An Anisotropic Model for Magnetostriction and Magnetization Computing for Noise Generation in Electric Devices

Abstract

:1. Introduction

2. Model Description

- Ed is the demagnetizing field energy.

- Ez is the applied magnetic field (Zeeman) energy.

- Ea is the anisotropy energy.

- Eσ is the stress induced anisotropy.

3. Energy Terms Definition and Identification of Parameters

3.1. Demagnetizing Field Energy

- Nd is a factor to take into account the considered demagnetizing field.

- μ0 is the vacuum permeability.

3.2. Zeeman Energy

3.3. Anisotropy Energy

3.4. Stress-Induced Anisotropy

4. Validation of the Model and Integration in a Finite Elements Simulation

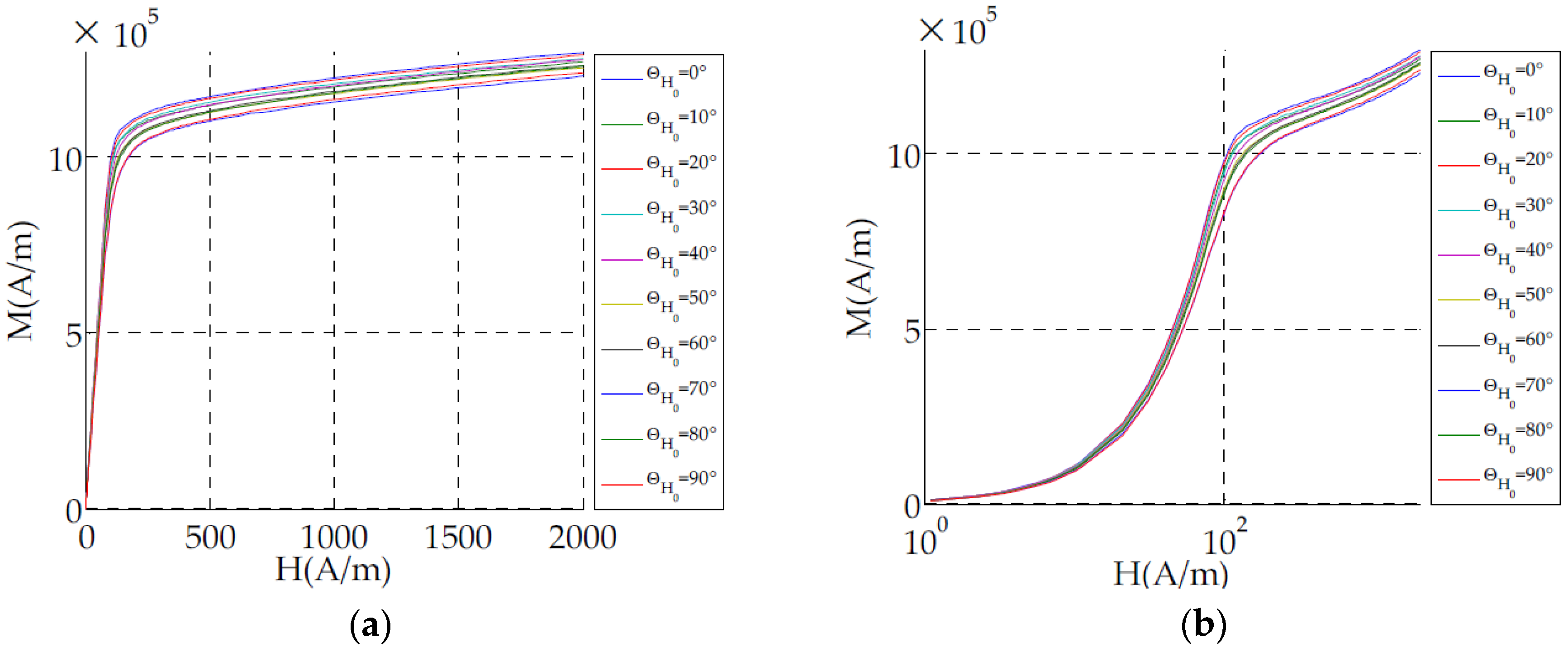

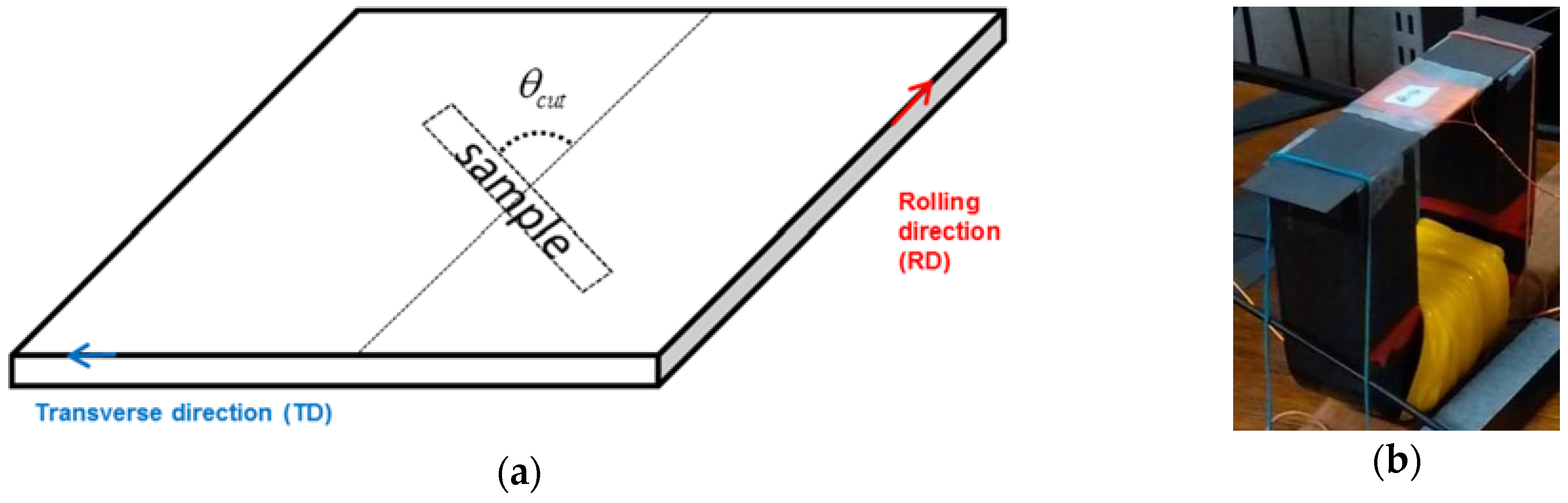

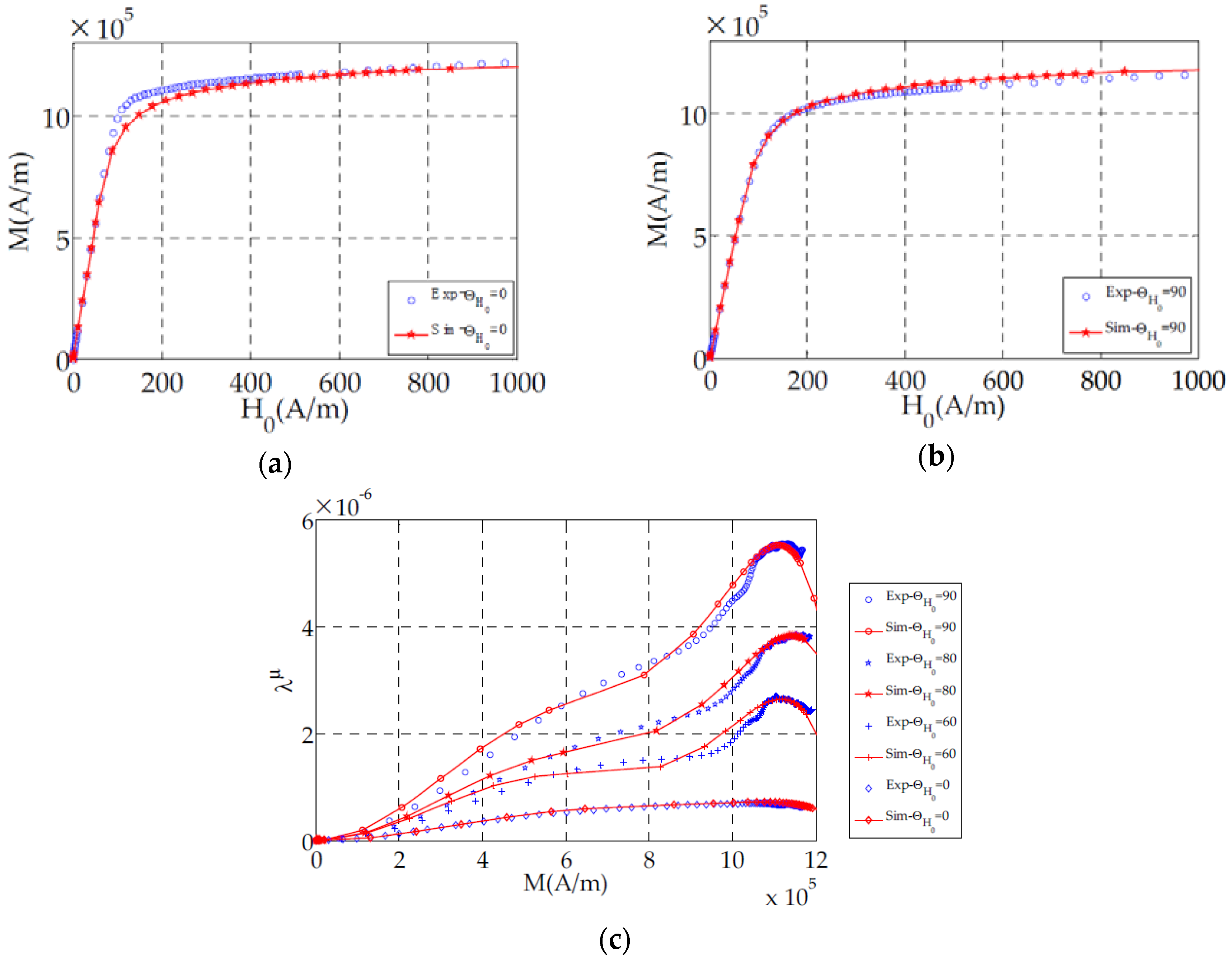

4.1. Comparison between Experiments on Single Sheet and Calculated Values

- M is the magnetization.

- B is the flux density measured by a b-coil (Figure 3b)

- μ0 is the vacuum permeability.

- H is the magnetic field measured by a H-coil.

