A Low-Cost Environmental Monitoring System: How to Prevent Systematic Errors in the Design Phase through the Combined Use of Additive Manufacturing and Thermographic Techniques

Abstract

:1. Introduction

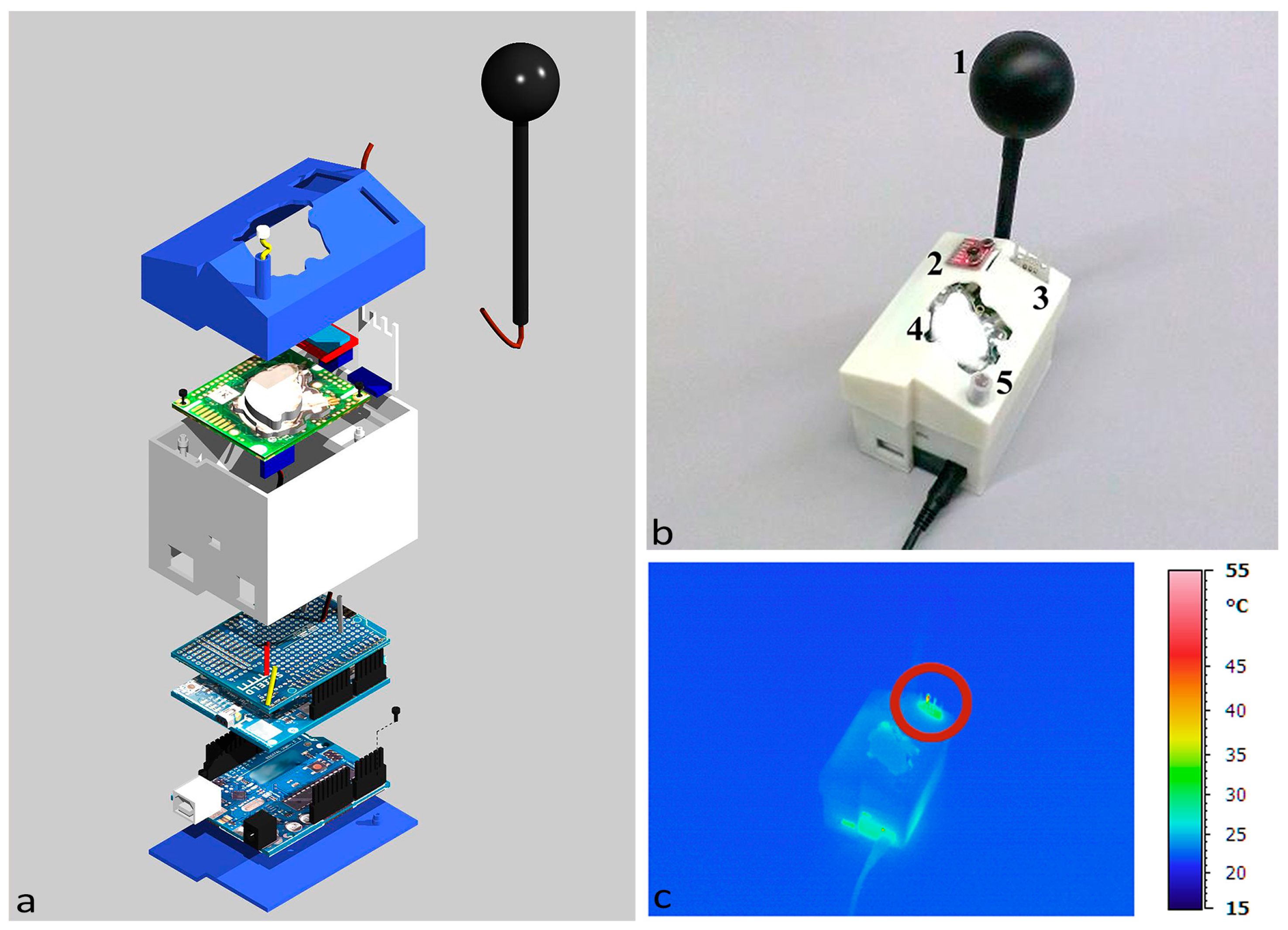

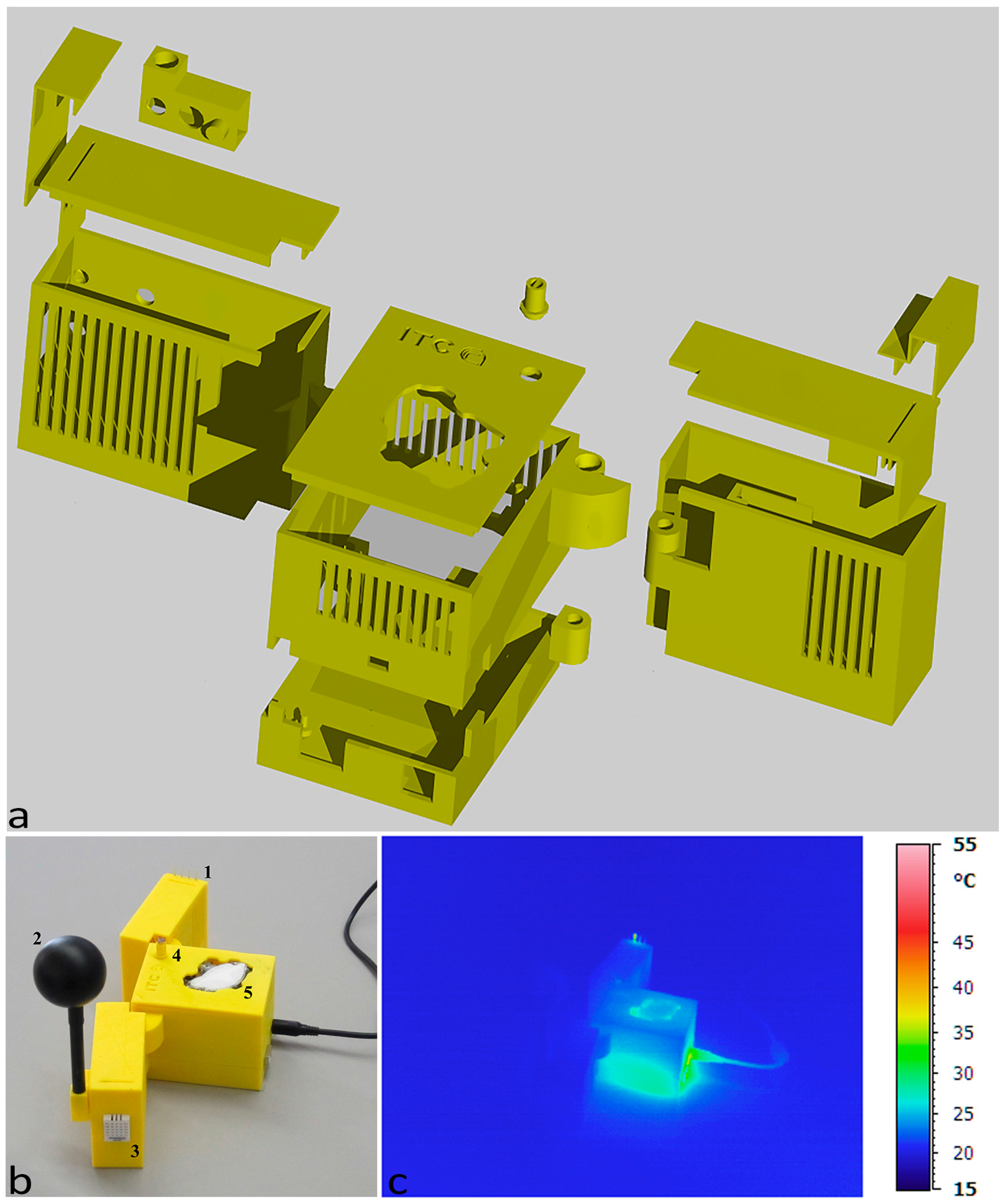

2. Materials and Methods

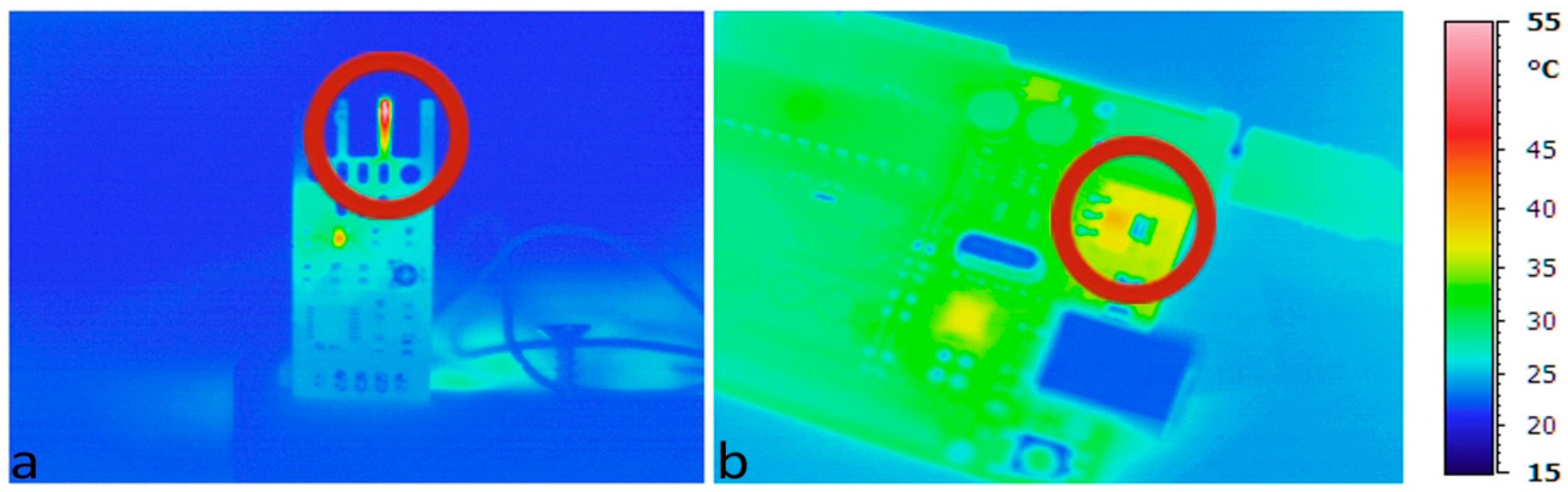

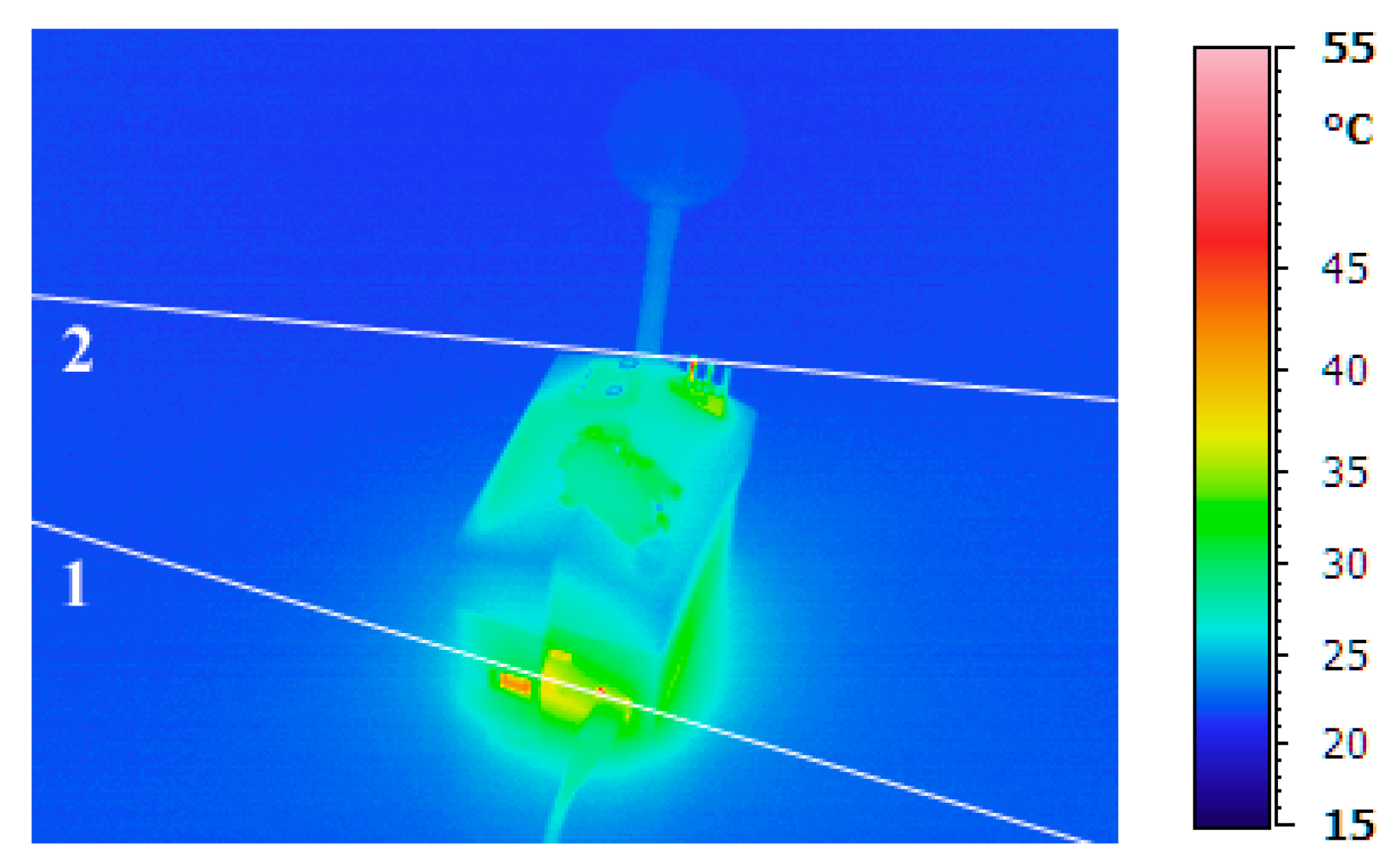

3. Thermal Analysis—First Test

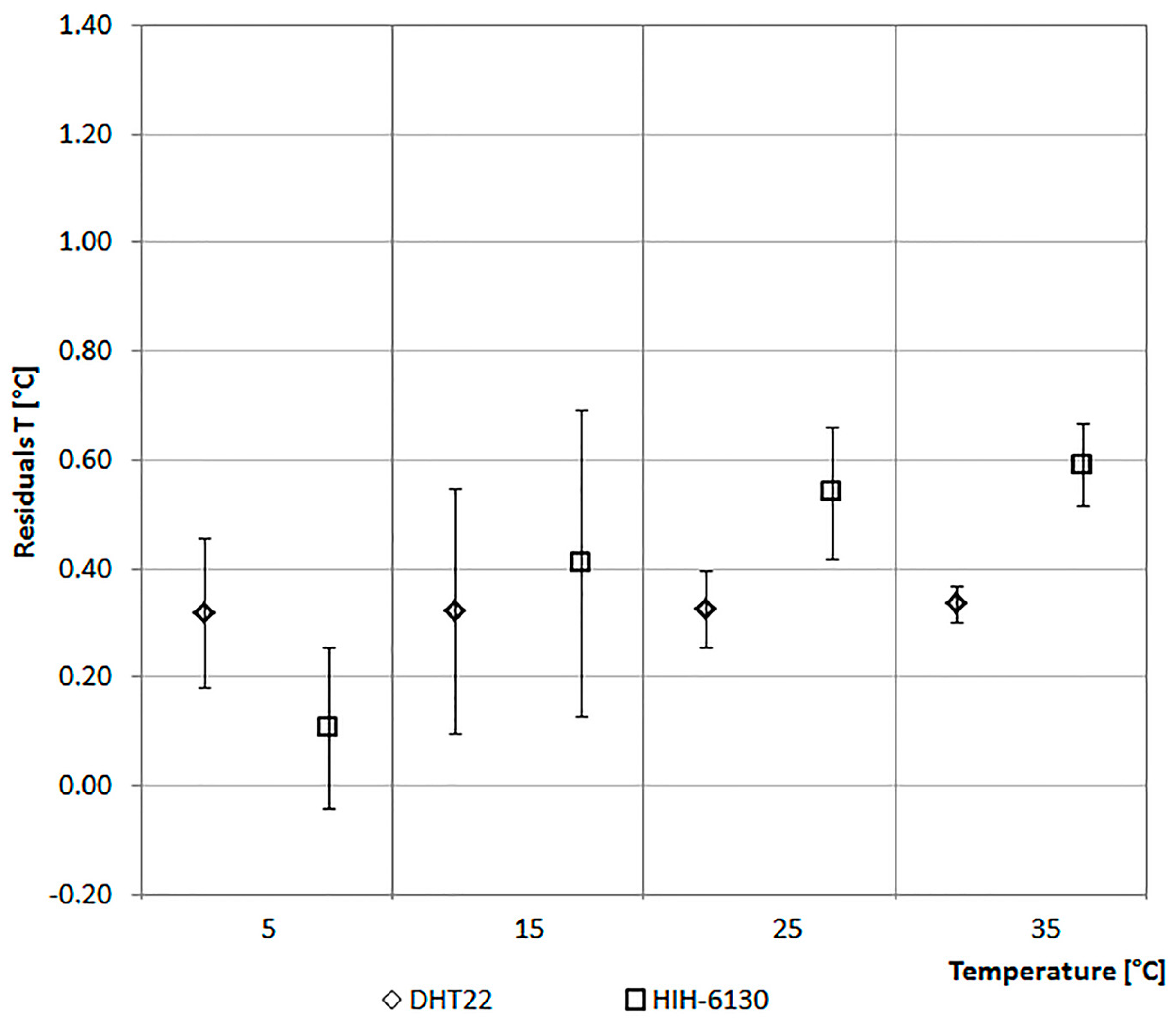

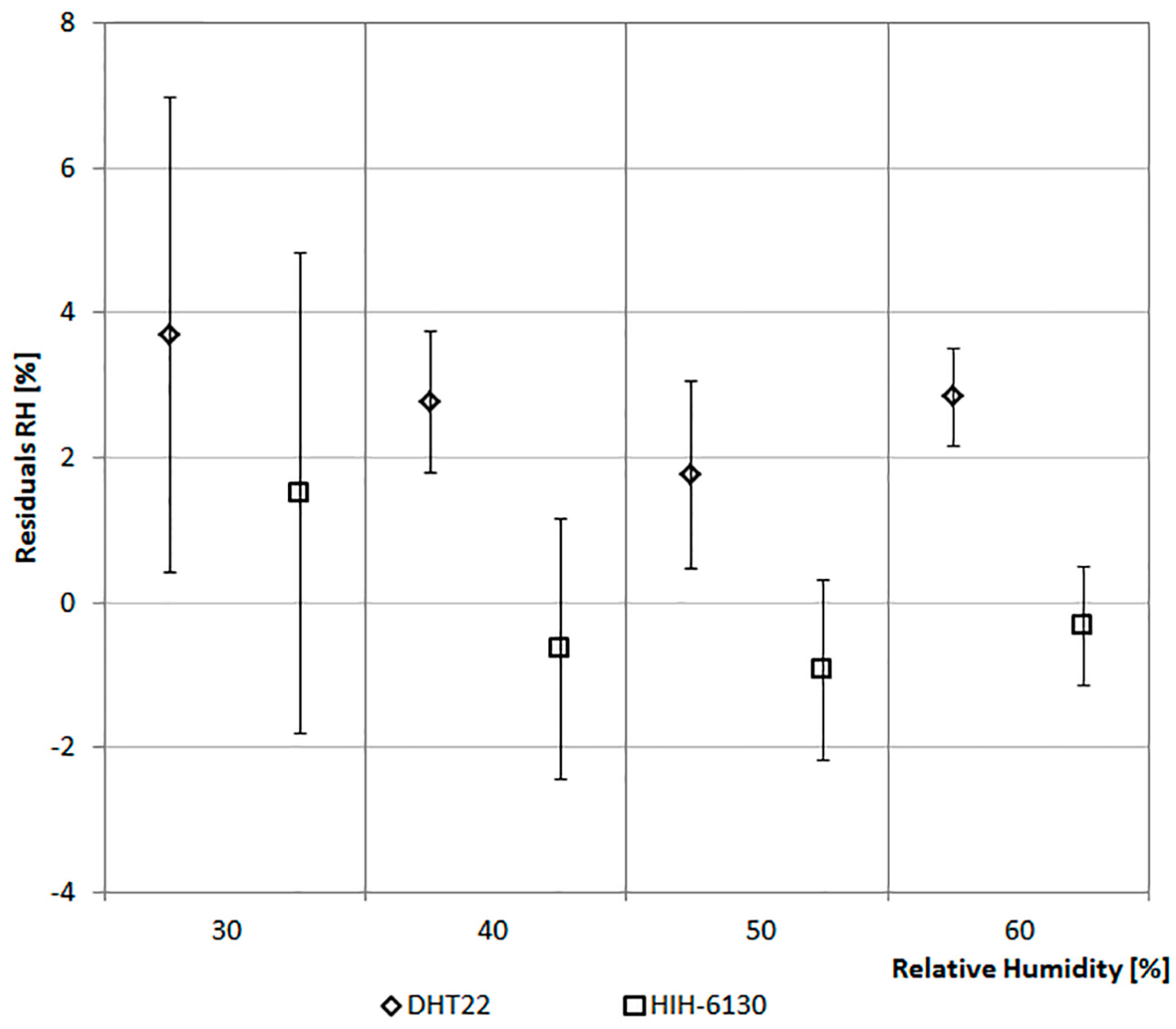

4. Calibration Phase of the Sensors

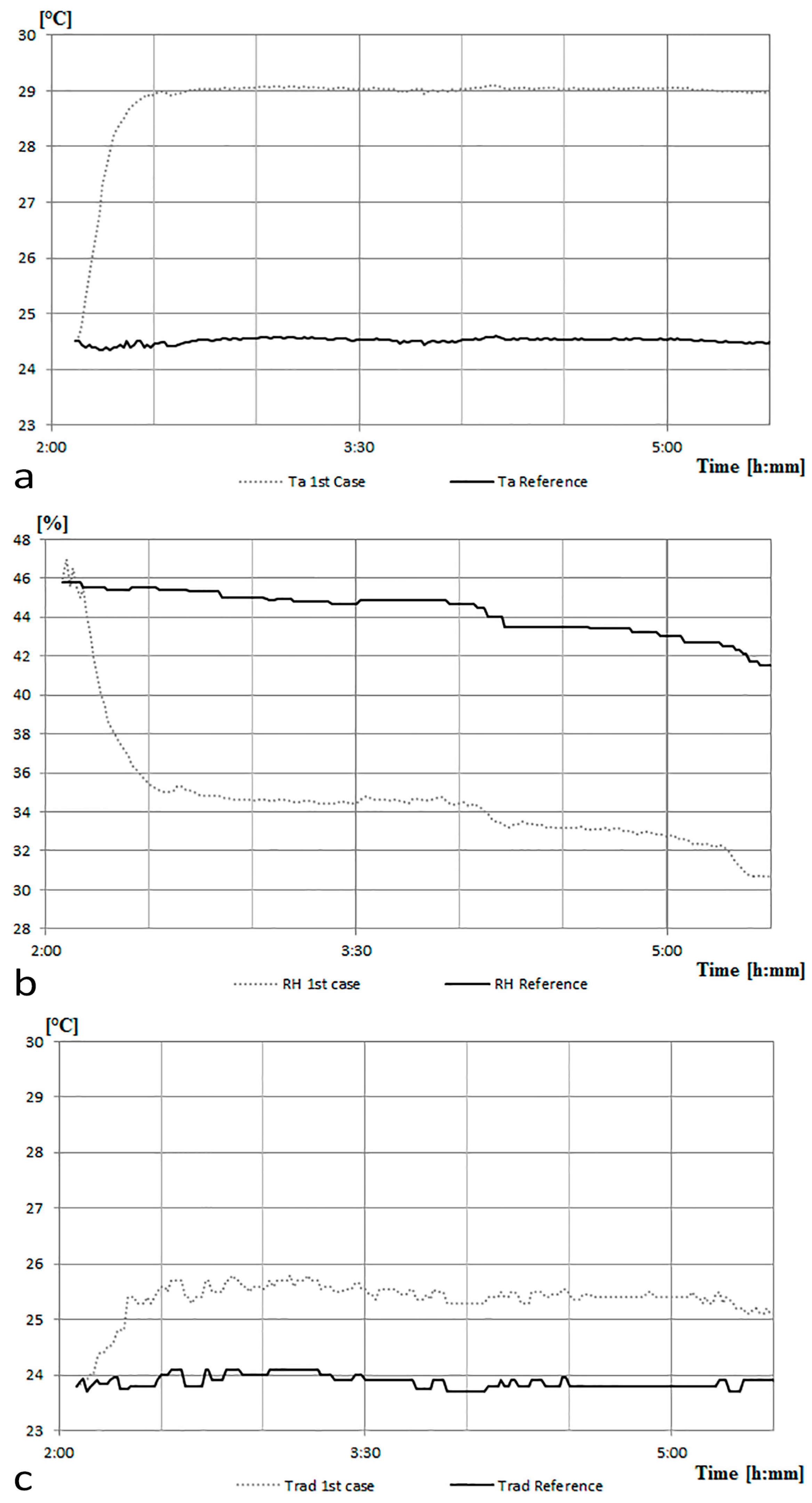

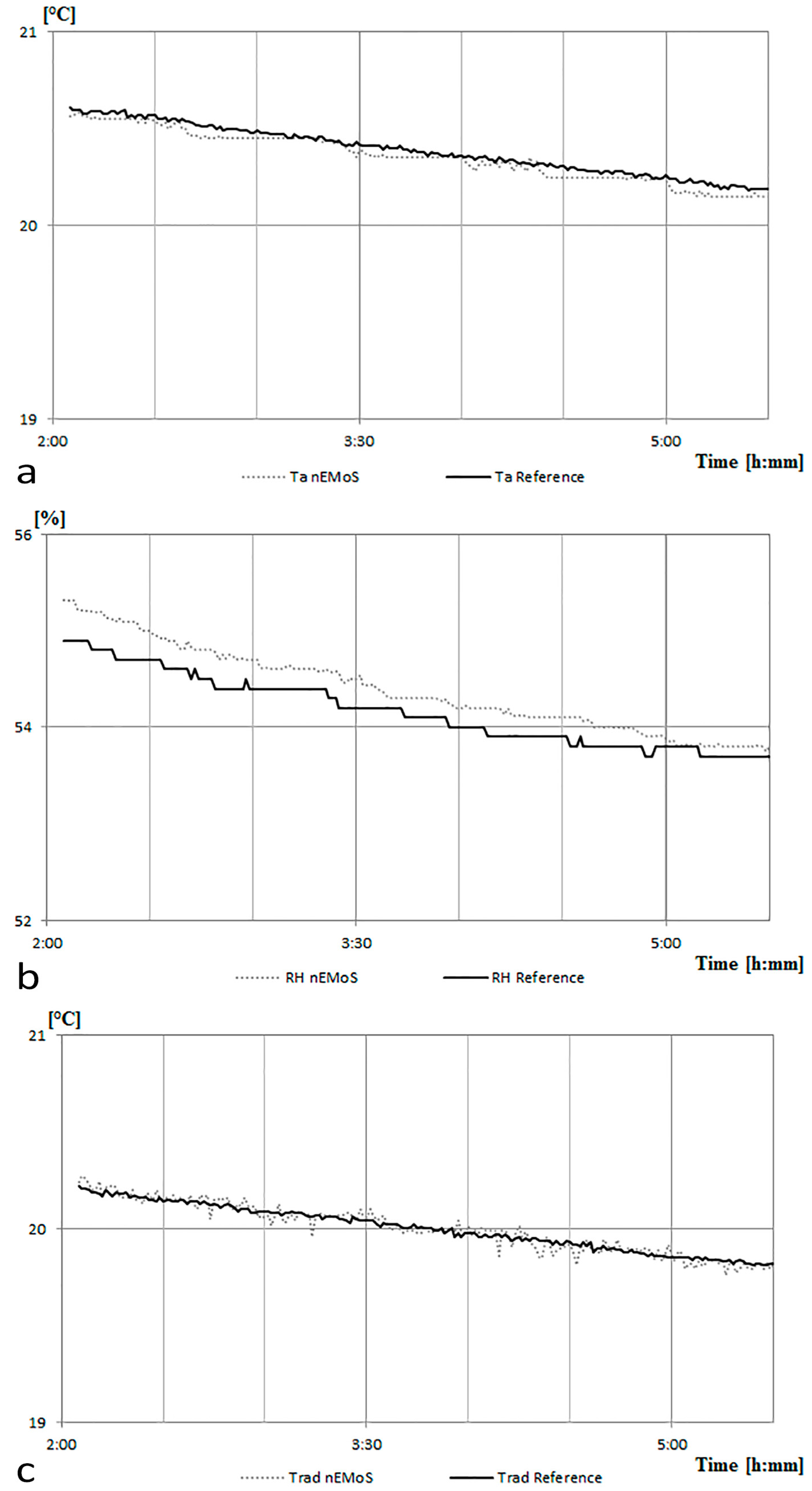

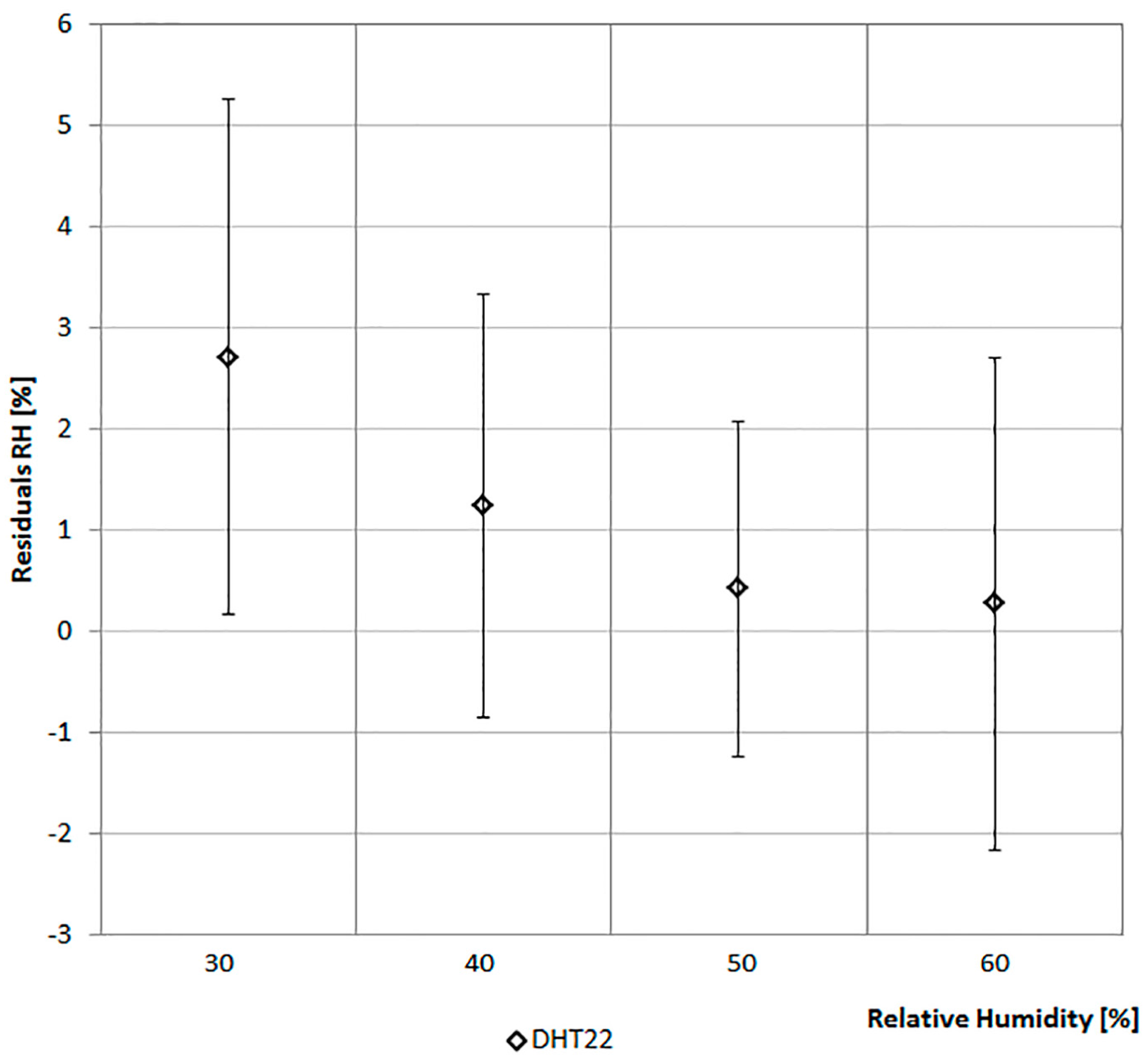

4.1. Ta and RH

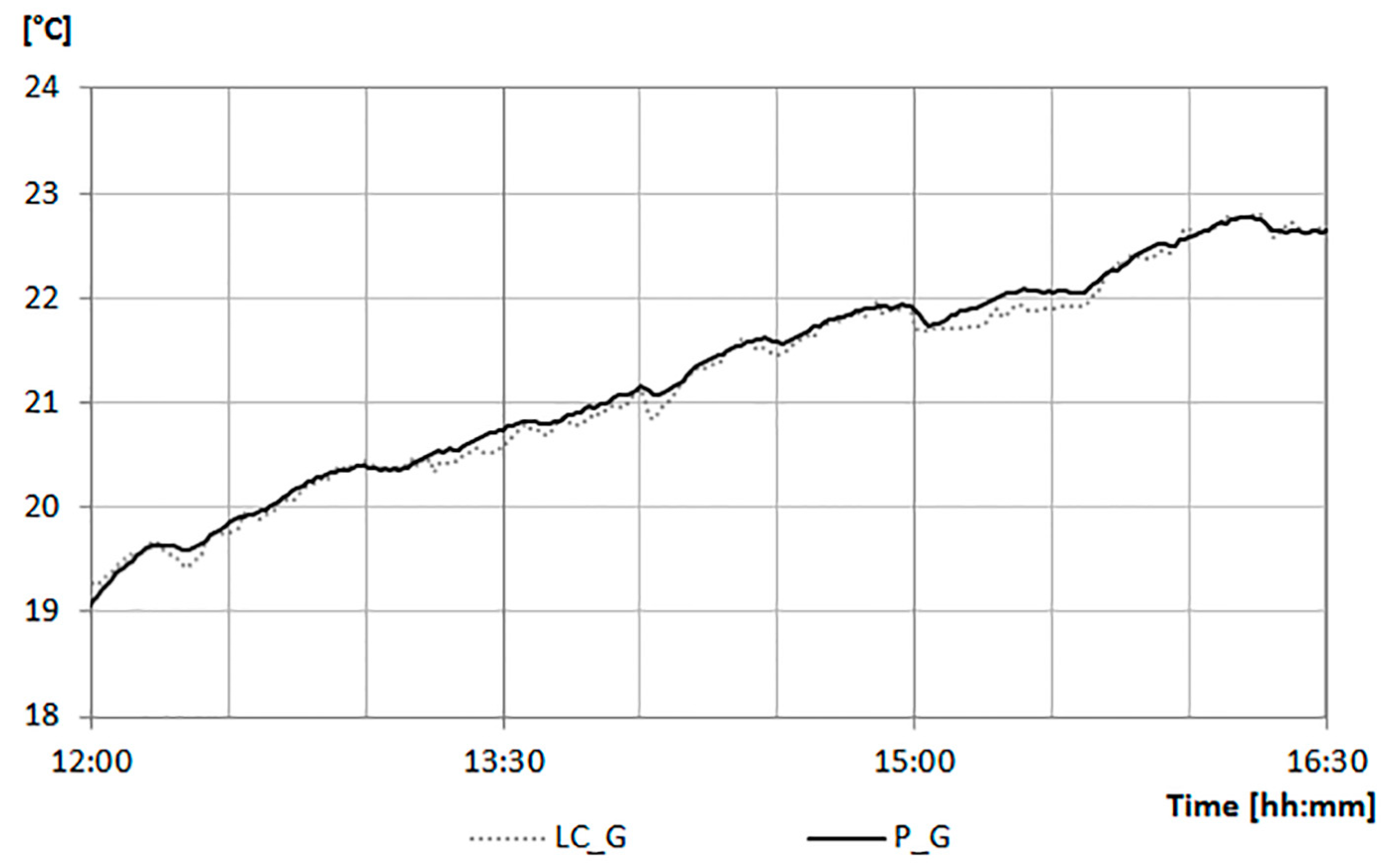

