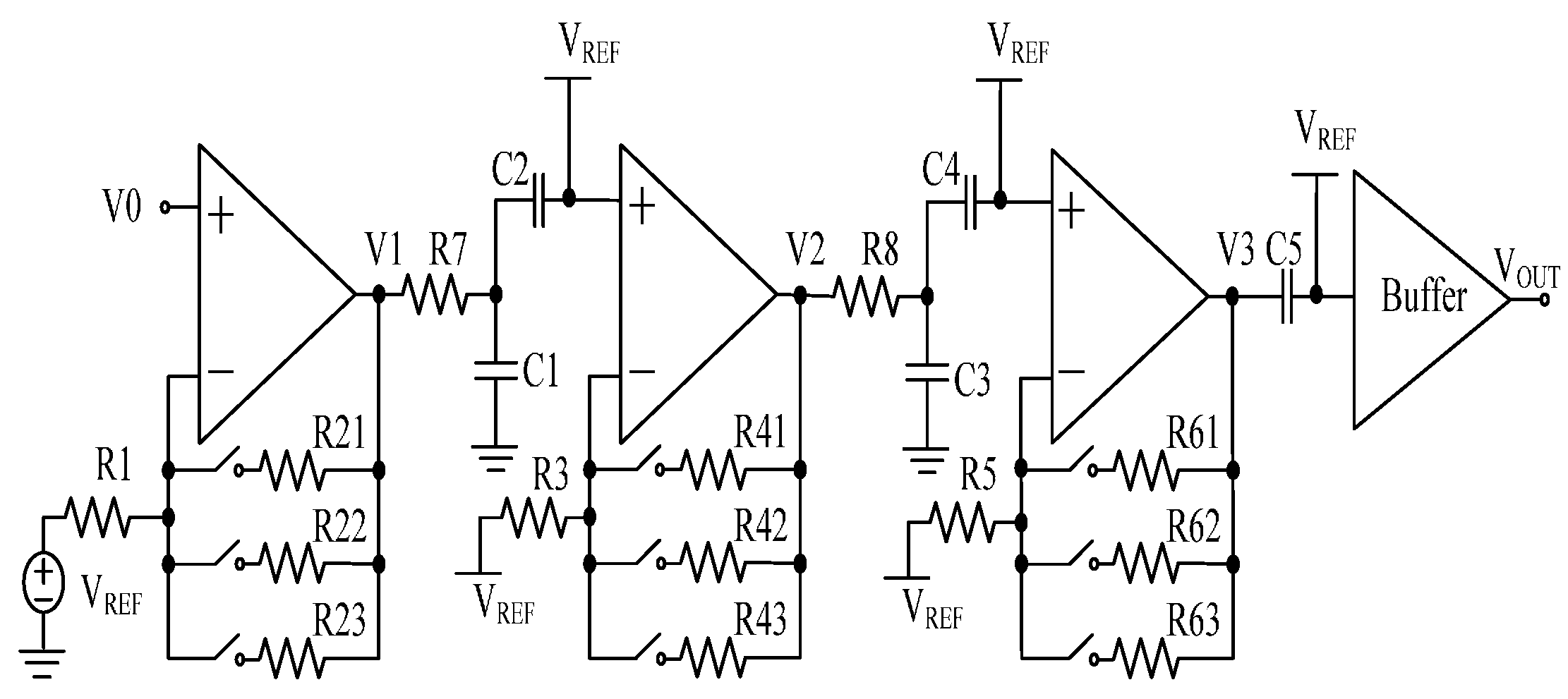

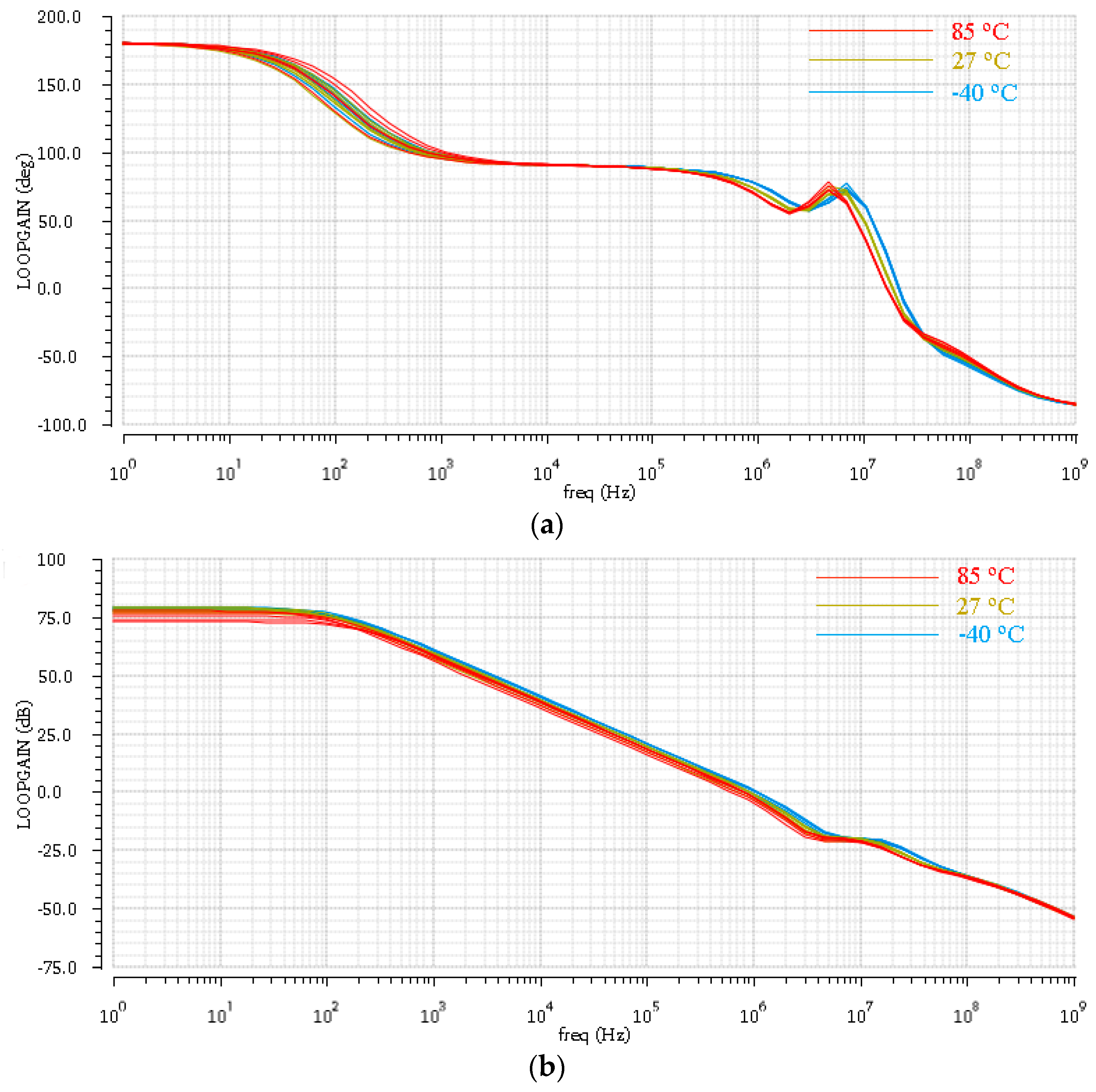

4.2. Programmable Gain Amplifiers of the LF Chip

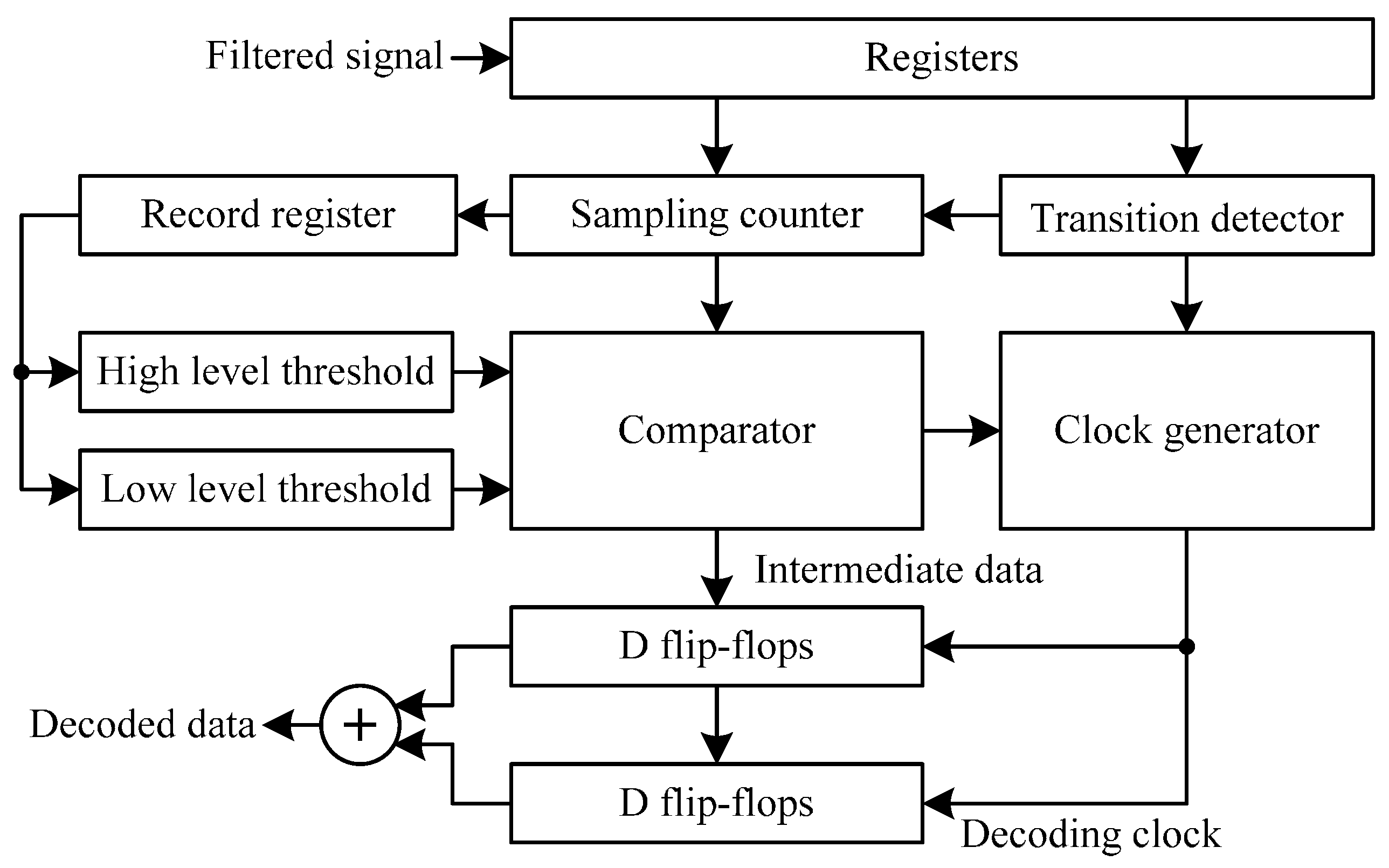

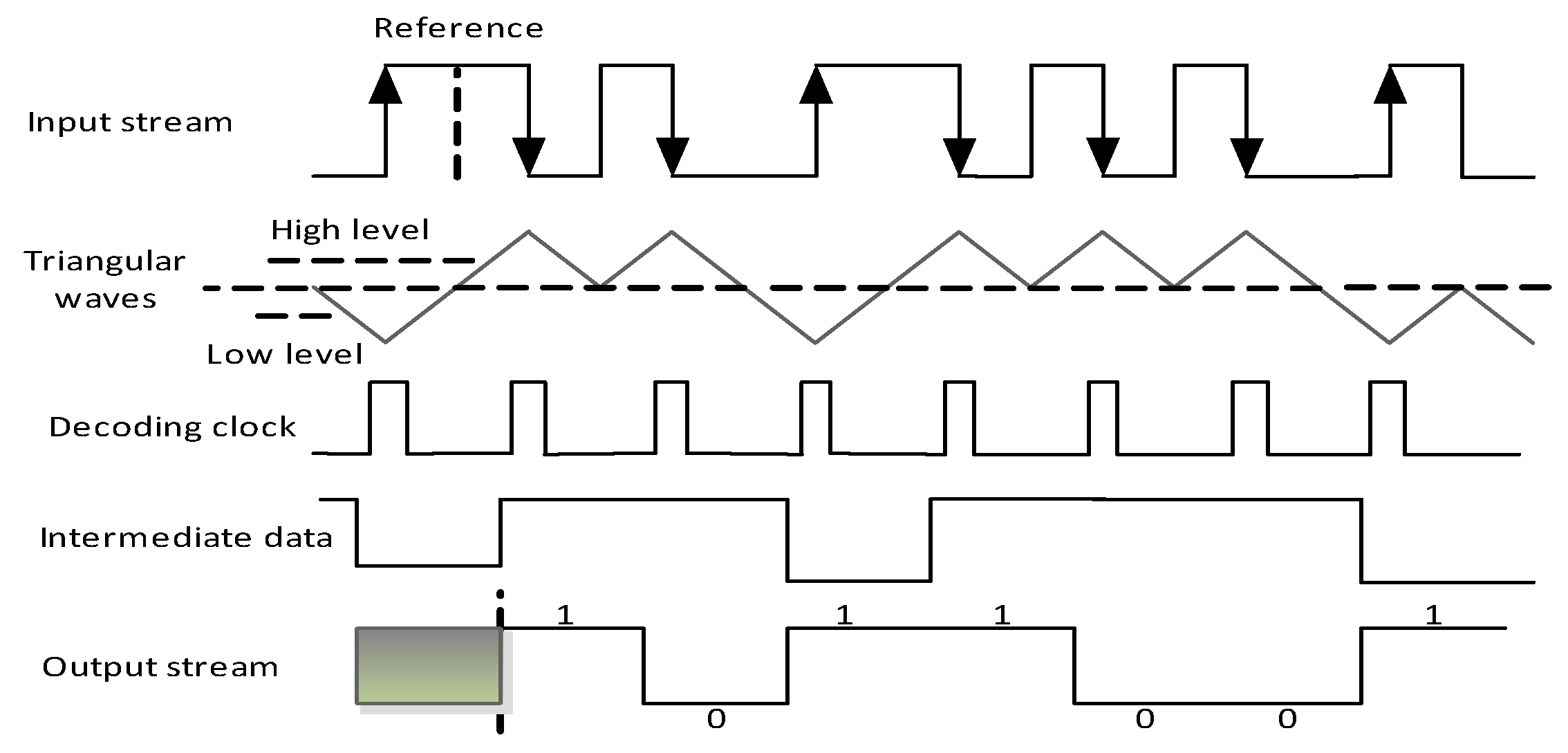

4.3. Differential Manchester Decoder

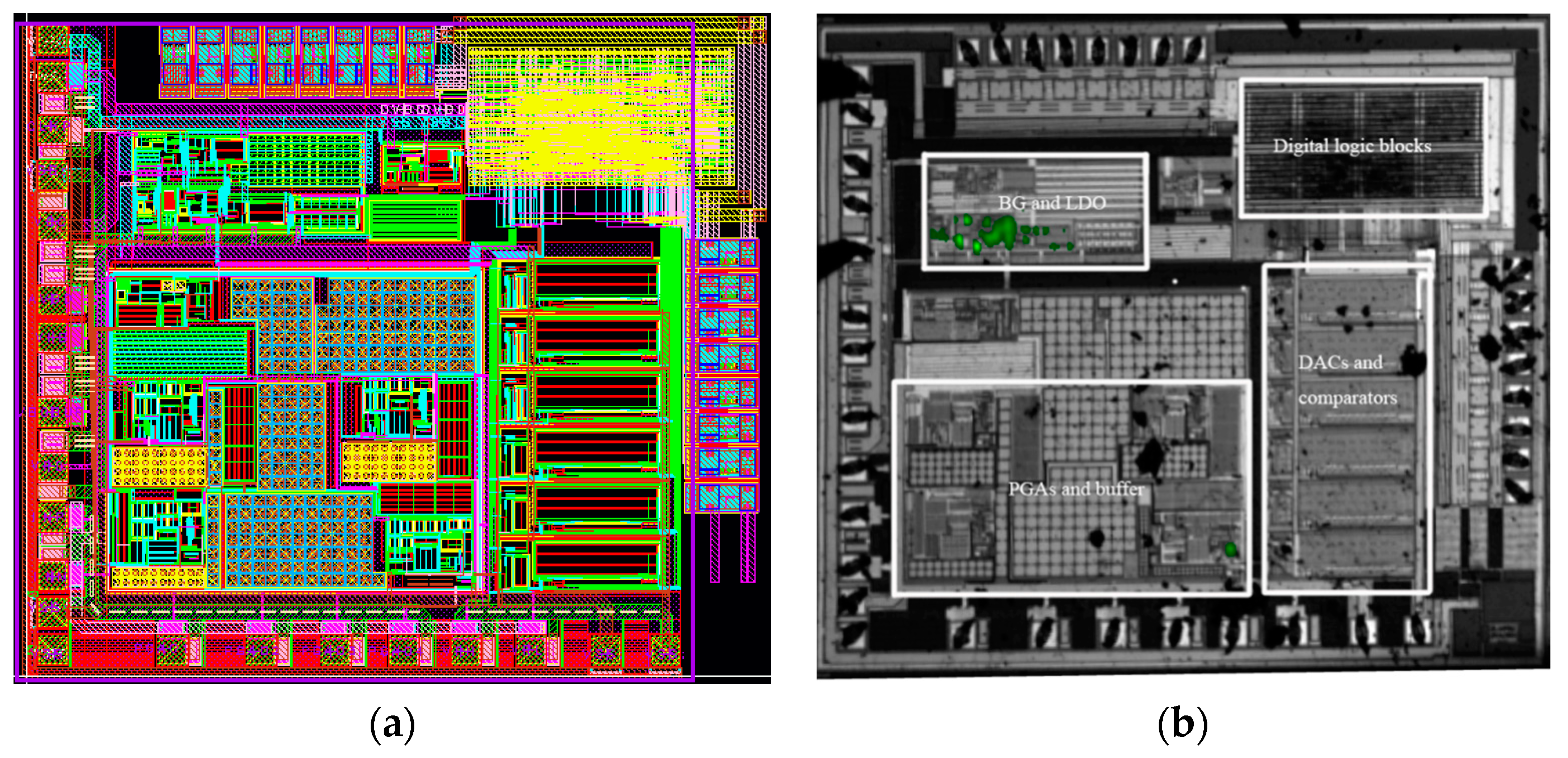

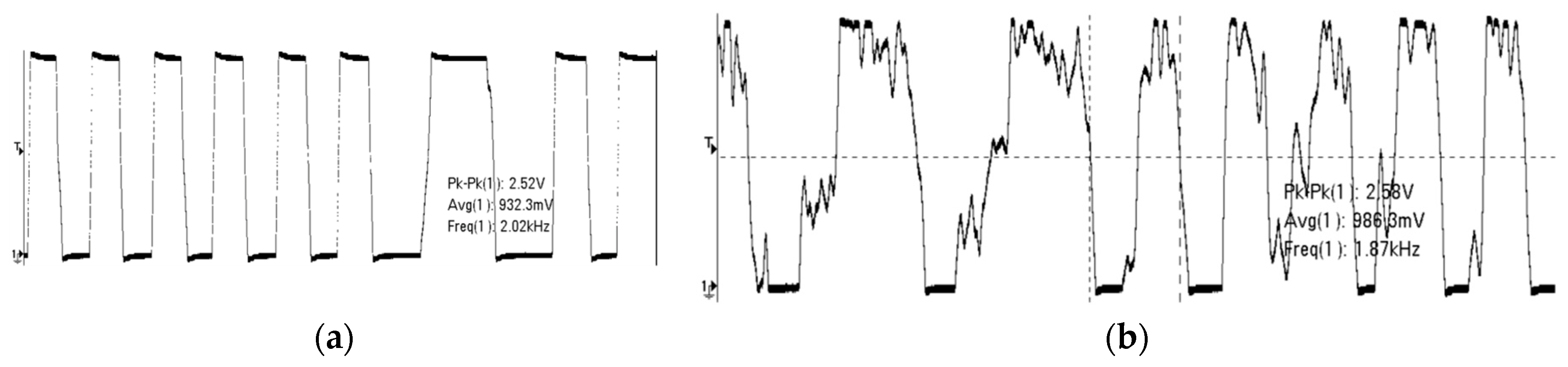

