Design and Simulation Test of an Open D-Dot Voltage Sensor

Abstract

:1. Introduction

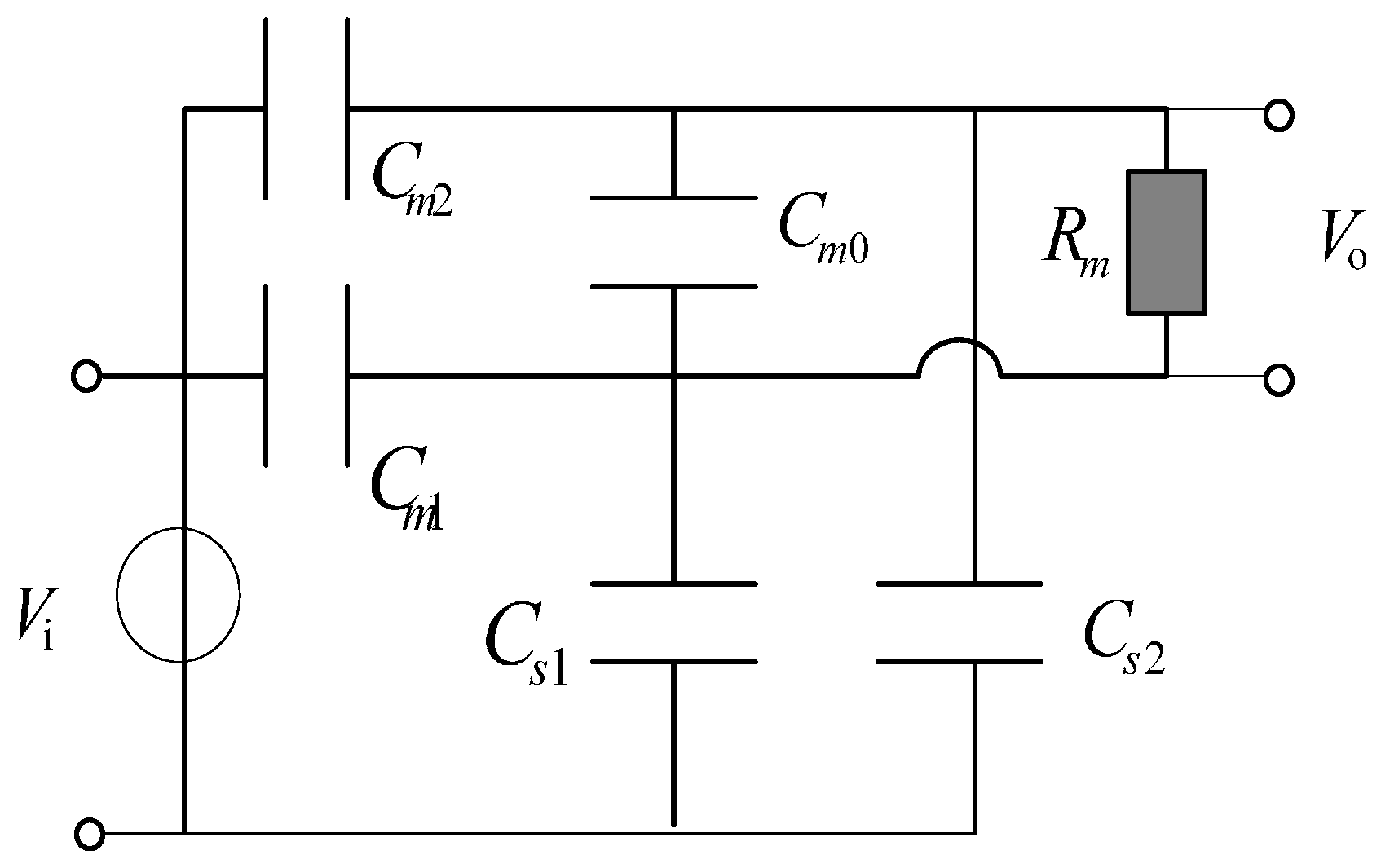

1.1. Principle of the Differential D-Dot Sensor

1.2. Symmetrical Differential D-Dot Sensor

1.3. Design of the Open D-Dot Voltage Mutual Transformer

