2.2. Liquid Absorption Using a Microcell in the Fiber Cavity

Standard fiber-optic cables have a core diameter between about 8–400 μm,

i.e., their dimensions are comparable to those of flow channels in micro-separation systems, such as capillary electrophoresis (CE), micro-liquid chromatography or microfluidic devices (“lab-on-a-chip”, or micro-total analysis systems, μ-TAS). The gap that is formed between the fiber ends when making a fiber loop cavity is a natural place to insert a small liquid sample and, consequently, waveguide-CRD or fiber loop ring-down spectroscopy has been used for absorption detection coupled to a variety of microseparation systems [

3,

18–

20,

39].

The dimensions of the sample gap should be similar to those of the flow channel to prevent pressure build-up or turbulences. Also, to achieve a good transmission across the gap, the diameter of the waveguide core needs to be equal to or larger than the width of the sample gap. Capillaries used for CE have inner diameters ranging from 50 to 100 μm, whereas commercial microfluidic devices have flow channel dimensions of typically 30 × 50 μm. Therefore, for these separation systems regular multimode fibers with core diameters of 30 to 100 μm can be used as cavity medium. Emerging nanofluidic separation system use much smaller channels with cross sectional dimensions <1 μm, whereas conventional HPLC uses much larger flow channels with dimensions of millimeters. In the latter case conventional CRD with very small mirrors demonstrated remarkable sensitivity of about α

min = 1.5 × 10

−4 cm

−1 [

15,

40]. Recently, micro-HPLC (flow channel diameters: 50 to 500 μm) has become increasingly popular, since it uses smaller sample volumes, allows higher pressures, and consumes less solvent compared to regular HPLC. Waveguide CRD is quite amenable to absorption detection in the sub-microliter detection volumes found in micro-HPLC.

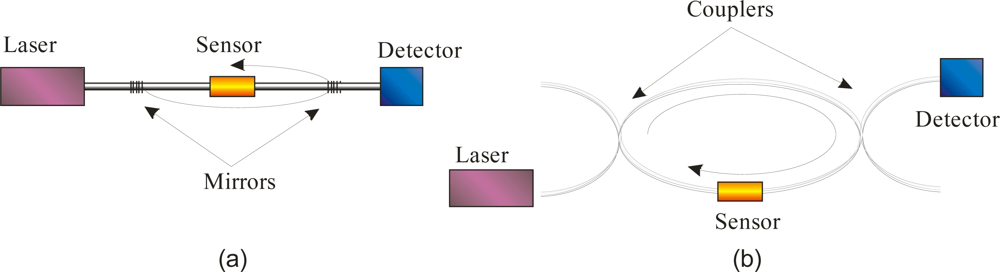

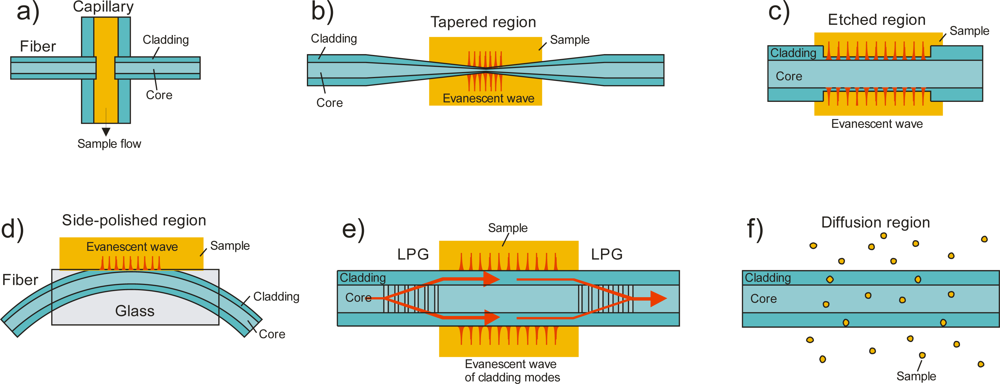

The principle of intersecting a fiber loop with a sample flow appears simple (see

Figure 3a), but the design of such an interface is quite challenging. The fiber ends need to be aligned carefully to achieve a good transmission through the sample gap and the flow channel has to be connected without causing a pressure build-up or a large dead volume. Especially the lateral alignment of the fiber ends is critical as a misalignment can cause large losses. For example, lateral misalignment by 10% (displacement/fiber diameter) leads to additional transmission losses of >10% but requires a precision of 5 μm for a multimode fiber with a core diameter of 50 μm or a precision of <1 μm for a single mode fiber [

41,

42].