4.2. Trad

5. Optimization and Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Danza, L.; Belussi, L.; Meroni, I.; Mililli, M.; Salamone, F. Hourly calculation method of air source heat pump behavior. Buildings 2016, 6, 16. [Google Scholar] [CrossRef]

- Dai, C.; Lan, L.; Lian, Z. Method for the determination of optimal work environment in office buildings considering energy consumption and human performance. Energy Build. 2014, 76, 278–283. [Google Scholar] [CrossRef]

- Katafygiotou, M.C.; Serghides, D.K. Indoor comfort and energy performance of buildings in relation to occupants’ satisfaction: Investigation in secondary schools of Cyprus. Adv. Build. Energy Res. 2014, 8, 216–240. [Google Scholar] [CrossRef]

- Belussi, L.; Danza, L.; Meroni, I.; Salamone, F.; Ragazzi, F.; Mililli, M. Energy performance of buildings: A study of the differences between assessment methods. In Energy Consumption: Impacts of Human Activity, Current and Future Challenges, Environmental and Socio-Economic Effects; Nova Science Publishers: New York, NY, USA, 2014; pp. 53–75. [Google Scholar]

- Terkaj, W.; Danza, L.; Devitofrancesco, A.; Gagliardo, S.; Ghellere, M.; Giannini, F.; Monti, M.; Pedrielli, G.; Sacco, M.; Salamone, F. A semantic framework for sustainable factories. Procedia CIRP 2014, 17, 547–552. [Google Scholar] [CrossRef]

- Gagliardo, S.; Giannini, F.; Monti, M.; Pedrielli, G.; Terkaj, W.; Sacco, M.; Ghellere, M.; Salamone, F. An ontology-based framework for sustainable factories. Comput. Aided Des. Appl. 2015, 12, 198–207. [Google Scholar] [CrossRef]