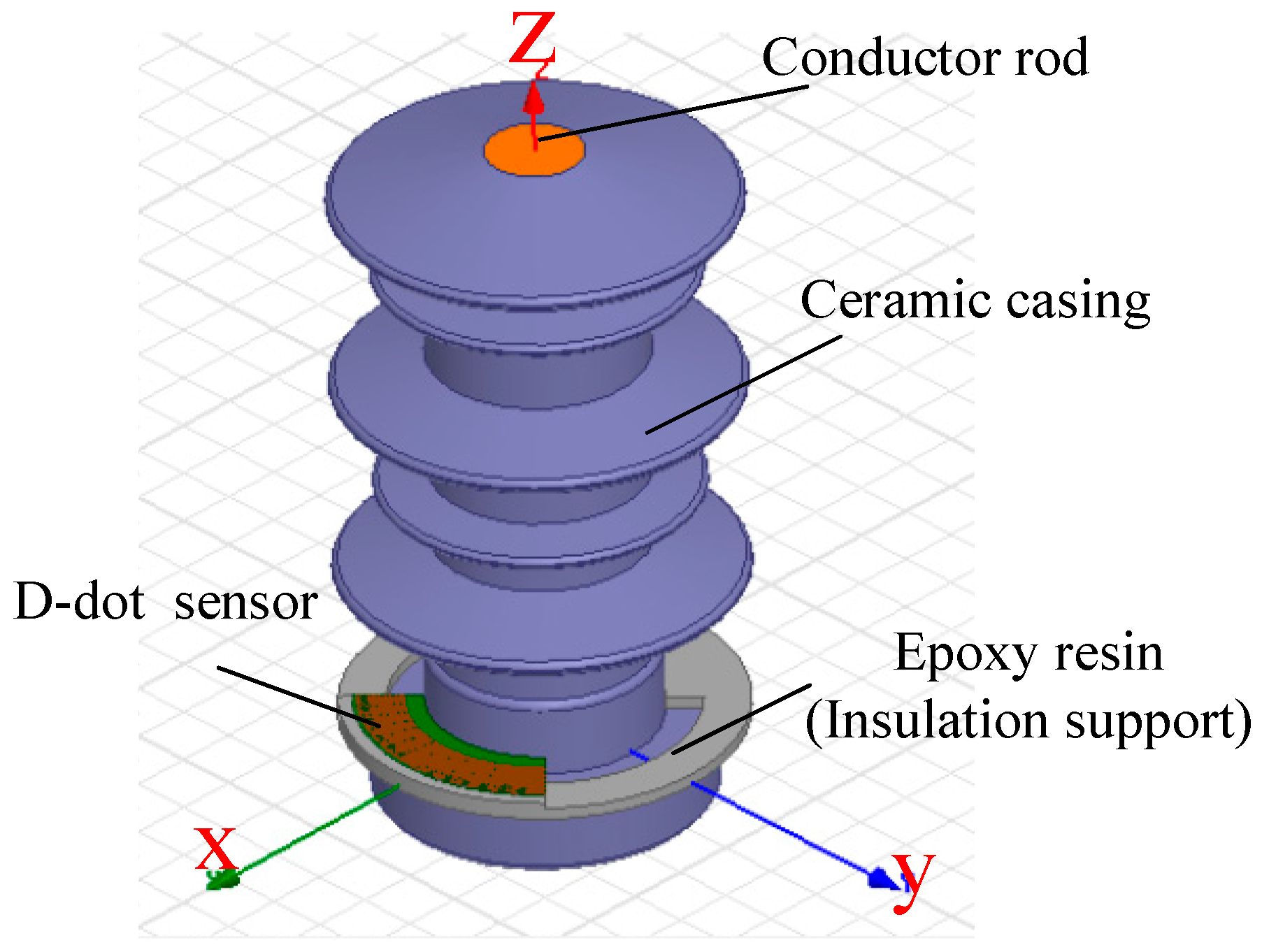

Sensor Structure Design

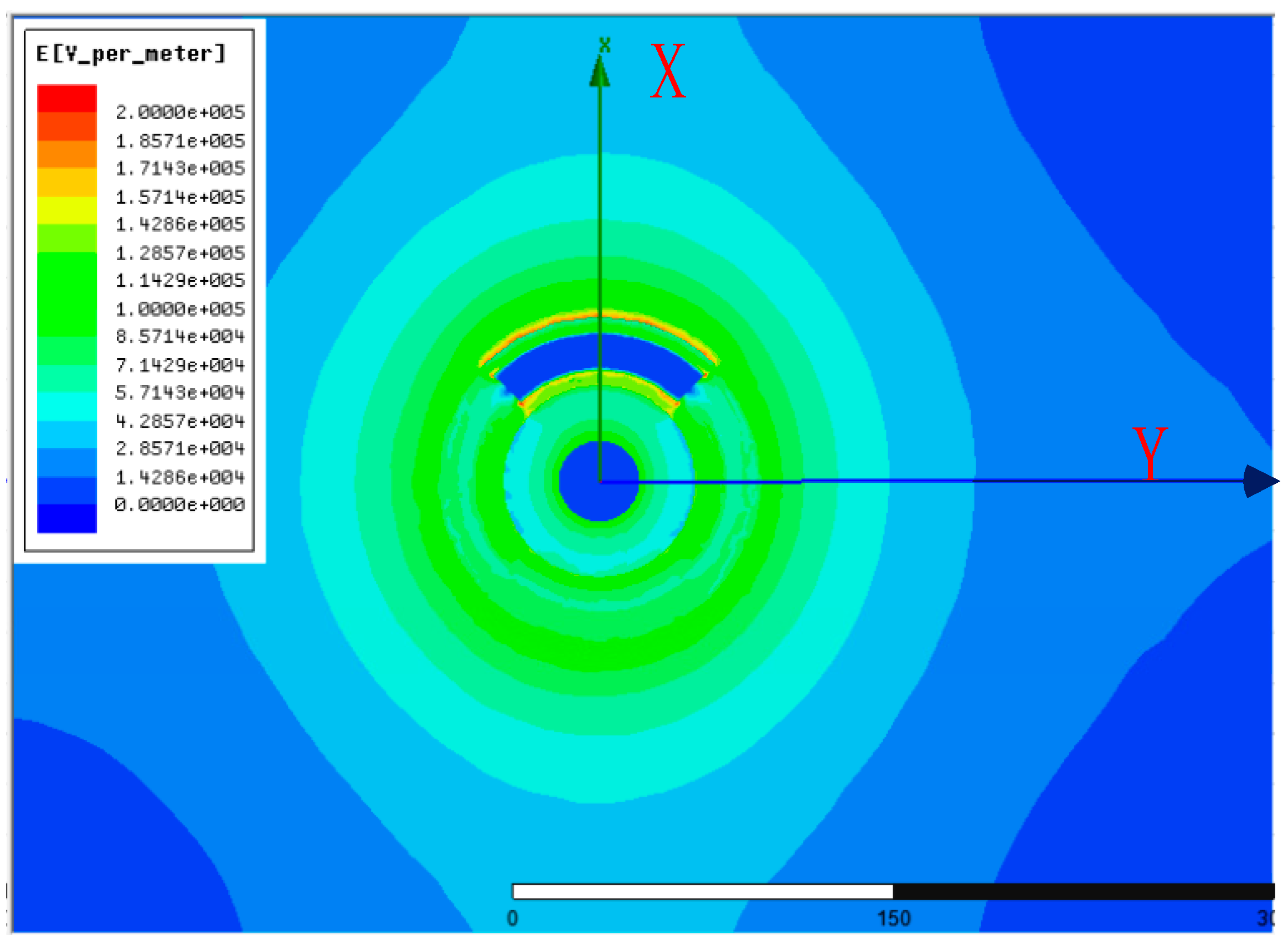

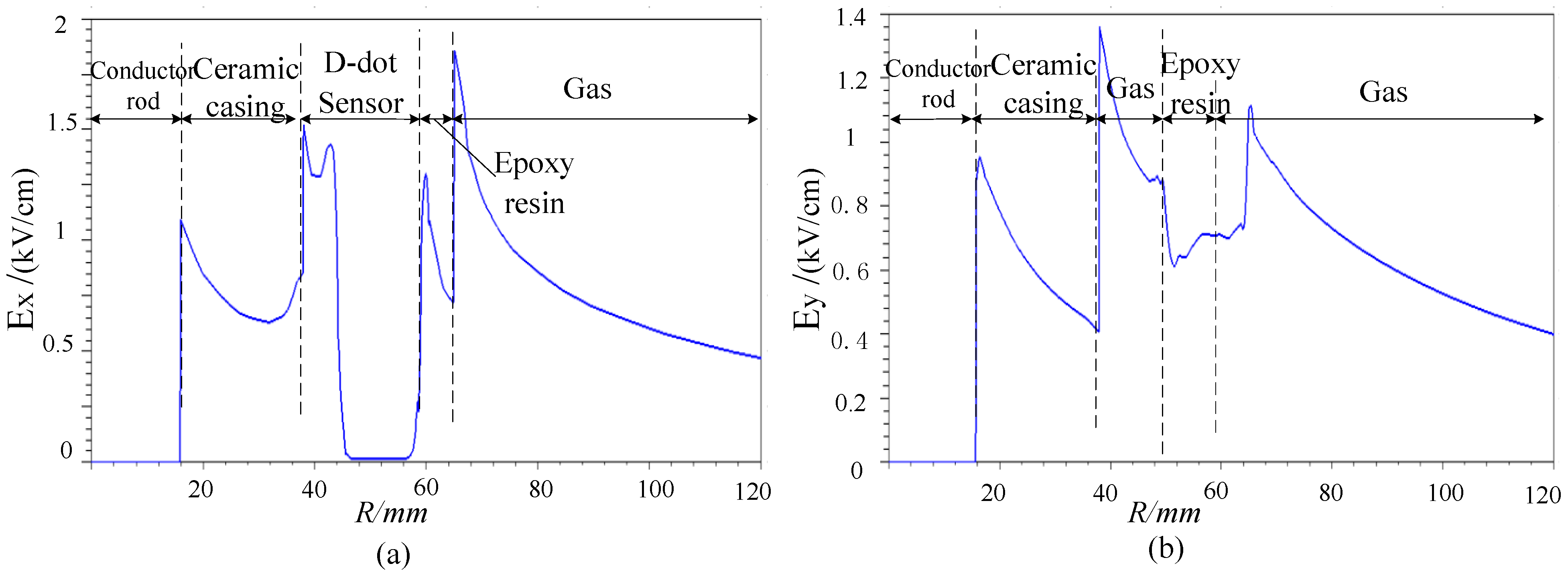

2. Simulation

Electric Field Distortion and Insulating Strength