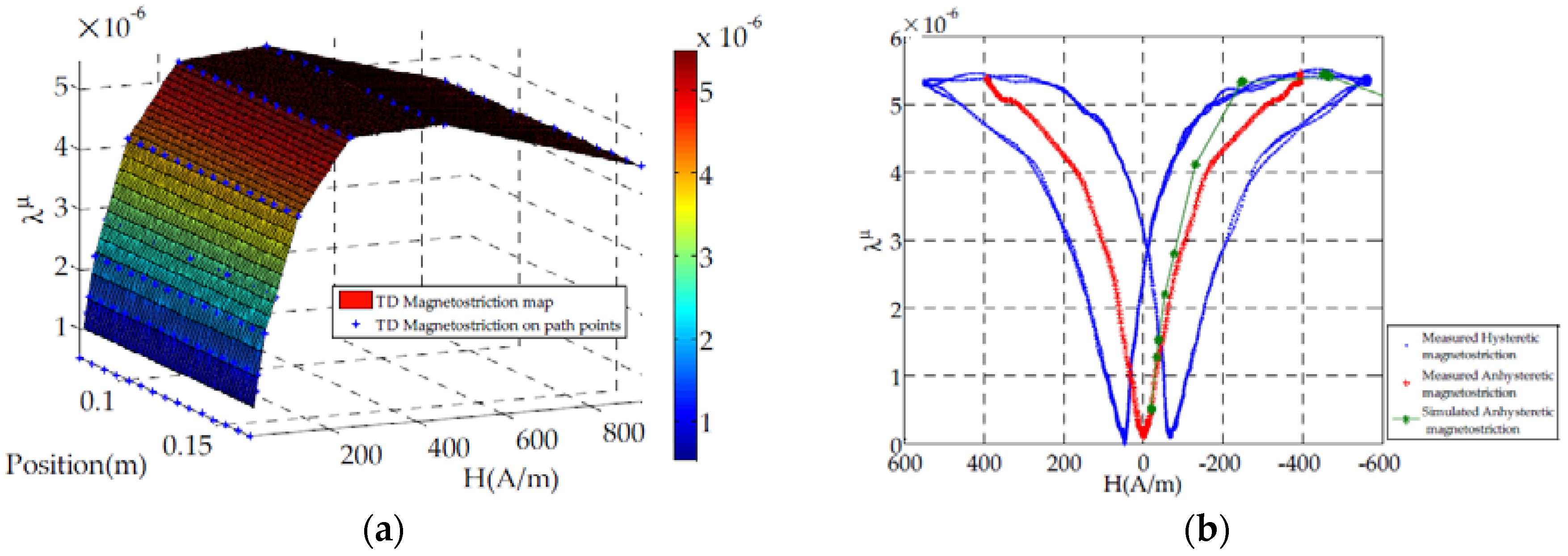

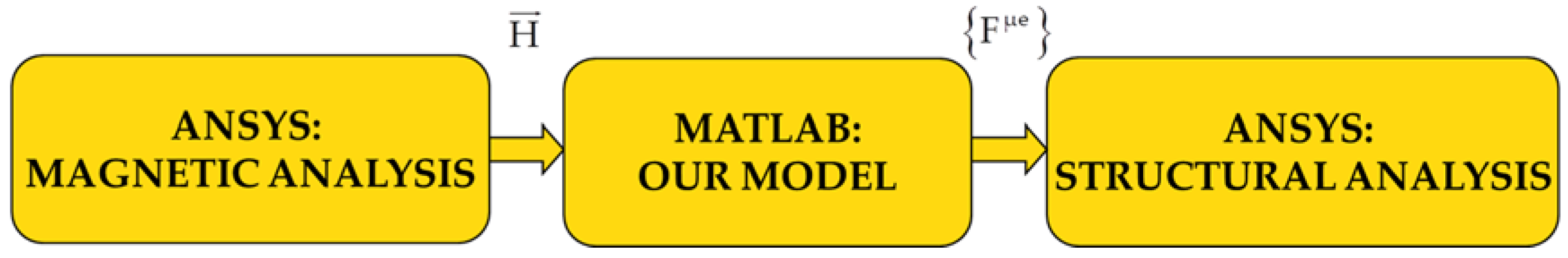

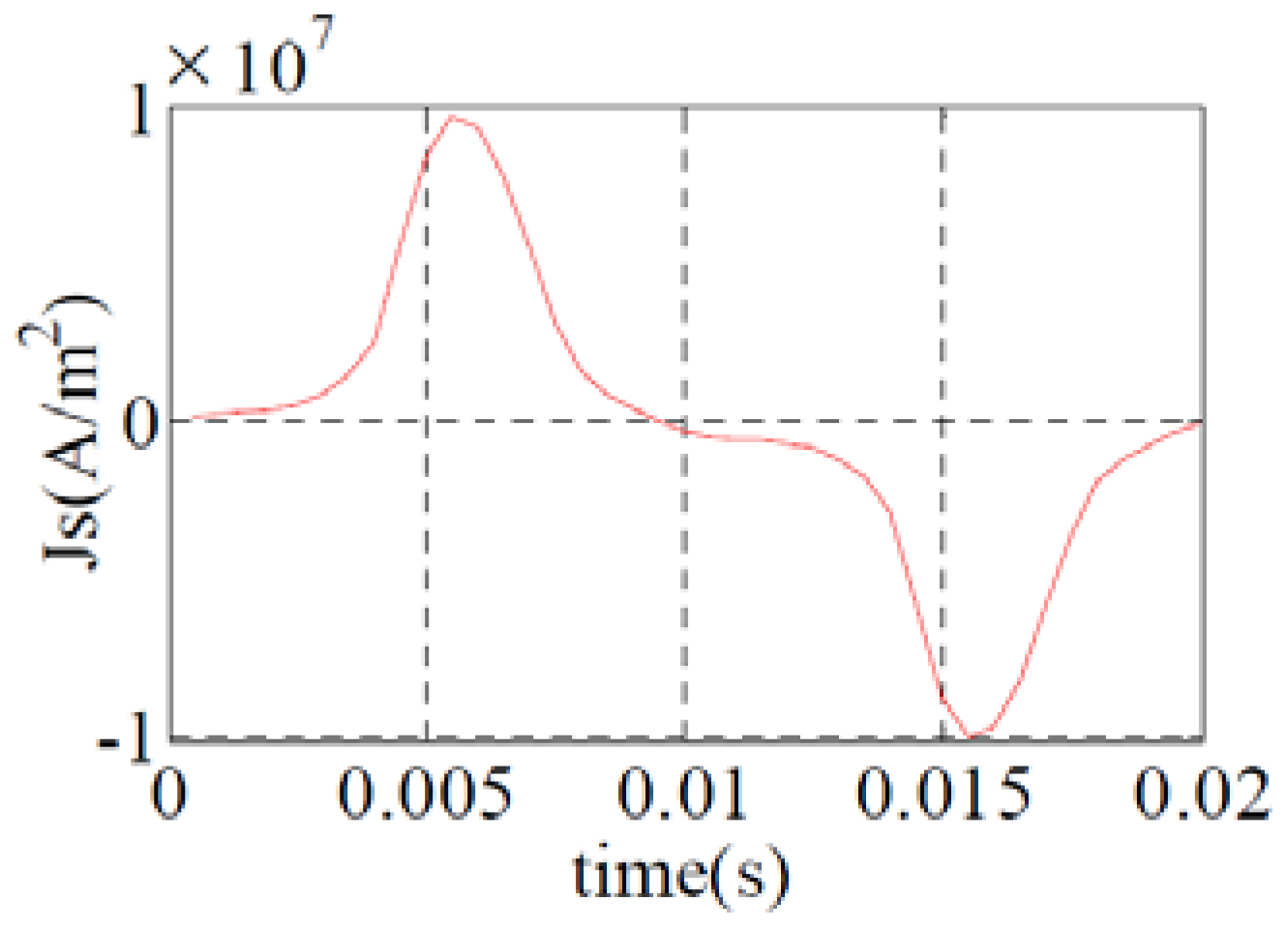

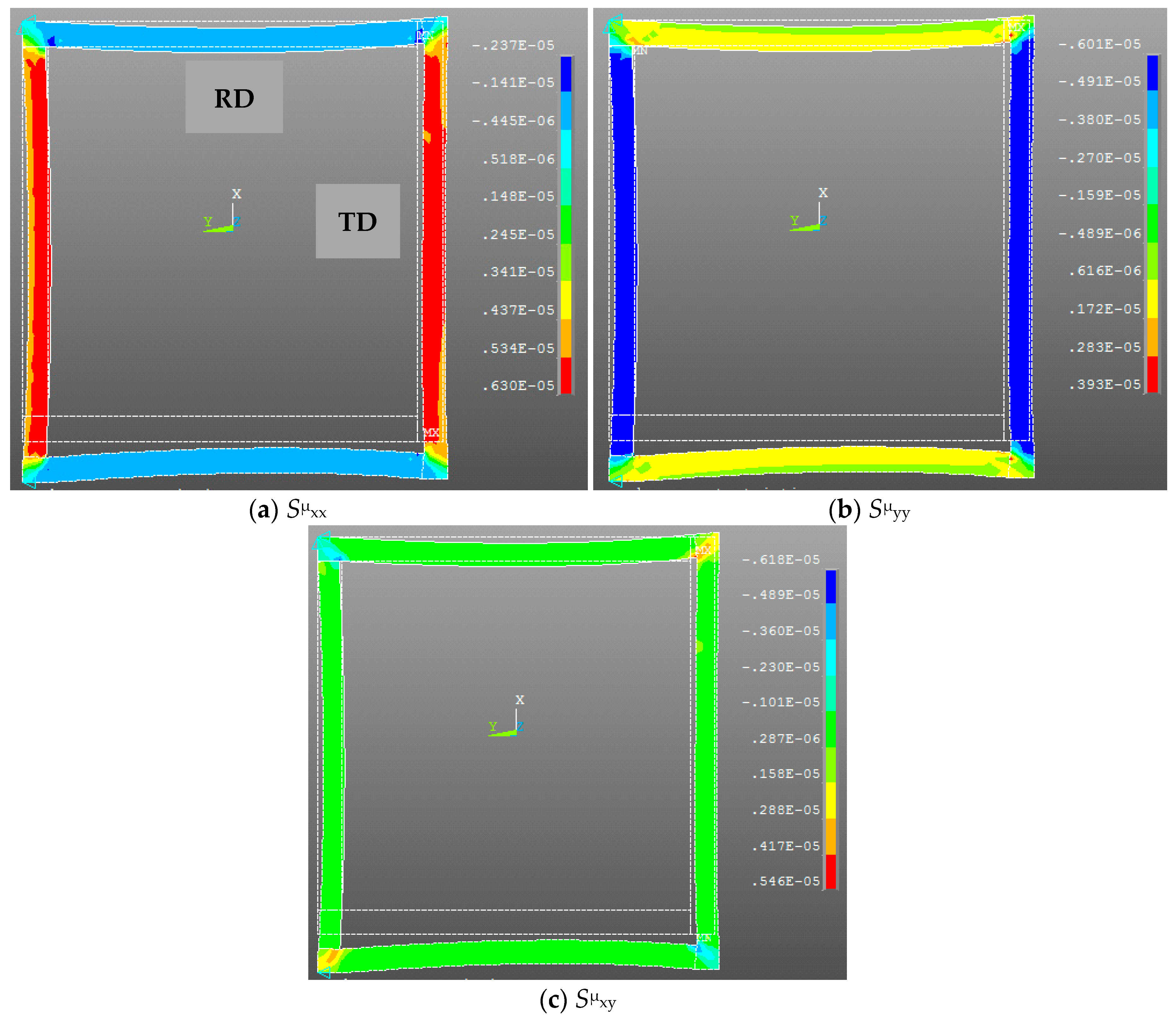

