Thin Film Differential Photosensor for Reduction of Temperature Effects in Lab-on-Chip Applications

Abstract

:1. Introduction

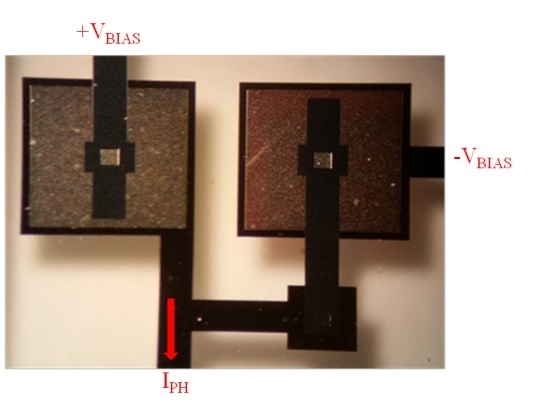

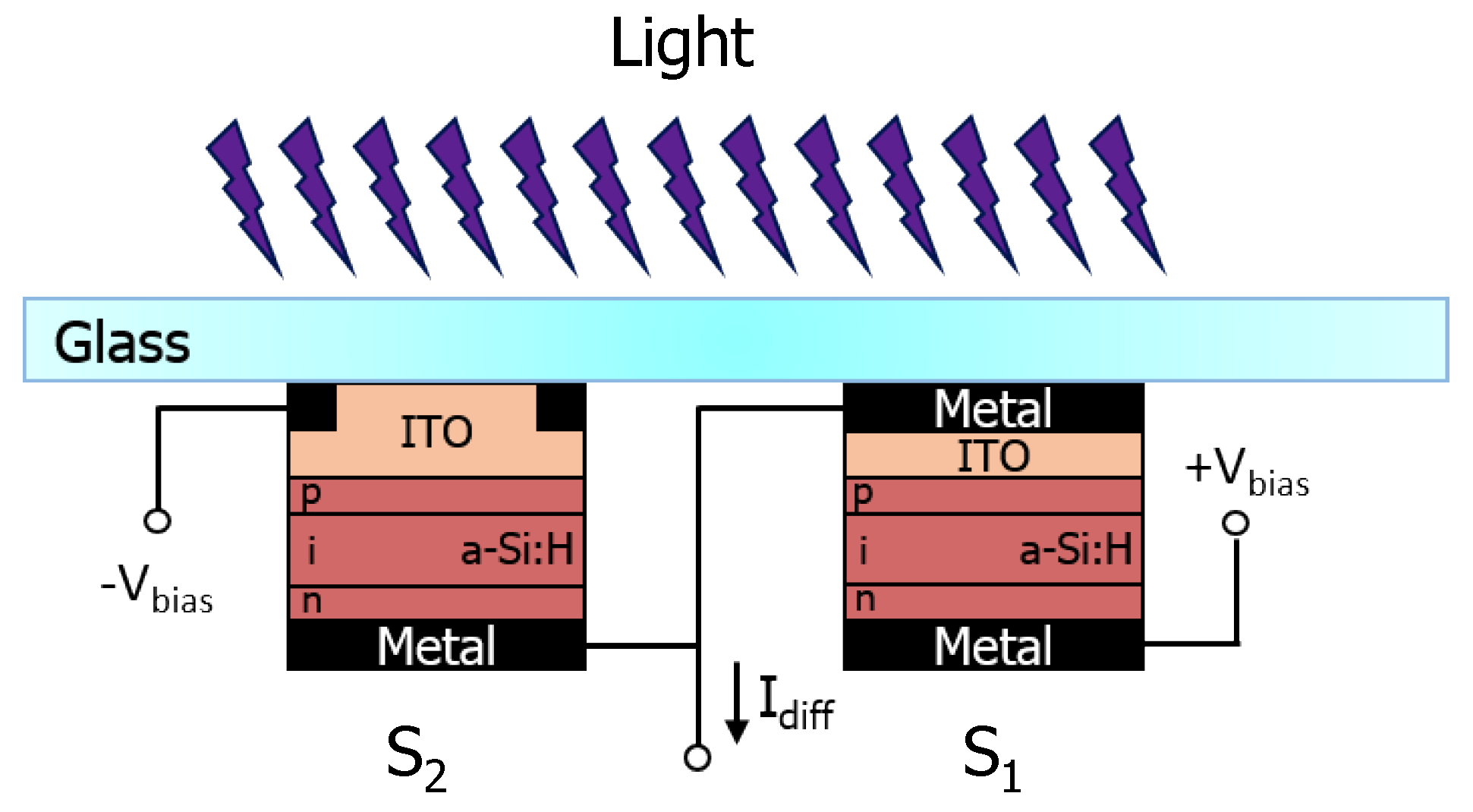