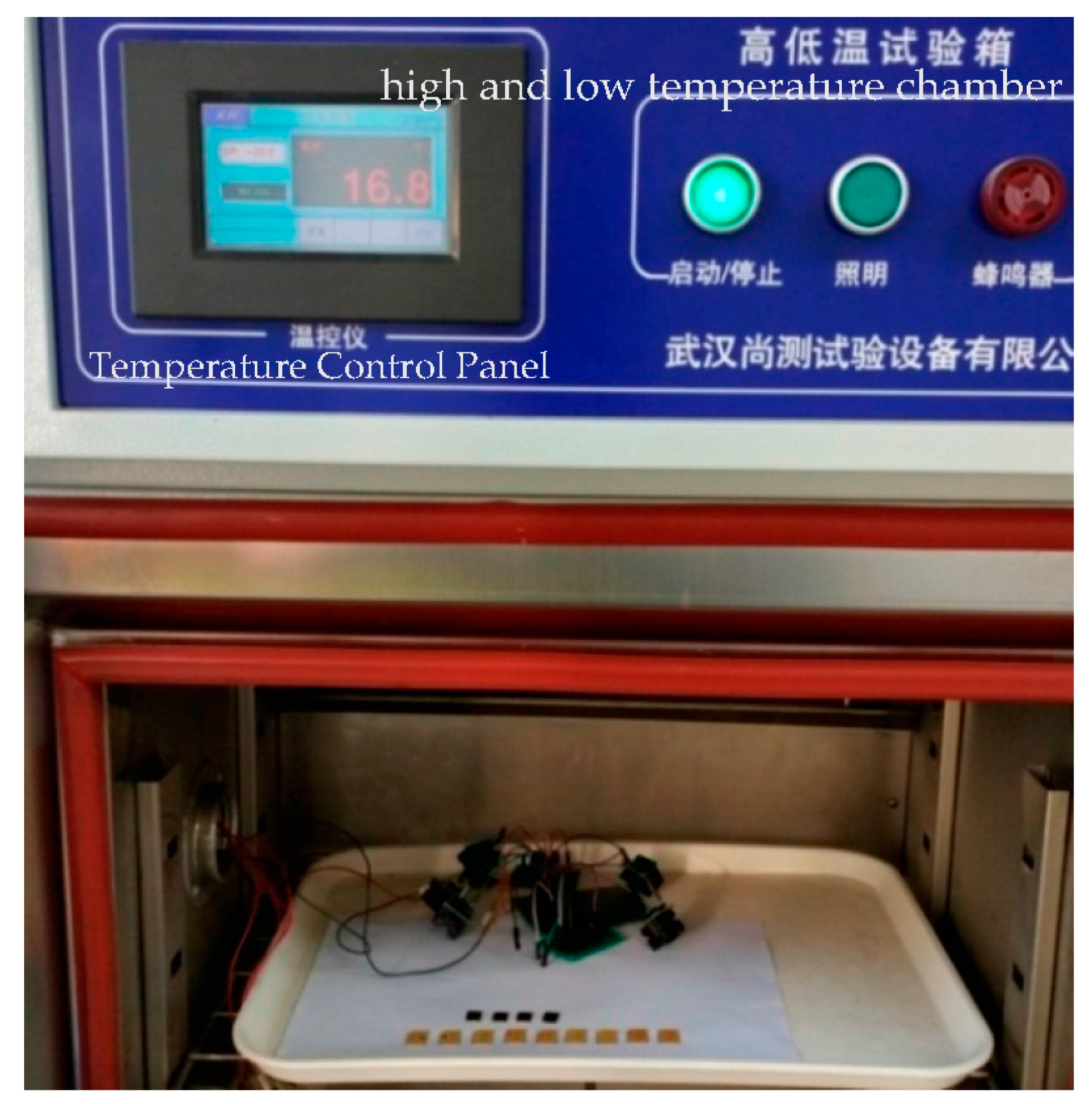

5. Implementation and Experimental Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Want, R. An Introduction to RFID Technology. IEEE Pervasive Comput. 2010, 5, 25–33. [Google Scholar] [CrossRef]

- Tan, W.H.; Ooi, K.B.; Chong, S.C.; Hew, T.S. NFC mobile credit card: