Nondestructive Evaluation of Carbon Fiber Bicycle Frames Using Infrared Thermography

Abstract

:1. Introduction

2. Experimental Investigation

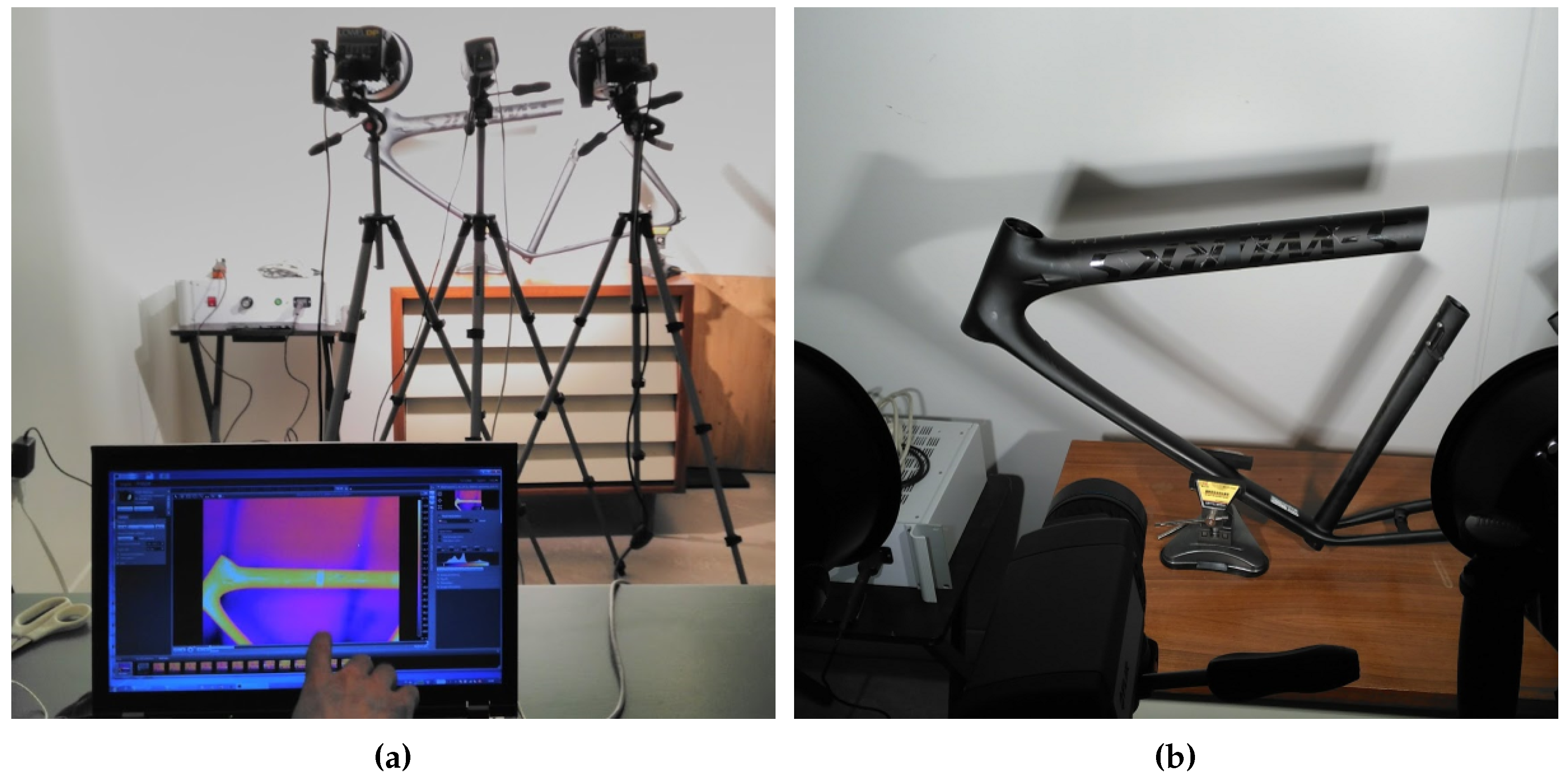

