1. Introduction

Nondestructive evaluation (NDE) techniques have been successfully applied for the past several decades in various fields, including civil, mechanical, and aerospace engineering [

1]. However, the structural integrity of some structures with restricted accessibility and high-precision geometry, such as nuclear power plants, is difficult to assess. Specifically, the most frequent issue encountered in structural health monitoring (SHM) of such structures is the development of corrosion. Corrosion jeopardizes structural safety when it grows to a critical size, and it can occur not only on the outer surfaces of structures, but also inside metal plate structures. Since damage to the back side of a metal plate is difficult to detect, damage detection methods for the back sides of structures are strongly required. This issue can be overcome using economical non-contact sensors, such as the classical SHM/NDE method that depends mostly on actuators and piezoelectric (PZT) sensors [

2,

3]. Such method can be used to measure wave signals to detect damage using installed PZT sensors [

4,

5,

6,

7,

8], which are inexpensive.

Effective corrosion detection methods in SHM should be intuitive, and the results should be easily understandable. To this end, some researchers have developed acoustic and ultrasonic wave technologies, including laser vibrometry, laser interferometry, and pulsed lasers. In a previous study [

9], a Lamb wave was generated in a duralumin plate immersed in water. The laser Doppler vibrometer (LDV) that was used in that study produced a laser beam perpendicular to the scanned surface. Changes in scan points can be achieved by moving the laser head. In 2003, Kehlenbach et al. [

10] published numerical results showing that Lamb waves can be propagated in an aluminum plate. They confirmed those results using a LDV and successfully visualized the propagating waves in a damaged area. Their results showed that the damage detection efficacy depends on the size of the damaged area. Other experimental results [

11,

12,

13] have used Lamb waves to detect damage to aluminum plates by scanning the surface around the damaged side using a LDV. Due to their low noise and narrow line widths (on the order of a few millihertz), those studies used a single-mode HeNe laser as the preferred light source for the LDV. Damage was successfully detected by finding areas with the maximum signal values.

A PZT sensor can also be used in LDV scanning, and the biggest advantage of using an LDV-PZT system is that any arbitrary waveform can be applied at the excitation location of the laser point with the highest energy level. However, even though some aspects of LDV systems have improved, such as automatic focusing and laser spot visibility when measuring very small objects [

14], there are still some disadvantages. For example, if the LDV scans the target structure too quickly, speckle noise, an optical phenomenon, could be unavoidable [

15]. Furthermore, in LDV-PZT method, it is very important for the LDV sensitivity to depend on the target surface condition and the incident angle of the laser beam. Therefore, it is advantageous for the laser beam to be perpendicular to a surface of the structure because most of the signal produced by the incident laser can be reflected straight back to the PZT sensor. However, when the laser beam scans a large area, the incident angle increases, and the intensity of the produced signal decreases, which will affect the quality of the signal. The signal-to-noise ratio (SNR) of the photodetector output is another limiting factor of LDV [

16], due to the low sensitivity of LDV, so multiple ultrasonic signals must be obtained at a single point, and these need to be averaged to improve the SNR [

17].

Other researchers have proposed using LDV with an air-coupled transducer (ACT) for NDE when scanning large surfaces. This method has effectively detected various types of damage [

18]. However, this transducer has a relatively low sensitivity due to the large mismatch in the acoustic impedance between air and the solid material as well as the high ultrasonic attenuation in air [

12]. In addition, two separate lasers have been used to implement a full non-contact damage detection technique, such as using a fixed Nd:YAG pulsed laser as an excitation laser at the same time as an LDV to scan the target area [

17,

19]. However, this method requires averaging the signal to improve the SNR due to an obviously reduced ultrasonic wave signal. In addition, it is also necessary to control the laser intensity, including the pulse energy, laser diameter, and wavelength, to prevent burning the target structure. Researchers should also pay attention to the input waveform of the laser excitation, which is usually limited to a pulse laser [

20,

21]. To address those issues, an Nd:YAG pulse laser system can be used to generate ultrasonic waves that can be received by a PZT sensor. In contrast with other technologies, this laser pulse system has many advantages including fast wave generation with a low pulse energy, high spatial resolution, and good detection in complex structures, especially to scan a large area because it is affected little by the incident angle of the laser beam and the irregular surface condition [

22]. Often, the allowable incident angle for the excitation laser is of up to ±70 degrees and ±20 degrees for the sensing laser [

23].

Many techniques have been developed using LDV, Nd:YAG pulsed laser, ACT, and PZT systems for damage detection by implementing filtering methods and wavenumber-based methods. Ultrasonic wave imaging has been achieved using methods based on wave propagations, and the results have shown good detection abilities for various kinds of damage [

24,

25,

26,

27]. In recent years, a new method was developed using a wavefield generated on the structure surface with a scanning laser or an externally scanned transducer, and many studies have verified the feasibility of this method for damage detection [

28,

29,

30,

31,

32,

33]. Several signal processing methods can be used to detect damage through damage-induced reflected and scattering waves. In this study, the non-contact NDE technique is applied by generating ultrasonic waves using a laser to visualize corrosion damage on aluminum plates. The ultrasonic waves are generated with an Nd:YAG pulse laser, and a galvanometer-based laser scanner is used to scan a specific area on the target structure. At the same time, an ultrasonic wave propagation image (UWPI) is obtained by measuring the wave responses with a PZT sensor attached to the central position on the back side of the target structure. The advantages of using such method are the high spatial resolution, ability to scan large complex structures, and ease of recognition.

