Towards Intelligent Interpretation of Low Strain Pile Integrity Testing Results Using Machine Learning Techniques

Abstract

:1. Introduction

2. Background

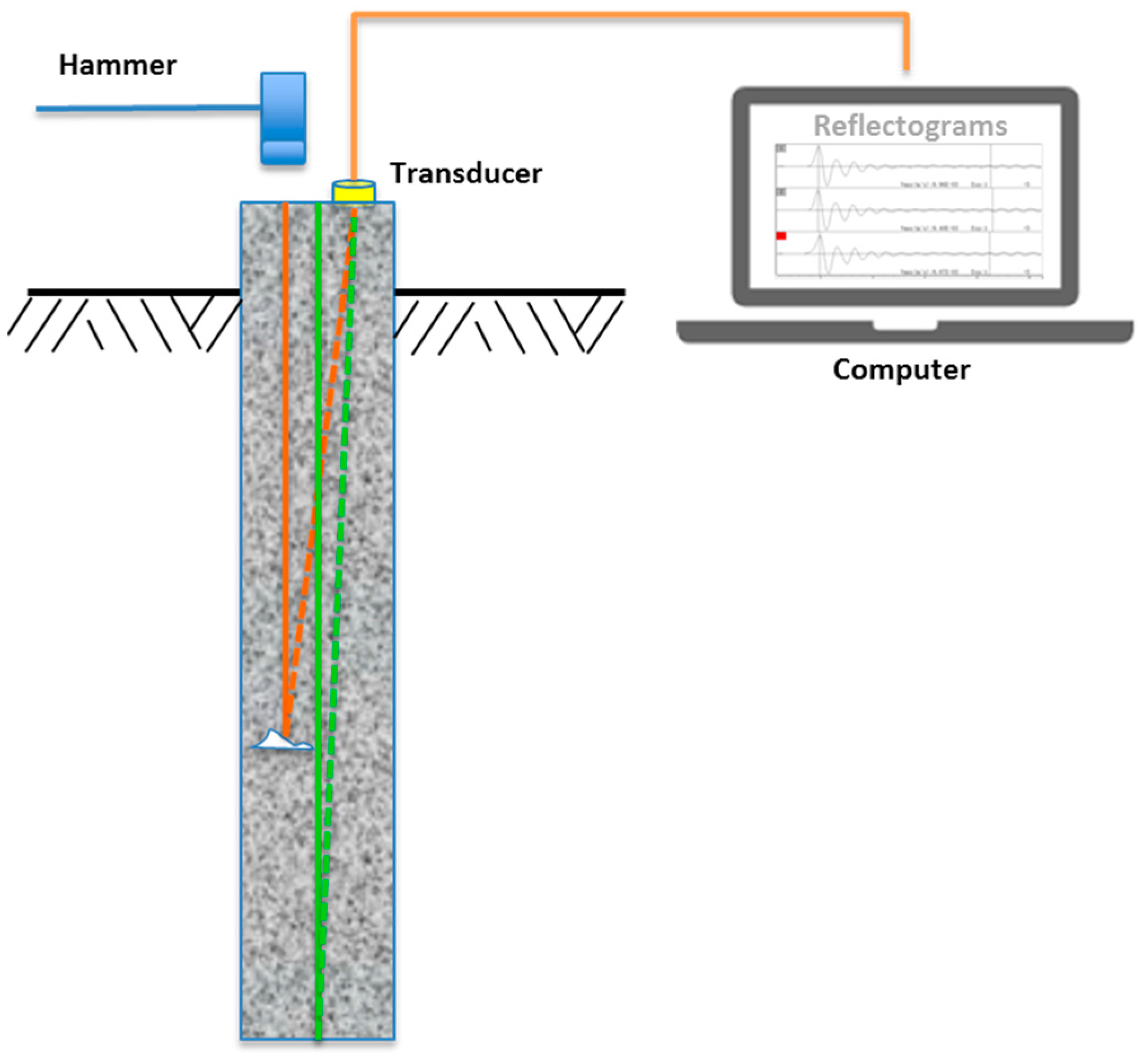

2.1. Principle of LSPIT

2.2. Related Work

3. Proposed Methodology

3.1. Signal Preprocessing

| Algorithm 1. Pseudo-code of our peak detection algorithm. |

| Inputs: // a n-point waveform T // A threshold value |

| Outputs: // peaks and corresponding indices |

| 1. Calculate the 1st-order difference of x, |

| 2. Determine the sign of |

| 3. Search for the sign changes from +1 to −1 |

| for j = 2 to n |

| end |

| 4. Remove those peaks with values being less than the threshold, T |

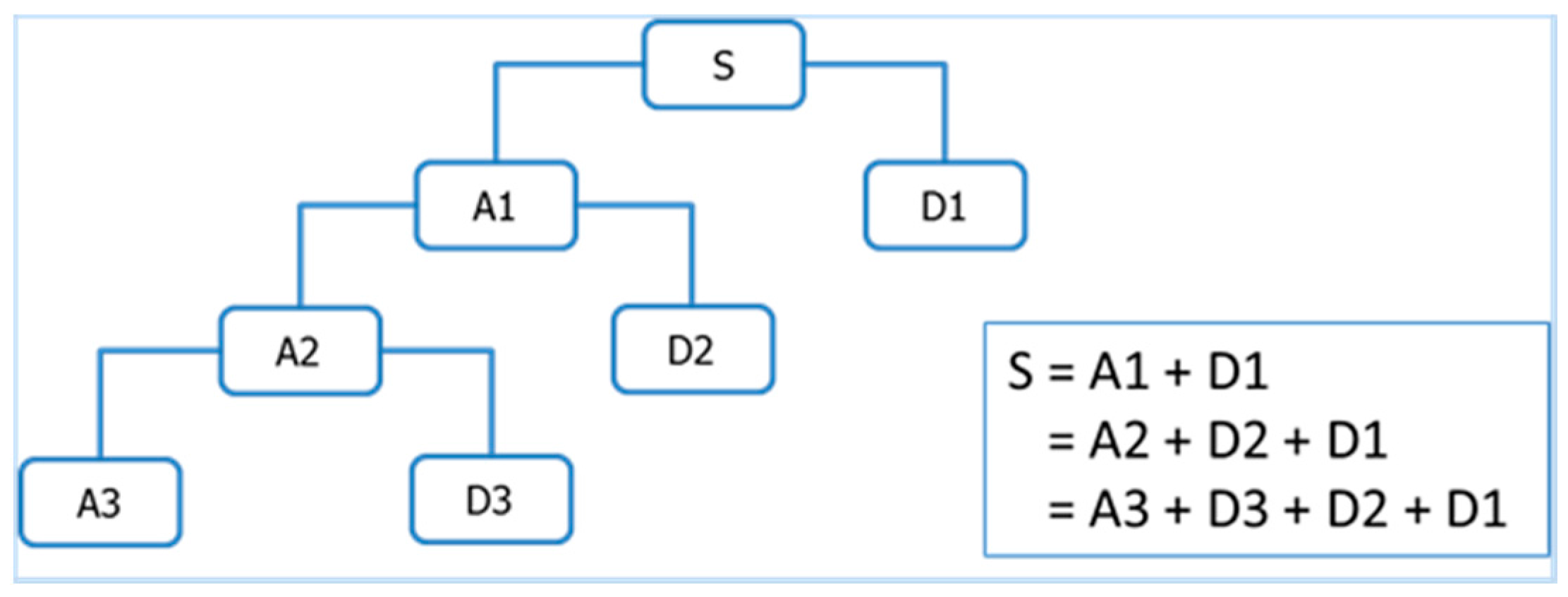

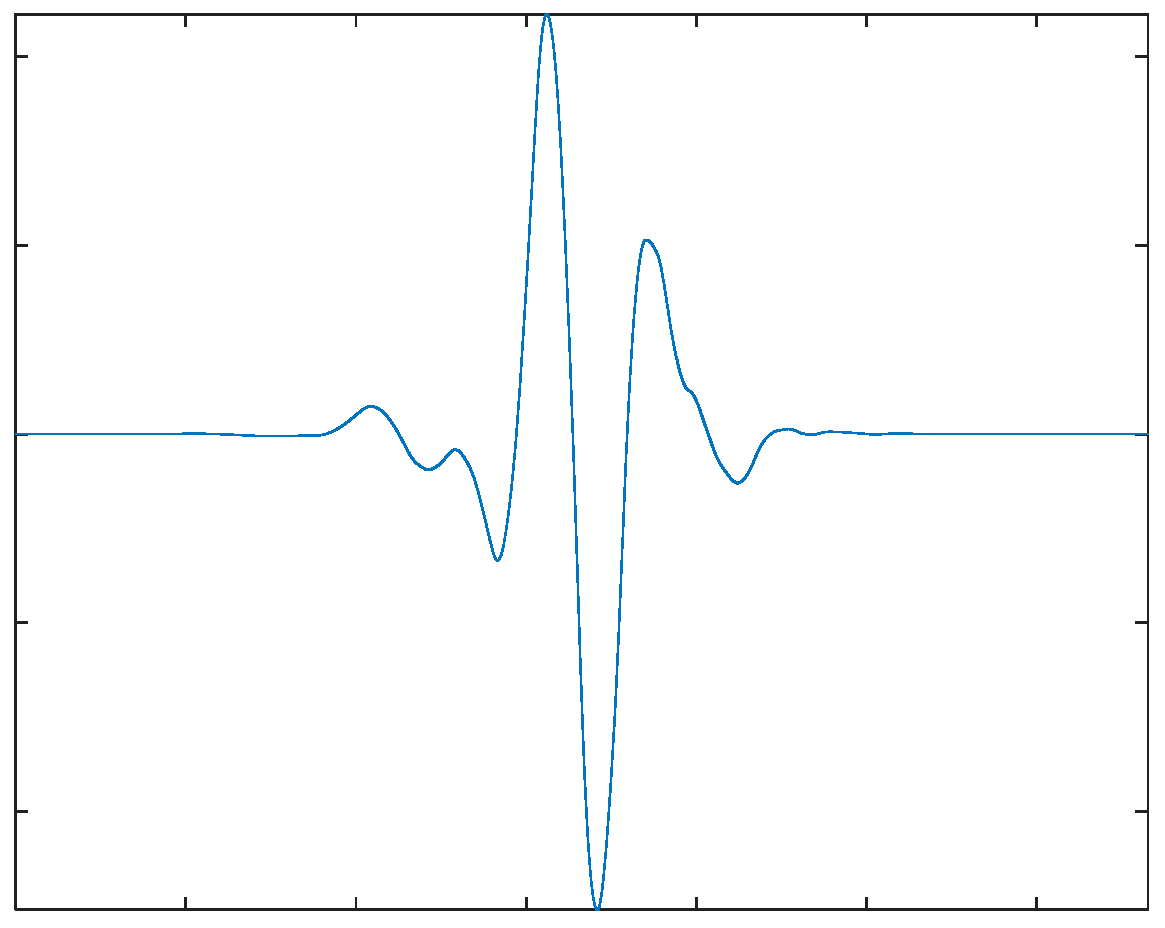