In one of our first fiber loop CRD experiments [

18,

39] the fiber ends of a multimode fiber loop (length of 65 meters, core diameter 400 μm, cladding diameter 440 μm) were joined by a commercial four-way microcross. The two fiber ends were inserted through opposing holes and two capillaries (inner diameter 100 μm) for the sample flow were inserted through the other two holes. The detection volume is defined by the distance between the fiber ends and the core diameter. The gap between the fiber ends was 31 μm, which created a detection volume of 4 nL. Samples of the laser dye 1,1′-diethyl-4,4′-dicarbocyanine iodide (DDCI) in dimethyl sulfoxide (DMSO) were measured with phase-shift CRDS at different concentrations at a wavelength of 810 nm. A detection limit of

Cmin = 6 μM DDCI in DMSO was obtained, which corresponds to an absorbance of

ε ·

Cmin = 2.0 cm

−1. Since the upper concentration limit was 5.5 mM, we determined a dynamic range of 3 orders of magnitude for this system.

Later our group used a similar system as an online detector for CE of biomolecules [

43]. The interface to the liquid was fabricated by drilling holes through a polymethyl methacrylate (PMMA) block, where the capillary and the two ends of the fiber strand were inserted and affixed using epoxy glue. The fibers were aligned to the capillary walls at a distance of 30 μm. To increase the transmission through this sample gap, a microlens with a radius of 76 μm was made at one of the fiber ends by melting the end in the electric arc of a fusion splicer. A fiber coupler with a split ratio of 99:1 was used to couple 810 nm light into the loop. Measurements were performed using capillary electrophoresis to separate dye-labeled human serum albumin (HSA) from the unbound NIR dye (ADS805WS). The excess free dye and the dye/protein complex were resolved using a run buffer of 10 mM boric acid with pH 10.0, the labeling coefficient was determined to be ∼6. The detection limit was 1.6 cm

−1, corresponding to 1.67 μM of the labeled HSA.

The above experiments all operated at near-infrared wavelengths, which limits the variety of substances that can be detected. More recently, the fiber loop ring-down method was adapted to shorter wavelengths. For example, Andachi

et al. [

44] used a picosecond pulsed diode laser at 660 nm with a fiber loop cavity. Two erbium doped fiber amplifiers were used in series to obtain stable and intense pulses of 40 ps duration by gain-switching. The fiber loop was made from 4.69 m of multimode fiber with a 50 μm core diameter. Two fiber couplers with a 99:1 split ratio were spliced into the loop, one for injecting laser light into the loop and the second one for directing a fraction of the light to a photomultiplier tube. The fiber loop contained a microcell (gap width: 100 μm, detection volume: 200 pL) to introduce a liquid sample between the fiber ends. A biexponential decay was observed with ring-down times of 399 ns (0.247 dB loss per round trip) and 118 ns (0.834 dB loss) corresponding to the decay of core and cladding modes, respectively. Measurements of methylene blue in an aqueous solution were performed at a wavelength of 660 nm. The detection limit was determined to be 50 μM, which corresponds to an absorption loss of 6 cm

−1.

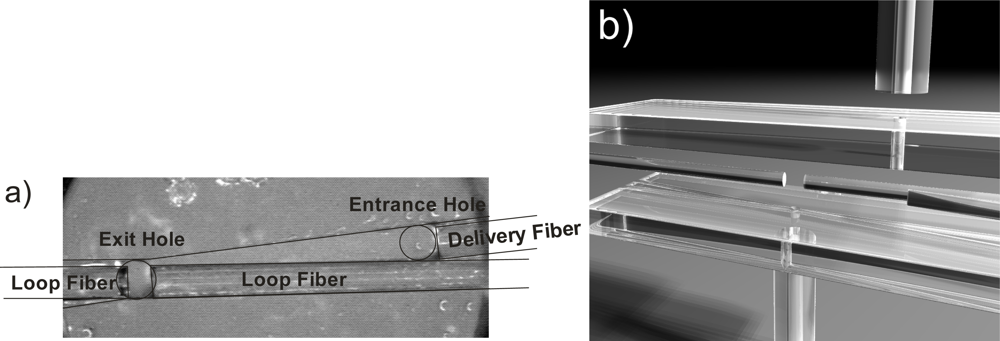

Our latest system [

20] operates at 405 nm since many biomolecules (e.g., proteins) have strong absorption features in this region. The optical attenuation of UV waveguides is orders of magnitude higher compared to near-IR waveguides. We designed a system that consisted of a comparably short fiber loop (10 m length), a photomultiplier tube attached to a bend in the fiber, and a fiber-coupled diode laser. Unfortunately, fiber optic couplers for multimode UV-waveguides are not commercially available. Therefore, we devised an interface that let us introduce the sample liquid and the light into the loop at the same time. In the interface the two fiber loop ends were placed 190 μm apart in a groove that was cut into PMMA polymer. Another fiber coming from the laser was affixed into a second groove that had been cut at a narrow angle to this sample gap. Here, it irradiated one of the fiber ends to couple light into the loop (see

Figure 4). The sample entered the interface through a hole in the top plate in front of the delivery fiber, flowed along the groove and between the gap in the fiber loop and then exited the interface through a hole below the sample gap. The detection volume was given by the distance between the fiber ends and the core diameter and had a size of 6.0 nL. This interface avoids introducing additional losses due to a fiber coupler and can be used with any type of fibers, including mid-infrared fibers or even photonic crystal fibers.

