Using Silver Nano-Particle Ink in Electrode Fabrication of High Frequency Copolymer Ultrasonic Transducers: Modeling and Experimental Investigation

Abstract

:1. Introduction

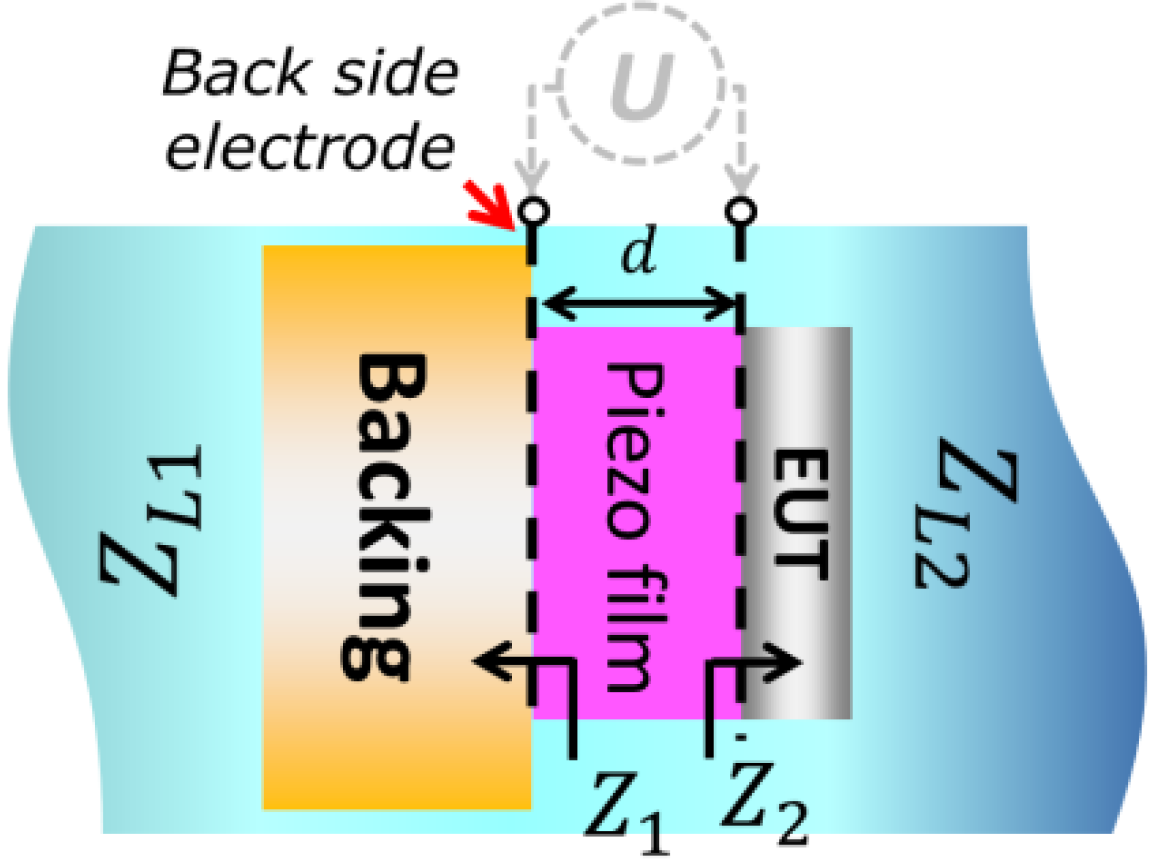

2. Basic Model Theory

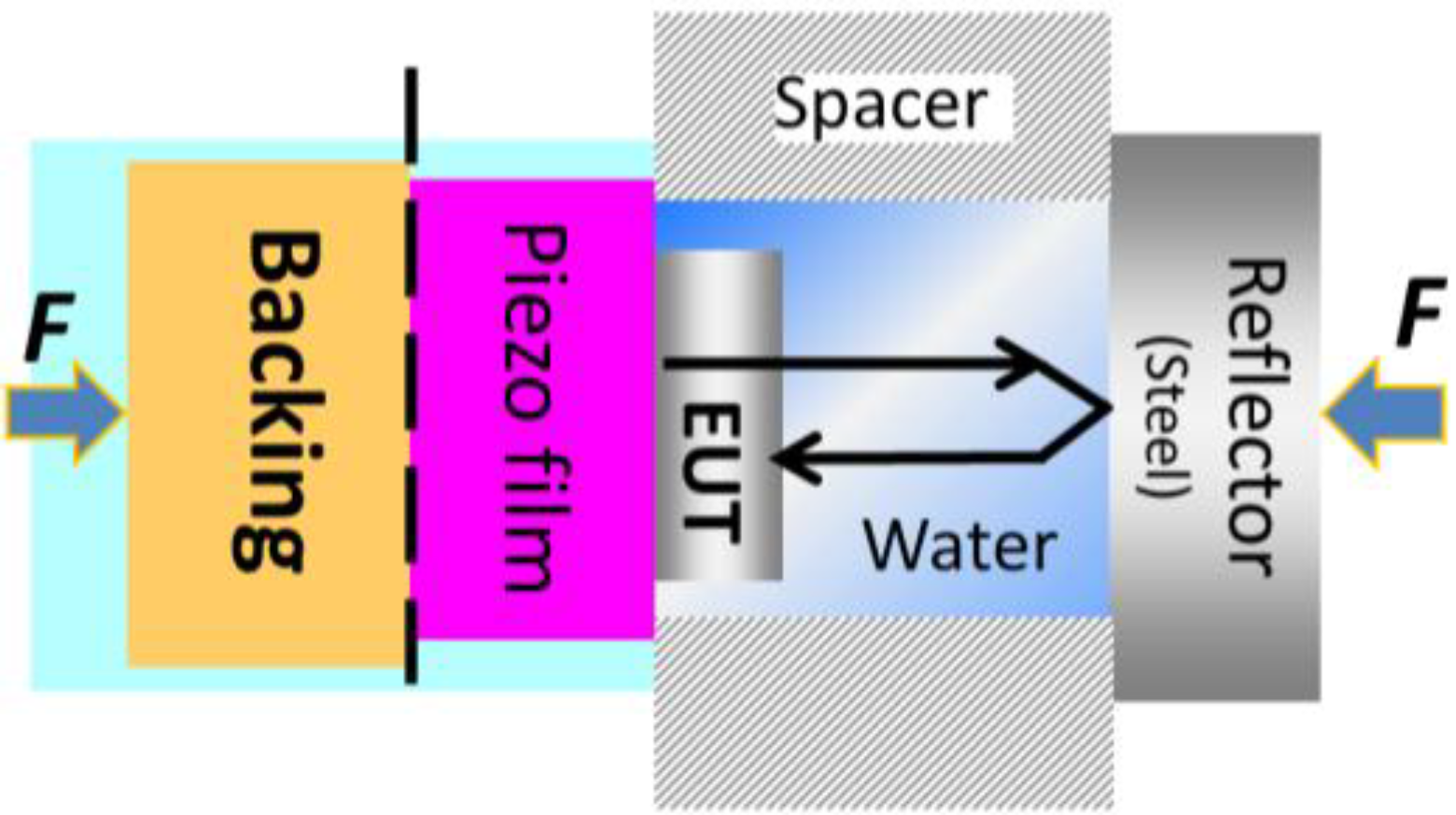

Model of Acoustic Delay Line

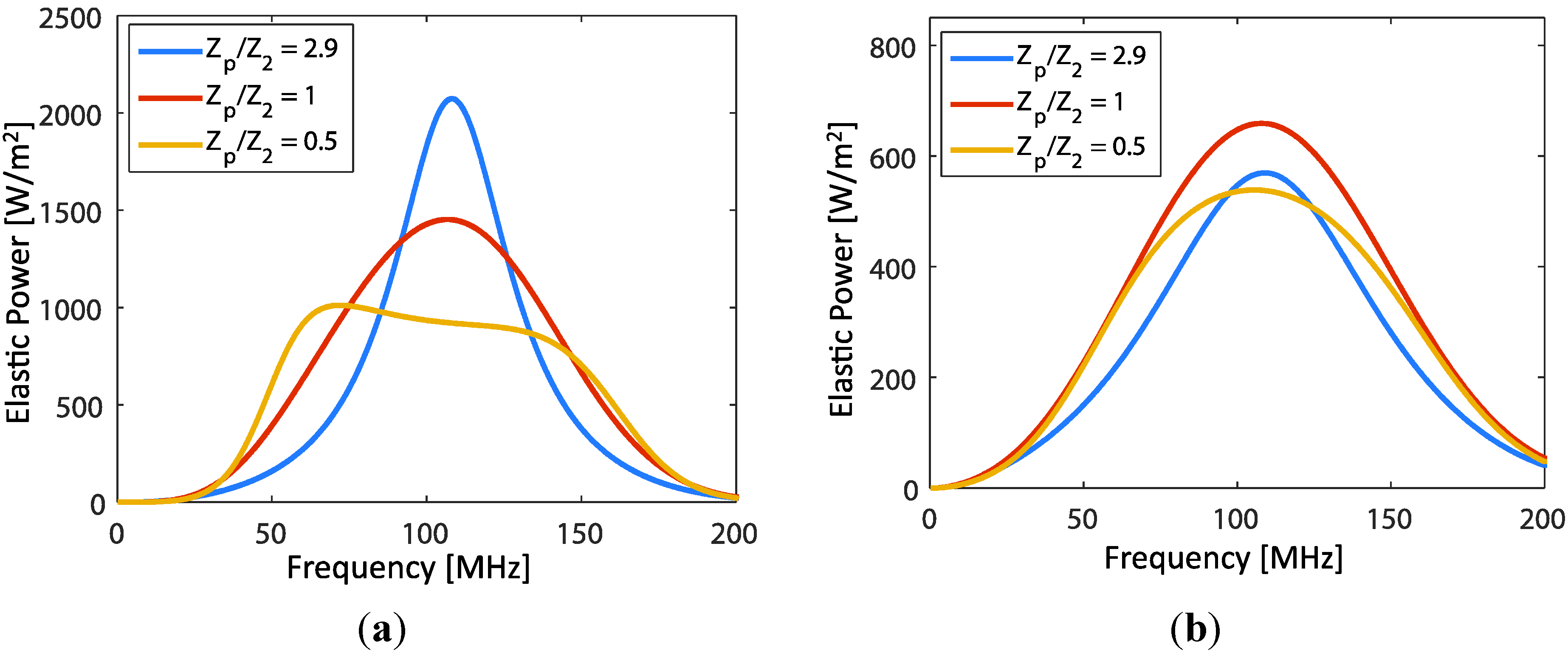

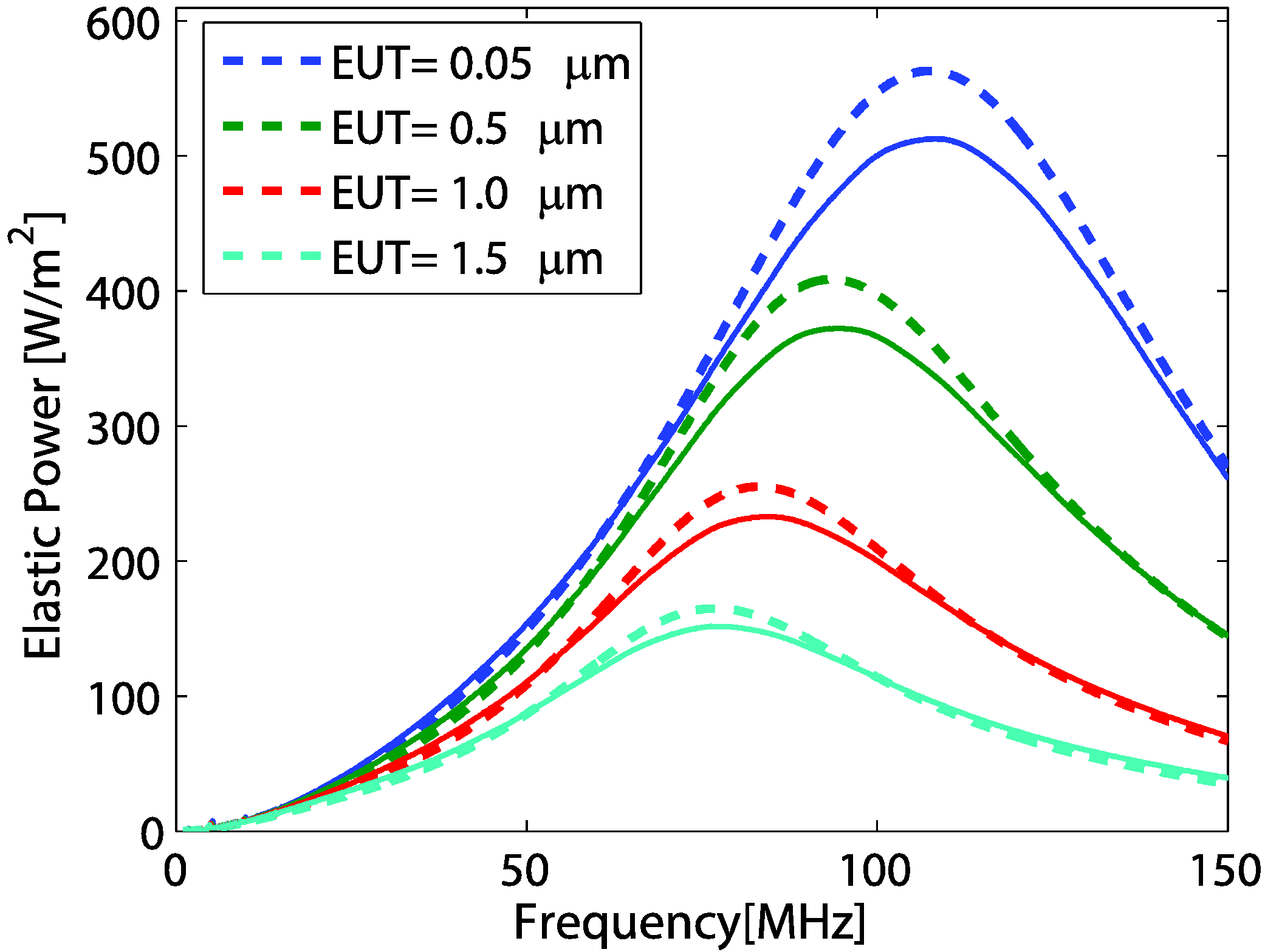

3. Constituent Layer Dependence of Transmitted Power Frequency Response

3.1. Particle Velocity

3.2. Acoustic Power Transmitted to Load

