Hybrid Signal Processing Technique to Improve the Defect Estimation in Ultrasonic Non-Destructive Testing of Composite Structures

Abstract

:1. Introduction

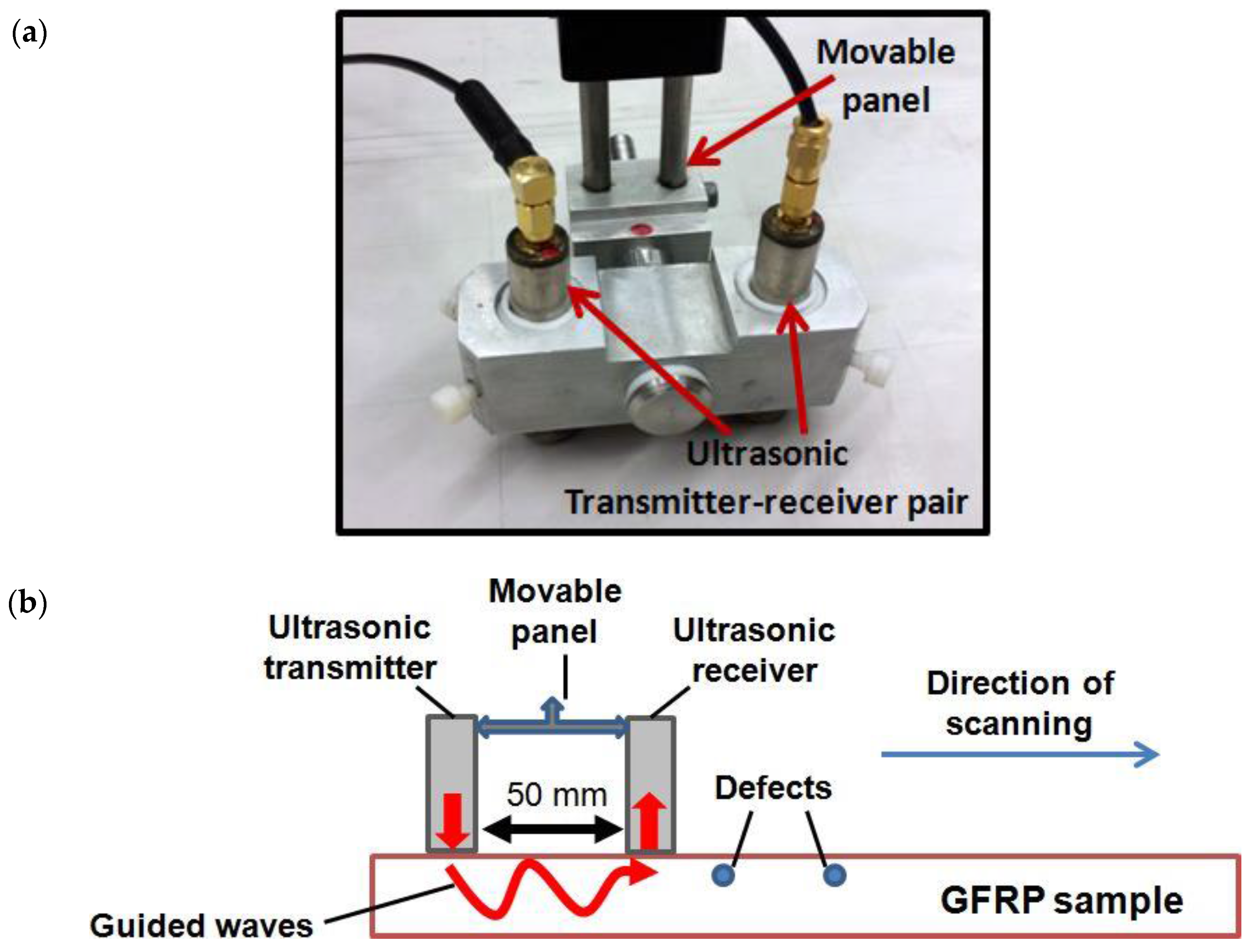

- The contact-type ultrasonic transmitter–receiver system fixed on a moving panel was developed to acquire the A-scans at each scanning step of 1 mm up to the overall scanning distance of 500 mm.

- The novel hybrid signal processing technique was proposed to extract the defect information from a single B-scan image.

- The WT with 8 level-Daubechies wavelets (db-16) and cross-correlation were applied on experimental data in order to size and locate the defects and estimate time delays between the arrival times of defect-free and defective signals.

- The instantaneous characteristics of the defect-free and defective signals were compared using the HHT.