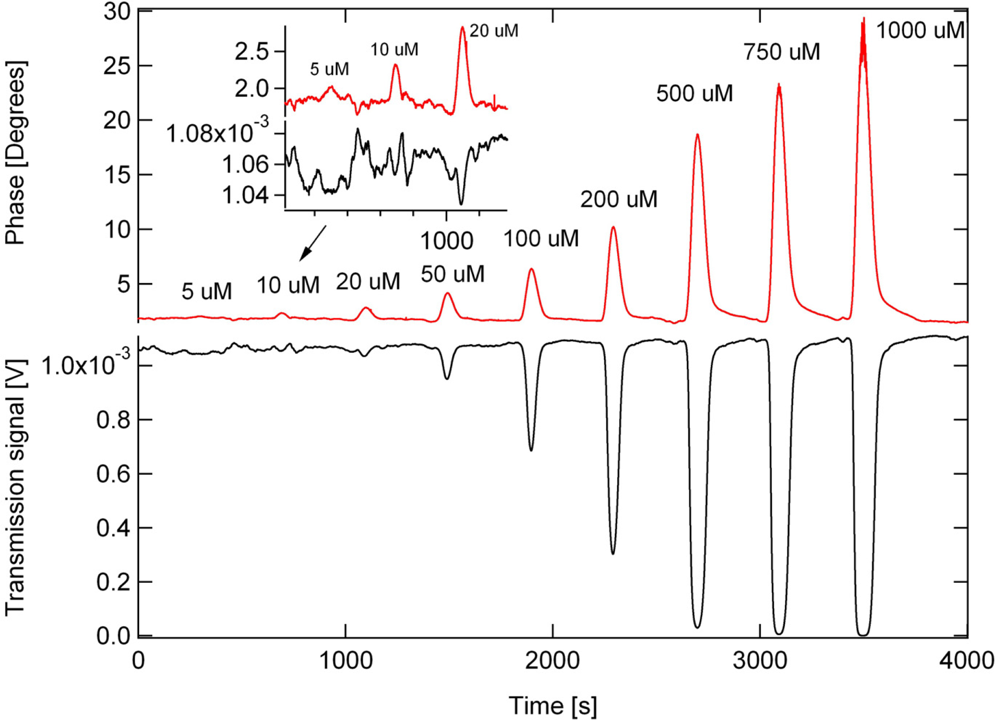

Phase-shift cavity ring-down detection was used because of the higher data acquisition rate and because short ring-down times could be compensated by increasing the modulation frequencies (modulation frequency: 1 MHz here, τ = 140 ns, effective absorption path: 550 μm). Measurements of tartrazine (yellow food dye), myoglobin and a pharmaceutical component provided by

Eli Lilly, Canada, were performed at low micromolar concentrations (see

Figure 5).

A detection limit of 5 μM tartrazine or 1 μM myoglobin is achieved; this corresponds to an extinction of 0.11 cm−1 or 30 femtomoles of tartrazine in the detection volume. At the same time transmission spectroscopy was performed on the sample flowing along the groove (path length: 3 mm). Despite the 15-fold larger absorption path (and sample volume!) for the transmission measurement, the ring-down measurement has a four-fold higher sensitivity and a larger dynamic range. The direct transmission measurement is limited by laser power fluctuation to which CDRS is insensitive. For a more accurate transmission measurement, a second detector would be needed to normalize the laser power.

