1. Introduction

Air-coupled ultrasonics is a non-contact technique which is already used in non-destructive testing, material characterization [

1,

2,

3,

4,

5] and even for secure wireless transmission of data [

6,

7]. Such a technique has many advantages over conventional ultrasonic techniques. The primary advantage of air-coupled ultrasonics is that there is no contact between the object under investigation and the ultrasonic transducer. For this reason, it is ideally suited for inspecting materials susceptible to interaction with or damage by water, including wood [

8,

9], some foams, certain composites [

10], paper [

11] and even foodstuffs [

12,

13]. Ultrasonic air-coupled methods are already being used for the characterization of elastic properties of various materials, especially in the case when direct acoustic contact with the investigated material is not allowed [

1,

8]. Applications of non-contact inspection range from testing of automotive tires [

14,

15] to the inspections in the aircraft structures [

16,

17,

18]. Modern airliners use significant amounts of composite materials reducing their weight [

19,

20]. Composites have found increasing application in commercial aircraft structures because of the strength, stiffness, fatigue and corrosion resistance and weight benefits jointly contributing to the improvement of performance [

21]. Airborne ultrasound is a useful non-contact method of detecting and imaging defects in aging aircraft structures, given efficient transducers for use as transmitters and receivers are available [

16,

18].

A spatial resolution of ultrasonic NDT techniques is improving with an increased frequency, which may reach even a few MHz [

4]. However, during the last years the air-coupled ultrasonics was applied and for testing of civil structures such as concrete structures. Due to attenuation and scattering of ultrasonic waves in concrete, usually frequencies lower than 100 kHz are used. Progress in this field is impeded by a lack of efficient air-coupled transducers in the frequency band up to 50 kHz [

2,

3]. On the other hand the frequency range used for a secure transmission of data is (50–100) kHz [

7]. It means that a frequency range below 100 kHz becomes attractive for various air-coupled applications.

The main currently encountered problem is big losses of ultrasonic signals up to (120–150) dB, which are caused by the attenuation and significant mismatch of acoustic impedances of ultrasonic transducers and air. The acoustic impedance of air is 0.445 kRayl at a room temperature and 30–35 MRayl of most piezoelectric materials. One of the ways of solving this issue is an application of piezoelectric composite whose specific acoustic impedance is lower than that of monolithic piezoelectric ceramics [

22,

23,

24,

25]. Further enhancement of the performance of ultrasonic air-coupled transducers is limited by the piezoelectric effect of the piezoelectric material being used. For this purpose, the 1–3 connectivity PMN-32%PT single crystal composites were used and their performance was compared with the sensitivity of the 1–3 PZT ceramic piezocomposites. It was found that sensitivities are very similar but the single crystal composites possessed a wider bandwidth up to 89% with respect to the central frequency, however their operation frequency range is between (0.5–1.5) MHz [

26]. Performance of the 1–3 connectivity piezoelectric composite transducers may be improved by matching layers made of materials with low acoustic impedance, for example, polypropylene foam ferroelectric film [

27,

28,

29,

30].

Another option is application of polyvinylidene fluoride (PVDF) films [

31,

32,

33]. A relatively strong piezoelectric response and mechanical durability make it a valuable material for use in surface acoustic wave (SAW) devices and air-coupled transducers [

31]. The piezoelectric polymer PVDF is flexible, has a low density (

ρ = 1780 kg/m

3), a low acoustic impedance (

Z = 3 MRayl) and a high piezoelectric constant (

g33 = 0.14–0.33 Vm/N). However the electromechanic coupling factor

kt is rather low (0.1–0.15) [

32] what makes it inefficient as a transmitter of ultrasonic waves. The dielectric constant is also low (

ε = 10–12) and consequently the electric input or output impedance is quite high (>1 MΩ). Application of such films in low frequency air-coupled arrays is complicated due to their flexibility and high output electric impedance.

Acoustic matching problems may be avoided by application of capacitive ultrasonic transducers [

1]. Electrostatic or capacitive transducers consist of a flexible membrane and a back plate or substrate. The membrane is made of a thin metal-plated polymer film, thickness of which is a few microns. The membrane may be also manufactured using microelectronic technologies [

34,

35]. A constant high voltage and driving electric signal are applied between the membrane and back plate and they force the membrane to vibrate. Such transducer possesses a quite wide bandwidth but usually operate in the frequency range higher than a few hundreds of kHz [

34,

35,

36]. In addition, they are not yet applied in low frequency air-coupled ultrasonic arrays.

For non-destructive testing of composite structures, guided waves are increasingly being used. Such waves may be excited by air-coupled techniques and they are well suited for a fast testing of large areas [

17,

19,

24,

37,

38,

39,

40]. Nowadays air-coupled instrumentation enables to achieve a scanning speed of flat components 500 mm/s [

20]. It has been shown that guided waves in composite structures for non-destructive evaluation may be efficiently excited and picked-up by air-coupled ultrasonic linear arrays [

41]. Such arrays at frequencies lower than 50 kHz enable excitation of anti-symmetric Lamb wave modes with velocities close or even lower than ultrasound velocity in air. It means that in this case there are no losses due to a wave leaking to air, that allows covering longer distances for a non-destructive testing [

11,

16]. For this purpose, we have proposed air-coupled multi-element array in which as individual elements piezoelectric strips made of PMN-32%PT crystals vibrating in a transverse-extension mode are used [

42]. PMN-32%PT crystals possess a very high piezoelectric properties. The electromechanical coupling factor for the transverse extension mode is

k32 > (0.84–0.91) [

42,

43,

44]. The Curie temperature for the PMN-32%PT crystals is 90 °C [

44]. It allows using them in majority of NDT applications. Performance of such elements and the array as a whole in a transmitting mode was described in detail in [

42]. It was shown that exploitation of a transverse extension mode allows developing efficient air-coupled ultrasonic transmitters in a low frequency range up to 100 kHz. For radiation of ultrasonic waves, the tip of the piezoelectric strip is exploited. The aperture in this case is rather small 1 × 5 mm, e.g., a few times smaller than the wavelength of ultrasonic wave in air at 40 kHz, but such dimensions enable to use such strips in electrically steered ultrasonic arrays. The developed transducer possesses low transduction losses of −11.4 dB at the frequency

fr = 41.5 kHz [

42]. However, the performed investigation limited to only a transmission mode.

In the case of a high electromechanical coupling, such as that observed in PMN-32%PT type single crystal piezoelectric elements novel problems and possibilities arise. Mainly they are caused by a high electromechanical coupling coefficient of the PMN-32%PT strips vibrating in a transverse-extension mode. The arising problems are the following.

Frequencies of maximal transmission and reception usually coincide with the resonance and antiresonance frequencies of the piezoelectric element respectively. Due to a very high electromechanical coupling coefficient, those frequencies are very different. For example in the case of 20 × 5 × 1 mm3 PMN-32%PT strip vibrating in a transverse-extension mode the maximum of a transmission coefficient is obtained at the resonance frequency fr = 31.4 kHz and maximum of the reception is obtained at the antiresonance frequency fa = 52.8 kHz, e.g., the difference is even 21.4 kHz. It means that the same element cannot efficiently operate in a transmitting-receiving mode and for that, two separate piezoelectric elements with different dimensions must be used.

On the other hand, we have found that the frequency bandwidth even in the case of the air-coupled transducers with acoustic matching elements between the piezoelectric element and air is rather narrow-less than 3%, what results in a long transient process in a pulse mode duration of which is longer than 50 periods. Such transducers are not suitable for many NDT techniques. The frequency bandwidth may be widened by a mechanical damping, for example by means of a special backing attached to the back end of a piezoelectric element, but we found that in this case transduction losses increase by −20 dB.

The named problems may be solved in the following ways:

Therefore, objective of this research was development of novel air-coupled ultrasonic receivers with PMN-32%PT strip-like piezoelectric elements vibrating in a transverse-extension mode with electromechanically controlled operation and suitable for applications in ultrasonic arrays.