the next frontier of mobile payment? Telemat. Inform. 2014, 31, 292–307. [Google Scholar] [CrossRef]

- Pasquet, M.; Reynaud, J.; Rosenberger, C. Secure Payment with NFC Mobile Phone in the Smart Touch Project. In Proceedings of the International Symposium on Collaborative Technologies and Systems, Irvine, CA, USA, 19–23 May 2008; pp. 19–23. [Google Scholar]

- Bolhuis, M. Using an NFC-Equipped Mobile Phone as a Token in Physical Access Control. Available online: http://essay.utwente.nl/65419/1/thesis_nfc_martijn_bolhuis_final.pdf (accessed on 3 May 2014).

- Liu, F.; Janssens, D.; Wets, G.; Cools, M. Annotating mobile phone location data with activity purposes using machine learning algorithms. Expert Syst. Appl. 2013, 8, 3299–3311. [Google Scholar] [CrossRef]

- Henpraserttae, A.; Thiemjarus, S.; Marukatat, S. Accurate Activity Recognition Using a Mobile Phone Regardless of Device Orientation and Location. In Proceedings of the 2011 International Conference on Body Sensor Networks, Dallas, TX, USA, 23–25 May 2011; pp. 23–25. [Google Scholar]

- Yang, G.; Huang, Z.; Wan, L. The development of RFID module in NFC phone. In Proceedings of the International Conference on Anti-Counterfeiting, Security, and Identification in Communication, Hong Kong, China, 20–22 August 2009. [Google Scholar]

