Optimisation of Simultaneous Saccharification and Fermentation (SSF) for Biobutanol Production Using Pretreated Oil Palm Empty Fruit Bunch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Pretreatment of Oil Palm Empty Fruit Bunch

2.2. Preparation of Inoculum

2.3. Medium Preparation and Fermentation

2.4. One Factor at a Time (OFAT)

2.5. Central Composite Design (CCD)

2.6. Analytical Methods

3. Results and Discussion

3.1. Effect of Temperature

3.2. Effect of Initial pH

3.3. Effect of Cellulase Loading

3.4. Effect of Substrate Concentration

3.5. Optimisation of Biobutanol Production

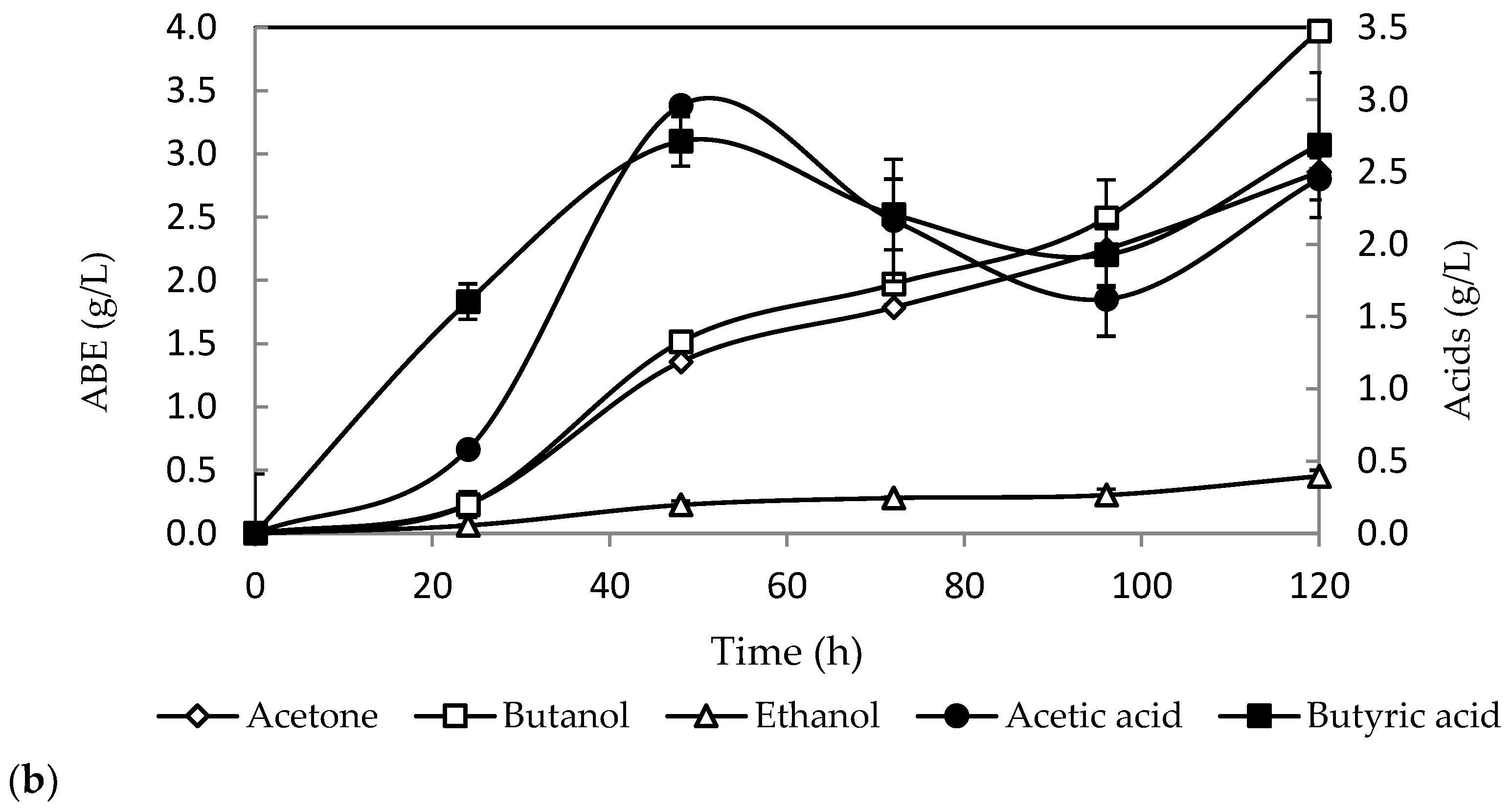

3.6. Validation of Biobutanol Optimisation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shao, M.; Chen, H. Feasibility of acetone-butanol-ethanol (ABE) fermentation from Armorphophallus konjac waste by Clostridium acetobutylicum ATCC 824. Process Biochem. 2015, 50, 1301–1307. [Google Scholar] [CrossRef]

- Gupta, A.; Verma, J.P. Sustainable bio-ethanol production from agro-residues: A review. Renew. Sustain. Energy Rev. 2015, 41, 550–567. [Google Scholar] [CrossRef]

- Begum, S.; Dahman, Y. Enhanced biobutanol production using novel clostridial fusants in simultaneous saccharification and fermentation of green renewable agriculture residues. Biofuels Bioprod. Biorefining 2015, 9, 529–544. [Google Scholar] [CrossRef]

- Kumar, M.; Gayen, K. Biobutanol: The future biofuel. In Biomass Conversion; Baskar, C., Baskar, S., Dhillon, R.S., Eds.; Springer: Heidelberg, Germany, 2012; pp. 221–236. [Google Scholar]

- Väisänen, S.; Havukainen, J.; Uusitalo, V.; Havukainen, M.; Soukka, R.; Luoranen, M. Carbon footprint of biobutanol by ABE fermentation from corn and sugarcane. Renew. Energy 2016, 89, 401–410. [Google Scholar] [CrossRef]