2. Electromechanical Damping of a Strip-Like Receiver

For reception of ultrasonic waves strip-like PMN-32%PT piezoelectric elements vibrating in a transverse-extension mode may be used. Exploitation of such mode enables to achieve rather low operation frequencies (<150 kHz) what is necessary for many air-coupled applications [

2,

3,

7,

8]. PMN-32%PT piezoelectric crystals are anisotropic therefore in order to get a high sensitivity the piezolelectric strips were cut of bigger crystal plates in the crystallographic direction 2. In this case, a very high electromechanical coupling coefficient up to 0.91 is observed [

42,

43,

44]. For reception of an ultrasonic wave the rectangular tip of the strip is exploited (

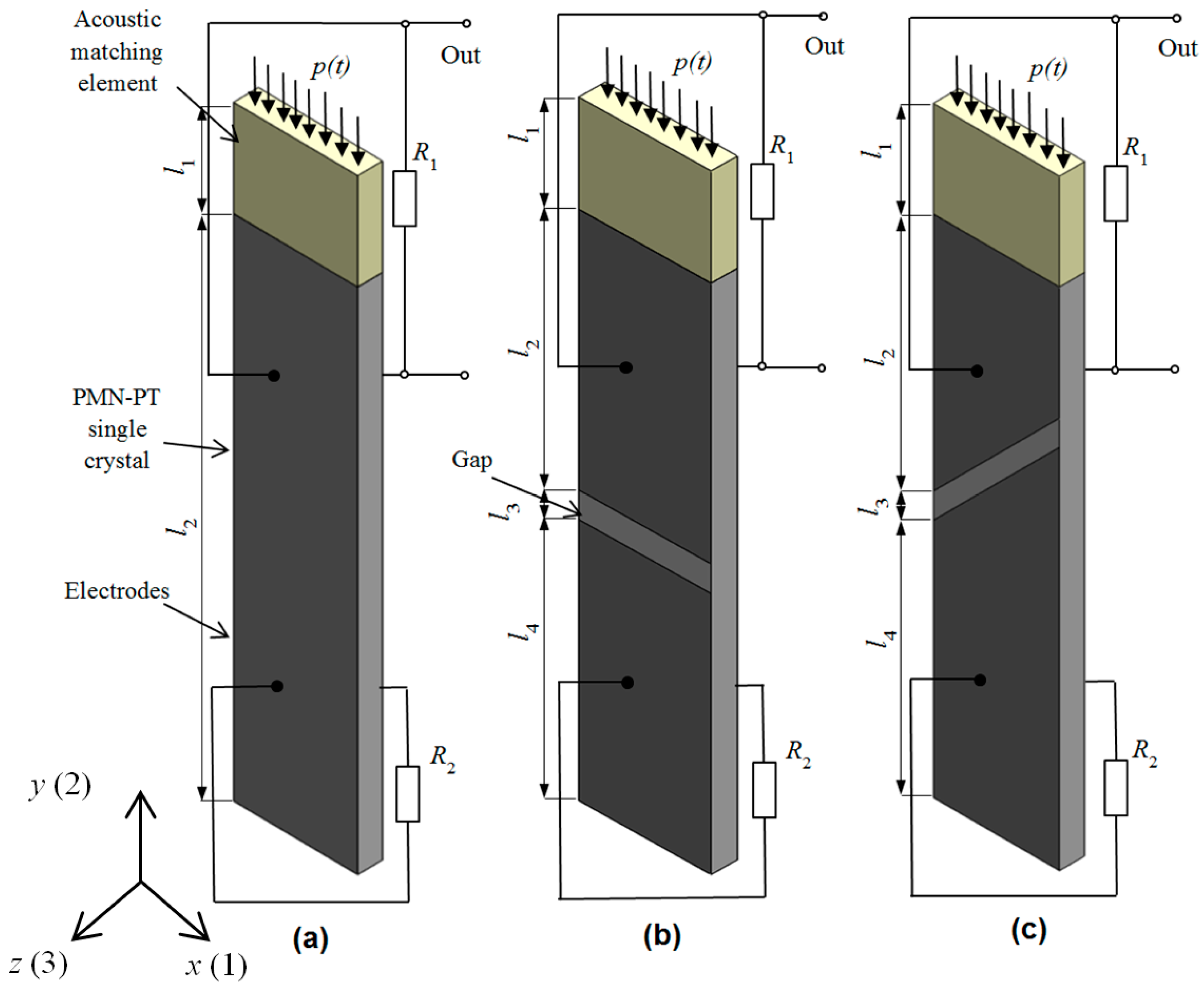

Figure 1a). Of course, the active area in this case is rather small, but a set of such strip-like receivers may be assembled into a multi-element array similar as in the case described by us in [

43]. The incident ultrasonic wave excites electric charges on lateral surfaces of the piezoelectric strip, which are coated by electrodes. For improvement of the sensitivity and the frequency bandwidth, the acoustic strip-like matching element attached to the tip of the piezoelectric element similar as in the case of transmitting transducer is used [

43]. Lateral dimensions of the matching strip are the same as of the piezoelectric element.

A further improvement of the frequency bandwidth of the transducer may be obtained dividing the lateral continuous electrodes into two pairs of electrodes (

Figure 1b,c). Then for the signal reception is exploited one pair (top) of electrodes, the second lower pair acts as electromechanically controlled backing element. The degree of damping may be controlled by changing resistance of the resistor

R2 connected to the bottom pair of electrodes. There may be various geometries of electrodes exploited, for example rectangular (

Figure 1b) or non-rectangular (

Figure 1c).

First, we have analyzed the case with two rectangular electrodes, e.g., when the gap between electrodes is oriented at 90° angle with respect to the longer edges of the piezoelectric element. The performance of the proposed receivers theoretically was investigated by a finite elements method (FEM). Operation of the transducer was simulated by ANSYS Mechanical APDL Product Launcher software. The piezoelectric strip was modelled by SOLID5 elements with a matching grid of 1 mm. There are 100 elements taking into account complete piezoelectric

eij, elastic

cij and dielectric

εij matrices of the PMN-32%PT crystal [

43,

44,

45]. The piezoelectric strip has four nodal degrees of freedom including three displacements in the

x,

y,

z directions and electric voltage

U. The modelling takes into account free boundary conditions coupling between internal electric and mechanic fields and electrical resistors

R1 and

R2 connected to the electrodes. Please note that in the finite element model the resistor

R1 includes not only separate resistor but also the input electric impedance of the external electric circuit, for example, a preamplifier connected to the top electrode.

It was assumed that the acoustic pressure of the incident wave in air is

p = 1 Pa. The part of the incident wave pressure

p is reflected by the active edge of the receiver and the total pressure acting on it is:

where:

pr is the acoustic pressure of reflected wave,

zin is the acoustic input impedance of the transducer,

zair is the acoustic impedance of air. In the case of air-coupled receiver

zin >>

zair and

pr ≈

p, e.g., the total pressure on the active surface of the receiver is

pt = 2

p. Therefore in finite element simulations it was assumed that the total pressure acting on the surface of the receiver is

pt = 2 Pa, what corresponds to the pressure

p = 1 Pa in the incident wave.