3.2. Wavelet-Based Feature Extraction

3.3. Defect Detection Using ELM

4. Experimental Results and Discussion

4.1. The Reflectogram Data

4.2. Detection Performance Evaluation and Methods

4.3. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rausche, F. Non-Destructive Evaluation of Deep Foundations. In Proceedings of the 5th International Conference on Case Histories in Geotechnical Engineering, New York, NY, USA, 13–17 April 2004. [Google Scholar]

- Likins, G.E.; Rausche, F.; Miner, R.; Hussein, M.H. Verification of Deep Foundations by NDT Methods. In Proceedings of the ASCE Annual Meeting, Irvine, CA, USA, 19–21 April 1993. [Google Scholar]

- Massoudi, N.; Teferra, W. Non-Destructive Testing of Piles Using the Low Strain Integrity Method. In Proceedings of the Fifth International Conference on Case Histories in Geotechnical Engineering, New York, NY, USA, 13–17 April 2004. [Google Scholar]

- Protopapadakis, E.; Schauer, M.; Pierri, E.; Doulamis, A.D.; Stavroulakis, G.E.; Böhrnsen, J.; Langer, S. A genetically optimized neural classifier applied to numerical pile integrity tests considering concrete piles. Comput. Struct. 2016, 162, 68–79. [Google Scholar] [CrossRef]

- Tam, C.M.; Tong, T.K.L.; Lau, T.C.T.; Chan, K.K. Diagnosis of prestressed concrete pile defects using probabilistic neural networks. Eng. Struct. 2004, 26, 1155–1162. [Google Scholar] [CrossRef]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- ASTM D5882-07: Standard Test Method for Low Strain Impact Integrity Testing of Deep Foundations; ASTM International: West Conshohocken, PA, USA, 2007.