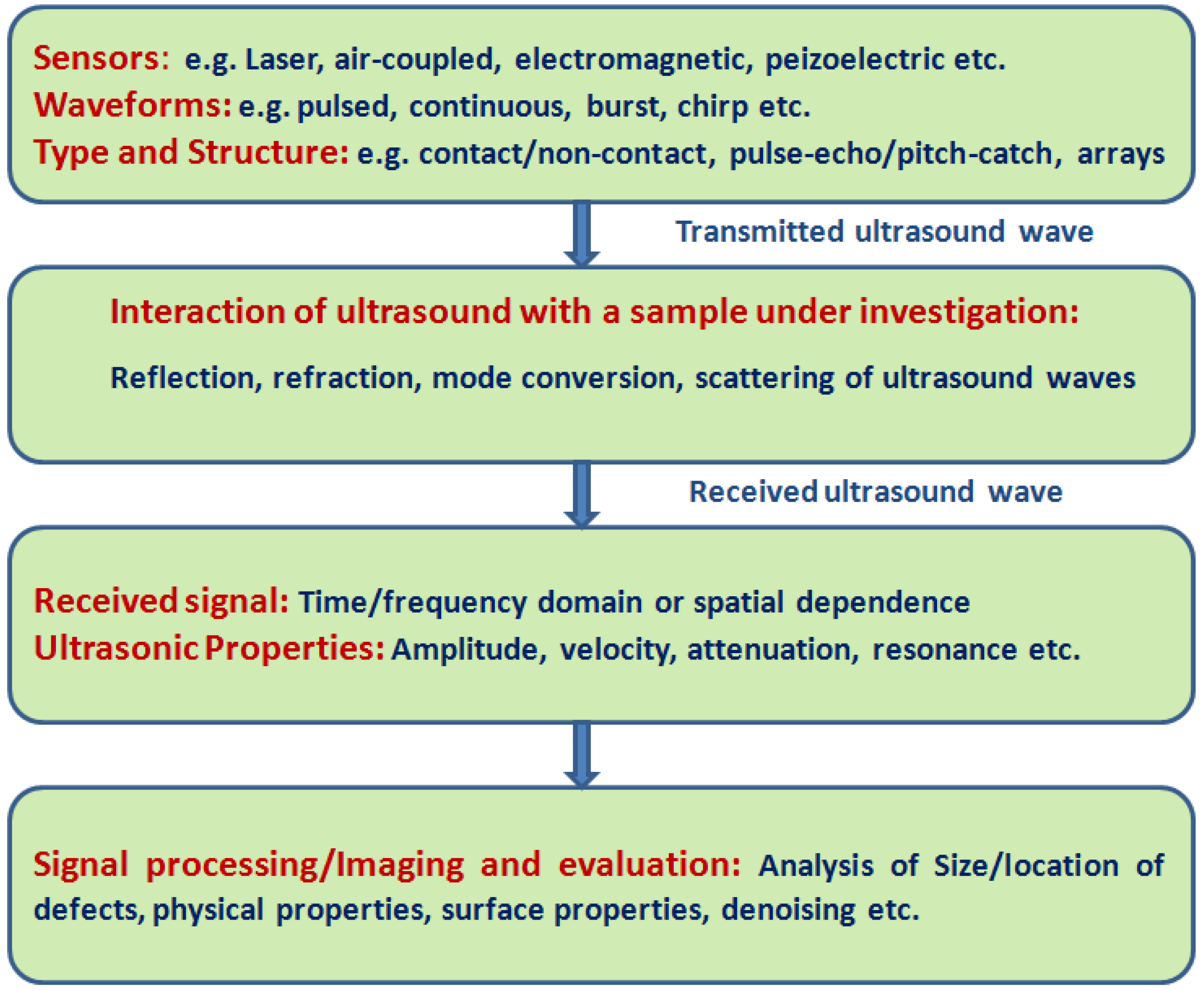

2. Ultrasonic Signal Processing

2.1. Cross-Correlation Technique

2.2. Wavelet Transform (WT)

2.3. Hilbert Huang Transform (HHT)

2.3.1. Ensemble Empirical Mode Decomposition (EEMD)

- The extremum numbers in the signal must be either equal to the number of zero-crossings or differ by one.

- Zero mean value of lower and upper envelope.

