Steady γ-Ray Effects on the Performance of PPP-BOTDA and TW-COTDR Fiber Sensing

Abstract

:1. Introduction

2. Distributed Sensing Measurements

2.1. Principle of PPP-BOTDA

2.2. Principle of TW-COTDR

3. Materials and Experimental Procedures

3.1. Tested Fibers

3.2. Fiber Sample Packaging for Radiation Tests

3.3. Fiber Calibration Procedure

3.4. Irradiation Conditions

4. Experimental Results

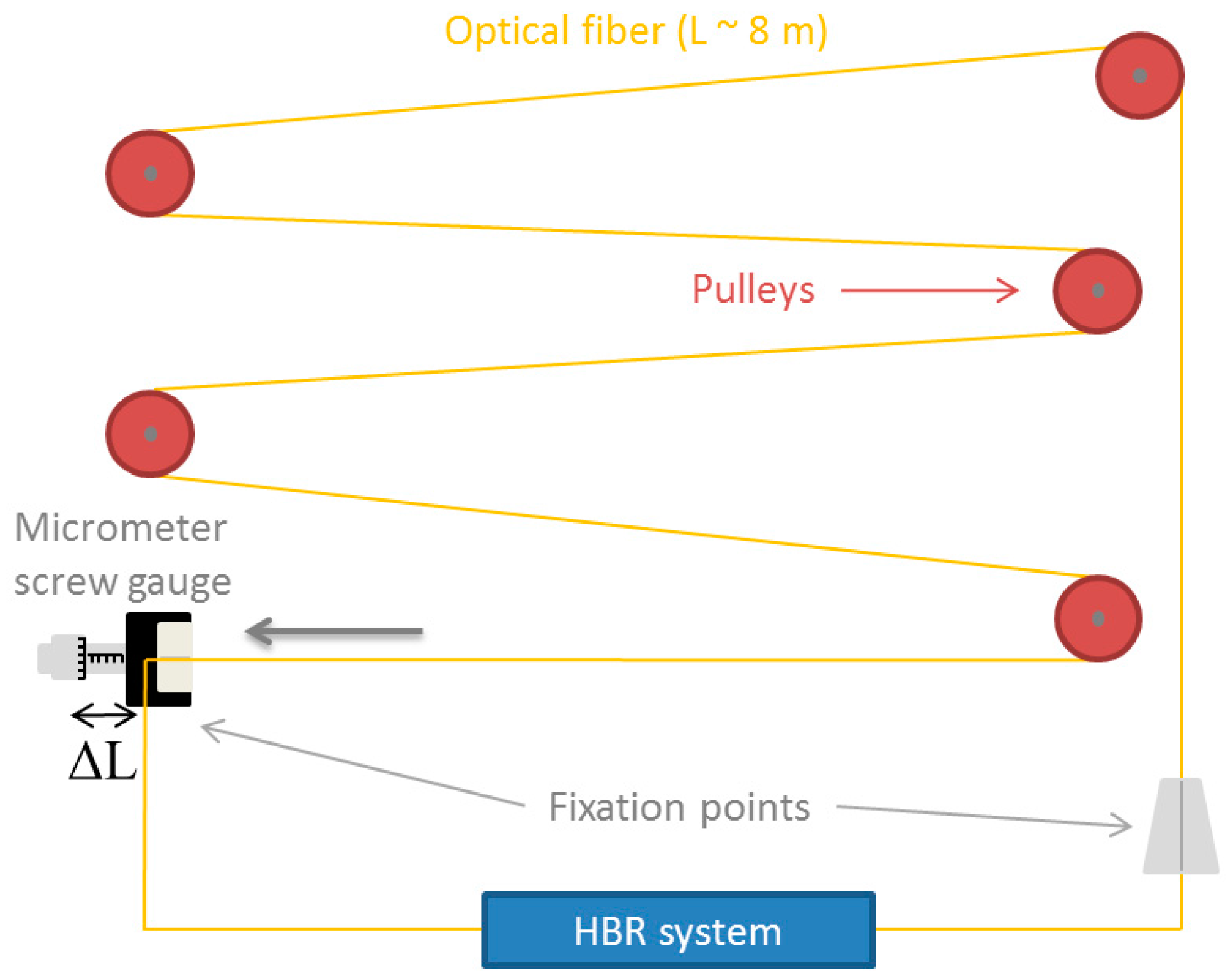

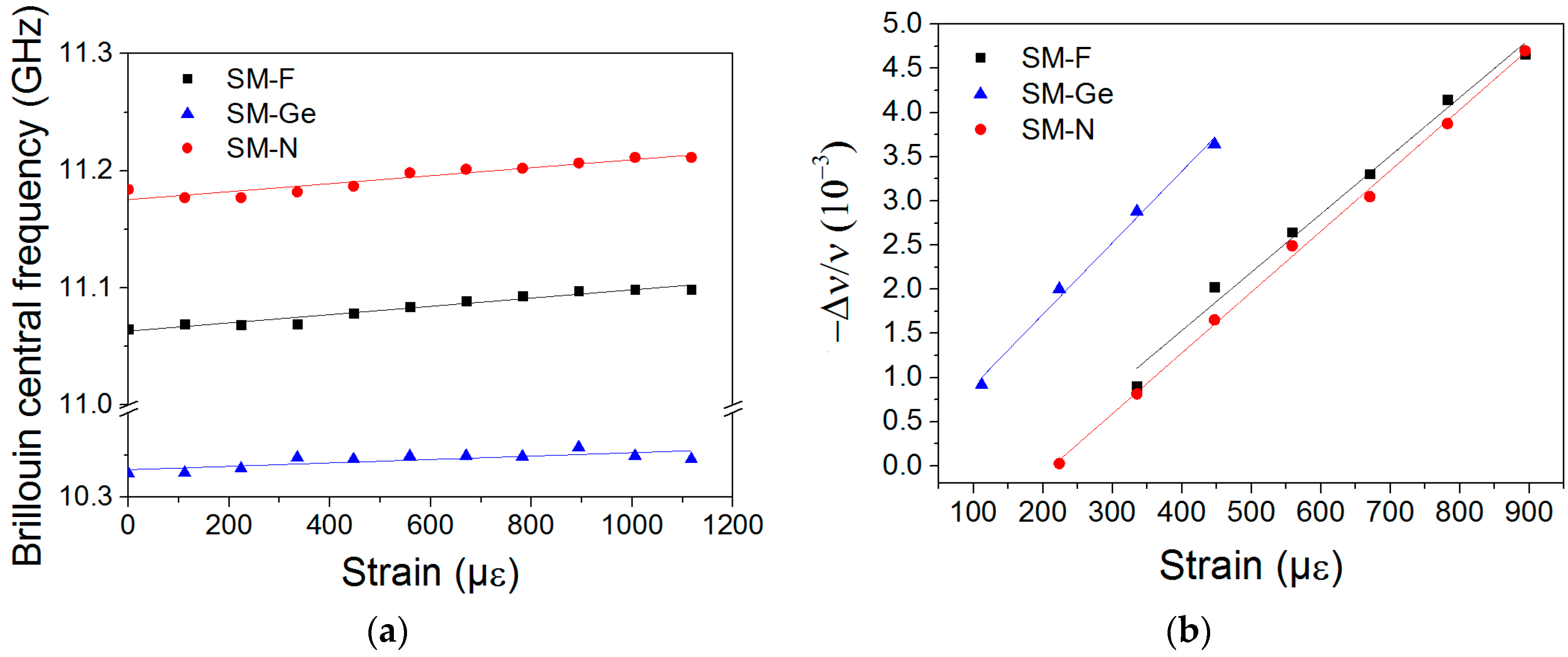

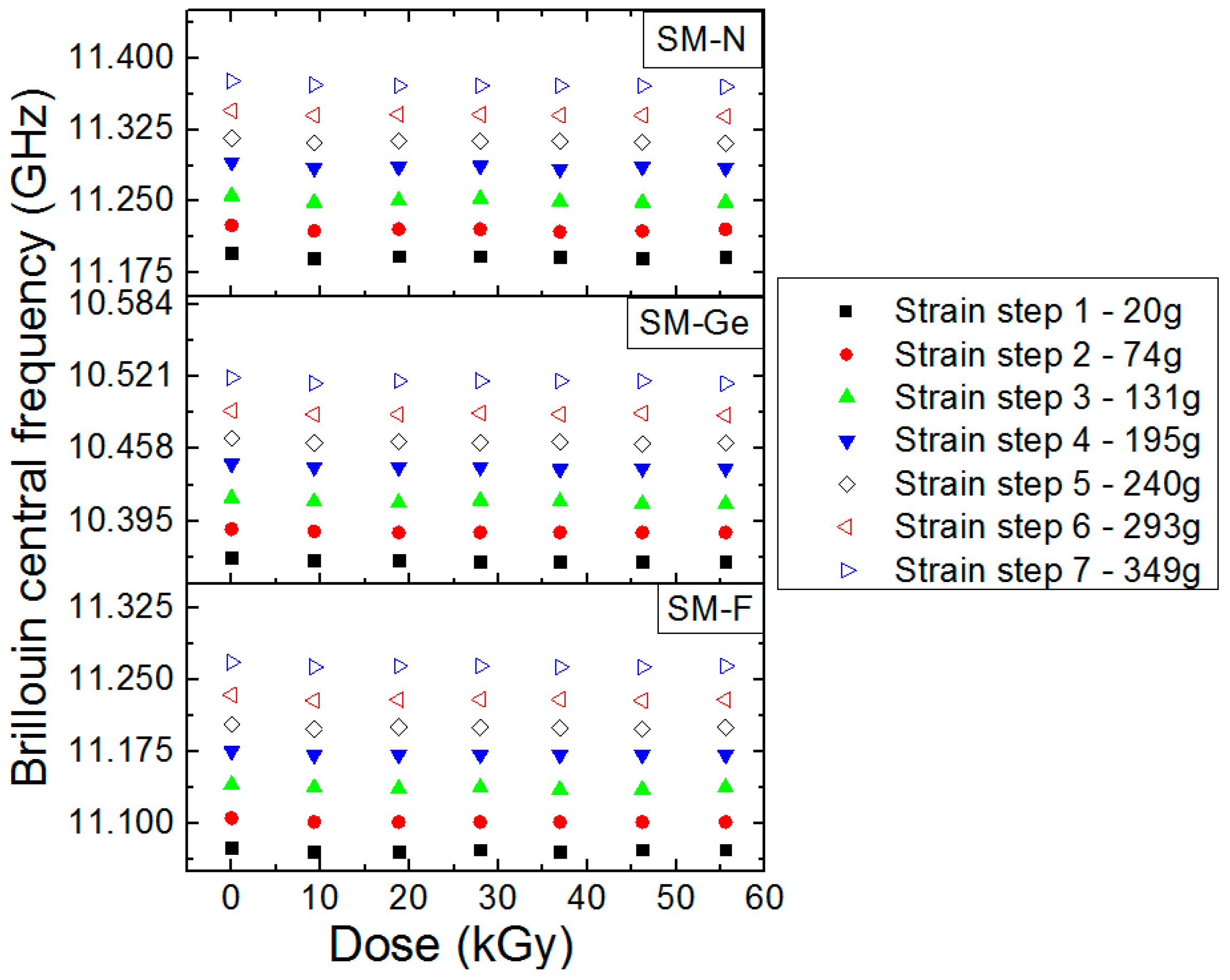

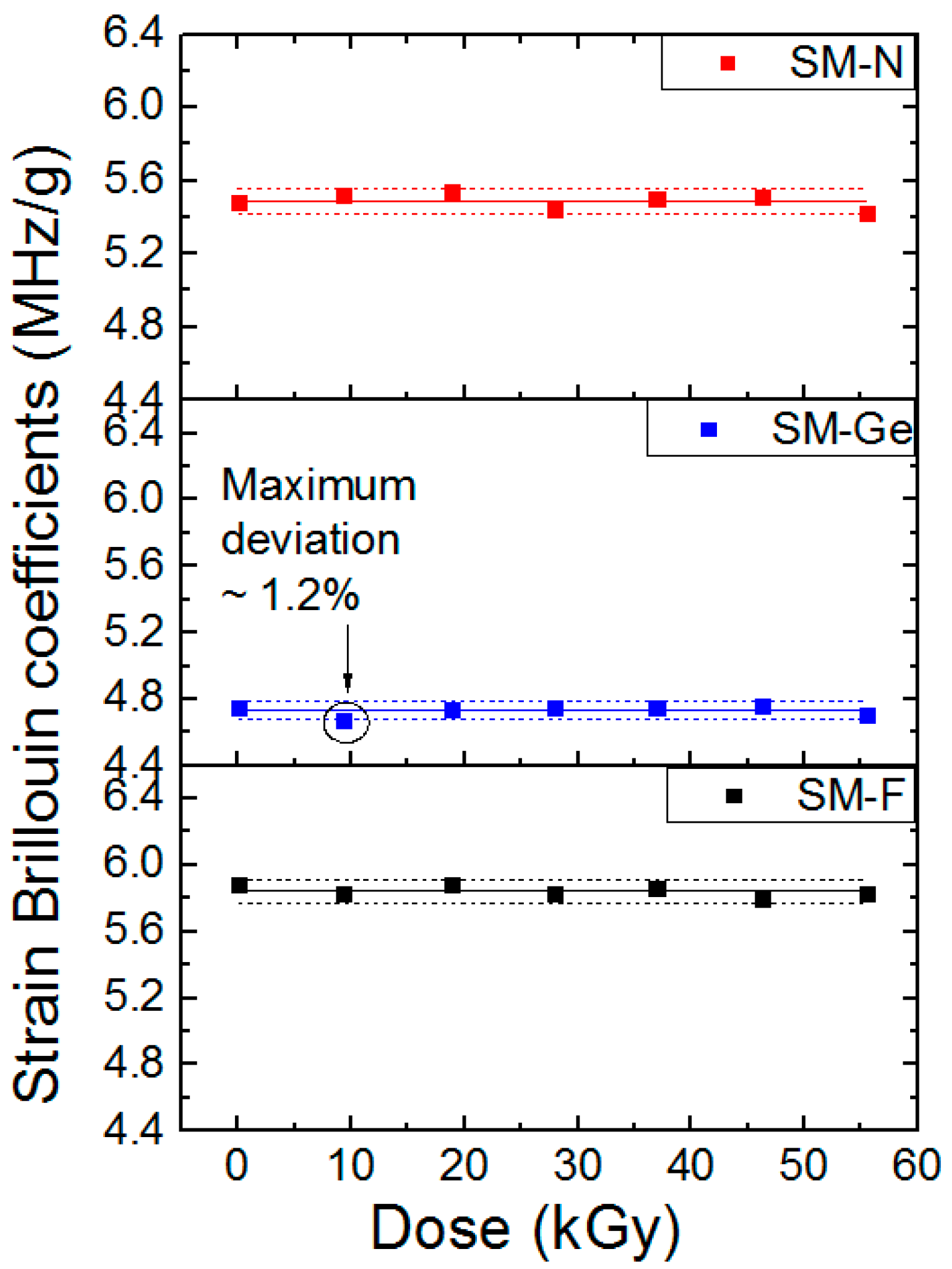

4.1. Determination of Strain Coefficients before Irradiation

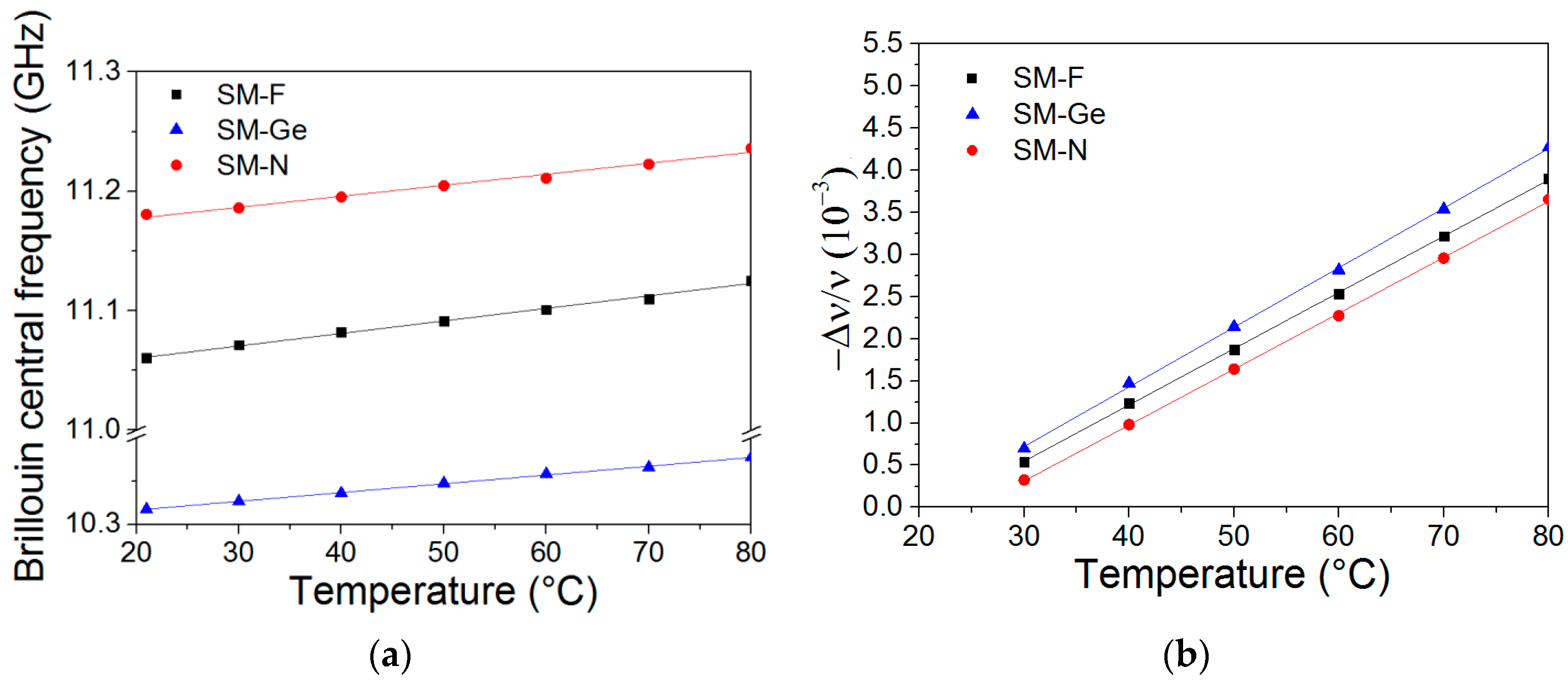

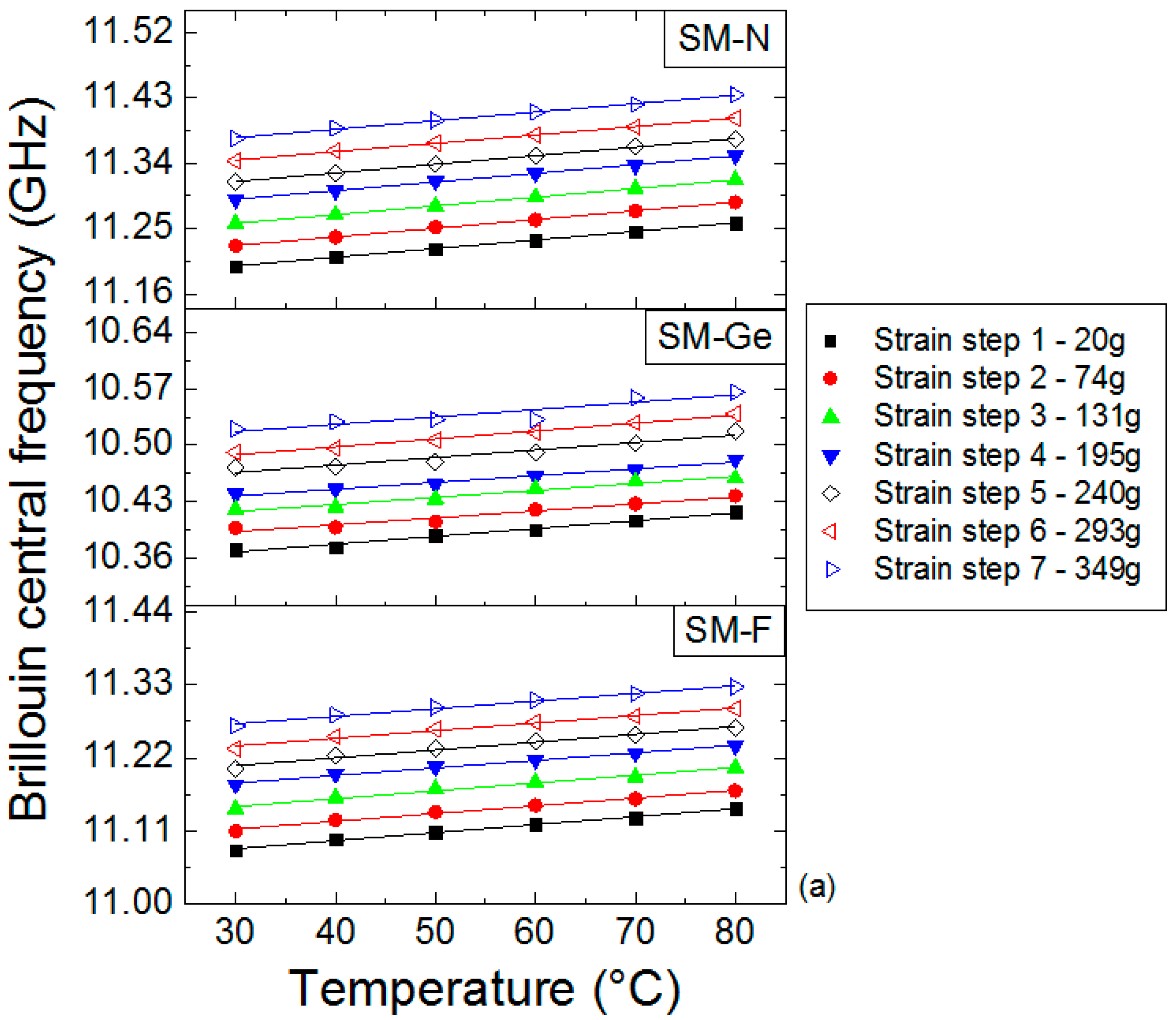