- Uyttebroek, M.; Hecke, W.V.; Vanbroekhoven, K. Sustainability metrics of 1-butanol. Catal. Today 2013, 239, 7–10. [Google Scholar] [CrossRef]

- Yoshizaki, T.; Shirai, Y.; Hassan, M.A.; Baharuddin, A.S.; Raja Abdullah, N.M.; Sulaiman, A.; Busu, Z. Improved economic viability of integrated biogas energy and compost production for sustainable palm oil mill management. J. Clean. Prod. 2013, 44, 1–7. [Google Scholar] [CrossRef]

- Ibrahim, M.F.; Razak, M.N.A.; Phang, L.Y.; Hassan, M.A.; Abd-Aziz, S. Crude cellulase from oil palm empty fruit bunch by Trichoderma asperellum UPM1 and Aspergillus fumigatus UPM2 for fermentable sugars production. Appl. Biochem. Biotechnol. 2013, 170, 1320–1335. [Google Scholar] [CrossRef] [PubMed]

- Geng, A. Conversion of oil palm empty fruit bunch to biofuels. In Liquid, Gaseous and Solid Biofuels-Conversion Techniques; Fang, Z., Ed.; Intech Open Limited: London, UK, 2013. [Google Scholar]

- Morone, A.; Pandey, R.A. Lignocellulosic biobutanol production: Gridlocks and potential remedies. Renew. Sustain. Energy Rev. 2014, 37, 21–35. [Google Scholar] [CrossRef]

- Triwahyuni, E.; Muryanto; Sudiyani, Y.; Abimanyu, H. The effect of substrate loading on simultaneous saccharification and fermentation process for bioethanol production from oil palm empty fruit bunches. Energy Procedia 2015, 68, 138–146. [Google Scholar] [CrossRef]

- Dahnum, D.; Tasum, S.O.; Triwahyuni, E.; Nurdin, M.; Abimanyu, H. Comparison of SHF and SSF processes using enzyme and dry yeast for optimization of bioethanol production from empty fruit bunch. Energy Procedia 2015, 68, 107–116. [Google Scholar] [CrossRef]

