1. Introduction

Precision motion stage is the kernel part of an ultra-precision system which has been playing a critical role in Integrated Circuit (IC) manufacturing, optical components production, Liquid Crystal Display (LCD) fabrication, IC encapsulation,

etc. Increased demand is putting stricter requirements on the precision stage, especially on the accuracy of its multiple degree-of-freedoms (DOFs) movement. To achieve high precision positioning of the stage, a sufficiently accurate measurement system is indispensable, for the measurement error in the feedback channel of the control loop will directly affect the system performance and cannot be suppressed by the controller in the forward channel [

1]. Since the 6-DOF displacements of a stage cannot be measured by a single sensor, a measurement system composed of multiple sensors is necessary. Mura measured a 6-DOF Stewart platform stage by constructing a sensor array, composed of wire extensometers or MEMS displacement sensors [

2,

3]. By solving the kinematic equations, the 6-DOF moving information could be estimated. Similarly, Allred used a simplified Stewart platform stage to measure the helicopter blade [

4]. Kim made use of some cooperative targets to design a measurement coordinate system, and the system parameters were determined by optimization. Then, the 6-DOF displacements could be calculated by coordinate transform [

5]. However, these methods are not effective for a non-cooperative and floating stage. As noncontact sensors [

6,

7], Hall sensors are widely used in various industrial applications, including position, velocity and magnetic fields measurement [

8,

9,

10,

11,

12,

13]. Also, it is shown to be insensitive to harsh environments. For measurement of a multi-DOF stage using Hall sensor, Zhao obtained an elliptic fitting function of the magnetic field for compensation, in the case that the height between the hall probe and permanent magnet is fixed [

14]. To estimate the maglev stage in planar DOFs, Kawato adopted two-axis Hall-effect sensors, constructed a model of magnetic field distribution according to the Halbach magnet matrix, and developed a Gaussian least-squares differential-correction (GLSDC) algorithm [

15,

16]. Sun established the model of the magnetic field and displacement using finite element analysis, and presented a 3-DOF measurement algorithm based on symmetry and linearization [

17].

Note that the study in reference [

14,

15,

16,

17] is based on the assumption that the distance between the Hall probe and the permanent magnetic is fixed which, however, could not be guaranteed in practice. The slope of the Hall sensor output would vary due to the change of magnetic flux. According to [

14], a variation of 1 mm in distance will cause a considerable change in the output slope, and a large error will be introduced to the Hall measurement system if only the designed parameters are employed and the influence of the relative distance variation is not calibrated.

In practice, the measurements of the precision stage by the array of Hall sensors are coupled, and should be decoupled before being utilized. However, the decoupling is subject to errors in its decoupling matrix caused by the uncertainty of mechanical parameters of the precision stage, since these parameters inevitably deviate from their designed values due to machining and assembling errors. These errors will degrade the positioning accuracy of the nano-or-micro-precision stage.

Since such mechanical parameters are hard to directly measure due to limitation of space and measurement principle, a “soft sensor” method is proposed. The so-called soft sensor technology makes use of the mathematical relationship between parameters that are directly measurable and those that are not, obtaining the concerned parameters by numerical calculation based on optimal approximating theory [

18]. After nearly 40 years of development, the soft measurement technology has been widely employed by process control systems in the chemical industry, metallurgy, biology,

etc. Up to now, modeling methods for soft sensors fall into two major categories: the mechanism based and the data driven. Using the mechanism based approach, Prasad [

19] obtained the model of a styrene polymerization process, and then estimated the average molecular weight of the polymer performance indexes using an extended Kalman filter. By the data driven method, Zamprogna performed principal component analysis for a batch distillation process using the regression process model and the temperature measurement [

20]; Gonzaga measured the viscosity of polymer using a feed-forward artificial neural network model [

21]; Liu solved the melt viscosity measurement problem in a polymer extrusion process using a nonlinear observer-based finite impulse response model, with the temperature and screw speed as its input [

22]. In mechatronic systems, the concept of soft sensors has been rarely mentioned. However, some parameter estimation methods based on the prior model structures, such as Luenberger observer, Kalman filter, and adaptive observer, have also been well developed and applied in practice. Elmas adopted a full-order Luenberger observer to estimate the rotator position of a switched reluctance machine, with satisfactory effect [

23]. Szabat estimated the internal states of a string-linked double mass system using a fuzzy Luenberger observer, to control the driven system [

24]. Sim designed a novel Kalman filter to estimate the parameters of PMSM online [

25]. Rajamani applied an adaptive observer in a vehicle suspension system [

26]. Lim proposed an online frequency parameter estimation method based on statistics, to measure the rigidity and damping coefficients in the electromagnet suspension system [

27].

The measurement model of the Hall sensor array, which is a mechatronic system, could be established based on mechanism analysis, which contains mechanical assembly errors and some unknown coefficients. As the relationship between these immeasurable parameters and the measurable ones is of high dimension, high order and nonlinear, the aforementioned state space-based methods are no longer suitable to this problem.

Meta-heuristic methods, inspired by natural activities, provide another approach to parameter estimation. As long as the fitness function is determined, they could be easily applied in practice without additional constraints. Owing to their simplicity, various kinds of meta-heuristic algorithms have been proposed and effectively applied in many fields, such as mechanical design and trajectory planning of robotics. The most popular meta-heuristic methods include Genetic Algorithm (GA) [

28], Differential Evolution (DE) [

29], Particle swarm optimization (PSO) [

30], and Teaching-Learning-Based Optimization (TLBO) [

31]. TLBO is newly proposed and is used for optimizing constrained mechanical design problems. Compared with other heuristic methods, the biggest advantage of TLBO is that fewer parameters are to be adjusted, with only the population size and maximum iterations to be determined [

32,

33,

34]. However, the TLBO is prone to prematurity for some practical problems [

35]. To address this issue, Ghasemi combined the traditional TLBO with the Gaussian-Based TLBO (GBTLBO), balancing the convergence rate and the solution quality [

36]. In this paper, the GBTLBO is further improved using an adaptive updating strategy for the parameter

p, the mutation probability. Applying this novel self-adaptive hybrid TLBO to the parameter estimation for the Hall measurement system, the measurement accuracy could be improved.