Structural damage can be visualized by calculating the root mean square (RMS) values of the measured wavefield-time signals at every laser excitation point [

34,

35]. In order to improve the quality of the RMS snapshots, the authors propose to use the logarithmic values of the RMS function. Not only that, a weighting parameter can obviously improve the color of the RMS snapshots and compensate for the attenuation caused by the geometrical spreading and wave dispersion. The RMS value has the following advantages: (1) it is possible to pinpoint the damage locations; (2) in practical applications, the RMS snapshots can be produced in a relatively short time; (3) this method can effectively classify the degree of damage.

Few studies have used this technology to detect corrosion on internal structures or on the backs of structures, so the authors scan both sides of the plate using the same scanning area. In addition, few research has previously considered the effects of both the corrosion depth and corrosion size. The corrosion conditions for different depths and sizes are also discussed to verify the abilities of this method, including fast scanning of a large area, sensitive locating for corrosion detection, and effective classification of the damage degree. The major focus is on the experimental analysis.

2. Ultrasonic Wave Propagation Imaging System

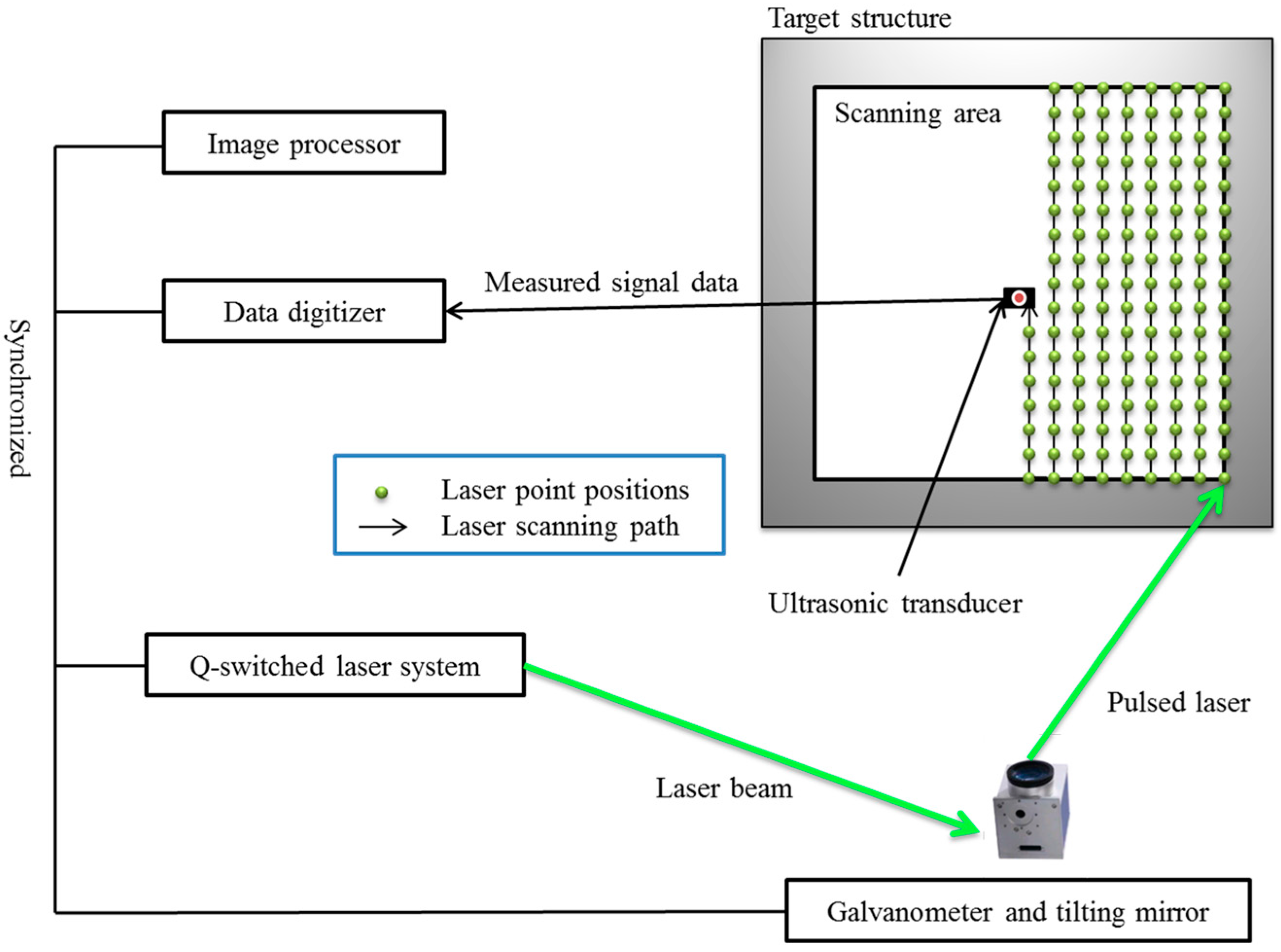

As shown in

Figure 1, the components of the proposed UWPI system include a Q-switched laser system, a galvanometer-based laser mirror scanner, an ultrasound sensor, a high-speed digitizer, and an image processor. This study used a Q-switched diode-pumped high-power solid-state Nd:YAG laser [

36] with a wavelength of 532 nm and a maximum pulse repetition rate of 20 Hz. The energy of each pulse is 0.658 mJ, the diameter of the laser beam is 0.45 mm, and the energy density is 4.15 mJ/mm

2. The laser mirror scanner can adjust the pulse laser scans for a specified location. The objective of this design is to operate two galvanometers at a wavelength of 532 nm. To ensure that the laser beam can efficiently scan the 2-D area of the target structure, the operating angles of the galvanometer are orthogonal to each other. The f-theta lens is installed at the end of the laser scanner system to reflect the laser beam, which focuses on the target detection area. As shown in

Figure 1, the laser beams scan the target area vertically in the horizontal direction, and the laser scanning path can be designed by the image processor. Furthermore, the spacing of each laser impingement point can also be adjusted by the laser control system. Since the laser intensity is adjusted over an appropriate range (1%), the pulsed laser cannot burn or damage the specimen. At the same time, a reduction in the laser intensity can prolong the life of the device.

During detection, the laser beams scan the target structure, and the ultrasonic waves are generated by a thermoelastic mechanism and are then propagated. An ultrasonic transducer installed on the front or back side of the structure measures the responses of the ultrasonic wave. In this study, the ultrasonic transducer is an amplifier-integrated acoustic emission (AE) sensor made of lead zirconate titanate piezoelectric ceramics.