- Ibrahim, M.F.; Abd-Aziz, S.; Razak, M.N.A.; Phang, L.Y.; Hassan, M.A. Oil palm empty fruit bunch as alternative substrate for acetone-butanol-ethanol production by Clostridium butylicum EB6. Appl. Biochem. Biotechnol. 2012, 166, 1615–1625. [Google Scholar] [CrossRef] [PubMed]

- Tracy, B.P.; Jones, S.W.; Fast, A.G.; Indurthi, D.C.; Papoutsakis, E.T. Clostridia: The importance of their exceptional substrate and metabolite diversity for biofuel and biorefinery applications. Curr. Opin. Biotechnol. 2012, 23, 364–381. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.F.; Ramli, N.; Kamal Bahrin, E.; Abd-Aziz, S. Cellulosic biobutanol by Clostridia: Challenges and improvements. Renew. Sustain. Energy Rev. 2017, 79, 1241–1254. [Google Scholar] [CrossRef]

- Ibrahim, M.F.; Abd-Aziz, S.; Yusoff, M.E.M.; Phang, L.Y.; Hassan, M.A. Simultaneous enzymatic saccharification and ABE fermentation using pretreated oil palm empty fruit bunch as substrate to produce butanol and hydrogen as biofuel. Renew. Energy 2015, 77, 447–455. [Google Scholar] [CrossRef]

- Sasaki, C.; Kushiki, Y.; Asada, C.; Nakamura, Y. Acetone–butanol–ethanol production by separate hydrolysis and fermentation (SHF) and simultaneous saccharification and fermentation (SSF) methods using acorns and wood chips of Quercus acutissima as a carbon source. Ind. Crops Prod. 2014, 62, 286–292. [Google Scholar] [CrossRef]

- Olofsson, K.; Bertilsson, M.; Lidén, G. A short review on SSF—An interesting process option for ethanol production from lignocellulosic feedstocks. Biotechnol. Biofuels 2008, 1. [Google Scholar] [CrossRef] [PubMed]

- Salehi, J.G.; Taherzadeh, M.J. Advances in consolidated bioprocessing systems for bioethanol and butanol production from biomass: A comprehensive review. Biofuel Res. J. 2015, 5, 152–195. [Google Scholar] [CrossRef]

- Razak, M.N.A.; Ibrahim, M.F.; Phang, L.Y.; Hassan, M.A.; Abd-Aziz, S. Statistical optimization of biobutanol production from oil palm decanter cake hydrolysate by Clostridium acetobutylicum ATCC 824. Bioresources 2013, 8, 1758–1770. [Google Scholar]

- Linggang, S.; Phang, L.Y.; Wasoh, H.; Abd-Aziz, S. Acetone–butanol–ethanol production by Clostridium acetobutylicum ATCC 824 using sago pith residues hydrolysate. Bioenergy Resource 2013, 6, 321–328. [Google Scholar] [CrossRef]

- Umikalsom, M.; Ariff, A.B.; Zulkifli, H.S.; Tong, C.C.; Hassan, M.A. The treatment of oil palm empty fruit bunch fibre for subsequent use as substrate for cellulase production by Chaetomium globosumkunze. Bioresour. Technol. 1997, 62, 1–9. [Google Scholar] [CrossRef]

- Goering, H.K.; Van Soest, P.J. Forage fiber analyses (Apparatus, reagents, procedures, and some applications). In Agriculture Handbook No 379; US Government Printing Office: Washington, DC, USA, 1970; pp. 1–19. [Google Scholar]

- Monot, F.; Martin, J.R.; Petitdemange, H.; Gay, R. Acetone and butanol production by Clostridium acetobutylicum in synthetic medium. Appl. Environ. Microbiol. 1982, 44, 1318–1324. [Google Scholar] [PubMed]