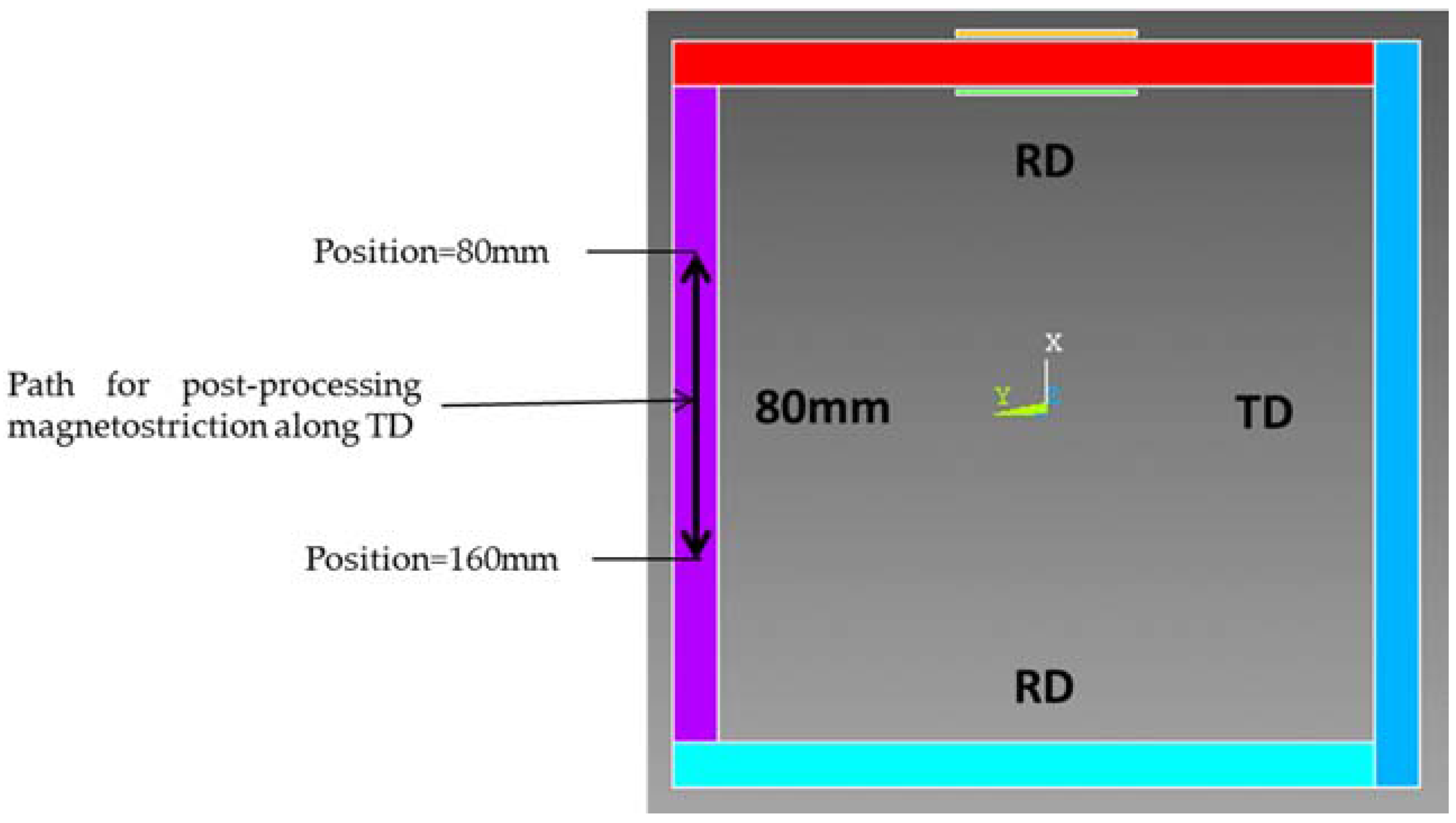

4.2. Integration in a Finite Elements Simulation and Comparison between Simulation and Measurements

- {Fμe} is the nodal forces vector of an element.

- ve is the element volume.

- [B] is the matrix of shape function depending on the chosen element.

- {σμ} is the equivalent magnetostriction stress in Voigt notation.

- C(E,ν) is the stiffness matrix depends on the Young modulus (E) and Poisson ratio (ν).

- Sμ is the magnetostriction strain in Voigt notation.