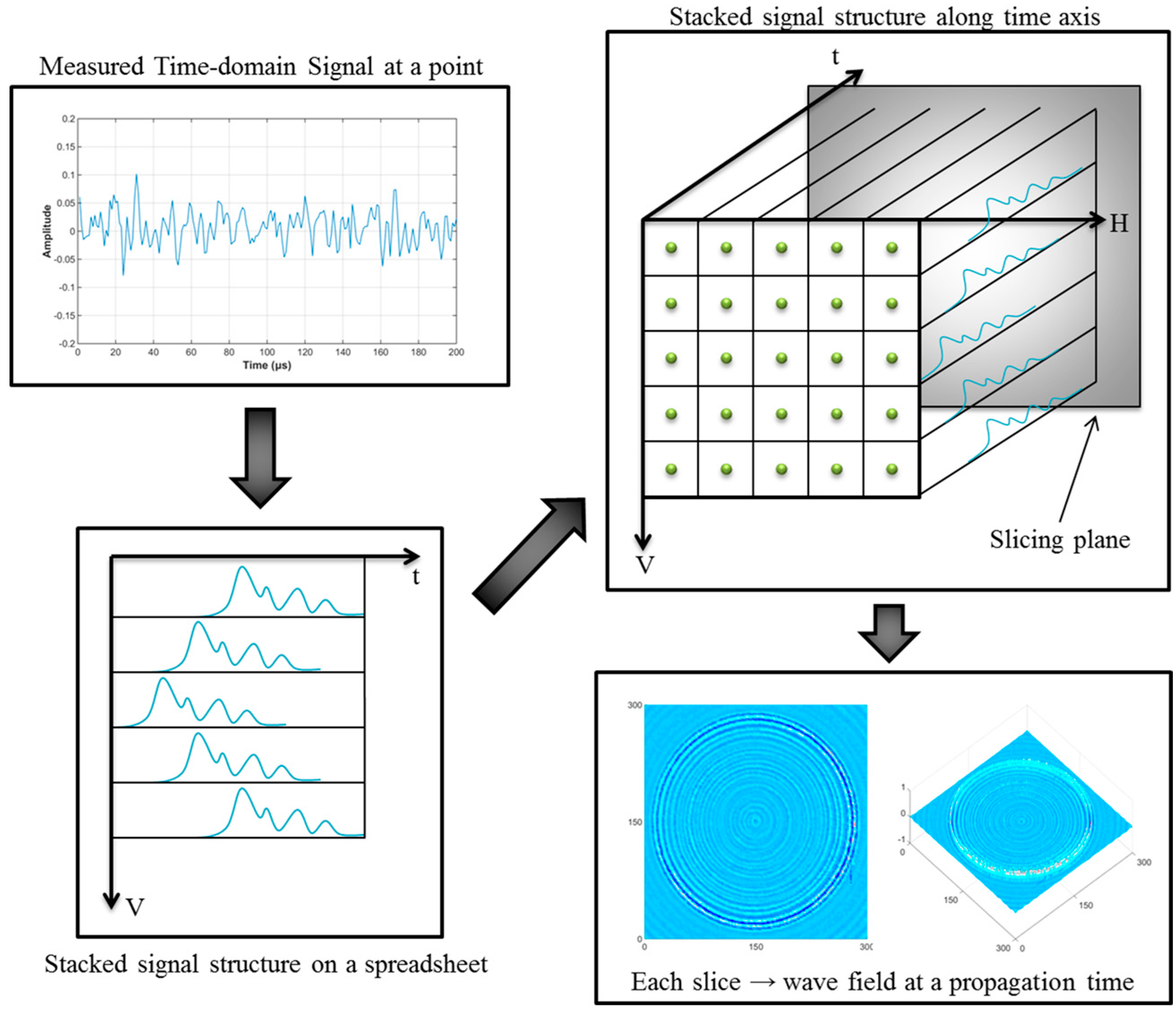

Figure 2 shows the process flow for the UWPI system. First, the signals of a wave reflected along the laser beam path are measured, and the time-domain signal is obtained at each laser impinging point. A band-pass filter was used in this step to filter the signal and improve the SNR, and filtered data for each laser beam impinging point on the vertical axis are stacked as signal groups in a vertical structure on a spreadsheet. Then, the stacked vertical data are stacked again serially on the horizontal axis of the spreadsheet. Thus, the spreadsheets can be integrated into a horizontal plane that can be considered as data for the horizontal scan. Finally, this horizontal plane can be transformed into a 3-D ultrasonic wave propagation image with three axes: the vertical scan, the horizontal scan, and the time frame [

37]. This method can be used for spreadsheet data to represent snapshots depicting the time intervals of the detection process. 3-D imaging of the structural damage analysis can then be generated by playing those snapshots in quick succession [

33].