- Von Oheimb, D.; Lotz, V.; Walter, G. Analyzing SLE 88 memory management security using Interacting State Machines. Int. J. Inf. Secur. 2005, 4, 155–171. [Google Scholar] [CrossRef]

- Hsu, C.C.; Chen, J.H. A novel sensor-assisted rfid-based indoor tracking system for the elderly living alone. Sensors 2011, 11, 10094–10113. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Park, H.; Bang, H.C.; Kim, D.H. An indoor location tracking based on mobile rfid for smart exhibition service. J. Comput. Virol. Hacking Tech. 2014, 2, 89–96. [Google Scholar] [CrossRef]

- Ni, L.M.; Liu, Y.; Lau, Y.C.; Patil, A.P. LANDMARC: Indoor location sensing using active RFID. In Proceedings of the IEEE International Conference on Pervasive Computing and Communications, Fort Worth, TX, USA, 23–26 March 2003. [Google Scholar]

- Qing, X.; Chen, Z.N. Proximity Effects of Metallic Environments on High Frequency RFID Reader Antenna: Study and Applications. IEEE Trans. Antennas Propag. 2007, 55, 3105–3111. [Google Scholar] [CrossRef]

- Lee, B.; Kim, B.; Mum, B.; Lee, H. NFC Antenna Design for Low-permeability Ferromagnetic Material. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 59–62. [Google Scholar]

- Yu, S.; Peng, Y.; Huang, X. Realization of Coordinative Control between Multi Readers and Multi RF-SIM Cards under Mobile RF-SIM Mode. In Proceedings of the International Conference on Computer Science and its Applications, Jeju, Korea, 22–25 November 2012. [Google Scholar]

- Ying, L.I.; Hong, L.I.; Chen, Y.T. Design on highway charge system based on RFSIM path recognition. Mod. Electron. Tech. 2014, 37, 60–63. [Google Scholar]

- Dai, W.; Luo, G.; Liu, S. A new technology of short-range communication for one card solutionin school. In Proceedings of the IET International Conference on Communication Technology and Application, Beijing, China, 14–16 October 2011. [Google Scholar]

- Wei, Q.; Wang, X. The Design and Implementation of the Minimal M2M Terminal Based on the SIM4100 Wireless Module. In Proceedings of the Third International Symposium on Information Processing, Qingdao, China, 15–17 October 2010. [Google Scholar]

- Shan, L.; Li, Z.; Hu, H. Converged Mobile Cellular Networks and Wireless Sensor Networks for Machine-to-Machine Communications. Ksii Trans. Internet Inf. Syst. 2012, 1, 147–161. [Google Scholar] [CrossRef]

- Smart Cards Embedded UICC Requirements Specification (Release 13): ETSI TS 103.383. Available online: http://www.etsi.org/index.php/technologies-clusters/technologies/smart-cards (accessed on 1 September 2013).

- Remote Provisioning Architecture for Embedded UICC Technical Specification Version 3.1: GSMA. SGP.02. Available online: http://www.gsma.com/newsroom/all-documents/sgp-02-v3-1-remote-provisioning-architecture-for-embedded-uicc-technical-specification/ (accessed on 27 May 2016).

- RSP Technical Specification Version 1.1: GSMA. SGP.2. Available online: http://www.gsma.com/newsroom/all-documents/sgp-22-technical-specification-v1-1/ (accessed on 9 September 2016).

- Understanding SIM Evolution: GSMA. Available online: https://www.gsmaintelligence.com/research/2015/03/understanding-sim-evolution/499/ (accessed on 3 March 2015).

- Klaus, F.; Müller, D. RFID Handbook: Fundamentals and Applications in Contactless Smart Cards, Radio Frequency Identification and Near-Field Communication, 3rd ed.; Wiley: Hoboken, NJ, USA, 2010; pp. 35–55. [Google Scholar]

- Chen, Y.; Zheng, Z. A low-power 2K/4K range-controlled communication chip design for mobile payment. In Proceedings of the IEEE International Nanoelectronics Conference, Chengdu, China, 9–12 April 2016. [Google Scholar]

- Hung, Y.C. Time-interleaved CMOS chip design of Manchester and Miller encoder for RFID application. Analog. Integr. Circuits Signal Process. 2012, 71, 549–560. [Google Scholar] [CrossRef]

- Saltzberg, B. An improved Manchester code receiver. In Proceedings of the IEEE International Conference on Communications, Atlanta, GA, USA, 16–19 April 1990. [Google Scholar]