2.1. Description of the Specimen

2.2. Infrared Camera

2.3. Estimation of Emissivity

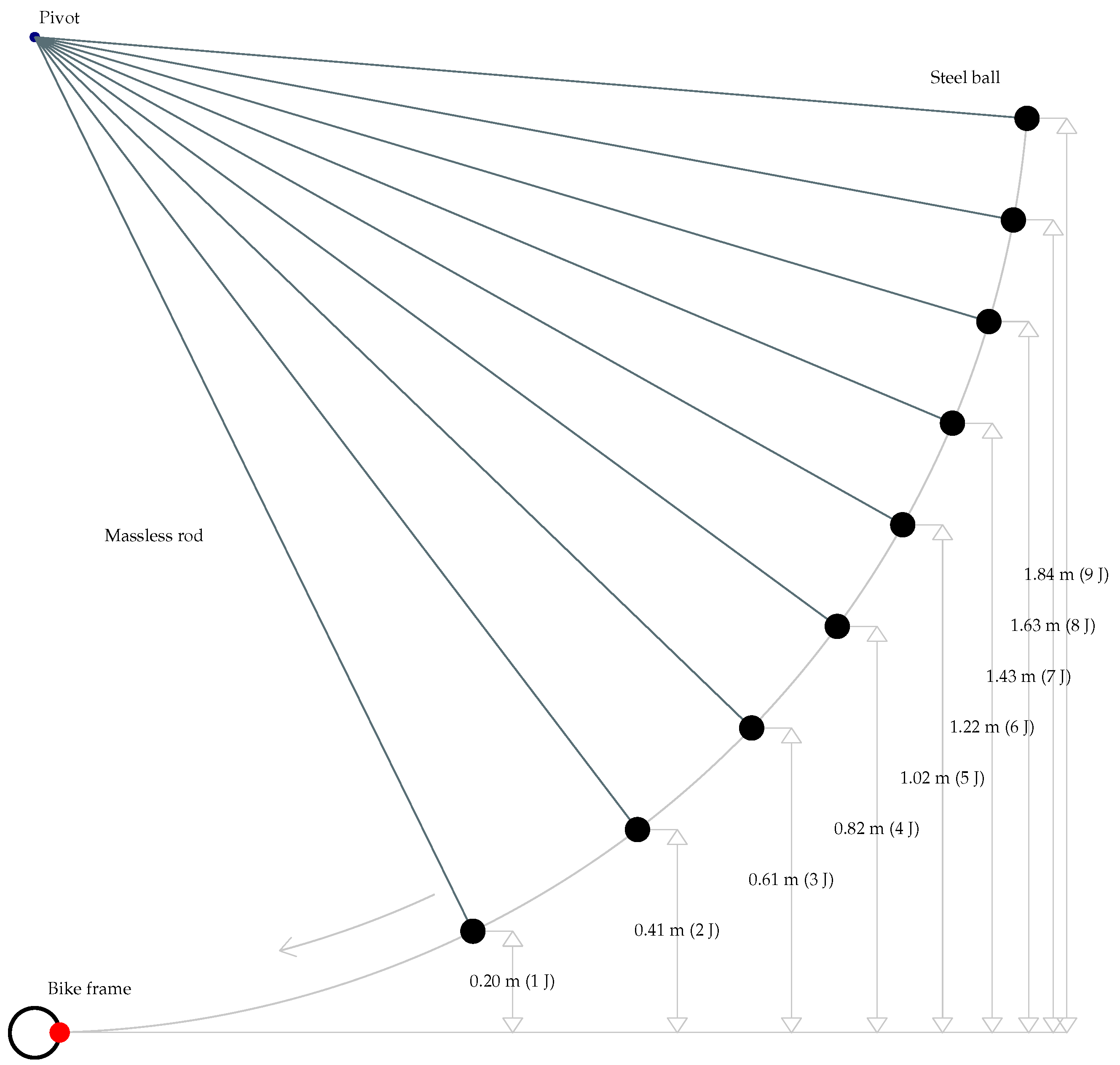

2.4. Impact Damage

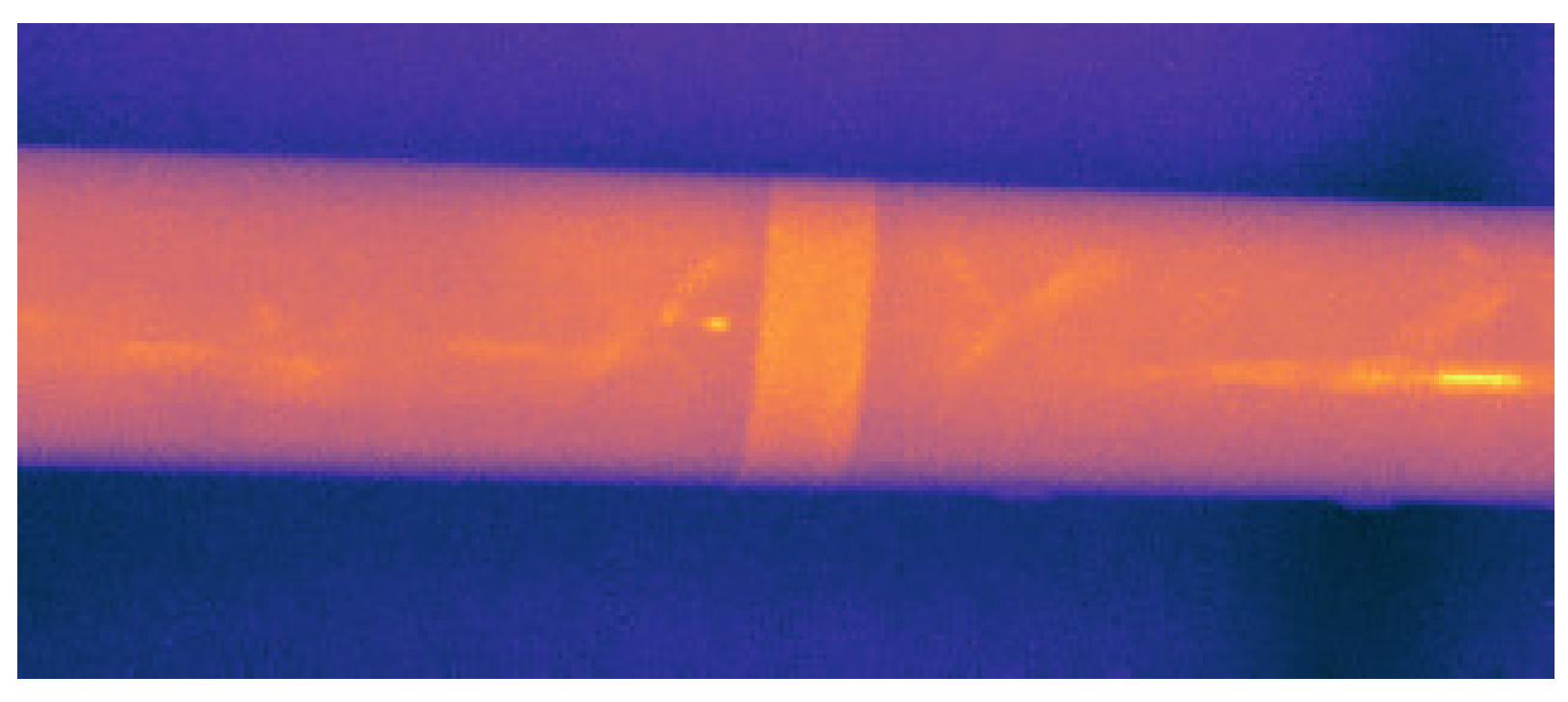