3. Description of the Experimental Specimens and Experimental Setup

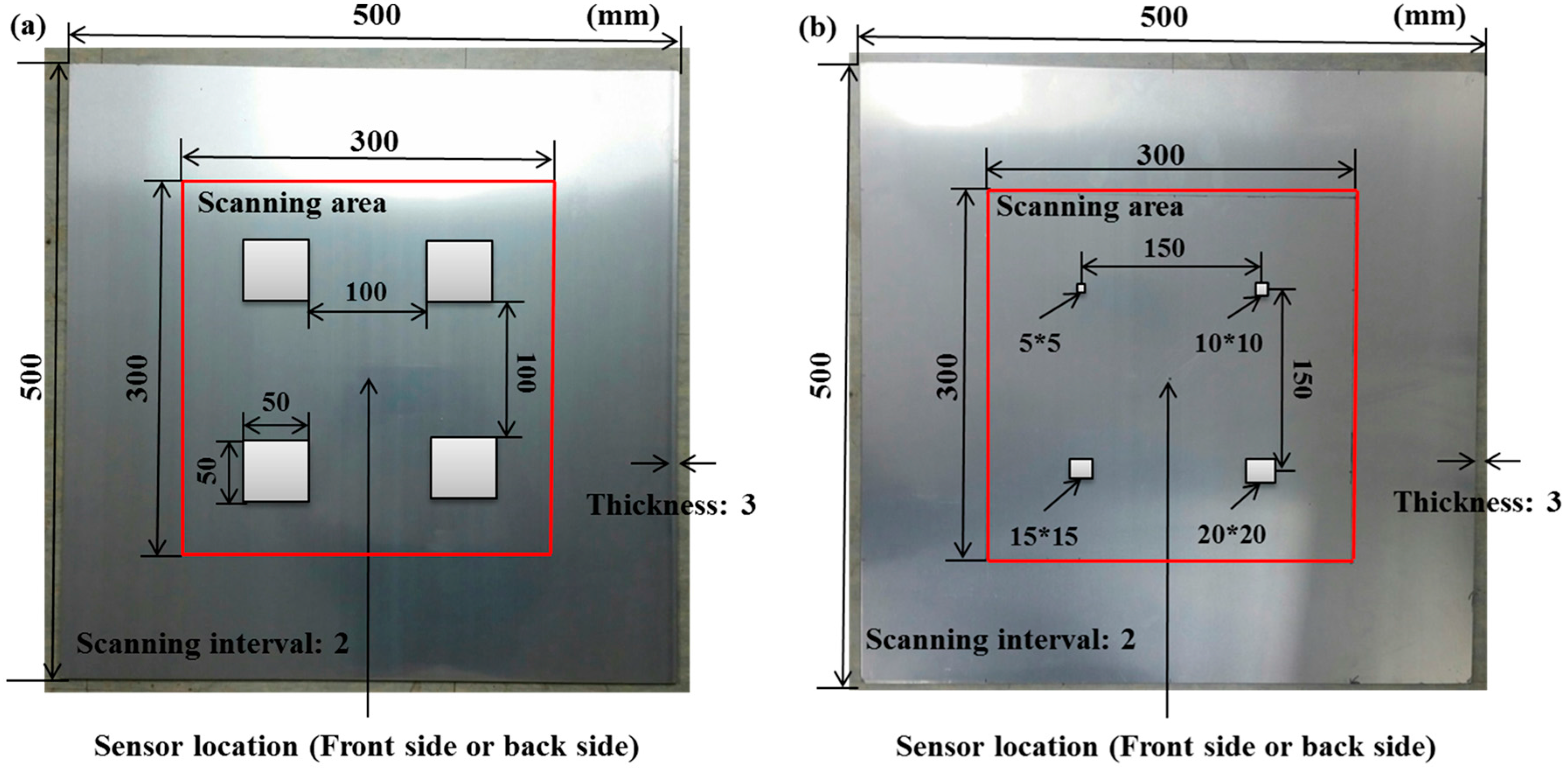

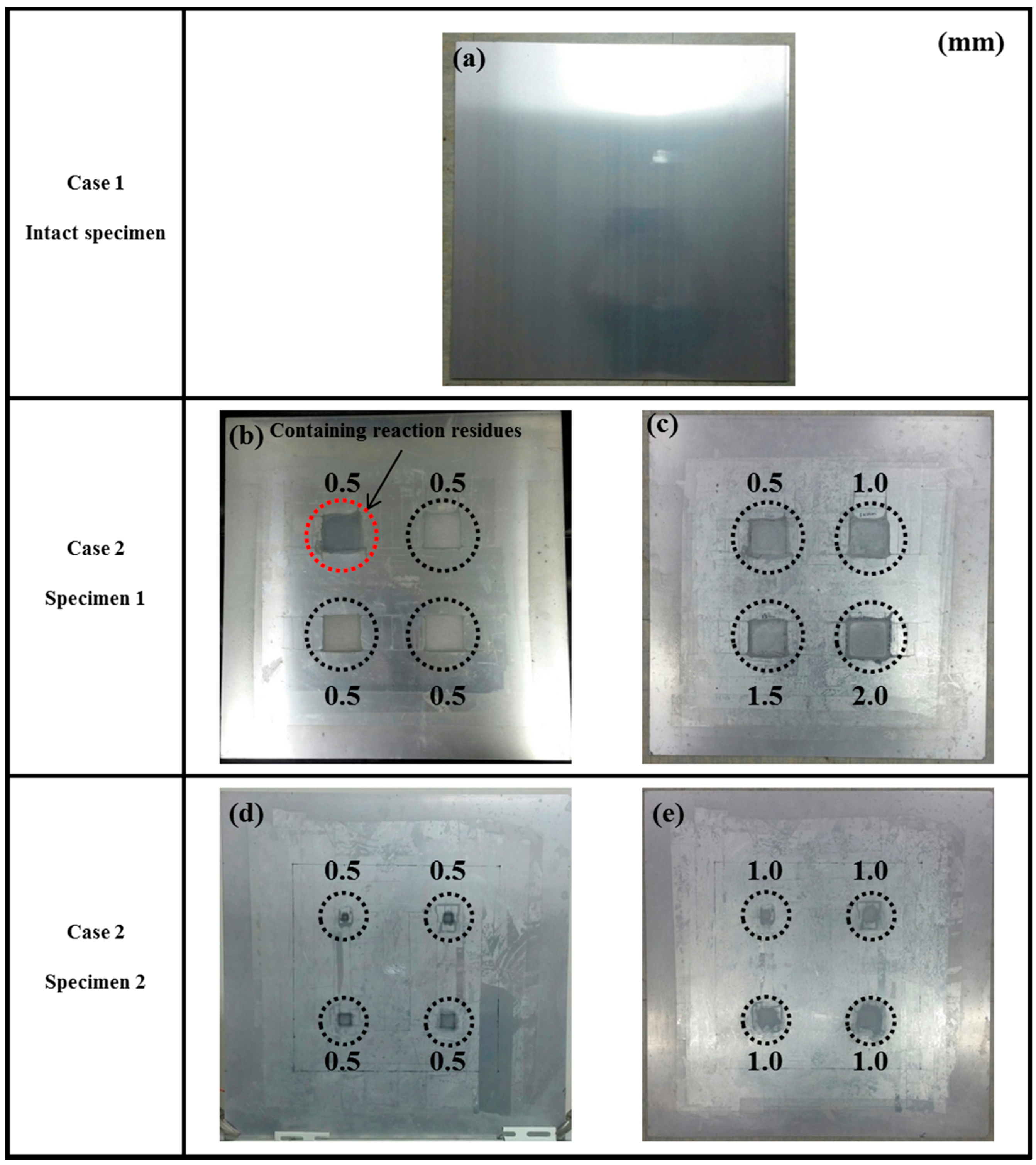

As shown in

Figure 3, the selected specimens were two 6061-T6 aluminum plates with a size of 500 mm × 500 mm and thickness of 3 mm. The scanned area was 300 mm × 300 mm at the central part of each specimen. In that area, the system can generate a 151 × 151 point grid (total = 22,801 points) with a 2-mm interval between points. That is, the spatial sampling rate is 2 mm. In this experiment, the scanning process was completed in 20 min. After scanning an intact specimen, corrosion damage was created on both plates using concentrated hydrochloric acid.

