Analysis of Hollow Fiber Temperature Sensor Filled with Graphene-Ag Composite Nanowire and Liquid

Abstract

:1. Introduction

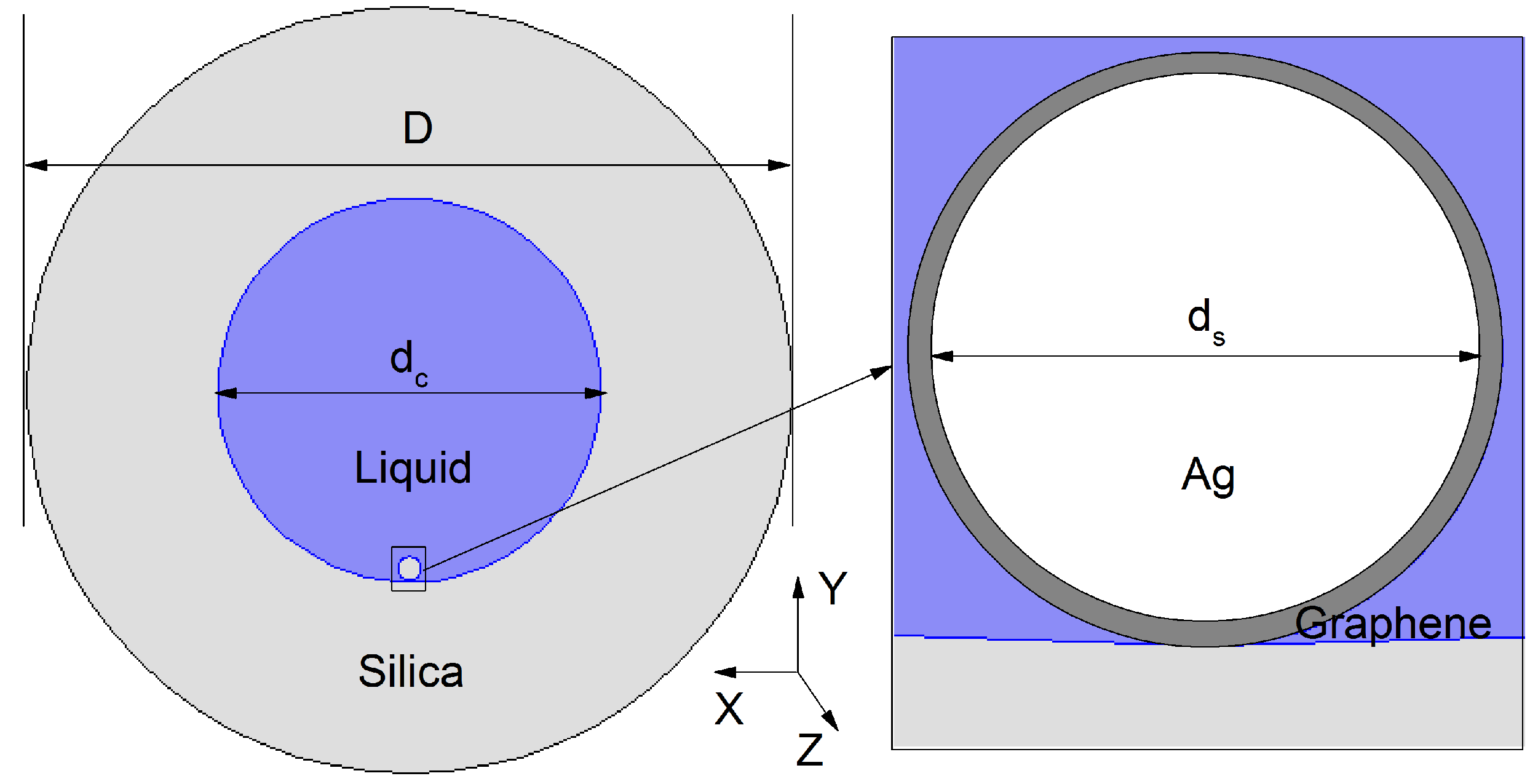

2. Sensor Design and Numerical Modeling

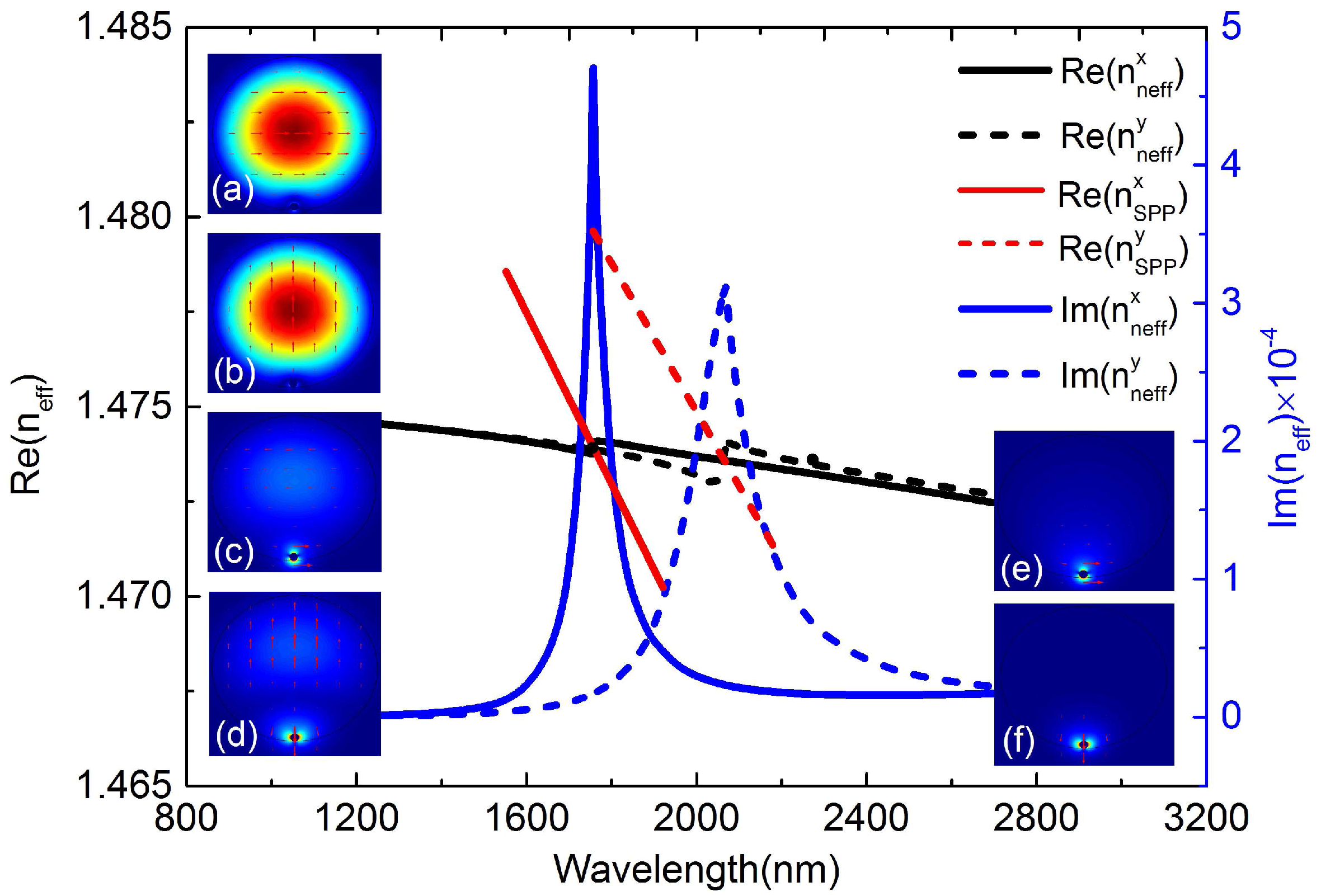

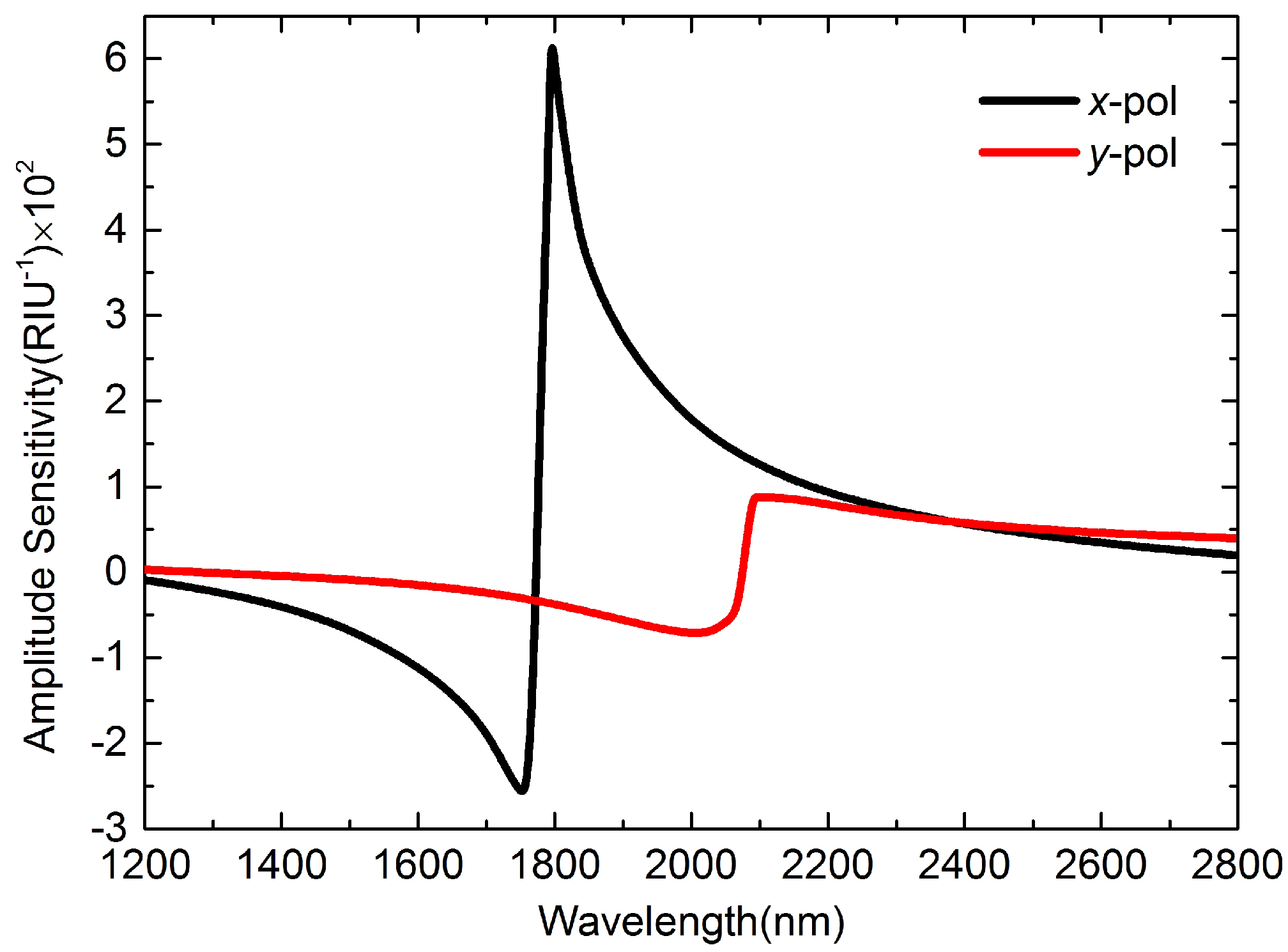

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Knight, J.C. Photonic crystal fibres. Nature 2003, 424, 847–851. [Google Scholar] [CrossRef] [PubMed]

- Russell, P. Photonic crystal fibers. Science 2003, 299, 358–362. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Hou, J.; Zhang, Y.; Huang, Z.H.; Xiao, R.; Lu, Q.S. Temperature sensing using the bandgap-like effect in a selectively liquid-filled photonic crystal fiber. Opt. Lett. 2013, 38, 263–265. [Google Scholar] [CrossRef] [PubMed]