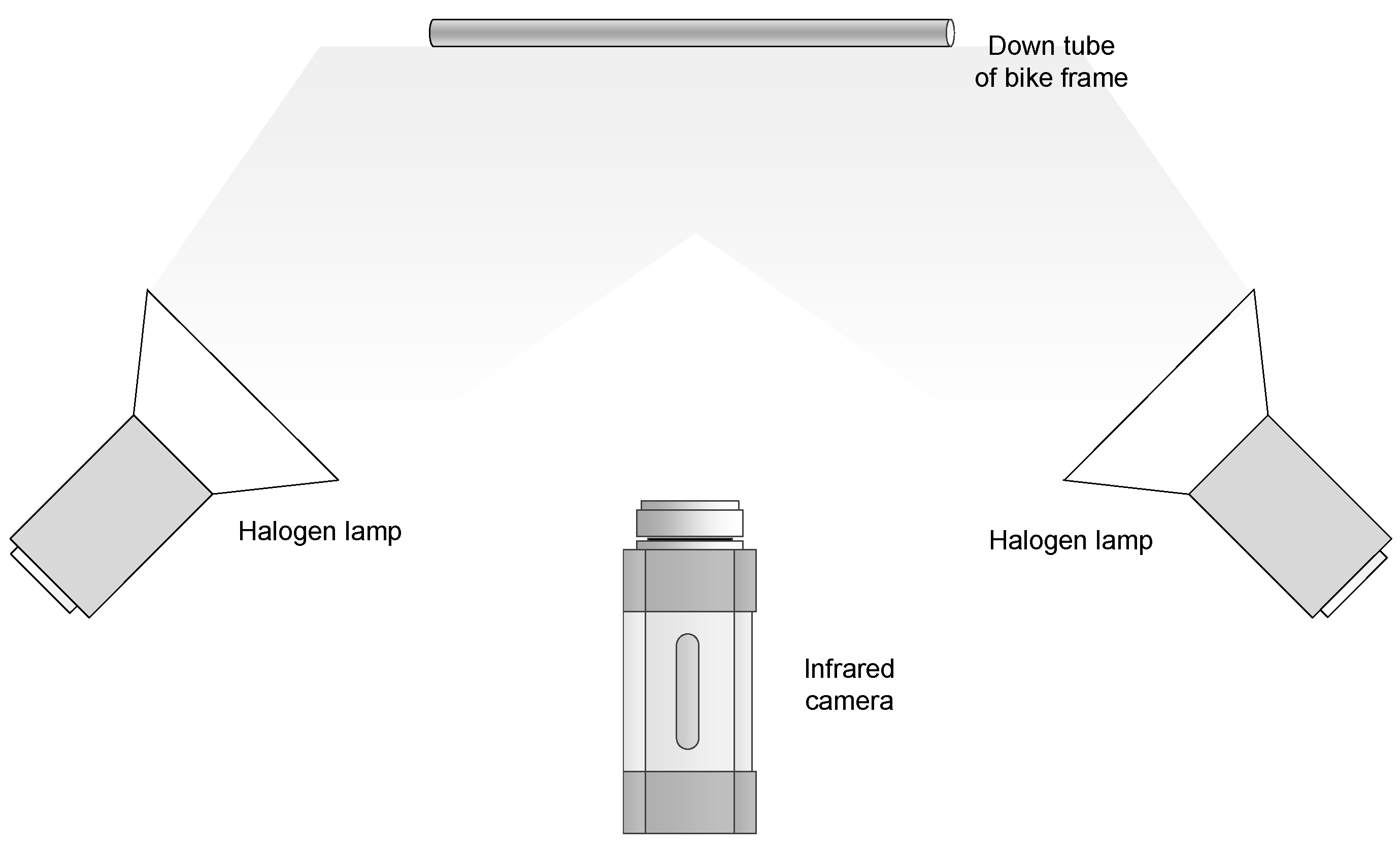

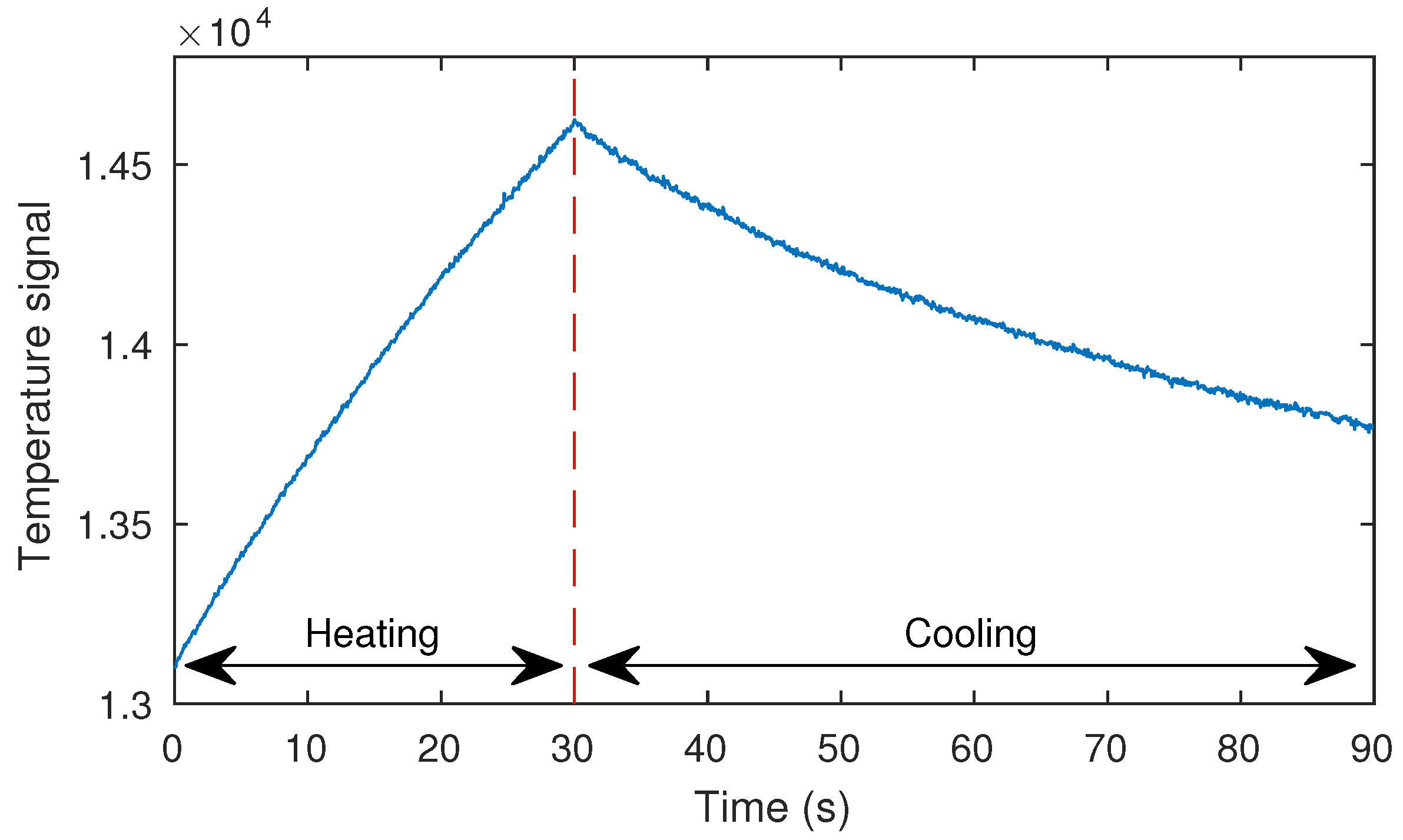

2.5. Infrared Inspection

2.6. Post-Processing

2.6.1. Pulsed Phase Thermography

2.6.2. Principal Component Thermography