Figure 3a shows the laser scanning area for Specimen 1. All corroded areas were the same size of 50 mm × 50 mm, but they had different depths of 0.5, 1.0, 1.5 and 2.0 mm.

Figure 3b shows the laser scanning area for Specimen 2. These had the same corrosion depth but different dimensions of 5 mm × 5 mm, 10 mm × 10 mm, 15 mm × 15 mm and 20 mm × 20 mm.

The specimens were corroded by applying concentrated hydrochloric acid every day. When the concentrated hydrochloric acid was no longer applied, the damage area ceased increasing as soon as the reaction of the aluminum plate had finished. To ensure safety, the specimens were cleaned after each reaction had finished. The damage depths were measured and recorded upon completion of each corrosion reaction, and the specimens were scanned after each corrosion reaction. Since the thickness of the specimens was small, the authors scanned the back side to compare the results to those of the front side. In fact, damage is not visible on the back side, so it is more important to be able to detect damage on the back side than on the front side.

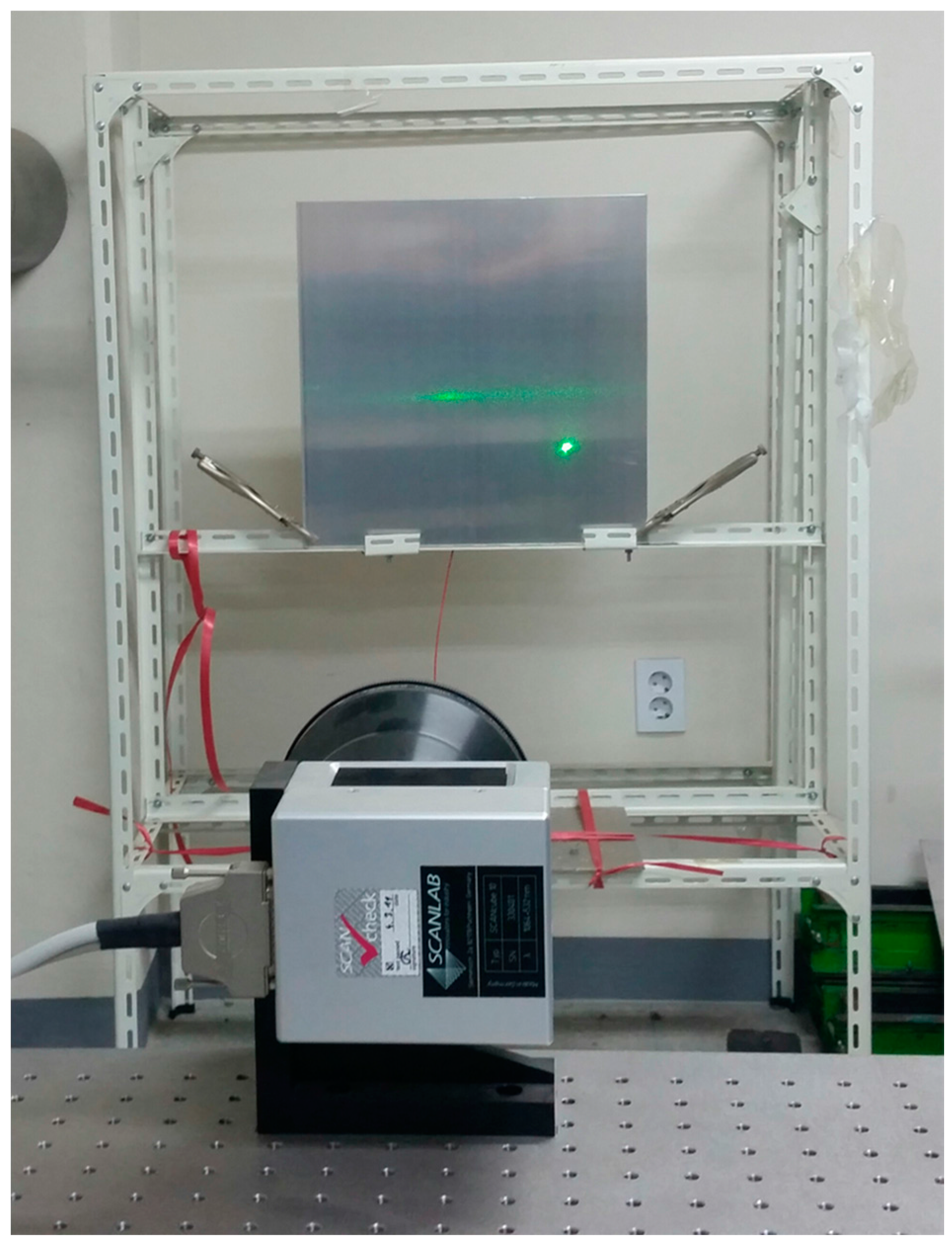

The specimen was fixed on a metal support, as shown in