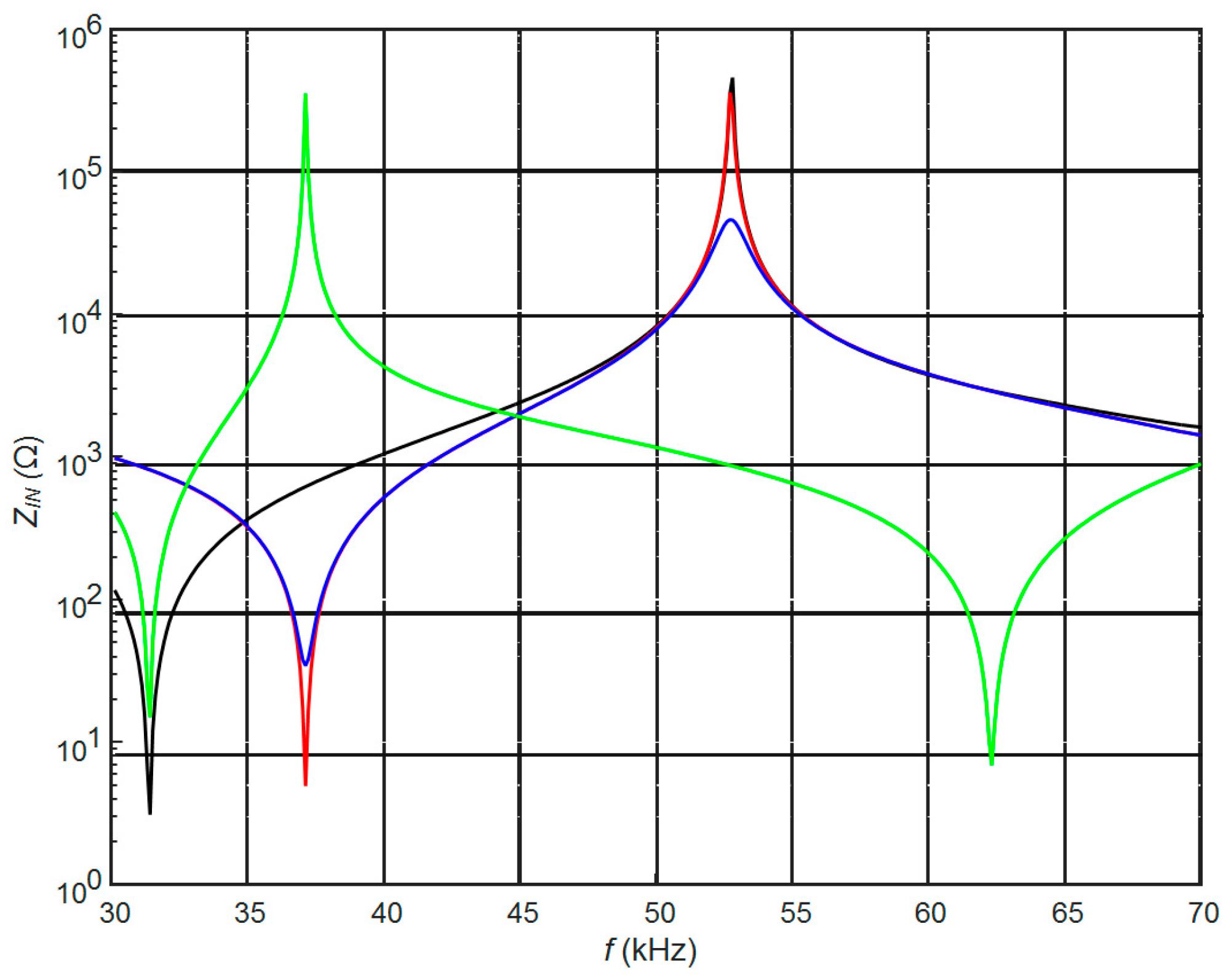

The calculated electric input impedances of the PMN-32%PT 20 × 5 × 1 mm

3 strip-like piezoelectric element with the continuous and split electrodes are shown in

Figure 2. The input electric impedance in the case of split electrodes was calculated on the top electrodes. From the results presented follows that in the case of the continuous electrode the resonance frequency

fr = 31.4 kHz is much lower (

Figure 2, black curve) than in the case of two rectangular electrodes of the same dimensions.

In the case of split electrodes, the resonance frequency depends on the electric load R2 connected to the bottom electrodes. The biggest changes are observed when the bottom electrodes are almost short-circuited (R2 = 1 Ω). Then the resonance frequency fr = 31.4 kHz coincides with the resonance frequency of the piezoelectric element covered by continuous electrodes. Correspondingly reduction of the resistance R2 from conditions close to the open circuit (R2 = 1 MΩ) down to the short-circuit conditions (R2 = 1 Ω) changes the antiresonance frequency from fa = 52.8 kHz down to fa = 31.4 kHz. It means that by selecting the resistor R1 it is possible to control resonance and antiresonance frequencies and the level of damping of the strip-like piezoelectric element.

The frequency response and consequently the pulse response of the ultrasonic receiver essentially depend on a material and dimensions of the acoustic matching strip. The acoustic impedance of the λ/4 length matching element material according to the ideal matching condition [

45] should be:

where

Zt =

ρtct = 13.52 MRayl is the specific acoustic impedance of the PMN-32%PT strip in the transverse-extension mode in direction 2 (

Figure 1),

ρt = 8100 kg/m

3—the density,

ct = 1669 m/s is the ultrasound velocity in the transverse-extension mode in direction 2 and

Zair = 0.445 kRayl is the specific acoustic impedance of air. From Equation (3) follows that the acoustic impedance of the matching strip material should be

Zs = 0.088 MRayl.

For the acoustic matching strip, we selected rigid polymer foams manufactured by Airex AG (Sins, Switzerland). The acoustic properties of some AIREX type materials are given in

Table 1. Ultrasound velocities in AIREX samples were measured by a through-transmission method [

46]. Ultrasound attenuation is rather small due to the short length—a quarter wavelength, therefore it has no influence on operation of the transducer and was not measured. The materials possessing the acoustic impedance

Zs closest to this value are AIREX C70.75 and T10.110. From the point of a view of mechanical processing better properties possesses AIREX T10.110, because its rigidity is more suitable for mechanical cutting of matching strips.

Frequency responses of the ultrasonic receivers with two rectangular pairs of electrodes with matching strips made of different AIREX type materials were calculated by FEM. Please note that both resistors

R1 and

R2 for all cases were the same

R1 =

R2 = 50 kΩ. The analyzed cases are presented in

Table 2. In this table, the obtained frequency bandwidths and sensitives are also presented.