2.3.2. Hilbert Transform (HT) and Instantaneous Characteristics

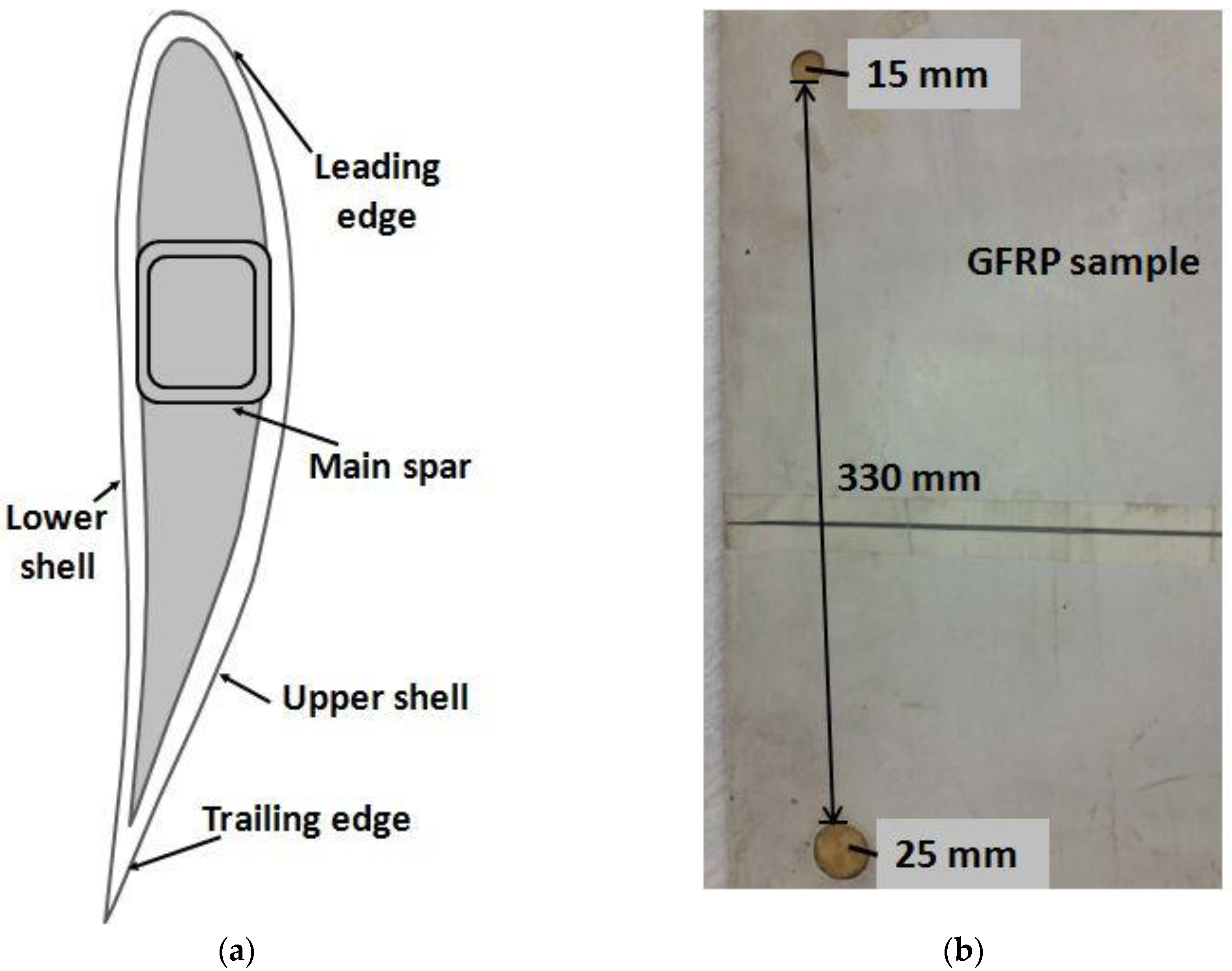

3. Experimental Investigation

3.1. Dispersive Characteristics of the Propagating Wave Modes

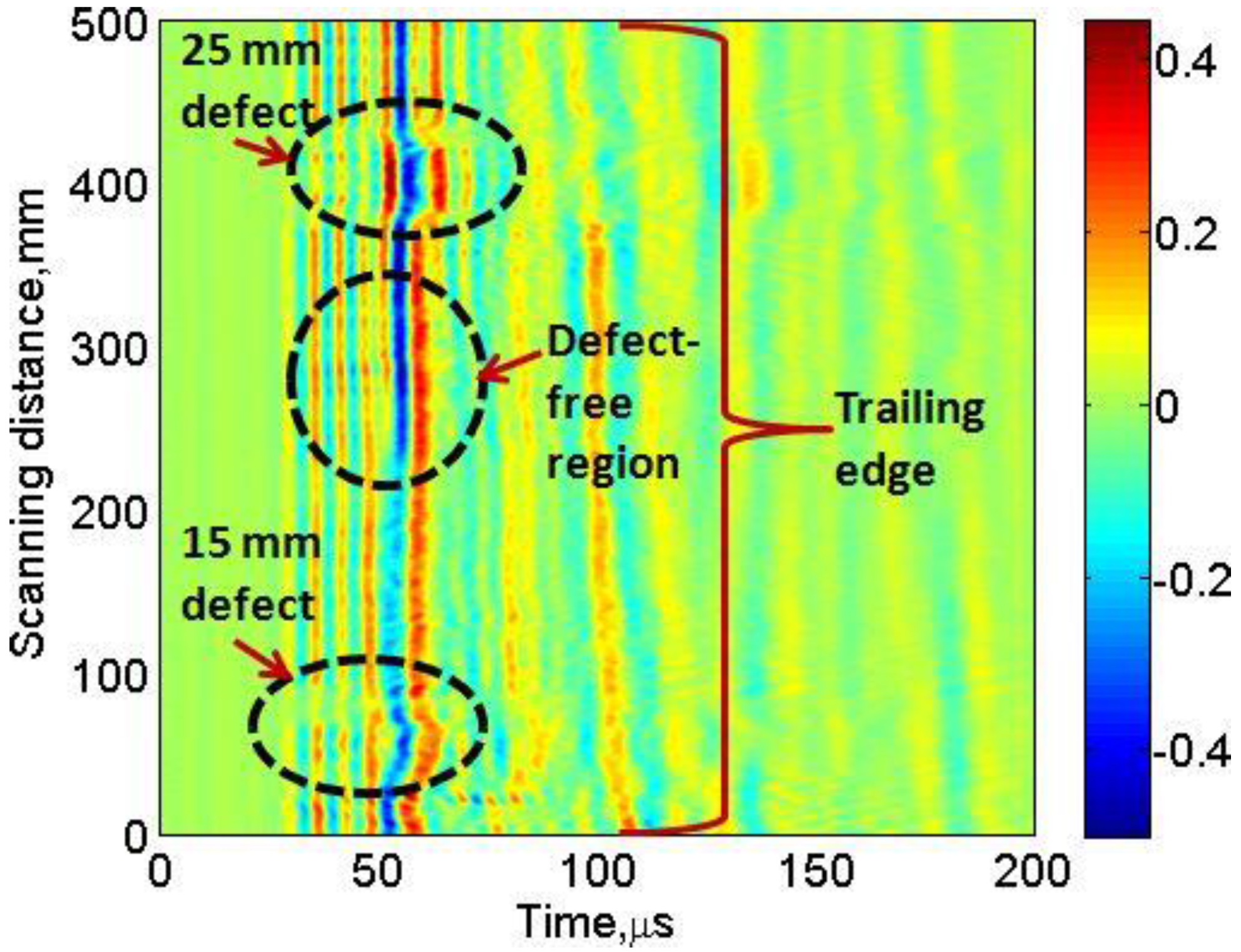

3.2. Experimental Analysis of the Defective Regions

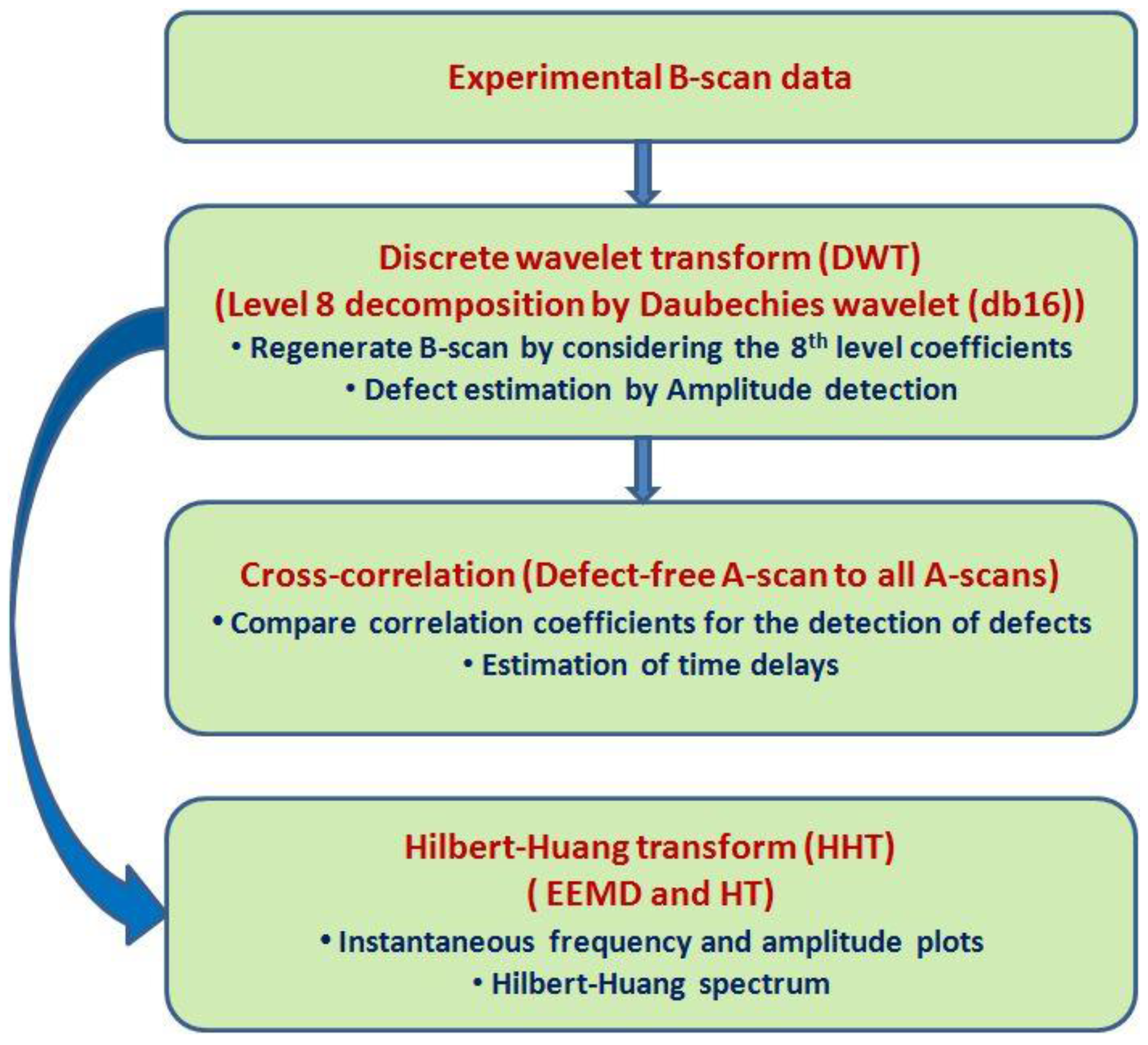

4. The Proposed Hybrid Signal Processing Technique

- Step 1: Wavelet transform

- Decompose all A-scans of experimental B-scan (Figure 5) into a sum of eight elementary wavelets by DWT using the Daubechies wavelet (db 16).

- Regenerate the filtered B-scan by using only the eighth level coefficients to minimize the noise.

- Select the defect-free region by applying proper time-window and estimate the averaged A-scan signal of the selected defect-free region (reference signal).

- Subtract the reference signal from all A-scans and regenerate the new B-scan image for clear visualization of defects.

- Compare the reference signal to all A-scans of filtered B-scans by amplitude detection method in order to estimate the size and position of defects.

- Step 2: Cross-correlation

- Find the cross-correlation between the reference signal and all A-scans of wavelet-filtered B-scan along the scanning distance in order to detect the defects by comparing maximum correlation coefficient.

- Estimate a time delay between the reference signal to each of A-scans along the scanning distance in order to detect the defects by comparing deviations of the time delay.

- Step 3: Hilbert–Huang transform

- Apply proper windowing in the wavelet processed B-scan and find the average value of signals (A-scans) in the selected defect-free and defective regions.

- Decompose each A-scan into the IMFs using EEMD.

- Select the appropriate IMFs for the further analysis.

- Estimate the instantaneous characteristics and Hilbert–Huang spectrum for defect-free and defective signals.