- Qiu, S.J.; Chen, Y.; Xu, F.; Lu, Y.Q. Temperature sensor based on an isopropanol-sealed photonic crystal fiber in-line interferometer with enhanced refractive index sensitivity. Opt. Lett. 2012, 37, 863–865. [Google Scholar] [CrossRef] [PubMed]

- Villatoro, J.; Finazzi, V.; Minkovich, V.P.; Pruneri, V.; Badenes, G. Temperature-insensitive photonic crystal fiber interferometer for absolute strain sensing. Appl. Phys. Lett. 2007, 91, 091109. [Google Scholar] [CrossRef]

- Villatoro, J.; Finazzi, V.; Pruneri, V. Functional photonic crystal fiber sensing devices. In Proceedings of the ACP Asia Communications and Photonics Conference and Exhibition, Shanghai, China, 13–16 November 2011; pp. 1–6.

- Zu, P.; Chan, C.C.; Jin, Y.X.; Gong, T.X.; Zhang, Y.F.; Chen, L.H.; Dong, X.Y. A Temperature-Insensitive Twist Sensor by Using Low-Birefringence Photonic-Crystal-Fiber-Based Sagnac Interferometer. Photonics Technol. Lett. 2011, 23, 920–922. [Google Scholar] [CrossRef]

- Liu, B.H.; Jiang, Y.X.; Zhu, X.S.; Tang, X.L.; Shi, Y.W. Hollow fiber surface plasmon resonance sensor for the detection of liquid with high refractive index. Opt. Express 2013, 21, 32349–32357. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.W.; Lu, Y.; Duan, L.C.; Zhao, Z.Q.; Shi, W.; Yao, J.Q. Intracavity absorption multiplexed sensor network based on dense wavelength division multiplexing filter. Opt. Express 2014, 22, 24545–24550. [Google Scholar] [CrossRef] [PubMed]