2.6.3. Polynomial Fit and Time Derivatives

2.6.4. Partial Least Squares Thermography

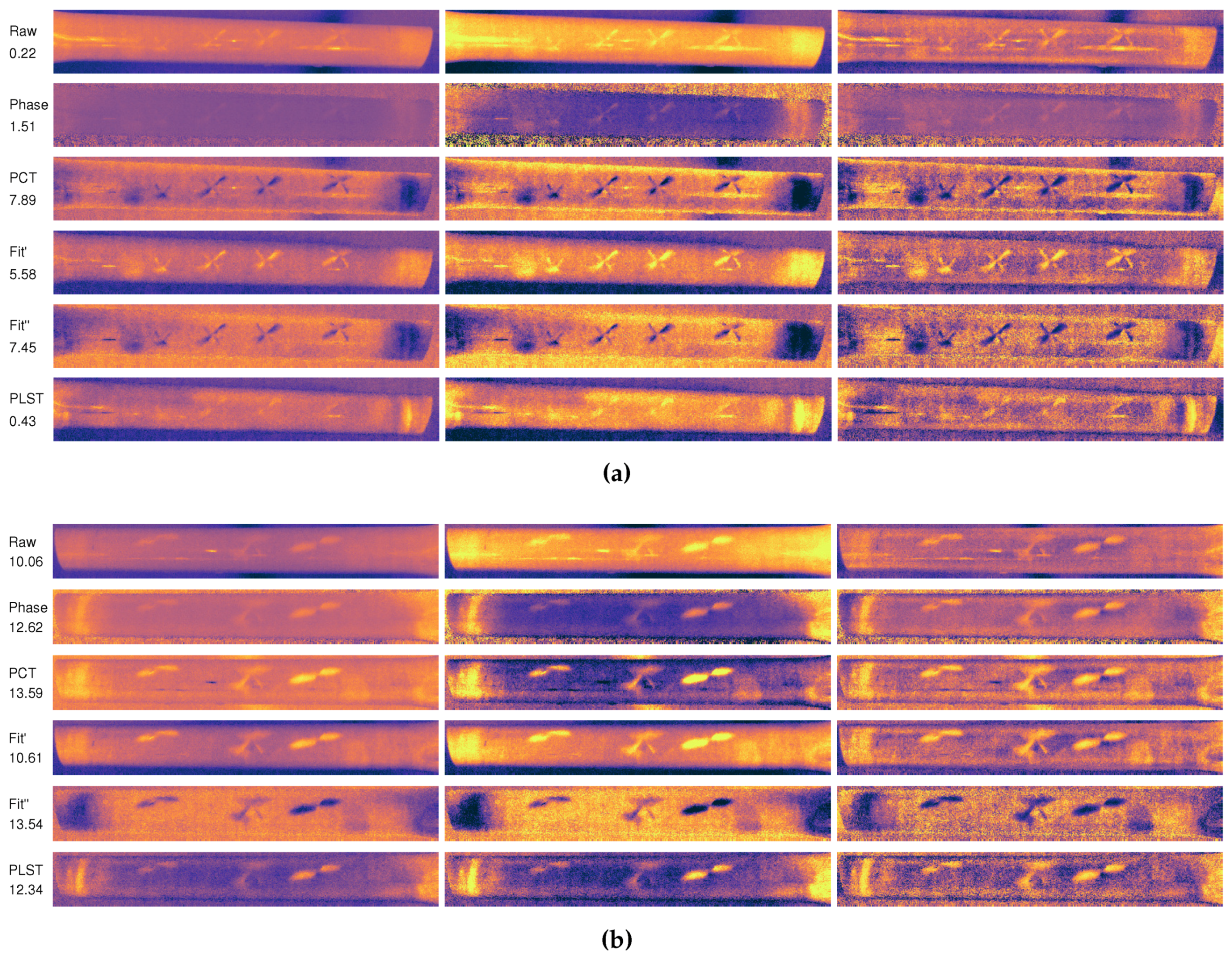

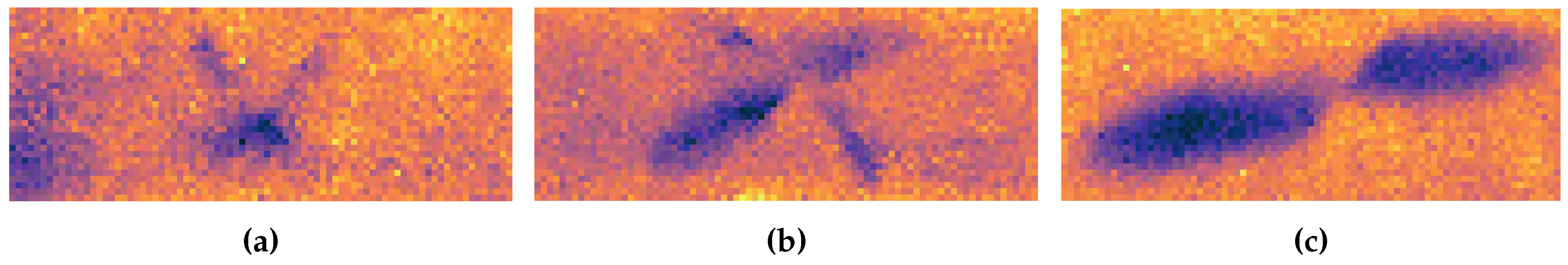

3. Results and Discussion