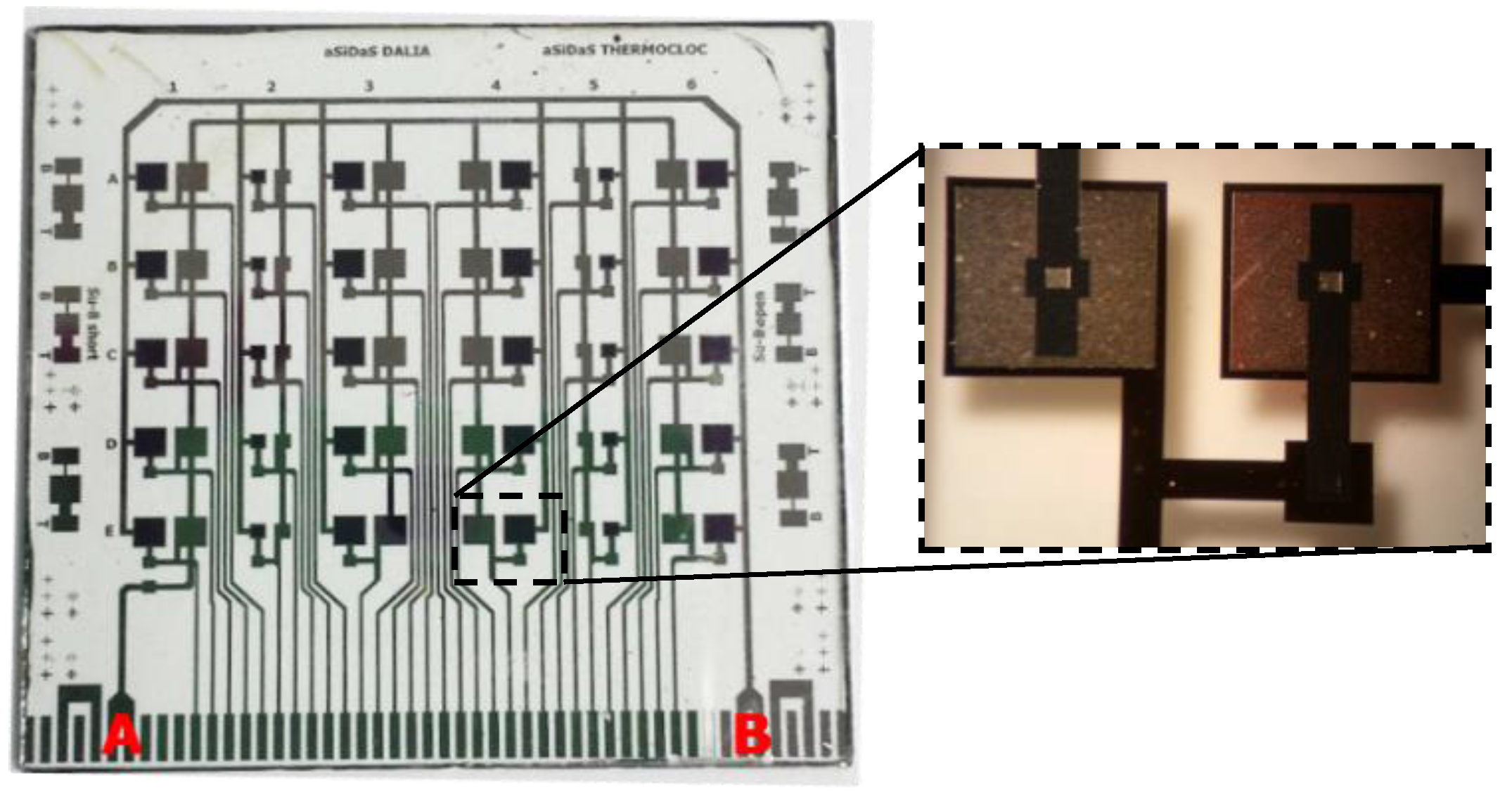

2. Device Structure and Fabrication

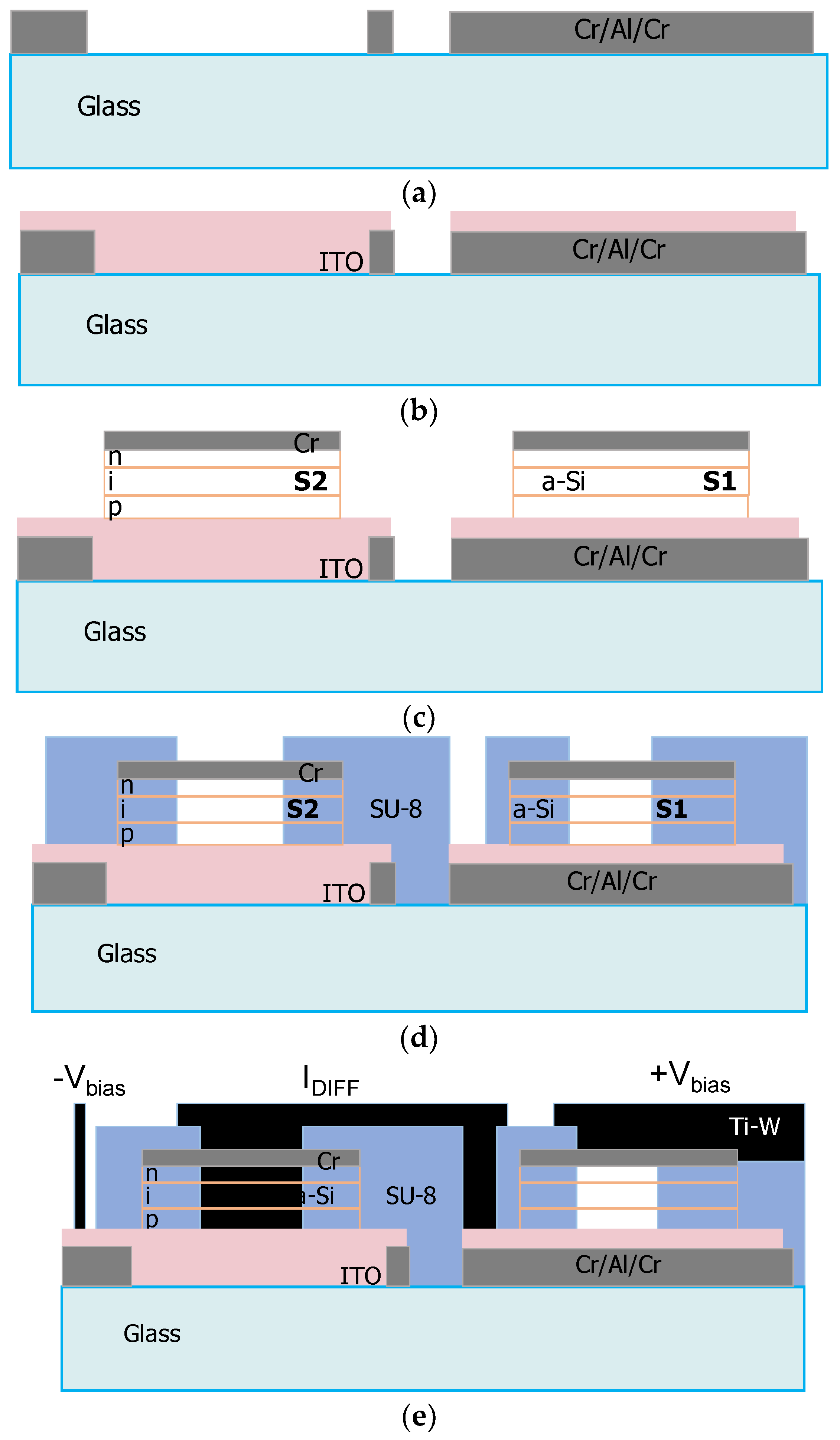

- (1)