- Adney, B.; Baker, J. Measurement of cellulase activities. Natl. Renew. Energy Lab. Tech. Rep. 2008, 8. [Google Scholar]

- Miller, G.L. Use of dinitrosalicyclic acid reagent for determination of reducing sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, J.; Wang, X.M.; Sun, X.H. Optimization of butanol production from corn straw hydrolysate by Clostridium acetobutylicum using response surface method. Chin. Sci. Bull. 2011, 56, 1422–1428. [Google Scholar] [CrossRef]

- Qi, B.; Chen, X.; Yi, S.; Wan, Y. Inhibition of cellulase, β-glucosidase, and xylanase activities and enzymatic hydrolysis of dilute acid pretreated wheat straw by acetone-butanol-ethanol fermentation products. Environ. Prog. Sustain. Energy 2013, 1–7. [Google Scholar] [CrossRef]

- Khamaiseh, E.I.; Kalil, M.S.; Dada, O.; El-Shawabkeh, I.; Yusoff, W.M.W. Date fruit as carbon source in RCM-modified medium to produce biobutanol by Clostridium acetobutylicum NCIMB 13357. J. Appl. Sci. 2012, 12, 1160–1165. [Google Scholar] [CrossRef]

- Zanirun, Z.; Bahrin, E.K.; Lai-Yee, P.; Hassan, M.A.; Abd-Aziz, S. Enhancement of fermentable sugars production from oil palm empty fruit bunch by ligninolytic enzymes mediator system. Int. Biodeterior. Biodegrad. 2015, 105, 13–20. [Google Scholar] [CrossRef]

- Yang, X.; Tu, M.; Xie, R.; Adhikari, S.; Tong, Z. A comparison of three pH control methods for revealing effects of undissociated butyric acid on specific butanol production rate in batch fermentation of Clostridium acetobutylicum. AMB Express 2013, 3, 3. [Google Scholar] [CrossRef] [PubMed]

- Chua, T.K.; Liang, D.; Qi, C.; Yang, K.; He, J. Characterization of a butanol-acetone-producing Clostridium strain and identification of its solventogenic genes. Bioresour. Technol. 2013, 135, 372–378. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Wen, Z.; Wu, M.; Li, H.; Yang, J.; Lin, J.; Lin, Y.; Yang, L.; Cen, P. The effect of pH control on acetone-butanol-ethanol fermentation by Clostridium acetobutylicum ATCC 824 with xylose and d-glucose and d-xylose mixture. Chin. J. Chem. Eng. 2014, 22, 937–942. [Google Scholar] [CrossRef]

- Jones, D.T.; Woods, D.R. Acetone-butanol fermentation revisited. Microbiol. Mol. Biol. Rev. 1986, 50, 484–524. [Google Scholar]

- Linggang, S.; Phang, L.Y.; Wasoh, M.H.; Abd-Aziz, S. Sago pith residue as an alternative cheap substrate for fermentable sugars production. Appl. Biochem. Biotechnol. 2012, 167, 122–131. [Google Scholar] [CrossRef] [PubMed]

- Shukor, H.; Al-Shorgani, N.K.N.; Abdeshahian, P.; Hamid, A.A.; Anuar, N.; Rahman, N.A.; Kalil, M.S. Production of butanol by Clostridium saccharoperbutylacetonicum N1-4 from palm kernel cake in acetone-butanol-ethanol fermentation using an empirical model. Bioresour. Technol. 2014, 170, 565–573. [Google Scholar] [CrossRef] [PubMed]

- Wingren, A.; Galbe, M.; Zacchi, G. Techno-economic evaluation of producing ethanol from softwood: Comparison of SSF and SHF and identification of bottlenecks. Biotechnol. Prog. 2003, 46, 1109–1117. [Google Scholar] [CrossRef] [PubMed]

