A Photonic Crystal Magnetic Field Sensor Using a Shoulder-Coupled Resonant Cavity Infiltrated with Magnetic Fluid

Abstract

:1. Introduction

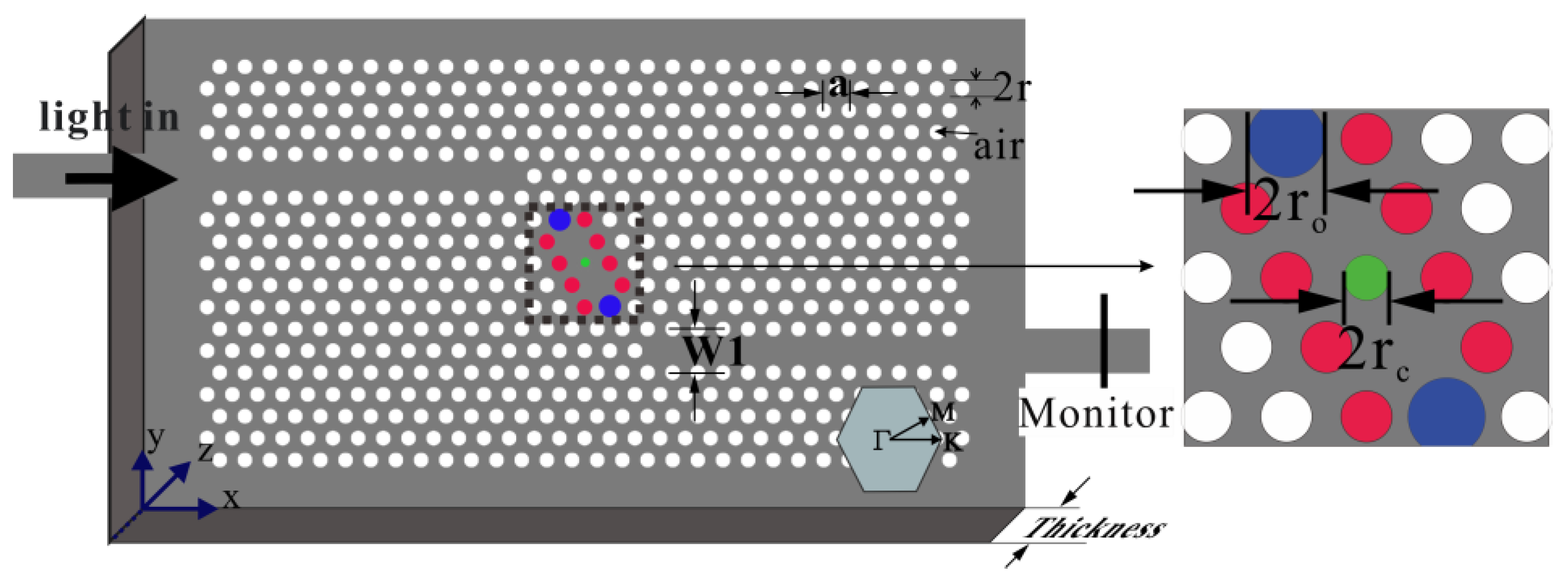

2. Device Configuration and Sensing Principle

2.1. Device Configuration

2.2. Sensing Principle

3. Modeling Methodology and Structure Optimization

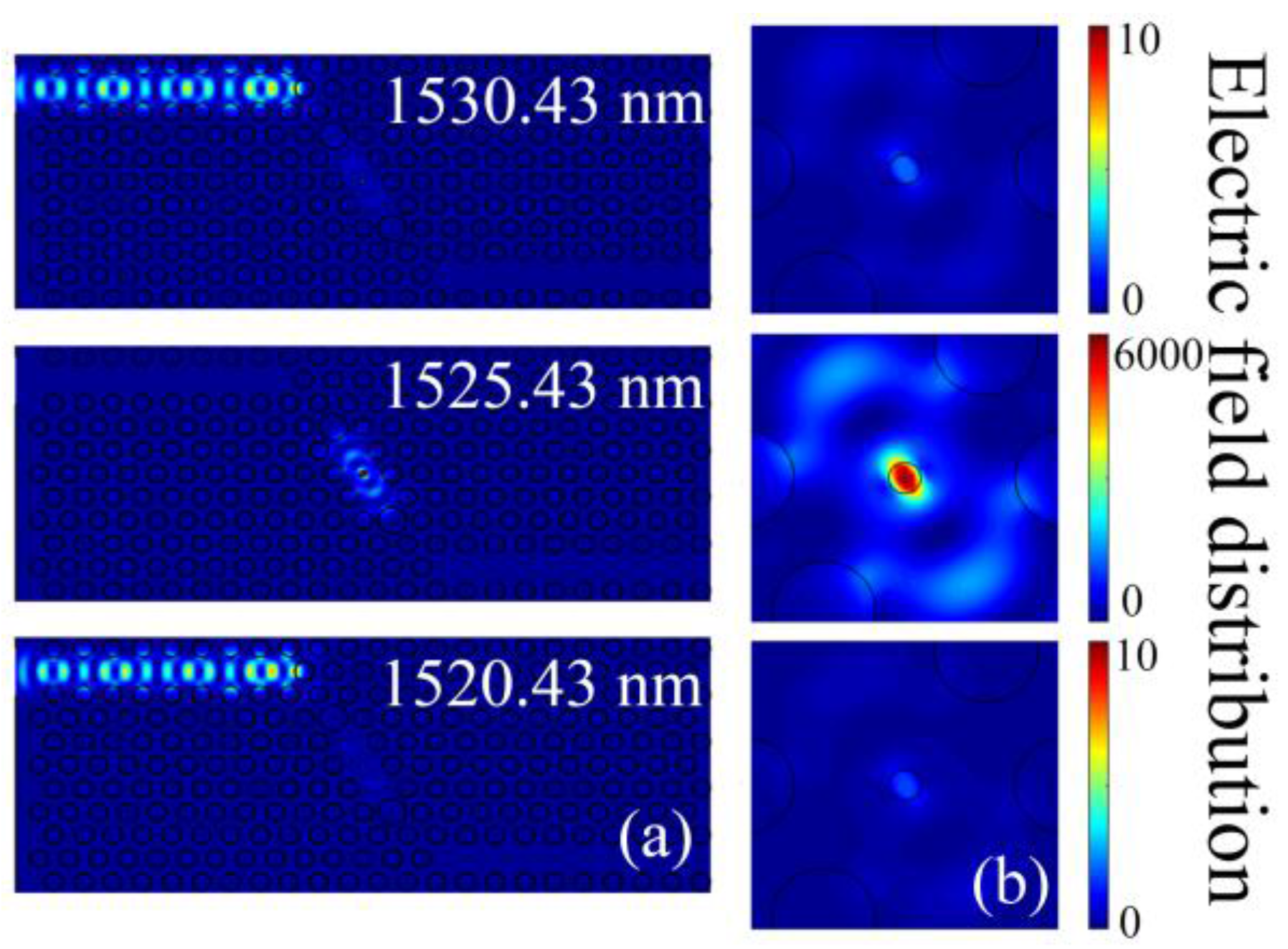

3.1. Modeling Methodology

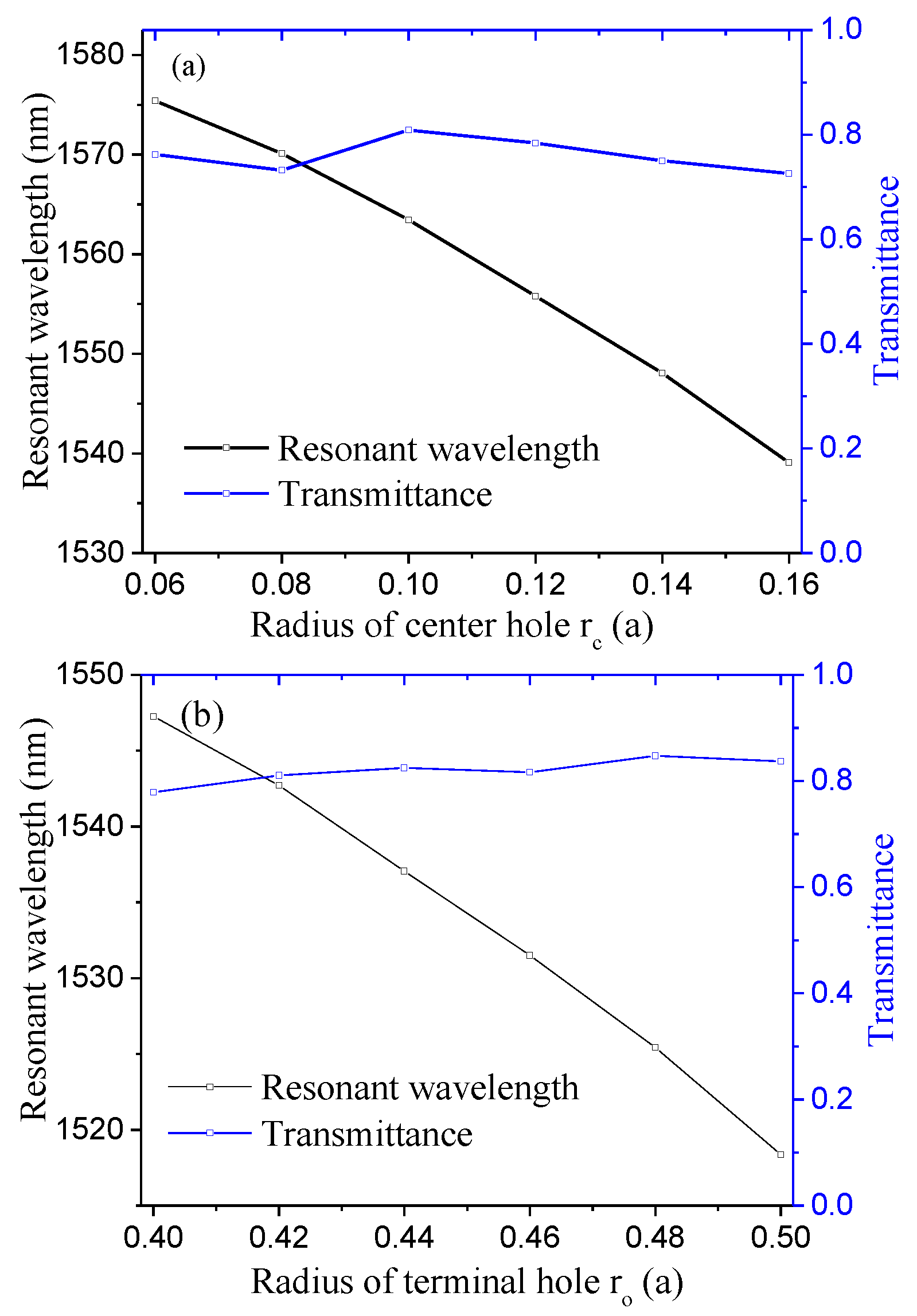

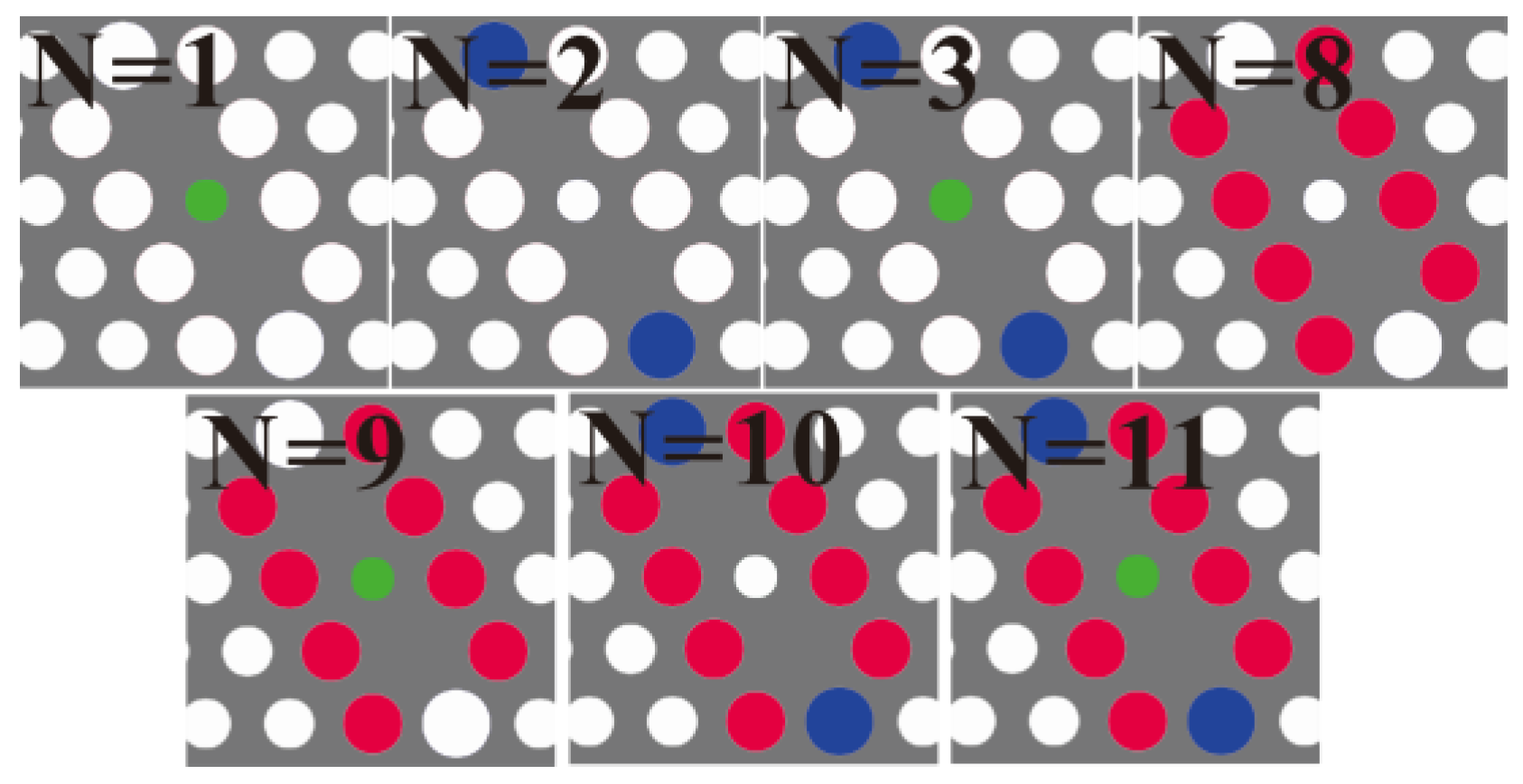

3.2. Optimization of Shoulder-Coupled Cavity