- Vacuum evaporation of a 30-150-30 nm-thick Cr/Al/Cr metal layers and their patterning with mask #1 for the bottom contact of the light-shielded diodes (S1), its connection to the output electrodes and the polarization line of the light sensitive sensors (see Figure 3a);

- (2)

- Deposition by magnetron sputtering of a 200 nm ITO layer and its etching in argon plasma, using mask #2, to define the transparent bottom contact of the photosensors (S2) (see Figure 3b);

- (3)

- Deposition by PECVD of the p-i-n structure followed by a 50 nm-thick vacuum evaporated chromium top electrode layer and patterning of the device structure through mask #3 by wet etching for the metal layer and reactive ion etching for the a-SiC:H/a-Si:H films (see Figure 3c);

- (4)

- Deposition of a 5 µm-thick insulation layer (SU-8 3005 from MicroChem, Westborough, MA, USA), definition of the via holes over the diodes through mask #4 (see Figure 3d);

- (5)

- Sputtering of a titanium/tungsten (Ti-W) alloy layer, and patterning with mask #5 for the definition of the two-diode series connection and the common bias line of the light shielded sensors (see Figure 3e);

- (6)

- Deposition of a protective 5 µm-thick passivation layer over the glass substrate.

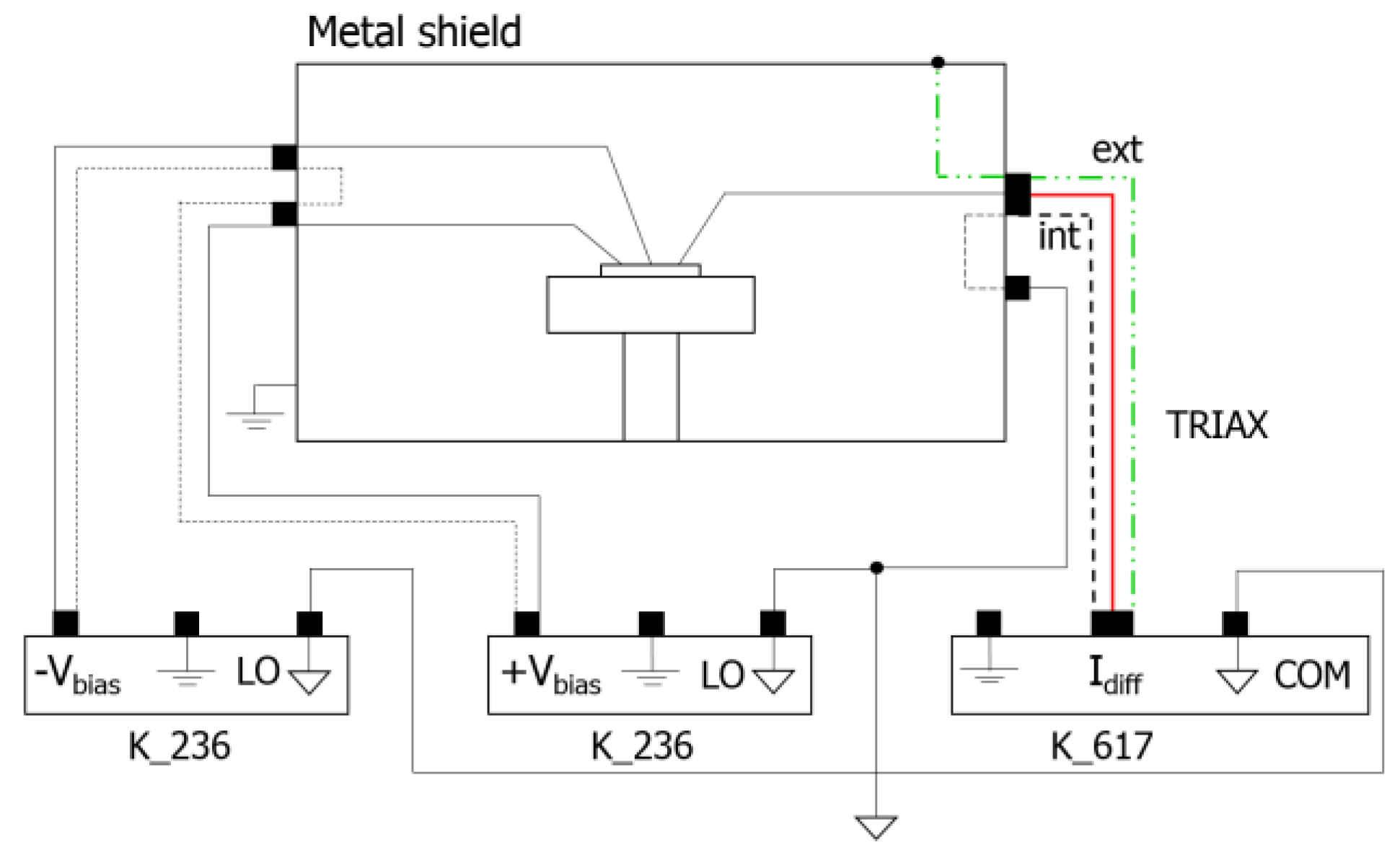

3. Device Characterization