3. Performance Test and Data Analysis of Sensor

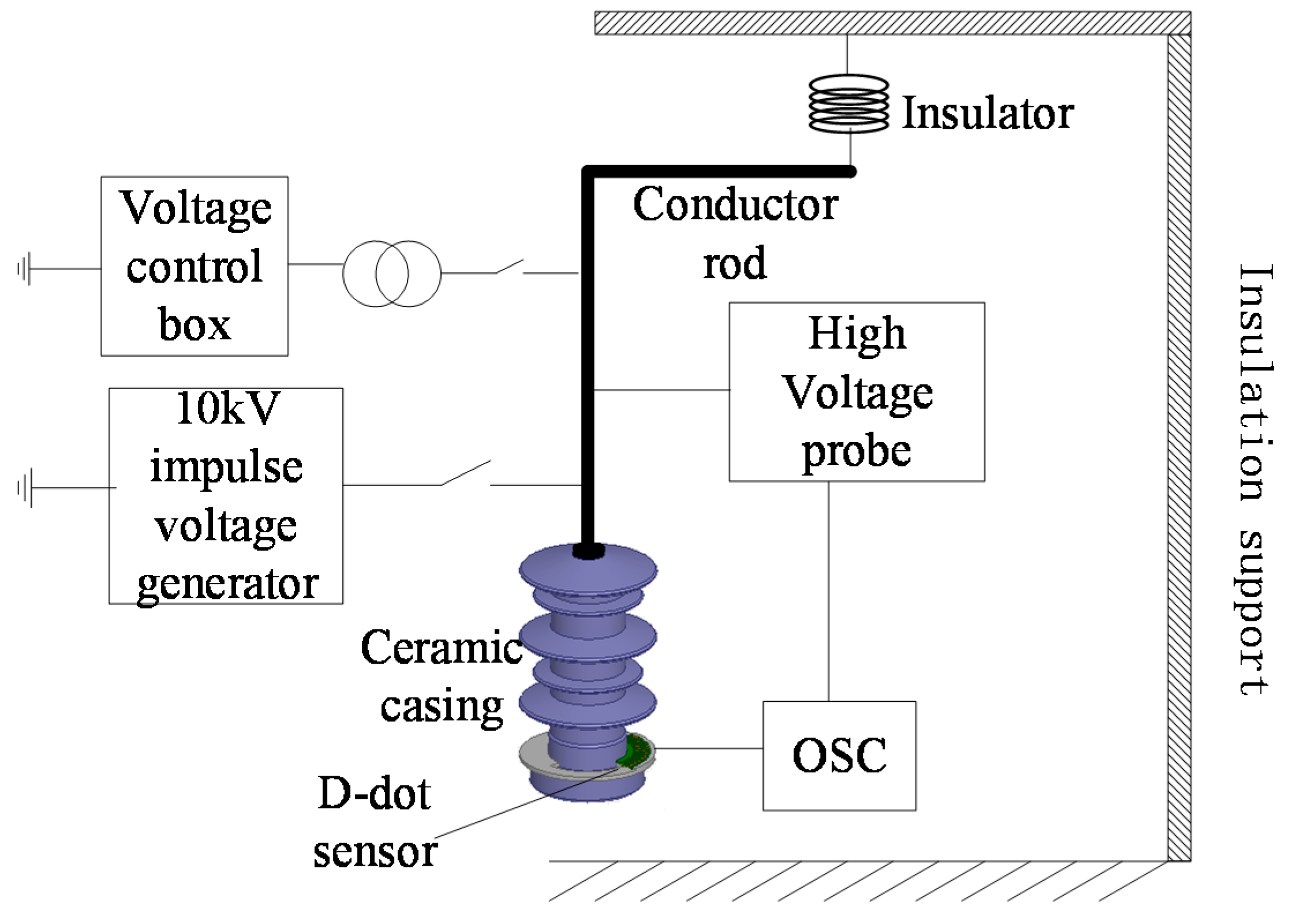

3.1. Testing Platform

3.2. Steady-State Error Test

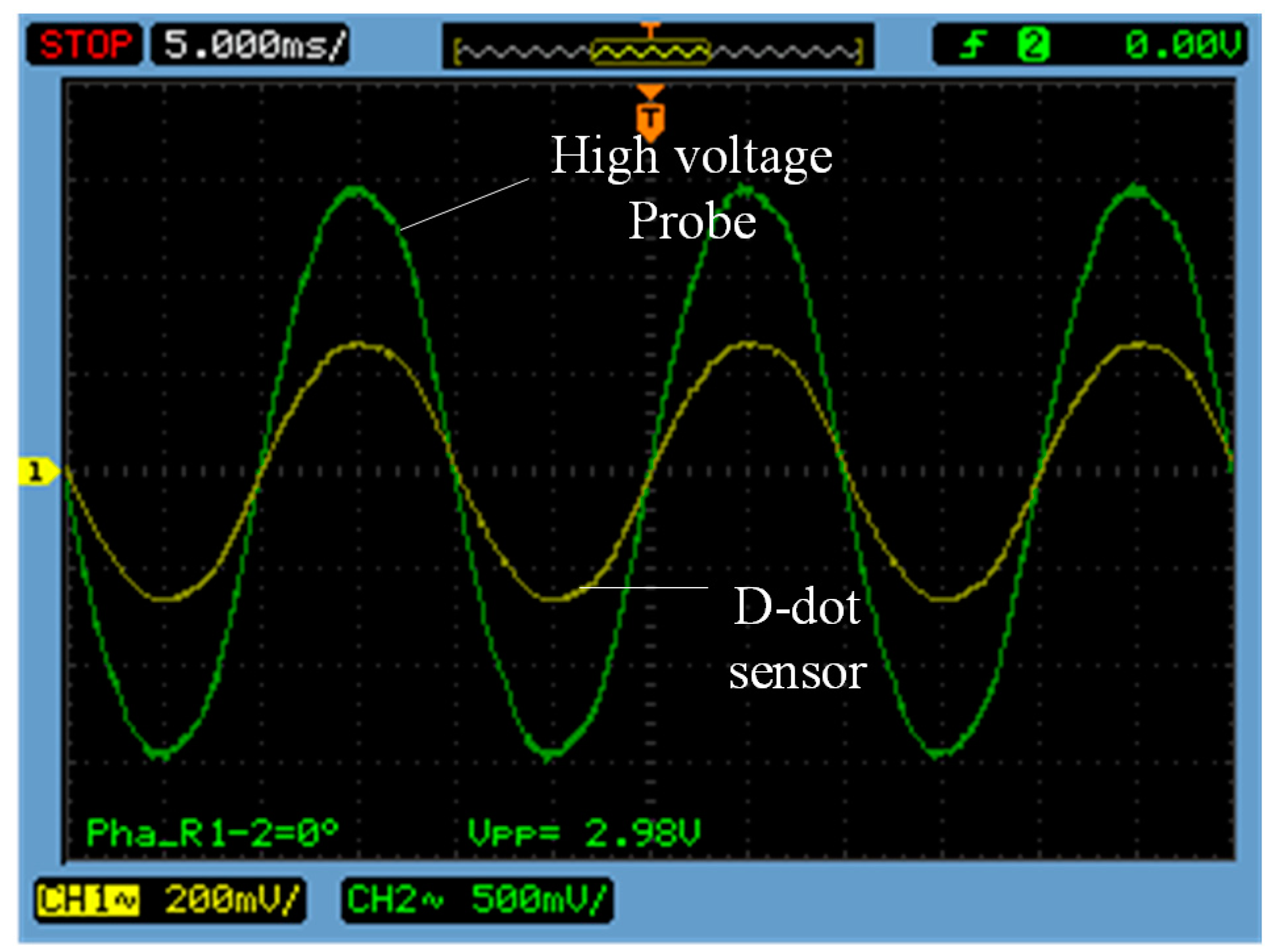

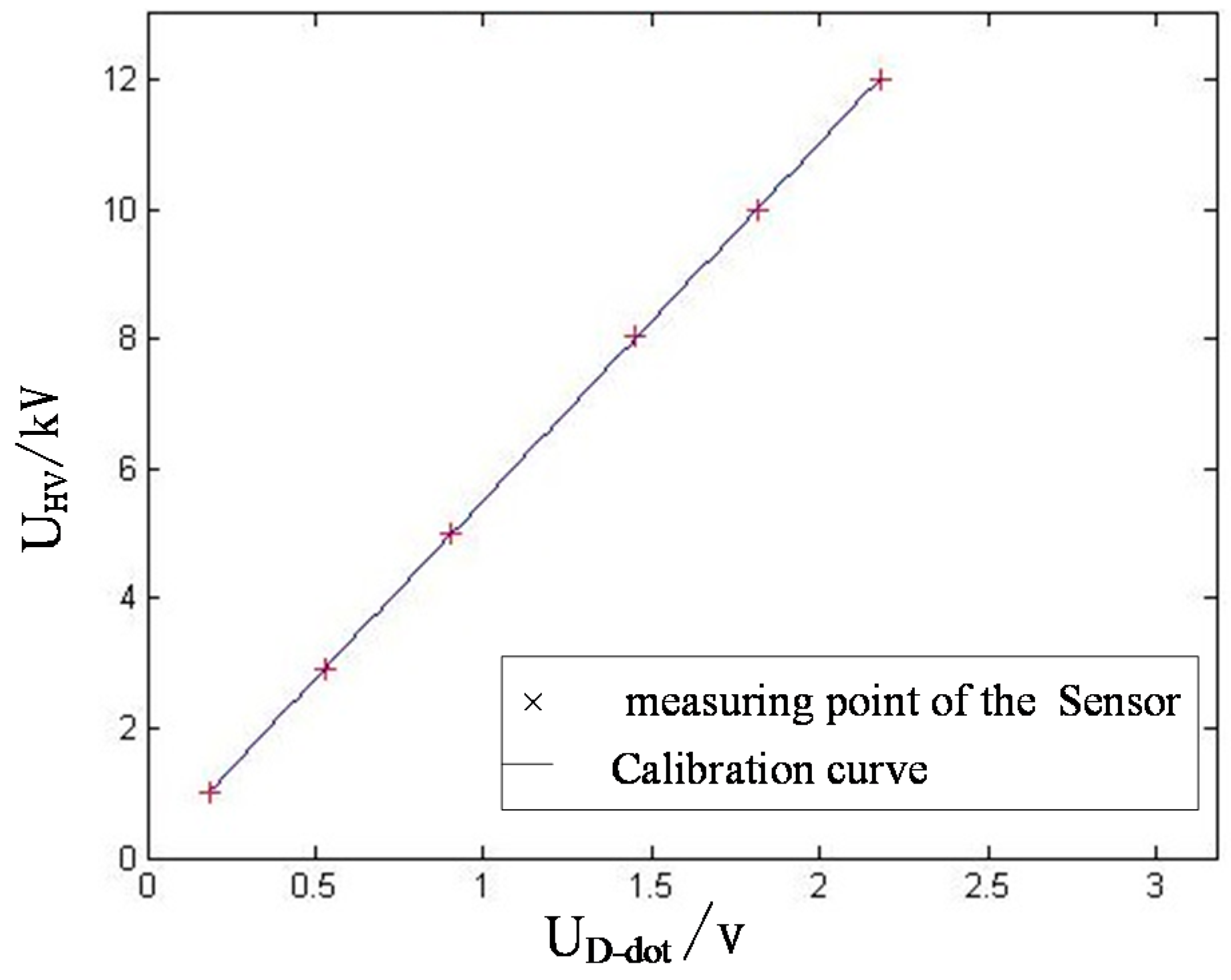

3.2.1. Power Frequency Steady-State Experiment