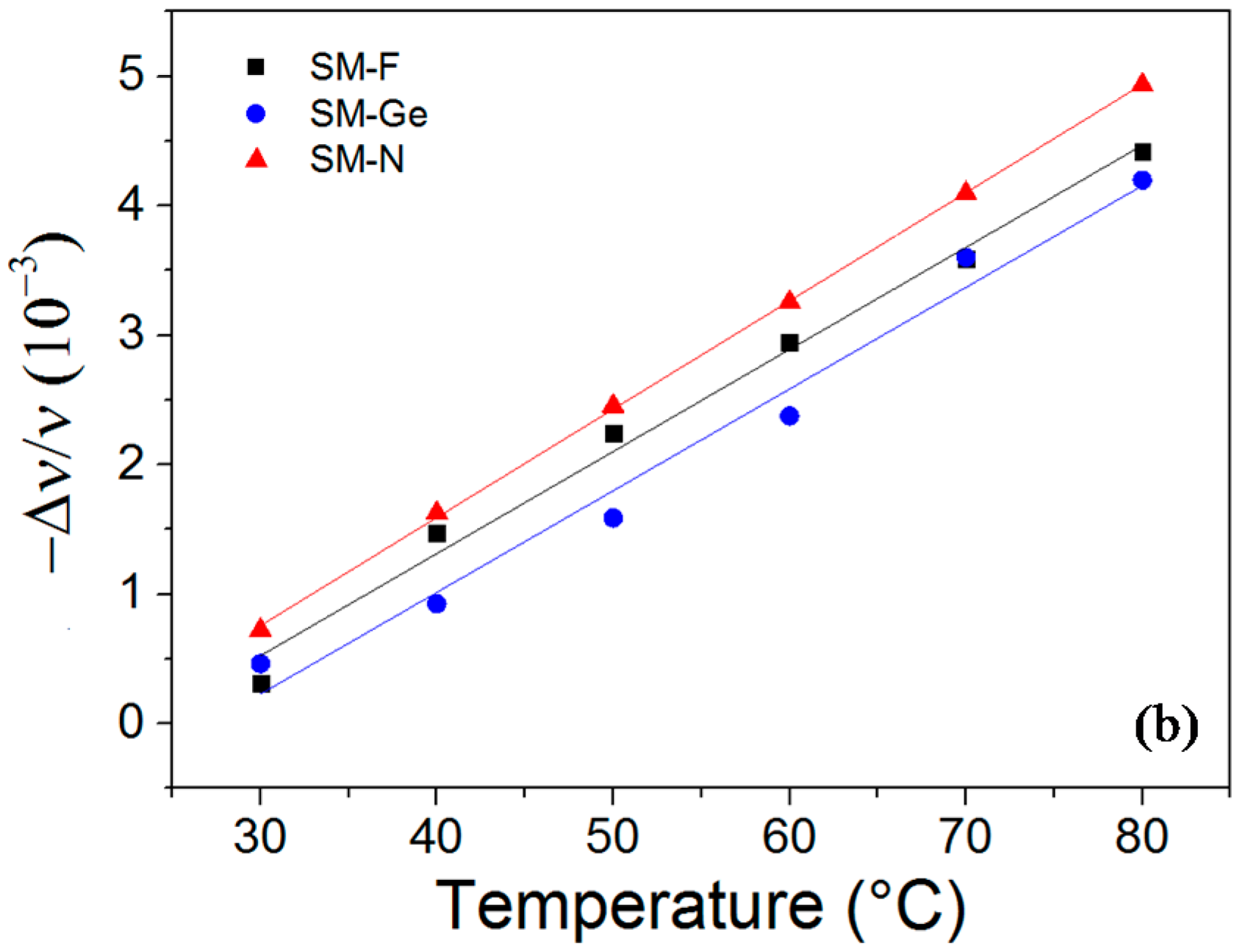

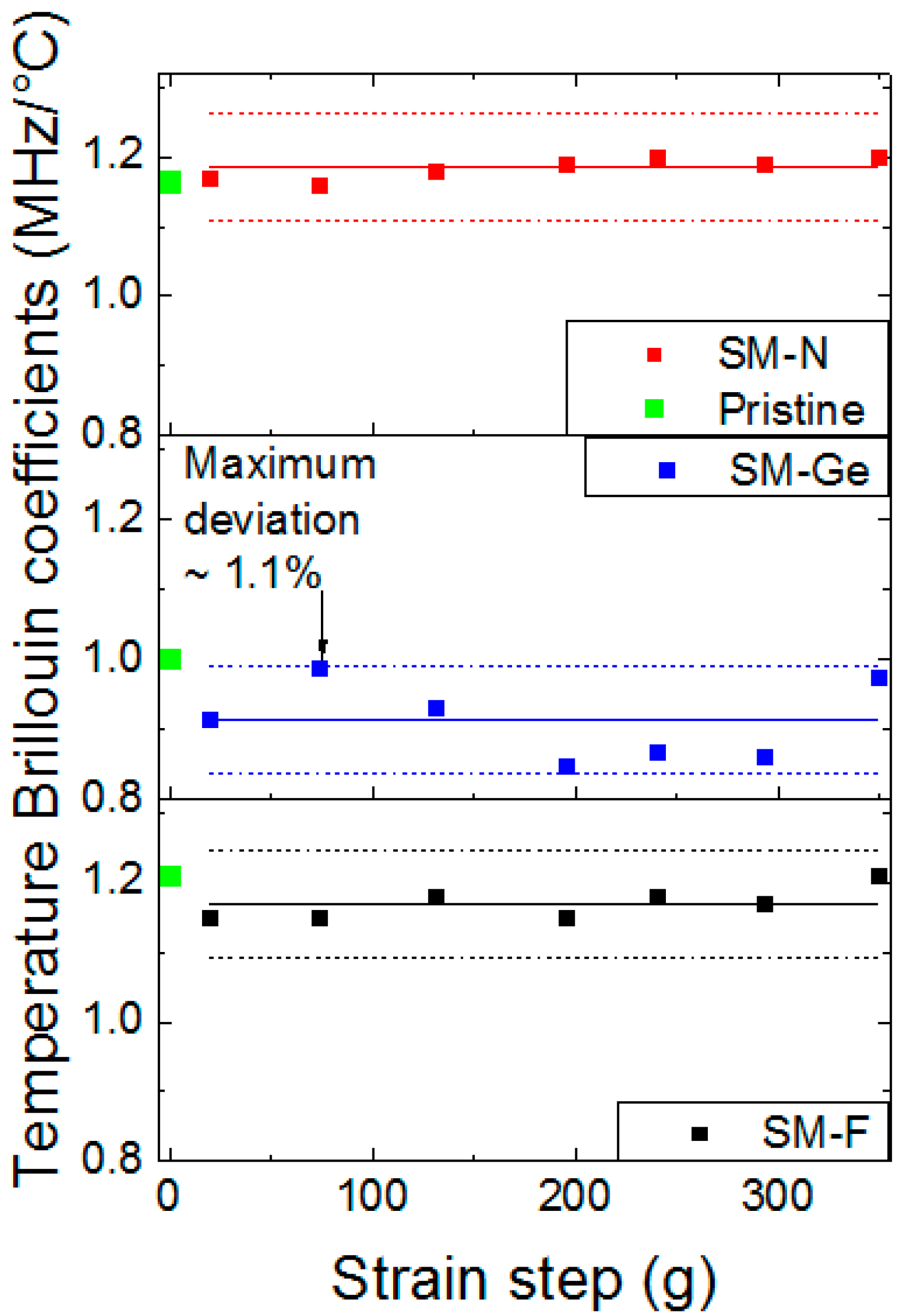

4.2. Determination of Temperature Coefficients before Irradiation

4.3. Steady γ-Ray RIA at 1550 nm

4.4. On-Line γ-Ray Effects on the PPP-BOTDA Response

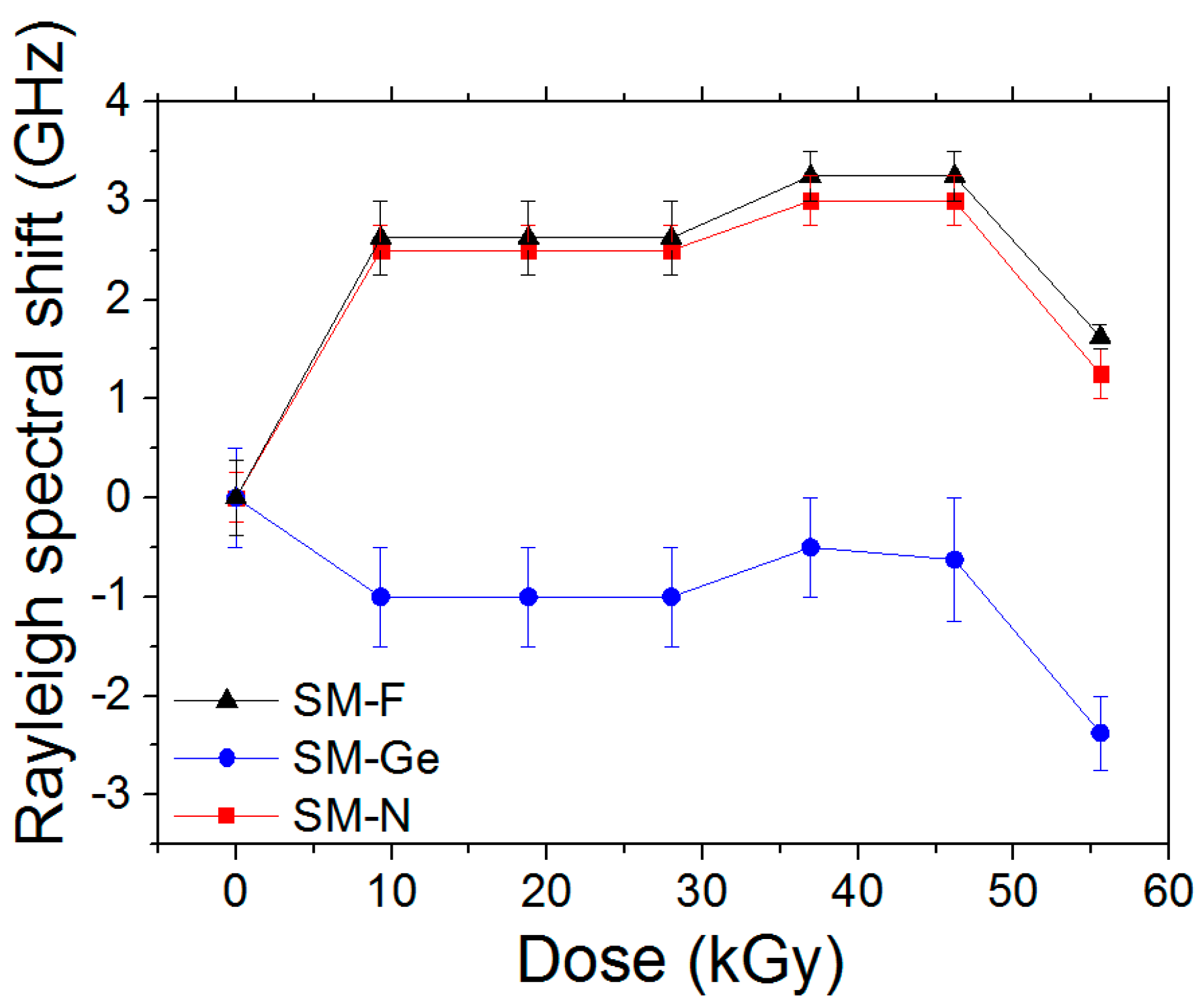

4.5. On-line γ-Ray Effects on the TW-COTDR Response