3.1. I-V Characterizations

3.2. Quantum Efficiency Measurements

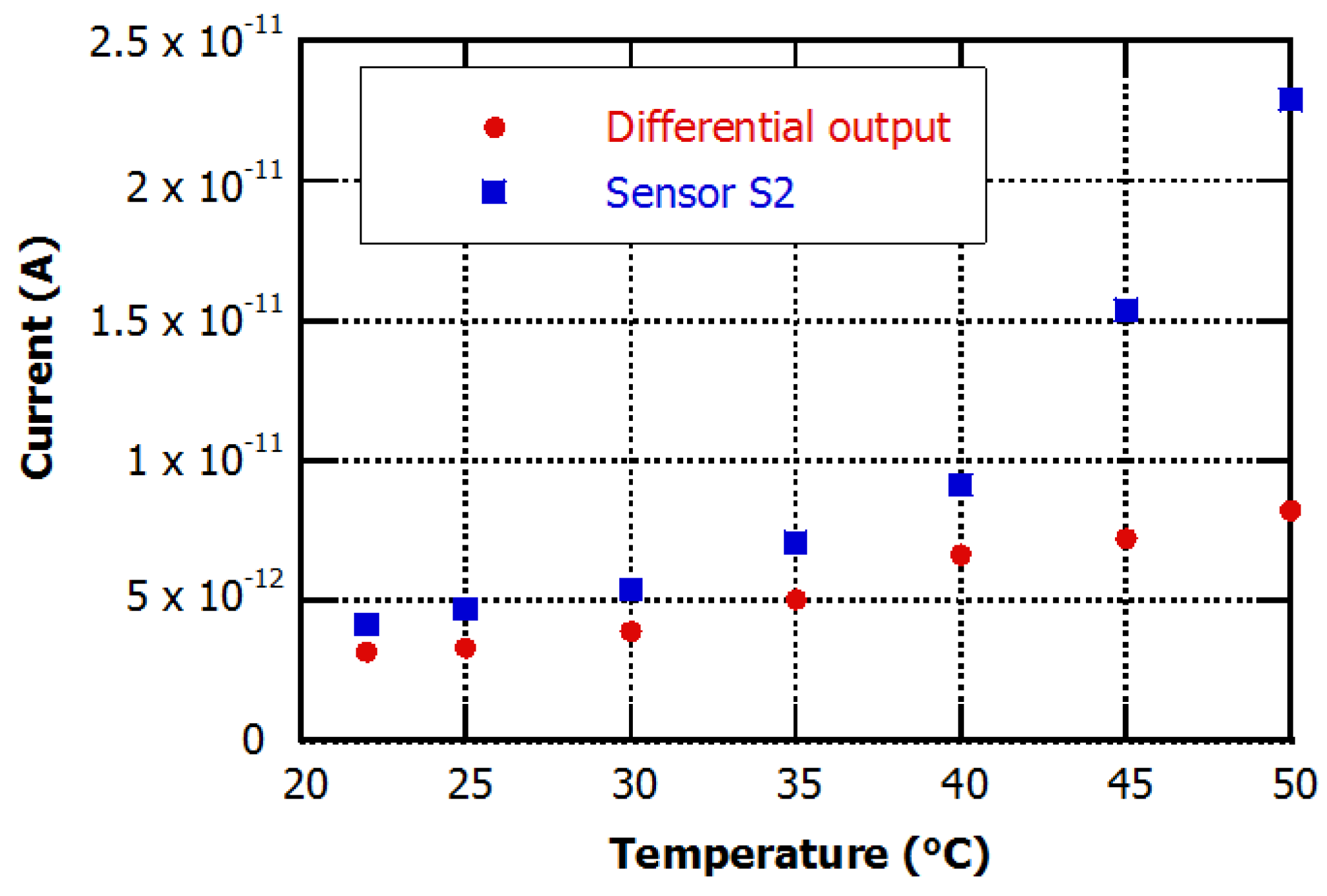

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jakeway, S.C.; de Mello, A.J.; Russell, E.L. Miniaturized total analysis systems for biological analysis. Fresenius’ J. Anal. Chem. 2000, 336, 525–539. [Google Scholar] [CrossRef]

- Pires, N.M.M.; Dong, T.; Hanke, U.; Hoivik, N. Recent Developments in Optical Detection Technologies in Lab-on-a-Chip Devices for Biosensing Applications. Sensors 2014, 14, 15458–15479. [Google Scholar] [CrossRef] [PubMed]

- Pais, A.; Banerjee, A.; Klotzkin, D.; Papautsky, I. High-sensitivity, disposable lab-on-a-chip with thin-film organic electronics for fluorescence detection. Lab Chip 2008, 8, 794–800. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Hofmann, O.; Das, R.; Barrett, E.M.; deMello, A.J.; deMello, J.C.; Bradley, D.D. Integrated thin-film polymer/fullerene photodetectors for on-chip microfluidic chemiluminescence detection. Lab Chip 2007, 7, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.H.; Chang, Y.C.; Norris, T.B.; Zhong, Z. Graphene photo-detectors with ultra-broadband and high responsivity at room tem-perature. Nat. Nanotechnol. 2014, 9, 273–278. [Google Scholar] [CrossRef] [PubMed]

