System Error Compensation Methodology Based on a Neural Network for a Micromachined Inertial Measurement Unit

Abstract

:1. Introduction

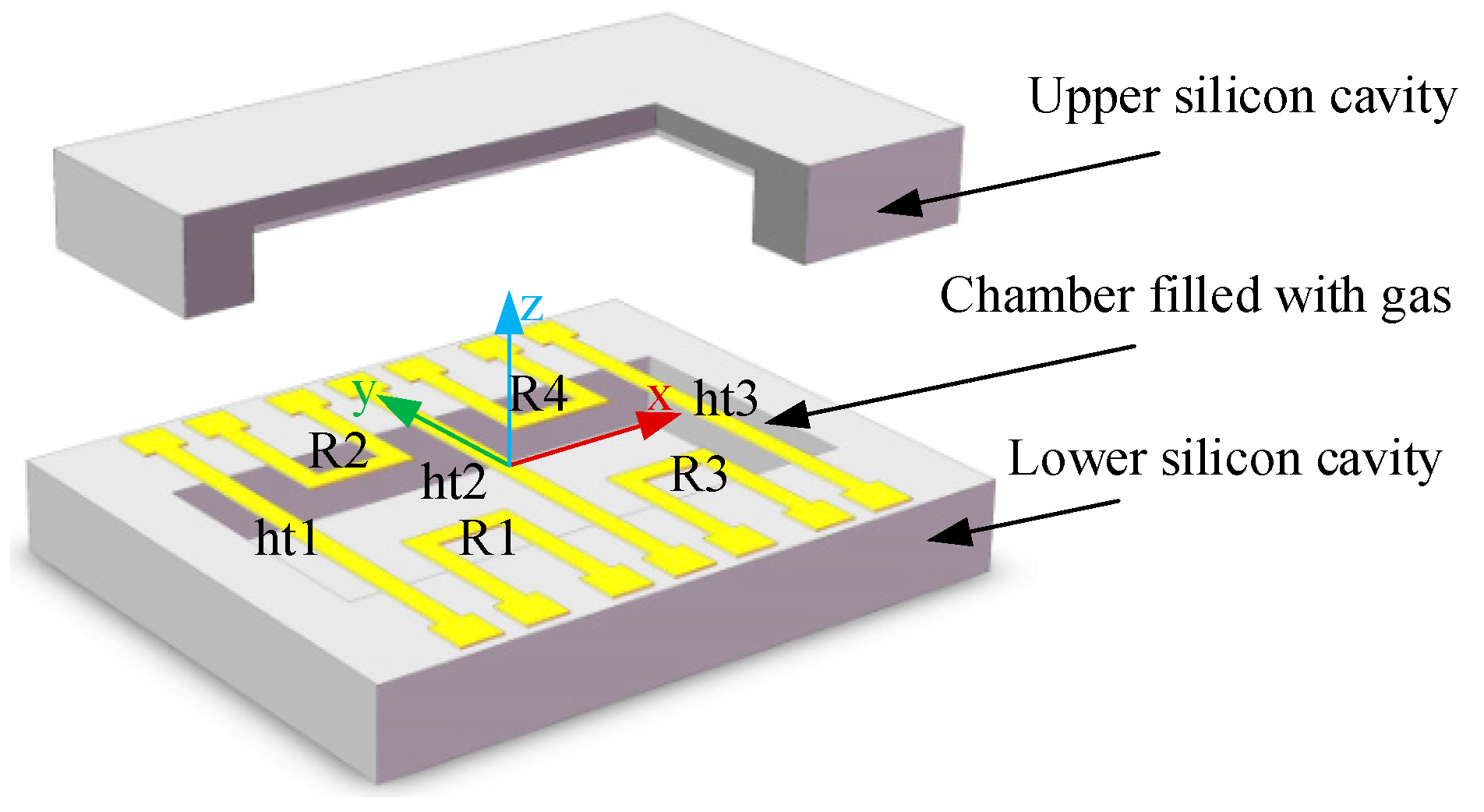

2. Design of Thermal Gas MIMU