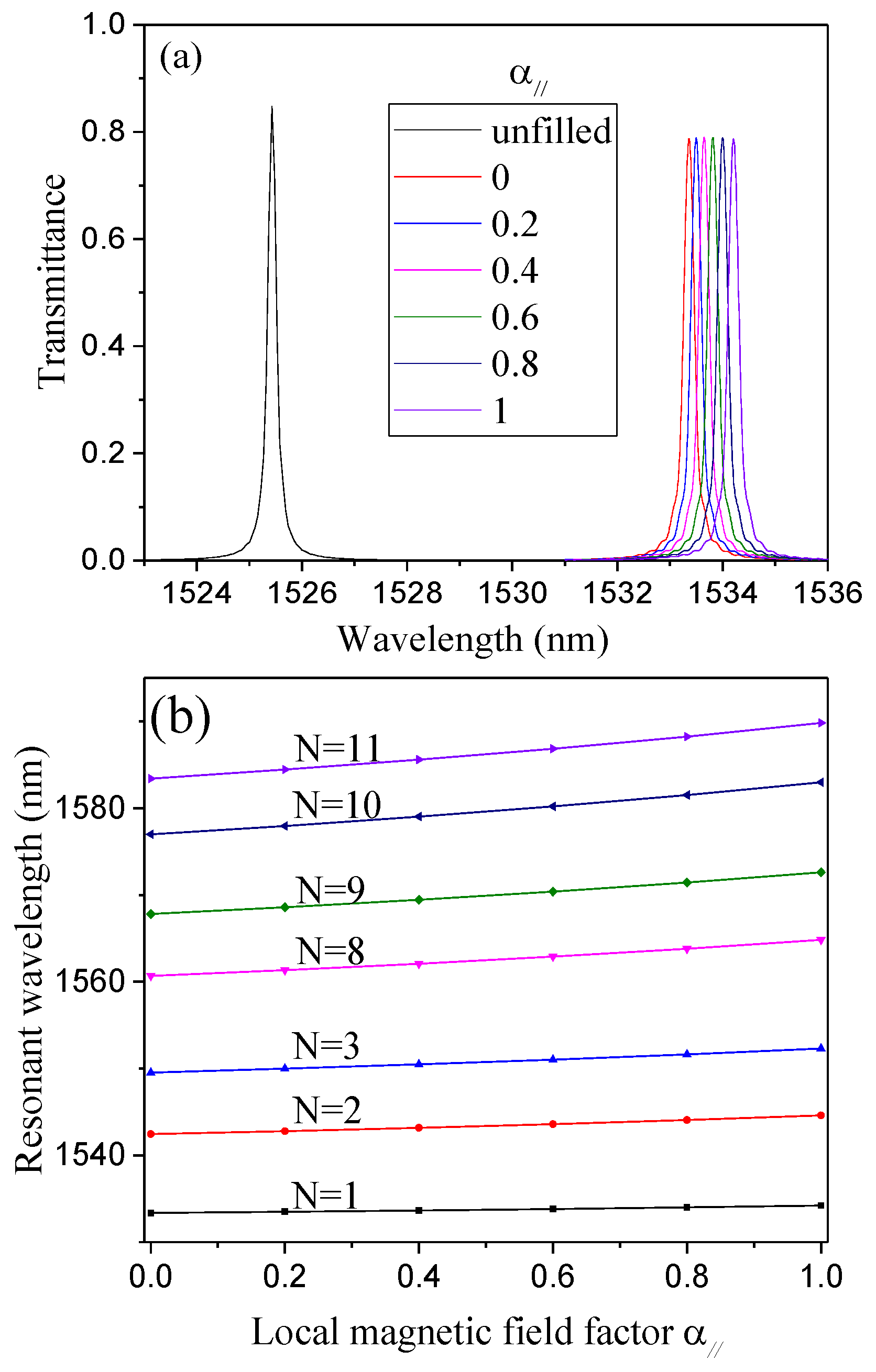

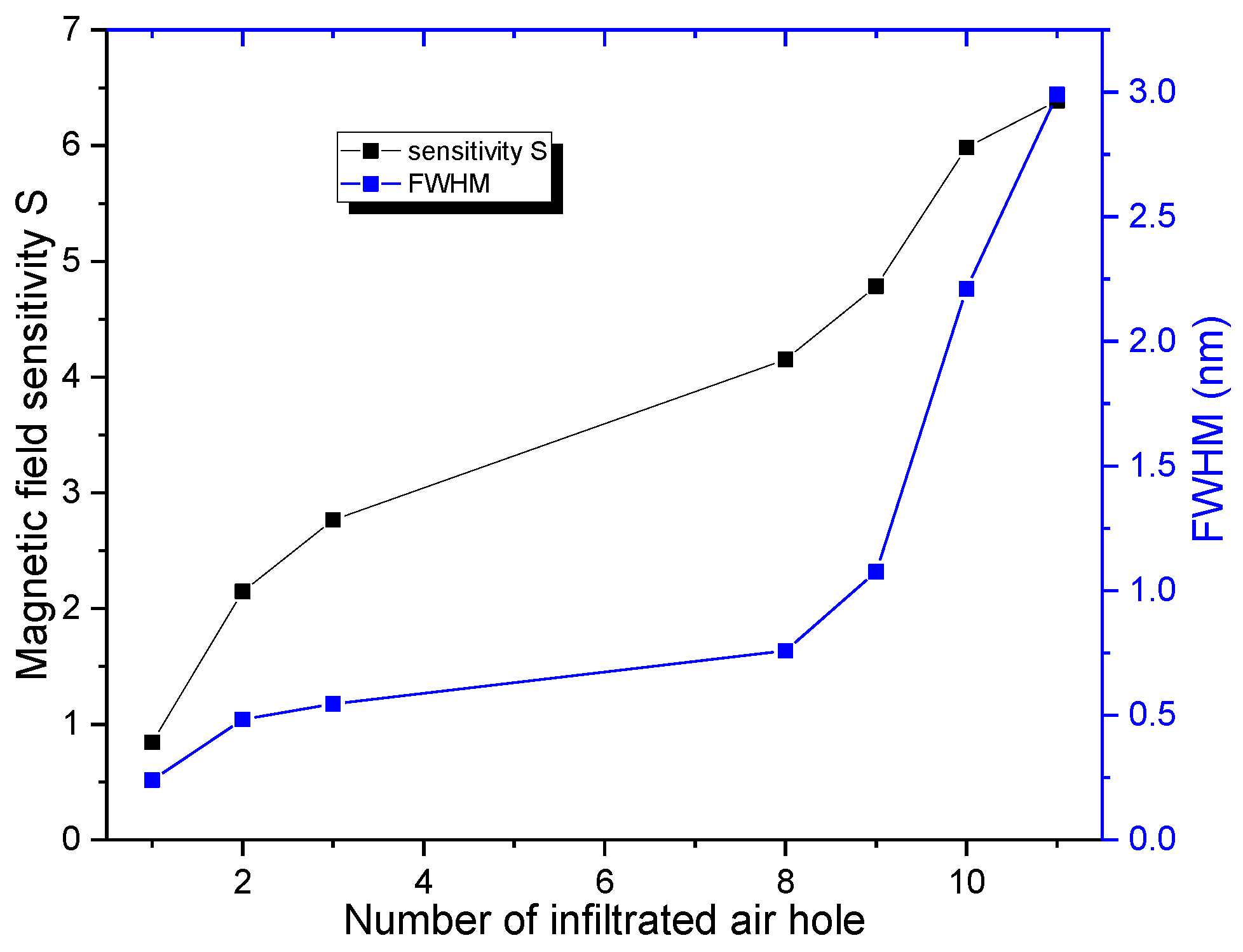

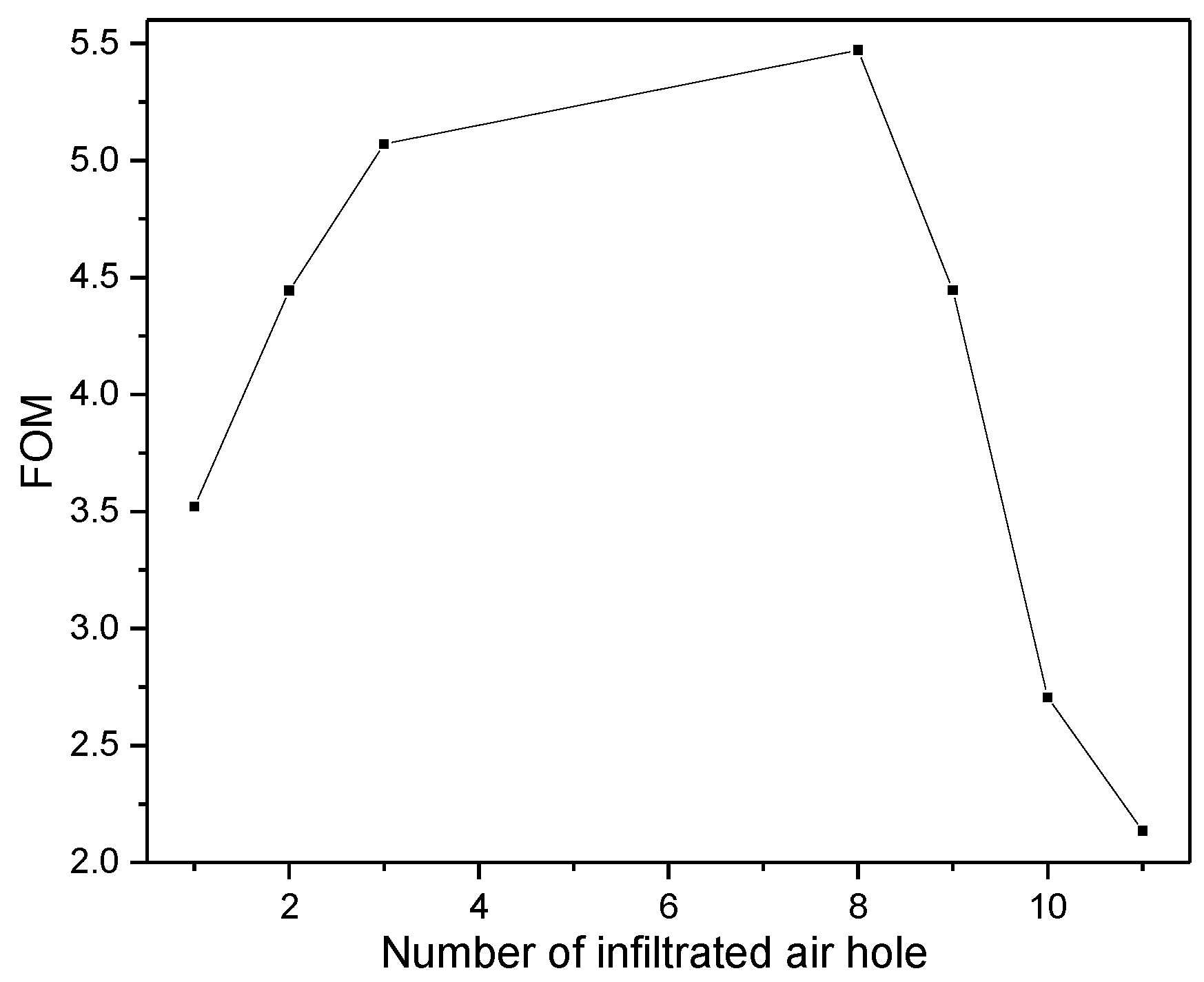

4. Sensing Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rosensweig, R.E. Ferrohydrodynamics; Cambridge University Press: New York, NY, USA, 1985. [Google Scholar]

- Chen, Y.F.; Yang, S.; Tse, W.S.; Horng, H.E.; Hong, C.-Y.; Yang, H.C. Thermal effect on the field-dependent refractive index of the magnetic fluid film. Appl. Phys. Lett. 2003, 82, 3481–3483. [Google Scholar] [CrossRef]