The rest of this paper is organized as follows:

Section 2 describes the configuration of the investigated precision stage.

Section 3 establishes the measurement and the calibration model of the Hall sensor array, which contains a mechanical assembly error.

Section 4 proposes a self-adaptive hybrid TLBO method for estimating parameters in the aforementioned model. Then,

Section 5 conducts experiments and analyzes the experimental results in different situations.

Section 6 concludes the paper.

2. System Configuration

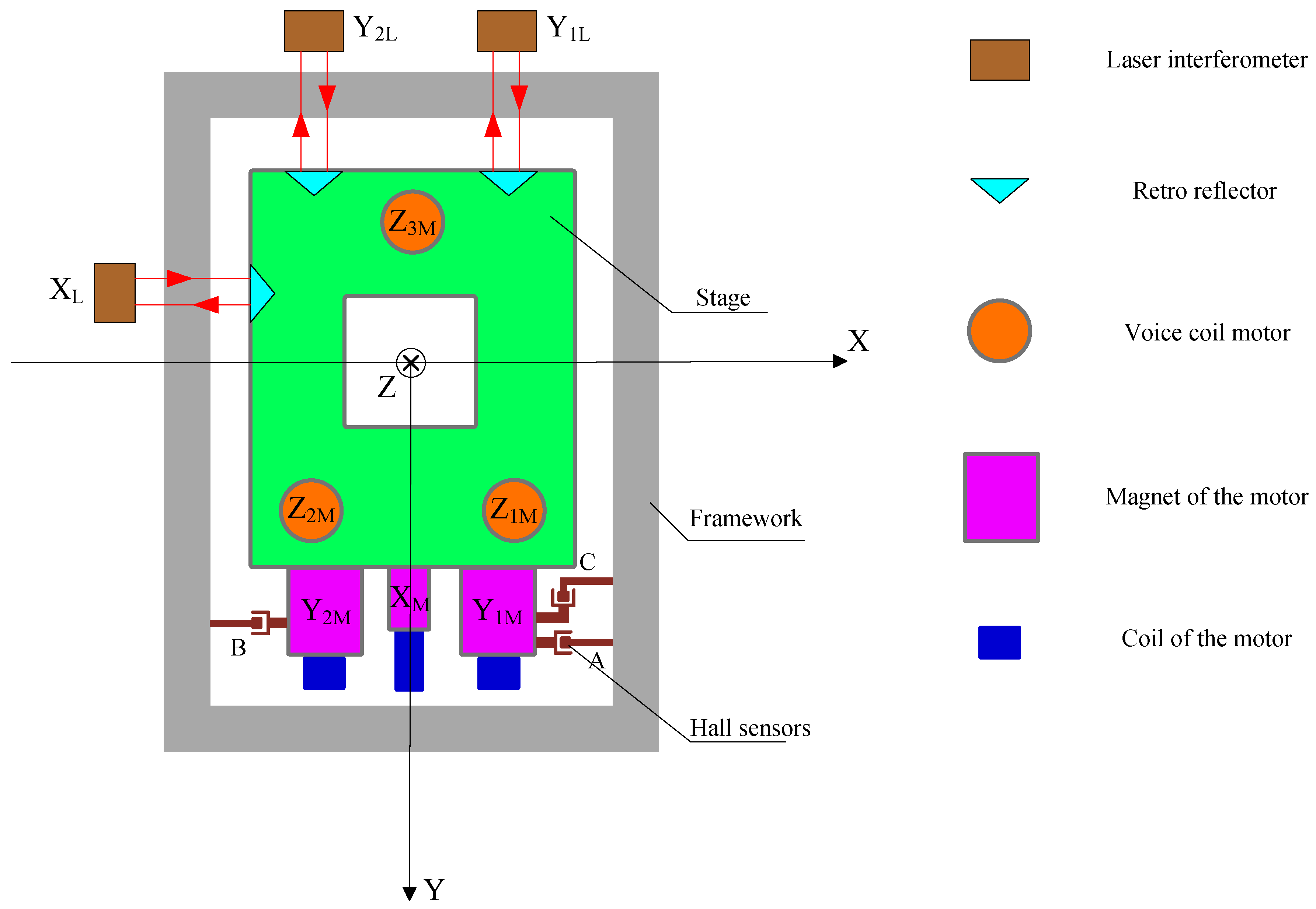

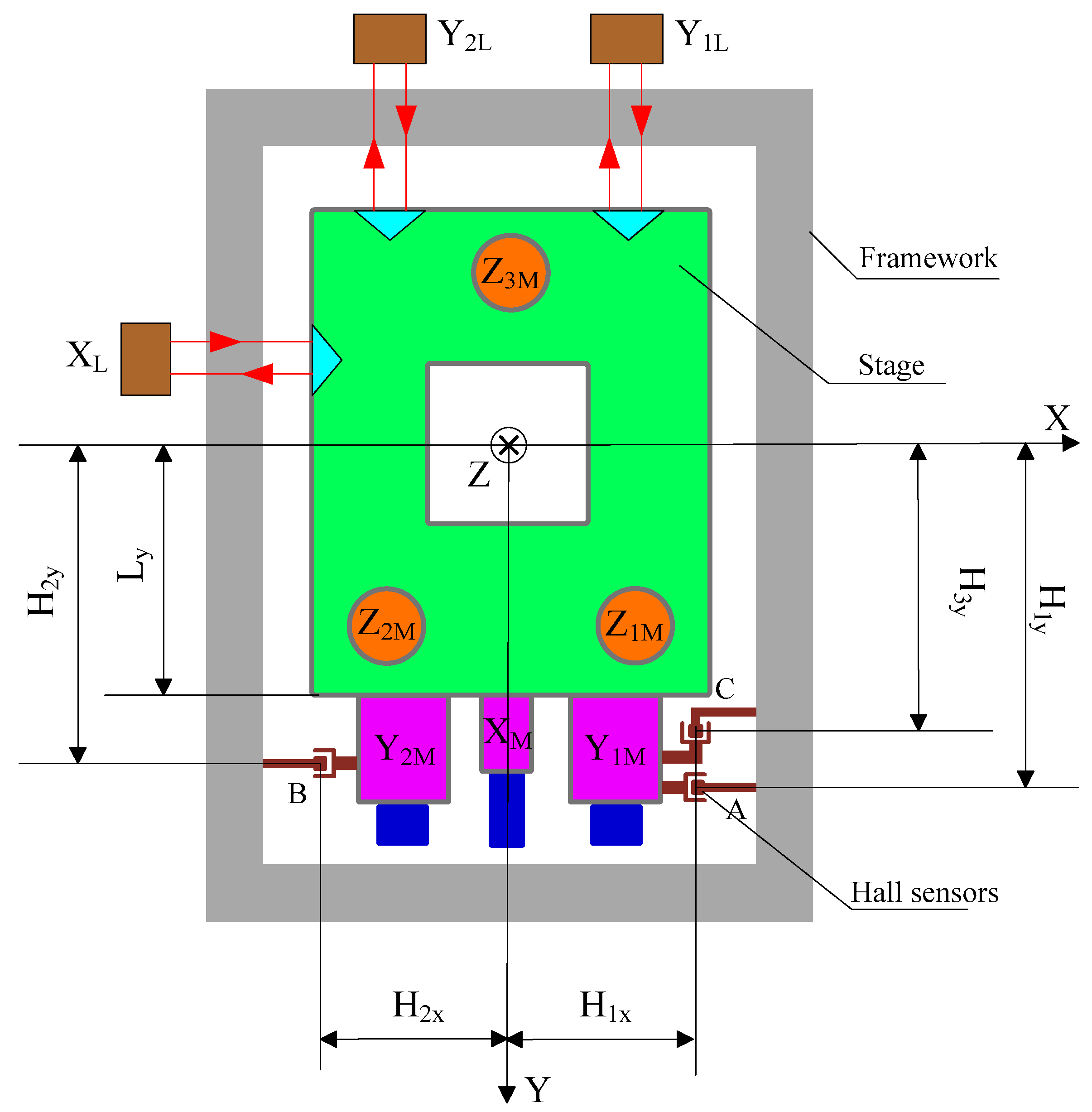

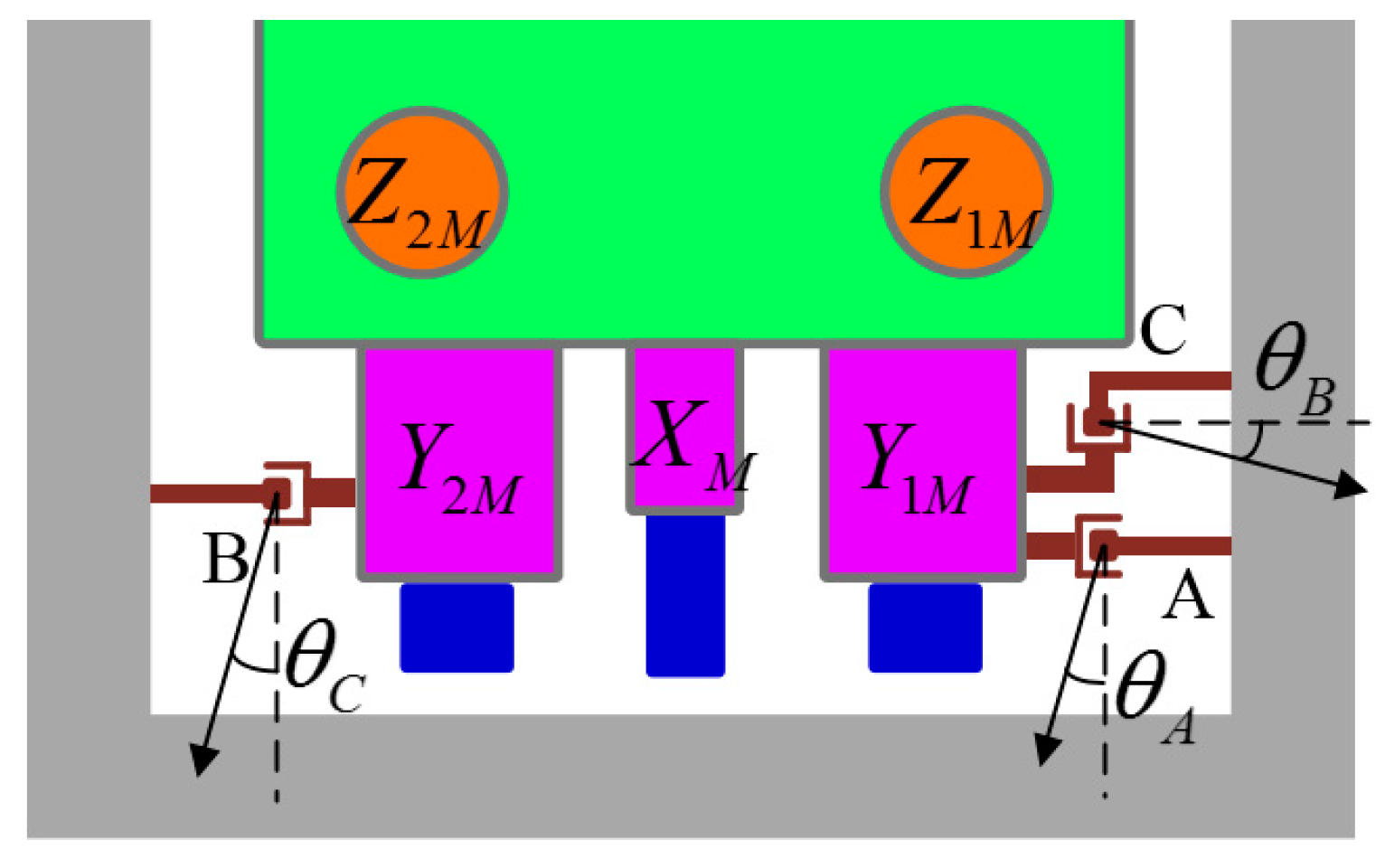

The structure of the 6-DOF precision stage investigated in this paper is shown in

Figure 1, whose coordinate system follows the right-hand rule.

The stage is driven by six voice coil motors. Three of them, , , , are in the vertical direction, constituting an isosceles triangle. Driven by these motors, the stage could realize translation in Z axis and rotation around X, Y axis. The driving centers of and are located in the first and second quadrants of the coordinate system respectively, symmetric to the Y axis. The driving center of is on the negative Y axis. The forces of these motors are parallel to the Z axis and have the same positive direction. In the horizontal plane, two symmetrically distributed voice coil motors, and , provide driving force in Y direction. While motor , located in the middle between the two Y-direction motors, provides the driving force in X direction. The driving point of motor is located on the positive Y axis, taking positive X direction as driving direction. The driving points of and are located in the first and second quadrants, symmetric to the Y axis, taking the positive direction of Y axis as driving direction. Since the driving points of these horizontal linear motors do not coincide, the stage can achieve horizontal rotation and translation.

