Strain Sharing Assessment in Woven Fiber Reinforced Concrete Beams Using Fiber Bragg Grating Sensors

Abstract

:1. Introduction

2. Materials and Methods

2.1. FBG Sensing Principle

2.2. Concrete Specimens Preparation

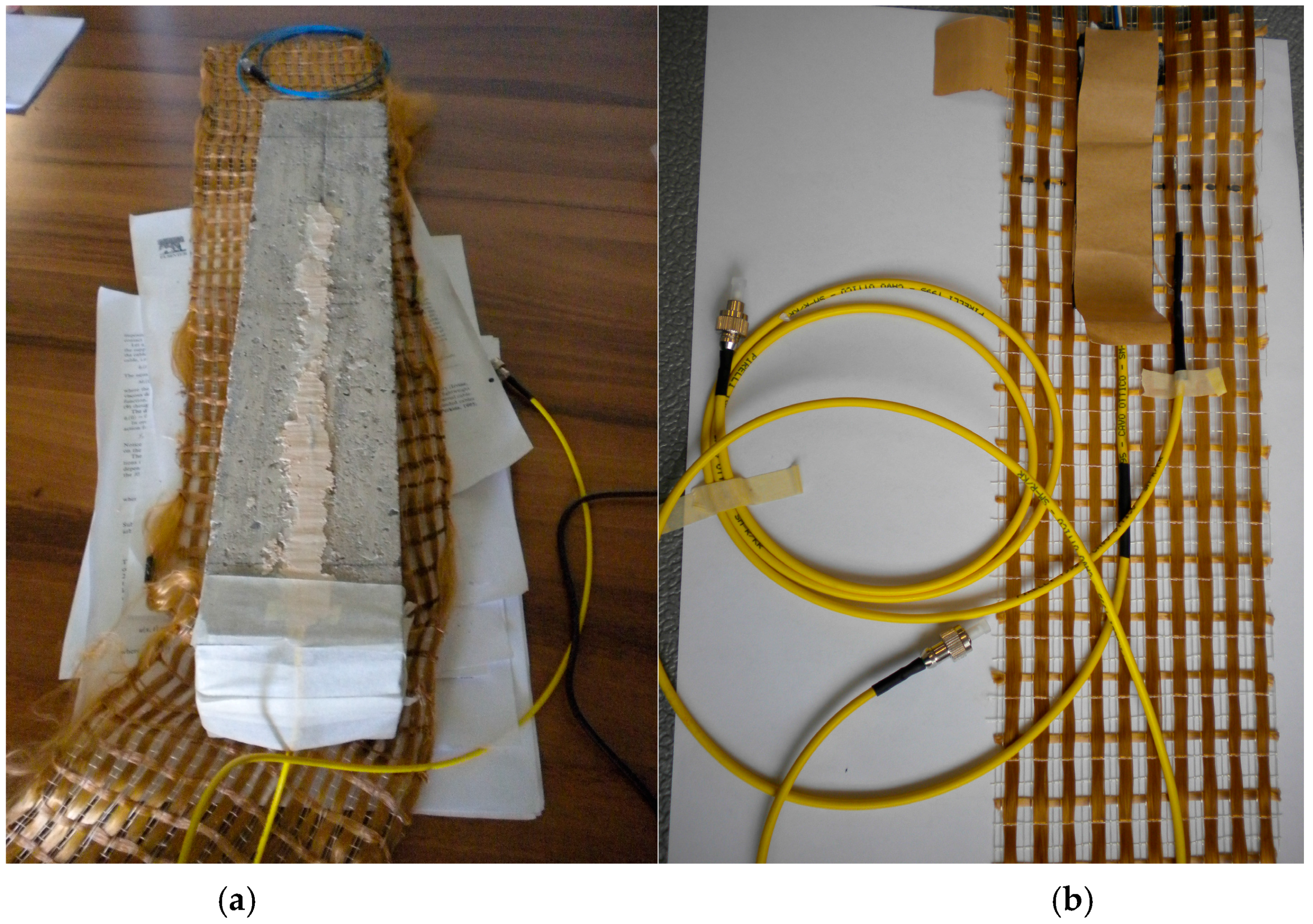

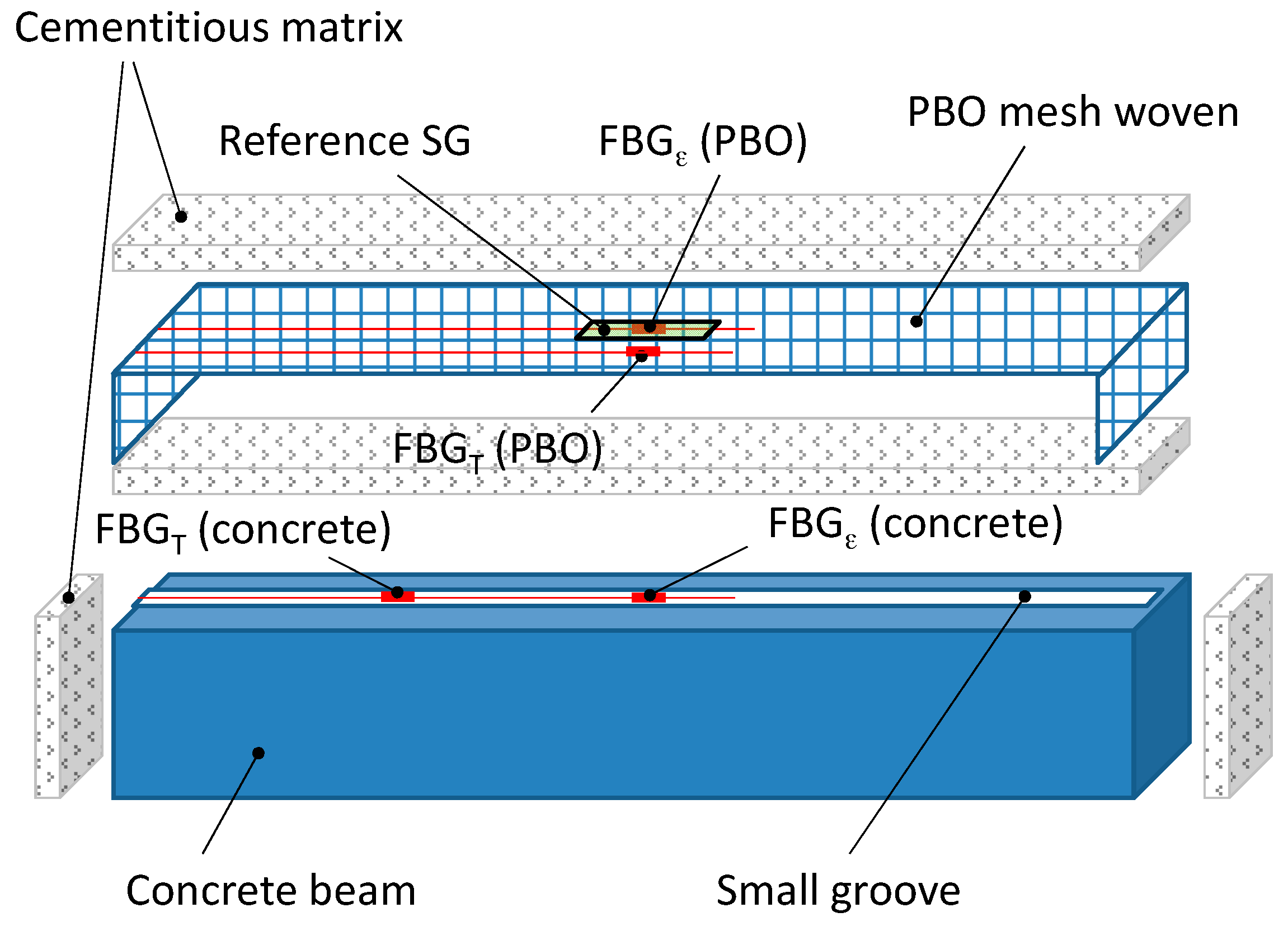

2.3. Fiber Reinforced Cementitious