- Guo, X.; Chen, Z. A New Circuit for Manchester Decoder Based on FPGA. Open J. Circuits Syst. 2014, 3, 31–36. [Google Scholar] [CrossRef]

- Xu, D.C.; Lu, J.F. Design of Manchester codec based on FPGA. Adv. Mater. Res. 2012, 614, 1357–1360. [Google Scholar] [CrossRef]

| Distance (cm) | BBT | PWM | PDM |

|---|---|---|---|

| Micro-SIM | 13.5 | 9.2 | 12.7 |

| Nano-SIM | 12.0 | 8.0 | 11.4 |

| −40 °C | −20 °C | 0 °C | 27 °C | 60 °C | 85 °C | |

|---|---|---|---|---|---|---|

| Distance in BBT (cm) | 11.2 | 11.8 | 12.0 | 12.0 | 12.0 | 12.0 |

| Distance in PWM (cm) | 6.5 | 7.9 | 7.9 | 8.0 | 7.9 | 7.9 |

| Distance in PDM (cm) | 9.2 | 11.2 | 11.3 | 11.4 | 11.3 | 11.3 |

| No. | D_VDD (V) | A_VDD (V) | V_BG (V) | P_BG (V) | OSC (kHz) | Current (µA) |

|---|---|---|---|---|---|---|

| 1 | 1.799 | 1.960 | 1.150 | 0.989 | 402.17 | 325.5 |

| 2 | 1.844 | 1.996 | 1.165 | 0.974 | 391.02 | 329.1 |

| 3 | 1.785 | 1.954 | 1.144 | 0.991 | 391.74 | 328.5 |

| 4 | 1.838 | 2.000 | 1.167 | 1.007 | 402.4 | 335.2 |

| 5 | 1.850 | 1.975 | 1.169 | 1.019 | 376.94 | 333.4 |

| 6 | 1.801 | 1.943 | 1.134 | 1.020 | 372.33 | 327.3 |

| 7 | 1.857 | 2.000 | 1.173 | 1.009 | 388.56 | 229.7 |

| 8 | 1.819 | 1.967 | 1.161 | 1.008 | 376.56 | 324.3 |

| 9 | 1.856 | 2.000 | 1.171 | 0.982 | 355.17 | 341.2 |

| 10 | 1.824 | 1.969 | 1.159 | 0.989 | 382.43 | 325.5 |

| No. | D_VDD (V) | A_VDD (V) | V_BG (V) | P_BG (V) | OSC (kHz) | Current (µA) |

|---|---|---|---|---|---|---|

| 1 | 1.801 | 1.963 | 1.151 | 0.99 | 401.95 | 331.5 |

| 2 | 1.848 | 1.994 | 1.167 | 0.974 | 391.3 | 340 |

| 3 | 1.782 | 1.955 | 1.147 | 0.993 | 391.53 | 330.4 |

| 4 | 1.846 | 2 | 1.184 | 1.007 | 402.67 | 339.4 |

| 5 | 1.854 | 1.977 | 1.172 | 1.02 | 377.61 | 338.8 |

| 6 | 1.805 | 1.947 | 1.14 | 1.024 | 372.35 | 331 |

| 7 | 1.864 | 2 | 1.176 | 1.01 | 386.24 | 335.8 |

| 8 | 1.824 | 1.966 | 1.163 | 1.011 | 376.55 | 328.5 |

| 9 | 1.859 | 2 | 1.172 | 0.982 | 356.58 | 347.8 |

| 10 | 1.820 | 1.963 | 1.155 | 0.986 | 381.56 | 330.4 |

| Iphone 6 | Iphone 5s | Huawei Mate 7 | Samsung I9200 | In Air | |

|---|---|---|---|---|---|

| Distance (cm) | 7.8 | 8.2 | 7.5 | 8.8 | 12 |

| Success ratio | 93% | 95% | 91% | 98% | 99% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Zheng, Z.; Gong, M.; Yu, F. Low Power Near Field Communication Methods for RFID Applications of SIM Cards. Sensors 2017, 17, 867. https://doi.org/10.3390/s17040867

Chen Y, Zheng Z, Gong M, Yu F. Low Power Near Field Communication Methods for RFID Applications of SIM Cards. Sensors. 2017; 17(4):867. https://doi.org/10.3390/s17040867

Chicago/Turabian StyleChen, Yicheng, Zhaoxia Zheng, Mingyang Gong, and Fengqi Yu. 2017. "Low Power Near Field Communication Methods for RFID Applications of SIM Cards" Sensors 17, no. 4: 867. https://doi.org/10.3390/s17040867