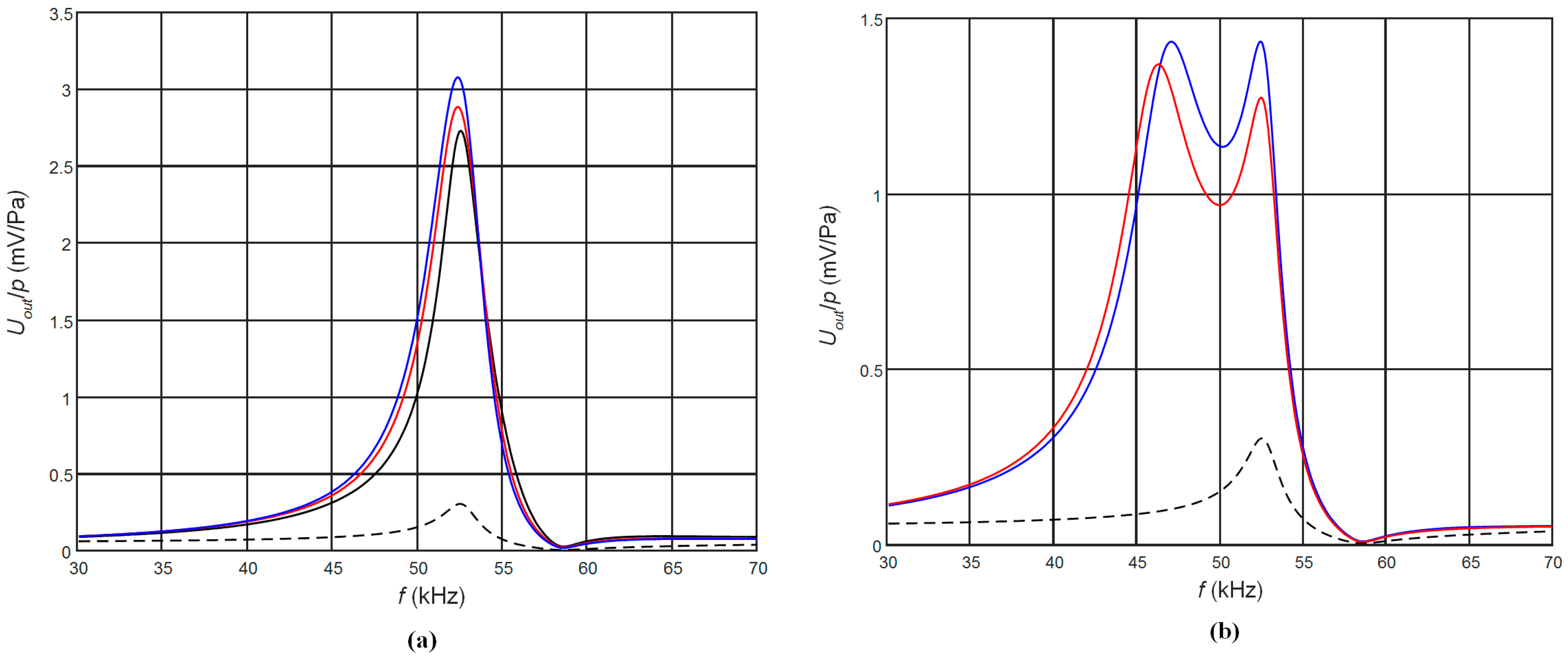

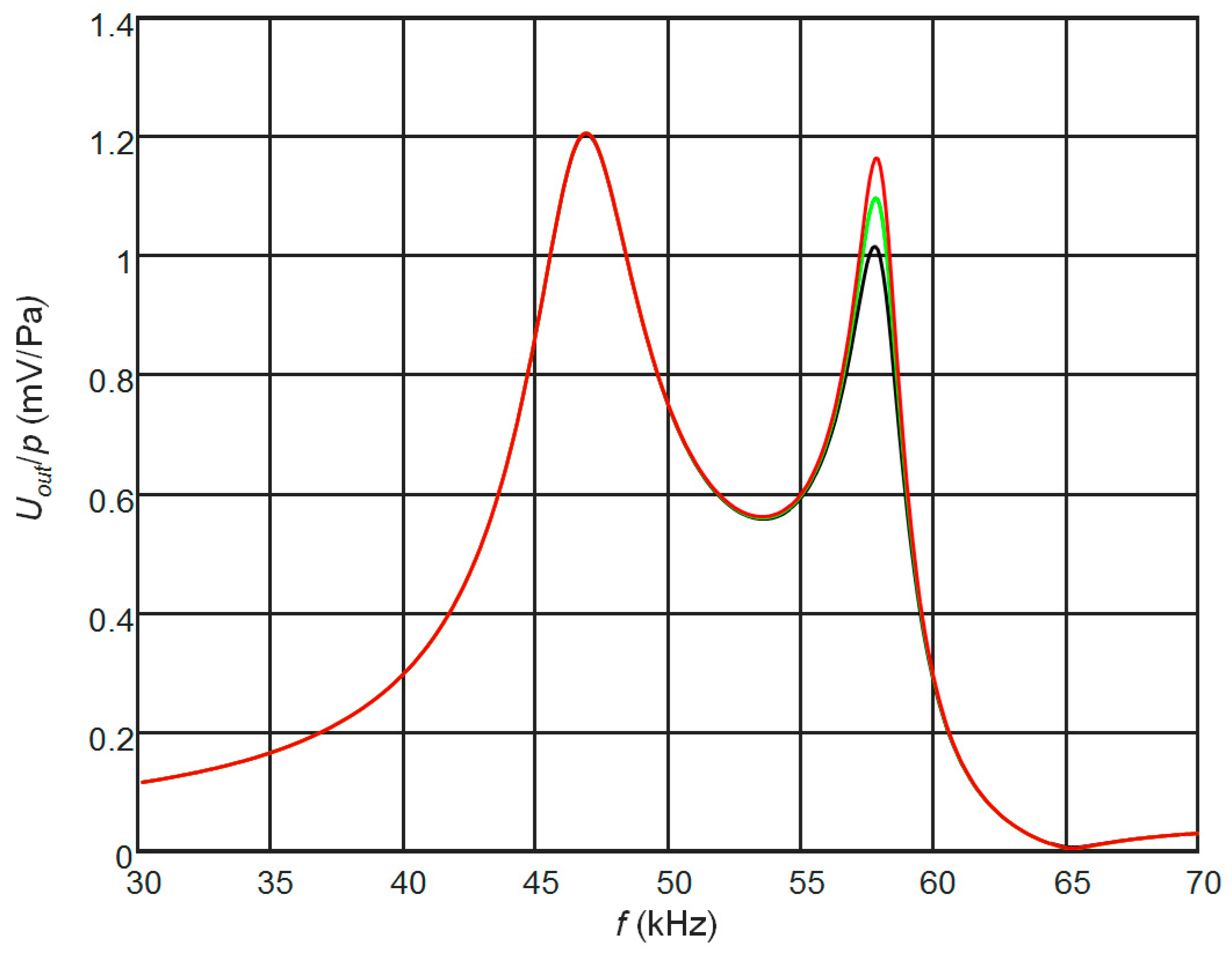

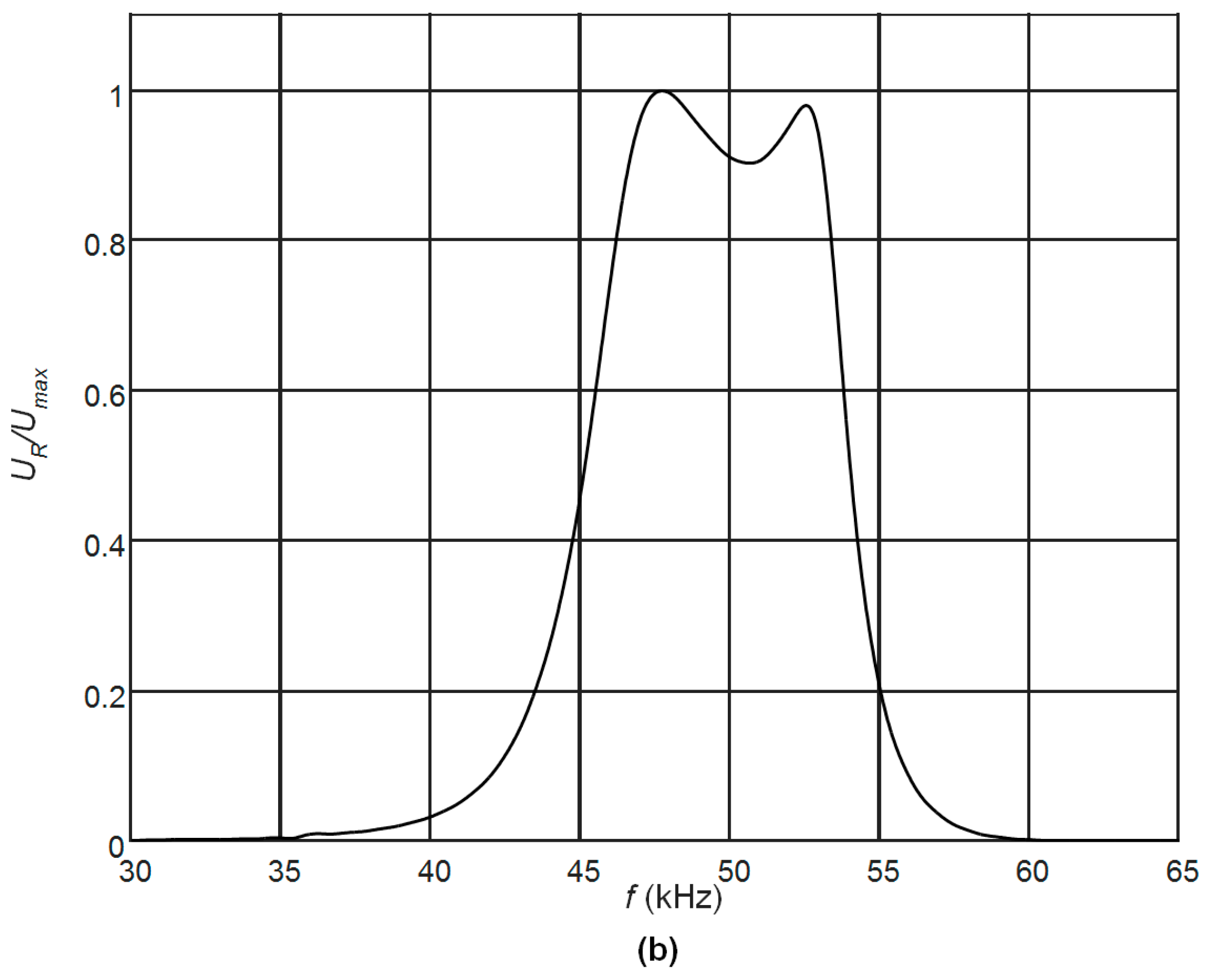

The corresponding frequency responses are shown in

Figure 3. The frequency responses presented in

Figure 3a are for the case of the matching strips the length of which is

l1 = λ/4 at the antiresonance frequency

fa = 53 kHz of the piezoelectric strip. Due to different ultrasound velocities in different AIREX foams, those lengths were different (

Table 2). The frequency responses were calculated as the electric potential at the output of the top rectangular electrode when the ultrasonic wave incident on the top edge of the receiver is 1 Pa. For comparison, the black dashed line shows the frequency response of the piezoelectric receiver without a matching strip. Please note that in this case the maximum sensitivity is obtained at the antiresonance frequency

fa = 53 kHz. From the results obtained follows that significant improvement up to ten times of the sensitivity is achieved, but the frequency bandwidth is narrow and not suitable for operation in a pulse mode (

Table 2). In order to increase the bandwidth we have investigated the cases when the length of the matching strip λ/4 was adjusted to the frequencies other than antiresonance frequency of the piezoelectric strip. The performed modelling showed that in this case in the frequency response another peak appears at the frequency

fl =

c/4

l1 (

Figure 3b). Selecting the proper length of the matching strip

l1 it is possible to control the frequency of this peak and to get a wider bandwidth. The frequency responses when the length of the matching strip

l1 = λ/4 was adjusted to the frequency

fl = 46 kHz are shown in

Figure 3b. It is possible to observe significant widening of the bandwidth, which reaches 8 kHz or 16% of the central frequency 50 kHz, but there is still a noticeable non-uniformity of the frequency responses. The ways, in which it is possible to improve the frequency response, we shall explain in the next paragraphs.