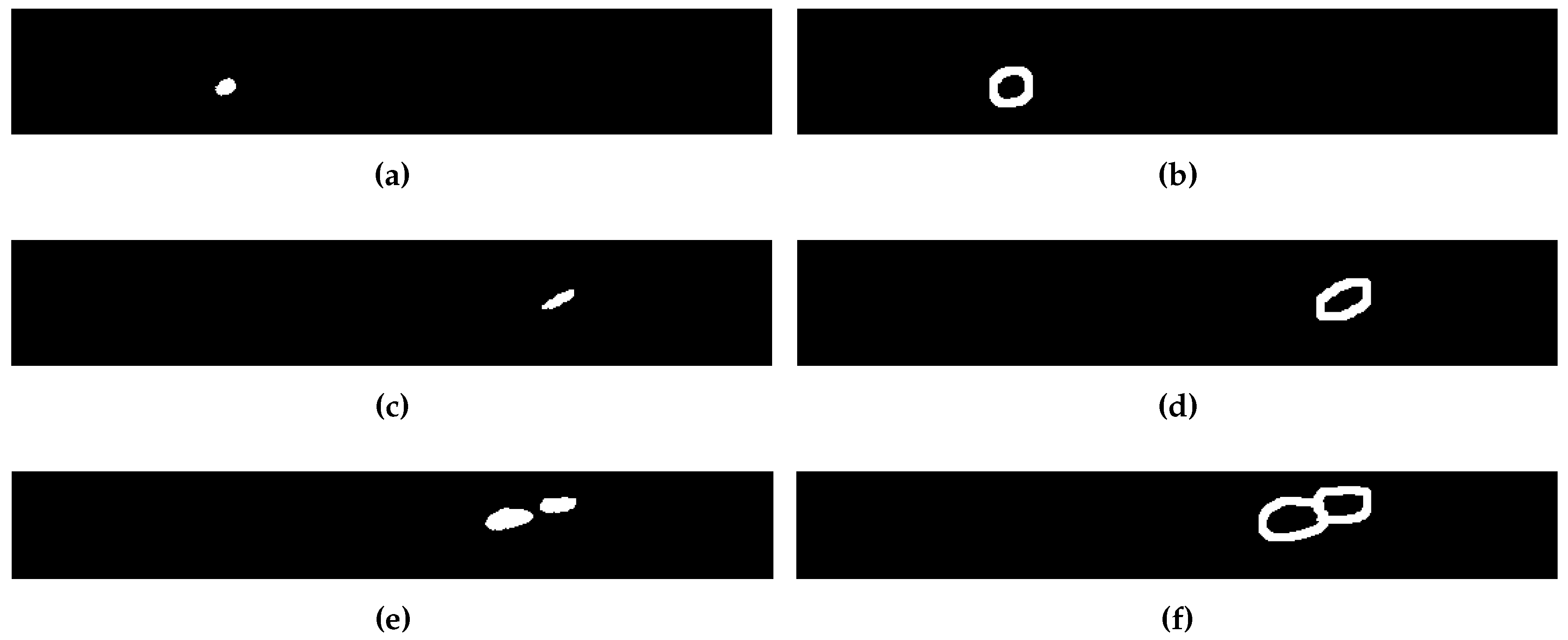

3.1. Quantitative Evaluation

3.2. Analysed Periods

3.3. Comparative Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shull, P.J. Nondestructive Evaluation: Theory, Techniques, and Applications; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Hellier, C. Handbook of Nondestructive Evaluation; McGraw-Hill: New York, NY, USA, 2001. [Google Scholar]