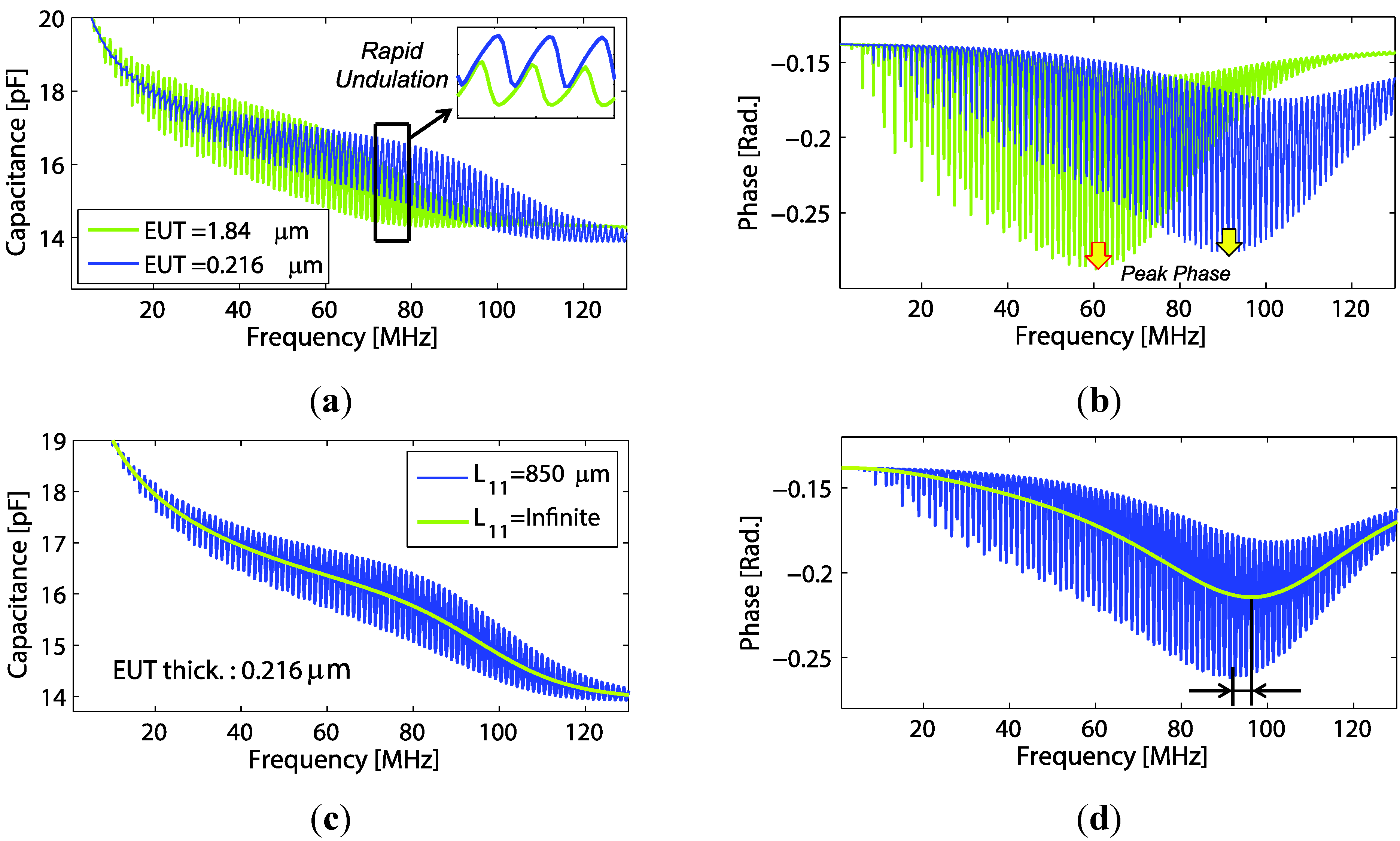

4. Constituent Layer Dependence of Transducer Electrical Properties

4.1. Transducer Electrical Impedance Model

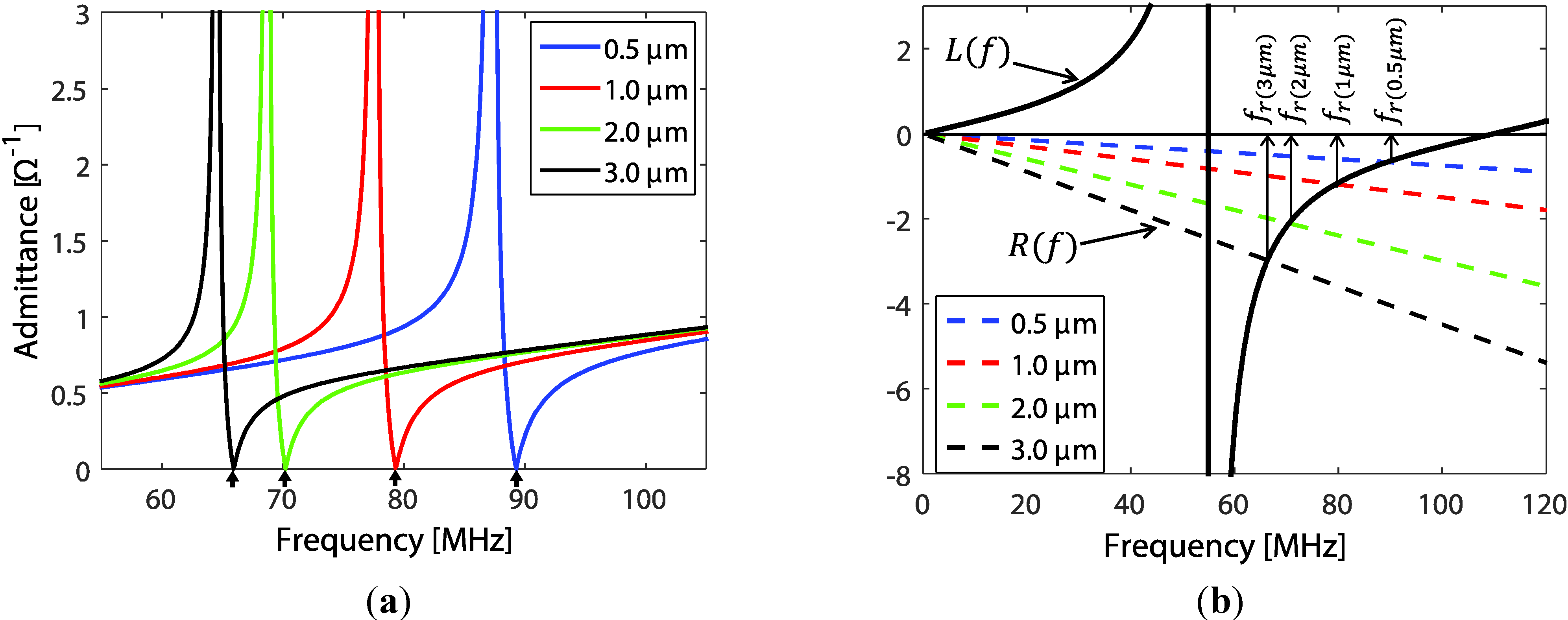

4.2. Effect of EUT Variation on Electrical Properties

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| , , | |||

| , | , , | ||

| , | |||

| , | |||

| , |

4.3. Effect on Electrical Property of Lossy Transducer with Constituent Layer System

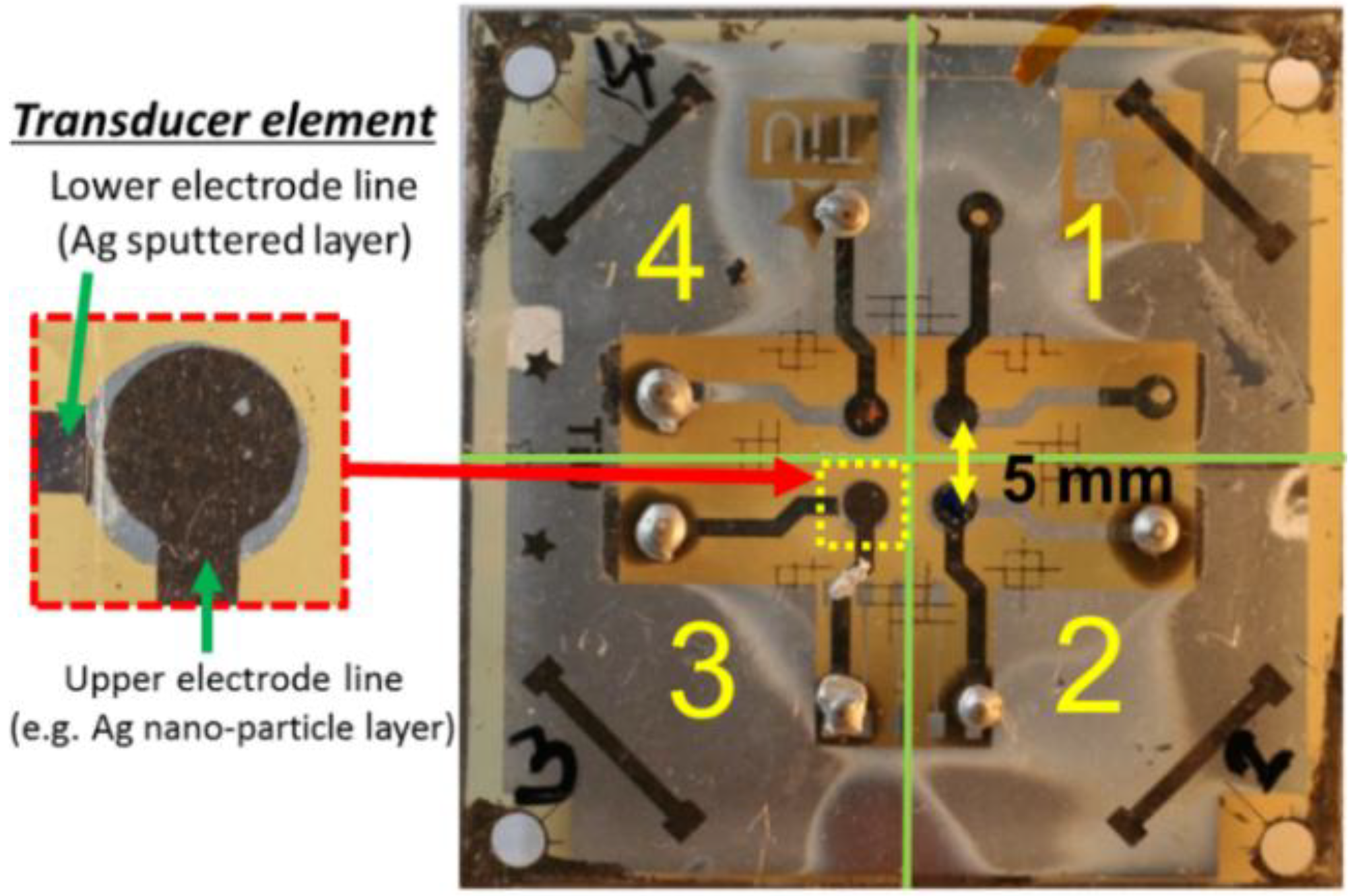

5. Prototyping

6. Characterization

7. Results and Discussion