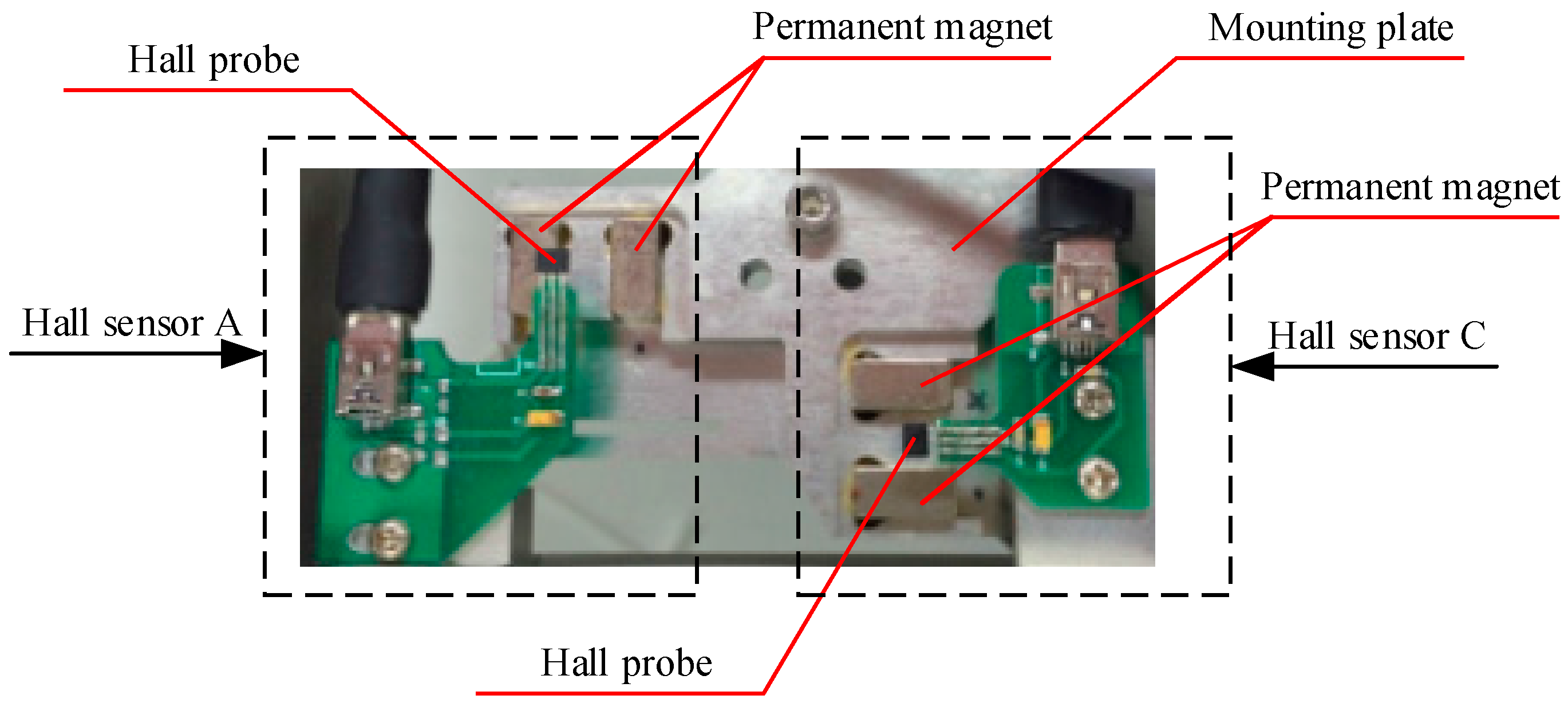

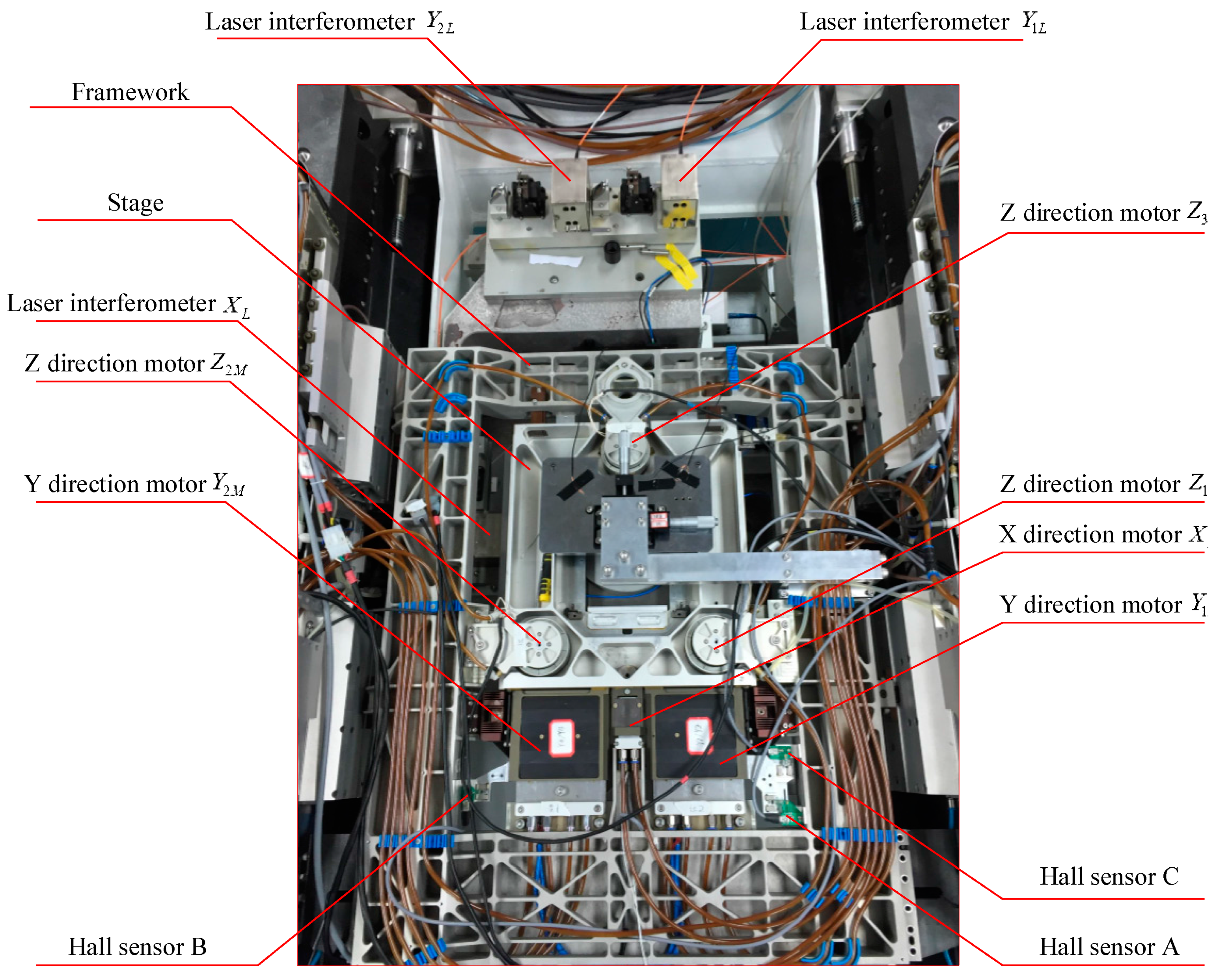

The motion of the stage is measured by the hall sensor array and the capacitance sensor. Three hall sensors, A, B, C, are responsible for measuring the displacement of the stage relative to the framework in the horizontal plane. Specifically, sensors A and B measure the relative displacements in the Y direction, and sensor C in the X direction. The output voltage of a Hall sensor is in direct proportion to the magnetic flux density where the sensor is placed, and zero output is desired in the middle of its measurement range. The structure of the Hall sensor used in the stage is shown in

Figure 2, in which the structure of the magnetic steel is simplified for better versatility and easier installation. The Hall probe is fixed on the stage, while the permanent magnets are installed on the mounting plate. The dimension of the magnet is 12.7 mm × 6.4 mm × 6.4 mm, and the installation mount is designed to be 43 mm × 25.5 mm × 6.5 mm. With this configuration, an arc-shape magnetic field is generated above the upper surface of the magnet. The Hall sensor array is shown in

Figure 3.

The vertical 3-DOF movement of the stage is measured by the capacitance sensors, whose layout is as shown in

Figure 4. The probe of capacitance sensor is fixed on a disc-shaped base below the stage. Two capacitance sensors are installed on the

X axis, symmetric to the origin, while the third capacitance sensor is located off the axis

X. Each capacitance sensor could obtain the displacement of the probe relative to the framework, and the 3-DOF vertical movement of the stage relative to the framework can be calculated.

To calibrate the Hall sensor array, laser interferometers are adopted to measure the planar 3-DOF motion of the stage, acting as a reference for Hall sensor array. The investigated precision stage is shown in

Figure 5.

5. Experiments and Analysis

In this section, the proposed Self-adaptive hybrid TLBO method is applied to estimate the mechanical parameters of the designed Hall measurement system for the 6-DOF precision stage illustrated in

Section 2. The desired accuracy of the Hall sensor array for each axis is 5 μm, and the vertical 3-DOF movement of the stage is obtained by capacitive sensors, CAPANCDT 6500 by Micro-Epsilon, with an accuracy of 12 nm.