5. Results and Discussion

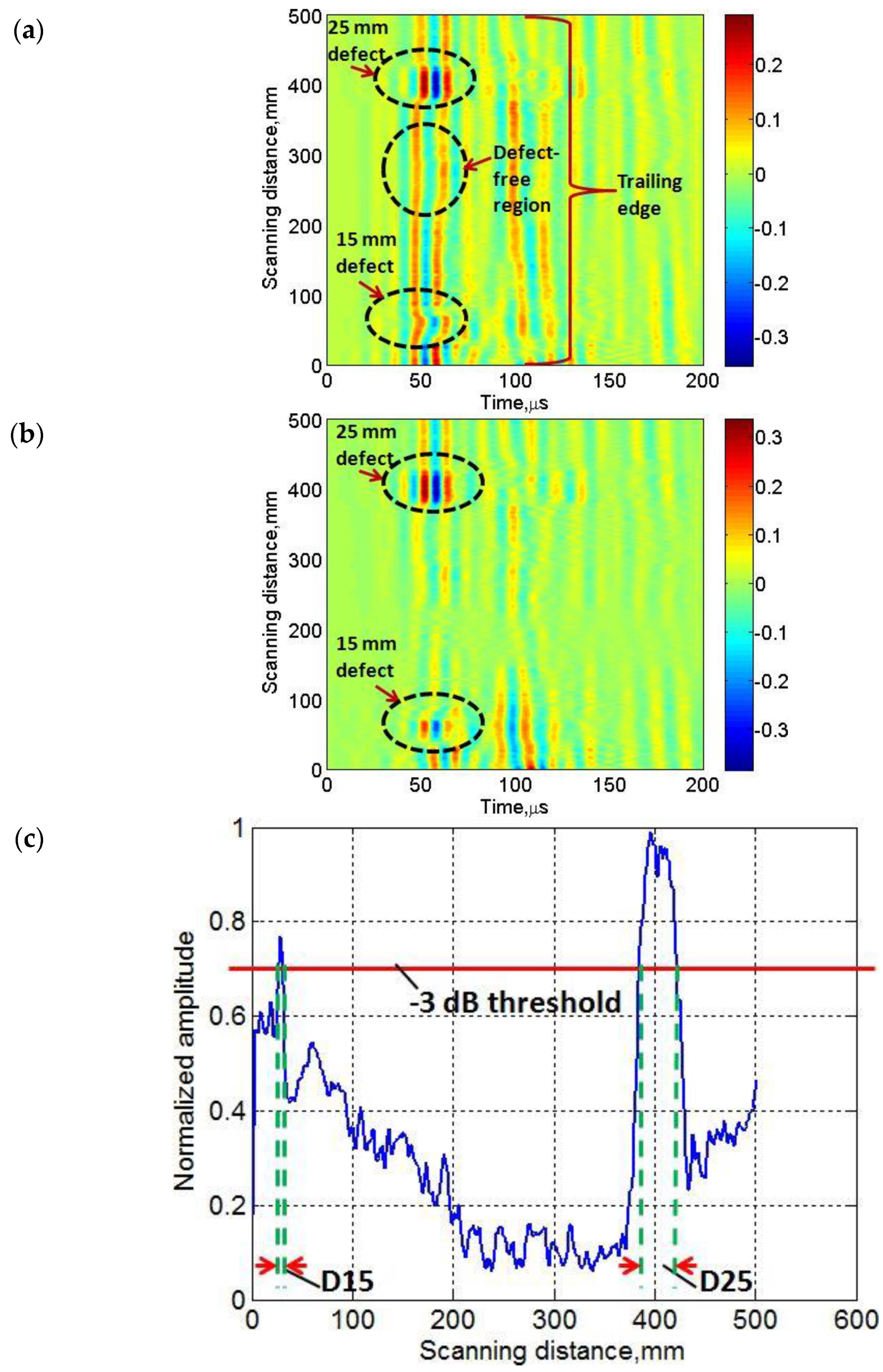

5.1. Defect Analysis Using WT

5.2. Cross-Correlation on Wavelet-Transformed Signals

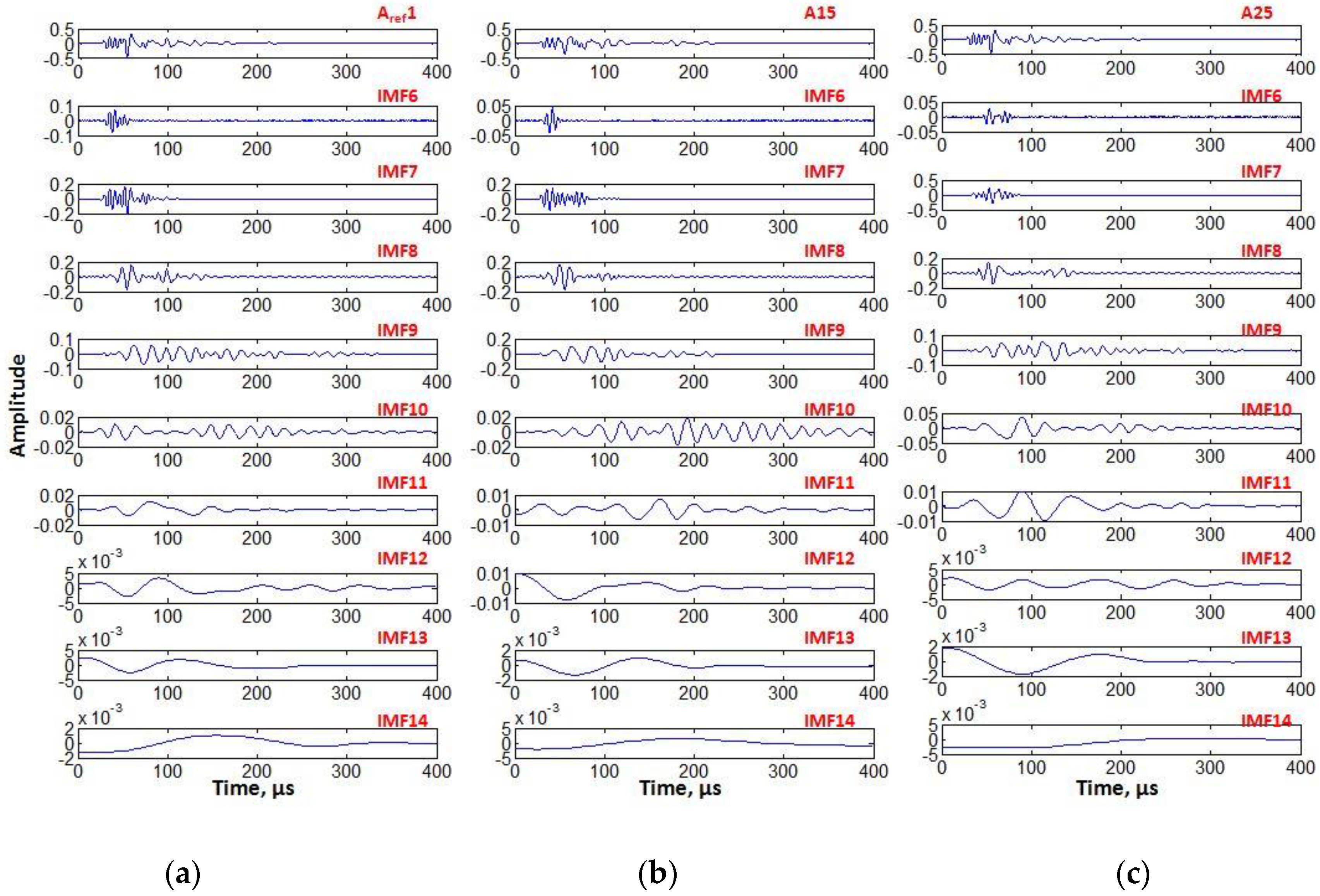

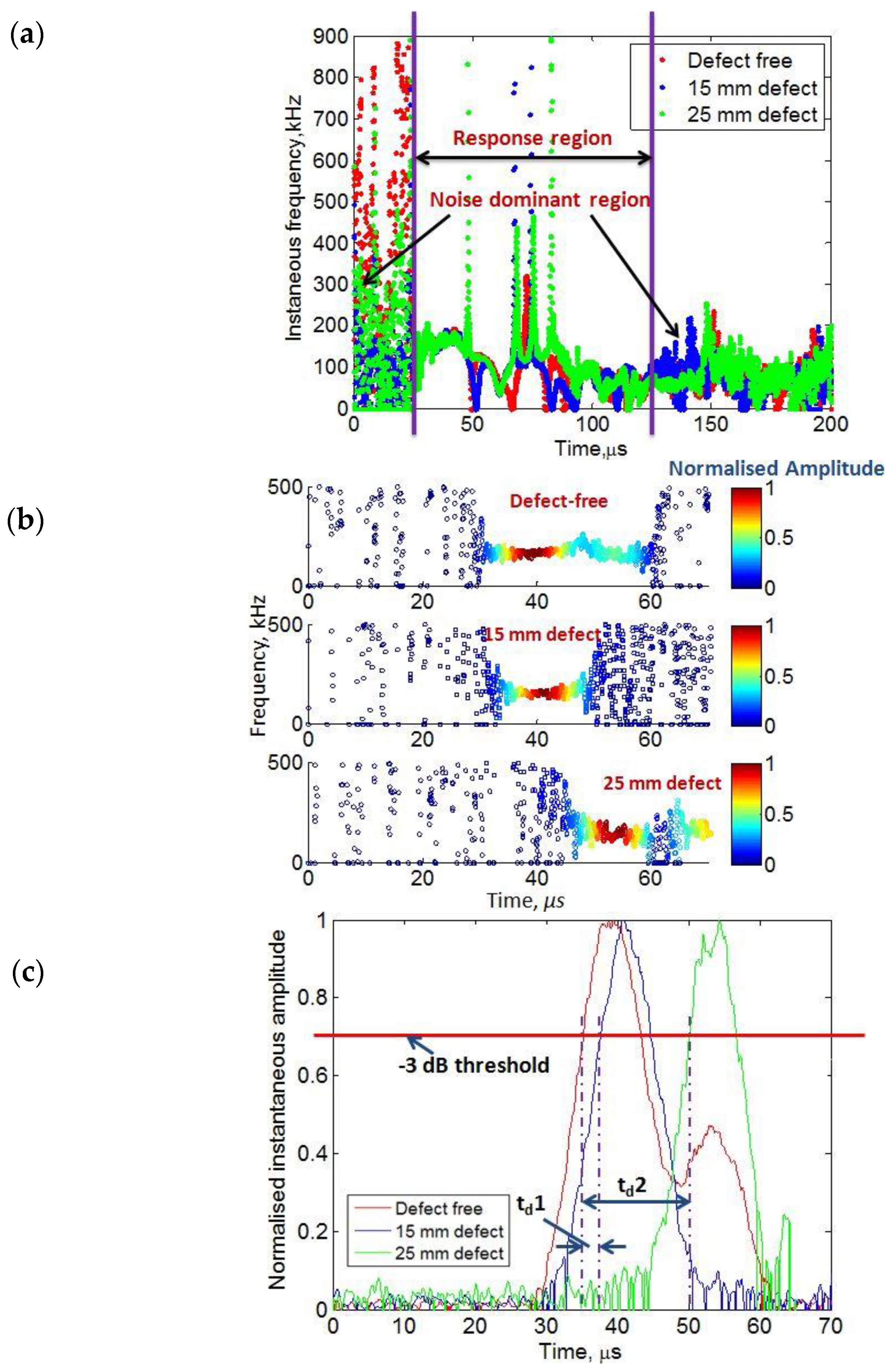

5.3. HHT on Wavelet-Transformed Signals

- The defect-free signal was the same as the reference A-scan signal (A1, ref) in the entire time interval.

- The A-scan signal in 15 mm defective region (A15) was estimated by selecting the space window within the range of (50 mm and 60 mm) and averaging it.

- The A-scan signal in 25 mm defective region (A25) was estimated by selecting the space window within the range of (400 mm and 410 mm) and averaging it.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cawley, P.; Adams, R.D. Defect types and non-destructive testing techniques for composites and bonded joints. Mater. Sci. Technol. 1989, 5, 413–425. [Google Scholar] [CrossRef]

- Maria, M. Advanced composite materials of the future in aerospace industry. INCAS Bulletin 2013, 5, 139–150. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 7th ed.; Wiley: Hoboken, NJ, USA, 2007; pp. 666–715. [Google Scholar]

- Tiwari, K.; Raisutis, R. Comparative analysis of non-contact ultrasonic methods for defect estimation of composites in remote areas. CBU Int. Conf. Proc. 2016, 4, 846–851. [Google Scholar]

- Kudva, J.N.; Grage, M.J.; Roberts, M.M. Aircraft structural health monitoring and other smart structures technologies-perspectives on development of smart aircraft. In Proceedings of the 2nd International Work shop on Structural Health Monitoring, Stanford, CA, USA, 8–10 September 1999; pp. 122–132. [Google Scholar]