- Fan, F.; Chen, S.; Lin, W.; Miao, Y.; Chang, S.-J.; Liu, B.; Wang, X.; Lin, L. Magnetically tunable terahertz magnetoplasmons in ferrofluid-filled photonic crystals. Appl. Phys. Lett. 2013, 103, 161115. [Google Scholar] [CrossRef]

- Chen, S.; Fan, F.; Chang, S.; Miao, Y.; Chen, M.; Li, J.; Wang, X.; Lin, L. Tunable optical and magneto-optical properties of ferrofluid in the terahertz regime. Opt. Express 2014, 22, 6313–6321. [Google Scholar] [CrossRef] [PubMed]

- Brojabasi, S.; Muthukumaran, T.; Laskar, J.M.; Philip, J. The effect of suspended Fe3O4 nanoparticle size on magneto-optical properties of ferrofluids. Opt. Commun. 2015, 336, 278–285. [Google Scholar] [CrossRef]

- Hong, C.-Y. Optical switch devices using the magnetic fluid thin films. J. Magn. Magn. Mater. 1999, 201, 178–181. [Google Scholar] [CrossRef]

- Horng, H.E.; Chen, C.S.; Fang, K.L.; Yang, S.Y.; Chieh, J.J.; Hong, C.-Y.; Yang, H.C. Tunable optical switch using magnetic fluid. Appl. Phys. Lett. 2004, 85, 5592. [Google Scholar] [CrossRef]

- Seo, J.-W.; Kim, H.; Sung, S. Design and fabrication of a magnetic microfluidic light modulator using magnetic fluid. J. Magn. Magn. Mater. 2004, 272–276, E1787–E1789. [Google Scholar] [CrossRef]