In addition, from the point of a view of the sensitivity all listed AIREX materials show a similar performance. Therefore taking into account suitability for a mechanical processing for a further analysis we have selected AIREX T10.110.

As it was pointed out above, the propagation direction of an ultrasonic wave inside the piezoelectric element is orthogonal to the direction of the electric field generated due a piezoelectric effect the internal electric field. It means that acoustic field depends on electric boundary conditions that allow manipulating geometry of the electrodes covering the side surfaces of the piezoelectric element to control frequency and pulse responses of the transducer.

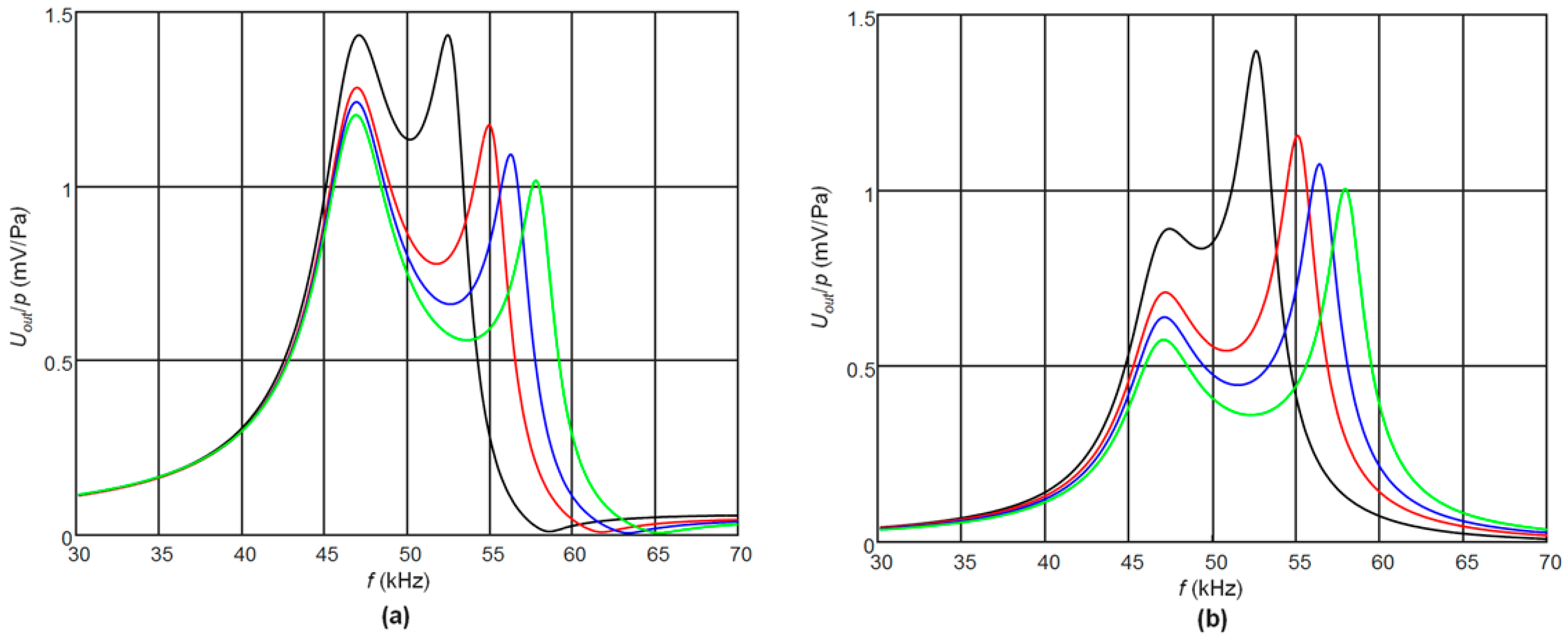

First, we have investigated how the frequency response depends on the width of the gap between two rectangular electrodes. The calculated frequency responses of the PMN-32%PT receivers with gaps of different width between the two pairs of electrodes are presented in

Figure 4a,b. In

Figure 4a are shown frequency responses on the top pair of electrodes (closest to the matching strip), in

Figure 4b—on the bottom electrodes. It is possible to see that the frequency responses observed on two pairs of electrodes have a similar character except that the second peak in the frequency responses is changing in opposite manner—on the top pair of electrodes it is reducing with the increasing gap, but on the bottom pair of electrodes it is increasing. From the results obtained follows that with increasing the gap the potential frequency bandwidth also increases, however non-uniformity of the responses is increasing significantly.

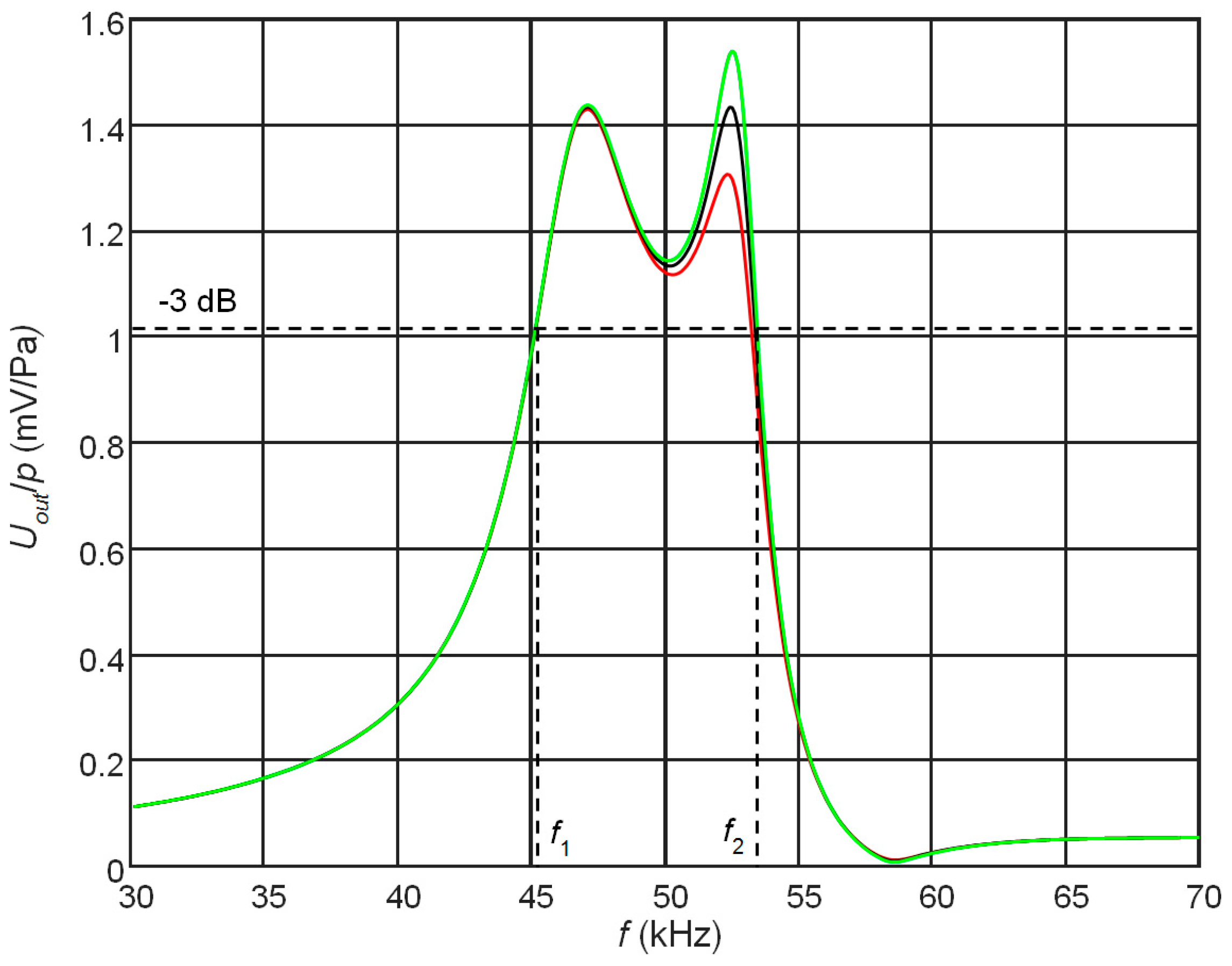

From simulations performed by FEM follows that a frequency response of the receiver also depends on the electrical resistors