- Danza, L.; Belussi, L.; Meroni, I.; Salamone, F.; Floreani, F.; Piccinini, A.; Dabusti, A. A Simplified Thermal Model to Control the Energy Fluxes and to Improve the Performance of Buildings. Energy Procedia 2016, 101, 97–104. [Google Scholar] [CrossRef]

- Salamone, F.; Belussi, L.; Danza, L.; Ghellere, M.; Meroni, I. New scenarios of characterization of internal environmental comfort. In Proceedings of the 40th IAHS World Congress on Housing Sustainable Housing Construction, Funchal, Portugal, 16–19 December 2014. [Google Scholar]

- Briand, D.; Heimgartner, S.; Gr tillat, M.; Schoot, B.; Rooij, N. Thermal optimization of micro-hotplates that have a silicon island. J. Micromech. Microeng. 2002, 12, 971–978. [Google Scholar] [CrossRef]

- Childs, P. Practical Temperature Measurement; Butterworth-Heinemann: Oxford, UK, 2001. [Google Scholar]

- Belussi, L.; Danza, L.; Meroni, I.; Salamone, F. Energy performance assessment with empirical methods: Application of energy signature. Opto Electron. Rev. 2015, 23, 83–87. [Google Scholar] [CrossRef]

- Tzifa, V.; Papadakos, G.; Papadopoulou, A.G.; Marinakis, V.; Psarras, J. Uncertainty and method limitations in a short-time measurement of the effective thermal transmittance on a building envelope using an infrared camera. Int. J. Sustain. Energy 2017, 36, 28–46. [Google Scholar] [CrossRef]