- Qiu, S.J.; Liu, Q.; Xu, F.; Lu, Y.Q. Ampere force based photonic crystal fiber magnetic field sensor. Sens. Actuators A Phys. 2014, 210, 95–98. [Google Scholar] [CrossRef]

- Lee, K.S.; Son, J.M.; Jeong, D.Y.; Lee, T.S.; Kim, W.M. Resolution enhancement in surface plasmon resonance sensor based on waveguide coupled mode by combining a bimetallic approach. Sensors 2010, 10, 11390–11399. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.W.; Schmidt, M.A.; Tyagi, H.K.; Prill Sempere, L.; Russell, P.S.J. Polarization-dependent coupling to plasmon modes on submicron gold wire in photonic crystal fiber. Appl. Phys. Lett. 2008, 93, 111102. [Google Scholar] [CrossRef]

- Csaki, A.; Jahn, F.; Latka, I.; Henkel, T.; Malsch, D.; Schneider, T.; Schröder, K.; Schuster, K.; Schwuchow, A.; Spittel, R.; et al. Nanoparticle layer deposition for plasmonic tuning of microstructured optical fibers. Small 2010, 6, 2584–2589. [Google Scholar] [CrossRef] [PubMed]

- Luan, N.N.; Wang, R.; Lv, W.H.; Lu, Y.; Yao, J.Q. Surface plasmon resonance temperature sensor based on photonic crystal fibers randomly filled with silver nanowires. Sensors 2014, 14, 16035–16045. [Google Scholar] [CrossRef] [PubMed]

- Sui, K.R.; Shi, Y.W.; Tang, X.L.; Zhu, X.S.; Katsumasa, I.; Mitsunobu, M. Optical properties of AgI/Ag infrared hollow fiber in the visible wavelength region. Opt. Lett. 2008, 33, 318–320. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.H.; Kim, Y.L.; Byun, K.M. Graphene-on-silver substrates for sensitive surface plasmon resonance imaging biosensors. Opt. Express 2011, 19, 458–466. [Google Scholar] [CrossRef] [PubMed]

- Dash, J.N.; Jha, R. Graphene-Based Birefringent Photonic Crystal Fiber Sensor Using Surface Plasmon Resonance. Photonics Technol. Lett. 2014, 26, 1092–1095. [Google Scholar] [CrossRef]

- Yang, X.C.; Lu, Y.; Liu, B.L.; Yao, J.Q. Analysis of Graphene-Based Photonic Crystal Fiber Sensor Using Birefringence and Surface Plasmon Resonance. Plasmonics 2016. [Google Scholar] [CrossRef]

- Wang, Y.P.; Tan, X.L.; Jin, W.; Ying, D.Q.; Hoo, Y.L.; Liu, S.J. Temperature-controlled transformation in fiber types of fluid-filled photonic crystal fibers and applications. Opt. Lett. 2010, 35, 88–90. [Google Scholar] [CrossRef] [PubMed]

- Lynch, D.W.; Hunter, W.R. Comments on the Optical Constants of Metals and on Introduction to the Data for Several Metals. In Handbook of Optical Constants of Solids; Edward, D.P., Ed.; Academic Press: Boston, MA, USA, 1985; pp. 350–357. [Google Scholar]

- Sharma, A.K.; Gupta, B.D. Fibre-optic sensor based on surface plasmon resonance with Ag-Au alloy nanoparticle films. Nanotechnology 2005, 17, 124. [Google Scholar] [CrossRef]

- Lu, Y.; Hao, C.J.; Wu, B.Q.; Huang, X.H.; Wen, W.Q.; Fu, X.Y.; Yao, J.Q. Grapefruit fiber filled with silver nanowires surface plasmon resonance sensor in aqueous environments. Sensors 2012, 12, 12016–12025. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Yao, J.; Yang, X.; Shi, J.; Zhao, J.; Zhang, C. Analysis of Hollow Fiber Temperature Sensor Filled with Graphene-Ag Composite Nanowire and Liquid. Sensors 2016, 16, 1656. https://doi.org/10.3390/s16101656

Xu W, Yao J, Yang X, Shi J, Zhao J, Zhang C. Analysis of Hollow Fiber Temperature Sensor Filled with Graphene-Ag Composite Nanowire and Liquid. Sensors. 2016; 16(10):1656. https://doi.org/10.3390/s16101656

Chicago/Turabian StyleXu, Wei, Jianquan Yao, Xianchao Yang, Jia Shi, Junfa Zhao, and Cheng Zhang. 2016. "Analysis of Hollow Fiber Temperature Sensor Filled with Graphene-Ag Composite Nanowire and Liquid" Sensors 16, no. 10: 1656. https://doi.org/10.3390/s16101656