4.6. Post-Mortem γ-Ray Effects on Temperature Coefficients

4.7. Post-Mortem γ-Ray Effects on the PPP-BOTDA Response

5. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bao, X.; Chen, L. Recent Progress in Distributed Fiber Optic Sensors. Sensors 2012, 12, 8601–8639. [Google Scholar] [CrossRef] [PubMed]

- Cangialosi, C.; Girard, S.; Boukenter, A.; Cannas, M.; Delepine-Lesoille, S.; Bertrand, J.; Paillet, P.; Marcandella, C.; Ouerdane, Y. Effects of radiation and hydrogen-loading on the performances of Raman distributed temperature fiber sensors. J. Lightwave Technol. 2015, 33, 2432–2438. [Google Scholar] [CrossRef]

- Rizzolo, S.; Marin, E.; Morana, A.; Boukenter, A.; Ouerdane, Y.; Cannas, M.; Périsse, J.; Bauer, S.; Macé, J.; Girard, S. Investigation of Coating Impact on OFDR Optical remote Fiber-based Sensors Performances for Their Integration in High Temperature and Radiation Environments. J. Lightwave Technol. 2015, 34, 4460–4465. [Google Scholar] [CrossRef]

- MoDeRn Partners. Case Studies: Final Report; Jobmann, M., Ed.; DBE Technology GmbH: Peine, Germany, 2013. [Google Scholar]