- Maldague, X.P. Nondestructive Evaluation of Materials by Infrared Thermography; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared thermography for temperature measurement and non-destructive testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef] [PubMed]

- Ibarra-Castanedo, C.; Maldague, X. Pulsed phase thermography reviewed. Quant. Infrared Thermogr. J. 2004, 1, 47–70. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.; Boffa, N.; Monaco, E.; Ricci, F. Nondestructive evaluation of carbon fibre reinforced composites with infrared thermography and ultrasonics. Compos. Struct. 2015, 134, 845–853. [Google Scholar] [CrossRef]

- Shrestha, R.; Park, J.; Kim, W. Application of thermal wave imaging and phase shifting method for defect detection in Stainless steel. Infrared Phys. Technol. 2016, 76, 676–683. [Google Scholar] [CrossRef]

- Tomić, L.D.; Jovanović, D.B.; Karkalić, R.M.; Damnjanović, V.M.; Kovačević, B.V.; Filipović, D.D.; Radaković, S.S. Application of pulsed flash thermography method for specific defect estimation in aluminium. Therm. Sci. 2015, 19, 1845–1854. [Google Scholar] [CrossRef]

- Pietrarca, F.; Mameli, M.; Filippeschi, S.; Fantozzi, F. Recognition of wall materials through active thermography coupled with numerical simulations. Appl. Opt. 2016, 55, 6821–6828. [Google Scholar] [CrossRef] [PubMed]

- Tran, Q.H.; Han, D.; Kang, C.; Haldar, A.; Huh, J. Effects of Ambient Temperature and Relative Humidity on Subsurface Defect Detection in Concrete Structures by Active Thermal Imaging. Sensors 2017, 17, 1718. [Google Scholar] [CrossRef] [PubMed]

- Santiago Cintrón, M.; Montalvo, J.G.; Von Hoven, T.; Rodgers, J.E.; Hinchliffe, D.J.; Madison, C.; Thyssen, G.N.; Zeng, L. Infrared Imaging of Cotton Fiber Bundles Using a Focal Plane Array Detector and a Single Reflectance Accessory. Fibers 2016, 4, 27. [Google Scholar] [CrossRef]

- Chung, D.D.; Chung, D. Carbon Fiber Composites; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Sohn, M.; Hu, X.; Kim, J.K.; Walker, L. Impact damage characterisation of carbon fibre/epoxy composites with multi-layer reinforcement. Compos. Part B Eng. 2000, 31, 681–691. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; López, I. Feature extraction and analysis for automatic characterization of impact damage in carbon fibre composites using active thermography. NDT E Int. 2013, 54, 123–132. [Google Scholar] [CrossRef]

- Viets, C.; Kaysser, S.; Schulte, K. Damage mapping of GFRP via electrical resistance measurements using nanocomposite epoxy matrix systems. Compos. Part B Eng. 2014, 65, 80–88. [Google Scholar] [CrossRef]

- Bowkett, M.; Thanapalan, K.; Williams, J. Review and analysis of failure detection methods of composites materials systems. In Proceedings of the 2016 22nd International Conference on Automation and Computing (ICAC), Colchester, UK, 7–8 September 2016; pp. 138–143. [Google Scholar]

- Angelidis, N.; Irving, P. Detection of impact damage in CFRP laminates by means of electrical potential techniques. Compos. Sci. Technol. 2007, 67, 594–604. [Google Scholar] [CrossRef]

- Castaings, M.; Singh, D.; Viot, P. Sizing of impact damages in composite materials using ultrasonic guided waves. NDT E Int. 2012, 46, 22–31. [Google Scholar] [CrossRef]

- Chady, T.; Lopato, P.; Szymanik, B. Terahertz and thermal testing of glass-fibre reinforced composites with impact damages. J. Sens. 2012, 2012. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.M. Infrared thermography to evaluate impact damage in glass/epoxy with manufacturing defects. Int. J. Impact Eng. 2014, 67, 1–11. [Google Scholar] [CrossRef]

- Kozak, M.W. Radiation Protection and Safety in Industrial Radiography; International Atomic Energy Agency Safety Series Number 13; International Atomic Energy Agency: Vienna, Austria, 2000. [Google Scholar]