2.3. Evanescent Field Absorption

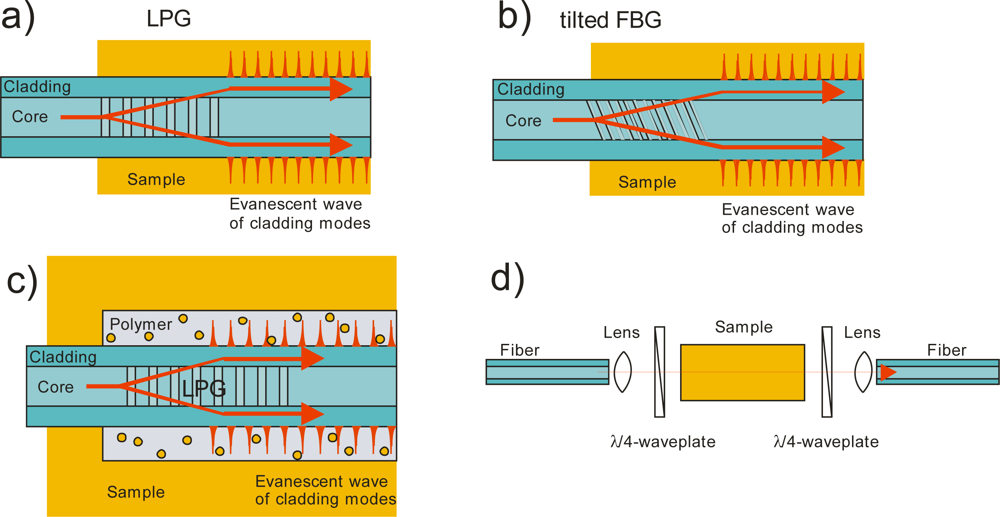

Instead of leaving a gap in the fiber cavity, which introduces large losses on its own, it is possible to use the evanescent wave of the circulating light for concentration measurements. The evanescent wave can interact with the surrounding medium leading to cavity losses, either by attenuation (absorption and scattering) of the evanescent field, or by dissipation of the energy, if the refractive index of the samples approaches that of the cladding. By measuring the ring-down time the cavity losses due to the evanescent wave interaction can be determined. Usually the evanescent field of the core mode(s) is contained entirely inside the cladding; thus for a measurable interaction with the sample it needs to be extended into the surrounding medium. This can be achieved by tapering, etching or side-polishing the fiber (see

Figure 3). An effective absorption path can be obtained from the evanescent field depth of all guided modes [

45]. For a single-mode fiber, the evanescent field of the core mode can be obtained directly from its mode field diameter [

3].

Sigrist’s group [

16] demonstrated the use of fiber CRD spectroscopy in combination with evanescent field absorption for chemical sensing applications. As the sensing element an etched single mode fiber was used in a linear cavity with a length of 0.576 meters. High reflectivity dielectric coatings (R > 99.9%) on both fiber ends acted as cavity mirrors. The sensor was prepared by stripping the coating from the fiber and etching in buffered hydrofluoric acid solution (caution: extremely dangerous). The evanescent field experiences absorption due to the water present in the etch solution. With decreasing fiber diameter, the evanescent tail expands into the solution, the absorption increases, and the ring-down time decreases. Before etching the fiber diameter was 125 μm and the ring-down time was 755 ns corresponding to a round trip loss of 0.016 dB. When the fiber was etched to a diameter of 63 μm the ring-down time was reduced to 550 ns (0.022 dB). A detection limit of 4.68 × 10

−4 dB loss was achieved.

Field access blocks have also been used to extend the evanescent field into the sample. Here, the fiber is side-polished to remove a part of the cladding. Gupta

et al. [

17] designed a single mode fiber cavity using fiber Bragg gratings (FBG) as mirrors and a 6.9 cm long evanescent-wave access block for chemical sensing. The block was immersed in a glycerin/water mixture so that the external refractive index could be varied from 1.4746 (pure glycerin) to 1.330 (pure water). From the increase of cavity losses with increasing refractive index a cavity gain factor of about 100 was determined.

Tapered fibers are a third method to extend the evanescent wave into the surrounding sample. Tarsa

et al. [

22] developed a fiber loop ring-down system with a tapered fiber region. The resonator consisted of a 2.2 km long single mode fiber, two fiber couplers with 99:1 split ratio and a tapered section. The taper was 28.0 mm long, has a waist radius of 10 μm, and was slightly bent to enhance the evanescent field. The small waist allowed complete conversion of the core mode to an evanescent cladding mode. For absorption measurements the taper was immersed in 1-octyne with an absorption line at 1532.5 nm. By scanning across this absorption line, the concentration was determined with a detection limit of 1.05% 1-octyne, corresponding to an absorption of 260 cm

−1. The same setup was also used for biological cell detection [

23]. Cells have a nucleus with a high optical density that leads to efficient scattering. The scattering loss varies with cell size and shape and the amount of high refractive index organelles. In order to localize the cells on the tapered region, the fiber taper was coated with a polypeptide (poly-D-lysine) that is optically transparent and has a strong binding affinity for cellular membrane proteins. Tarsa

et al. performed measurements on mammalian cancer cells since they are of considerable interest, are relatively large (10 μm) and have high melanin content. By adding trypsin the adhered cell can be detached from the coated fiber. After the cell was attached to the coating the surrounding solution was removed to increase the difference in refractive index. The ring-down time changed linearly for 0 to 150 cells attached to the fiber. The rate of change in the ring-down time was 0.23 μs/cell, thus allowing single-cell detection.