R1 and

R2 connected to the top and bottom electrodes. It is due to the dissipation of the electrical energy of the converted acoustic signal by the resistors

R1 and

R2. The resistor

R2 connected to the bottom electrodes creates an additional damping of the piezoelectric strip, which may be called an electromechanical damping. It means that changing the level of the electromechanical damping by means of the resistor

R2 we can expect to flatten the frequency response what would be beneficial for operation of the receiver in a transient mode. The frequency responses of the receiver with different resistors

R2 connected to the bottom electrode are shown in

Figure 5. The resistor

R1 which takes into account the input impedance of the preamplifier in all cases was the same

R1 = 50 kΩ. We can see that the amplitude of the second peak in the frequency response at 57 kHz really depends on the resistor

R2, however it is still impossible to flatten sufficiently those responses only by selection of the electric load.

Therefore, the best solution is to keep the gap narrow, for example 1 mm, and to modify the frequency response by selecting the electric resistances of the resistors

R1 and

R2 connected to the both electrodes. The simulated frequency responses in this case are presented in

Figure 6.

The shown frequency responses were obtained at different values of the resistor

R2 connected to the bottom electrodes (

Figure 1). Please note that higher values of the resistor

R2 give lower damping and the second peak amplitude increases. From the results presented follows that controlling level of the electromechanical damping allows to achieve a quite wide frequency bandwidth ∆

f = 8 kHz. The further improvement of the frequency response and the bandwidth is possible by changing geometry of the electrodes. This is discussed in the next paragraph.

3. Piezoelectric Receiver with Two Pairs of Non-Rectangular Electrodes

The PMN-32%PT receiver with two non-rectangular electrodes and with the λ/4 matching strip is shown in

Figure 1c. The gap between electrodes may be oriented at different angles. We have performed FEM simulations in the range of angles from 35° to 65° and have found that in all directions of the gap additional modes in the plane of the piezoelectric strip are excited, which cause strong artefacts in the frequency response. The highest sensitivity and widest bandwidth is obtained at the 45°. Therefore, we have analyzed the case with the gap oriented at 45°. The electric input impedance, sensitivity and frequency responses of the receiver depend on dimensions of both the top and bottom pairs of electrodes. For estimation of this influence, we have analyzed three cases B

1, B

2 and B

3 (

Table 3,

Figure 1b).

The width of the gap

l3 between electrodes along

y axis in all cases was the same

l3 = 1 mm (

Figure 1). The calculated electric input impedance of the PMN-32%PT piezoelement without the matching strip is presented in

Figure 7. Comparison of this impedance with the electric impedance of the transducer with continuous and two pairs of rectangular electrodes (

Figure 2) clearly shows significant differences. The dimensions of the electrodes influence antiresonance frequencies, which for presented cases are the following: case B

1—

fa1 = 54.2 kHz; case B

2—

fa2 = 53.2 kHz; case B

3—

fa3 = 52.7 kHz.

The frequency responses for those cases when the length of the matching strip λ/4 was adjusted to the different antiresonance frequencies

fa1,

fa2 and

fa3 are presented in

Figure 8. Those results are quite similar to the modelling results in the case of two rectangular electrodes of equal area (

Figure 3a) except that an additional peak in the frequency responses close to the frequency of 35.5 kHz is observed. By means of the finite element modelling, we have determined that this peak is due to the additional vibration mode excited in the plane of the piezoelectric strip by a sharper corner of the non-rectangular electrodes. The biggest displacements are in the

x direction. Amplitude of this mode is reducing with the increasing angle of the electrodes cusp. In the case of the 45° gap the amplitude of this artefact depends on dimensions of the top and bottom electrodes and it completely disappears when the areas of the electrodes are equal, e.g., case B

3. In this case the highest sensitivity is obtained, but the observed bandwidth is rather narrow −1.9 kHz and is not suitable for operation in a pulse mode.

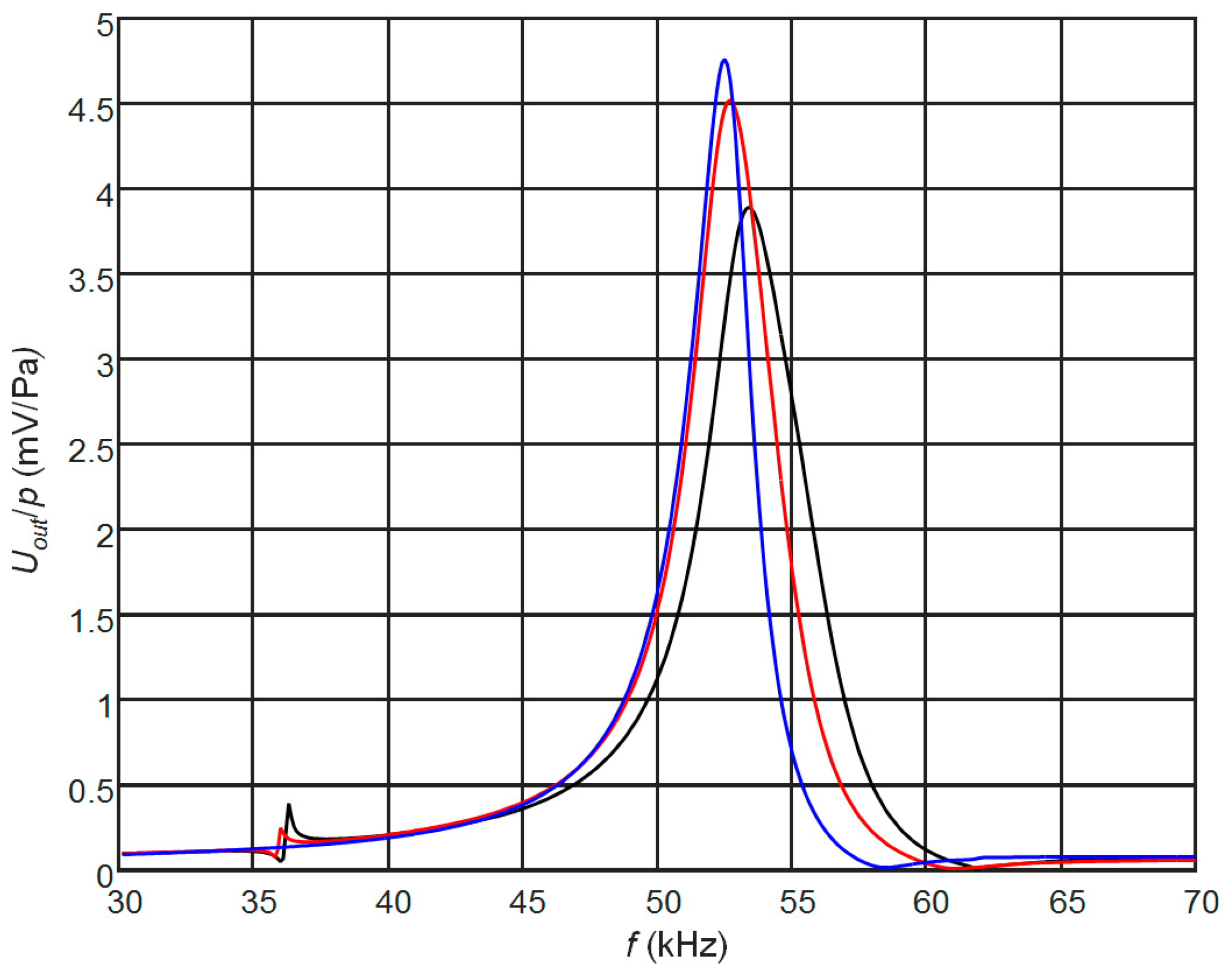

The frequency bandwidth may be improved adjusting the length of the matching strip λ/4 to the frequencies lower than the antiresonance frequency

fa. In those cases, the length of matching strips is different (

Figure 9) and the potential bandwidth may be significantly wider, however they are non-uniform.