Figure 4, tightly clamping the bottom part of the specimen with two clamps on the metal frame. An AE sensor was fixed in a central position on the back side of the measured surface to measure the multiple wave signals. The broadband AE sensor has lower and higher cut-off frequencies of 100 kHz and 2 MHz, respectively. The resonant frequency of the sensor is 200 kHz ± 20%, and at the resonant frequency, the maximum sensitivity of the sensor is 120 ± 3 dB. The scanning distance between the laser mirror scanner and the specimen was 2 m. In this circumstance, the pulsed laser was operated in an open space, and the researcher must ensure the safety of the operation via access restriction, eye protection, and adequate training.

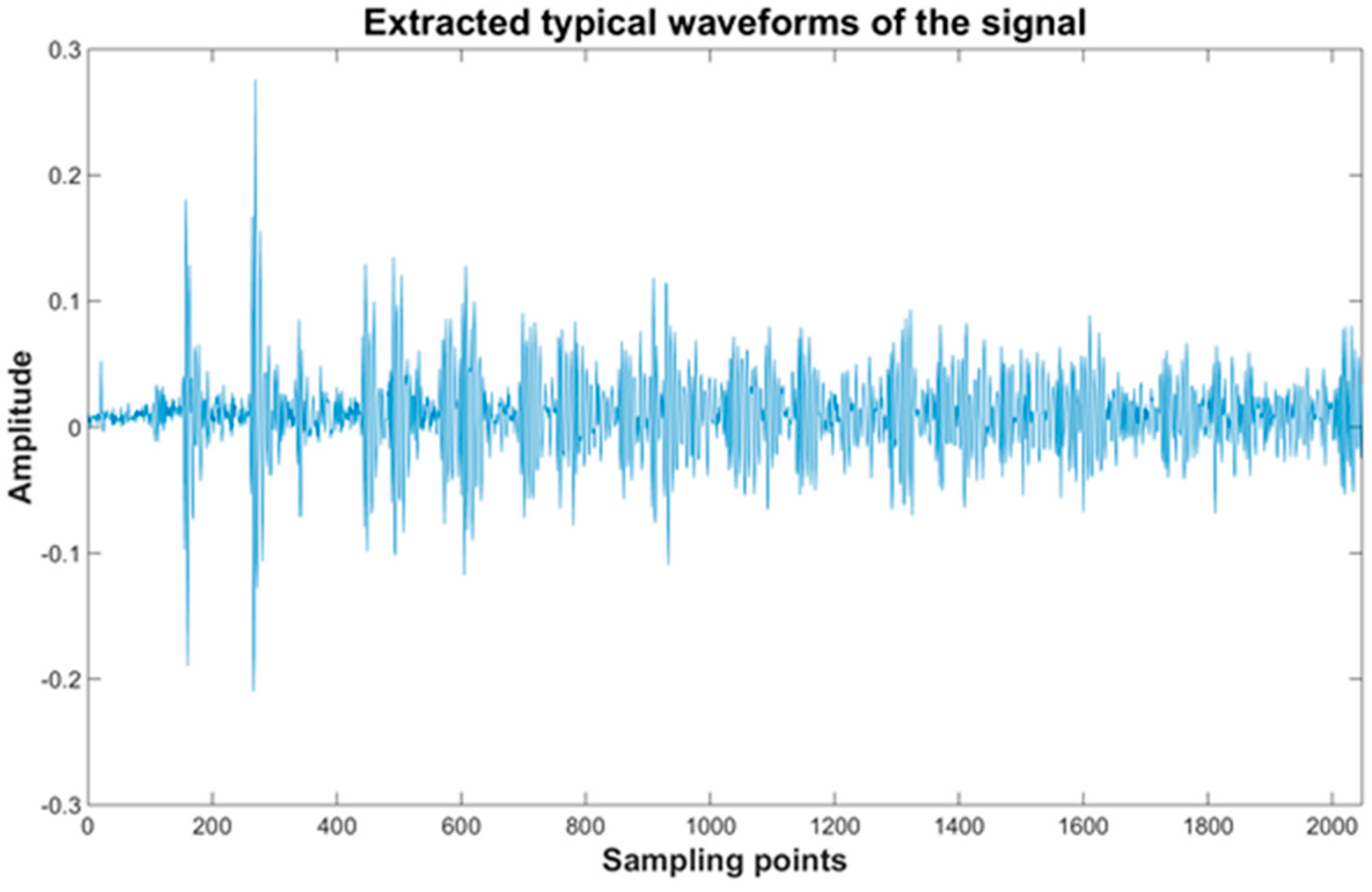

Figure 5 shows typical waveforms of the signal measured in the intact specimen. In general, the pulsed laser generates waves contain various frequency components, but as

Figure 5 shows, the original signals already had a low noise level, so it is not necessary to apply further processing. In addition, the untreated signal can better show the test results due to the various waveforms, especially to detect some small cracks.