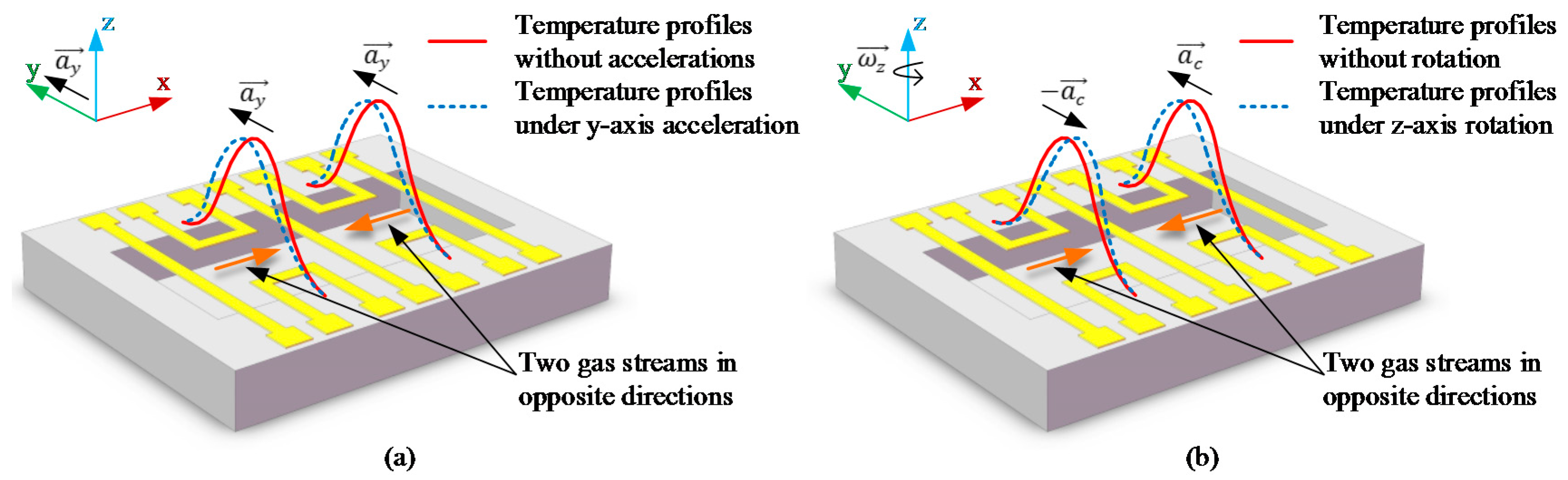

2.1. Thermal Gas Inertial Sensor Used in the Gas MIMU

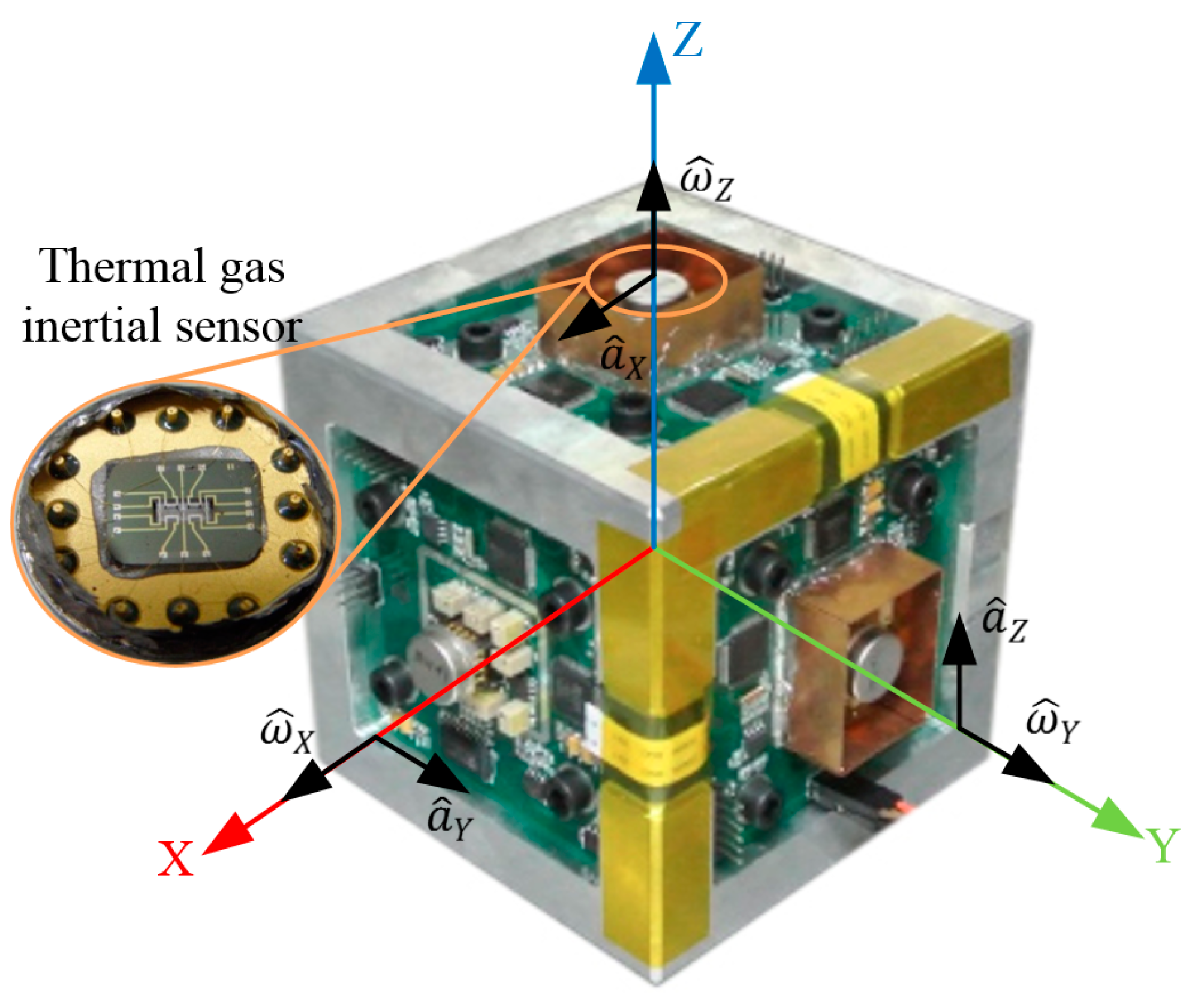

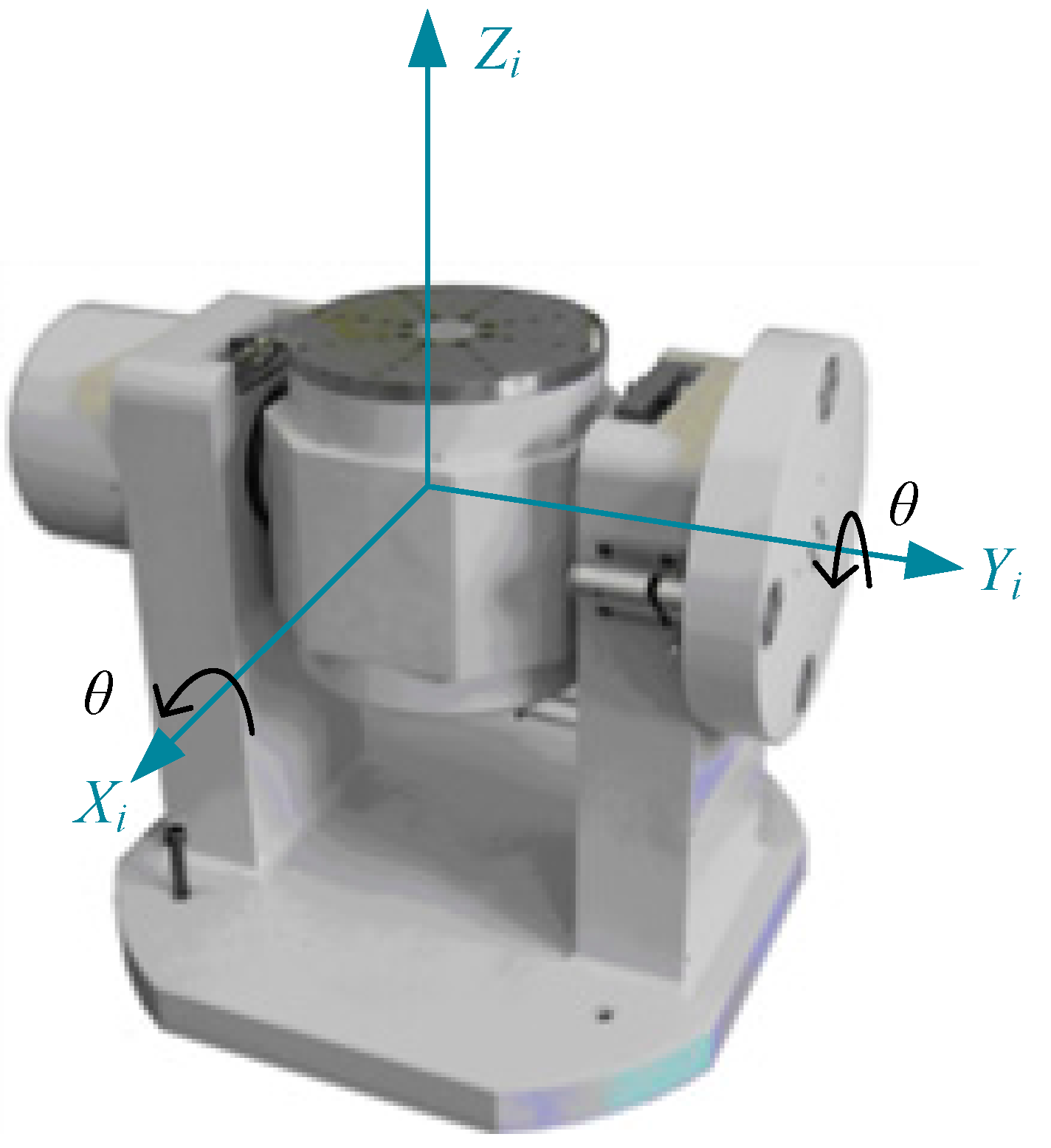

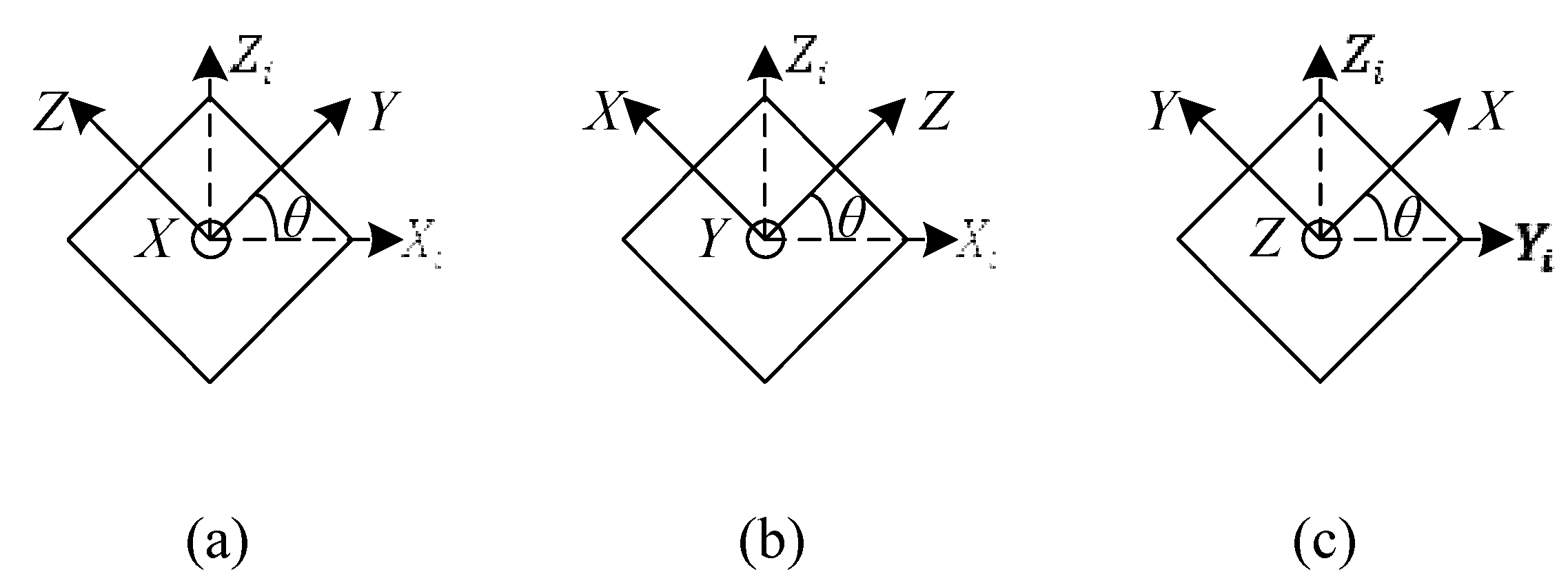