- He, B.; Xu, D.; Nian, R.; van Heeswijk, M.; Yu, Q.; Miche, Y.; Lendasse, A. Fast face recognition via sparse coding and extreme learning machine. Cognit. Comput. 2014, 6, 264–277. [Google Scholar] [CrossRef]

- Bazi, Y.; Alajlan, N.; Melgani, F.; AlHichri, H.; Malek, S.; Yager, R.R. Differential evolution extreme learning machine for the classification of hyperspectral images. IEEE Geosci. Remote Sens. Lett. 2014, 11, 1066–1070. [Google Scholar] [CrossRef]

- Kaya, Y.; Uyar, M. A hybrid decision support system based on rough set and extreme learning machine for diagnosis of hepatitis disease. Appl. Soft Comput. 2013, 13, 3429–3438. [Google Scholar] [CrossRef]

- Yang, X.; Mao, K. Reduced ELMs for causal relation extraction from unstructured text. IEEE Intell. Syst. 2013, 28, 48–52. [Google Scholar]

- Yan, W.Z.; Yu, L.J. On Accurate and Reliable Anomaly Detection for Gas Turbine Combustors: A Deep Learning Approach. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 18–24 October 2015. [Google Scholar]

- Wong, P.K.; Yang, Z.X.; Vong, C.M.; Zhong, J.H. Real-time fault diagnosis for gas turbine generator systems using extreme learning machine. Neurocomputing 2014, 128, 249–257. [Google Scholar] [CrossRef]

- Ertel, J.P.; Niederleithinger, E.; Grohmann, M. Advanced in pile integrity testing. Near Surface Geophysics. 2016, 14, 503–512. [Google Scholar] [CrossRef]

- Watson, J.N. The Application of Neural Networks to Non-destructive Testing Techniques. Ph.D. Thesis, School of the Build Environment, Napier University, Edinburgh, UK, 2001. [Google Scholar]

- Zhang, C.; Zhang, J. Application of Artificial Neural Network for Diagnosing Pile Integrity Based on Low Strain Dynamic Testing. In Computational Structural Engineering; Yuan, Y., Cui, J., Mang, H.A., Eds.; Springer: Dordrecht, The Netherlands, 2009; pp. 857–862. [Google Scholar]

- Garcia, S.; Romero, J.; Lopez-Molina, J. An intelligent pattern recognition model to automate the categorization of pile damage. In Proceedings of the 19th International Conference on Soil Mechanics and Geotechnical Engineering, Seoul, Korea, 17–22 September 2017. [Google Scholar]

- Daubechies, I. Ten Lectures on Wavelets; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 1992. [Google Scholar]

- Zhang, G.; Jiang, X.L.; Liu, Z.J.; Chen, C.C. Pile Defect Intelligent Identification Based on Wavelet Analysis and Neural Networks. Appl. Mech. Mater. 2014, 608–609, 899–902. [Google Scholar] [CrossRef]

- Ying, Y.; Garrett, J., Jr.; Oppenheim, I.; Soibelman, L.; Harley, J.; Shi, J.; Jin, Y. Toward Data-Driven Structural Health Monitoring: Application of Machine Learning and Signal Processing to Damage Detection. J. Comput. Civ. Eng. 2013, 27, 667–680. [Google Scholar] [CrossRef]

- Farrar, C.R.; Worden, K. Structural Health Monitoring: A Machine Learning Perspective; John Wiley and Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Srivastava, A.N.; Han, J. Machine Learning and Knowledge Discovery for Engineering Systems Health Management; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Dackermann, U.; Skinner, B.; Li, J. Guided-wave-based condition assessment of in-situ timber utility poles using machine learning algorithms. Struct. Health Monit. 2014, 13, 374–388. [Google Scholar] [CrossRef]

- Peng, C.; Yan, J.; Duan, S.; Wang, L.; Jia, P.; Zhang, S. Enhancing Electronic Nose Performance Based on a Novel QPSO-KELM Model. Sensors 2016, 16, 520. [Google Scholar] [CrossRef] [PubMed]

- Jian, Y.; Huang, D.; Yan, J.; Lu, K.; Huang, Y.; Wen, T.; Zeng, T.; Zhong, S.; Xie, Q. A Novel Extreme Learning Machine Classification Model for e-Nose Application Based on the Multiple Kernel Approach. Sensors 2017, 17, 1434. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Xiao, W.; Zhang, S.; Huang, S. Device-Free Localization via an Extreme Learning Machine with Parameterized Geometrical Feature Extraction. Sensors 2017, 17, 879. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.K.; Yan, W.; Cui, D.M. Concrete Condition Assessment Using Impact-Echo Method and Extreme Learning Machines. Sensors 2016, 16, 447. [Google Scholar] [CrossRef] [PubMed]

- Nijm, G.M.; Sahakian, A.V.; Swiryn, S.; Larson, A.C. Comparison of Signal Peak Detection Algorithms for Self-Gated Cardiac Cine MRI. In Proceedings of the Computers in Cardiology, Durham, NC, USA, 30 September–3 October 2007. [Google Scholar]

- Brownlee, J. 2014. Discover Feature Engineering, How To Engineer Features and How to Get Good at it. Available online: Machinelearningmastery.com/discover-feature-engineering-how-to-engineer-features-and-how-to-get-good-at-it/ (accessed on 5 August 2015).