- Oberoi, H.S.; Vadlani, P.V.; Saida, L.; Bansal, S.; Hughes, J.D. Ethanol production from banana peels using statistically optimized simultaneous saccharification and fermentation process. Waste Manag. 2011, 31, 1576–1584. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.J.; Ding, J.C.; Zhang, Y.; Ma, L.; Xu, G.C.; Han, R.Z.; Ni, Y. Simultaneous saccharification and fermentation of dilute alkaline-pretreated corn stover for enhanced butanol production by Clostridium saccharobutylicum DSM 13864. FEMS Microbiol. Lett. 2016, 363. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Gayen, K. Developments in biobutanol production: New insights. Appl. Energy 2011, 88, 1999–2012. [Google Scholar] [CrossRef]

- Khamaiseh, E.I.; Abdul Hamid, A.; Abdeshahian, P.; Wan Yusoff, W.M.; Kalil, M.S. Enhanced butanol production by Clostridium acetobutylicum NCIMB 13357 grown on date fruit as carbon source in P2 medium. Sci. World J. 2014, 2014. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Chen, Y.; Lin, J. Evaluation of biobutanol production from non-pretreated rice straw hydrolysate under non-sterile envinronmental conditions. Bioresour. Technol. 2013, 135, 262–268. [Google Scholar] [CrossRef] [PubMed]

- Yamanobe, T.; Mitsuishi, Y.; Takasaki, Y. Method for Manufacture Cellulase. U.S. Patent 4,562,150, 31 December 1985. [Google Scholar]

- Shen, J.; Agblevor, F.A. Optimization of enzyme loading and hydrolytic time in the hydrolysis of mixtures of cotton gin waste and recycled paper sludge for the maximum profit rate. Biochem. Eng. J. 2008, 41, 241–250. [Google Scholar] [CrossRef]

- Hideno, A.; Inoue, H.; Tsukahara, K.; Yano, S.; Fang, X.; Endo, T.; Sawayama, S. Production and characterization of cellulases and hemicellulases by Acremonium cellulolyticus using rice straw subjected to various pretreatments as the carbon source. Enzyme Microb. Technol. 2011, 48, 162–168. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, L.; Chen, H. Periodic peristalsis increasing acetone-butanol-ethanol productivity during simultaneous saccharification and fermentation of steam exploded corn straw. J. Biosci. Bioeng. 2016, 122, 620–626. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Ramaswamy, S.; Liu, Y. Separation and purification of biobutanol during bioconversion of biomass. Sep. Purif. Technol. 2014, 132, 513–540. [Google Scholar] [CrossRef]

- Guan, W.; Shi, S.; Tu, M.; Lee, Y.Y. Acetone–butanol–ethanol production from Kraft paper mill sludge by simultaneous saccharification and fermentation. Bioresour. Technol. 2016, 200, 713–721. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boonsombuti, A.; Tangmanasakul, K.; Nantapipat, J.; Komolpis, K.; Luengnaruemitchai, A.; Wongkasemjit, S. Production of biobutanol from acid pretreated corncob using Clostridium beijerinckii TISTR 1461: Process optimization studies. Prep. Biochem. Biotechnol. 2016, 46, 141–149. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, N.; Singh, V.; Liu, S.; Ezeji, T.C.; Saha, B.C.; Cotta, M.A. Process integration for simultaneous saccharification, fermentation and recovery (SSFR): Production of butanol from corn stover using Clostridium beijerinckii P260. Bioresour. Technol. 2014, 154, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Sangkharak, K.; Yunu, T.; Paichid, N.; Prasertsan, P. The production of acetone-butanol-ethanol from oil palm wastes by Clostridium acetobutyricum and utilisation of the wastewater for polyhydroxybutyrate production. J. Oil Palm Res. 2016, 28, 52–63. [Google Scholar] [CrossRef]