Uniformity of the frequency responses can be improved selecting the proper length of the matching strip

l1 and adjusting electromechanical damping by means of the resistor

R2. In this case, a trade-off between the sensitivity and bandwidth of the receiver can be obtained (

Figure 10). The results presented in

Figure 10 show that in this case a quite wide bandwidth ∆

f = 9.2 kHz or 18.4% with respect to the central frequency 50 kHz is obtained. For air-coupled ultrasonic transducer it is good result.

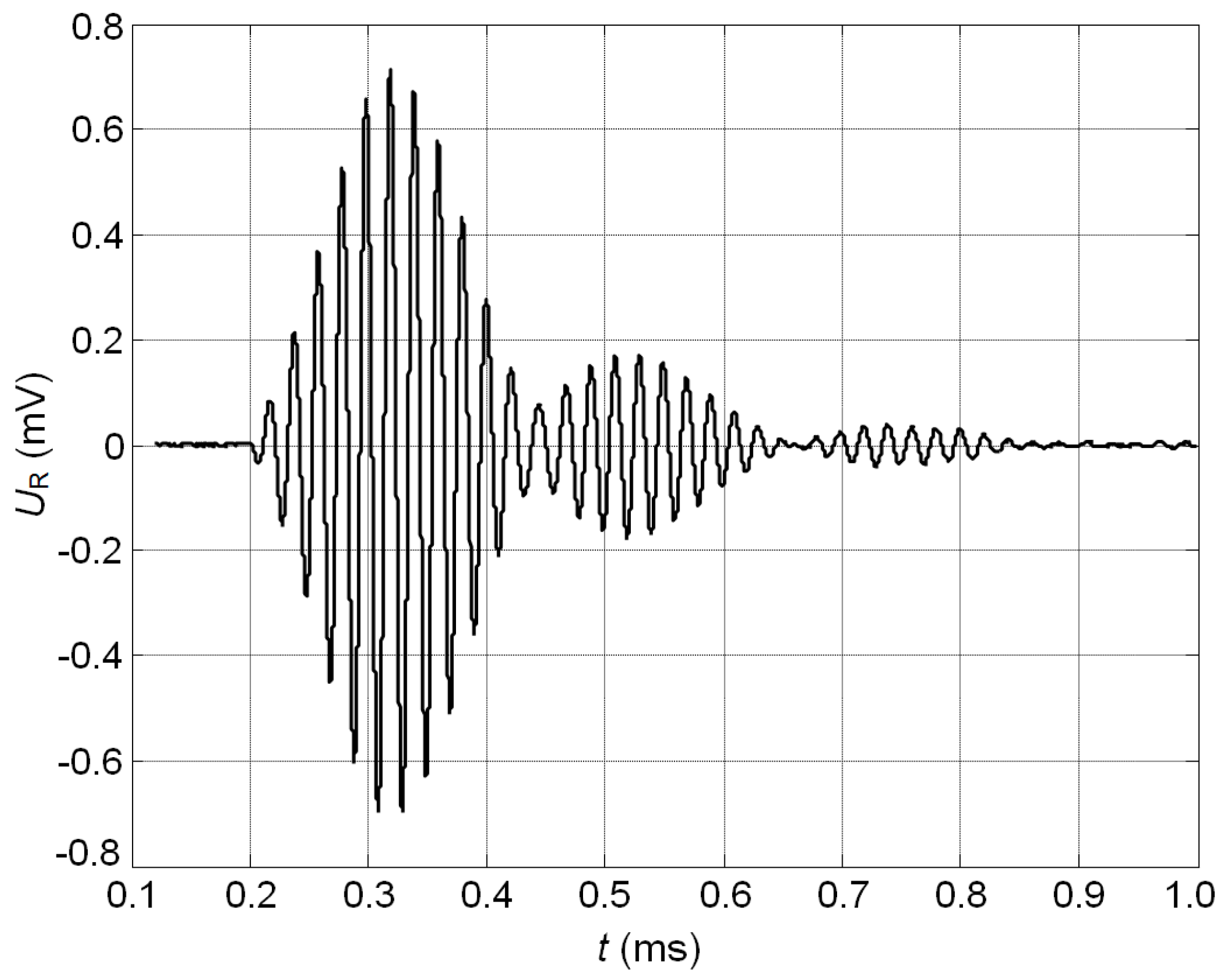

The pulse response of the receiver with the optimal matching strip

l = 5.75 mm and two non-rectangular pairs of electrodes to the excitation by the 5 periods of 50 kHz ultrasonic pulse with the amplitude of 1 Pa is presented in

Figure 11a. The spectrum of the received signal is shown in

Figure 11b. Please note, that the width of this spectrum due to a band limited spectrum of the excitation pulse is ∆

f = 7.5 kHz. The presented results demonstrate a good performance of the developed air-coupled receiver in a pulse mode also.

4. Experimental Investigation

The experimental investigation of the proposed air- coupled ultrasonic receiver (

Figure 1c) was performed using PMN-32%PT crystals plates with <011> cut and [001] poling direction from the H.C. Materials Corporation (HCMC, Bolingbrook, IL, USA). The strips-like piezoelectric elements of necessary dimensions 20 × 5 × 1 mm

3 were cut of the 20 × 20 × 1 mm

3 poled PMN-32%PT crystal and were coated by gold electrodes. The necessary non-rectangular shapes of electrodes were obtained by the “aqua regia”, e.g., nitrohydrochloric acid etching technique [

47] of the 45° gaps whole electrodes. The piezoelectric PMN-32%PT receiver element prepared for experimental investigation is shown in

Figure 12.

The two pairs of electrodes were connected to electrical circuits by electrical semi-rigid wires connected to the electrodes using the 3022 type e-solder from Von Roll Isola (Shenectady, NY, USA, (

Figure 12). Those wires also serve as a support of the piezoelectric elements in the experimental transducer set. The matching λ/4 strip made of AIREX T10.110 was glued to the PMN-32%PT element using cyanoacrylate type glue (FixPoint, Braunschweig, Germany). During investigation, the piezoelectric strip and wiring with electrical connectors were placed into a housing, which shields them from electromagnetic and acoustical fields. Only the front edge of the matching layer contacted with air environment.

The purpose of the experiments was to check how mathematical modelling is close to the experimental results and to estimate performance of the receiver. The experiments were performed with the set-up presented in

Figure 13.

As a source of ultrasonic waves the high frequency tweeter of the multimedia speaker B77 from the Microlab (Shenzhen, China) was used. The HP 33120A type function/arbitrary waveform generator (HP 33120A, Hewlett-Packard, Palo Alto, CA, USA) excites this loudspeaker by the voltage burst of a selected frequency and shape and generates an acoustic pressure burst p(t). In order to eliminate the influence of the frequency response of the loudspeaker B77 on measurement results reception of the radiated ultrasonic wave is performed by two measurement channels. One channel used as a reference channel consists of the B&K4138 type microphone and B&K NEXUS WH 3219 type amplifier (Brüel & Kjær, Naerum, Denmark) and enables to perform absolute measurements of the acoustic pressure in the frequency band up to 140 kHz. The investigated PMN-32%PT receiver is connected to the second channel. The signals from both channels were stored, processed and analysed by the ultrasonic measurement system ULTRALAB (Ultrasound Institute, Kaunas University of Technology, Kaunas, Lithuania).