- Domingos, P. A few useful things to know about machine learning. Commun. ACM 2012, 55, 78. [Google Scholar] [CrossRef]

- NIPS (2014). Deep Learning and Representation Learning Workshop: NIPS 2014. Available online: http://www.dlworkshop.org/ (accessed on 7 August 2015).

- ICLR (2015), International conference on learning representations. Available online: http://www.iclr.cc/doku.php (accessed on 7 August 2015).

- Samuel, P.D.; Pines, D.J. Classifying helicopter gearbox faults using a normalized energy metric. Smart Mater. Struct. 2001, 10, 145–153. [Google Scholar] [CrossRef]

- Lotfollahi, Y.M.A.; Hesari, M.A. Using Wavelet Analysis in Crack Detection at the Arch Concrete Dam Under Frequency Analysis with FEM. Res. India Publ. J. Wavelet Theory Appl. 2008, 2, 61–81. [Google Scholar]

- Noh, H.Y.; Nair, K.; Lignos, D.G.; Kiremidjian, A. Application of Wavelet Coefficient Energies of Stationary and Non-Stationary Response Signals for Structural Damage Diagnosis. In Proceedings of the 7th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 9–11 September 2009. [Google Scholar]

- Luk, B.L.; Jiang, Z.D.; Liu, L.K.P.; Tong, F. Impact Acoustic Non-Destructive Evaluation in Noisy Environment Based on Wavelet Packet. In Proceedings of the International Multi Conference of Engineers and Computer Scientists (IMECS 2008), Volume II. Hong Kong, China, 19–21 March 2008. [Google Scholar]

- Yeh, P.L.; Liu, P.L. Application of the Wavelet Transform and the Enhanced Fourier Spectrum in the Impact Echo Test. NDT E Int. 2008, 41, 382–394. [Google Scholar] [CrossRef]

- Navarro, P.; Fernández-Isla, C.; Alcover, P.M.; Suardíaz, J. Defect Detection in Textures through the Use of Entropy as a Means for Automatically Selecting the Wavelet Decomposition Level. Sensors 2016, 16, 1178. [Google Scholar] [CrossRef] [PubMed]

- Boukabache, H.; Escriba, C.; Fourniols, J.Y. Toward Smart Aerospace Structures: Design of a Piezoelectric Sensor and Its Analog Interface for Flaw Detection. Sensors 2014, 14, 20543–20561. [Google Scholar] [CrossRef] [PubMed]

- Yu, B.; Liu, D.; Zhang, T. Fault Diagnosis for Micro-Gas Turbine Engine Sensors via Wavelet Entropy. Sensors 2011, 11, 9928–9941. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.B.; Zhou, H.M.; Ding, X.J.; Zhang, R. Extreme learning machine for regression and multiclass classification. IEEE Trans. Syst. Man Cybern. Part B 2012, 42, 513–529. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.B. An Insight into Extreme Learning Machines: Random Neurons, Random Features and Kernels. Cognit. Comput. 2014, 6, 376–390. [Google Scholar] [CrossRef]

- Zong, W.; Huang, G.-B.; Chen, Y. Weighted extreme learning machine for imbalance learning. Neurocomputing 2013, 101, 229–242. [Google Scholar] [CrossRef]

- Bradley, A.P. The use of the area under the ROC curve in the evaluation of machine learning algorithms. Pattern Recognit. 1997, 30, 1145–1159. [Google Scholar] [CrossRef] [Green Version]

- Provost, F.; Fawcett, T. Analysis and visualization of classifier performance: Comparison under imprecise class and cost distributions. In Proceedings of the 3rd International Conference on Knowledge Discovery and Data Mining (KDD-97), Newport Beach, CA, USA, 14–17 August 1997; pp. 43–48. [Google Scholar]

- Yu, C.H. Resampling Methods: Concepts, Applications, and Justification. Pract. Assess Res. Eval. 2003, 8, 1–23. Available online: http://PAREonline.net/getvn.asp?v=8&n=19 (accessed on 17 October 2017).