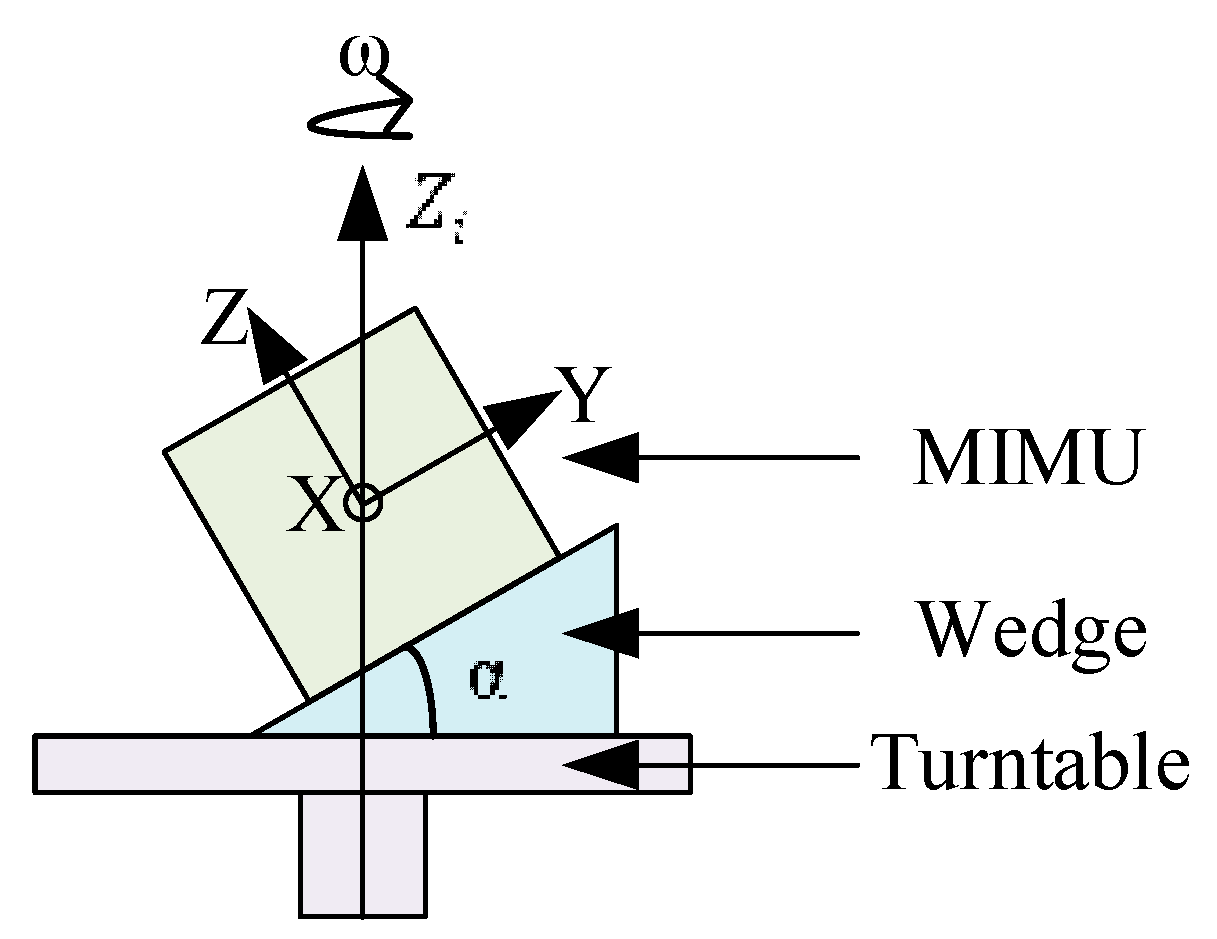

2.2. Design of the Thermal Gas MIMU

3. Error Source Analysis of the MIMU

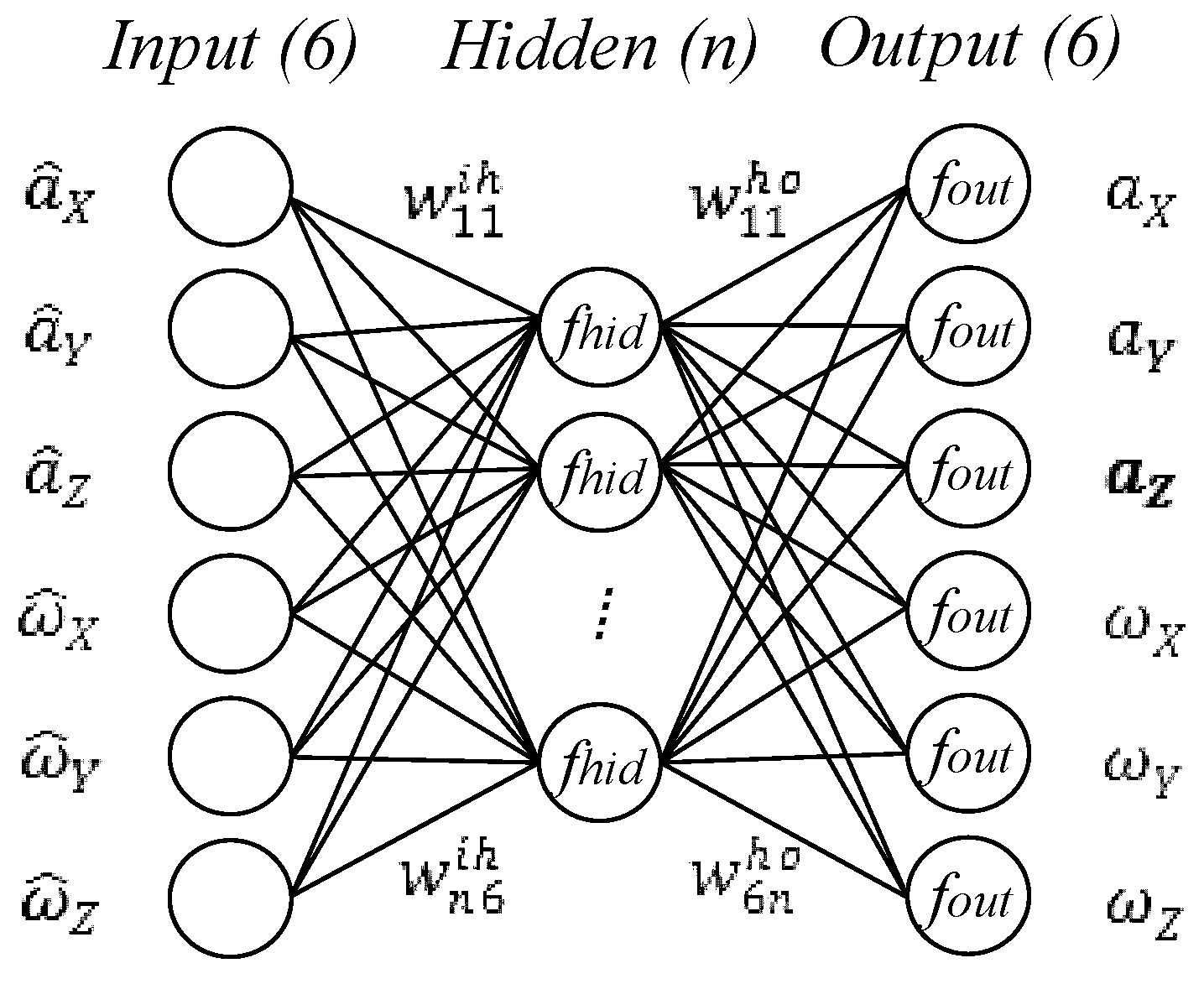

4. Error Compensation Method Based on a BP Neural Network