Another method uses identical pairs of long-period gratings (LPG) to extend the evanescent field by converting the core mode into a specific low-order cladding mode - depending on the period of the grating and the wavelength of the light [

46]—and then recouple into the core mode. The device would form a Mach-Zehnder interferometer, if the light was split approximately evenly between the core and the single cladding mode [

47]. However, if most of the light is transferred into the cladding mode and then recoupled into the fiber core, the absorption of the evanescent wave may be measured. Pu

et al. made such an absorption sensing element from two identical LPGs that were placed 16 cm apart into a fiber loop and that transferred 99% of the light from core to cladding and back to the core mode [

48]. The absorption length is larger than what is usually achieved with tapered fibers or D-shaped fibers and the insertion losses are lower than that of a microcell. Decane is transparent at the detection wavelength near 1,535 nm and has a refractive index of n = 1.412. Immersing the fiber with the LPGs into decane shifted the LPG attenuation peak to shorter wavelength by 10 nm but its spectral shape remained the same. 1-octyne (refractive index

n = 1.417) has an absorption peak near the laser emission of 1534.3 nm and, as expected, an increase in the concentration resulted in larger losses in the fiber cavity and decreased the ring-down time. A detection limit of 0.62% 1-octyne was determined corresponding to an absorption of 150 cm

−1.

Evanescent wave absorption is limited by the small fraction of the mode volume that has a chance of interacting with the sample. For many evanescent wave sensors shown above no more than a few percent of the light intensity can be attenuated with each roundtrip, even if the evanescent portion of the mode was completely absorbed. On the other hand, the insertion loss for many of these sensors is much lower compared to direct absorption through, for example, a gap in the fiber loop.

2.4. Refractive Index Measurements

Refractive index changes can also be correlated to sample concentrations and fiber-optic based refractive index sensors have a long history. Some of the most sensitive devices are based on interferometry [

49] and will not be reviewed here. When a fiber cavity is used as a sensing element, the change in the refractive index of the medium surrounding the fiber can have two effects. First, the

wavelength of the cavity mode resonances shifts when the mode’s refractive index (propagation constant) is changed. Second, the

attenuation associated with a cavity resonance may change when refractive index sensitive components, such as LPGs, are placed into the cavity (see

Figure 6). LPGs show attenuation spectra that are strongly dependent on the refractive index of the environment, and by placing them into a fiber cavity their attenuation is amplified.

The relationship between refractive index changes and concentration changes is given by the Lorentz-Lorenz equation [

50]. With this equation the refractive index

nmix of a mixture (volume fractions

q1 and

q2) can be calculated when the refractive indices

ni of each component is known.

In very recent experiments (published in this issue of Sensors) Gagliardi and co-workers demonstrated refractive index measurements through both changes in the wavelength position of the cavity resonances and ring-down time (attenuation) measurements in a 2.5 m fiber loop cavity. Using a 1 mm evanescent field block they have exposed the core mode to solutions of increasing refractive index. It was found that the cavity finesse decreases and the free spectral range increases, as expected, with higher optical loss in their evanescent field block. As a consequence of the increased refractive index of the evanescent wave the mode spectrum appears red-shifted.

In an interesting variation of this theme, Song

et al. [

51] had earlier used a free-space Fabry-Pérot cavity formed between two gold-coated fiber ends to measure the refractive index and the size of living cells. A micropipette held the cell in the cavity and, again, the spectral shift in the cavity modes was measured. The shift was related to the refractive index in the cavity and by comparing the spectral shift of two buffer solutions (with different refractive indices) with and without cell in the cavity, the refractive index of the cell was determined without knowledge of the actual refractive index of the buffers. The cavity and the cell holder were incorporated into a microchip with channels for the two buffer solutions. The cavity had a length of 35.5 μm and the mirrors had a reflectivity of 80%. The refractive index and the size of Madin-Darby canine kidney cells (diameter 16–20 μm) were measured with a precision of 0.2% for the refractive index and 4.0% for their size.

There are many examples of refractive index sensors, which exploit the sensitivity of fiber gratings to the refractive index of the environment. Their optical loss can be amplified in a fiber-optic cavity. For example, Liu

et al. [

52] presented a system consisting of a linear cavity with two chirped FBGs as mirrors and a long-period grating (LPG) for refractive index change measurements (see

Figure 6a). The FWHM of the FBG reflectivity was much broader than the linewidth of the laser pulses (1.50 nm

versus 0.08 nm), and the system was relatively insensitive to thermal drifts of the FBG’s central wavelength. The LPG was chosen so that its attenuation peak was outside the reflection wavelength range of the chirped FBGs. When the surrounding refractive index changed, the attenuation peak shifted into the wavelength range of the FBGs, thereby increasing the cavity losses. The system was tested by applying index-matching liquids with refractive indices between 1.40 and 1.44 to the LPG. Liu

et al. achieved a refractive index resolution of 9.93 × 10

−4 at 1.410 and 4.19 × 10

−4 at 1.440.

The LPG can also be coated with a polymer that changes its refractive index by uptake of chemicals (see

Figure 6c). With customized coatings these LPG sensors can be made very sensitive, since the partition coefficient of the compound of interest can be quite high. Solid-phase microextraction then preconcentrates, say, environmental pollutants in the polymer matrix by 2 to 3 orders of magnitude. In addition, rudimentary chemical selectivity can be achieved by functionalizing the polymer coating.