Sample Availability: Samples of the raw and alkaline pretreated OPEFB fibres is available from the authors. |

| Temperature (°C) | 30 | 35 | 37 | 40 | 45 | 50 |

|---|---|---|---|---|---|---|

| Solvents and acids production | ||||||

| Biobutanol (g/L) | 1.53 ± 0.15 a | 1.96 ± 0.04 a | 1.74 ± 0.06 a | 1.55 ± 0.07 a | 0.08 ± 0.02 b | 0.07 ± 0.003 b |

| Acetic acid (g/L) | 10.97 ± 0.86 | 7.43 ± 0.50 | 7.37 ± 0.11 | 6.27 ± 0.05 | 6.72 ± 0.33 | 6.35 ± 0.25 |

| Butyric acid (g/L) | 6.86 ± 0.69 | 4.00 ± 0.45 | 3.67 ± 0.23 | 3.32 ± 0.19 | 2.65 ± 0.02 | 2.80 ± 0.47 |

| Total acetone-butanol-ethanol (ABE) concentration (g/L) | 2.01 | 2.62 | 2.74 | 2.14 | 0.08 | 0.07 |

| Total ABE yield (g ABE/g sugar) | 0.08 | 0.10 | 0.11 | 0.08 | 0.003 | 0.003 |

| Biobutanol yield (g butanol/g sugar) | 0.06 | 0.08 | 0.07 | 0.06 | 0.003 | 0.003 |

| Biobutanol productivity (g/L/h) | 0.015 | 0.02 | 0.02 | 0.016 | 0.0008 | 0.0007 |

| Final pH | 4.81 ± 0.08 | 4.92 ± 0.11 | 4.82 ± 0.09 | 4.85 ± 0.03 | 4.45 ± 0.09 | 4.95 ± 0.38 |

| Reducing sugars (g/L) | ||||||

| SSF | 3.84 ± 0.18 | 4.54 ± 0.03 | 8.38 ± 0.01 | 13.00 ± 0.79 | 19.99 ± 0.17 | 22.53 ± 0.22 |

| SO | 10.90 ± 0.93 | 19.55 ± 0.39 | 25.61 ± 0.27 | 23.49 ± 0.00 | 21.75 ± 0.26 | 16.38 ± 0.06 |

| Initial PH | 4.5 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 |

|---|---|---|---|---|---|---|

| Solvents and acids production | ||||||

| Biobutanol (g/L) | 0.25 ± 0.04 c | 1.06 ± 0.18 b | 1.96 ± 0.04 a | 1.22 ± 0.02 c | 0.64 ± 0.20 c | 0.57 ± 0.40 c |

| Acetic acid (g/L) | 3.91 ± 0.05 | 4.11 ± 0.00 | 7.43 ± 0.50 | 3.34 ± 0.17 | 3.34 ± 0.42 | 3.39 ± 0.00 |

| Butyric acid (g/L) | 4.18 ± 0.25 | 2.87 ± 0.97 | 4.00 ± 0.45 | 2.40 ± 0.27 | 2.65 ± 0.29 | 2.75 ± 0.00 |

| Total ABE concentration (g/L) | 0.46 | 1.52 | 2.62 | 1.77 | 1.05 | 0.90 |

| Total ABE yield (g ABE/g sugar) | 0.02 | 0.06 | 0.10 | 0.07 | 0.04 | 0.04 |

| Biobutanol yield (g butanol/g sugar) | 0.01 | 0.04 | 0.08 | 0.05 | 0.03 | 0.02 |

| Biobutanol productivity (g/L/h) | 0.002 | 0.02 | 0.02 | 0.01 | 0.006 | 0.006 |

| Final pH | 4.75 ± 0.29 | 4.60 ± 0.14 | 4.92 ± 0.11 | 4.60 ± 0.10 | 4.61 ± 0.14 | 4.69 ± 0.15 |

| Reducing sugars (g/L) | ||||||

| SSF | 12.46 ± 0.28 | 7.65 ± 0.14 | 4.54 ± 0.03 | 8.52 ± 0.00 | 9.49 ± 0.04 | 8.63 ± 0.03 |

| SO | 24.80 ± 0.98 | 22.67 ± 0.17 | 19.55 ± 0.39 | 17.66 ± 0.31 | 18.55 ± 1.33 | 19.30 ± 0.17 |

| Cellulase Loading (FPU/g-Substrate) | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|