- Kamei, T.; Paegel, B.M.; Scherer, J.R.; Skelley, A.M.; Street, R.A.; Mathies, R.A. Integrated hydrogenated amorphous Si photodiode detector for microfluidic bioanalytical devices. Anal. Chem. 2003, 75, 5300–5305. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.T.; Novo, P.; Prazeres, D.M.F.; Chu, V.; Conde, J.P. Heterogeneous immunoassays in microfluidic format using fluorescence detection with integrated amorphous silicon photodiodes. Biomicrofluidics 2011, 5. [Google Scholar] [CrossRef] [PubMed]

- Caputo, D.; de Cesare, G.; Dolci, L.S.; Mirasoli, M.; Nascetti, A.; Roda, A.; Scipinotti, R. Microfluidic Chip with Integrated a-Si:H Photodiodes for Chemiluminescence-Based Bioassays. IEEE Sens. J. 2013, 13, 2595–2602. [Google Scholar] [CrossRef]

- Costantini, F.; Nascetti, A.; Scipinotti, R.; Domenici, F.; Sennato, S.; Gazza, L.; Bordi, F.; Pogna, N.; Manetti, C.; de Cesare, D.C.G. On-chip detection of multiple serum antibodies against epitopes of celiac disease by an array of amorphous silicon sensors. RSC Adv. 2014, 4, 2073–2080. [Google Scholar] [CrossRef]

- Samusenko, A.; Hamedan, V.J.; Pucker, G.; Ghulinyan, M.; Ficorella, F.; Guider, R.; Gandolfi, D.; Pavesi, L. Integrated silicon photodetector for lab-on-chip sensor platform. In Proceedings of the 2015 XVIII AISEM Annual Conference, Trento, Italy, 3–5 February 2015; pp. 1–4.