7.1. Modeling Results of the Effect on Transmitted Power Frequency Response

| EUT Thickness (µm) | Peak | 3 dB-BW (MHz) | |

|---|---|---|---|

| Frequency (MHz) | Power Mag. W/m2 | ||

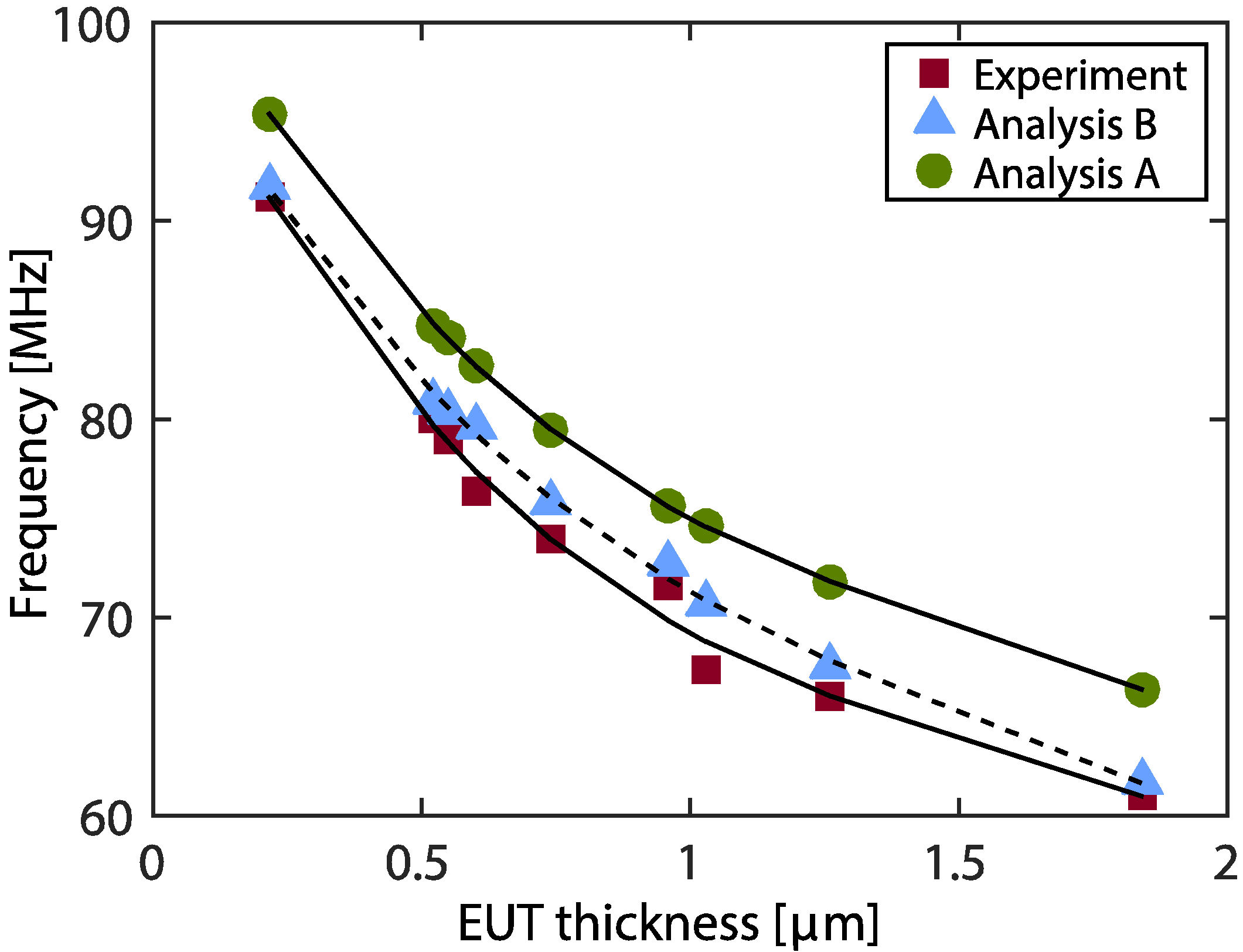

7.2. Effects on Electrical Properties

7.2.1. Analytical Results

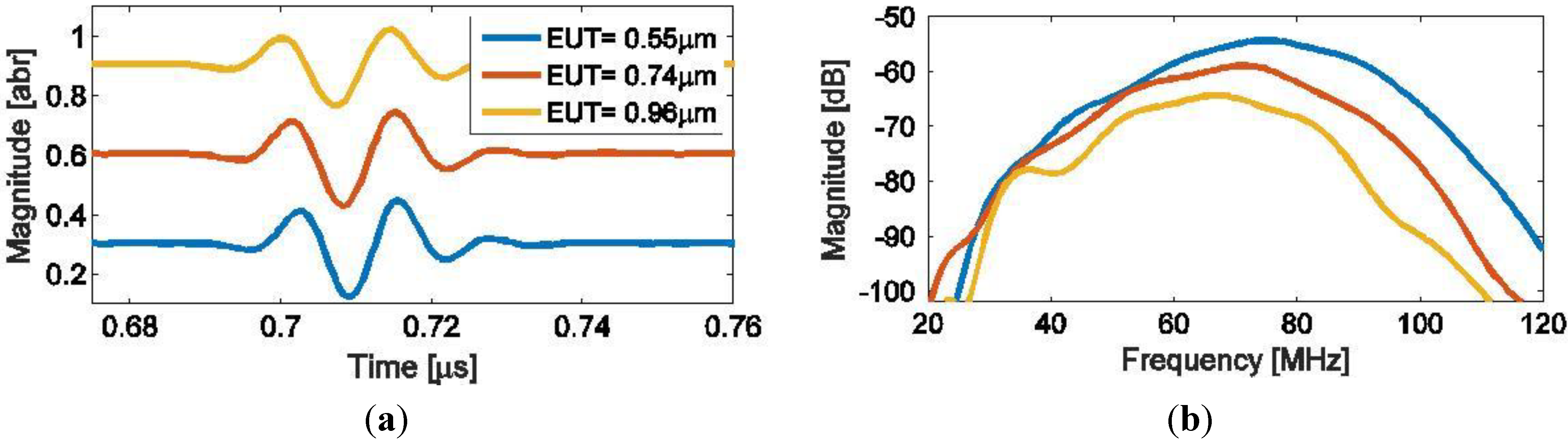

7.2.2. Experimental Results

| EUT Thickness (µm) | Peak Frequency (MHz) | Bandwidth (6 dB) (MHz) | Bandwidth % |

|---|---|---|---|