- Bar-Cohen, Y. Emerging NDE technologies and challenges at the beginning of the 3rd millennium, Part 2. Mater. Eval. 2000, 58, 141–150. [Google Scholar]

- Katunin, A.; Dragan, K.; Dziendzikowski, M. Damage identification in aircraft composite structures: A case study using various non-destructive testing techniques. Compos. Struct. 2015, 127, 1–9. [Google Scholar] [CrossRef]

- Diamanti, K.; Soutis, C.; Hodgkinson, J. Non-destructive inspection of sandwich and repaired composite laminated structures. Compos. Sci. Technol. 2005, 65, 2059–2067. [Google Scholar]

- Li, S.; Shi, K.; Yang, K.; Xu, J. Research on the defect types judgment in wind turbine blades using ultrasonic NDT. IOP Conf. Ser. Mater. Sci. Eng. 2015, 87, 012056. [Google Scholar] [CrossRef]

- Mal, A.; Ricci, F.; Samajder, H.; Baid, H. NDE of composite structures using ultrasonic guided waves. Health Monit. Struct. Biol. Syst. 2013, 8695, 1–11. [Google Scholar]

- Lee, J.R.; Shin, H.J.; Chia, C.C.; Jeong, H.M.; Yoon, D.J. Ultrasonic Propagation Imaging for Wind Turbine Blade Quality Evaluation. Adv. Mater. Res. 2010, 123, 847–850. [Google Scholar]

- Ambu, R.; Aymerich, F.; Ginesu, F.; Priolo, P. Assessment of NDT interferometric techniques for impact damage detection in composite laminates. Compos. Sci. Technol. 2006, 66, 199–205. [Google Scholar]

- Nakamura, K. Ultrasonic Transducers, 1st ed.; Woodhead Publishing: Oxford, UK, 2012; p. 722. [Google Scholar]

- Jen, C.K.; Wu, K.T.; Kobayashi, M.; Blouin, A. NDE using laser generated ultrasound and integrated ultrasonic transducer receivers. In Proceedings of the 2008 IEEE Ultrasonics Symposium, Beijing, China, 2–5 November 2008; pp. 1516–1519. [Google Scholar]