| Solvents and acids production | ||||||

| Biobutanol (g/L) | 0.70 ± 0.10 b | 2.31 ± 0.30 a | 1.92 ± 0.05 b | 1.64 ± 0.45 b | 0.84 ± 0.25 c | 0.03 ± 0.00 c |

| Acetic acid (g/L) | 5.38 ± 0.44 | 4.75 ± 0.09 | 6.26 ± 0.27 | 4.38 ± 0.09 | 3.81 ± 0.84 | 5.97 ± 0.64 |

| Butyric acid (g/L) | 4.62 ± 0.30 | 3.53 ± 0.20 | 4.05 ± 0.36 | 4.35 ± 0.31 | 5.34 ± 0.42 | 3.74 ± 0.32 |

| Total ABE concentration (g/L) | 1.26 | 2.80 | 2.73 | 2.85 | 1.61 | 0.12 |

| Total ABE yield (g ABE/g sugar) | 0.05 | 0.11 | 0.11 | 0.11 | 0.063 | 0.005 |

| Biobutanol yield (g butanol/g sugar) | 0.03 | 0.09 | 0.07 | 0.07 | 0.033 | 0.001 |

| Biobutanol productivity (g/L/h) | 0.007 | 0.024 | 0.02 | 0.017 | 0.009 | 0.0003 |

| Final pH | 4.69 ± 0.08 | 4.78 ± 0.02 | 4.85 ± 0.08 | 4.72 ± 0.06 | 4.58 ± 0.01 | 4.55 ± 0.15 |

| Reducing sugars (g/L) | ||||||

| SSF | 0.62 ± 0.05 | 0.90 ± 0.00 | 5.91 ± 0.75 | 9.71 ± 0.13 | 11.63 ± 0.06 | 14.06 ± 0.83 |

| SO | 7.61 ± 0.79 | 11.51 ± 0.08 | 11.84 ± 0.40 | 17.91 ± 0.04 | 21.12 ± 0.95 | 22.68 ± 0.15 |

| Substrate Concentration w/v (%) | 1 | 3 | 5 | 7 |

|---|---|---|---|---|

| Solvents and acids production | ||||

| Biobutanol (g/L) | 0.50 ± 0.03 c | 0.95 ± 0.01 c | 2.47 ± 0.06 a | 1.79 ± 0.03 b |

| Acetic acid (g/L) | 3.58 ± 0.16 | 4.71 ± 0.61 | 3.52 ± 0.62 | 4.51 ± 0.32 |

| Butyric acid (g/L) | 2.54 ± 0.10 | 4.93 ± 0.13 | 4.36 ± 0.34 | 5.88 ± 0.41 |

| Total ABE concentration (g/L) | 0.54 | 1.29 | 4.34 | 3.48 |

| Total ABE yield (g ABE/g sugar) | 0.02 | 0.05 | 0.17 | 0.14 |

| Biobutanol yield (g butanol/g sugar) | 0.02 | 0.04 | 0.10 | 0.07 |

| Biobutanol productivity (g/L/h) | 0.01 | 0.01 | 0.03 | 0.02 |

| Final pH | 5.29 ± 0.10 | 4.82 ± 0.01 | 4.85 ± 0.04 | 4.77 ± 0.06 |

| Reducing sugars (g/L) | ||||

| SSF | 0.48 ± 0.05 | 0.35 ± 0.20 | 1.73 ± 0.12 | 8.65 ± 2.74 |

| SO | 1.29 ± 0.72 | 12.01 ± 0.19 | 18.73 ± 0.52 | 28.20 ± 0.44 |

| Source | Sum of Squares | df | MS | F Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 0.06915 | 14 | 0.00494 | 5.62465 | 0.0010 | Significant |