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lang, S.B.; Muensit, S. Review of some lesser-known applications of piezoelectric and pyroelectric polymers. Appl. Phys. A 2006, 85, 125–134. [Google Scholar] [CrossRef]

- Chung, C.-H.; Lee, Y.-C. Fabrication of poly(vinylidene fluoride-trifluoroethylene) ultrasound focusing transducers and measurements of elastic constants of thin plates. NDT&E Int. 2010, 43, 96–105. [Google Scholar] [CrossRef]

- Foster, F.S.; Harasiewicz, K.A.; Sherar, M.D. A history of medical and biological imaging with polyvinylidene fluoride (PVDF) transducers. IEEE Trans. Ultrason. Ferr. 2000, 47, 1363–1371. [Google Scholar] [CrossRef]

- Zirkl, M.; Sawatdee, A.; Helbig, U.; Krause, M.; Scheipl, G.; Kraker, E.; Ersman, P.A.; Nilsson, D.; Platt, D.; Bodö, P.; et al. An all-printed ferroelectric active matrix sensor network based on only five functional materials forming a touchless control interface. Adv. Mater. 2011, 23, 2069–2074. [Google Scholar] [CrossRef] [PubMed]

- Fuller, S.B.; Wilhelm, E.J.; Jacobson, J.M. Ink-jet printed nanoparticle microelectromechanical systems. J. Microelectromech. Syst. 2002, 11, 54–60. [Google Scholar] [CrossRef]