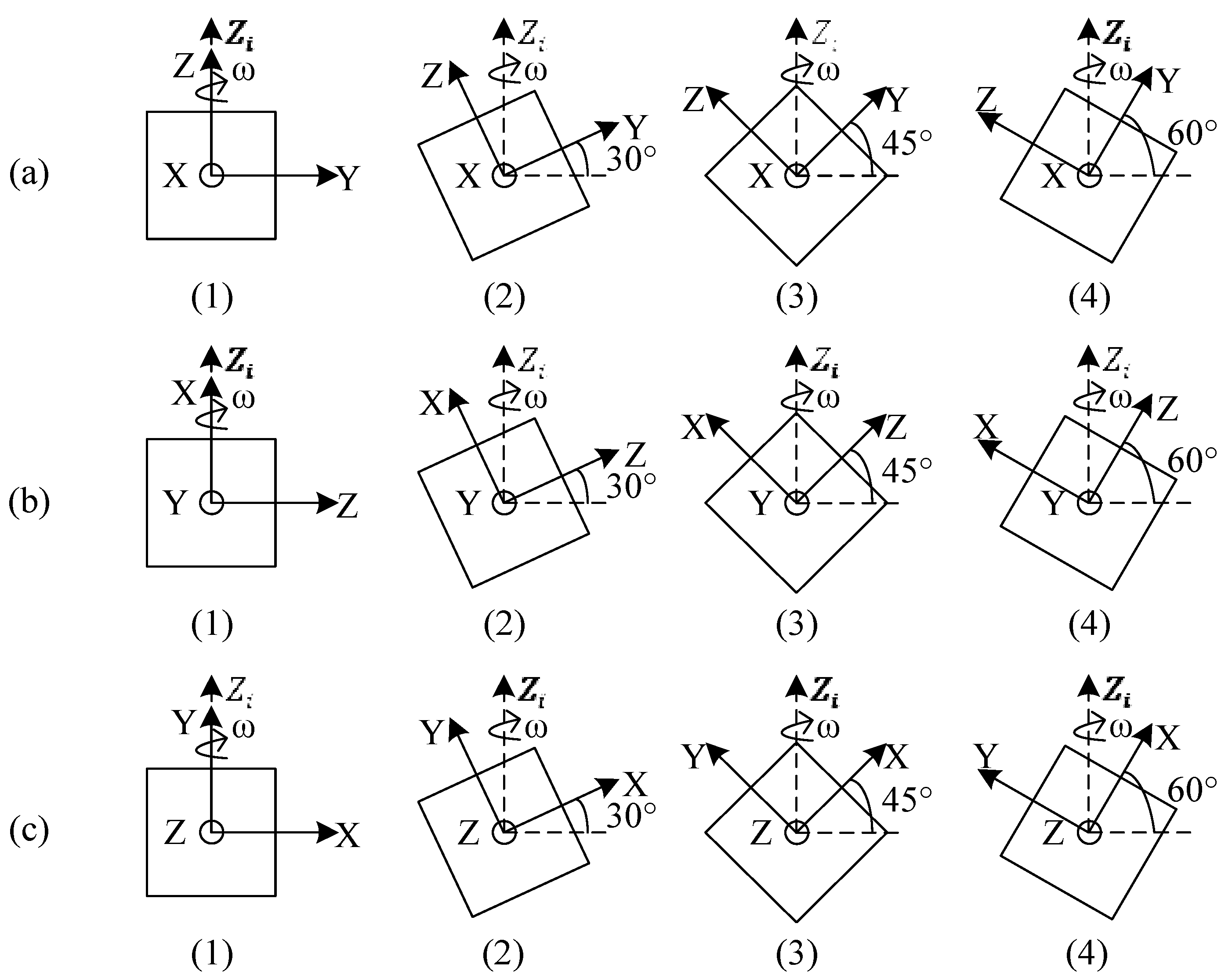

4.1. System Error Modelling

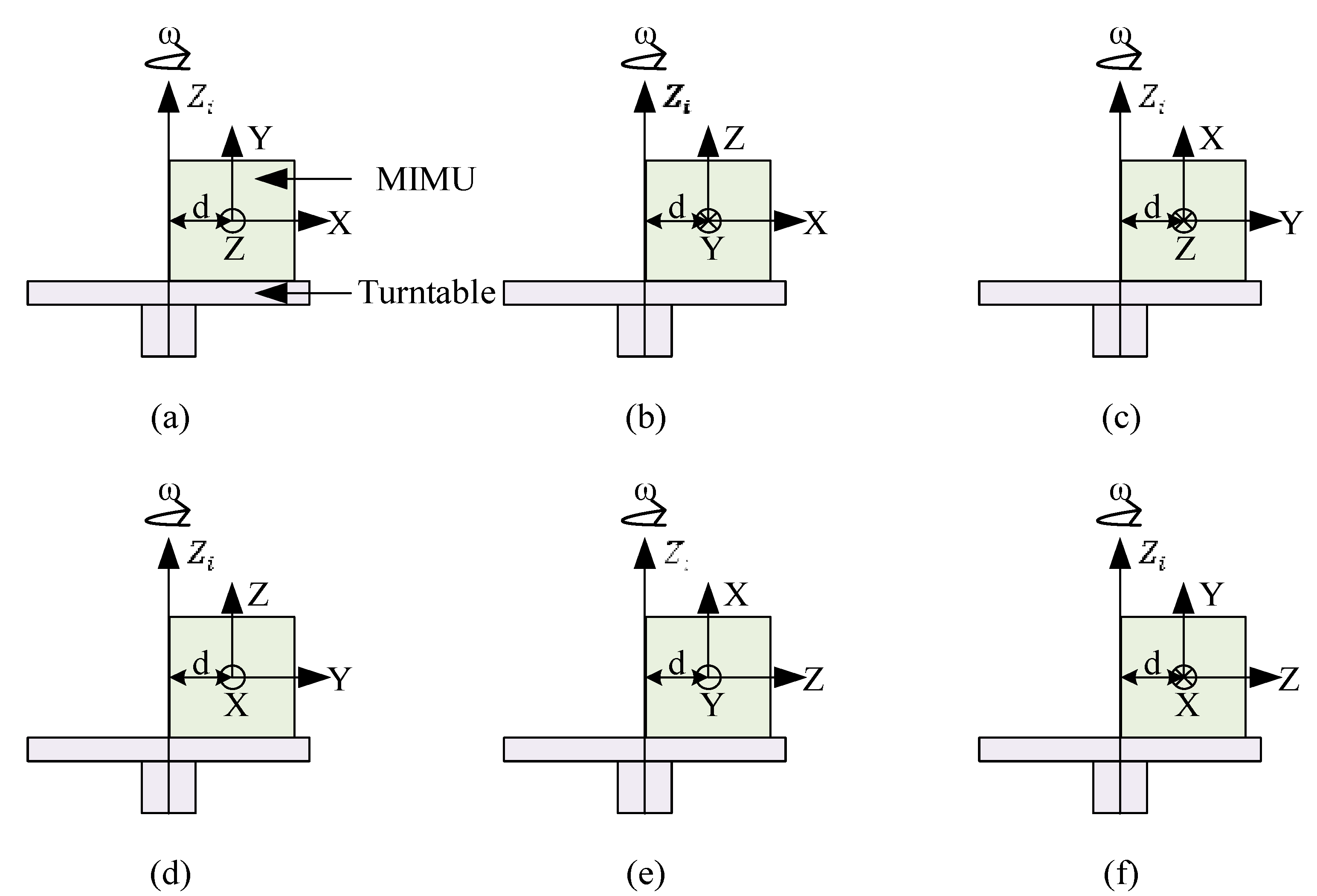

4.2. Calibration Method

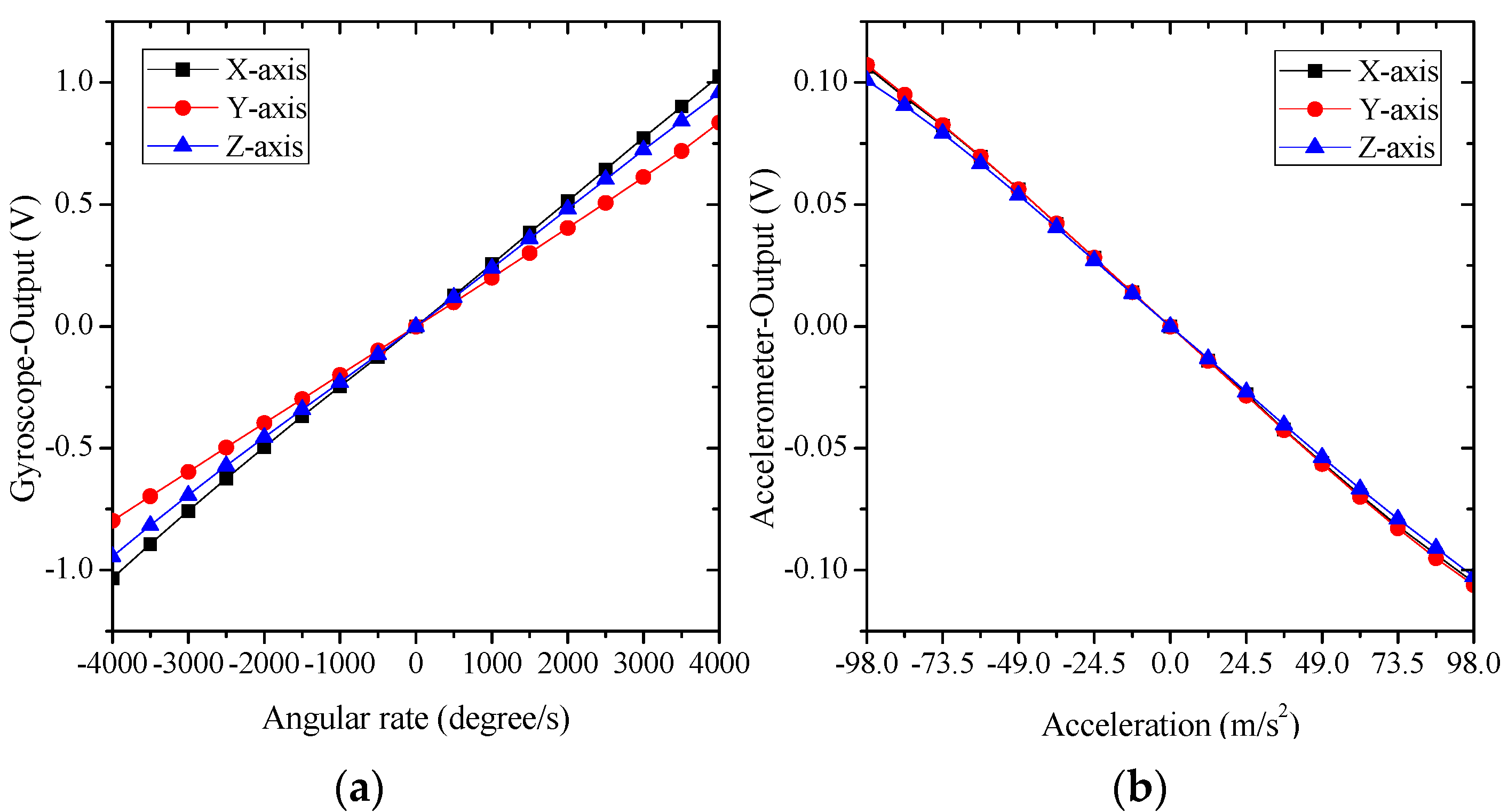

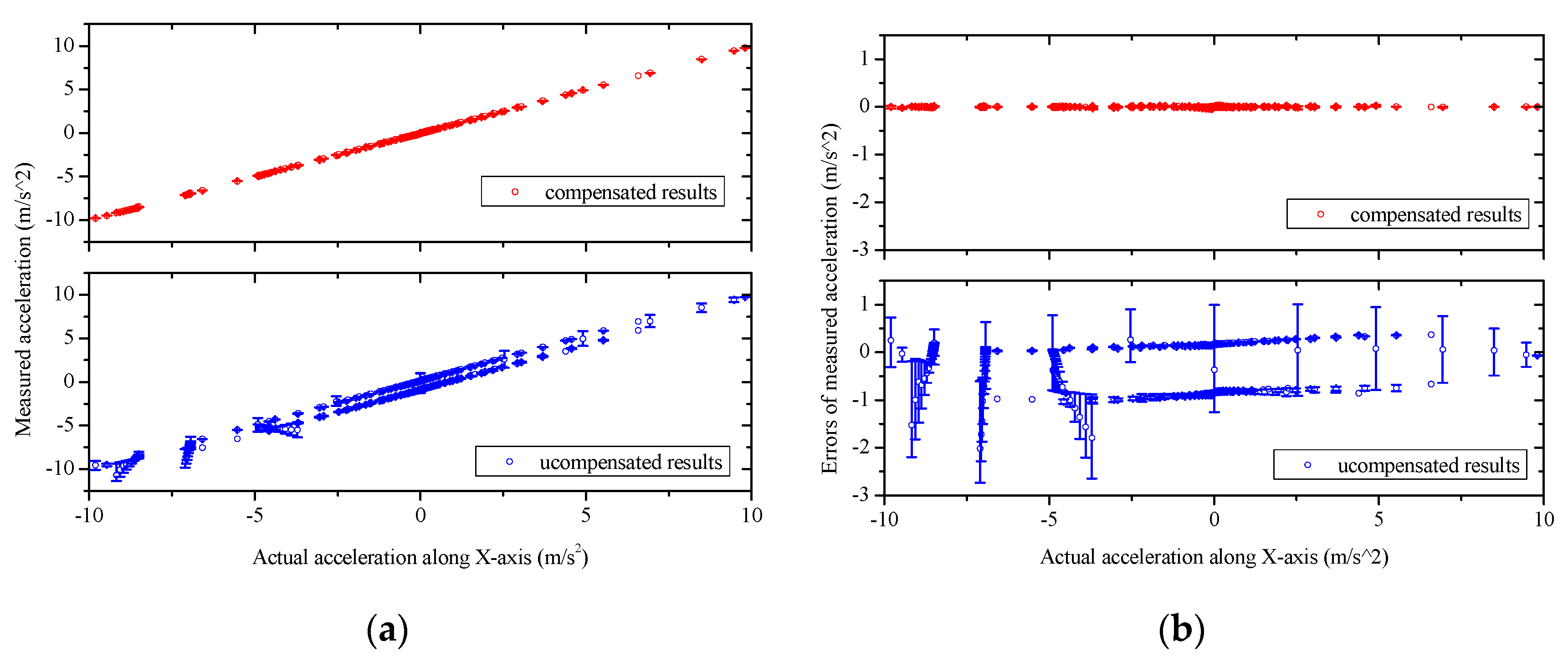