- Huang, Y.-W.; Hu, S.-T.; Yang, S.-Y.; Horng, H.-E.; Hung, J.-C.; Hong, C.-Y.; Yang, H.-C.; Chao, C.-H.; Lin, C.-F. Tunable diffraction of magnetic fluid films and its potential application in coarse wavelength-division multiplexing. Opt. Lett. 2004, 29, 1867–1869. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Han, Q.; Liu, T. All-fiber optical modulator based on no-core fiber and magnetic fluid as cladding. Chin. Phys. B 2015, 24, 014214. [Google Scholar] [CrossRef]

- Candiani, A.; Argyros, A.; Leon-Saval, S.G.; Lwin, R.; Selleri, S.; Pissadakis, S. A loss-based, magnetic field sensor implemented in a ferrofluid infiltrated microstructured polymer optical fiber. Appl. Phys. Lett. 2014, 104, 111106. [Google Scholar] [CrossRef]

- Wu, J.; Miao, Y.; Song, B.; Lin, W.; Zhang, H.; Zhang, K.; Liu, B.; Yao, J. Low temperature sensitive intensity-interrogated magnetic field sensor based on modal interference in thin-core fiber and magnetic fluid. Appl. Phys. Lett. 2014, 104, 252402. [Google Scholar] [CrossRef]

