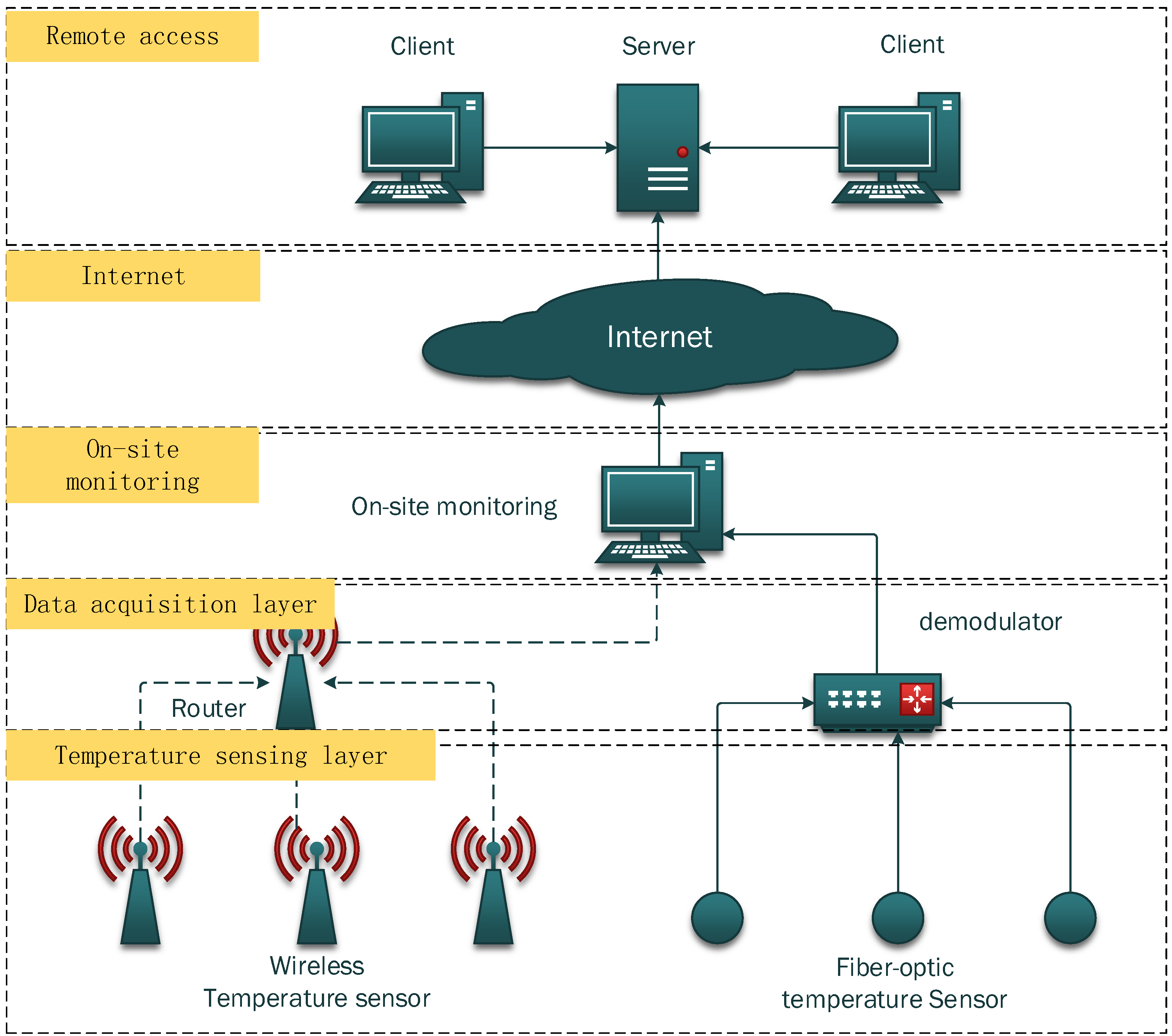

Figure 1.

Hardware design for the monitoring system.