- Bianchi, F.; Pisello, A.L.; Baldinelli, G.; Asdrubali, F. Infrared thermography assessment of thermal bridges in building envelope: Experimental validation in a test room setup. Sustainability 2014, 6, 7107–7120. [Google Scholar] [CrossRef]

- Ferrarini, G.; Bison, P.; Bortolin, A.; Cadelano, G. Thermal response measurement of building insulating materials by infrared thermography. Energy Build. 2016, 133, 559–564. [Google Scholar] [CrossRef]

- Barreira, E.; Almeida, R.M.; Moreira, M. An infrared thermography passive approach to assess the effect of leakage points in buildings. Energy Build. 2017, 140, 224–235. [Google Scholar] [CrossRef]

- Ghahramani, A.; Castro, G.; Becerik-Gerber, B.; Yu, X. Infrared thermography of human face for monitoring thermoregulation performance and estimating personal thermal comfort. Build. Environ. 2016, 109, 1–11. [Google Scholar] [CrossRef]

- Anzalone, G.; Glover, A.; Pearce, J. Open-Source Colorimeter. Sensors 2013, 13, 5338–5346. [Google Scholar] [CrossRef] [PubMed]

- Salamone, F.; Belussi, L.; Danza, L.; Ghellere, M.; Meroni, I. An Open Source Low-Cost Wireless Control System for a Forced Circulation Solar Plant. Sensors 2015, 15, 27990–28004. [Google Scholar] [CrossRef] [PubMed]

- Martínez, M.; Andújar, J.; Enrique, J. A New and Inexpensive Pyranometer for the Visible Spectral Range. Sensors 2009, 9, 4615–4634. [Google Scholar] [CrossRef] [PubMed]

- Anderson, C. Makers; Crown Business: New York, NY, USA, 2012. [Google Scholar]