- Layeghi, A.; Latifi, H.; Frazão, O. Magnetic field sensor based on non-adiabatic tapered optical fiber with magnetic fluid. IEEE Photonics Technol. Lett. 2014, 26, 1904–1907. [Google Scholar] [CrossRef]

- Pu, S.; Chen, X.; Chen, L.; Liao, W. Tunable magnetic fluid grating by applying a magnetic field. Appl. Phys. Lett. 2005, 87, 021901. [Google Scholar] [CrossRef]

- Zu, P.; Chan, C.C.; Lew, W.S.; Jin, Y.; Zhang, Y.; Liew, H.F.; Chen, L.H.; Wong, W.C.; Dong, X. Magneto-optical fiber sensor based on magnetic fluid. Opt. Lett. 2012, 37, 398–400. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.; Jiang, Y.; Abdelaziz, S. All-fiber magnetic field sensors based on magnetic fluid-filled photonic crystal fibers. Opt. Lett. 2013, 38, 1539–1541. [Google Scholar] [CrossRef] [PubMed]

- Thakur, H.V.; Nalawade, S.M.; Gupta, S.; Kitture, R.; Kale, S.N. Photonic crystal fiber injected with Fe3O4 nanofluid for magnetic field detection. Appl. Phys. Lett. 2011, 99, 161101. [Google Scholar] [CrossRef]

- Wang, H.; Pu, S.; Wang, N.; Dong, S.; Huang, J. Magnetic field sensing based on singlemode–multimode–singlemode fiber structures using magnetic fluids as cladding. Opt. Lett. 2013, 38, 3765–3768. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Fan, F.; He, X.; Chen, M.; Chang, S. Multifunctional magneto-metasurface for terahertz one-way transmission and magnetic field sensing. Appl. Opt. 2015, 54, 9177–9182. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Du, L.; Xu, Z.; Jiang, Y.; Xu, J.; Wang, M.; Bai, Y.; Wang, H. Magnetic field sensing based on tilted fiber Bragg grating coated with nanoparticle magnetic fluid. Appl. Phys. Lett. 2014, 104, 061903. [Google Scholar] [CrossRef]

- Liu, Z.J.; Yu, Y.S.; Zhang, X.Y.; Chen, C.; Zhu, C.C.; Meng, A.H.; Jing, S.M.; Sun, H.B. An optical microfiber taper magnetic field sensor with temperature compensation. IEEE Sens. J. 2015, 15, 4853–4856. [Google Scholar] [CrossRef]

- Luo, L.; Pu, S.; Tang, J.; Zeng, X.; Lahoubi, M. Highly sensitive magnetic field sensor based on microfiber coupler with magnetic fluid. Appl. Phys. Lett. 2015, 106, 193507. [Google Scholar] [CrossRef]

- Joannopoulos, J.D.; Johnson, S.G.; Winn, J.N. Photonic Crystals: Molding the Flow of Light; Princeton University Press: Princeton, NJ, USA, 2008. [Google Scholar]

- Inoue, M.; Levy, M.; Baryshev, A.V. Magnetophotonics: From Theory to Applications; Springer: Berlin, Germany, 2013. [Google Scholar]

- Baba, T. Slow light in photonic crystals. Nat. Photonics 2008, 2, 465–473. [Google Scholar] [CrossRef]

- Hao, R.; Peng, X.-L.; Li, E.-P.; Xu, Y.; Jin, J.-M.; Zhang, X.-M.; Chen, H.-S. Improved slow light capacity in graphene-based waveguide. Sci. Rep. 2015, 5, 15335. [Google Scholar] [CrossRef] [PubMed]

- Pu, S.; Dong, S.; Huang, J. Tunable slow light based on magnetic-fluid-infiltrated photonic crystal waveguides. J. Opt. 2014, 16, 045102. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.-N.; Wang, Q.; Hu, H. Review on the optimization methods of slow light in photonic crystal waveguide. IEEE Trans. Nanotechnol. 2015, 14, 407–426. [Google Scholar] [CrossRef]

- Han, Z.; Checoury, X.; Haret, L.D.; Boucaud, P. High quality factor in a two-dimensional photonic crystal cavity on silicon-on-insulator. Opt. Lett. 2011, 36, 1749–1751. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.T.; Zhou, Y.S.; Wang, F.H.; Gu, B.Y. Theory of ultra-narrow bandwidth optical filter consisting of anomalous dispersion photonic crystal. Acta Phys. Sin. 2004, 53, 3336–3340. [Google Scholar]

- Rao, W.; Song, Y.; Liu, M.; Jin, C. All-optical switch based on photonic crystal microcavity with multi-resonant modes. Optik 2010, 121, 1934–1936. [Google Scholar] [CrossRef]

- Song, Y.; Liu, M.; Zhang, Y.; Wang, X.; Jin, C. High-Q photonic crystal slab nanocavity with an asymmetric nanohole in the center for QED. J. Opt. Soc. Am. B 2011, 28, 265–274. [Google Scholar] [CrossRef]