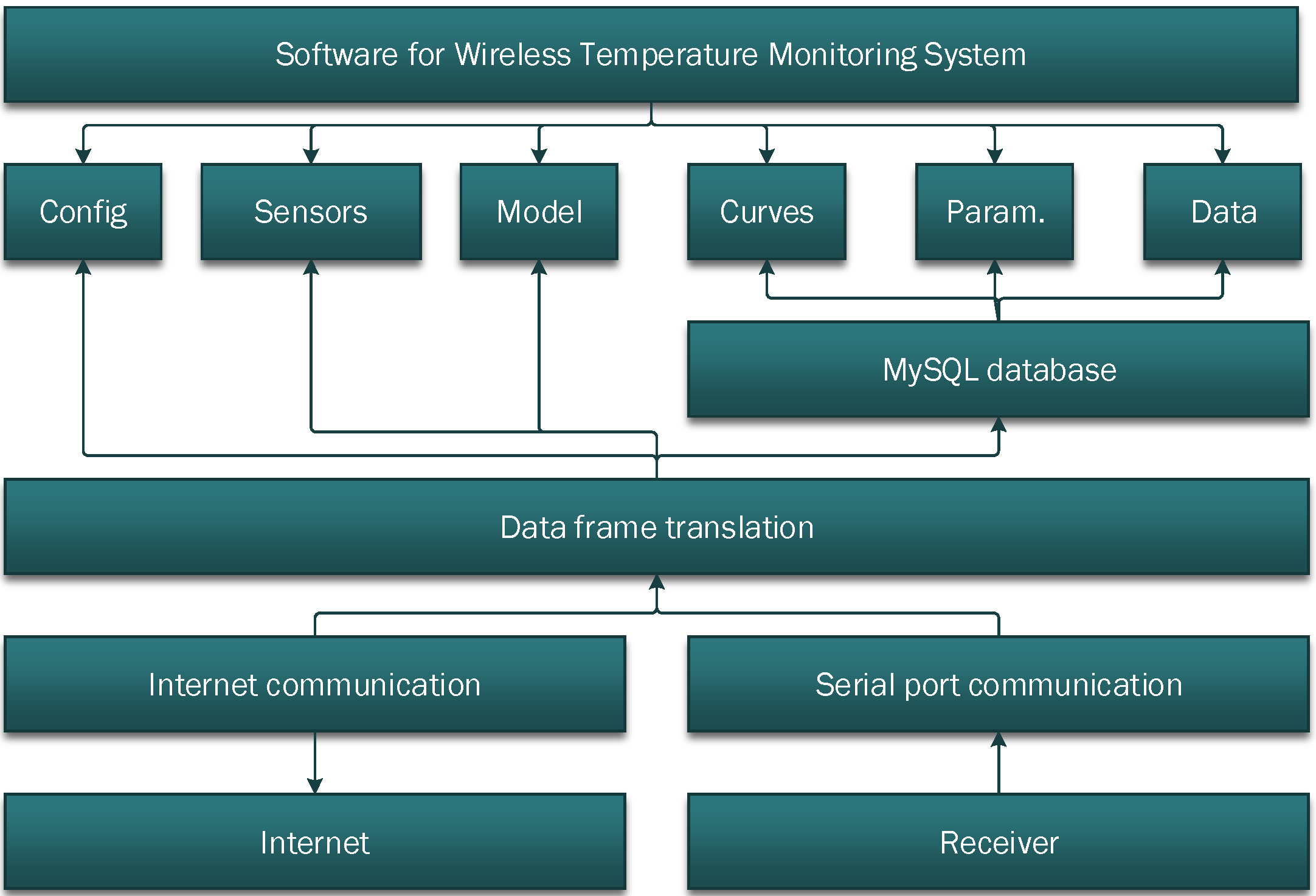

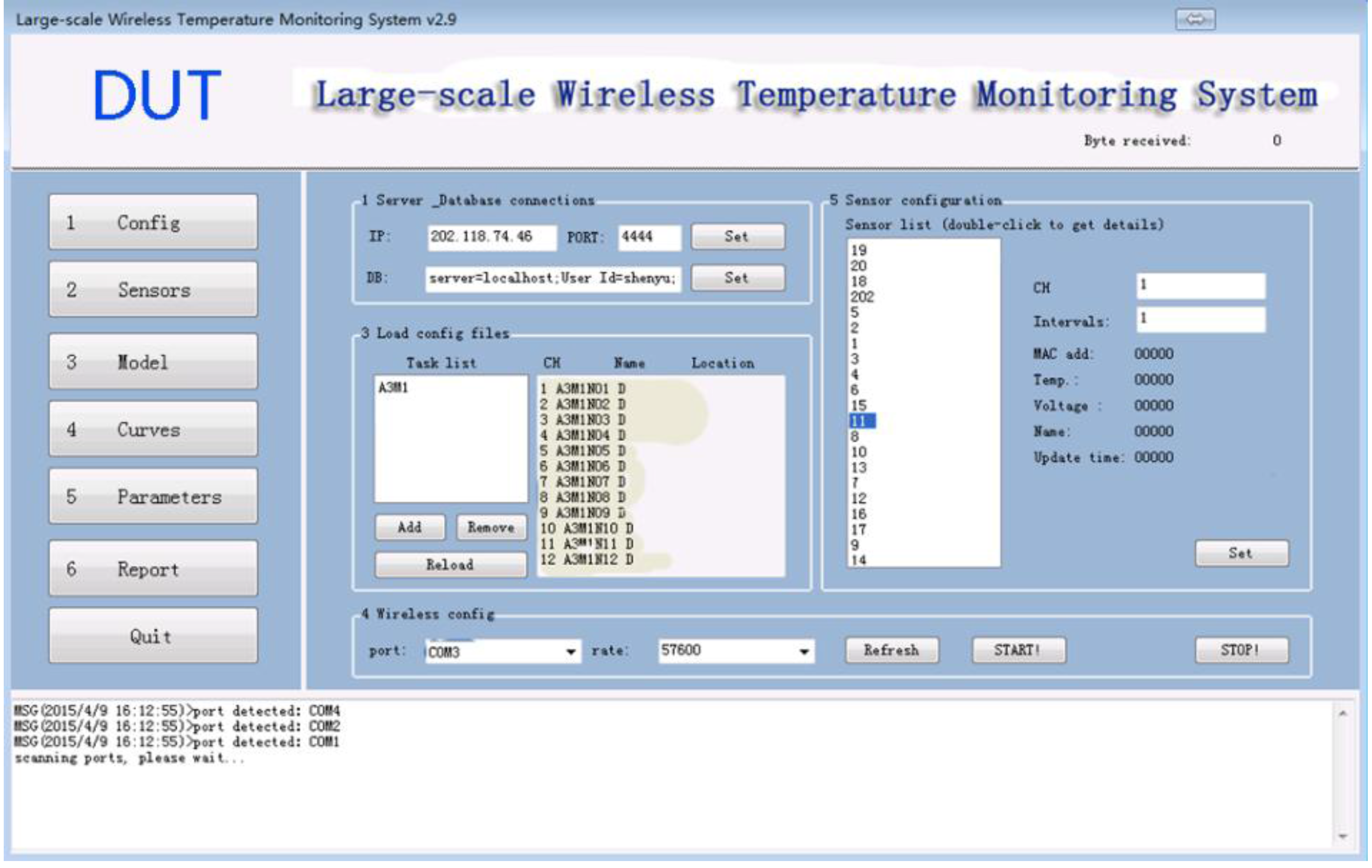

The temperature sensing layer is responsible to measure the raw temperature data from the LPG storage tanks. In this layer, both wireless temperature sensors and fiber optic temperature sensors are utilized. The wireless temperature sensors are easy to deploy while the fiber optic sensor is free of electric shock and can be deployed in certain critical areas. The data acquisition layer is to collect the data from the temperature sensing layer. This layer has routers to receive data from the wireless temperature sensors and demodulators to obtain data from the fiber optic sensors. The demodulator is an OSA with MATLAB programs inside. The programs can calculate the L parameter of the FP cavity and further to get the temperature data by using cavity length