To calibrate the Hall sensor array, a 3-DOF laser interferometer array is adopted to provide reference. Although environmental variations, such as temperature, humidity and vibration, limited the static accuracy of the interferometer to 500 nm, it is still adequate for calibration of the Hall sensor array. To synchronize different sensors, a clock with 2 ms is designed.

To conduct the calibration experiment, the designed values of parameters in the Hall sensor array are listed in

Table 1.

The precision stage is first controlled to stop at a fixed vertical level to avoid the disturbance induced by vertical moment. Considering the influence of vertical states on the measurements of Hall arrays, the stage is fixed at two heights: Z = −250 μm and Z = −250 μm. Then, the stage conducts the planar reset operation, providing the zero points for the 3-DOF interferometer array. After the reset, the planar motion of the stage could be measured by both the Hall sensors and the interferometers. Next, the stage is controlled to track certain trajectory with feedback from the interferometers. Then the output of the interferometers can be utilized to calibrate the Hall sensors. In this experiment, the trajectory along each axis is a sinusoidal wave: with amplitude of 300 μm and frequency of 1 Hz along

X axis; 500 μm and 1 Hz along

Y; 300 μrad and 1 Hz along

Z. The corresponding outputs from the sensors are shown in

Figure 9.

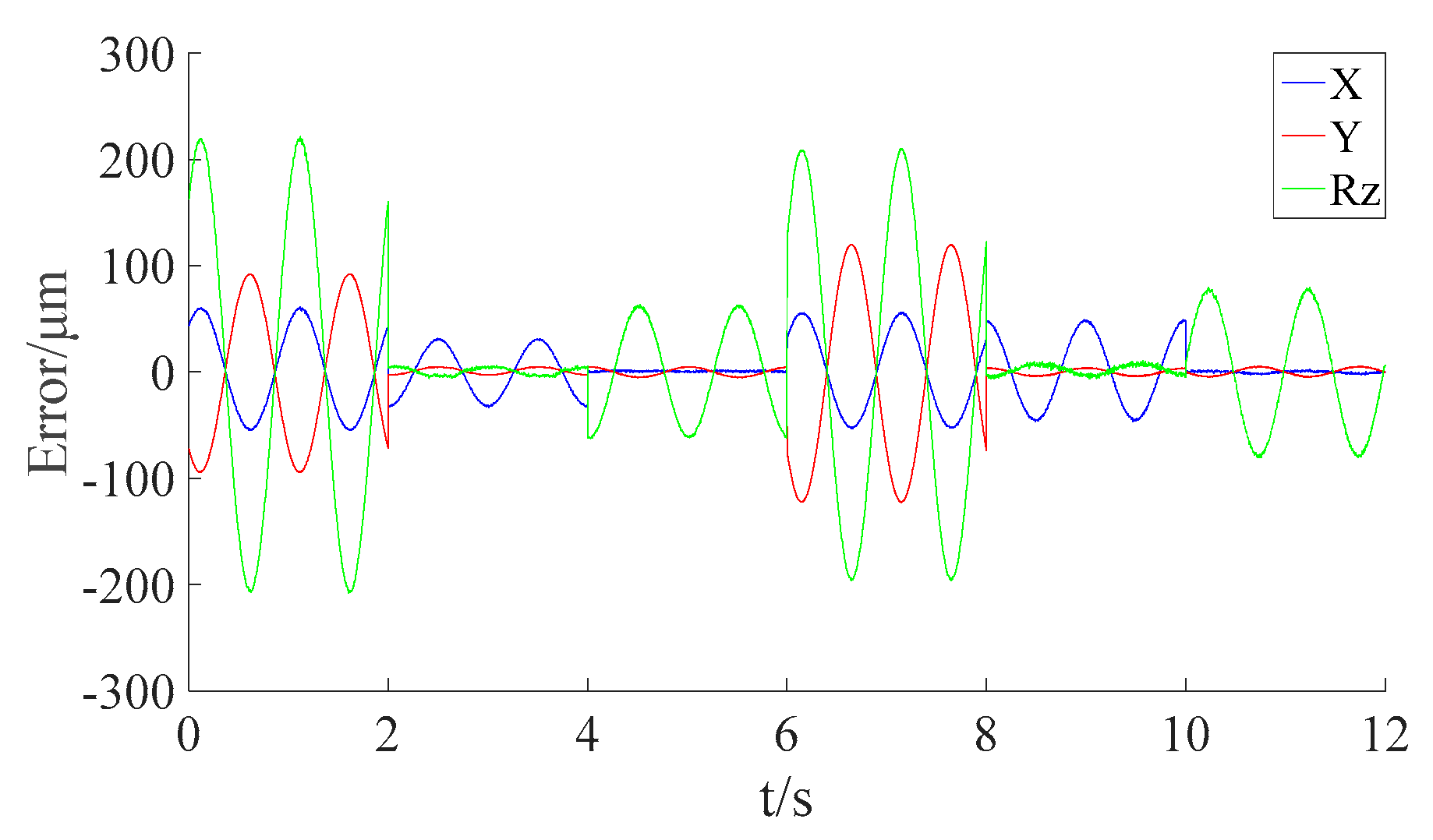

Using the designed parameters listed in

Table 1 and the measurement model of the Hall sensor array built in

Section 3, the output errors of Hall sensors with the designed parameters could be obtained, as shown in

Figure 10.

The peak errors and the standard deviations (RMSE) of each DOF with the designed parameters are listed in

Table 2.