- American Section of the International Association for Testing Materials (ASTM E1933-97). Standard Test Methods for Measuring and Compensating for Emissivity Using Infrared Imaging Radiometers; ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Thyng, K.M.; Greene, C.A.; Hetland, R.D.; Zimmerle, H.M.; DiMarco, S.F. True colors of oceanography: Guidelines for effective and accurate colormap selection. Oceanography 2016, 29, 9–13. [Google Scholar] [CrossRef]

- Maldague, X.; Marinetti, S. Pulse phase infrared thermography. J. Appl. Phys. 1996, 79, 2694–2698. [Google Scholar] [CrossRef]

- Rajic, N. Principal component thermography for flaw contrast enhancement and flaw depth characterisation in composite structures. Compos. Struct. 2002, 58, 521–528. [Google Scholar] [CrossRef]

- Shepard, S.M.; Lhota, J.R.; Rubadeux, B.A.; Wang, D.; Ahmed, T. Reconstruction and enhancement of active thermographic image sequences. Opt. Eng. 2003, 42, 1337–1342. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; López, I. Automatic detection of impact damage in carbon fibre composites using active thermography. Infrared Phys. Technol. 2013, 58, 36–46. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; López, I. A quantitative comparison of stimulation and post-processing thermographic inspection methods applied to aeronautical carbon fibre reinforced polymer. Quant. InfraRed Thermogr. J. 2013, 10, 55–73. [Google Scholar] [CrossRef]

- Lopez, F.; Ibarra-Castanedo, C.; de Paulo Nicolau, V.; Maldague, X. Optimization of pulsed thermography inspection by partial least-squares regression. NDT E Int. 2014, 66, 128–138. [Google Scholar] [CrossRef]

- Balageas, D.L. Defense and Illustration of Time-Resolved Pulsed Thermography for NDE. In Proceedings of the SPIE 8013, Thermosense: Thermal Infrared Applications XXXIII, Orlando, FL, USA, 10 May 2011. [Google Scholar] [CrossRef]

- American Section of the International Association for Testing Materials (ASTM E2737). Standard Practice for Digital Detector Array Performance Evaluation and Long-Term Stability; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Sethian, J.A. Level set methods and fast marching methods. J. Comput. Inf. Technol. 2003, 11, 1–2. [Google Scholar]

- Madruga, F.J.; Ibarra-Castanedo, C.; Conde, O.M.; López-Higuera, J.M.; Maldague, X. Infrared thermography processing based on higher-order statistics. NDT E Int. 2010, 43, 661–666. [Google Scholar] [CrossRef]

- Reza, A.M. Realization of the contrast limited adaptive histogram equalization (CLAHE) for real-time image enhancement. J. VLSI Signal Process. 2004, 38, 35–44. [Google Scholar] [CrossRef]

- Thompson, D.O.; Chimenti, D.E. Review of Progress in Quantitative Nondestructive Evaluation; Springer Science & Business Media: Berlin, Germany, 2012; Volume 18. [Google Scholar]

- Derusova, D.A.; Vavilov, V.P.; Pawar, S.S. Evaluation of equivalent defect heat generation in carbon epoxy composite under powerful ultrasonic stimulation by using infrared thermography. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015; Volume 81, p. 012084. [Google Scholar]

| Camera | FLIR A655sc |

| Temperature range | to +140 C |

| Thermal sensitivity/Noise Equivalent Temperature Difference (NETD) | 30 mK at 30 C |

| Detector | 640 × 480 UFPA |

| Spectral range | 7.5–14 |

| Image frequency | 50 Hz |

| Spatial resolution | 0.68 mrad |

| Field of view (FOV) | 25 × 19 |

| Detector pitch | 17 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Usamentiaga, R.; Ibarra-Castanedo, C.; Klein, M.; Maldague, X.; Peeters, J.; Sanchez-Beato, A. Nondestructive Evaluation of Carbon Fiber Bicycle Frames Using Infrared Thermography. Sensors 2017, 17, 2679. https://doi.org/10.3390/s17112679

Usamentiaga R, Ibarra-Castanedo C, Klein M, Maldague X, Peeters J, Sanchez-Beato A. Nondestructive Evaluation of Carbon Fiber Bicycle Frames Using Infrared Thermography. Sensors. 2017; 17(11):2679. https://doi.org/10.3390/s17112679

Chicago/Turabian StyleUsamentiaga, Rubén, Clemente Ibarra-Castanedo, Matthieu Klein, Xavier Maldague, Jeroen Peeters, and Alvaro Sanchez-Beato. 2017. "Nondestructive Evaluation of Carbon Fiber Bicycle Frames Using Infrared Thermography" Sensors 17, no. 11: 2679. https://doi.org/10.3390/s17112679