- Phéron, X. Durabilité des Capteurs à fibres Optiques Sous Environnement Radiatif. Ph.D. Thesis, Université de Saint-Etienne, Saint-Etienne, France, 2013. [Google Scholar]

- Phéron, X.; Girard, S.; Boukenter, A.; Brichard, B.; Delepine-Lesoille, S.; Bertrand, J.; Ouerdane, Y. High γ-ray dose radiation effects on the performance of Brillouin scattering based optical fiber sensors. Opt. Express 2012, 20, 26978–26985. [Google Scholar] [CrossRef] [PubMed]

- Pheron, X.; Ouerdane, Y.; Girard, S.; Tortech, B.; Delepine-Lesoille, S.; Bertrand, J.; Mamdem, Y.S.; Boukenter, A. UV irradiation influence on stimulated Brillouin scattering in photosensitive optical fibers. Electron. Lett. 2011, 47, 132–133. [Google Scholar] [CrossRef]

- Nikles, M. La diffusion Brillouin Dans les Fibres Optique: Etude et Application aux Capteurs Distribués. Ph.D. Thesis, Ecole Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 1997. [Google Scholar]

- Cangialosi, C.; Girard, S.; Boukenter, A.; Marin, E.; Cannas, M.; Delepine-Lesoille, S.; Marcandella, C.; Paillet, P.; Ouerdane, Y. Steady state γ-radiation effects on Brillouin fiber sensors. SPIE Proc. Ser. 2015, 96344V. [Google Scholar]

- Rizzolo, S.; Boukenter, A.; Marin, E.; Cannas, M.; Perisse, J.; Bauer, S.; Mace, J.; Ouerdane, Y.; Girard, S. Vulnerability of OFDR-based distributed sensors to high γ-ray doses. Opt. Express 2015, 23, 18997–19009. [Google Scholar] [CrossRef] [PubMed]

- Neubrex. Available online: www.neubrex.com (accessed on 19 December 2016).

- Kishida, K.; Yamauchi, Y.; Guzik, A. Study of optical fibers strain-temperature sensitivities using hybrid Brillouin-Rayleigh System. Photonic Sens. 2014, 4, 1–11. [Google Scholar] [CrossRef]

- Kishida, K.; Li, C.H.; Nishiguchi, K.; Yamauchi, Y.; Guzik, A.; Tsuda, T. Hydrid Brillouin-Rayleigh distributed sensing system. SPIE Proc. Ser. 2012, 84212G. [Google Scholar] [CrossRef]

- Delepine-Lesoille, S.; Bertrand, J.; Pilorget, G.; Farhoud, R.; Buschaert, S.; Vogt, T.; Verstricht, J. Monitoring natural and engineered clay in geological repository with optical fiber sensors—Lessons learnt from large scale experiments. In Proceedings of the International Conference on Clays in Natural and Engineered Barriers for Radioactive Waste Confinement, Brussels, Belgium, 23–26 March 2015.

- Dubois, J.-P. Raman versus Brillouin optical fiber distributed temperature sensing: An outdoor comparison (metallic beam & concrete slap). In Proceedings of the 4th International Conference on Structural Health Monitoring on Intelligent Infrastructure (SHMII-4) 2009, Zurich, Switzerland, 22–24 July 2009.

- Girard, S.; Keurinck, J.; Boukenter, A.; Meunier, J.P.; Ouerdane, Y.; Azais, B.; Charre, P.; Vié, M. Gamma-rays and pulsed X-ray radiation responses of nitrogen-, germanium-doped and pure silica core optical fiber. Nucl. Instrum. Methods Phys. Res. 2004, 215, 187–195. [Google Scholar] [CrossRef]

- Henschel, H.; Kohn, O.; Schmidt, H.U. Radiation induced loss measurements of optical fibres with optical time domain reflectometers (OTDR) at high and low dose rates. In Proceedings of the First European Conference on Radiation and its Effects on Devices and Systems, La Grande-Motte, France, 9–12 September 1991.

- Girard, S.; Kuhnhenn, J.; Gusarov, A.; Brichard, B.; van Uffelen, M.; Ouerdane, Y.; Boukenter, A.; Marcandella, C. Radiation effects on silica-based optical fibers: Recent advances and future challenges. IEEE Trans. Nucl. Sci. 2013, 60, 2015–2036. [Google Scholar] [CrossRef]

- Dianov, E.M.; Golant, K.M.; Khrapko, R.R.; Tomashuk, A.L. Low-loss nitrogen-doped silica fibers: The prospects for applications in radiation environment. In Proceedings of the 1996 Optical Fiber Communications (OFC’96), San Jose, CA, USA, 25 February–1 March 1996.