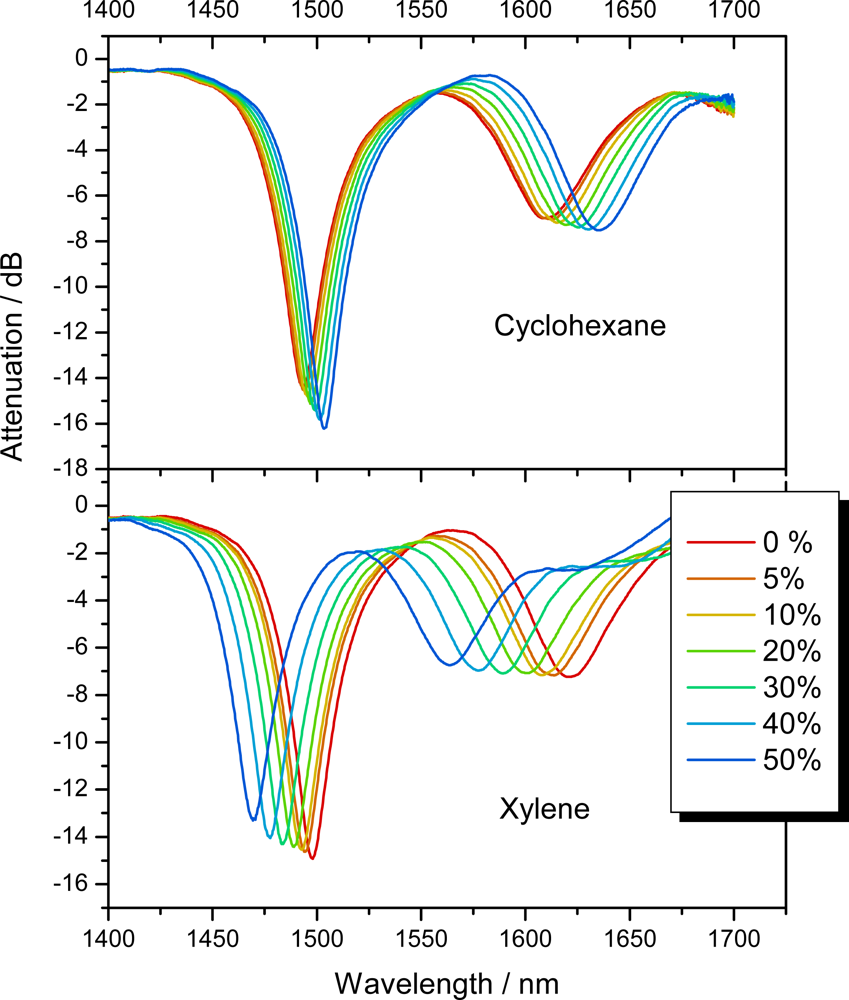

We developed such a sensor with a polymer that is based on polydimethylsiloxane (PDMS) polymer which was functionalized with diphenylsiloxane units to enhance sensitivity to aromatic compounds [

21]. The titanium isopropoxide crosslinker not only rigidifies the polymer but also helps adjusting the refractive index. Tuning the refractive index of the polymer coating is critical, since optimum sensitivity is achieved when the refractive index of the polymer is slightly below that of the cladding,

i.e., between 1.423 and 1.438 at 1,550 nm. Here, the polymer had a refractive index of 1.4237 and the thickness of the polymer coating was about 20 μm.

The coated LPG was mounted in a fiber loop cavity with two fiber couplers to couple light in and out of the cavity, and phase-shift CRD was used as the detection method. Measurements of xylene and cyclohexane were performed by adding their vapors to a nitrogen flow with concentrations up to 5,400 ppm for xylene and 62,700 ppm for cyclohexane, corresponding respectively to 50% saturation pressure. Xylene has a refractive index of 1.4802 and therefore causes an increase in the refractive index of the polydimethylsiloxane (PDMS)-based coating and thus a shift of the LPG peak to shorter wavelengths. Cyclohexane has a refractive index of 1.4141, which causes the peak to shift to longer wavelengths allowing differentiation of the two substances (see

Figure 7). The laser wavelength was set to the slope of the long wavelength attenuation peak so that even a small shift in peak position resulted in a large change of the loop losses. The detection limit of xylene is 320 ppm. The coating fully recovers when the vapor is removed so the same LPG and coating may be reused many times [

21].