- Yang, D.; Tian, H.; Ji, Y. Nanoscale photonic crystal sensor arrays on monolithic substrates using side-coupled resonant cavity arrays. Opt. Express 2011, 19, 20023–20034. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Tian, H.; Yang, D.; Wu, N.; Zhou, J.; Liu, Q.; Ji, Y. Nanomechanical three dimensional force photonic crystal sensor using shoulder-coupled resonant cavity with an inserted pillar. Sens. Actuators A Phys. 2014, 209, 33–40. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.-N.; Wang, Q. Research advances of photonic crystal gas and liquid sensors. Sens. Actuators B Chem. 2011, 160, 1288–1297. [Google Scholar] [CrossRef]

- Yang, D.; Tian, H.; Wu, N.; Yang, Y.; Ji, Y. Nanoscale torsion-free photonic crystal pressure sensor with ultra-high sensitivity based on side coupled piston-type microcavity. Sens. Actuators A Phys. 2013, 199, 30–36. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.-N.; Lv, R.-Q. Simultaneous measurement of magnetic field and temperature based on magnetic fluid-infiltrated photonic crystal cavity. IEEE Trans. Instrum. Meas. 2015, 64, 1055–1062. [Google Scholar] [CrossRef]

- Kim, G.-H.; Lee, Y.-H.; Shinya, A.; Notomi, M. Coupling of small, low-loss hexapole mode with photonic crystal slab waveguide mode. Opt. Express 2004, 12, 6624–6631. [Google Scholar] [CrossRef] [PubMed]

- Fan, C.Z.; Wang, G.; Huang, J.P. Magnetocontrollable photonic crystals based on colloidal ferrofluids. J. Appl. Phys. 2008, 103, 094107. [Google Scholar] [CrossRef]

- Huang, J.P.; Yu, K.W. Enhanced nonlinear optical responses of materials: Composite effects. Phys. Rep. 2006, 431, 87–172. [Google Scholar] [CrossRef]

- Fan, C.Z.; Huang, J.P. Second-harmonic generation with magnetic-field controllabilities. Appl. Phys. Lett. 2006, 89, 141906. [Google Scholar] [CrossRef]

- Taflove, A.; Hagness, S.C. Computational Electrodynamics: The Finite-Difference Time-Domain Method; Artech House Publishers: Boston, MA, USA, 1995. [Google Scholar]

- Hammer, M.; Ivanova, O.V. Effective index approximation of photonic crystal slabs: A 2-to-1-D assessment. Opt. Quantum Electron. 2009, 41, 267–283. [Google Scholar] [CrossRef]

- Chow, E.; Grot, A.; Mirkarimi, L.W.; Sigalas, M.; Girolami, G. Ultracompact biochemical sensor built with two-dimensional photonic crystal microcavity. Opt. Lett. 2004, 29, 1093–1095. [Google Scholar] [CrossRef] [PubMed]

- Dorfner, D.F.; Hürlimann, T.; Zabel, T.; Frandsen, L.H.; Abstreiter, G.; Finley, J.J. Silicon photonic crystal nanostructures for refractive index sensing. Appl. Phys. Lett. 2008, 93, 181103. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Tian, H.; Yang, D.; Liu, Q.; Ji, Y. Integration of high transmittance photonic crystal H2 nanocavity and broadband waveguide for biosensing applications based on silicon-on-insulator substrate. Opt. Commun. 2014, 330, 175–183. [Google Scholar] [CrossRef]

- Ameling, R.; Langguth, L.; Hentsche, M.; Mesch, M.; Braun, P.V.; Giessen, H. Cavity-enhanced localized plasmon resonance sensing. Appl. Phys. Lett. 2010, 97, 253116. [Google Scholar] [CrossRef]

- Sherry, L.J.; Chang, S.-H.; Schatz, G.C.; van Duyne, R.P.; Wiley, B.J.; Xia, Y. Localized surface plasmon resonance spectroscopy of single silver nanocubes. Nano Lett. 2005, 5, 2034–2038. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, D.; Pu, S.; Mao, L.; Wang, Z.; Qian, K. A Photonic Crystal Magnetic Field Sensor Using a Shoulder-Coupled Resonant Cavity Infiltrated with Magnetic Fluid. Sensors 2016, 16, 2157. https://doi.org/10.3390/s16122157

Su D, Pu S, Mao L, Wang Z, Qian K. A Photonic Crystal Magnetic Field Sensor Using a Shoulder-Coupled Resonant Cavity Infiltrated with Magnetic Fluid. Sensors. 2016; 16(12):2157. https://doi.org/10.3390/s16122157

Chicago/Turabian StyleSu, Delong, Shengli Pu, Lianmin Mao, Zhaofang Wang, and Kai Qian. 2016. "A Photonic Crystal Magnetic Field Sensor Using a Shoulder-Coupled Resonant Cavity Infiltrated with Magnetic Fluid" Sensors 16, no. 12: 2157. https://doi.org/10.3390/s16122157