| Measurement Points | UHV/kV | UD-dot/V | Ratio Error/% |

|---|---|---|---|

| 10%Un | 1.016 | 0.185 | 0.41 |

| 30%Un | 2.98 | 0.540 | −0.09 |

| 50%Un | 5.002 | 0.903 | −0.46 |

| 80%Un | 8.032 | 1.45 | −0.46 |

| 100%Un | 9.995 | 1.815 | 0.13 |

| 120%Un | 12.018 | 2.179 | −0.03 |

3.2.2. Steady Harmonic Wave Test

| Measurement Points | UHV/kV | UD-dot/mV | Angular Difference (°) |

|---|---|---|---|

| 50 Hz | 1.84 | 94.4 | 3.974 |

| 150 Hz | 1.98 | 104 | 1.057 |

| 250 Hz | 1.94 | 104 | 1.092 |

| 350 Hz | 1.92 | 103 | 0.6717 |

| 450 Hz | 1.8 | 96.8 | 0.5 |

3.3. Transient-State Error Test

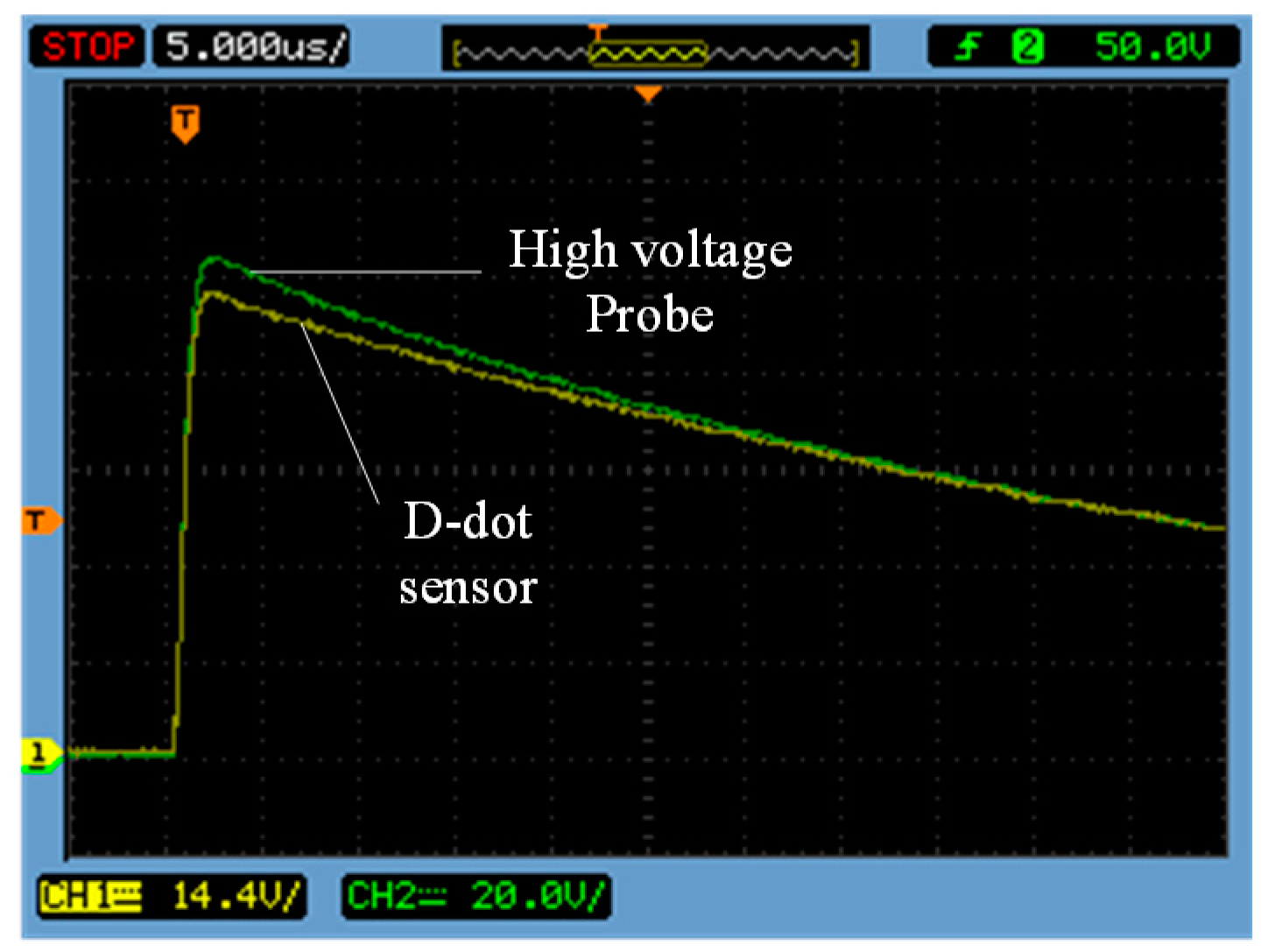

3.3.1. Impulse Voltage Test

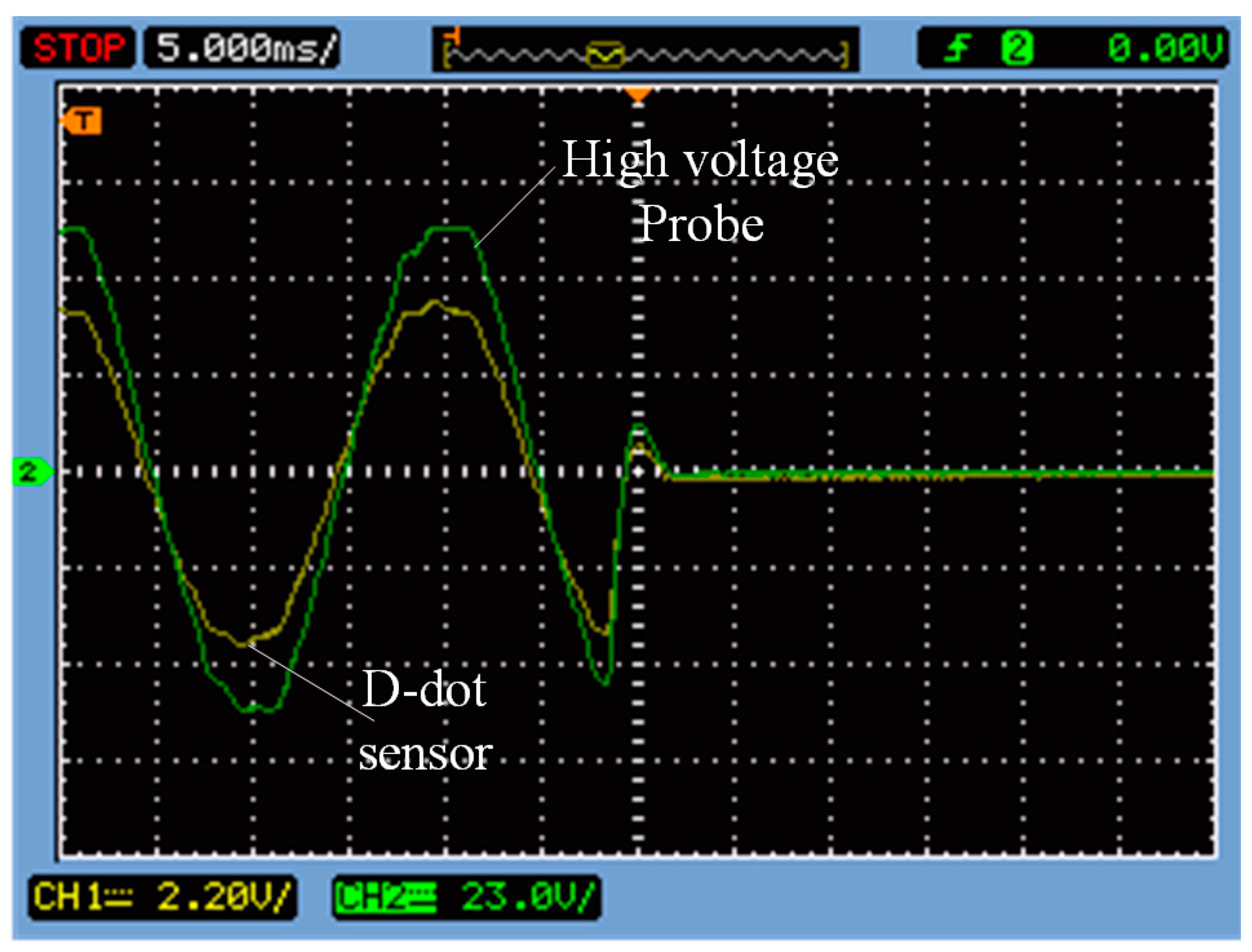

3.3.2. Transient-State Test of Switching Operation

4. Conclusions/Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Metwally, I.A. Coaxial D-dot probe: Design and testing. In Proceedings of the 1995 Annual Report on Electrical Insulation and Dielectric Phenomena, Virginia Beach, VA, USA, 22–25 October 1995; pp. 298–301.