- Caputo, D.; Ceccarelli, M.; de Cesare, G.; Nascetti, A.; Scipinotti, R. Lab-on-glass system for DNA analysis using thin and thick film technologies. MRS Proc. 2009, 1191. [Google Scholar] [CrossRef]

- Wilhelm, J.; Pingoud, A. Real-time polymerase chain reaction. Chembiochem 2003, 4, 1120–1128. [Google Scholar] [CrossRef] [PubMed]

- Diakité, M.L.; Champ, J.; Descroix, S.; Malaquin, L.; Amblard, F.; Viovy, J.L. A low-cost, label-free DNA detection method in lab-on-chip format based on electrohydrodynamic instabilities, with application to long-range PCR. Lab Chip 2012, 12, 4738–4747. [Google Scholar]

- De Cesare, G.; Nascetti, A.; Caputo, D. Amorphous Silicon p-i-n Structure Acting as Light and Temperature. Sensors 2015, 15, 12260–12272. [Google Scholar] [CrossRef] [PubMed]

- Caputo, D.; de Cesare, G.; Nardini, M.; Nascetti, A.; Scipinotti, R. Monitoring of temperature distribution in a thin film heater by an array of a-Si:H temperature sensors. IEEE Sens. J. 2012, 12, 1209–1213. [Google Scholar] [CrossRef]

- De Cesare, G.; Nascetti, A.; Scipinotti, R.; Zahra, A.; Caputo, D. On-chip detection performed by amorphous silicon balanced photosensor for lab-on chip application. Sens. Bio-Sens. Res. 2015, 3, 53–58. [Google Scholar] [CrossRef]

- Carpentiero, M.; Caputo, D.; Gambino, J.; Lovecchio, N.; de Cesare, G.; Nascetti, A. Array of differential photodiodes for thermal effects minimization in biomolecular analysis. In Proceedings of the 2015 6th IEEE International Workshop of Advances in Sensors and Interfaces (IWASI), Gallipoli, Italy, 18–19 June 2015; pp. 17–20.

- Costantini, F.; Sberna, C.; Petrucci, G.; Manetti, C.; de Cesare, G.; Nascetti, A.; Caputo, D. Lab-on-chip system combining a microfluidic-ELISA with an array of amorphous silicon photosensors for the detection of celiac disease epitopes. Sens. Bio-Sens. Res. 2015, 6, 51–58. [Google Scholar] [CrossRef]

- Mirasoli, M.; Nascetti, A.; Caputo, D.; Zangheri, M.; Scipinotti, R.; Cevenini, L.; de Cesare, G.; Roda, A. Multiwell cartridge with integrated array of amorphous silicon photosensors for chemiluminescence detection: development, characterization and comparison with cooled-CCD luminograph. Anal. Bioanal. Chem. 2014, 406, 5645–5656. [Google Scholar] [CrossRef] [PubMed]

- Sze, S.M. Physics of Semiconductor Devices; Wiley & Sons, Wiley Interscience Corporation: Hoboken, NJ, USA, 1981. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Cesare, G.; Carpentiero, M.; Nascetti, A.; Caputo, D. Thin Film Differential Photosensor for Reduction of Temperature Effects in Lab-on-Chip Applications. Sensors 2016, 16, 267. https://doi.org/10.3390/s16020267

De Cesare G, Carpentiero M, Nascetti A, Caputo D. Thin Film Differential Photosensor for Reduction of Temperature Effects in Lab-on-Chip Applications. Sensors. 2016; 16(2):267. https://doi.org/10.3390/s16020267

Chicago/Turabian StyleDe Cesare, Giampiero, Matteo Carpentiero, Augusto Nascetti, and Domenico Caputo. 2016. "Thin Film Differential Photosensor for Reduction of Temperature Effects in Lab-on-Chip Applications" Sensors 16, no. 2: 267. https://doi.org/10.3390/s16020267

APA StyleDe Cesare, G., Carpentiero, M., Nascetti, A., & Caputo, D. (2016). Thin Film Differential Photosensor for Reduction of Temperature Effects in Lab-on-Chip Applications. Sensors, 16(2), 267. https://doi.org/10.3390/s16020267