vs. temperature function we will discuss in

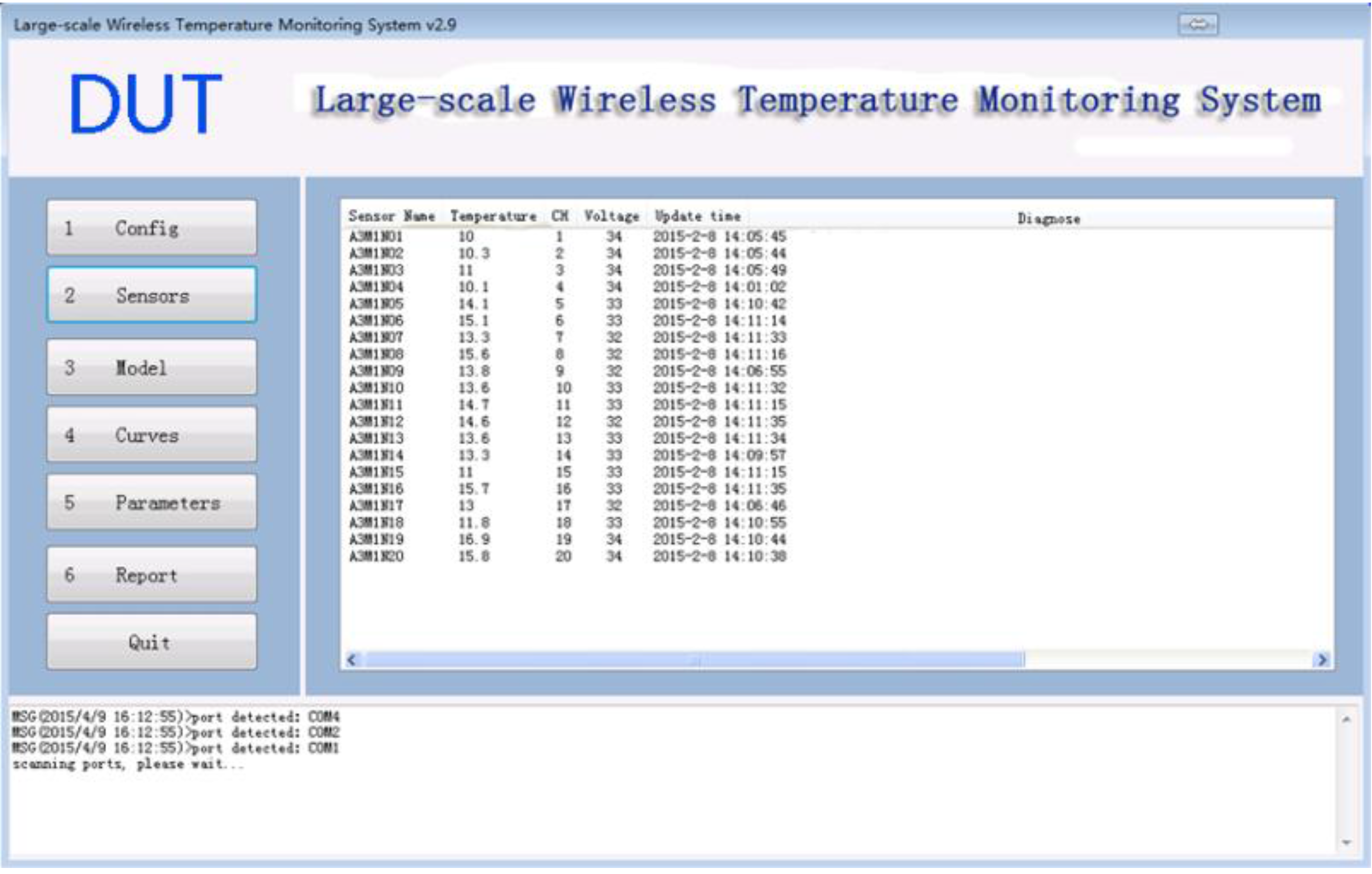

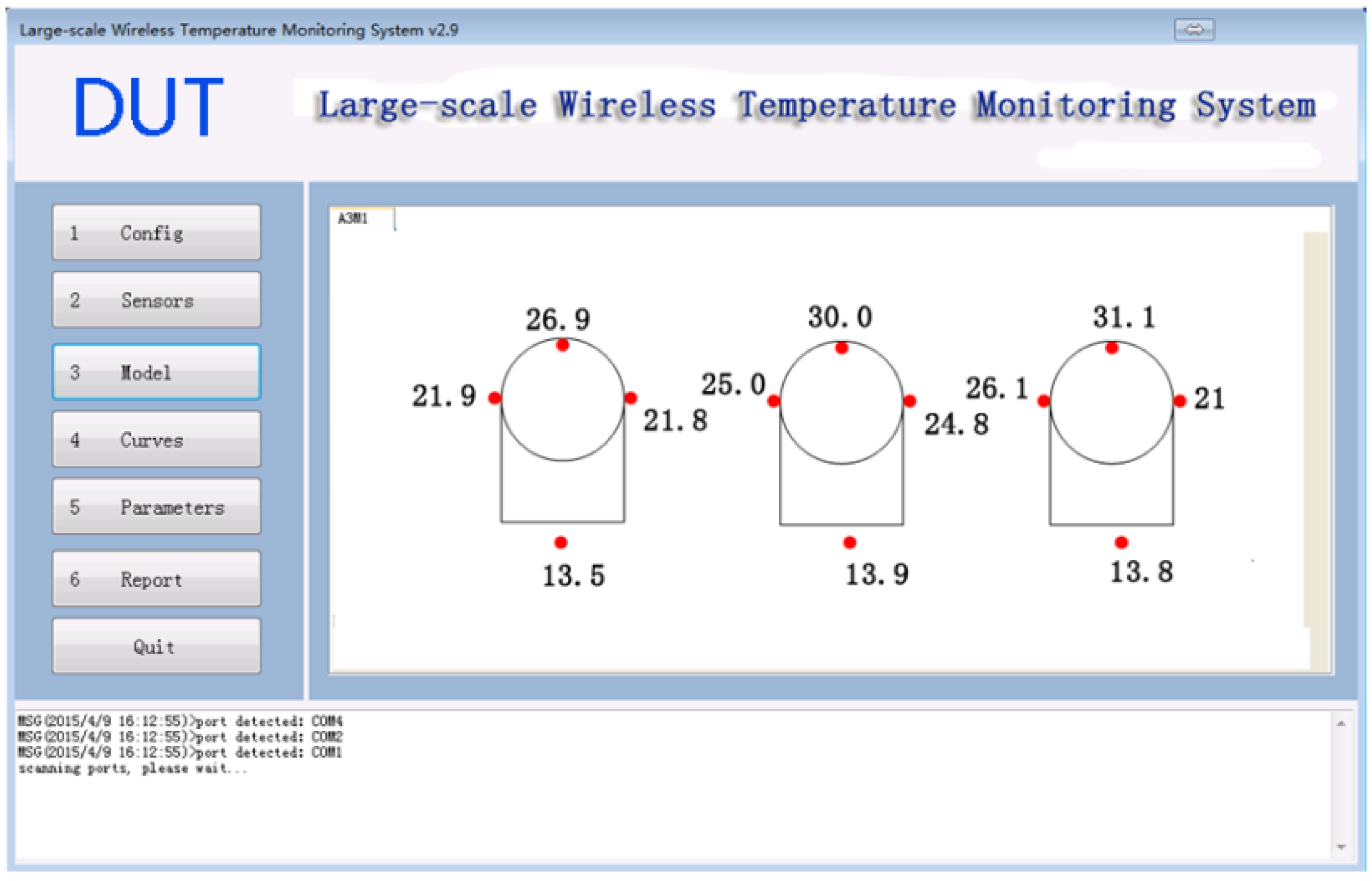

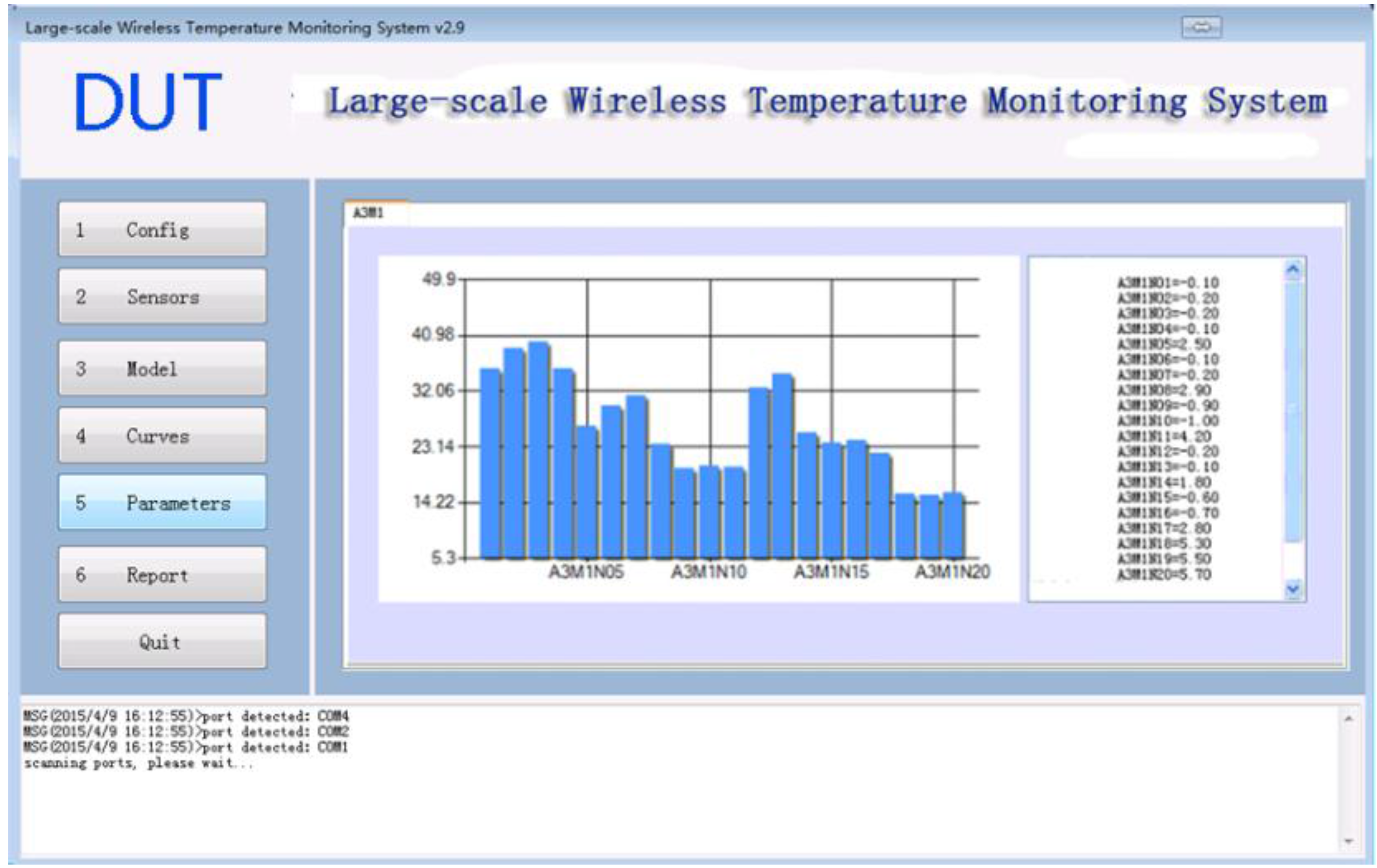

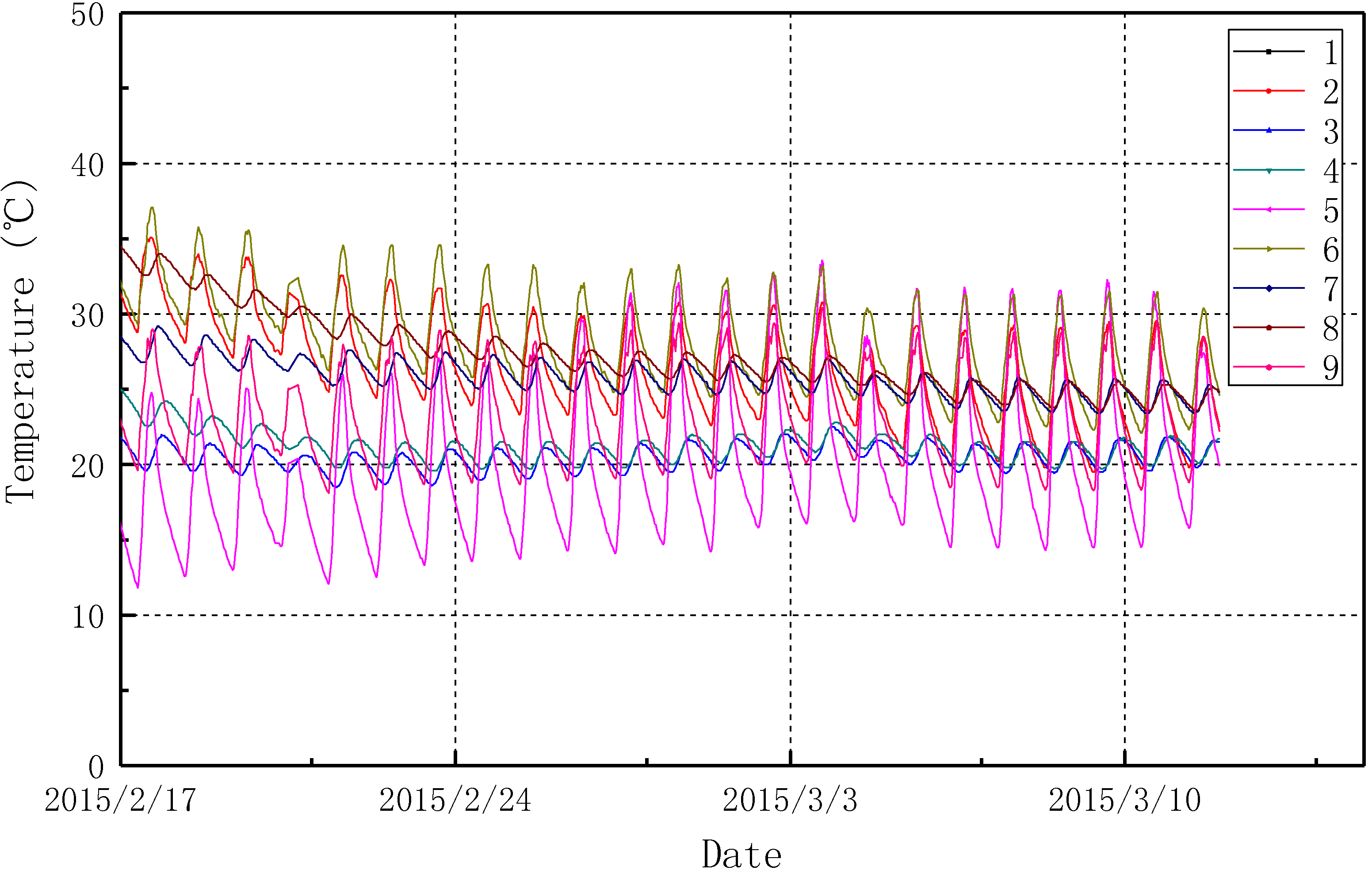

Section 2.2. The routers deployed in the fields cover a wide range of area, enabling a large number of wireless temperature sensors to monitor the LPG storage tanks. The on-site monitoring layer, therefore, collects data from routers and demodulators. The on-site monitoring system gets the data from the routers via a wireless receiver and from the demodulator through a LAN cable. With the collected data, the on-site monitoring server displays all the temperature information via monitoring software, which will be further discussed in next section. In addition to data display, the on-site monitoring layer also forwards all the monitored temperature data to the remote server allowing remote access from the clients, which is the top layer of this system. The remote access layer has one server and several clients. The server