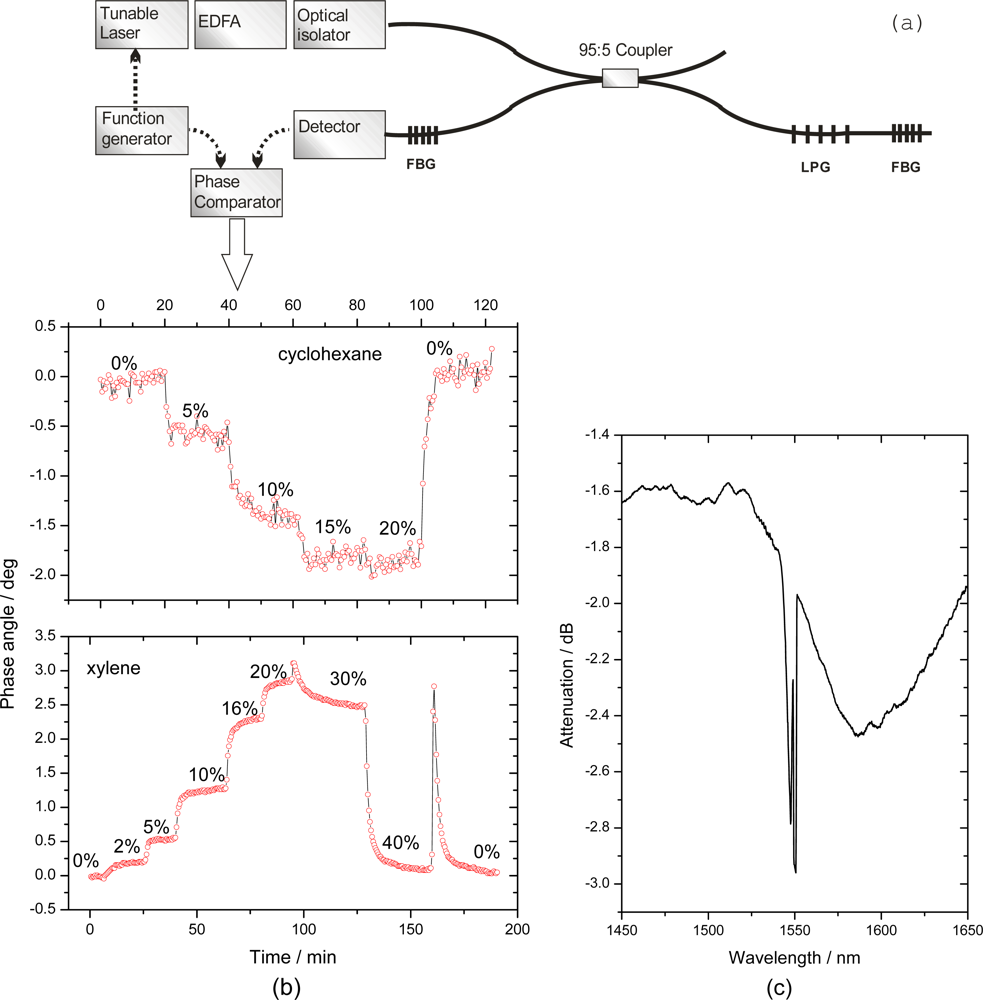

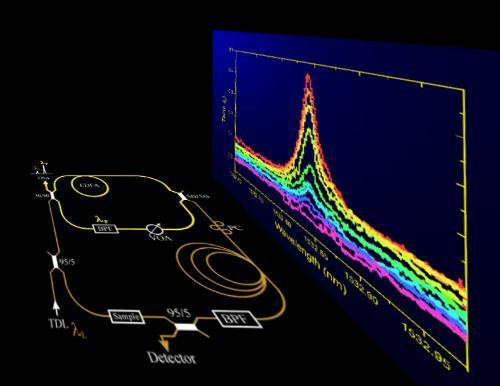

The same chemical system was used in our group very recently on another fiber sensing platform,

i.e., a cavity defined by two identical narrow-band FBGs. The coated LPG was spliced into this cavity and light was introduced using a 95:5 fiber-fiber coupler (see

Figure 8). A similar setup has been previously used by Bo

et al. for temperature and strain measurements [

53]. Xylene and cyclohexane were introduced at different saturation pressures between 2.5% and 50% and their concentrations were measured through the change in phase angle at 1550 nm. Laser radiation from a tunable diode laser was modulated at 300 kHz. A coating containing 35 mol% of PDMS and 65 mol% polymethyloctylsiloxane (PMOS) was used to enhance the selectivity to cyclohexane uptake and to tune the refractive index of the coating in the vicinity of 1.428, just below that of the silica cladding. The detection limit in this preliminary experiment was 1.7% saturation pressure (1900 ppm) for cyclohexane and 1.25% (140 ppm) for xylene.

A direct comparison of the fiber loop sensor and the linear fiber cavity sensor shows that the sensitivity is higher and detection limit lower for our linear fiber cavity system. This is likely due to slightly lower round trip losses and a larger light output at the detector. On the other hand, it was difficult to tune the refractive index of the coating in such a way that it would shift the attenuation peak of the coated LPG to align with the FBG cavity reflection spectrum. Calibration measurement of the etched Λ = 236 μm LPGs used in the both cavities show a sensitivity of 40,000 nm/RIU (RIU = refractive index unit).