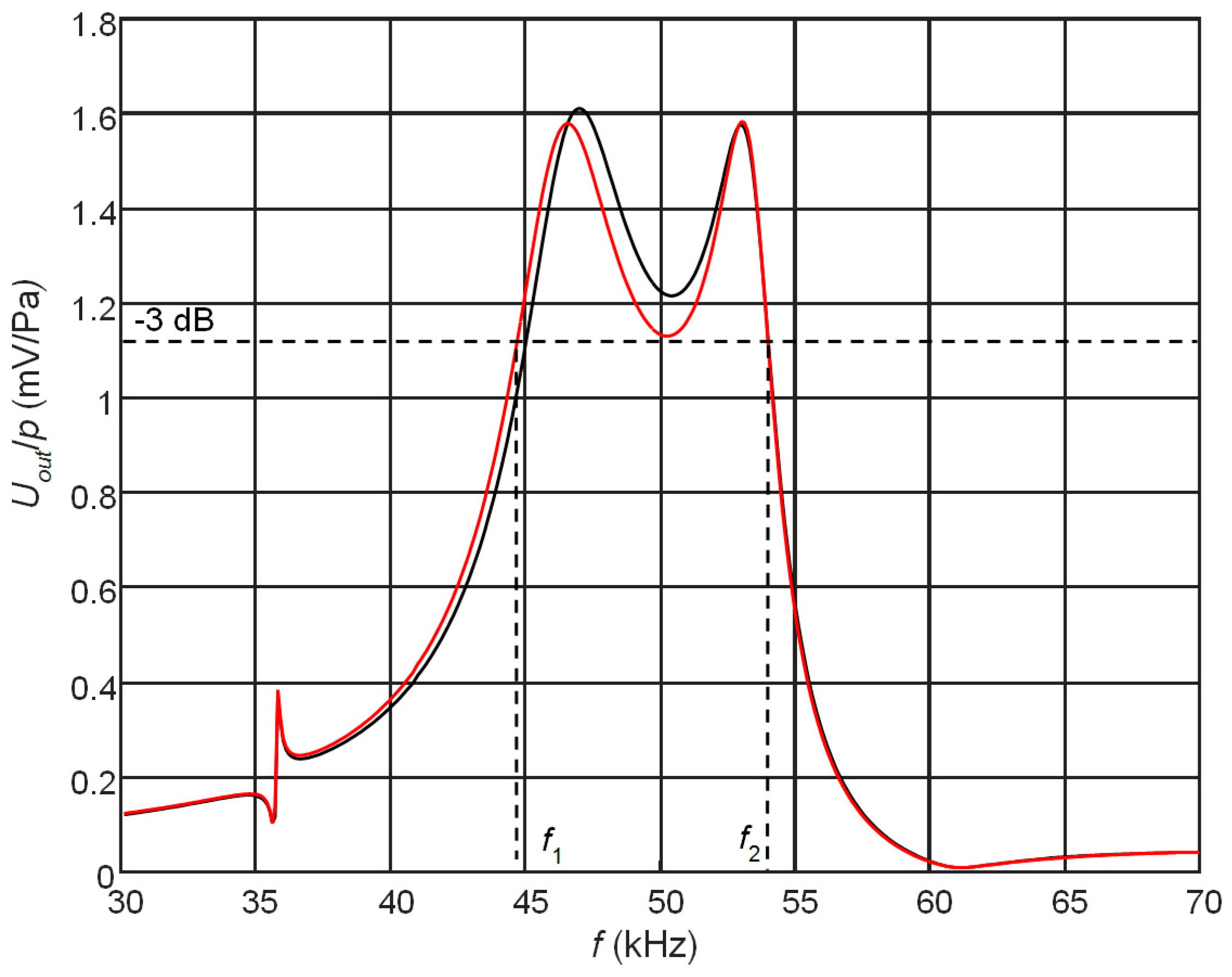

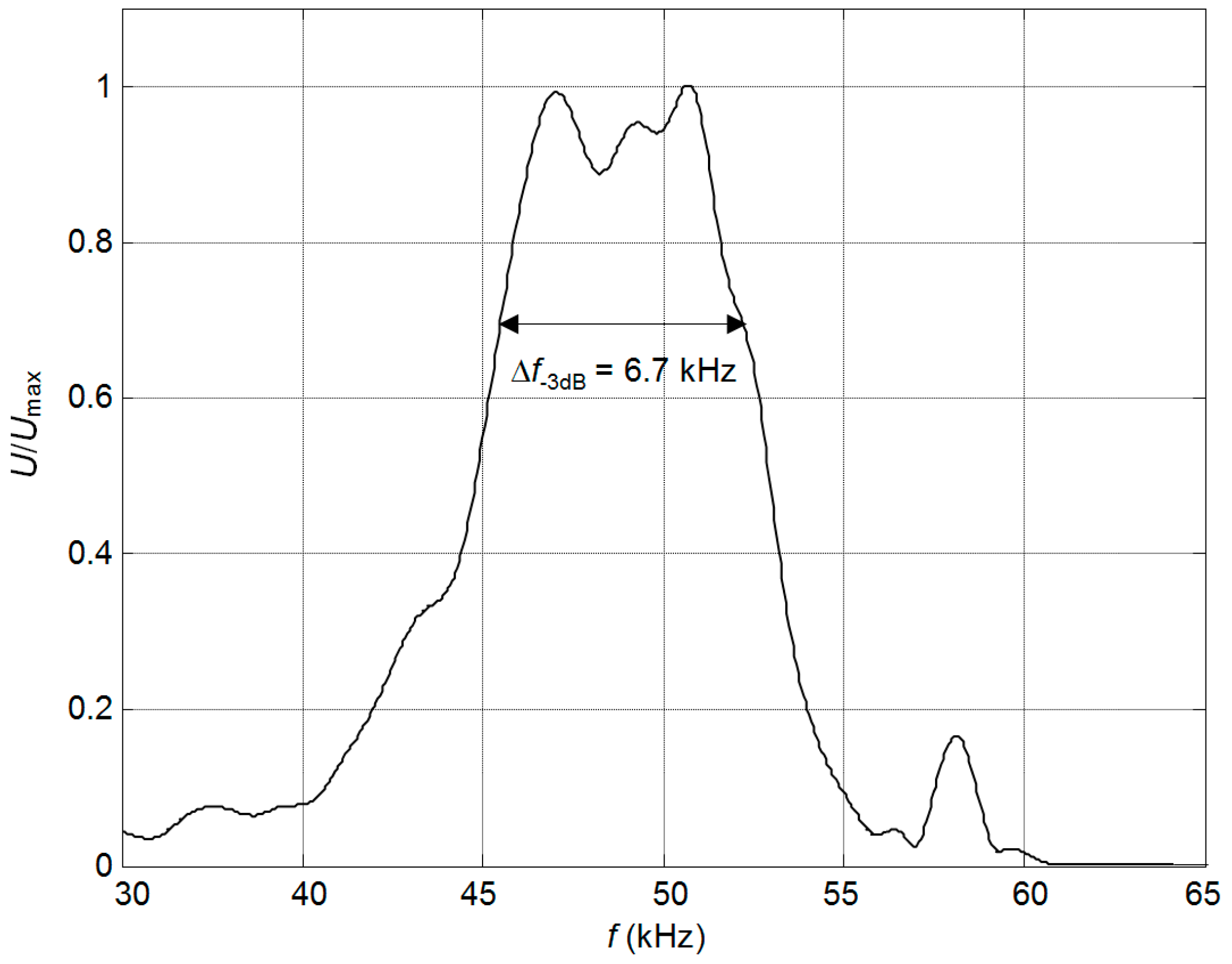

The measured frequency response of the PMN-32%PT strip-like receiver with a matching strip made of AIREX T10.110 with the length

l = 5.9 mm and two non-rectangular electrodes (

Figure 1c) is presented in

Figure 14. The measured bandwidth of the receiver at −3 dB level is ∆

f = 6.7 kHz or (∆

f/

f0) 100% = 14% with respect to the central frequency

f0 = 49 kHz. It is narrower than the obtained in the simulation bandwidth ∆

f = 7.5 kHz (

Figure 11b), because influence of the glue between the piezoelectric element and the matching strip in the simulation was not taken into account. The obtained relative frequency bandwidth is wider than of the ultrasonic transducers used in air-coupled NDT [

20]. For example, the frequency bandwidth of the air-coupled transducers AirTech50 with the central frequency 50 kHz and used for NDT of aerospace structures is only ∆

f = 5 kHz or 10% of the central frequency [

20].

The ultrasonic pulse with a rectangular envelope radiated by the loudspeaker B77 duration of which was five periods of 51 kHz was picked up by the developed PMN-32%PT receiver.

Figure 15 shows the waveform of the electric signal at the output of the receiver. The obtained results demonstrate a good performance of the air-coupled ultrasonic receiver both in harmonic and transient modes.

Comparison of the simulation and experiment’s results of the PMN-32%PT transducer with the matching strip made of the AIREX T10.110 are presented in

Table 4.

Presented comparison of the experimental results with the modelling results indicates a rather good correspondence (

Figure 11a and

Figure 15).