Matrix Strengthening System

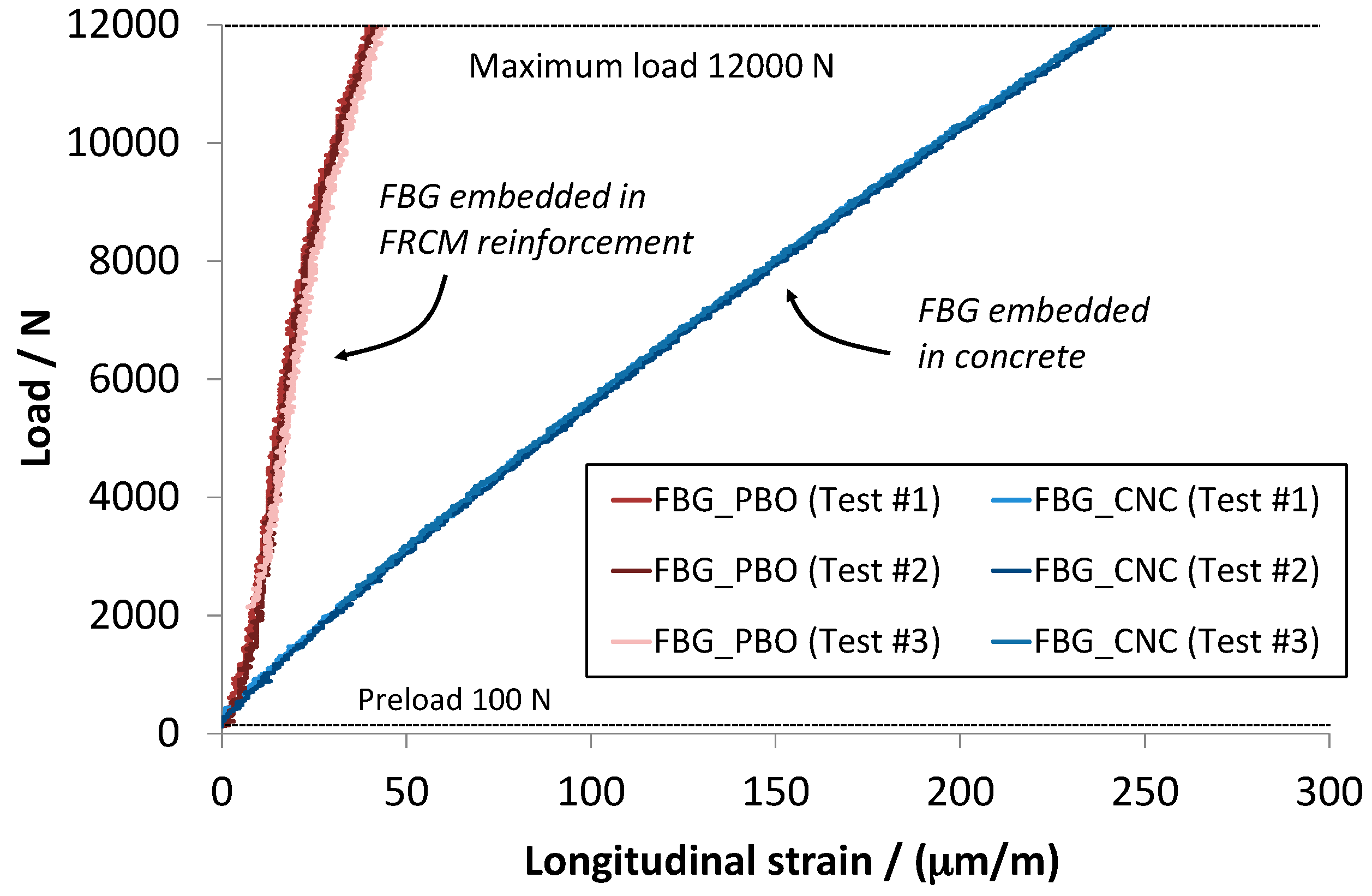

2.4. Strain Measurements

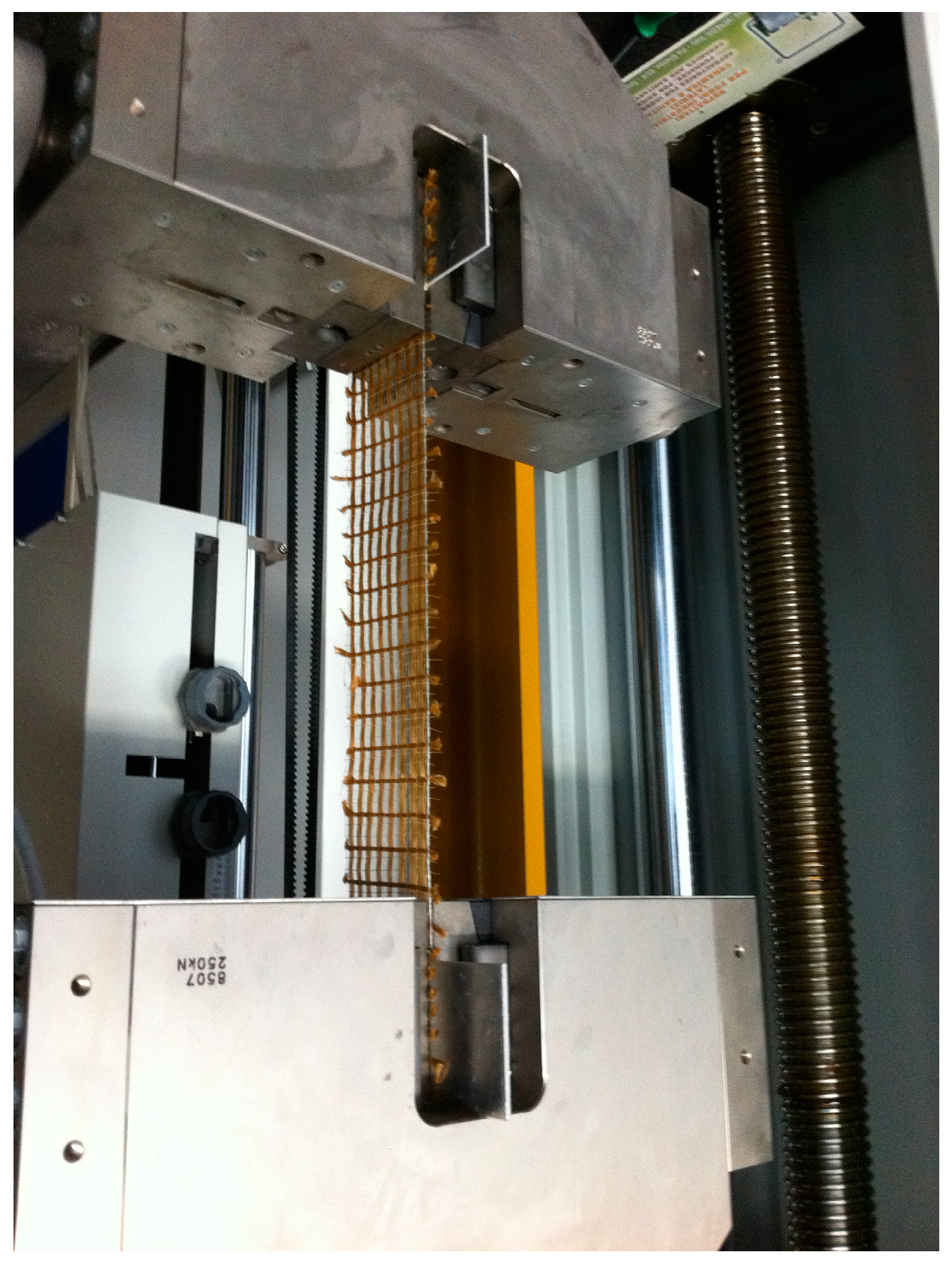

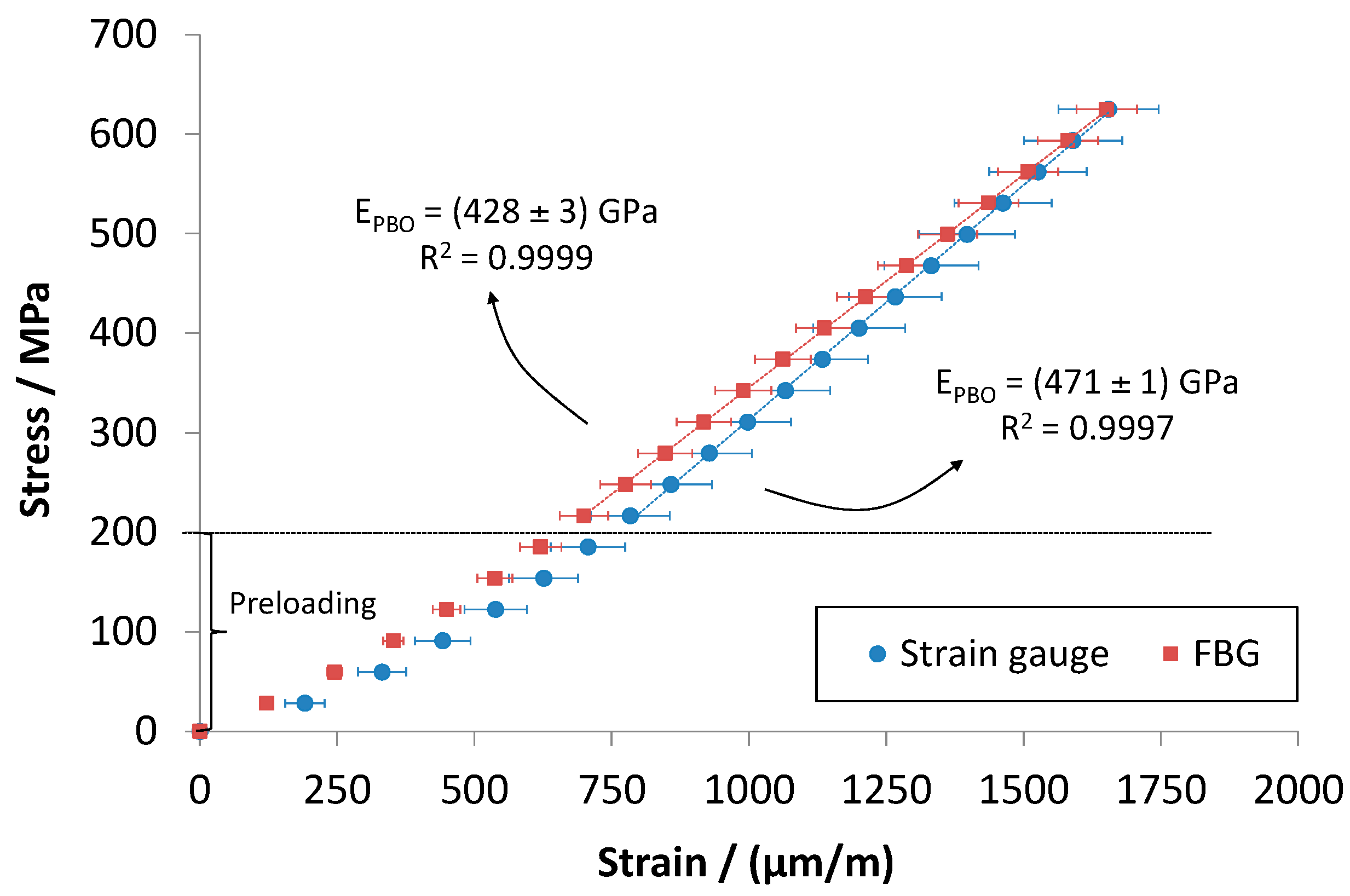