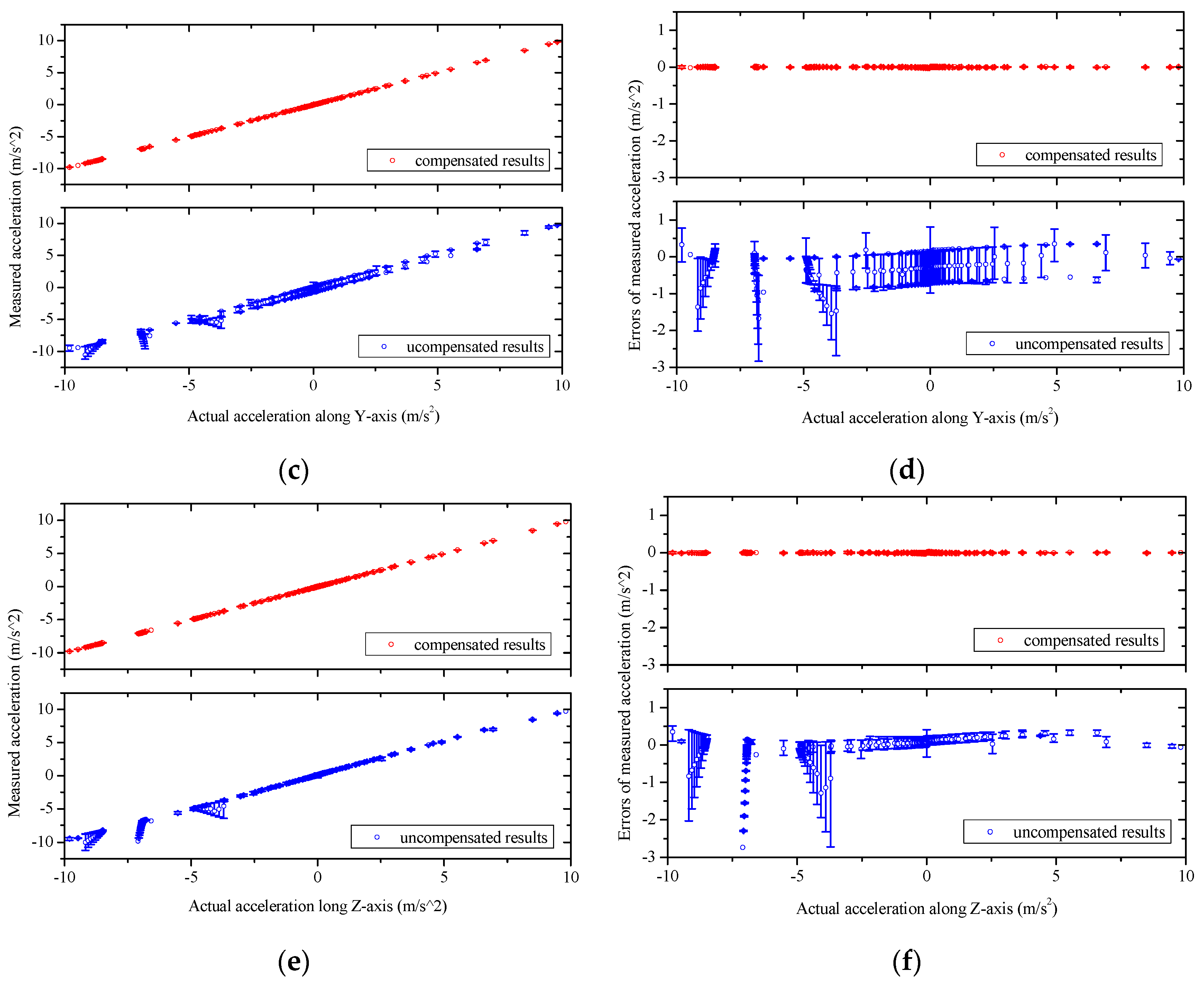

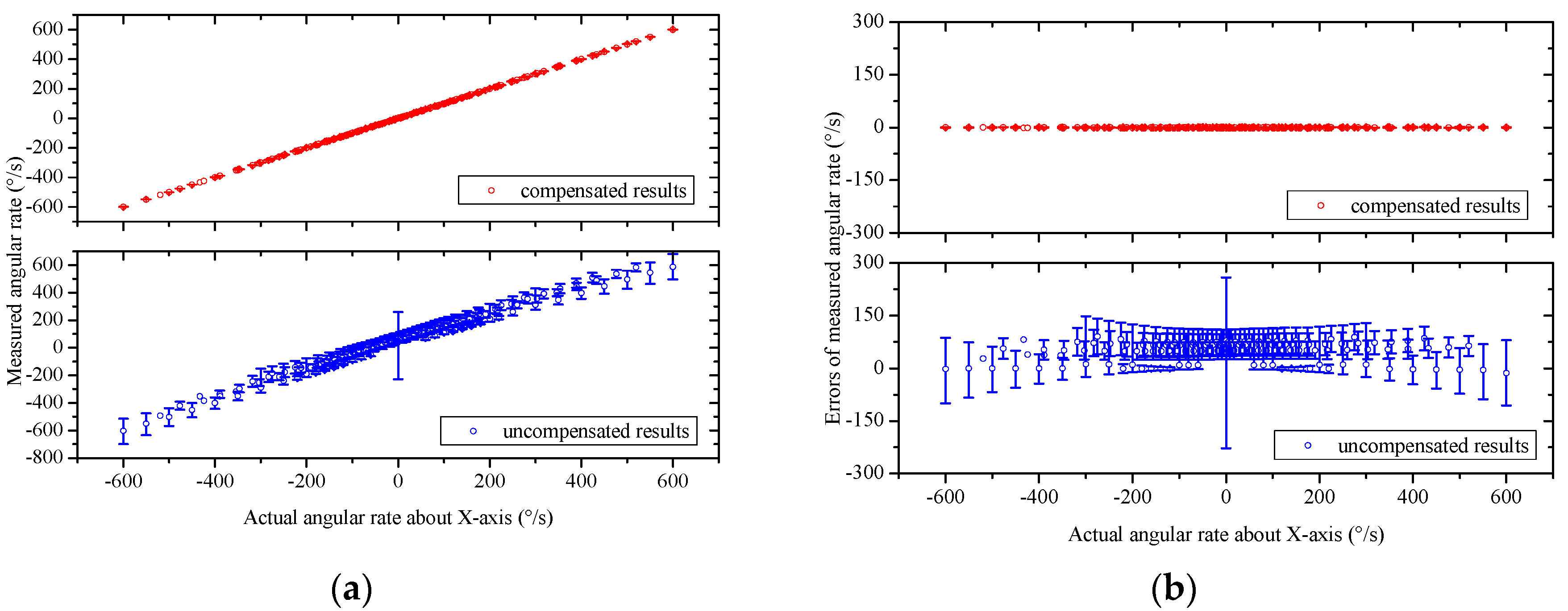

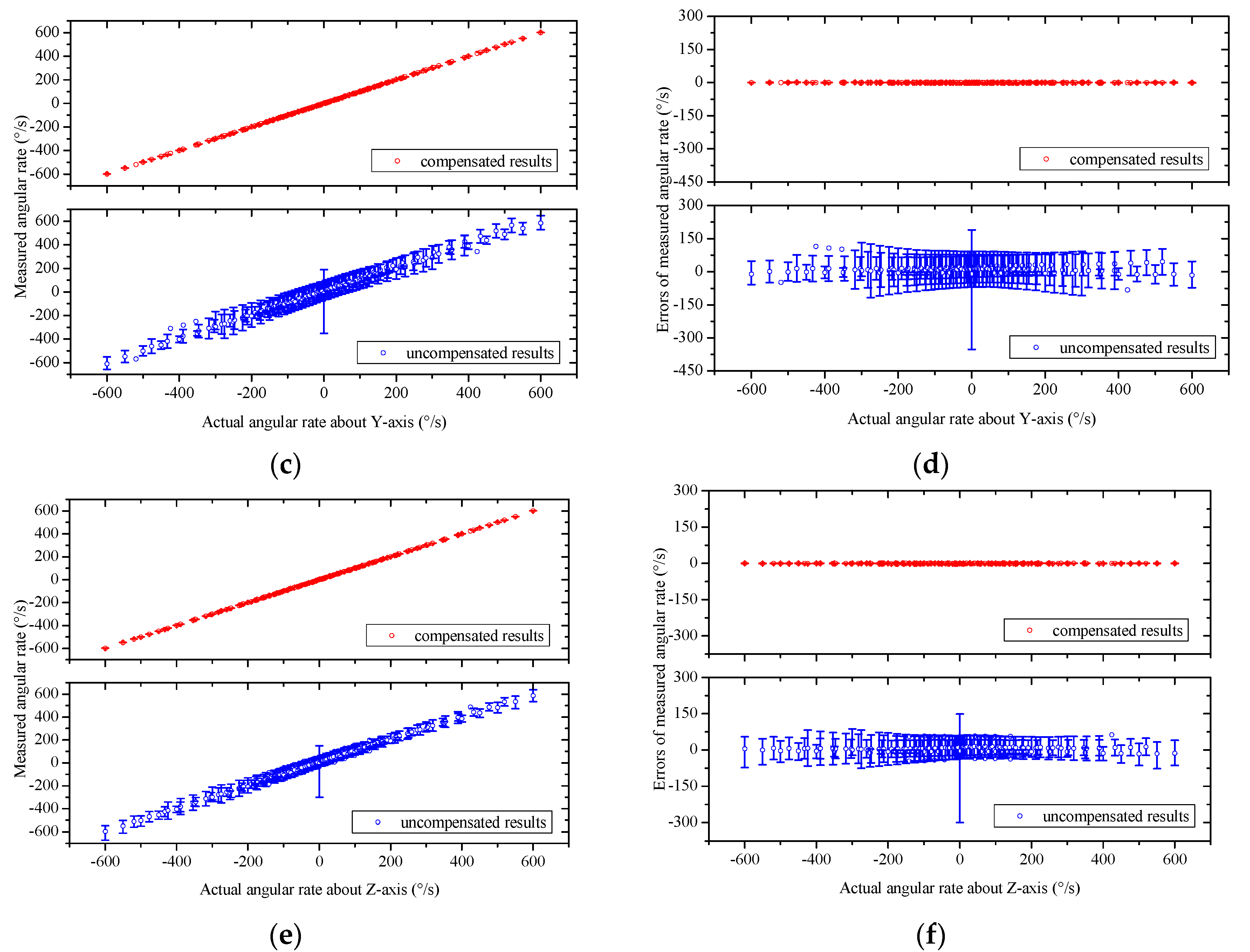

5. Experimental Results and Discussions

| RMS Error | aX (m/s2) | aY (m/s2) | aZ (m/s2) | ωX (°/s) | ωY (°/s) | ωZ (°/s) |

|---|---|---|---|---|---|---|

| Compensated | 0.0100 | 0.0085 | 0.0093 | 0.44 | 0.55 | 0.52 |

| Uncompensated | 0.5784 | 0.5129 | 0.3294 | 88.58 | 87.43 | 62.56 |

| Comp./Uncomp. (%) | 1.73 | 1.66 | 2.83 | 0.50 | 0.63 | 0.84 |

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Barbour, N.; Schmidt, G. Inertial Sensor Technology Trends. IEEE Sens. J. 2001, 1, 332–339. [Google Scholar] [CrossRef]