| A-Temperature | 0.00050 | 1 | 0.00050 | 0.56371 | 0.4644 | |

| B-Initial pH | 0.00116 | 1 | 0.00116 | 1.32323 | 0.2680 | |

| C-Cellulase loading | 0.00001 | 1 | 0.00001 | 0.00802 | 0.9298 | |

| D-Substrate conc. | 0.00004 | 1 | 0.00004 | 0.03990 | 0.8444 | |

| AC | 0.00047 | 1 | 0.00047 | 0.53868 | 0.4743 | |

| AD | 0.00064 | 1 | 0.00064 | 0.72600 | 0.4076 | |

| BC | 0.00092 | 1 | 0.00092 | 1.04199 | 0.3235 | |

| CD | 0.00028 | 1 | 0.00028 | 0.31948 | 0.5803 | |

| A2 | 0.02312 | 1 | 0.02312 | 26.32385 | 0.0001 | |

| B2 | 0.02474 | 1 | 0.02474 | 28.16857 | <0.0001 | |

| C2 | 0.01841 | 1 | 0.01841 | 20.96173 | 0.0004 | |

| D2 | 0.02599 | 1 | 0.02599 | 29.59310 | <0.0001 | |

| Residual | 0.01317 | 15 | 0.00088 | - | - | Not significant |

| Lack of Fit | 0.01116 | 10 | 0.00112 | 2.76894 | 0.1362 | |

| Pure Error | 0.00201 | 5 | 0.00040 | - | - | |

| Cor Total | 0.08233 | 29 | - | - | - |

| Clostridium Strain | Temp. (°C) | Initial PH | Substrate Conc. (g/L) | Sugar Conc. (g/L) | Cellulase Loading | Biobutanol Conc. (g/L) | Biobutanol Yield | Biobutanol Productivity (g/L/h) | References | |

|---|---|---|---|---|---|---|---|---|---|---|

| (g/g) (Biobutanol/Sugar) | (g/g) (Biobutanol/Substrate) | |||||||||

| C. acetobutylicum NBRC 13948 | 37 | 5.0 | 50 g/L Wood chips | 25 | 7.8 mg protein/g of substrate | 7.77 | 0.31 | 0.16 | 0.05 | [17] |

| C. beijerinckii TISTRI461 | 37 | 6.6 | 40 g/L Corncob | 8 | 10 FPU/g-substrate | 2.00 | 0.25 | 0.05 | 0.03 | [49] |

| C. acetobutylicum | 36 | 6.7 | 58 g/L Avicel | 60 | 20 FPU/g of glucan | 9.50 | 0.16 | 0.16 | 0.08 | [48] |

| 6.7 | 74 g/L De-ashed paper mill sludge | 71 | 10 FPU/g of glucan | 9.70 | 0.14 | 0.13 | 0.08 | |||

| C. acetobutylicum ATCC 824 | 35 | 5.5 | 50 g/L OPEFB | 25 | 15 FPU/g-substrate | 3.97 | 0.16 | 0.08 | 0.03 | This study |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Md Razali, N.A.A.; Ibrahim, M.F.; Kamal Bahrin, E.; Abd-Aziz, S. Optimisation of Simultaneous Saccharification and Fermentation (SSF) for Biobutanol Production Using Pretreated Oil Palm Empty Fruit Bunch. Molecules 2018, 23, 1944. https://doi.org/10.3390/molecules23081944

Md Razali NAA, Ibrahim MF, Kamal Bahrin E, Abd-Aziz S. Optimisation of Simultaneous Saccharification and Fermentation (SSF) for Biobutanol Production Using Pretreated Oil Palm Empty Fruit Bunch. Molecules. 2018; 23(8):1944. https://doi.org/10.3390/molecules23081944

Chicago/Turabian StyleMd Razali, Nur Atheera Aiza, Mohamad Faizal Ibrahim, Ezyana Kamal Bahrin, and Suraini Abd-Aziz. 2018. "Optimisation of Simultaneous Saccharification and Fermentation (SSF) for Biobutanol Production Using Pretreated Oil Palm Empty Fruit Bunch" Molecules 23, no. 8: 1944. https://doi.org/10.3390/molecules23081944