2.5. Preliminary Experimental Tests on PBO Mesh Woven

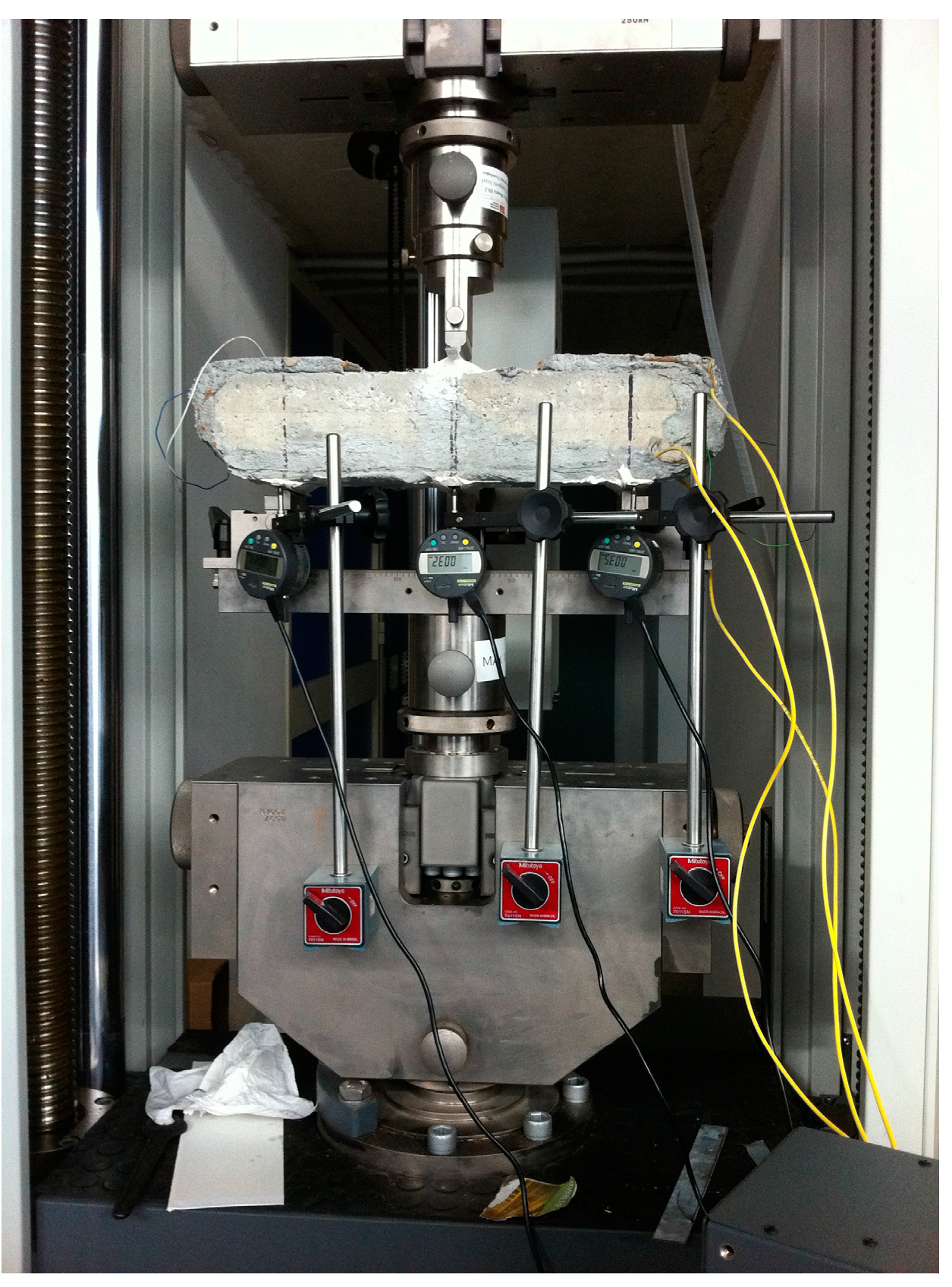

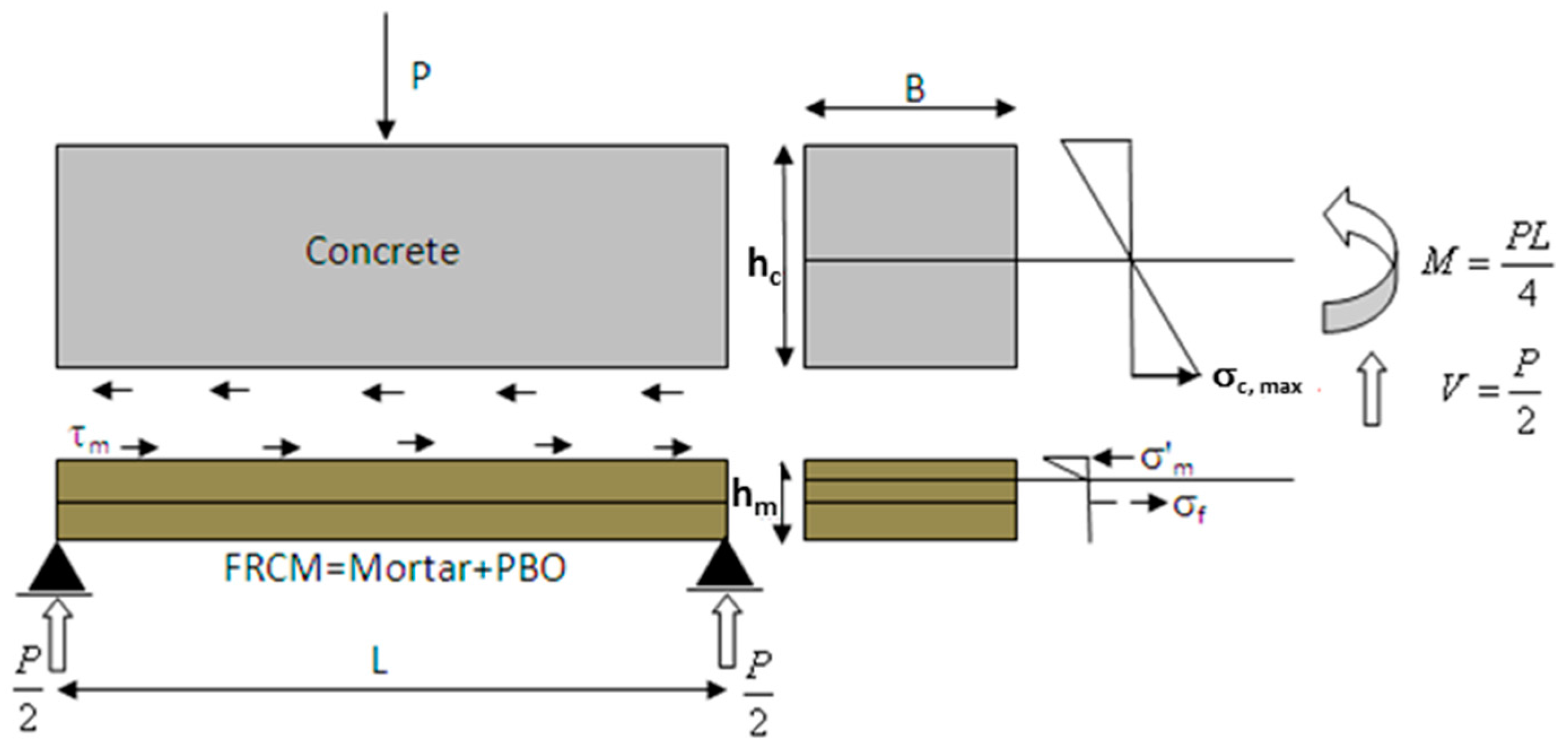