- Watanabe, Y. How to make almost anything: The possibility of FabLabs around the world and Kamakura. J. Inf. Process. Manag. 2014, 57, 641–650. [Google Scholar] [CrossRef]

- Hatch, M. The Maker Movement Manifesto; McGraw-Hill Education: Columbus, OH, USA, 2014. [Google Scholar]

- Fox, S. Third Wave Do-It-Yourself (DIY): Potential for prosumption, innovation, and entrepreneurship by local populations in regions without industrial manufacturing infrastructure. Technol. Soc. 2014, 39, 18–30. [Google Scholar] [CrossRef]

- Fox, S. Paradigm shift: Do-it-yourself (DIY) invention and production of physical goods for use or sale. J. Manuf. Technol. Manag. 2013, 24, 218–234. [Google Scholar] [CrossRef]

- Salamone, F.; Belussi, L.; Danza, L.; Ghellere, M.; Meroni, I. An Open Source “Smart Lamp” for the Optimization of Plant Systems and Thermal Comfort of Offices. Sensors 2016, 16, 338. [Google Scholar] [CrossRef] [PubMed]

- Salamone, F.; Belussi, L.; Danza, L.; Ghellere, M.; Meroni, I. Integration of a do it yourself Hardware in a Lighting Device for the Management of Thermal Comfort and Energy Use. Energy Procedia 2016, 101, 161–168. [Google Scholar] [CrossRef]

- Ray, P.P. Internet of things cloud enabled MISSENARD index measurement for indoor occupants. Measurement 2016, 92, 157–165. [Google Scholar] [CrossRef]

- Mejías, A.; Herrera, R.S.; Márquez, M.A.; Calderón, A.J.; González, I.; Andújar, J.M. Easy Handling of Sensors and Actuators over TCP/IP Networks by Open Source Hardware/Software. Sensors 2017, 17, 94. [Google Scholar] [CrossRef] [PubMed]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Weber, R.; Weber, R. Internet of Things; Springer: Berlin, Germany, 2010. [Google Scholar]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Torchia, F.; Ricciardi, P.; Scrosati, C.; Scamoni, F. Improvement of Façades’ Sound Insulation of Schools near the Bergamo-Orio al Serio International Airport: Case Study. Build. Acoust. 2015, 22, 123–142. [Google Scholar] [CrossRef]

- Casini, D.; Cellai, G.; Fogola, J.; Scamoni, F.; Secchi, S. Correlation between facade sound insulation and urban noise: A contribution to the acoustic classification of existing buildings. Build. Acoust. 2016, 23, 145–158. [Google Scholar] [CrossRef]

- Salamone, F.; Belussi, L.; Danza, L.; Ghellere, M.; Meroni, I. Design and Development of nEMoS, an All-in-One, Low-Cost, Web-Connected and 3D-Printed Device for Environmental Analysis. Sensors 2015, 15, 13012–13027. [Google Scholar] [CrossRef] [PubMed]

- Lanzoni, D. Termografia; Maggioli Editore: Rimini (RN), Italy, 2014. [Google Scholar]

- Danza, L.; Barozzi, B.; Belussi, L.; Meroni, I.; Salamone, F. Assessment of the performance of a ventilated window coupled with a heat recovery unit through the co-heating test. Buildings 2016, 6, 3. [Google Scholar] [CrossRef]

- Test of DHT22. Available online: https://www.kandrsmith.org/RJS/Misc/Hygrometers/calib_dht22.html#time (accessed on 14 March 2017).

| Function/Parameters to Measure | Sensor |

|---|---|

| Data logging function | Arduino UNO |

| Web connection | Wi-Fi shield |

| Bluetooth connection | BlueSMiRF |

| Air temperature and Relative humidity | HIH6130/DHT22 |

| Radiant temperature | Thermistor within a globe of black color with a diameter of 40 mm |

| Air velocity | Wind sensor |

| Illuminance | LDR sensor |

| CO2 concentration | k-30 sensor |

| Technical Data | HIH-6130 | DHT22 |

|---|---|---|

| Power supply | 2.3–5.5 V | 3.3–6 V |

| Typical range | RH: 10–90%; | RH: 0–100%; |

| Ta: −40 to +85 °C | Ta: −40 to +80 °C | |

| Accuracy | RH: ±4%; | RH: ±2%; |

| Ta: <±0.5 °C | Ta: <±0.5 °C | |

| Resolution | RH: 0.04%; | RH: 0.1%; |

| Ta: 0.025 °C | Ta: 0.1 °C | |

| Long-term stability | - | RH: ±0. 5%/year |

| Response time | Average: 5 s | Average: 2 s |

| Dimensions | 18 × 16 × 4 mm (module) | 14 × 18 × 4 mm (module) |

| Cost | ~30€ | ~10€ |

| Technical Data | LC_G | P_G |

|---|---|---|

| Power supply | 3.3–5 V | 10–30 V |

| Typical range | −40 to +60 Celsius | −40 to +60 Celsius |

| Accuracy | ±0.2 Celsius | ±0.2 Celsius |

| Resolution | - | 0.01 Celsius |

| Long-term stability | ±0.02 Celsius/year | - |

| Response time | <10 s | <10 s |

| Dimensions | 40 mm (ø) | 150 mm (ø) |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salamone, F.; Danza, L.; Meroni, I.; Pollastro, M.C. A Low-Cost Environmental Monitoring System: How to Prevent Systematic Errors in the Design Phase through the Combined Use of Additive Manufacturing and Thermographic Techniques. Sensors 2017, 17, 828. https://doi.org/10.3390/s17040828

Salamone F, Danza L, Meroni I, Pollastro MC. A Low-Cost Environmental Monitoring System: How to Prevent Systematic Errors in the Design Phase through the Combined Use of Additive Manufacturing and Thermographic Techniques. Sensors. 2017; 17(4):828. https://doi.org/10.3390/s17040828

Chicago/Turabian StyleSalamone, Francesco, Ludovico Danza, Italo Meroni, and Maria Cristina Pollastro. 2017. "A Low-Cost Environmental Monitoring System: How to Prevent Systematic Errors in the Design Phase through the Combined Use of Additive Manufacturing and Thermographic Techniques" Sensors 17, no. 4: 828. https://doi.org/10.3390/s17040828