receives the temperature data obtained from several different on-site monitoring servers, store, and analyze the temperature information in the database. The server also provide web services for the clients, allowing people to have access to the temperature information from everywhere in the world. Details for all the layers are discussed in following subsections.

2.1. Wireless Sensor and Sensor Network

A Zigbee wireless sensor network is used in this study.

Figure 2 shows the framework of the applied network, which consist of wireless temperature sensing nodes, routers and receivers (also known as coordinator). The wireless temperature sensing node, as shown in

Figure 3, measures the raw temperature and sends the data to the router. The router, as shown in

Figure 4, then forwards the data to the wireless receiver, as shown in

Figure 5. A plurality of routers operate in multi-hop transmission; hence, the wireless signal is able to cover a wide range of area.

Figure 2.

Framework for ZigBee wireless sensor network.

Figure 2.

Framework for ZigBee wireless sensor network.

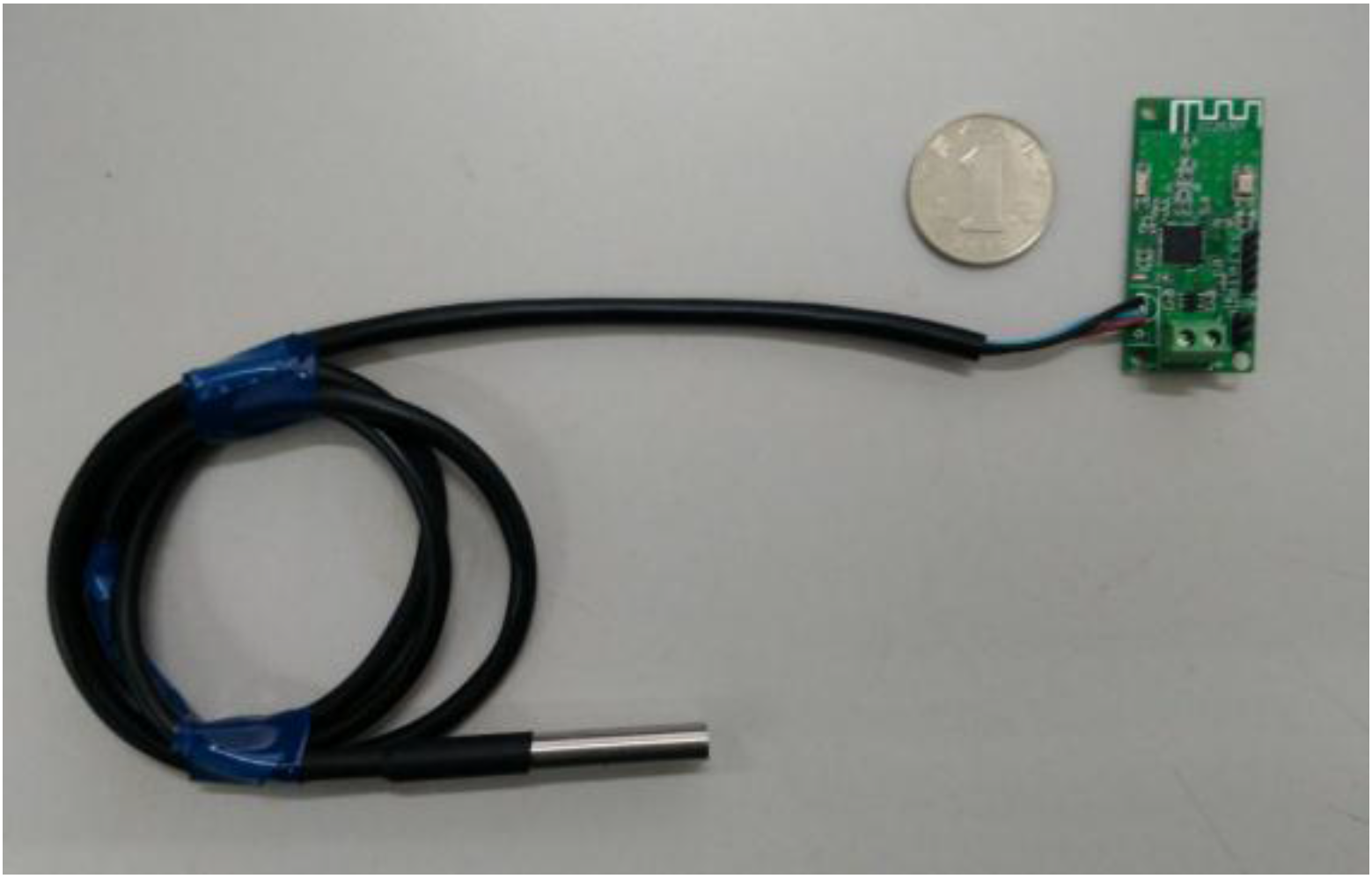

Figure 3.

Wireless sensing node.

Figure 3.

Wireless sensing node.

As shown in

Figure 3, a digital temperature sensor (model DS18B20) and a system-on-chip solution (SoC chip CC2530) were utilized to form the wireless sensing network. The DS18020 digital temperature sensor has a unique one-wire interface which requires only one port pin for communication. It has a temperature measurement range from −55 to +125 °C and an accuracy of ±0.5 °C, which make it an excellent choice for the temperature monitoring. The CC2530 chip is an IEEE 802.15.4 compliant true system-on chip, supporting the proprietary 802.15.4 market as well as the ZigBee standards. The CC2530 offers a 101 dB link budget, which has an excellent receiver sensitivity and robustness to interference, four power modes, multiple FLASH sizes, and extensive peripheral set including two USARTs, 12Bit ADC, and 21 general-purpose GPIO, as well as an industry-standard enhanced 8051 MCU core.