2.6. Three Point Bending Tests on Woven Fiber Reinforced Concrete Beams

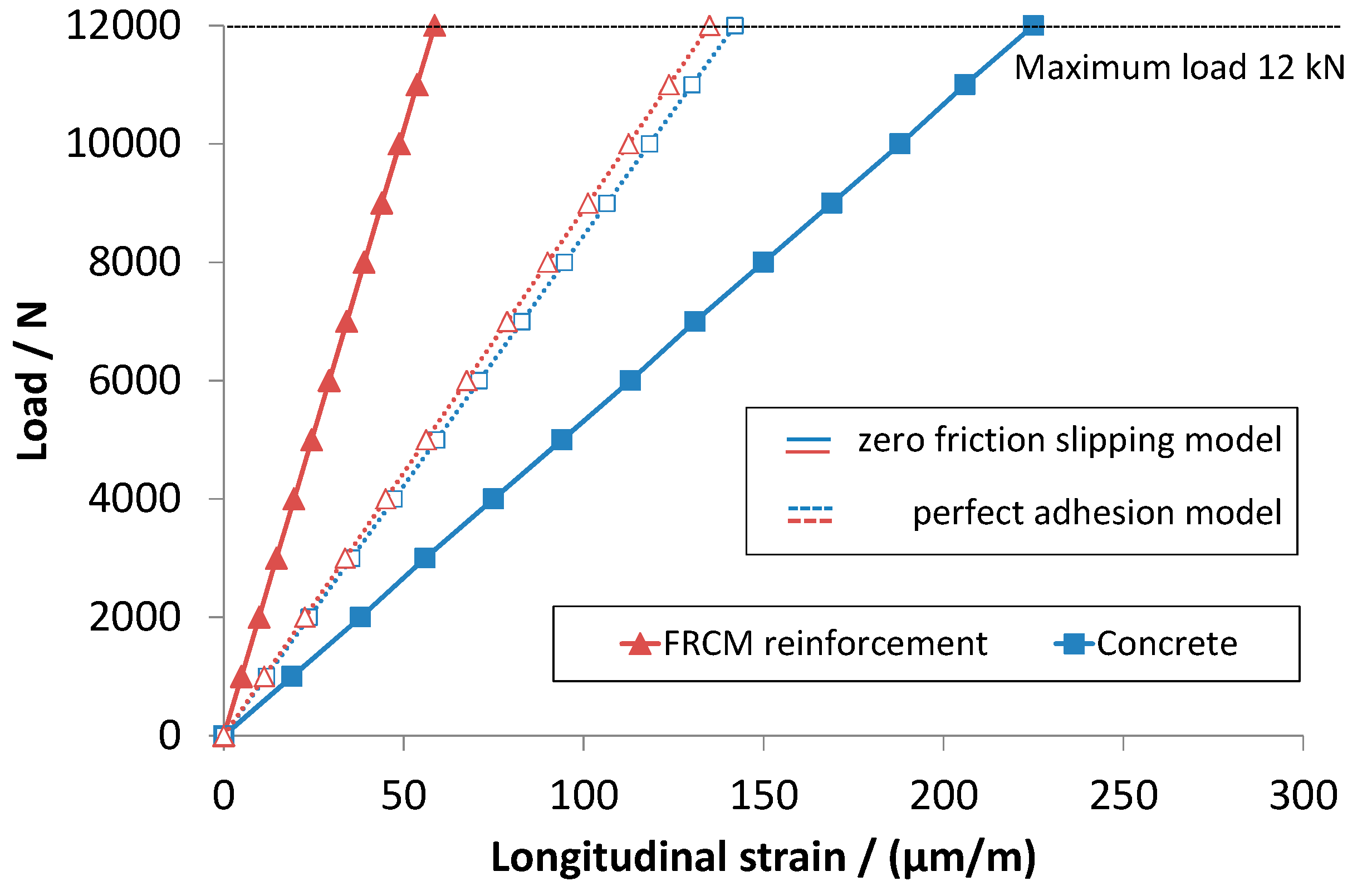

3. Theoretical Model

- i)

- The whole cross-section of the concrete beam (B × hc) is able to withstand the applied load until failure occurs;

- ii)

- The tensile strength of the cementitious matrix is negligible with respect to that of the PBO.