- Struve, K.W.; Horry, M.L.; Spielman, R.B. Design, calibration, and performance of water diagnostics on the PBFA Z. In Proceedings of the 11th IEEE International Pulsed Power Conference, Baltimore, MA, USA, 29 June–2 July 1997; pp. 1303–1308.

- Wagoner, T.C.; Stygar, W.A.; Ives, H.C. Differential-output B-dot and D-dot monitors for current and voltage measurements on a 20 MA, 3 MV pulsed-power accelerator. Phys. Rev. ST. Accel. Beams 2008, 11. [Google Scholar] [CrossRef]

- Yarovoy, A.; de Jongh, R.; Ligthart, L. Ultra-wideband sensor for electromagnetic field measurements in time domain. Electron. Lett. 2000, 36, 1679–1680. [Google Scholar] [CrossRef]

- Wang, J.; Ban, S.; Yang, J. A Differential Self-integration D-dot Voltage Sensor and Experimental Research. Sens. J. 2015, 15, 3846–3852. [Google Scholar] [CrossRef]

- Wang, J.; Gao, C.; Yang, J. Design, Experiments and Simulation of Voltage Transformers on the Basis of a Differential Input D-dot Sensor. Sensors 2014, 14, 12771–12783. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yang, J.; Luo, R. Non-contact transient high-voltage measurement with self-integrating D-dot probe. Int. J. Appl. Electromagn. Mech. 2014, 47, 837–845. [Google Scholar]

- Hei, W.; Luo, R.; Wang, J. Principles and Experiments of Voltage Transformer Based on Self-integrating D-dot Probe. Proc. CSEE. 2014, 34, 2445–2451. [Google Scholar]

- Metwally, I.A. D-dot probe for fast-front high-voltage measurement. IEEE Trans. Instrum. Meas. 2010, 59, 2211–2219. [Google Scholar] [CrossRef]

- Metwally, I.A. Comparative measurement of surge arrester residual voltages by D-dot probes and dividers. Electr. Power Syst. Res. 2011, 81, 1274–1282. [Google Scholar] [CrossRef]

- Reinhard, M. Experimental Research on Single-Impulse Energy Handling Capability of MO-Varistors Used in High-Voltage Systems in Consideration of a Complex Failure Criterion. Ph.D. Thesis, Darmstadt University of Technology, Hesse Darmstadt, Germany, 2009. [Google Scholar]

- Li, W. Study of Sensor Theory Centered on Rogowski Coil for Heavy Current Measurement Application for Heavy Current Measurement Application. Ph.D. Thesis, Hua Zhong University of Science and Technology, Wuhan, China, 2005. [Google Scholar]

- Wei, B.; Fu, Z.; Wang, Y. Frequency response analysis of passive RC integrator. High Volt. Eng. 2008, 34, 53–56. [Google Scholar]

- Yan, Z.; Zhu, D. High Voltage Insulation Technology; China Electric Power Press: Beijing, China, 2002; pp. 5–8. [Google Scholar]

- Wang, Q.; Zhang, H. Electromagnetic Field; Science Press: Beijing, China, 2013; pp. 37–40. [Google Scholar]

- Focia, R.J.; Frost, C.A. A compact, low jitter, 1 kHz pulse repetition rate gas-switched pulse generator system. In Proceedings of the IEEE 2005 Pulsed Power Conference, Monterey, CA, USA, 13–17 June 2005; pp. 1341–1344.

- EN 60044-7:2000 Instrument Transformers—Part 7: Electronic Voltage Transformers. Available online: http://infostore.saiglobal.com/store/details.aspx?ProductID=365655 (accessed on 14 September 2015).

- Chen, D. Reserch of the Methods for Measurement and Analysis on Power System Harmonics. Ph.D. Thesis, HoHai University, Nanjing, China, 2005. [Google Scholar]

- Hou, D.; Roberts, J. Capacitive voltage transformer: Transient overreach concerns and solutions for distance relaying. In Proceedings of the 1996 IEEE Electrical and Computer Engineering Conference, Calgary, AB, Canada, 26–29 May 1996; pp. 119–125.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Y.; Wang, J.; Wei, G.; Yang, Y. Design and Simulation Test of an Open D-Dot Voltage Sensor. Sensors 2015, 15, 23640-23652. https://doi.org/10.3390/s150923640

Bai Y, Wang J, Wei G, Yang Y. Design and Simulation Test of an Open D-Dot Voltage Sensor. Sensors. 2015; 15(9):23640-23652. https://doi.org/10.3390/s150923640

Chicago/Turabian StyleBai, Yunjie, Jingang Wang, Gang Wei, and Yongming Yang. 2015. "Design and Simulation Test of an Open D-Dot Voltage Sensor" Sensors 15, no. 9: 23640-23652. https://doi.org/10.3390/s150923640