- Hoflinger, F.; Muller, J.; Zhang, R.; Reindl, L.M.; Burgard, W. A Wireless Micro Inertial Measurement Unit (IMU). IEEE Trans. Instrum. Meas. 2013, 62, 2583–2595. [Google Scholar] [CrossRef]

- Brown, A.K.; Lu, Y. Performance test results of an integrated GPS/MEMS inertial navigation package. In Proceedings of the ION GNSS 2004, Long Beach, CA, USA, 21–24 September 2004; pp. 825–832.

- Hanse, J.G. Honeywell MEMS inertial technology product status. In Proceedings of the Plans 2004 Position Location and Navigation Symposium, Minneapolis, MN, USA, 26–29 April 2004; pp. 43–48.

- Aggarwal, P.; Syed, Z.; Niu, X.; El-Sheimy, N. A standard testing and calibration procedure for low cost MEMS inertial sensors and units. J. Navig. 2008, 61, 323–336. [Google Scholar] [CrossRef]

- Jafari, M.; Najafabadi, T.A.; Moshiri, B.; Tabatabaei, S.S.; Sahebjameyan, M. PEM Stochastic Modeling for MEMS Inertial Sensors in Conventional and Redundant IMUs. IEEE Sens. J. 2014, 14, 2019–2027. [Google Scholar] [CrossRef]

- Naseri, H.; Homaeinezhad, M.R. Improving measurement quality of a MEMS-based gyro-free inertial navigation system. Sens. Actuators A Phys. 2014, 207, 10–19. [Google Scholar] [CrossRef]

- El-Sheimy, N. Inertial Techniques and INS/DGPS Integration. In Engo 623-Course Notes; Department of Geomatics Engineering, University of Calgary: Calgary, AB, Canada, 2006. [Google Scholar]

- Chatfield, A.B. Fundamentals of High Accuracy Inertial Navigation; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1997. [Google Scholar]

- Nieminen, T.; Kangas, J.; Suuriniemi, S.; Kettunen, L. An enhanced multi-position calibration method for consumer-grade inertial measurement units applied and tested. Meas. Sci. Technol. 2010, 21, 1069–1076. [Google Scholar] [CrossRef]

- Zhang, H.L.; Wu, Y.X.; Wu, W.Q.; Wu, M.P.; Hu, X.P. Improved multi-position calibration for inertial measurement units. Meas. Sci. Technol. 2009, 21, 209–213. [Google Scholar] [CrossRef]

- Ma, L.; Chen, W.W.; Li, B.; You, Z.; Chen, Z.G. Fast Field Calibration of MIMU Based on the Powell Algorithm. Sensors 2014, 14, 16062–16081. [Google Scholar] [CrossRef] [PubMed]

- Zhu, R.; Zhou, Z.Y. Calibration of three-dimensional integrated sensors for improved system accuracy. Sens. Actuators A Phys. 2006, 127, 340–344. [Google Scholar] [CrossRef]

- Ayazi, F.; Najafi, K. A Harpss polysilicon vibrating ring gyroscope. J. Microelectromechan. Syst. 2001, 10, 169–179. [Google Scholar] [CrossRef]

- Bernstein, J.; Cho, S.; King, A.T.; Kourepenis, A.; Maciel, P.; Weinberg, M. A micromachined comb-drive tuning fork rate gyroscope. In Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS), Cambridge, MA, USA, 7–10 February 1993; pp. 143–148.

- Maenaka, K.; Shiozawa, T. A study of silicon angular rate sensors using anisotropic etching technology. Sens. Actuators A Phys. 1994, 43, 72–77. [Google Scholar] [CrossRef]

- Dao, D.V.; Dau, V.T.; Dinh, T.X.; Sugiyama, S. A fully integrated MEMS-based convective 3-DOF gyroscope. In Proceedings of the International Transducers 2007 Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 1211–1214.

- Dau, V.T.; Tomonori, O.; Dinh, T.X.; Dao, D.V.; Sugiyama, S. A multi axis fluidic inertial sensor. In Proceedings of the 2008 IEEE Sensors, Lecce, Italy, 26–29 October 2008; pp. 666–669.

- Bahari, J.; Feng, R.; Leung, A.M. Robust MEMS Gyroscope Based on Thermal Principles. J. Microelectromech. Syst. 2014, 23, 100–116. [Google Scholar] [CrossRef]

- Garraud, A.; Combette, P.; Gosalbes, J.M.; Charlot, B.; Giani, A. First high-g measurement by thermal accelerometers. In Proceedings of the 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5 June 2011; pp. 84–87.

- Feng, R.; Bahari, J.; Jones, J.D.; Leung, A.M. MEMS thermal gyroscope with self-compensation of the linear acceleration effect. Sens. Actuators A Phys. 2013, 203, 413–420. [Google Scholar] [CrossRef]

- Garraud, A.; Giani, A.; Combette, P.; Charlot, B.; Richard, M. A dual axis CMOS micromachined convective thermal accelerometer. Sens. Actuators A Phys. 2011, 170, 44–50. [Google Scholar] [CrossRef]

- Zhu, R.; Cai, S.L.; Ding, H.G.; Yang, Y.J.; Su, Y. A micromachined gas inertial sensor based on thermal expansion. Sens. Actuators A Phys. 2014, 212, 173–180. [Google Scholar] [CrossRef]

- Zhu, R.; Ding, H.G.; Su, Y.; Zhou, Z.Y. Micromachined gas inertial sensor based on convection heat transfer. Sens. Actuators A Phys. 2006, 130, 68–74. [Google Scholar] [CrossRef]

- Cai, S.L.; Zhu, R.; Ding, H.G.; Yang, Y.J.; Su, Y. A micromachined integrated gyroscope and accelerometer based on gas thermal expansion. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII, Barcelona, Spain, 16–20 June 2013; pp. 50–53.

- Lau, C. Neural Networks: Theoretical Foundations and Analysis; IEEE Press: Piscataway, NJ, USA, 1991. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.Q.; Zhu, R. System Error Compensation Methodology Based on a Neural Network for a Micromachined Inertial Measurement Unit. Sensors 2016, 16, 175. https://doi.org/10.3390/s16020175

Liu SQ, Zhu R. System Error Compensation Methodology Based on a Neural Network for a Micromachined Inertial Measurement Unit. Sensors. 2016; 16(2):175. https://doi.org/10.3390/s16020175

Chicago/Turabian StyleLiu, Shi Qiang, and Rong Zhu. 2016. "System Error Compensation Methodology Based on a Neural Network for a Micromachined Inertial Measurement Unit" Sensors 16, no. 2: 175. https://doi.org/10.3390/s16020175