4. Results and Discussion

5. Conclusions

- 1)

- Strain in concrete can be much higher than that developed in the reinforcement if slipping between the interface surfaces occurs.

- 2)

- For FRCM strengthened concrete beams, almost complete de-coupling has been observed. A zero friction slipping model was developed which fit very well the experimental data.

- 3)

- Otherwise, if perfect adhesion occurs, strains in concrete and in reinforcement tend to be similar.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Merzbacher, C.I.; Kersey, A.D.; Friebele, E.J. Fiber optic sensors in concrete structures: A review. Smart Mate. Struct. 1996, 5, 196–208. [Google Scholar] [CrossRef]

- Ansari, F. State-of-the-art in the application of fiber optic sensors to cementitious composites. Cement Concr. Compos. 1997, 19, 3–19. [Google Scholar] [CrossRef]

- Lau, K.T.; Zhou, L.M.; Tse, P.C.; Yuan, L.B. Applications of composites, optical fibre sensors and smart composites for concrete rehabilitation: An overview. Appl. Compos. Mater. 2002, 9, 221–247. [Google Scholar] [CrossRef]

- Li, H.N.; Li, D.S.; Song, G.B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Habel, W.R.; Höpcke, M.; Basedau, F.; Polster, H. The influence of concrete and alkaline solutions on different surfaces of optical fibres for sensors. In Proceedings of the 2nd European Conference on Smart Structures and Materials, Glasgow, UK, 12–14 October 1994.

- Lau, K.T.; Chan, C.; Zhou, L.; Jin, W. Strain monitoring in composite-strengthened concrete structures using optical fibre sensors. Compos. Part B 2001, 32, 33–45. [Google Scholar] [CrossRef]

- Banholzer, B.; Brockmann, T.; Brameshuber, W. Material and bonding characteristics for dimensioning and modeling of textile reinforced concrete (TRC) elements. Mater. Struct. 2006, 39, 749–763. [Google Scholar] [CrossRef]

- Montanini, R.; D’Acquisto, L. Simultaneous measurement of temperature and strain in glass fiber/epoxy composites by embedded fiber optic sensors: I. Cure monitoring. Smart Mater. Struct. 2007, 16, 1718–1726. [Google Scholar] [CrossRef]

- Montanini, R.; D’Acquisto, L. Simultaneous measurement of temperature and strain in glass fiber/epoxy composites by embedded fiber optic sensors: II. Post-cure testing. Smart Mater. Struct. 2007, 16, 1727–1735. [Google Scholar] [CrossRef]

- Mèndez, A.; Morse, T.F.; Mèndez, F. Applications of embedded optical fiber sensors in reinforced concrete buildings and structures. In Proceedings of the SPIE 1170, Fiber Optic Smart Structures and Skins II, Boston, MA, USA, 5 September 1989; pp. 60–69.

- Measures, R.M.; Alavie, A.T.; Maaskant, R.; Ohn, M.; Karr, S.; Huang, S. Bragg grating structural sensing system for bridge monitoring. In Proceedings of SPIE 2294, Distributed and Multiplexed Fiber Optic Sensors IV, San Diego, CA, USA, 24 July 1994; pp. 53–60.

- Zângaro, R.A.; Silveira, L., Jr.; Silva Barreto, R. Optical fiber sensors for measurement of stress in concrete structures. Measurement 1995, 16, 103–105. [Google Scholar] [CrossRef]

- De Vries, M.; Arya, V.; Meller, S.; Masri, S.F.; Richard, O. Implementation of EFPI-based optical fiber sensor instrumentation for the NDE of concrete structures. Cement Concr. Compos. 1997, 19, 69–79. [Google Scholar] [CrossRef]

- Davis, M.A.; Bellemore, D.G.; Kersey, A.D. Distributed fiber Bragg grating strain sensing in reinforced concrete structural components. Cement Concr. Compos. 1997, 19, 45–57. [Google Scholar] [CrossRef]

- Deif, A.; Martin-Perez, B.; Cousin, B.; Zhang, C.; Li, W.; Bao, X. A comparison of strains measured by optical fibres and strain gauges with theory for a loaded bridge deck. In Proceedings of the Non-Destructive Testing in Civil Engineering Conference (NDTCE’09), Nantes, France, 30 June–3 July 2009.

- Bravo, M.; Sáenz, J.; Bravo-Navas, M.; López-Amo, M. Fiber optic sensors for monitoring a concrete beam high strain bending test. In Proceedings of the SPIE 7753, 21st International Conference on Optical Fibre Sensors (OFS-21), Ottawa, ON, Canada, 15–19 May 2011; pp. 266–269.