- Kim, D.; Jeong, S.; Lee, S.; Park, B.K.; Moon, J. Organic thin film transistor using silver electrodes by the ink-jet printing technology. Thin Solid Films 2007, 515, 7692–7696. [Google Scholar] [CrossRef]

- Wagle, S.; Decharat, A.; Bodö, P.; Melandsø, F. Ultrasonic properties of all-printed piezoelectric polymer transducers. Appl. Phys. Lett. 2013, 103, 262902. [Google Scholar] [CrossRef]

- Decharat, A.; Wagle, S.; Melandsø, F. Effect of polymer electrode thickness on the acoustical properties of all-screen printed piezoelectric pvdf copolymer transducers. Jpn. J. Appl. Phys. 2014, 53, 05HB16. [Google Scholar] [CrossRef]

- Sherar, M.D.; Foster, F.S. The design and fabrication of high frequency poly(vinylidene fluoride) transducers. Ultrason. Imaging 1989, 11, 75–94. [Google Scholar] [CrossRef] [PubMed]

- Kosmala, A.; Wright, R.; Zhang, Q.; Kirby, P. Synthesis of silver nano particles and fabrication of aqueous ag inks for inkjet printing. Mater Chem. Phys. 2011, 129, 1075–1080. [Google Scholar] [CrossRef] [Green Version]