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| VPI | Vacuum-Pressure Impregnation |

| RD | Rolling Direction |

| TD | Transverse Direction |

References

- Jang, P.; Choi, G. Acoustic noise characteristics and magnetostriction of Fe–Si powder cores. IEEE Trans. Magn. 2012, 48, 1549–1552. [Google Scholar] [CrossRef]

- Weiser, B.; Pfutzner, H.; Anger, J. Relevance of magnetostriction and forces for the generation of audible noise of transformer cores. IEEE Trans. Magn. 2000, 36, 3759–3777. [Google Scholar] [CrossRef]

- Delaere, K.; Heylen, W.; Belmans, R.; Hameyer, K. Finite element based expressions for Lorentz, reluctance and magnetostriction forces. COMPEL 2001, 20, 20–31. [Google Scholar] [CrossRef]

- Mohammed, O.A.; Calvert, T.; McConnell, R. Coupled magnetoelastic finite element formulation including anisotropic reluctivity tensor and magnetostriction effects for machinery applications. IEEE Trans. Magn. 2001, 37, 3388–3392. [Google Scholar] [CrossRef]

- Hubert, O.; Daniel, L.; Billardon, R. Experimental analysis of the magnetoelastic anisotropy of a non-oriented silicon iron alloy. J. Magn. Magn. Mater. 2003, 254–255, 352–354. [Google Scholar] [CrossRef]

- Moses, A.J.; Anderson, P.I.; Somkun, S. Modeling 2-D Magnetostriction in Nonoriented Electrical Steels Using a Simple Magnetic Domain Model. IEEE Trans. Magn. 2015, 51. [Google Scholar] [CrossRef]

- Belahcen, A.; Singh, D.; Rasilo, P.; Martin, F.; Ghalamestani, S.G.; Vandevelde, L. Anisotropic and Strain-Dependent Model of Magnetostriction in Electrical Steel Sheets. IEEE Trans. Magn. 2015, 51. [Google Scholar] [CrossRef]

- Lundgren, A. On Measurement and Modelling of 2D Magnetization and Magnetostriction of Sife Sheets. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 1999. [Google Scholar]

- Somkun, S.; Moses, A.J.; Anderson, P.I.; Klimczyk, P. Magnetostriction Anisotropy and Rotational Magnetostriction of a nonoriented Electrical Steel. IEEE Trans. Magn. 2010, 46, 302–305. [Google Scholar] [CrossRef]

- Du Trémolet de Lacheisserie, E. Magnétisme, 1st ed.; EDP Sciences: Grenoble, France, 2000; Volume 1, pp. 151–208, 318–332. [Google Scholar]

- Mudivarthi, C. Equivalence of magnetoelastic, elastic and mechanical work energies with stress-induced anisotropy. Behav. Mech. Multifunct. Compos. Mater. 2008, 6929, 1–9. [Google Scholar]

- Mbengue, S.S.; Buiron, N.; Lanfranchi, V. Macroscopic modeling of anisotropic magnetostriction and magnetization in soft ferromagnetic materials. J. Magn. Magn. Mater. 2016, 404, 74–78. [Google Scholar] [CrossRef]

- Spornic, S.A.; Lebouc, A.K.; Cornut, B. Anisotropy and texture influence on 2D magnetic behaviour for silicon, cobalt and nickel iron alloys. J. Magn. Magn. Mater. 2000, 215–216, 614–616. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials, 2nd ed.; Wiley: Toronto, ON, Canada, 2009; pp. 241–257. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mbengue, S.S.; Buiron, N.; Lanfranchi, V. An Anisotropic Model for Magnetostriction and Magnetization Computing for Noise Generation in Electric Devices. Sensors 2016, 16, 553. https://doi.org/10.3390/s16040553

Mbengue SS, Buiron N, Lanfranchi V. An Anisotropic Model for Magnetostriction and Magnetization Computing for Noise Generation in Electric Devices. Sensors. 2016; 16(4):553. https://doi.org/10.3390/s16040553

Chicago/Turabian StyleMbengue, Serigne Saliou, Nicolas Buiron, and Vincent Lanfranchi. 2016. "An Anisotropic Model for Magnetostriction and Magnetization Computing for Noise Generation in Electric Devices" Sensors 16, no. 4: 553. https://doi.org/10.3390/s16040553