- Wang, M.; Zhou, Y. Design of piezoelectric micromachined ultrasonic transducers (pMUTs) for high pressure output. Microsys. Technol. 2016, 23, 1761–1766. [Google Scholar] [CrossRef]

- Kazys, R.; Sliteris, R.; Sestoke, J. Air-Coupled Low Frequency Ultrasonic Transducers and Arrays with PMN-32% PT Piezoelectric Crystals. Sensors 2017, 17, 95. [Google Scholar]

- Davis, C.L. Non-Contact Non-Destructive Measurement of Texture Using an Electro-Magnetic Acoustic Transducer (EMAT) Sensor. In Microstructure Texture in Steels; Haldar, A., Suwas, S., Bhattacharjee, D., Eds.; Springer: Berlin, Germany, 2009; pp. 285–305. [Google Scholar]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Liu, G.; Lam, K.; Shang, H. Scattering of waves by flaws in anisotropic laminated plates. Compos. Part B Eng. 1996, 27, 431–437. [Google Scholar]

- Castaings, M.; Hosten, B. Guided waves propagating in sandwich structures made of anisotropic, viscoelastic, composite materials. J. Acoust. Soc. Am. 2003, 113, 2622–2634. [Google Scholar] [PubMed]

- Jung, T.H.; Datta, S.K. Scattering of impact wave by a crack in composite plate. NDT E Int. 1996, 29, 250. [Google Scholar]

- Osman, A.; Hassler, U.; Kaftandjian, V.; Hornegger, J. An automated data processing method dedicated to 3D ultrasonic non destructive testing of composite pieces. IOP Conf. Ser. Mater. Sci. Eng. 2012, 42, 012005. [Google Scholar]

- Grandin, R.; Gray, J. Implementation of automated 3d defect detection for low signal-to noise features in nde data. AIP Conf. Proc. 2014, 1581, 1840–1847. [Google Scholar]

- Yeh, P.L.; Liu, P.L. Imaging of internal cracks in concrete structures using the surface rendering technique. NDT E Int. 2009, 42, 181–187. [Google Scholar] [CrossRef]

- Tiwari, K.A.; Raisutis, R.; Samaitis, V. Signal processing methods to improve the Signal-to-noise ratio (SNR) in ultrasonic non-destructive testing of wind turbine blade. Procedia Struct. Integr. 2017, 5, 1184–1191. [Google Scholar] [CrossRef]

- Mahmud, K.M.; Baba, N.; Ohba, R. Using of a diverse field algorithm in ultrasonic signal processing for nondestructive testing. Eur. Phys. J. Appl. Phys. 2001, 15, 3–6. [Google Scholar] [CrossRef]

- Wu, H.C.; Gupta, N.; Mylavarapu, P. Blind multiridge detection for automatic nondestructive testing using ultrasonic signals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 1902–1911. [Google Scholar] [CrossRef] [PubMed]

- Satyanarayan, L.; Kumaran, K.B.; Krishnamurthy, C.; Balasubramaniam, K. Inverse method for detection and sizing of cracks in thin sections using a hybrid genetic algorithm based signal parametrisation. Theor. Appl. Frac. Mech. 2008, 49, 185–198. [Google Scholar] [CrossRef]

- Raghavan, A.; Cesnik, C.E.S. Review of guided-wave structural health monitoring. Shock Vibr. Digest 2007, 39, 91–114. [Google Scholar] [CrossRef]

- Varghese, T.; Donohue, K.; Genis, V.; Halpern, E. Order selection criteria for detecting mean scatterer spacings with the AR model. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1996, 43, 979–984. [Google Scholar] [CrossRef]

- Abbate, A.; Koay, J.; Frankel, J.; Schroeder, S.; Das, P. Signal detection and noise suppression using a wavelet transform signal processor: Application to ultrasonic flaw detection. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 14–26. [Google Scholar] [CrossRef] [PubMed]

- Shankar, P.; Karpur, P.; Newhouse, V.; Rose, J. Split-spectrum processing: Analysis of polarity threshold algorithm for improvement of signal-to-noise ratio and detectability in ultrasonic signals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1989, 36, 101–108. [Google Scholar] [CrossRef] [PubMed]

- Mallett, R.; Mudge, P.J.; Gan, T.-H.; Balachandra, W. Analysis of cross-correlation and wavelet de-noising for the reduction of the effects of dispersion in long-range ultrasonic testing. Insight Non-Destr. Test. Condition Monit. 2007, 49, 350–355. [Google Scholar] [CrossRef]

- Bouden, T.; Dib, S.; Aissaous, K.; Grimes, M. Signal processing methods for materials defects detection. In Proceedings of the IEEE International Ultrasonics Symposium, Rome, Italy, 20–23 September 2009. [Google Scholar]

- Raišutis, R.; Tumšys, O.; Kažys, R.; Mažeika, L. A comparative study of time-frequency analysis techniques in the case of signal processing for ultrasonic NDT. Insight Non-Destr. Test. Condition Monit. 2008, 50, 628–633. [Google Scholar]

- Huang, N.E.; Shen, S.S. Hilbert–Huang Transform and Its Applications, 2nd ed.; World Scientific Publishing Company: Singapore, 2014. [Google Scholar]

- Oppenheim, A.V.; Schafer, R.W.; Buck, J.R. Discrete-Time Signals and Systems. In Discrete-Time Signal Processing, 2nd ed.; Horton, M., Clark, E., Eds.; Prentice-Hall, Inc.: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Varghese, T.; Bilgen, M.; Ophir, J. Multiresolution imaging in elastography. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1989, 36, 101–108. [Google Scholar] [CrossRef] [PubMed]

- Rodrı́guez, M.; Emeterio, J.S.; Lázaro, J.; Ramos, A. Ultrasonic flaw detection in NDE of highly scattering materials using wavelet and Wigner–Ville transform processing. Ultrasonics 2004, 42, 847–851. [Google Scholar] [CrossRef] [PubMed]

- Vermaak, H.; Nsengiyumva, P.; Luwes, N. Using the Dual-Tree Complex Wavelet Transform for Improved Fabric Defect Detection. J. Sens. 2016, 2016, 1–8. [Google Scholar] [CrossRef]

- Yu, G.; Wang, X. Ultrasonic signal processing using wavelet transform for automatic rail defect detection. In Proceedings of the 2016 International Forum on Management, Education and Information Technology Application, Guangzhou, China, 30–31 January 2016. [Google Scholar]

- The Engineer’s Ultimate Guide to Wavelet Analysis-the Wavelet Tutorial. Available online: http://users.rowan.edu/%7Epolikar/WAVELETS/WTtutorial.html (accessed on 3 March 2017).