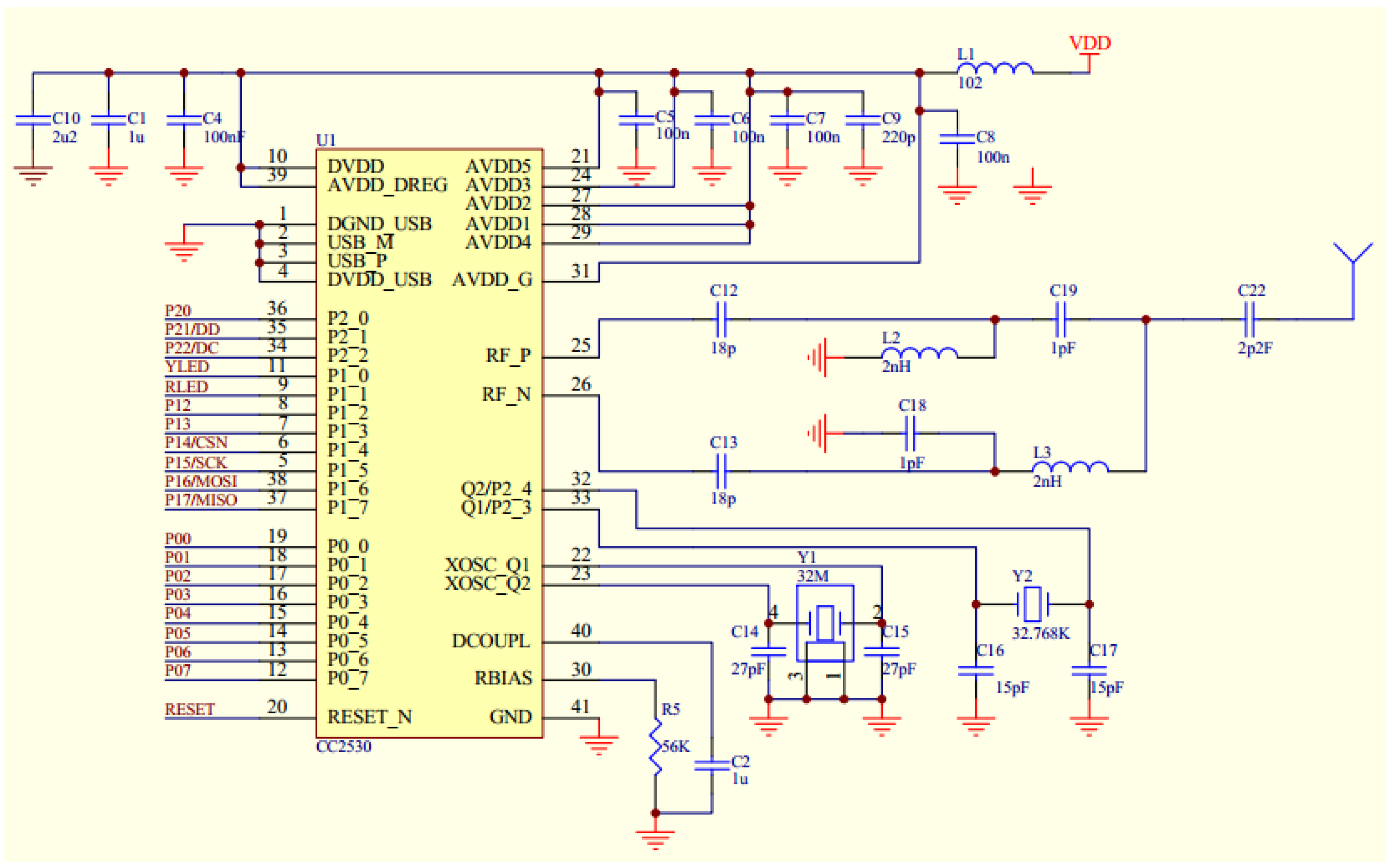

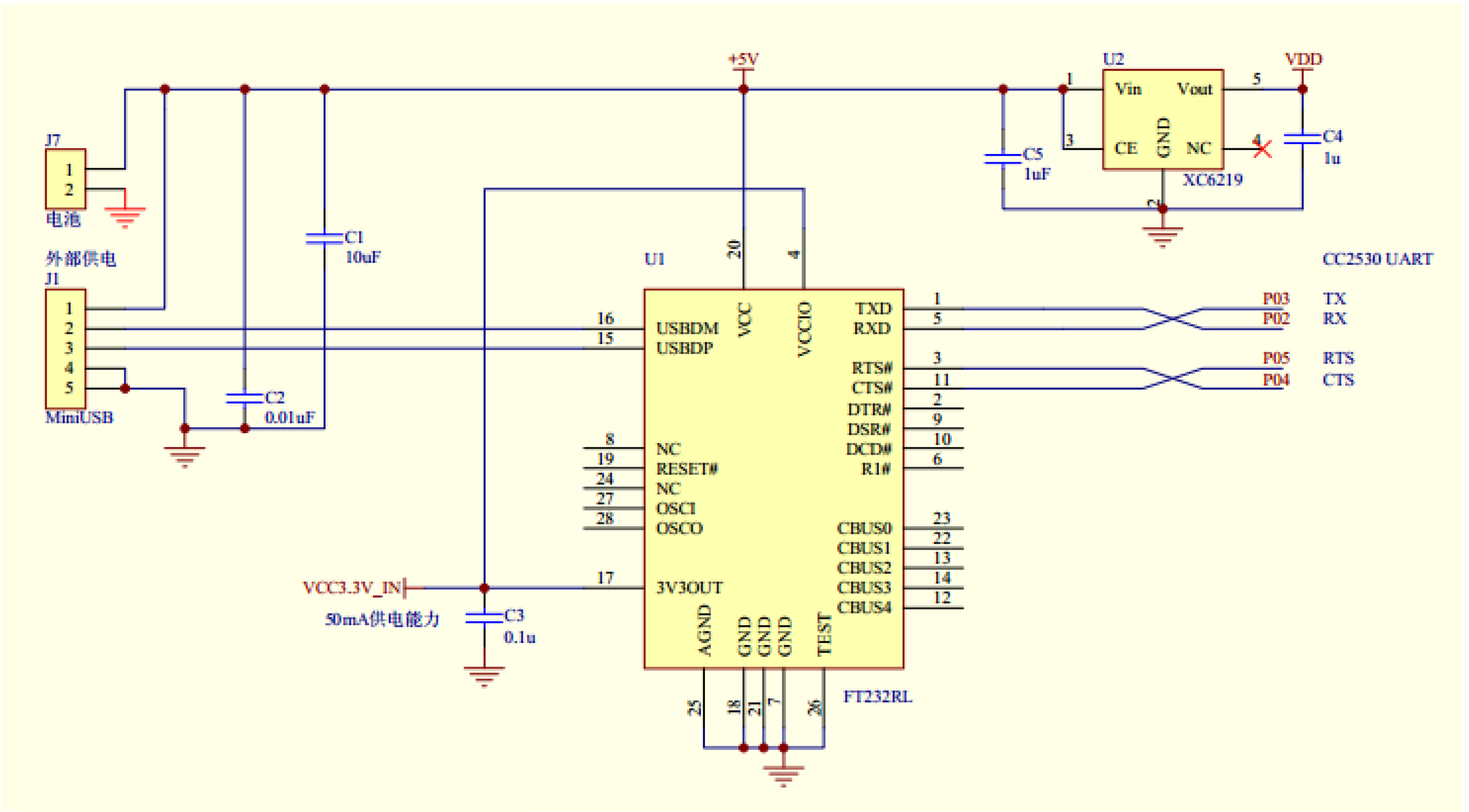

The excellent functionalities provided by the DS18B20 and the CC2530 make it possible to achieve a unified design. Schematic design of the Printed Circuit Board for the wireless temperature sensing node, router and receiver are outlined in

Figure 6. In the design of the wireless temperature sensing node, an onboard PCB antenna was utilized in order to make the sensing node to be compact in size. In the design of the router and receiver, an external antenna was utilized to achieve high signal to noise ratio.

Figure 6.

Schematic design of PCB.

Figure 6.

Schematic design of PCB.

The performances of hardware were tested and

Table 1 shows the tested results. The temperature measurement range is 0 °C~+125 °C which meet the basic temperature monitoring requirements for the LPG storage tanks. The measurement resolution is 0.1 °C and the measurement precision is ±0.5 °C. The data acquisition interval ranges from one second to 24 h and the default set up is 10 min. The wireless transmission range is 50 to 300 m and can be extended by adding more routers. The working frequency is 2.4 GHz and the system power voltage is 3.0–5.5 VDC, which can be powered by battery or by solar energy based on the users’ needs. The system has a relative low energy consumption, which is mainly due to the onboard sleep mode. In the normal operation mode the system has a working current of 10 mA, while in the sleep mode the current drops to 10 µA. The normal operation mode activates only when the data acquisition interval is arrive. The sleep mode activates by the onboard software when the data transmission completed. Considering the transmission rate of the ZigBee system, the data transmission is done in less than 5 ms. Thus, most of the time the system is working in the sleep mode. Based on the experiment data and the on-site experience a single sensor node powered by a typical 2000 mAh lithium battery has a life of more than two years working at a data acquisition interval of two minutes.