- Okada, I.; Shimoda, K.; Miyazaki, K. Development of fine circuit pattern formation process using nano-metal ink. SEI Tech. Rev. 2006, 62, 54–57. [Google Scholar]

- Kim, D.; Jeong, S.; Moon, J.; Kang, K. Ink-jet printing of silver conductive tracks on flexible substrates. Mol. Cryst. Liq. Cryst. 2006, 459. [Google Scholar] [CrossRef]

- Yin, W.; Lee, D.-H.; Choi, J.; Park, C.; Cho, S. Screen printing of silver nanoparticle suspension for metal interconnects. Korean J. Chem. Eng. 2008, 25, 1358–1361. [Google Scholar] [CrossRef]

- Joo, S.; Baldwin, D.F. Adhesion mechanisms of nanoparticle silver to substrate materials: Identification. Nanotechnology 2010, 21. [Google Scholar] [CrossRef] [PubMed]

- Greer, J.R.; Street, R.A. Thermal cure effects on electrical performance of nanoparticle silver inks. Acta Mater. 2007, 55, 6345–6349. [Google Scholar] [CrossRef]

- Park, J.-W.; Baek, S.-G. Thermal behavior of direct-printed lines of silver nanoparticles. Scripta Mater. 2006, 55, 1139–1142. [Google Scholar] [CrossRef]

- Mason, W.P. Electromechanical Transducers and Wave Filters; D. Van Nostrand Co.: New York, NY, USA, 1948. [Google Scholar]

- Krimholtz, R.; Leedom, D.A.; Matthaei, G.L. New equivalent circuits for elementary piezoelectric transducers. Electron. Lett. 1970, 6, 398–399. [Google Scholar] [CrossRef]

- Royer, D.; Dieulesaint, E. Elastic Waves in Solids i: Free and Guided Propagation; Springer: Berlin, Germany, 2000; Volume 1. [Google Scholar]

- Royer, D.; Dieulesaint, E. Elastic Waves in Solids ii: Generation, Acousto-Optic Interaction, Applications; Springer Science & Business Media: Berlin, Germany, 2000; Volume 2. [Google Scholar]

- Wilcox, P.D.; Monkhouse, R.S.C.; Cawley, P.; Lowe, M.J.S.; Auld, B.A. Development of a computer model for an ultrasonic polymer film transducer system. NDT&E Int. 1998, 31, 51–64. [Google Scholar] [CrossRef]

- Brown, L.F. Design considerations for piezoelectric polymer ultrasound transducers. IEEE Trans. Ultrason. Ferr. 2000, 47, 1377–1396. [Google Scholar] [CrossRef]

- Ohigashi, H.; Itoh, T.; Kimura, K.; Nakanishi, T.; Suzuki, M. Analysis of frequency response characteristics of polymer ultrasonic transducers. J. Appl. Phys. 1988, 27, 354. [Google Scholar] [CrossRef]

- Westerlund, S.; Ekstam, L. Capacitor theory. IEEE Trans. Dielect. Electr. Insul. 1994, 1, 826–839. [Google Scholar] [CrossRef]

- Ranucci, E.; Sandgren, Å.; Andronova, N.; Albertsson, A.-C. Improved polyimide/metal adhesion by chemical modification approaches. J. Appl. Polym. Sci. 2001, 82, 1971–1985. [Google Scholar] [CrossRef]

- Brown, L.F.; Carlson, R.L.; Sempsort, J.M. Spin-Cast P(VDF-TrFE) films for high performance medical ultrasound transducers. In Proceeding of the IEEE-International Ultrasonic Symposium, Toronto, ON, Canada, 5–8 October 1997; pp. 1725–1727.

- Wagle, S.; Decharat, A.; Wenger, M.; Melandsø, F. PVDF copolymer Transducers used to evaluate micro particle suspensions. In Proceeding of the IEEE-International Ultrasonic Symposium, Chicago, IL, USA, 3–6 September 2014; pp. 1586–1590.

- Haiying, H.; Paramo, D. Broadband electrical impedance matching for piezoelectric ultrasound transducers. IEEE Trans. Ultrason. Ferr. 2011, 58, 2699–2707. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Decharat, A.; Wagle, S.; Jacobsen, S.; Melandsø, F. Using Silver Nano-Particle Ink in Electrode Fabrication of High Frequency Copolymer Ultrasonic Transducers: Modeling and Experimental Investigation. Sensors 2015, 15, 9210-9227. https://doi.org/10.3390/s150409210

Decharat A, Wagle S, Jacobsen S, Melandsø F. Using Silver Nano-Particle Ink in Electrode Fabrication of High Frequency Copolymer Ultrasonic Transducers: Modeling and Experimental Investigation. Sensors. 2015; 15(4):9210-9227. https://doi.org/10.3390/s150409210

Chicago/Turabian StyleDecharat, Adit, Sanat Wagle, Svein Jacobsen, and Frank Melandsø. 2015. "Using Silver Nano-Particle Ink in Electrode Fabrication of High Frequency Copolymer Ultrasonic Transducers: Modeling and Experimental Investigation" Sensors 15, no. 4: 9210-9227. https://doi.org/10.3390/s150409210