- Mallat, S.G. A Theory for Multiresolution Signal Decomposition: The Wavelet Representation. IEEE Trans. Pattern Anal. Mach. Intell. 1989, 11, 674–693. [Google Scholar] [CrossRef]

- Lázaro, J.; Emeterio, J.S.; Ramos, A.; Fernández-Marrón, J. Influence of thresholding procedures in ultrasonic grain noise reduction using wavelets. Ultrasonics. 2002, 40, 263–267. [Google Scholar] [CrossRef]

- Johnstone, I.M.; Silverman, B.W. Wavelet Threshold Estimators for Data with Correlated Noise. J. R. Stat. Soc. Ser. B (Stat. Method.) 1997, 59, 319–351. [Google Scholar] [CrossRef]

- Modelling Wind Forcing in Phase Resolving Simulation of Nonlinear Wind Waves. Available online: http://hdl.handle.net/1721.1/57791 (accessed on 17 June 2017).

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. A Math. Phys. Eng. Sci. 1971, 454, 903–995. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R. A new view of nonlinear water waves: The Hilbert Spectrum. Annu. Rev. Fluid Mech. 1999, 31, 417–457. [Google Scholar] [CrossRef]

- Addison, A.D.; Battista, B.M.; Knapp, C.C. Improved Hydrogeophysical Parameter Estimation from Empirical Mode Decomposition Processed Ground Penetrating Radar Data. J. Environ. Eng. Geophys. 2009, 14, 171–178. [Google Scholar] [CrossRef]

- Huang, N.E.; Wu, M.L.C.; Long, S.R.; Shen, S.P.S.; Qu, W.; Gloersen, P.; Fan, K.L. A confidence limit for the empirical mode decomposition and Hilbert spectral analysis. Proc. R. Soc. London Ser. A Math. Phys. Eng. Sci. 2003, 459, 2317–2345. [Google Scholar]

- Wu, Z.; Huang, N.E. Ensemble Empirical Mode Decomposition: A Noise-Assisted Data Analysis Method. Adv. Adapt. Data Anal. 2009, 1, 1–41. [Google Scholar]

- Pavlopoulou, S.; Staszewski, W.J.; Soutis, C. Evaluation of instantaneous characteristics of guided ultrasonic waves for structural quality and health monitoring. Struct. Control Health Monit. 2012, 20, 937–955. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, M.; Yu, Q.; Zhang, H. Comparing the applications of EMD and EEMD on time–frequency analysis of seismic signal. J. Appl. Geophys. 2012, 83, 29–34. [Google Scholar] [CrossRef]

- Chen, H.G.; Yan, Y.J.; Jiang, J.S. Vibration-Based Damage Detection of Composite Wingbox Structures Using Improved Hilbert–Huang Transform. Key Eng. Mater. 2006, 324, 539–542. [Google Scholar]

- Torres, M.E.; Colominas, M.A.; Schlotthauer, G.; Flandrin, P. A complete ensemble empirical mode decomposition with adaptive noise. In Proceedings of the IEEE International Conference Acoustic Speech Signal Processing (ICASSP), Prague, Czech Czech, 22–27 May 2011; pp. 4144–4147. [Google Scholar]

- Feldman, M. Hilbert transform, envelope, instantaneous phase, and frequency. In Encyclopedia of Structural Health Monitoring; Boller, C., Chang, F.K., Fujino, Y., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2009; pp. 1–16. [Google Scholar]

- Saliu, S. Definition of instantaneous frequency on real signals. In Proceedings of the European Signal Processing Conference, Tampere, Finland, 4–8 September 2000; pp. 343–346. [Google Scholar]

- Vladišauskas, A.; Šliteris, R.; Raišutis, R.; Seniūnas, G.; Žukauskas, E. Contact ultrasonic transducers for mechanical scanning systems. Ultrasound 2010, 65, 30–35. [Google Scholar]

- Su, Z.; Ye, L.; Lu, Y. Guided Lamb waves for identification of damage in composite structures: A review. J. Sound Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Alleyne, D.; Cawley, P. A two-dimensional Fourier transform method for the measurement of propagating multimode signals. J. Acoust. Soc. Am. 1991, 89, 1159–1168. [Google Scholar] [CrossRef]

- Graps, A. An introduction to wavelets. IEEE Comput. Sci. Eng. 1995, 2, 50–61. [Google Scholar] [CrossRef]

- Mahmoud, M.I.; Dessouky, M.M.; Deyab, S.; Elfouly, F.H. Comparison between haar and daubechies wavelet transformions on FPGA technology. Int. J. Electron. Commun. Eng. 2007, 26, 68–72. [Google Scholar]

- Singh, B.N.; Tiwari, A.K. Optimal selection of wavelet basis function applied to ECG signal denoising. Digit. Signal Process. 2006, 16, 275–287. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tiwari, K.A.; Raisutis, R.; Samaitis, V. Hybrid Signal Processing Technique to Improve the Defect Estimation in Ultrasonic Non-Destructive Testing of Composite Structures. Sensors 2017, 17, 2858. https://doi.org/10.3390/s17122858

Tiwari KA, Raisutis R, Samaitis V. Hybrid Signal Processing Technique to Improve the Defect Estimation in Ultrasonic Non-Destructive Testing of Composite Structures. Sensors. 2017; 17(12):2858. https://doi.org/10.3390/s17122858

Chicago/Turabian StyleTiwari, Kumar Anubhav, Renaldas Raisutis, and Vykintas Samaitis. 2017. "Hybrid Signal Processing Technique to Improve the Defect Estimation in Ultrasonic Non-Destructive Testing of Composite Structures" Sensors 17, no. 12: 2858. https://doi.org/10.3390/s17122858