As can be seen from

Figure 10 and

Table 2, the measurement accuracies of the Hall sensor array with the designed parameters fall far short of the requirements. The peak error in the translational direction is 119.9458 μm, while the peak error in the rotational direction is 221.5275 μrad. This is caused by the afore-mentioned mechanical assembly errors in the Hall sensor array. So, it is necessary to conduct the calibration. To set proper constraints on the optimization algorithm, the search ranges are given according to the mechanical design of the stage, as listed in

Table 3.

In this experiment, the interferometers need to be reset using the feedback from the Hall measuring system, which contains about 5 μm measurement noise. As a result, the zero points of the interferometers vary between different rounds of movements, introducing uncertainty to the calibration system. To eliminate this offset, the initial aligning parameters should be considered in the calibration model. Therefore, Equation (15) is modified as

where

,

,

denote the reset errors of HALL sensors A, B and C during the

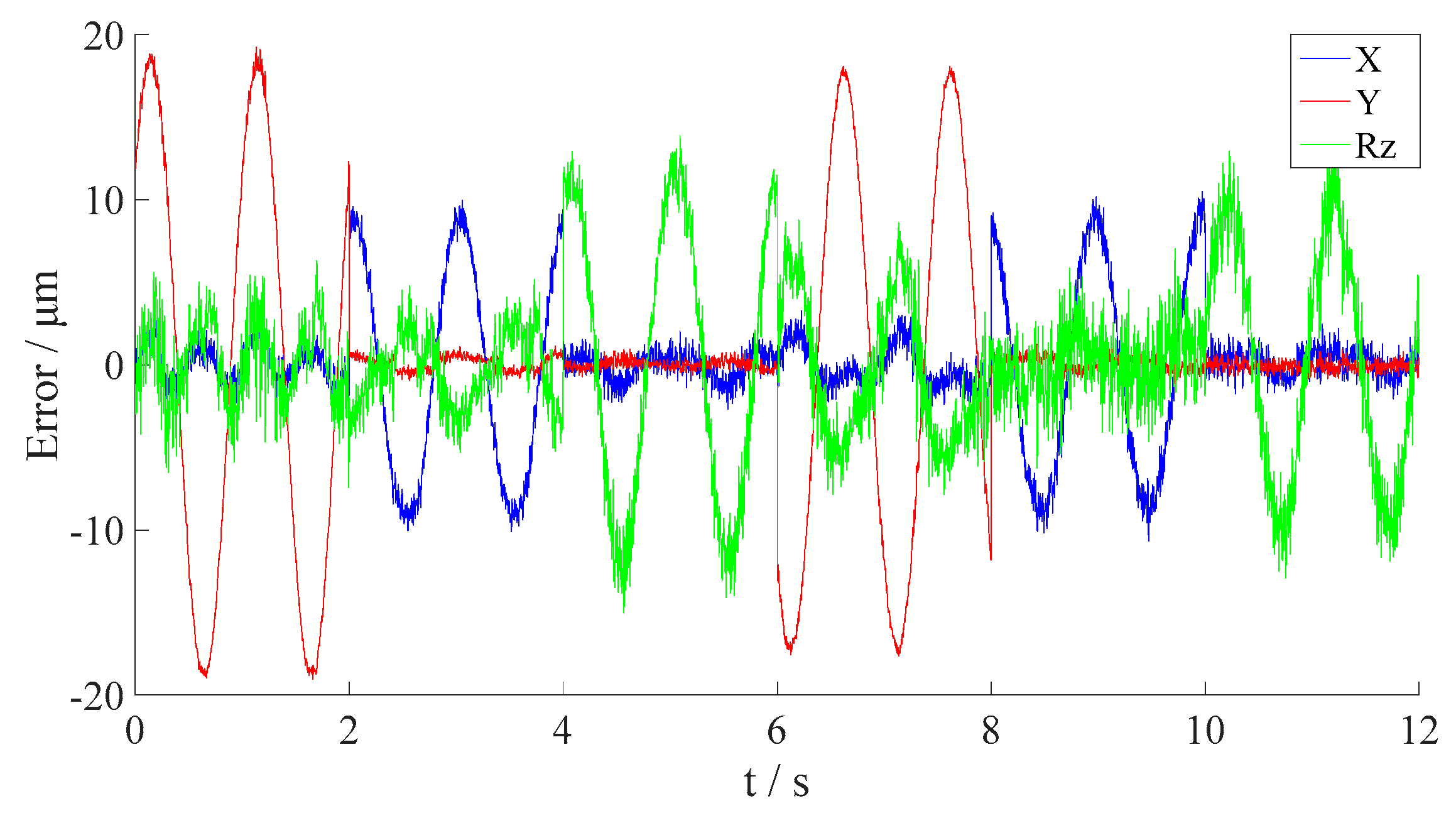

i-th movement, respectively. The range of these variables are all [−10 μm, 10 μm]. Then, parameter estimation for the measurement Model (30) was conducted, and the corresponding results are shown in

Figure 11, while the RMSE and the peak errors are listed in

Table 4. To estimate the parameters, the proposed self-adaptive hybrid TLBO is adopted. The training data is composed of 100 randomly selected data from the experimental results. The setting of the optimization algorithm is:

Np =

Gm = 100. The stop criterion is

.

As can be seen from

Figure 11 and

Table 4, the measurement accuracy of the Hall sensor array is improved by the parameter estimation. The peak error in translational direction is reduced to 19.2473 μm, and that in rotational direction to 15.0316 μrad, approaching the desired accuracy. But this accuracy is still far from desired value, which means that the measurement Model (30) is not accurate enough for the purpose. Therefore, the influence of vertical moments should be incorporated in the model. According to the principle of Hall measurement, the slope of the magnetic flux density sensed by the Hall probe would change with the distance between the Hall sensor and the upper surface of the permanent magnet. To accommodate this feature, a new calibration model is constructed as in Equation (31), which considers the linear combinations of vertical movements.

where

PM is the matrix containing the error parameters,

,

,

denote respectively the calibration coefficients of the three Hall sensors’ outputs which vary with the vertical moments of the stage.

denote the coefficients of different DOFs, which are to be optimized.