| No | Site Name | # of Piles | # of Defect Piles | Pile Length (m) | Pile Type |

|---|---|---|---|---|---|

| 1 | Jing-Ao Bldg.#7 | 21 | 0 | 11 | I |

| 2 | Jing-Ao Bldg.#9 | 19 | 0 | 14 | I |

| 3 | Jing-Ao Bldg.#10 | 20 | 0 | 12 | II |

| 4 | Jing-Ao Bldg.#26 | 15 | 0 | 11 | II |

| 5 | Jing-Ao Bldg.#28 | 20 | 0 | 12 | II |

| 6 | Jing-Ao Bldg.#29 | 38 | 0 | 13 | II |

| 7 | Jing-Ao Bldg.#30 | 19 | 0 | 13 | II |

| 8 | Jing-Ao Bldg.#31 | 20 | 0 | 13 | II |

| 9 | Jing-Ao Bldg.#32 | 37 | 0 | 14 | II |

| 10 | Jing-Ao Bldg.#35 | 36 | 0 | 12 | II |

| 11 | Jing-Ao Bldg.#36 | 36 | 0 | 12 | II |

| 12 | Jing-Ao Bldg.#37 | 20 | 0 | 13 | II |

| 13 | Jing-Ao Bldg.#38 | 35 | 0 | 12 | II |

| 14 | Ye-Ji 35kvRoad | 66 | 8 | 6.8–10.5 | III |

| 15 | Fong-Fang RailroadBldg #4 | 46 | 3 | 11, 12, 14 | III |

| 16 | Fong-Fang RailroadBldg #5 | 47 | 2 | 11, 12, 14 | III |

| 17 | Fong-Fang RailroadBldg #7 | 50 | 6 | 11, 12, 14 | III |

| 18 | Fong-Fang Railroad Pump Station | 34 | 3 | 16, 18 | III |

| 19 | Shang-Shui-Guang | 37 | 6 | 10.5 | III |

| 20 | Yi-Shi-Jia Bldg # 3 | 27 | 4 | 16, 17 | II |

| 21 | Yi-Shi-Jia Package Bldg | 33 | 3 | 15, 16 | II |

| 22 | Yi-Shi-Jia Bldg # 2 | 56 | 3 | 17 | II |

| 23 | Ying-Chao-Yang | 6 | 6 | 9.8–18.8 | II |

| 24 | Yi-Shi-Jia Bldg # 1 | 65 | 3 | 16, 17 | III |

| 25 | Lu-An FongHuanBldg # 5 | 87 | 7 | 5–9.47 | IV |

| 26 | Long-Hua 35KV Engr. Site | 19 | 8 | 7.5–13.5 | IV |

| 27 | Bing-He Shuandung Power Station | 14 | 1 | 9–12 | IV |

| Total | 923 | 63 | N/A | N/A |

| AUCs | |

|---|---|

| ELM | 0.9841 ± 0.0022 |

| FFNN | 0.9780 ± 0.0112 |

| Predicted | |||

|---|---|---|---|

| Normal | Defective | ||

| True | Normal | 94.45% | 5.55% |

| Defective | 0.00% | 100.00% | |

| Pile Type | # of Piles | # of Defect Piles | TPR (%) | FPR (%) |

|---|---|---|---|---|

| I | 40 | 0 | - | 0.20 |

| II | 418 | 16 | 93.75 | 4.78 |

| III | 345 | 31 | 96.77 | 5.51 |

| IV | 120 | 16 | 87.50 | 5.83 |

| Total | 923 | 63 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, D.-M.; Yan, W.; Wang, X.-Q.; Lu, L.-M. Towards Intelligent Interpretation of Low Strain Pile Integrity Testing Results Using Machine Learning Techniques. Sensors 2017, 17, 2443. https://doi.org/10.3390/s17112443

Cui D-M, Yan W, Wang X-Q, Lu L-M. Towards Intelligent Interpretation of Low Strain Pile Integrity Testing Results Using Machine Learning Techniques. Sensors. 2017; 17(11):2443. https://doi.org/10.3390/s17112443

Chicago/Turabian StyleCui, De-Mi, Weizhong Yan, Xiao-Quan Wang, and Lie-Min Lu. 2017. "Towards Intelligent Interpretation of Low Strain Pile Integrity Testing Results Using Machine Learning Techniques" Sensors 17, no. 11: 2443. https://doi.org/10.3390/s17112443