Figure 6 shows the dimensions of the corroded areas. The intact specimen is shown in

Figure 6a as reference for the corroded specimens. The corrosion conditions for Specimen 1 are shown in

Figure 6b,c.

Figure 6b shows the early stage of corrosion, where the depths of all damaged areas were 0.5 mm. It is worth noting that the specimen was not adequately cleaned after the corrosion reaction, so the top left corrosion area has some reaction residue. This was a mistake by the operator, but the experimental results of this mistake were unexpected. Therefore, in

Figure 6b, the color for the top left corrosion area differs from that of the other three corrosion areas. In

Figure 6c, the corrosion depths for specimen 1 were 0.5, 1.0, 1.5 and 2.0 mm.

Figure 6d,e show the corrosion depths for Specimen 2, 0.5 and 1.0 mm, respectively.

4. Damage Detection Algorithm

The filtered UWPI data can be inversely transformed to effectively obtain the damage visualization image. The figures can be used to describe this process according to the RMS distribution of a reflected signal. The equation is given in [

19]:

where

T denotes the total simulation time, and

w(

x,

y,

t) are the signals of the reflected waves.

In addition, the energy distributions of standing waves are not uniform, so the color distribution in the RMS snapshots will be not uniform. To address that problem, the authors used the logarithmic values of the RMS function to ease the uniform distribution of the standing wave energy.

Figure 7 shows the

wRMS(

x,

y) and log(

wRMS(

x,

y)) function snapshots of

Figure 6c at 400 μs. The result in

Figure 6a shows that the image was too dark, although the damaged areas were successfully detected. On the other hand, the RMS snapshots were clearly improved by using the logarithmic values of the

wRMS(

x,

y) function, as shown in

Figure 7b. Although the visual effect in

Figure 7b improved significantly, the color distribution is still not sufficiently uniform. For example, more wave packet signals accumulated in the middle part of the scanning area (the sensor position) at the early stage, so the color was lighter (gold). This also signifies that in the color axis, the color becomes lighter as the RMS value increases. On the other hand, the figures also show a significant level of corrosion, and the greater depth is shown as a deeper color (a smaller value of RMS) in the RMS snapshots.

Since the accumulations of standing wave energy in the vicinity of the sensor are more frequent, larger values are produced near the location of the sensor in the RMS function. Therefore, the farther the damage is from the sensor, the harder it is to detect. However, the RMS value of the entire area can be equalized during the subsequent time period by multiplying it with the following weighting parameter:

where

k is the weighting parameter and

wRMS(

x,

y)_

Wk is the proposed weighted RMS function. Therefore, the RMS snapshots can be improved by using the logarithmic values of the

wRMS(

x,

y)_

Wk function.

Figure 8 shows the log(

wRMS(

x,

y)_

Wk) function for Specimen 1 (the specimen condition in

Figure 6c) when

k = 0, 0.5, 1 and 2. The value that produces the best visual effect can easily be found through observation, which is

k = 2. Therefore, the value of the weighting parameter is 2 in this study.

6. Conclusions

In this study, numerical and experimental measurements showed that the proposed method can be successfully employed to detect and locate corrosion. The proposed method allows for high-precision measurements of the Lamb wave propagation phenomenon. The RMS method is very sensitive for corrosion detection in aluminum plate and can pinpoint multiple corroded areas, even when the depth was 0.5 mm at both sides of the specimen. At the same time, it is important that the RMS method is much less sensitive to noise. Furthermore, the logarithmic values of the RMS-based functions can be used to improve the corrosion detection quality. A weighting parameter can be used to compensate for the attenuation caused by the geometrical spreading and dispersion of the waves, and this study obtained the best results using a weighting factor of k = 2 and the logarithmic value of the RMS-based function.

If the damage is deep enough (i.e., more than 1 mm), the reflected wave becomes a source of new waves in the UWPI snapshots when the propagating waves encounter the corroded area, whether the damage was on the front or on the back side. To detect damage on the front side, the color becomes deeper as the damage becomes more severe because the RMS value of the corroded areas decreases. However, to detect damage on the back side, the color becomes lighter as the corrosion becomes more severe because the RMS value of the corroded areas increases. Therefore, the depth of the corrosion can be distinguished. Since all damaged areas were located on the front sides of the specimens, the results for the front side were clearer than those for the back side. When the corrosion depth for Specimens 1 and 2 was 0.5 mm, the corroded areas could not be clearly detected from the back side of Specimen 2, possibly because the damaged areas were too small. It is worth noting that in

Table 2, even though the depths of the four corroded areas was the same, the corrosion which has the reaction residue remaining may have the different result, but it can also be obviously detected.

This method can be applied in SHM systems with potential for high detection rates and greatly reduced operator effort and setup time. Further studies will improve the accuracy of the damage level classification as well as the visual effects for damage detection. In addition, the study will be extended for more complex structures to further verify the usability of this technique.