- Leung, C.K.Y. Fiber optic sensors in concrete: the future? NDT E Int. 2001, 34, 85–94. [Google Scholar] [CrossRef]

- Fuhr, P.L.; Huston, D.R.; Kajenski, P.J.; Ambrose, T.P. Performance and health monitoring of the Stafford Medical Building using embedded sensors. Smart Mater. Struct. 1992, 1, 63–68. [Google Scholar] [CrossRef]

- Huston, D.R.; Fuhr, P.L.; Ambrose, T.P.; and Barker, D.A. Intelligent civil structures—Activity in Vermont. Smart Mater. Struct. 1994, 3, 129–139. [Google Scholar] [CrossRef]

- Maaskant, R.; Alavie, T.; Measures, R.M.; Tadros, G.; Rizkalla, S.H.; Gua-Thakurta, A. Fiber optic Bragg grating sensors for bridge monitoring. Cement Concr. Compos. 1997, 19, 21–33. [Google Scholar] [CrossRef]

- Ye, X.W.; Su, Y.H.; and Han, J.P. Structural health monitoring of civil infrastructure using optical fiber sensing technology: A comprehensive review. Sci. World J. 2014. 652329. [Google Scholar] [CrossRef] [PubMed]

- Inaudi, D.; Casanova, N.; Vurpillot, S.; Kronenberg, P.; Martinola, G.; Steinmann, G.; Mathier, J.F. SOFO: Structural monitoring with fiber optic sensors. In Monitoring and Safety Evaluation of Existing Concrete Structures, Proceedings of the Fédération Internationale du Béton (FIB) Commission Meeting, Vienna, Austria, 12–13 February 1999.

- Zhou, Z.; Ou, J. Development of FBG sensors for structural health monitoring in civil infrastructures. In Proceedings of the North American Euro-Pacific Workshop “Sensing Issues in Civil Structural Health Monitoring”, Waikiki Beach, Oahu, HI, USA, 10–13 November 2004.

- Uva, G.; Porco, F.; Fiore, A.; Porco, G. Structural monitoring using fiber optic sensors of a pre-stressed concrete viaduct during construction phases. Case Stud. Nondestr. Test. Eval. 2014, 2, 27–37. [Google Scholar] [CrossRef]

- Sundaram, B.A.; Kesavan, K.; Parivallal, S.; Farvaze, A.A.K.; Ravisankar, K. Monitoring of FRP Strengthened Concrete Structures Using FBG Sensors. Procedia Eng. 2011, 14, 1549–1556. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, Q.; Zhou, Z.; Ou, J. Experimental investigation of smart FRP-concrete composite beam with embedded FBG sensors. In Proceedings of the International Conference on Smart Materials and Nanotechnology in Engineering, Harbin, China, 1–4 July 2007.

- Wang, Y.; Li, Y.; Ran, J.; Cao, M. Experimental investigation of a self-sensing hybrid GFRP-concrete bridge superstructure with embedded FBG sensors. Int. J. Distrib. Sens. Netw. 2012. 902613. [Google Scholar] [CrossRef]

- Lau, K.T.; Yuan, L.; Zhou, L.M.; Wu, J.; Woo, C.H. Strain monitoring in FRP laminates and concrete beams using FBG Sensors. Compos. Struct. 2001, 51, 9–20. [Google Scholar] [CrossRef]

- Chan, P.K.C.; Jin, W.; Lau, K.T.; Zhou, L.M.; Demokan, M.S. Multi-point strain measurement of composite-bonded concrete materials with a RF-band FMCW multiplexed FBG sensor array. Sens. Actuators 2000, 87, 19–25. [Google Scholar] [CrossRef]

- Montanini, R.; De Domenico, F.; Freni, F.; Maugeri, N.; Recupero, A. Structural health monitoring of reinforced concrete beams by means of embedded fiber Bragg grating sensors. In Proceedings of the 22th International Conference on Optical Fiber Sensors (OFS-22), Beijing, China, 15–19 October 2012; pp. 1–4.

| Symbol | Value | Unit | Description |

|---|---|---|---|

| L | 300 | mm | distance between supports |

| B | 85 | mm | beam cross section |

| hc | 85 | mm | concrete cross section height |

| hm | 8 | mm | mortar cross section height |

| hf | 0.05 | mm | PBO cross section height |

| Ec | 39,300 | MPa | concrete modulus of elasticity |

| Em | 6200 | MPa | mortar modulus of elasticity |

| Ef | 450,000 | MPa | PBO modulus of elasticity |

| νc, νm | 0.25 | - | Poisson’s number |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montanini, R.; Recupero, A.; De Domenico, F.; Freni, F. Strain Sharing Assessment in Woven Fiber Reinforced Concrete Beams Using Fiber Bragg Grating Sensors. Sensors 2016, 16, 1564. https://doi.org/10.3390/s16101564

Montanini R, Recupero A, De Domenico F, Freni F. Strain Sharing Assessment in Woven Fiber Reinforced Concrete Beams Using Fiber Bragg Grating Sensors. Sensors. 2016; 16(10):1564. https://doi.org/10.3390/s16101564

Chicago/Turabian StyleMontanini, Roberto, Antonino Recupero, Fabrizio De Domenico, and Fabrizio Freni. 2016. "Strain Sharing Assessment in Woven Fiber Reinforced Concrete Beams Using Fiber Bragg Grating Sensors" Sensors 16, no. 10: 1564. https://doi.org/10.3390/s16101564