Table 1.

Performances of hardware

Table 1.

Performances of hardware

| Item | Performances |

|---|

| Temperature Range | 0 °C~+125 °C |

| Resolution | 0.1 °C |

| Precision | ±0.5 °C |

| Data acquisition interval | 1 s~24 h |

| Wireless transmission range | 50~300 m |

| Max sensing nodes | 65,535 |

| Working frequency | 2.4 GHz |

| System power voltage | 3.0~5.5 V/DC |

2.2. Fiber Optic Temperature Sensor

Fiber optic sensor has several advantages over conventional sensors: immunity to electromagnetic interference, ability to operate in harsh environments and potential for multiplexing. It has high sensitivity and is widely used in the demanding measurements of various physical quantities, such as temperature, strain, pressure, refractive index, displacement, vibration, etc. It is an excellent candidate to use on the oil storage tank where electric charge and discharge are strictly prohibited as even a tiny spark can light the flammable gas and causing disasters. Therefore, the application of fiber optic sensors not only allow for high precision but also minimize the risk of fire hazard caused by monitoring system.

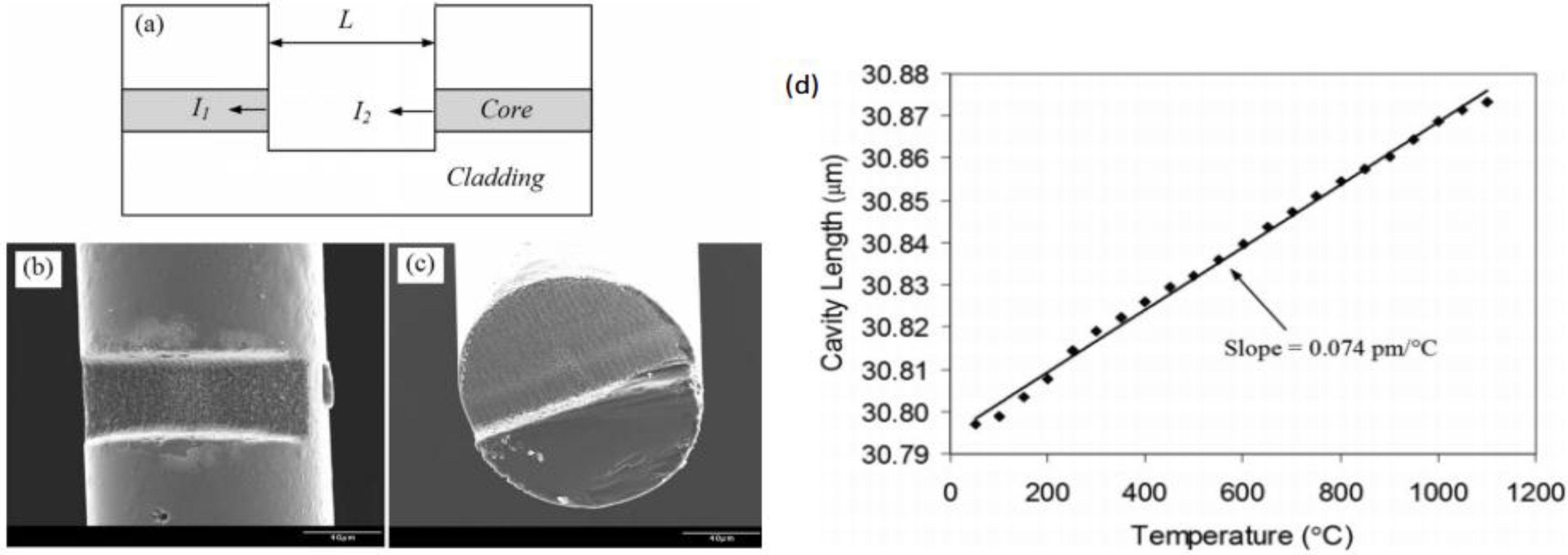

In this study, we used a miniaturized fiber inline FP interferometer temperature sensor fabricated by femtosecond laser. As shown in

Figure 7a–c, an open cavity was formed by one-step micromachining a micro notch in a single-mode optical fiber using a femtosecond laser. The device has an all-glass structure and does not involve the assembly of multiple components. As a result, we expect that the device will survive very high temperatures which make it suitable for temperature monitoring in the oil storage tank.