,

,

denote the calibration coefficients of the vertical zero plane;

,

,

denote the zero deviations of the three Hall sensors at the

i-th movement.

During the experiment, the vertical moving range is ±250 μm; the rotational ranges of

Rx and

Ry are both ±500 μrad. Considering the achievable assembly accuracy, the boundary of the TLBO searching is set to be 5000. Furthermore, the sign of the boundary could be determined according to reference [

14]. Taking Hall sensor A as an example: the distance between the Hall probe and the upper surface of the permanent magnetic will increase if the stage moves in the positive vertical direction. As a result, the output slope of the Hall sensor A would decrease. Therefore, the coefficient

should be negative. The signs of other coefficients can be determined likewise. Finally, the search boundary of the coefficients can be determined, as listed in

Table 5.

In the experiment, the stage is set at different vertical states as listed in

Table 6. Under each vertical setting, the stage is controlled in the same manner as mentioned above. Alsom the sensors’ data are sampled in the same way. Then, the parameters in Model (31) are optimized by the hybrid adaptive TLBO. The setting of the optimizing algorithm is the same as mentioned above. The training data is set to 200 points.

The estimated results of the measurement parameters are listed in

Table 7, while the corresponding coefficients of zero deviations are shown in

Table A1 (

Appendix A).

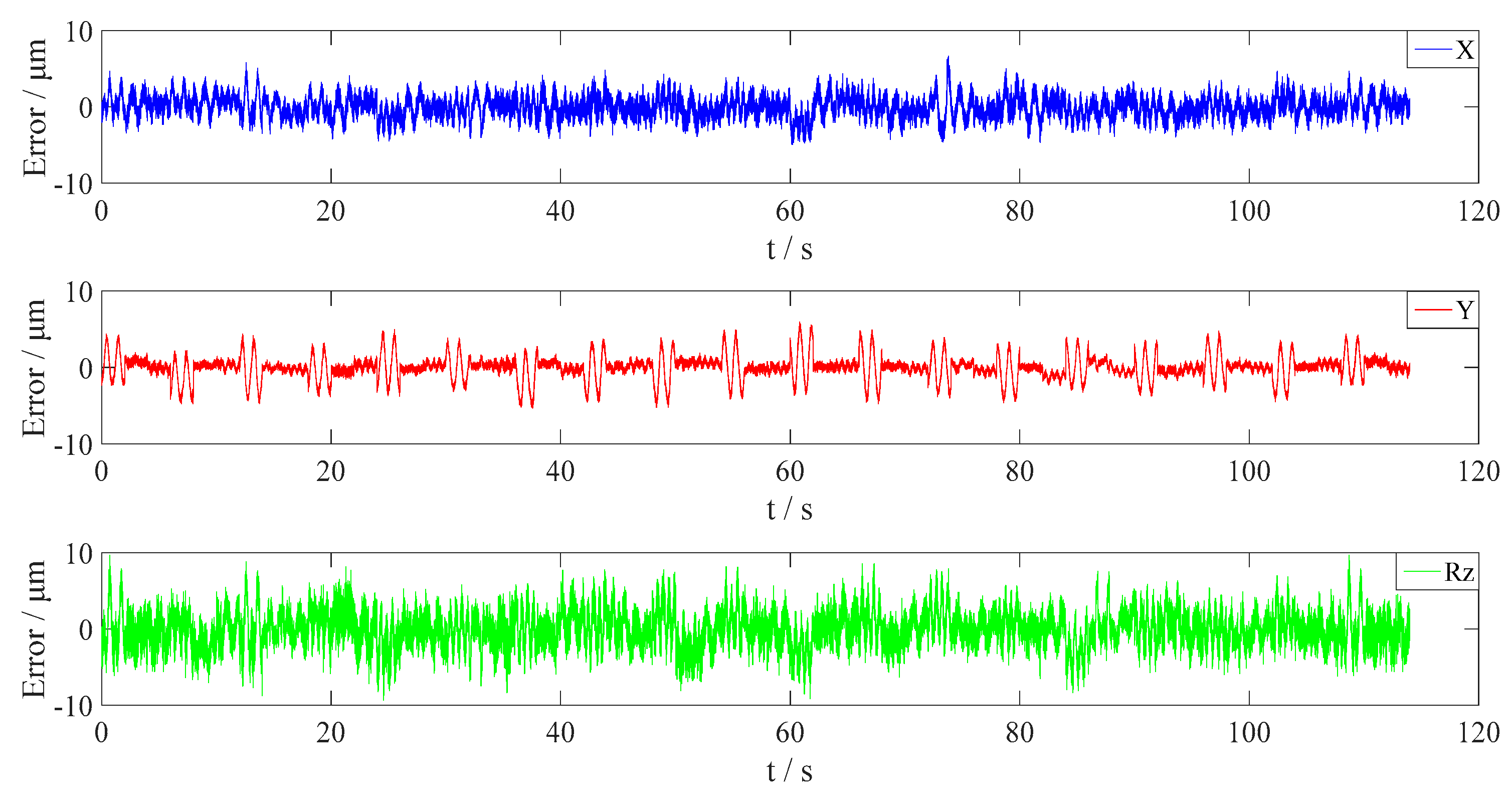

Apply the estimated results to Model (31), and then validate it using all the sampling data. The output errors of X, Y and Rz are shown in

Figure 12 and

Table 8.

As seen from

Figure 12 and

Table 8, by calibration, the maximum translational and rotational errors of the Hall sensor array are reduced to 6.6368 μm and 9.63 μrad, respectively, which meets the measurement accuracy requirement.