| Type | Core | Cladding | Coating |

|---|---|---|---|

| SM-F | F-SiO2 (0.2 wt %) | F-SiO2 (1.8 wt %) | Acrylate |

| SM-Ge | Ge-SiO2 (28 wt %) | Pure silica | Acrylate |

| SM-N | N-SiO2 | Pure silica | Acrylate |

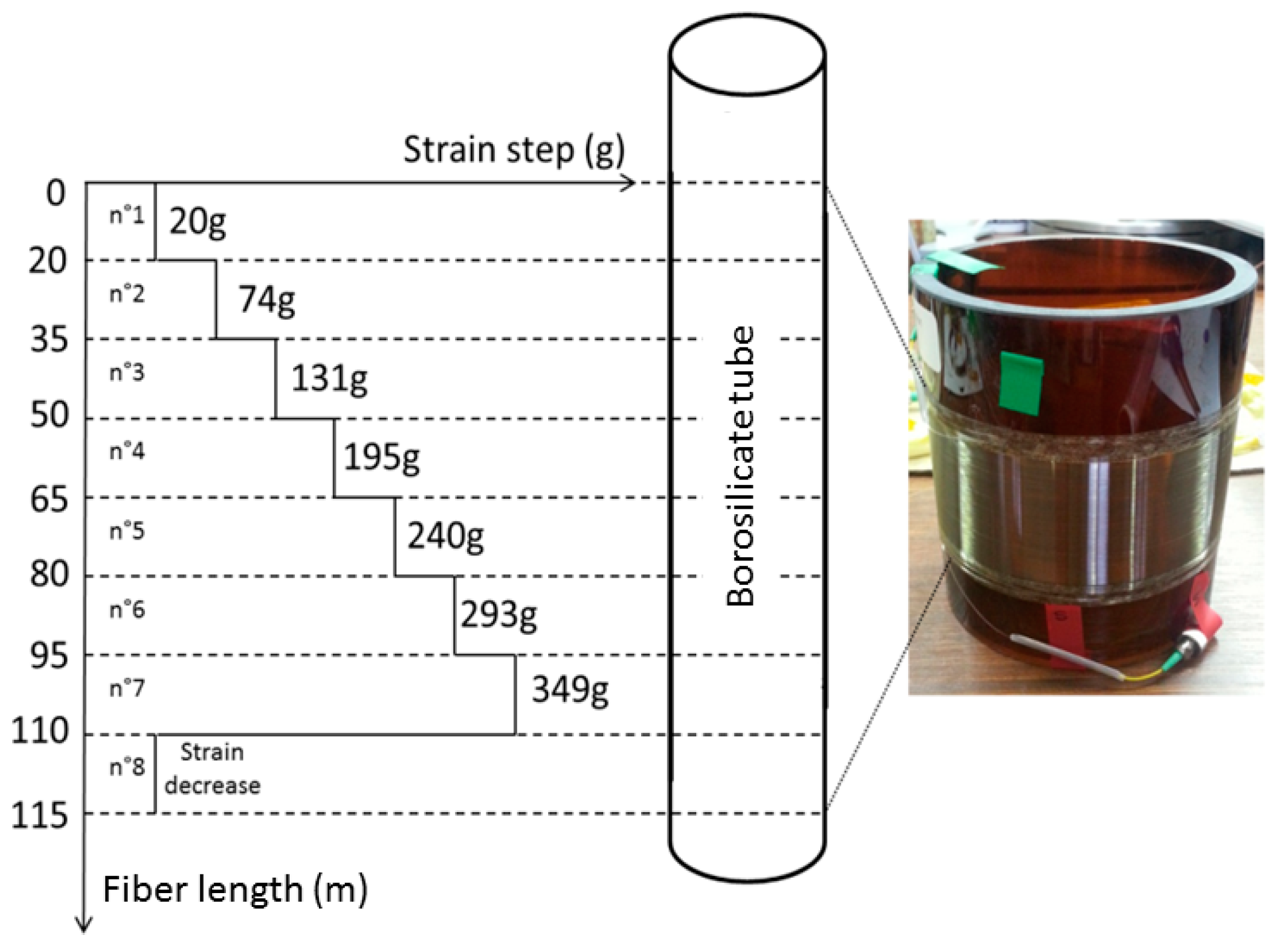

| N°Step | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Length (m) | 0 to 20 | 20 to 35 | 35 to 50 | 50 to 65 | 65 to 80 | 80 to 96 | 95 to 110 | 110 to 115 |

| Strain step (g) | 20 | 74 | 131 | 195 | 240 | 293 | 349 | Strain decrease |

| CTB (MHz/°C) | CTR‘ (10−6 C−1) | |||||||

|---|---|---|---|---|---|---|---|---|

| N°Step | 1 | 2 | 3 | 4 | 5 | 6 | 7 | / |

| Strain step (g) | 20 | 74 | 131 | 195 | 240 | 293 | 349 | / |

| SM-F | 1.15 ± 0.06 | 1.15 ± 0.07 | 1.18 ± 0.07 | 1.15 ± 0.05 | 1.18 ± 0.07 | 1.17 ± 0.06 | 1.21 ± 0.05 | 7.80 ± 0.04 |

| SM-Ge | 0.91 ± 0.18 | 0.99 ± 0.05 | 0.93 ± 0.13 | 0.85 ± 0.06 | 0.87 ± 0.07 | 0.86 ± 0.09 | 0.87 ± 0.06 | 7.86 ± 0.05 |

| SM-N | 1.17 ± 0.02 | 1.16 ± 0.02 | 1.18 ± 0.02 | 1.19 ± 0.02 | 1.20 ± 0.00 | 1.19 ± 0.02 | 1.20 ± 0.03 | 8.44 ± 0.06 |

| Fibers | CεB before Irradiation (MHz/µε) | CεB’ before Irradiation (MHz/g) | CεB’ after Irradiation to 56 kGy (MHz/g) |

|---|---|---|---|

| F-doped fiber | 0.035 ± 0.015 | 5.88 ± 0.02 | 5.83 ± 0.06 |

| Ge-doped fiber | 0.017 ± 0.039 | 4.75 ± 0.02 | 4.71 ± 0.06 |

| N-doped fiber | 0.034 ± 0.016 | 5.48 ± 0.02 | 5.42 ± 0.05 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Planes, I.; Girard, S.; Boukenter, A.; Marin, E.; Delepine-Lesoille, S.; Marcandella, C.; Ouerdane, Y. Steady γ-Ray Effects on the Performance of PPP-BOTDA and TW-COTDR Fiber Sensing. Sensors 2017, 17, 396. https://doi.org/10.3390/s17020396

Planes I, Girard S, Boukenter A, Marin E, Delepine-Lesoille S, Marcandella C, Ouerdane Y. Steady γ-Ray Effects on the Performance of PPP-BOTDA and TW-COTDR Fiber Sensing. Sensors. 2017; 17(2):396. https://doi.org/10.3390/s17020396

Chicago/Turabian StylePlanes, Isabelle, Sylvain Girard, Aziz Boukenter, Emmanuel Marin, Sylvie Delepine-Lesoille, Claude Marcandella, and Youcef Ouerdane. 2017. "Steady γ-Ray Effects on the Performance of PPP-BOTDA and TW-COTDR Fiber Sensing" Sensors 17, no. 2: 396. https://doi.org/10.3390/s17020396