Figure 7.

Schematic structure and SEM images of fiber inline FPI device fabricated by femtosecond laser ablation and corresponding response to temperature variation. (a) Structural illustration; (b) Top view; (c) Cross-section; (d) Temp. vs. Cavity Length.

Figure 7.

Schematic structure and SEM images of fiber inline FPI device fabricated by femtosecond laser ablation and corresponding response to temperature variation. (a) Structural illustration; (b) Top view; (c) Cross-section; (d) Temp. vs. Cavity Length.

The device fabrication was carried out using a home-integrated fs laser 3D micromachining system. The repetition rate, center wavelength, and pulse width of the femotosecond (fs) laser (Legend-F, Coherent, Inc. Santa Clara, CA, USA) were 1 kHz, 800 nm, and 120 fs, respectively. The maximum output power of the fs laser was approximately 1 W. We used the combination of waveplates and polarizers to reduce the laser power to about 20 mW, and then used several neutral density (ND) filters to further reduce the laser power to desirable values. The attenuated laser beam was directed into an objective lens (Olympus UMPLFL 20X) with a numerical aperture (NA) of 0.45 and focused onto the single mode optical fiber (Corning SMF 28) mounted on a computer-controlled five-axis translation stage (Aerotech, Inc. Pittsburgh, PA, United States) with a resolution of 1 mm.

During fabrication, the interference signal of the fiber FP device was continuously monitored. A tunable laser source (HP 8168E) was connected to one of the input ports of the 3 dB fiber coupler. The output port of the coupler was connected to the device under fabrication. Controlled by the computer, the tunable laser continuously scanned through its wavelength range (1475–1575 nm) at the rate of 1 nm per step. The signal reflected from the device at each wavelength step was recorded by an optical power meter (Agilent 8163A). The fabrication was stopped after a well-formed interference pattern was recorded. The interference signal is interrogated based on the two-beam optical interference equation as follows:

where

is the intensity of the interference signal,

and

are the reflections at the cavity surfaces, respectively,

is the initial phase of the interference,

is the optical length of the cavity, and

is the optical wavelength. According to Equation (2), the two adjacent interference minimums have a phase difference of 2π. That is

where λ

1 and λ

2 are the wavelengths of two adjacent valleys (

Figure 3) in the interference spectrum. The optical length of the FP cavity can thus be found as

. Based on the interference spectrum we obtained from the optical power meter (Agilent 8163A) in the fabrication process, the two neighboring valleys are 1489.1 nm and 1525.1 nm, we calculated that the FP cavity length was 30.797 μm, which was very close to the length estimated by SEM imaging.

The fabricated device was tested for its ability to survive high temperatures. The sensor was placed horizontally in a quartz tube with one-inch inner diameter, hosted inside a programmable electric tubular furnace. The temperature of the furnace was increased from room 50 °C to 1100 °C (limited by the highest temperature of the furnace used) at a step of 50 °C and the interference spectra at these temperatures were recorded. However, to improve the accuracy, we replaced the tunable laser with a broadband source made by multiplexing a C-band and an L-band Erbium doped fiber ASE (amplified spontaneous emission) sources. The interference fringe reflected from the device was recorded by an optical spectrum analyzer (OSA, HP 70952B).

The cavity length as a function of the temperature is plotted in

Figure 1d, where it increased nearly linearly following the increase of temperature. The fiber FP device successfully survived high temperatures up to 1100 °C. Even if not lasting long at the very high temperature, it is good enough to meet the needs of early warning of the LPG storage tank fire hazards. The temperature sensitivity of this particular FP device was estimated to be 0.074 pm/°C based on the linear fit of the measurement data. The equivalent CTE of the device was calculated to be 2.4 × 10

−6/°C, which was about four times larger than the known CTE of the fiber cladding (fused silica, 5.5 × 10

−7/°C). The thermal test was repeated several times and the results were quite reproducible.

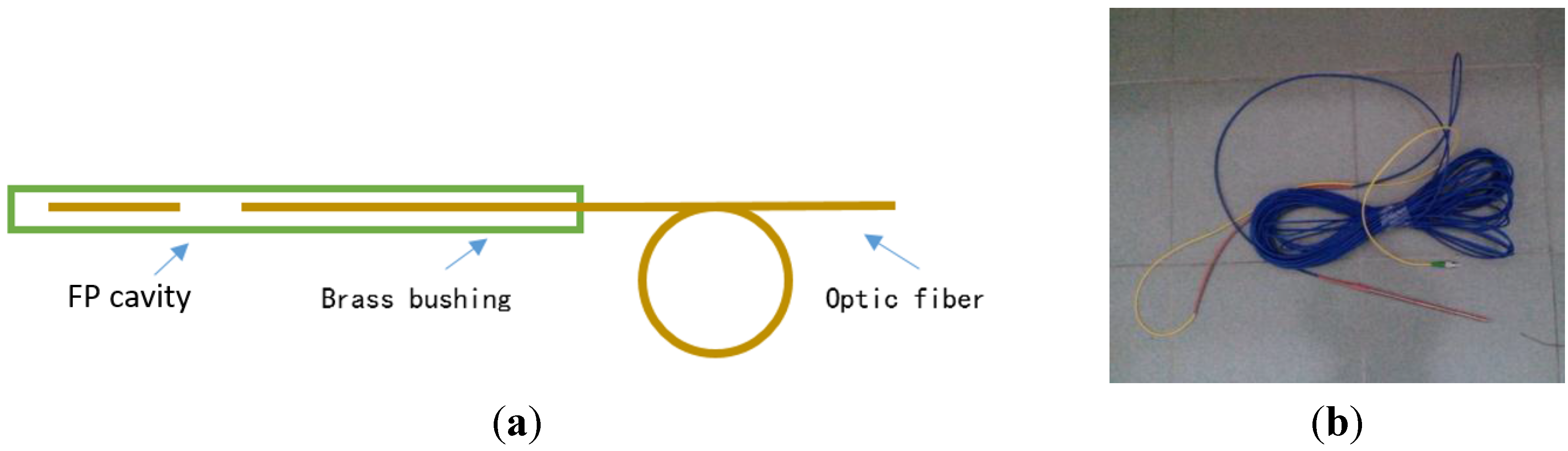

For the protection of the miniaturized fiber inline FP interferometer temperature sensor, a brass bushing packaging technique was introduced.

Figure 8a shows the schematic design of the packaged sensor and

Figure 8b shows the actual packaged temperature sensor.

Figure 8.

Schematic design and photo of the actual sensor. (a) Schematic design of fiber optical temperature sensor; (b) The actual temperature sensor.

Figure 8.

Schematic design and photo of the actual sensor. (a) Schematic design of fiber optical temperature sensor; (b) The actual temperature sensor.