A tilted FBG may be used instead of the LPG as a refractive index sensing element (see

Figure 6b), as shown by Zhou

et al. [

54]. Similar to an LPG, a FBG with a large tilt angle couples narrow bandwidth radiation from the core mode to the cladding modes, but it exhibits a lower thermal sensitivity and greater insensitivity to bending. The 1 m long fiber cavity consisted of two FBGs acting as mirrors and a tilted FBG for sensing refractive index changes. As in the case of the LPG described above, the coupling between core and cladding modes caused large losses in the cavity depending on the propagated wavelength and the refractive index of the surrounding material. The attenuation peak shifted in response to the refractive index of the tilted FBG’s environment and, like the LPGs, the sensor was most sensitive in a 50 nm wavelength window near the FBG’s mid-attenuation point. As stated earlier, the cavity losses change with an increase of the environment’s refractive index, which leads to a change in ring-down time. A sensitivity of 154 μs per refractive index unit (RIU) was achieved. The system was optimized to operate in water and the largest sensitivity was near a refractive index of 1.33. By monitoring the peak position instead of the ring-down time, refractive index changes can be monitored with a sensitivity of 340 nm/RIU.

Meng

et al. also developed and characterized a related fiber loop CRD sensor [

55] for refractive index. The sensing element in their loop was a 2 cm long section of the single mode fiber that was etched from a 125 μm diameter to only 13.62 μm. The etched fiber part was immersed in dimethyl sulfoxide (DMSO) and a water-DMSO mixture. DMSO has a refractive index that is only slightly higher than that of silica and solutions of different refractive indices can be obtained by mixing water with DMSO. A model for the optical loss was developed that took optical absorption and refractive index into consideration.

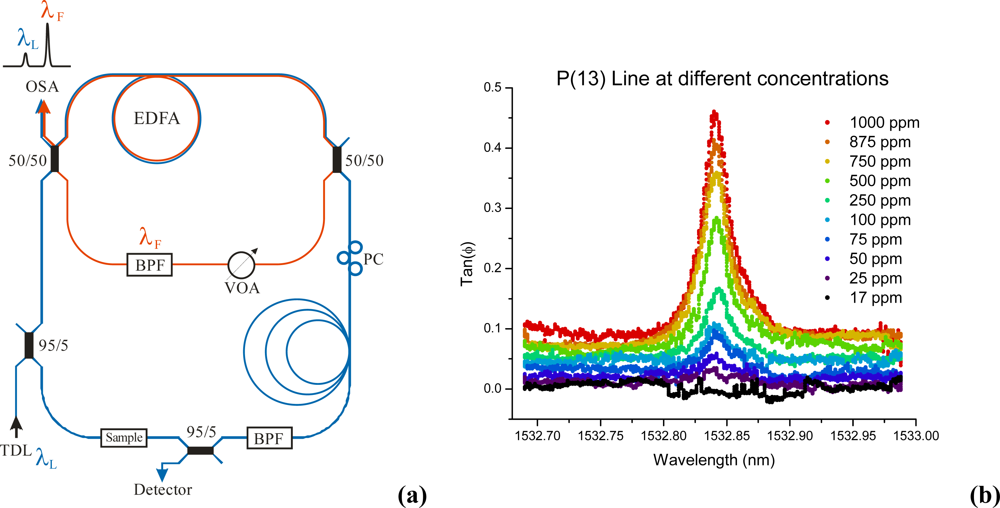

Chiral liquids are a particularly interesting target for refractive index measurements. When chiral liquids are enriched in one of their two enantiomers, they become optically active,

i.e., the refractive indices for left and right circularly polarized light are different and the polarization plane of linearly polarized light is rotated. The circular birefringence (optical rotation) may be very small, even in pure chiral liquids. Therefore, Vollmer

et al. [

56] used fiber cavities to enlarge the effective interaction path length without increasing the sample volume. They demonstrated that the resonator modes for left- and right-circularly polarized light shift by an equal amount in wavelength but in opposite directions. The resonator is made of a single-mode fiber, of which 20 cm have been replaced by a U-bench containing collimators, quarter-wave plates and a 10 cm liquid cuvette (see

Figure 6). The quarter-wave plate in front of the cuvette transforms the quasi-linear modes into left-circularly and right-circularly polarized light; the second quarter-wave plate restores the linear polarization. A tunable DFB laser at 763 nm is used to examine the two distinct resonator mode spectra associated with left and right polarized light. By inserting chiral liquids into the cuvette these two resonator mode spectra shift with respect to each other. With a wavelength shift resolution limit of 0.02 pm Vollmer

et al. were able to quantify birefringence of only 2 × 10

−7. Measurements of three chiral substances, limonene, pinene, and carvone, were performed. Enantiomers induce birefringence with opposite sign, and by mixing the chiral molecule with its enantiomer the amount of birefringence is adjusted. As expected, a 50:50 (racemic) mixture of enantiomers did not exhibit any birefringence, while the measured birefringence varied linearly with the amount of enantiomer added to the chiral liquid.